Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

482 results about "Isooctyl alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of isooctyl alcohol. : an octyl alcohol of branched-chain structure or a mixture of such alcohols; especially : a mixture of isomeric primary alcohols C7H15CH2OH obtained by reaction of heptylenes with carbon monoxide and hydrogen and used especially in synthesis (as of plasticizers) —not used scientifically.

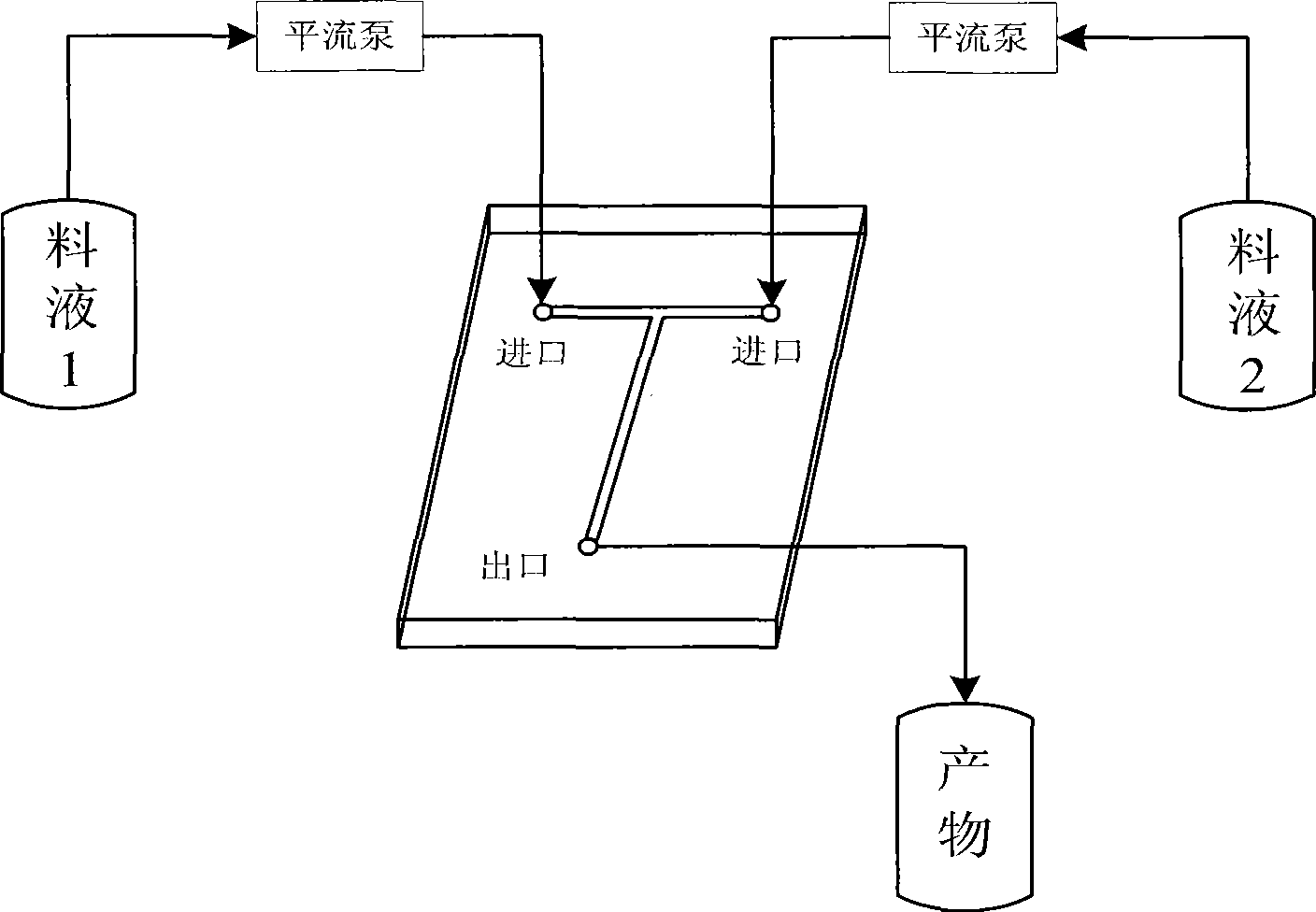

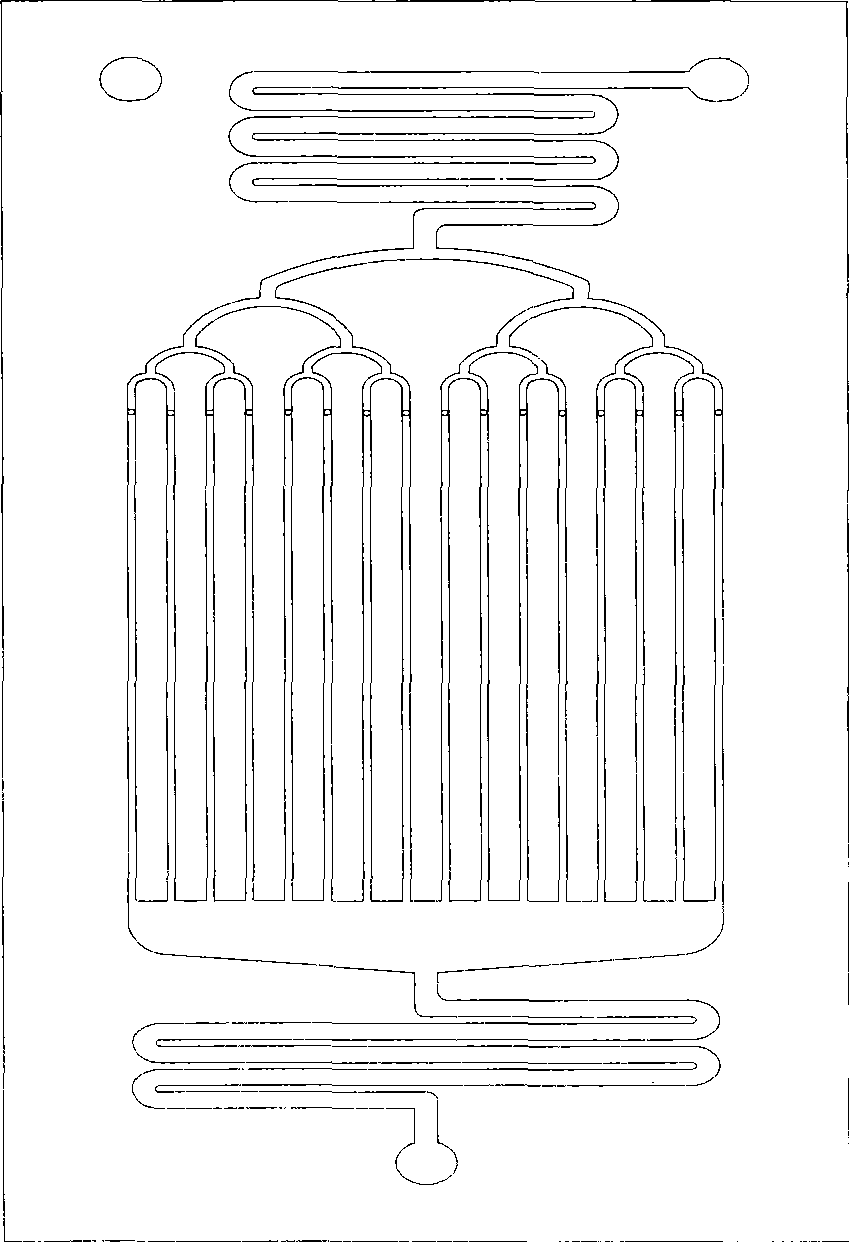

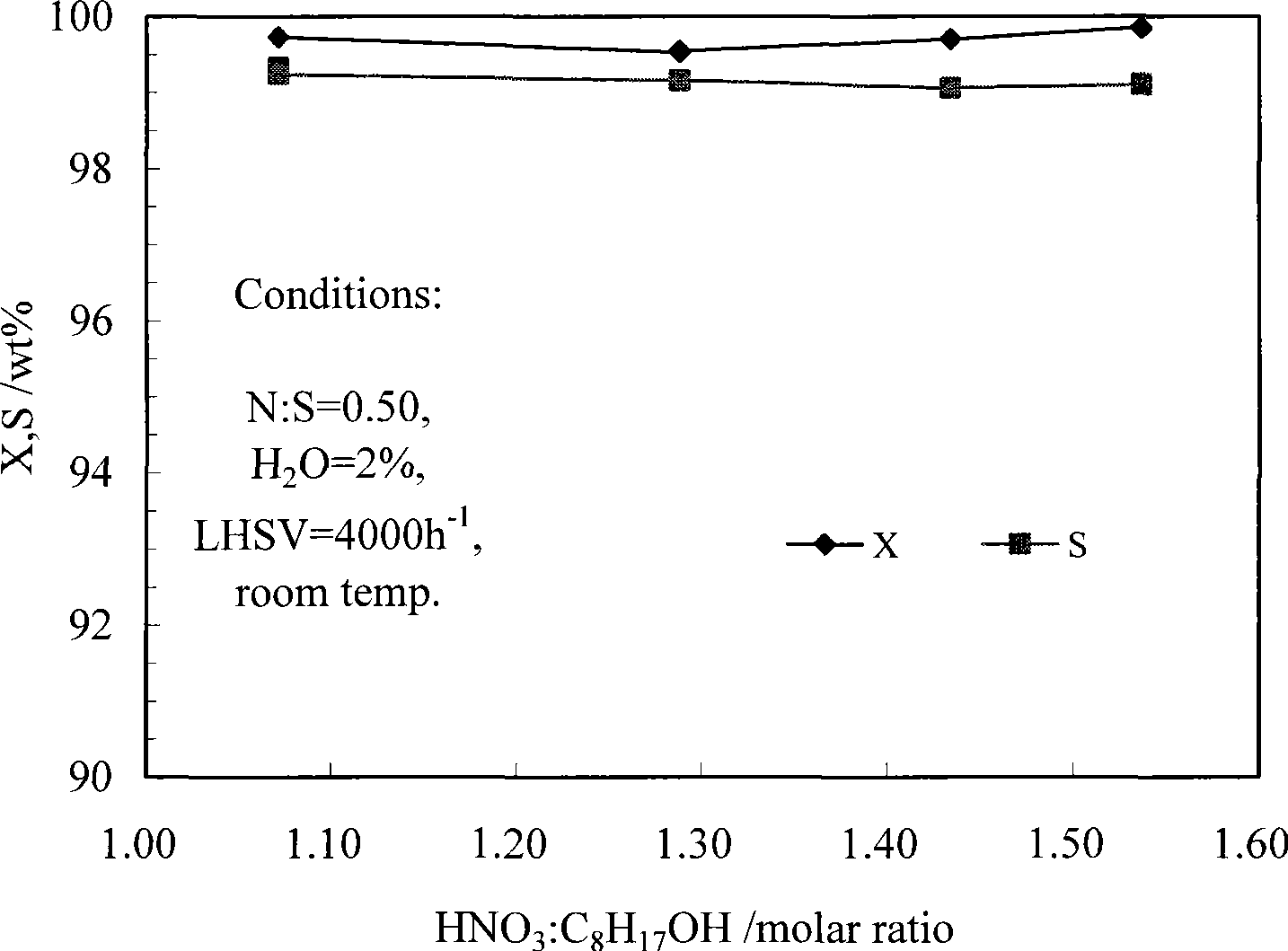

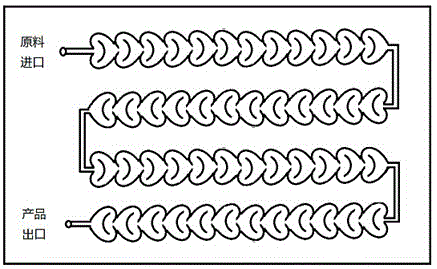

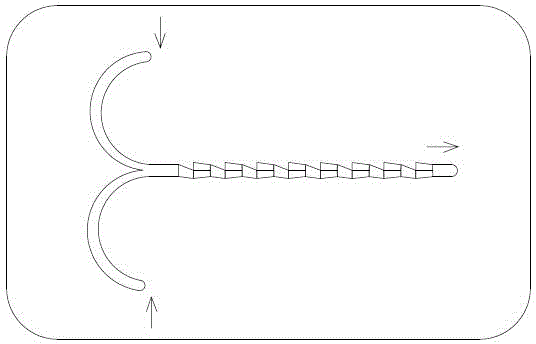

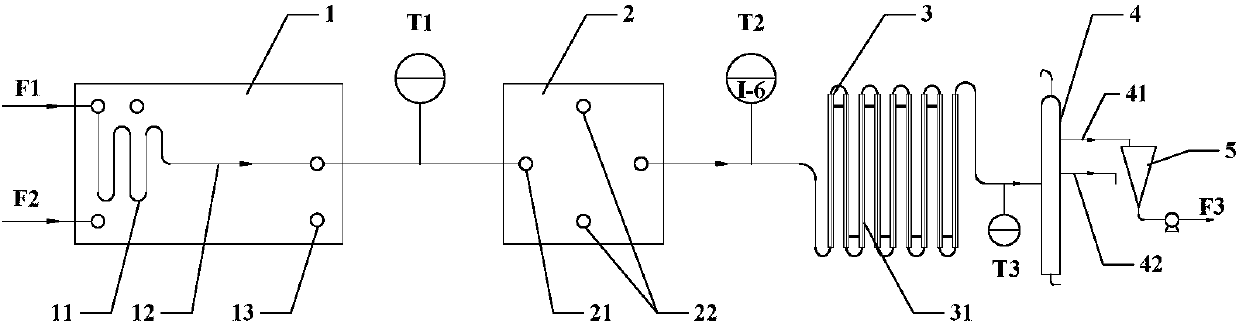

Method for synthesizing isooctyl nitrate and microchannel reactor

ActiveCN101462962AAvoid production accidentsLow costNitric acid ester preparationSynthesis methodsSolvent

The invention relates to the synthesis of isooctyl nitrate; in particular to a synthesis method of isooctyl nitrate and a microchannel reactor. Isooctyl alcohol is taken as raw material and an acid mixture of nitric acid and sulphuric acid is taken as nitrating agent, and the raw material and the nitrating agent are pumped into the microchannel reactor at normal temperature and pressure to carry out direct esterification. The process needs no catalyst or solvent, makes full use of the efficient heat and mass transfer capability of the microchannel as well as the characteristic of direct amplification and adopts two microreactors, of which one is a single-channel microreactor and the other is a multichannel microreactor; liquid hourly space velocity in the microreactor is 3000-10000h<-1>, the once-through conversion ratio of isooctyl alcohol is higher than 99% and the yield coefficient of isooctyl nitrate is higher than 98%. The process has high operation safety and high selectivity and can realize approximate isothermal operation in the reaction. The reactor is small in volume, is easy to integrate and amplify and space-time productive rate is high, thus being significant for strengthening and guaranteeing the safe production of isooctyl nitrate.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

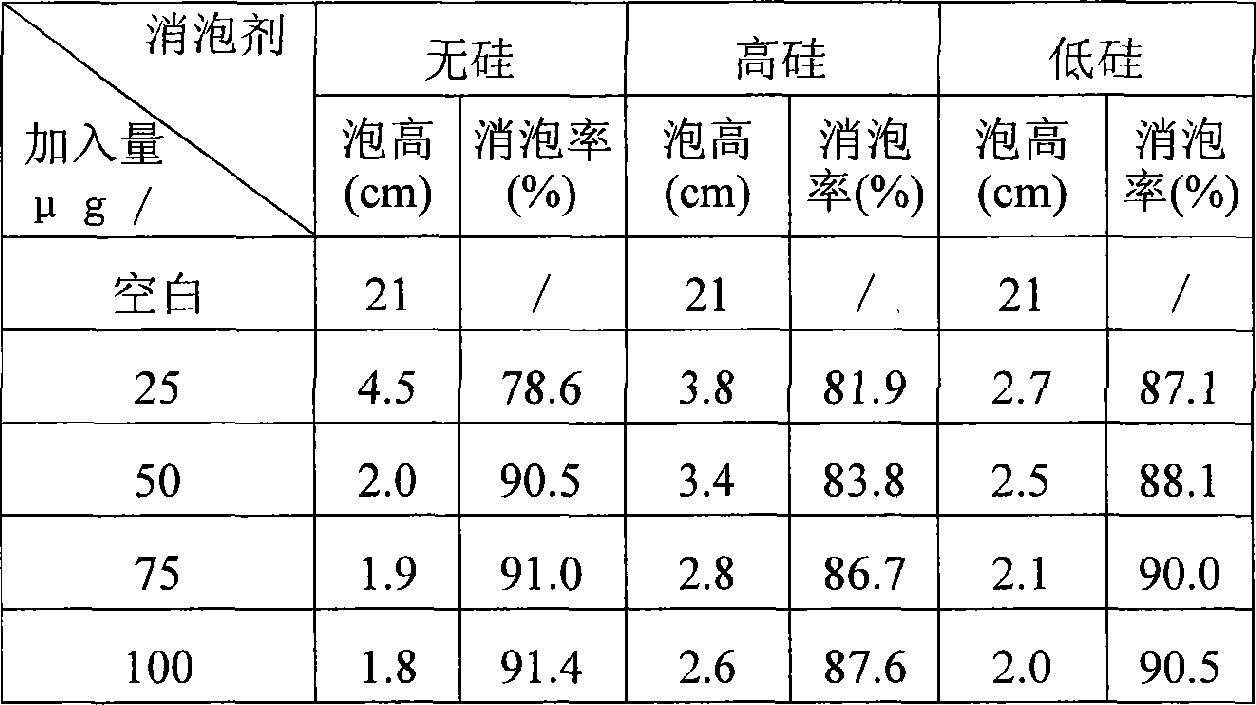

Additive for suppressing and delaying foam generation in coking reaction tower and its prepn process

InactiveCN101045880ASuppress and eliminate generationReduce entrainmentThermal non-catalytic crackingEpoxyHeptyl alcohol

The present invention is additive for suppressing and delaying foam generation in coking reaction tower and its preparation process, and relates to oil refining additive technology. The additive is prepared through compounding high molecular weight block polyether 30-50 wt%, fatty alcohol 20-40 wt% and solvent 20-40 wt%, where, the high molecular weight block polyether is block copolymer of ethylene glycol, epoxy ethane and epoxy propane of molecular weight 10,000-20,000, and the fatty alcohol is isocotanol or 3-enanthol, and the solvent is water solution of alcohol. The preparation process includes the first feeding solvent into reaction kettle and heating slowly to 40-60 deg.c, adding block polyether and fatty alcohol in the ratio via stirring to react for 1-2 hr, cooling and filtering off solid impurity to obtain the product. The additive can suppress and delay foam generation in coking reaction tower effectively.

Owner:SHENYANG POLYTECHNIC UNIV

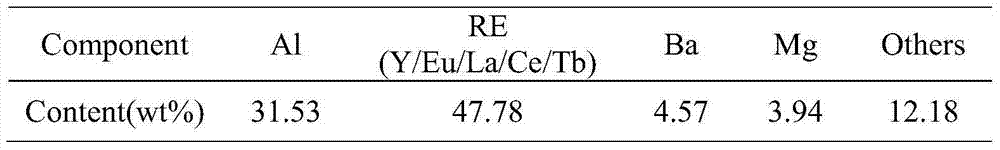

Method for recovering valuable metal element in waste phosphor by using phosphonium ionic liquid

InactiveCN103924084AImprove use valueReduce acid consumptionProcess efficiency improvementRare-earth elementPhosphonium

The invention relates to a method for recovering a valuable metal element in waste phosphor by using phosphonium ionic liquid. The method comprises the following steps: collecting phosphor in a waste fluorescent lamp and taking as an initial raw material, using a strong alkaline compound for high temperature roasting to prepare an alkali fusion object, directly using nitric acid for leaching to obtain an insoluble substance leached by water and an acidic material liquid, wherein acidity of the material liquid is 0.1-3.0mol / L, a difunctional ionic liquid extractant [P6,6,6,14][P204] or [P6,6,6,14][P507] as an extractant, isooctyl alcohol is taken as an additive, a diluent selects n-heptane or kerosene, under condition of weak acid, using coexisted mass aluminium nitrate salt as a salting-out agent, extracting and recovering the rare earth element in a phosphor leachate, and then acquiring an organic extract loaded with rare earth ions and a raffinate aqueous solution with rich aluminium nitrate salt. According to the invention, valuable metals in the waste fluorescent lamp can be recovered and used, the process flow is simple, and the method has the advantages of and friendly environment.

Owner:NANTONG UNIVERSITY

Method of synthesizing isooctyl nitrate

InactiveCN105566120AHigh mixing mass transfer effectImprove thermal conductivityNitric acid ester preparationIsooctyl alcoholNitrate

The invention relates to a method of synthesizing isooctyl nitrate. The method comprises the steps that mixed acid obtained by mixing concentrated nitric acid and concentrated sulfuric acid and isooctyl alcohol are conveyed into a micro-channel reactor through conveying equipment for a reaction for 5-60 seconds in the reactor at the temperature of 5-50 DEG C, the reaction product stands for skimming, and the organic phase is washed and dried to obtain the isooctyl nitrate. According to the method, the reaction is performed in a triangular three-layer structure reaction plate, mass and heat transfer is quick, the reaction can be performed at constant temperature, and operation safety is high. In the process, the single-pass conversion rate of the isooctyl alcohol is 99% or above, and the yield is also 99% or above.

Owner:CHINA PETROLEUM & CHEM CORP +1

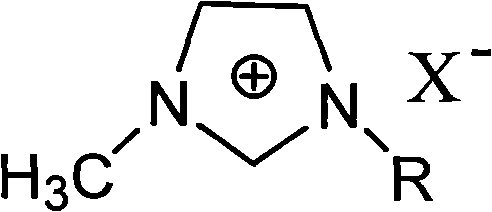

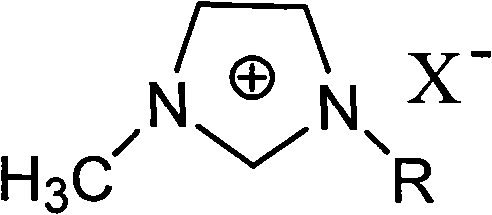

Method for catalytically synthesizing di-2-ethyhexyl carbonate by alkali ionic liquid

InactiveCN101735064AImprove catalytic performanceHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation from organic carbonatesIsooctyl alcoholMethyl carbonate

The invention provides a catalytic synthesis method for ionic liquid of di-2-ethyhexyl carbonate and belongs to the technical field of synthesis of ester compounds in organic chemistry. The method comprises the following steps of: performing the two-step ester exchange reaction of isooctanol and methyl carbonate serving as raw materials by alkali ionic liquid serving as a catalyst, and distilling the products by decompression to obtain the di-2-ethyhexyl carbonate, wherein the negative ion in the alkali ionic liquid is one of [OAc]-, Im-, OH-, Br-, Cl- and I- ions or a compound system formed by more of [OAc]-, Im-, OH-, Br-, Cl- and I- ions, the positive ion is 1-alkyl 3-methylimidazole, and the length of the carbon chain of the alkyl group is 1 to 13. The ionic liquid is added in an amount of 1 to 50 percent based on the total mass of the reaction raw materials, and the yield of the di-2-ethyhexyl carbonate is 45 to 85 percent. The alkali ionic liquid is used as the catalyst in the method, so that the method has the advantages of recovery of the catalyst, stable quality and yield of the product, advanced and reasonable process and easy operation.

Owner:DALIAN POLYTECHNIC UNIVERSITY

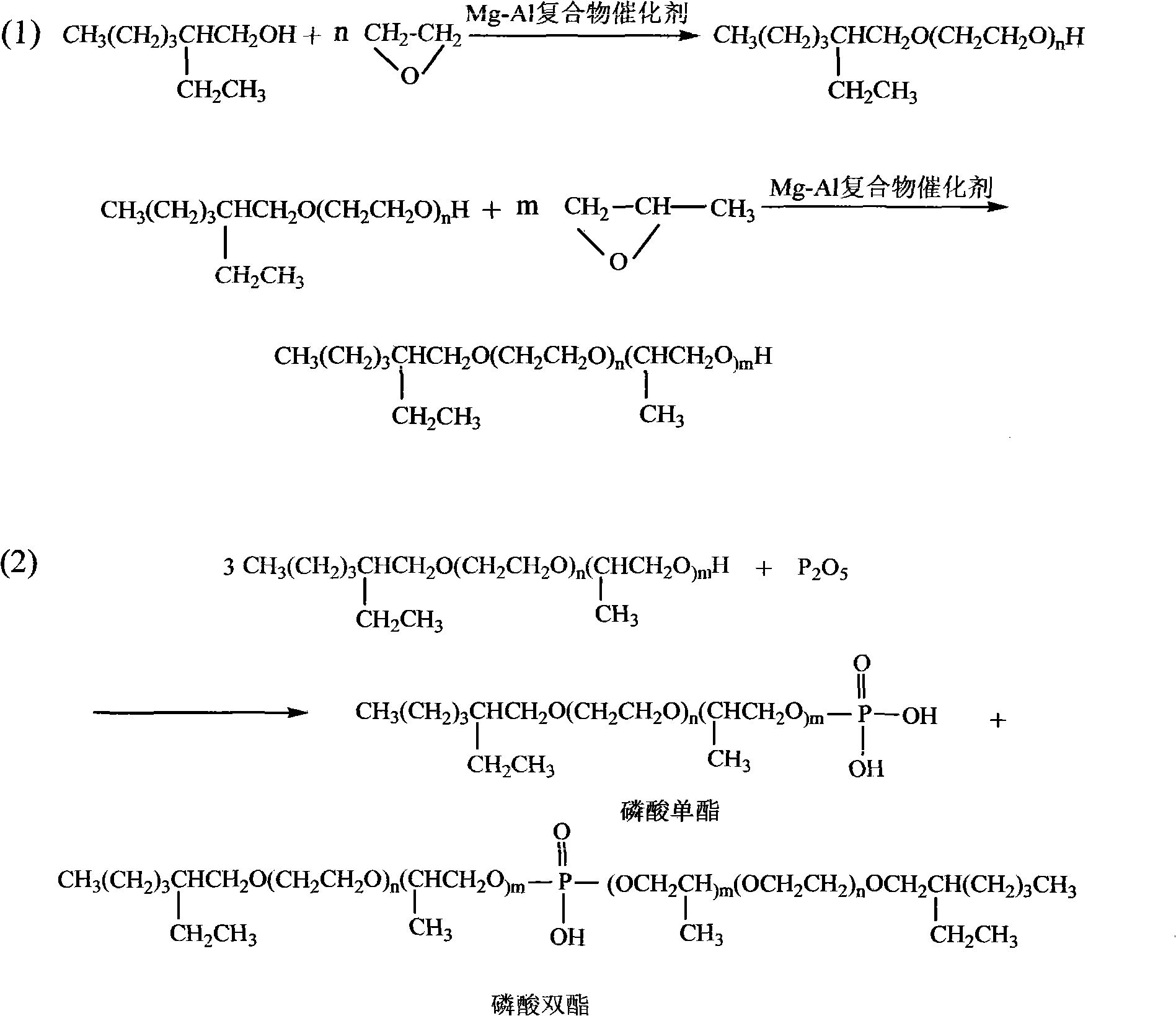

Method for preparing isooctanol polyoxyethylene polyoxypropylene ether phosphate ester

ActiveCN101941987AExcellent alkali resistance and permeabilityImprove permeabilityPhosphorus organic compoundsVegetal fibresFiberIsooctyl alcohol

The invention discloses a method for preparing isooctanol polyoxyethylene polyoxypropylene ether phosphate ester. The method comprises the following step of: adding ethylene oxide into isooctanol serving as an initiator to perform polymerization reaction in the presence of a Mg-Al compound catalyst; adding propylene oxide to perform the polymerization reaction to obtain isooctanol polyoxyethylene polyoxypropylene ether and performing esterification reaction with phosphorus pentoxide; and hydrolyzing by using deionized water to obtain the isooctanol polyoxyethylene polyoxypropylene ether phosphate ester which is a mixture mainly comprising phosphate monoester and phosphate diester. The product prepared by the method of the invention has the characteristics of concentrated alkali resistance, low foam and capacity of quickly promoting water to wet and penetrate fibers and fabrics.

Owner:ZHEJIANG HUANGMA TECH

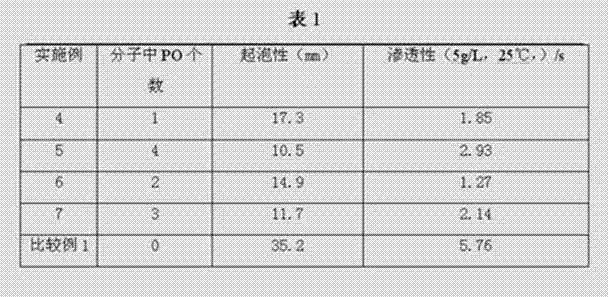

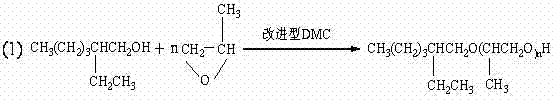

Preparation method of isooctanol polyoxypropylene ether sodium sulfosuccinate diester

InactiveCN102391158AHigh activityReduce dosageTransportation and packagingSulfonic acids salts preparationPtru catalystMethyl carbonate

The invention discloses a preparation method of isooctanol polyoxypropylene ether sodium sulfosuccinate diester. The method comprises the following steps of: adding epoxy propane into isooctanol serving as an initiator under the action of a modified DMC (Di Methyl Carbonate) catalyst for undergoing a condensation reaction to obtain isooctanol polyoxypropylene ether; undergoing an esterification reaction on the isooctanol polyoxypropylene ether and maleic anhydride under the catalytic action of a solid super acid S2O8<2-> / ZrO2 to obtain isooctanol polyoxypropylene ether sulfosuccinate diester; and undergoing a sulfonation reaction on the isooctanol polyoxypropylene ether sulfosuccinate diester and a sodium metabisulfite solution under the action of a phase transfer catalyst, and adding a NaOH aqueous solution till the pH of a reactant is 4-7 to obtain the isooctanol polyoxypropylene ether sodium sulfosuccinate diester. The preparation method has the advantages of clean, environmentally-friendly and simple production process, higher permeability and remarkable reduction in foams produced in the using process.

Owner:ZHEJIANG HECHENG CHEM

Process of recycling terephthalic acid to produce DOTP (dioctyl terephthalate) by using polyester alkaline to reduce wastewater

InactiveCN104230714AExcellent ester contentSolve the problem that the color is difficult to meet the downstream use standardPreparation from carboxylic acid saltsOrganic compound preparationBenzeneActivated carbon

The invention discloses a process of recycling terephthalic acid to produce DOTP (dioctyl terephthalate) by using polyester alkaline to reduce wastewater. The process comprises the following process steps: adding terephthalic acid reclaimed materials and isooctyl alcohol into a reaction kettle in a certain proportion, stirring and heating, adding a catalyst and activated carbon when water yield is obviously reduced, continuously stirring and heating the mixture, controlling the temperature of the mixture to 190-230 DEG C, carrying out dealcoholization in vacuum after reaction is ended, heating to 265-285 DEG C and distilling under reduced pressure under -0.09MPa to -0.1MPa to obtain raw ester, adding H2O2 in a certain proportion to discolor; and finally, absorbing impurities by use of activated carbon and kaolin and carrying out filter-pressing to obtain a nearly colorless DOTP finished product. According to the process, the raw materials can adopt untreated alkaline which is low in purity and chromaticity to reduce wastewater to recycle the terephthalic acid, so that a complex pretreatment process is avoided, the terephthalic acid reclaimed materials are utilized to the greatest extent, and the high ester content and the low colour and luster of the DOTP product are guaranteed while the efficiency is high and the energy consumption is low.

Owner:上海蓓奕化工有限公司 +1

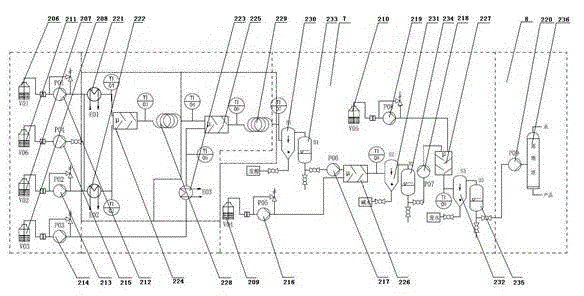

Continuous preparation process for environment-friendly plasticizer and device used in process

InactiveCN103242164ASmall granularityIncrease return flowOrganic compound preparationCarboxylic acid esters preparationIsooctyl alcoholAlcohol

The invention relates to a continuous preparation process for an environment-friendly plasticizer and a device used in the process. The process comprises the following steps of: enabling solid terephthalic acid and isooctyl alcohol which serve as raw materials to react in the existence of an esterification catalyst and an antioxidant for continuously preparing dioctyl terephthalate (DOTP); pulpifying the solid terephthalic acid in the isooctyl alcohol until the particle size of the solid terephthalic acid reaches 5 to 20 mu m; adding the isooctyl alcohol so as to adjust the mole ratio of alcohol to acid in pulp liquid as 2:1 to 4:1; adding into a slurry tank, preheating, and entering a reaction kettle from the bottom; reacting with the preheated isooctyl alcohol which enters from the bottom of the reaction kettle in the reaction kettle in the existence of the esterification catalyst and / or the antioxidant; reacting until an acid value decreases to be below 2, and continuously feeding the raw materials namely the solid terephthalic acid and the isooctyl alcohol; and adding the DOTP which is generated in reaction from the upper part of the reaction kettle to a product tank, condensing the isooctyl alcohol which does not completely reacts and the generated steam through a condenser on the top of the reaction kettle, separating through an oil water separator, and entering an octyl alcohol tank for recirculation.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for synthesizing isooctyl nitrate

InactiveCN1814581AThe synthesis process is smooth and safeProcess safety and stabilityNitric acid ester preparationIsooctyl alcoholNitrate

The invention discloses Isooctyl nitrate compounding method. It includes the following steps: mixing nitric acid and sulfuric acid with mol ratio 1:1-5; adding latent solvent with 10-50% volume ratio to the mixed acid or isooctyl alcohol; adding isooctyl alcohol into mixed acid or adding the mixture of isooctyl alcohol and latent solvent into the mixed acid; reacting for 0.5-1h; static layering; discharging acid liquor; water washing; alkali washing; water washing to neutrality; separating ester from latent solvent; and drying by dryer. The latent solvent can be cycling using.

Owner:CHINA PETROCHEMICAL CORP +1

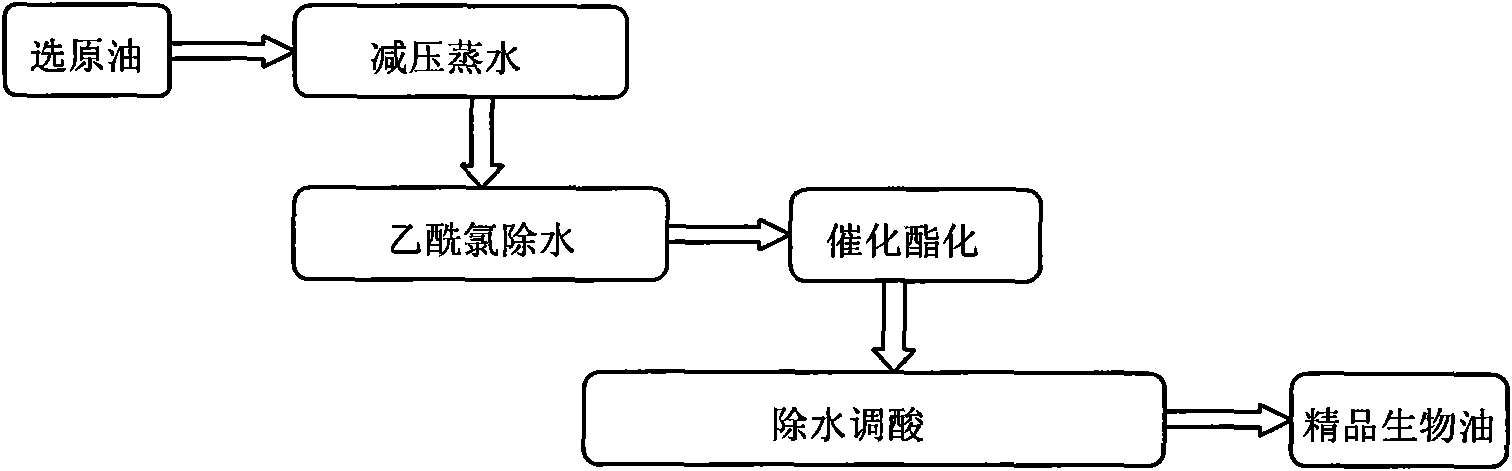

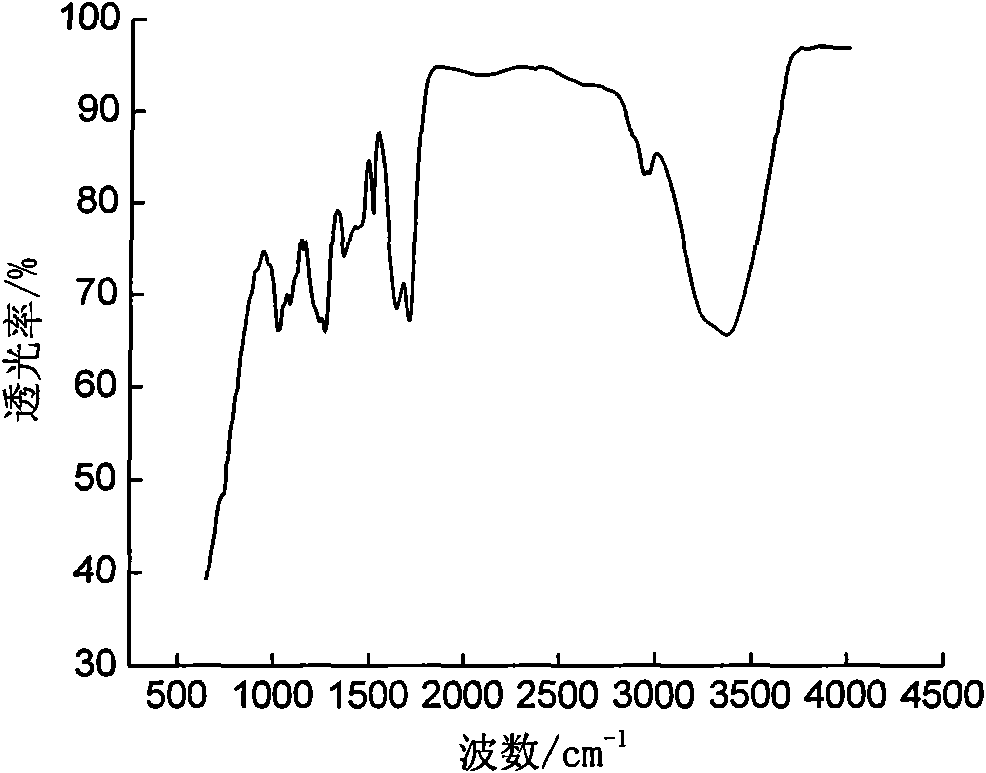

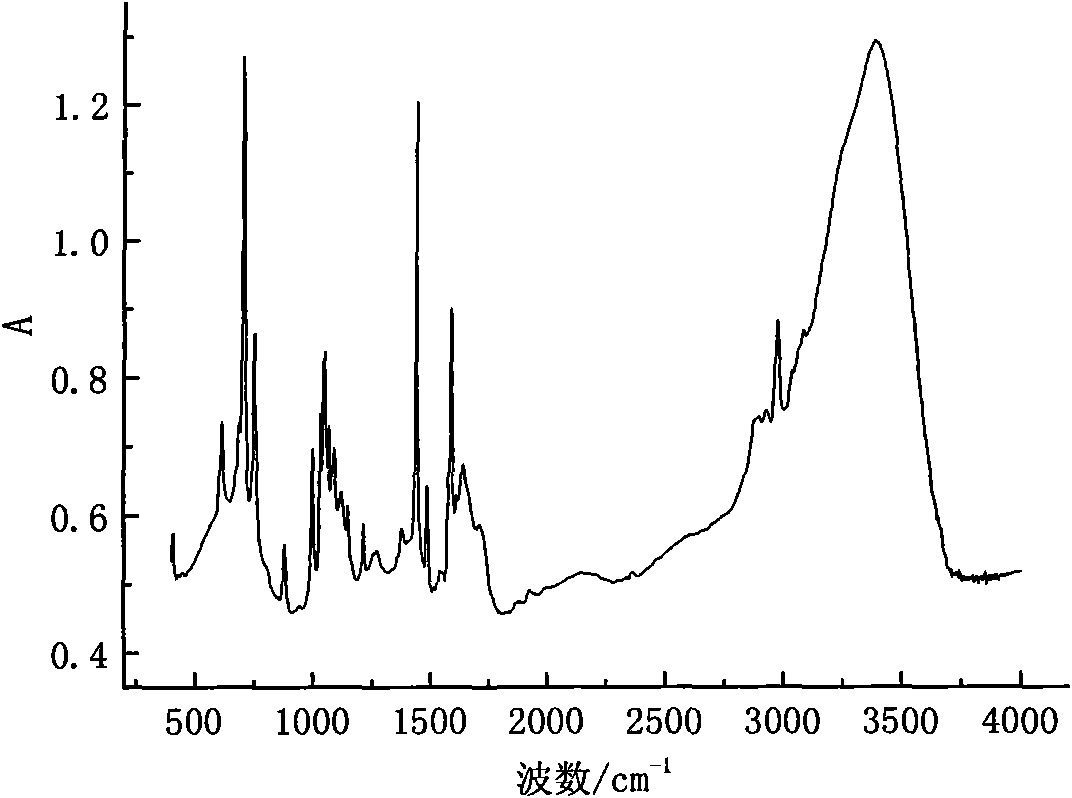

Biomass pyrolysis oil refining method

InactiveCN101899334AWith surfactantRaise the pHLiquid carbonaceous fuelsHydrocarbon oils treatmentWater bathsMass ratio

The invention belongs to the technical field of biomass energy conversion, and relates to a biomass pyrolysis oil refining method. The method comprises the following steps: mixing biological oil stock solution and isooctyl alcohol in the volume ratio of 5:1, adding 2-10 zeolite grains, keeping the low vacuum of 0.02 Mpa, and distilling under reduced pressure in a 80 DEG C water bath until no water can be distilled off, thereby obtaining low-water biological oil; during magnetic stirring, adding equal volume of acetyl chloride to react until no bubbles burst out, thereby obtaining anhydrous biological oil; calculating the generation amount of acetic acid according to the amount of the anhydrous biological oil, adding ethanol to acetic acid in the mol ratio of 2.8:1, mixing catalyst and theanhydrous biological oil in the mass ratio of 1:35, adding 2-10 zeolite grains, stirring, heating for back flow at 80 DEG C, and esterifying to obtain the esterified biological oil; adding anhydrous magnesium sulfate to esterified biological oil in the mass ratio of 1:5 to dehydrate and regulate the acidity; and filtering under reduced pressure to remove solid, thereby obtaining the refined biological oil. The invention has the advantages of simple process route, favorable dehydration effect and high product yield.

Owner:QINGDAO UNIV

Process for producing diisooctyl terephthalate

InactiveCN104262158AHigh purityHigh activityCatalyst carriersOrganic compound preparationIsooctyl alcoholEsterification reaction

The invention discloses a process for producing diisooctyl terephthalate. The process comprises the steps of carrying out esterification in the presence of tetrabutyl titanate catalyst loaded by mesoporous carbon with a high surface area or porous titania, carrying out the rectification, separation, neutralization and impurity removing of isooctyl alcohol and water and the like in a negative-pressure tabulation tower. The esterification reaction in the production process disclosed by the invention can be finished within 3 hours, the reaction and separation processes are simple, the yield is high, diisooctyl terephthalate obtained according to the process for producing diisooctyl terephthalate has the purity higher than 99.8 percent, and the first-grade quality rate of the product reaches 100 percent.

Owner:NANJING COLLEGE OF CHEM TECH

Method for preparing isooctanoic acid

InactiveCN101125810AReasonable recyclingShort reaction timeOrganic compound preparationCarboxylic compound preparationIsooctyl alcoholHydrogen

The invention relates to an isooctyl acid preparation method: isooctyl alcohol and sodium hydroxide are positioned in an inert atmosphere for reaction, with zinc acetate being the catalyst and the temperature being 250-260 DEG C and the pressure being 2.8-3.2 MPa, until no hydrogen is produced, after which the reaction continues under the same pressure for 30-50min, then the reaction product is acidized at normal pressure and at a temperature of 65-80 DEG C, thereby acquiring the crude isooctyl acid which is finely distilled and purified to produce the fine isooctyl acid. The reaction time of the method is short, and the production cycle is essentially confined to 8-10 hours; the method has high purity, as much as 99.5 percent, high yield, fundamentally non-pollution and reasonably recyclable by-products.

Owner:河南庆安化工高科技股份有限公司

Preparation method of dioctyl phthalate (DOP)

InactiveCN104072372ASimple processImprove product qualityOrganic compound preparationCarboxylic acid esters preparationDistillationPhthalate

The invention discloses a preparation method of dioctyl phthalate (DOP). The preparation method comprises the following steps: adding the raw materials including phthalic anhydride and superfluous isooctyl alcohol to a reaction kettle, adding concentrated sulfuric acid as a catalyst, controlling the temperature in the reaction kettle to be 0-150 DEG C, reacting for 16-20 hours, neutralizing the catalyst and unreacted phthalic anhydride with an alkaline solution after the reaction is completed, standing for layering and then carrying out washing with clear water for several times. After alcohol-containing wastewater is collected, alcohols are recovered with a recovery tower and are reused. A lower ester layer after layering is heated to recover alcohols at reduced pressure (isooctyl alcohol is recovered by using a supergravity bed and is reused). After activated carbon is added for decoloration, the finished product of DOP is obtained through filter pressing by adopting a plate-and-frame filter press. The preparation method has the beneficial effects that the superfluous alcohol serves as a water-carrying agent, so that the esterification reaction is gradually carried through to the end, the technological process is simplified and the product quality is good; relative to a process of distillation in a rectifying tower, the preparation method has the advantages that the supergravity bed is used to recover isooctyl alcohol in the process, so that the energy consumption is effectively reduced and the process has better environment-friendly significance.

Owner:池银萍

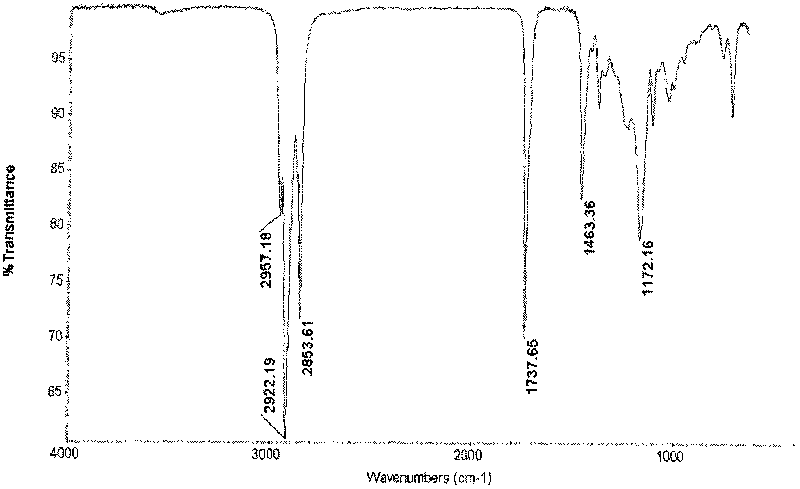

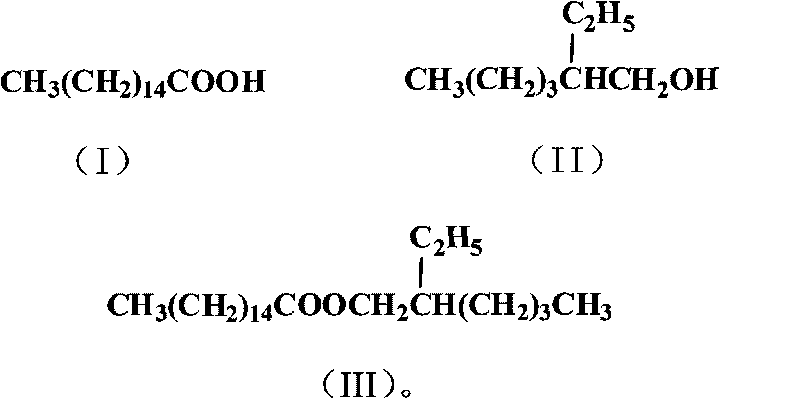

Method for preparing iso-octyl palmitate

ActiveCN101747187AQuality improvementMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationOxalateIsooctyl alcohol

The invention relates to a method for preparing iso-octyl palmitate shown in the formula (III), which comprises the following steps: in the nitrogen atmosphere, making palmitic acid shown in the formula (I) and isooctyl alcohol shown in the formula (II) react with a solid-acid catalyst for 2 to 6 hours at a temperature of between 100 and 180 DEG C; using a water segregator to add a water-carrying agent to carry out water carrying in the reaction process; and carrying out post-treatment on reaction solution after the reaction is finished to obtain the iso-octyl palmitate shown in the formula (III), wherein an amount-of-substance ratio of the total charging of the palmitic acid and the isooctyl alcohol is 1:1-4, the solid-acid catalyst is stannous oxalate, SO42- / ZrO2-Al2O3 or SO42- / TiO2-SnO2-Al2O3, and the usage of the solid-acid catalyst is 1 to 5 percent of the total charging mass of the palmitic acid and the isooctyl alcohol. The invention has the advantages of mild reaction condition, adoption of solid acid serving as the catalyst, reusable property, low equipment investment and operation cost and the like.

Owner:ZHEJIANG UNIV OF TECH

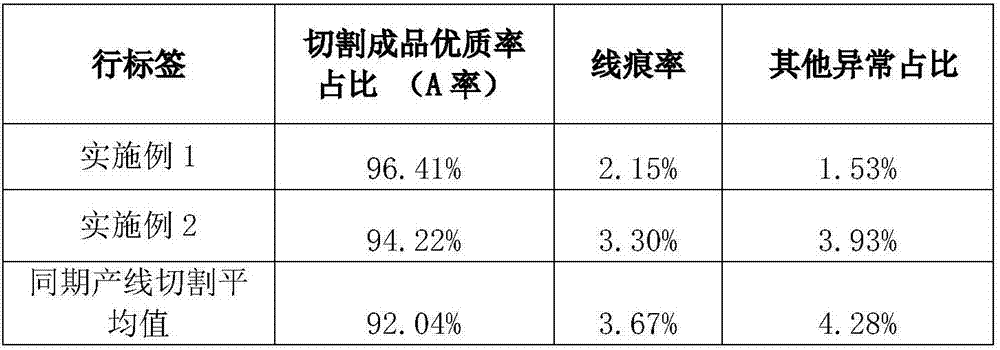

Low-foam water-based diamond wire cutting liquid

InactiveCN107011981AReduce stabilityReduce controllabilityLubricant compositionWater basedWire cutting

The invention provides low-foam water-based diamond wire cutting liquid which comprises the following components in percentage by weight: 3-15 percent of low-foam polyether with a molecular weight of 1500-2000, 2-10 percent of polyether modified polysiloxane with a silicone oil molecular weight of 220-20000 and a polyether molecular weight of 500-2000, 0.5-7 percent of an emulsifying agent, 0.5-5 percent of a PH regulating agent, 0.5-5 percent of a complexing agent, 0.2-1.5 percent of an extrusion agent and 70-95 percent of water, wherein the emulsifying agent uses one or more of isodecanol polyoxyethylene ether, iso-tridecanol polyoxyethylene ether, isooctyl alcohol polyoxyethylene ether, glyceryl monostearate, sorbitan polyethylene laurate and sorbitan stearate; the PH regulating agent is organic amine; the complexing agent is one of or a mixture of more of sodium gluconate, potassium gluconate, sodium nitrilotriacetate, sodium citrate, potassium citrate and sodium potassium tartrate; the extrusion agent preferably selects one or several of sodium carbonate, sodium silicate and sodium sulfate. The low-foam water-based diamond wire cutting liquid provided by the invention can realize a lubricating effect, the abrasion resistance, the cooling performance and the like required to be met in the cutting process.

Owner:ZHENJIANG RENDE NEW ENERGY TECH

Water-ethylene glycol nonflame hydraulic fluid and preparation thereof

The invention discloses water-glycol nonflammable hydraulic liquid which comprises the following compositions and the portion contents: 45 to 55 portions of demineralized water, 25 to 35 portions of glycol, 15 to 25 portions of polyether, 1.5 to 2.5 portions of octanoic acid, 3.0 to 4.0 portions of diethanolamine, 0.1 to 0.2 portion of isooctanol, 0.5 to 0.8 portion of morpholine, 0.3 to 0.8 portion of defoaming agent and 0.1 to 0.2 portion of dye. The preparation method comprises the following steps: (1) according to the portion ratio, the octanoic acid and the diethanolamine are heated to the temperature of between 50 and 80 DEG C in a reaction kettle and evenly stirred and react for 50 minutes; (2) under the condition of continuously stirring and keeping the temperature unchanged, the demineralized water, the glycol, the isooctanol, the morpholine, the dye and the defoaming agent with certain content of portion proportion are added in turn; and (3) finally the mixture is subjected to fine filtration by a filtering device to obtain the product. The product has the characteristics of flame resistance, abrasion resistance, good defoaming performance, etc.

Owner:张亚

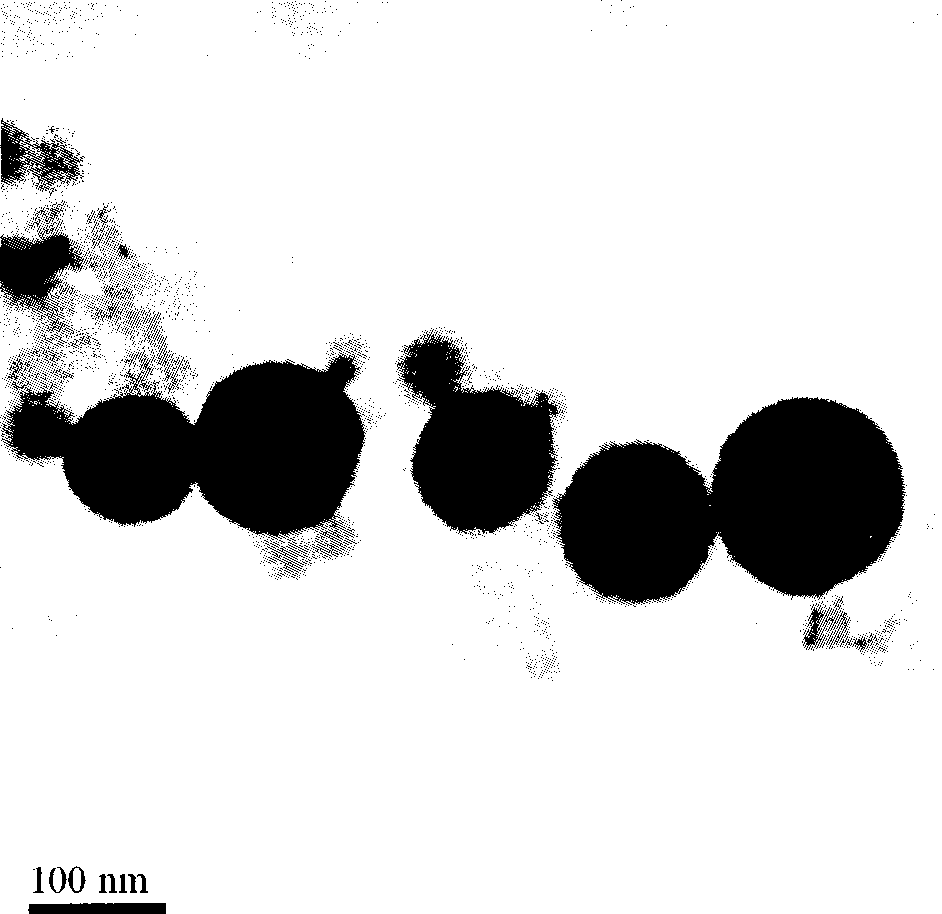

Process for producing spherical FeOOH nano-powder

InactiveCN101428863AFacilitate the control of the generation processLow costIron oxides/hydroxidesIsooctyl alcoholAlcohol

The invention discloses a method for preparing spherical FeOOH nano-powder, which comprises the following steps: blending a liquid A, a liquid B and Fe<3+> water solution while stirring; adjusting the pH value; stirring; separating the liquids into the organic phase and the water phase loading metal Fe, wherein, the liquid A is tributyl phosphate (TBP), and the liquid B is isooctyl alcohol and kerosene; blending the organic phase and the inorganic base solution; stirring; conducting the hydrothermal back-extraction reaction at the temperature of 100 to 200 DEG C; cooling to 20 to 35 DEG C; opening the autoclave; taking out the materials; carrying out the solid-liquid separation; rinsing the solid part with absolute alcohol; and drying to obtain the spherical FeOOH nano-powder. The invention has the advantages that only the raw material of iron salt is consumed, thereby ensuring the low cost; the purity of the product is high; the average particle diameter is about 100 nm; the reaction is mild; the reaction time is short; the high-temperature calcination is not required; the process is simple; the energy consumption is low; the extracting agent can be directly recycled; the discharge of the waste liquid is avoided; and the method belongs to green synthesis technology.

Owner:TIANJIN UNIV

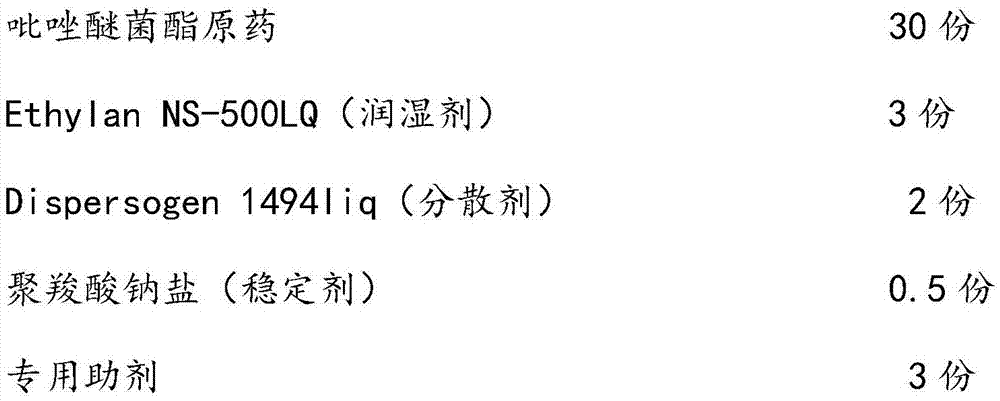

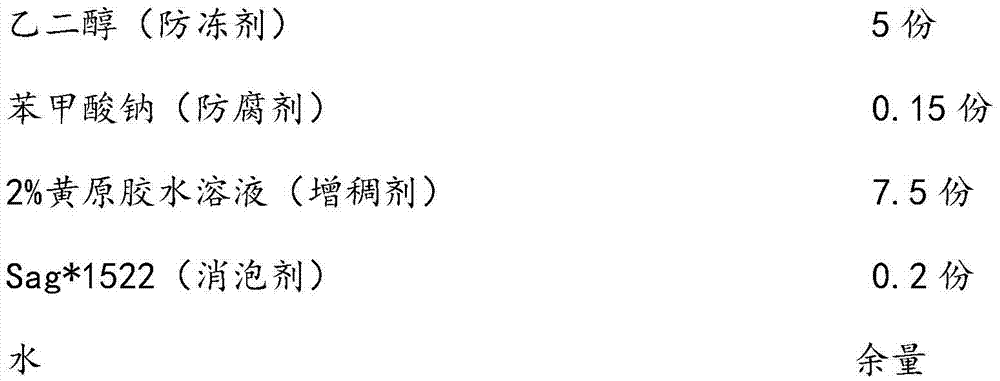

Low-melting-point compound suspension and preparation method thereof

ActiveCN105432604AMeet environmental protection requirementsWide application areaBiocideAnimal repellantsOctanolDodecylbenzenesulfonic acid

The invention discloses a low-melting-point compound suspension. The low-melting-point compound suspension comprises the following components in parts by weight: 5 to 55 parts of a low-melting-point compound, 1 to 7 parts of a moisturizing agent, 2 to 5 parts of a dispersant, 0.5 to 3 parts of a stabilizing agent, 2 to 6 parts of an anti-freezing agent, 0.1 to 0.5 part of a preservation, 1 to 8 parts of a thickening agent, 0.1 to 0.5 part of an anti-foaming agent, 1 to 15 parts of a special auxiliary agent, and the balance of water; the low-melting-point compound is a compound with the melting point between 35 and 70 DEG C; the auxiliary agent comprises the following components in parts by weight: 8 to 40 parts of isooctyl alcohol polyoxyethylene ether, 8 to 30 parts of calcium dodecyl benzene sulfonate, 6 to 20 parts of dioctyl sodium sulfosuccinate, 6 to 18 parts of octanol, and 3 to 5 parts of liquid paraffin. The invention also discloses a preparation method for the suspension. The preparation method comprises the following steps: mixing uniformly, grinding, adding the thickening agent and stirring uniformly. The low-melting-point compound suspension is high in fluidity, obvious in medicinal effect, easy to prepare, and low in production cost.

Owner:ZHEJIANG TIANFENG BIOLOGICAL SCI

Solid superstrong acid catalyst of esterification of preparation thereof

InactiveCN1680028AReduce dosageHigh catalytic activityPhysical/chemical process catalystsOrganic compound preparationAluminium nitrateIsooctyl alcohol

An ultra-strong solid acid catalyst used for esterifying reaction to synthesize tetraisooctyl sym-phenyltetraformate (TOPM) from sym-phenyl tetraformic dianhydride and isooctanol is prepared from titanium sulfate, aluminium nitrate, sulfuric acid and RE salt. Its formula is SO4 / Ti-Al-M-O, where M is chosen from Re, Tm and La. Its advantages are high activity and selectivity, long service life and low reaction temp.

Owner:NANJING TECH UNIV

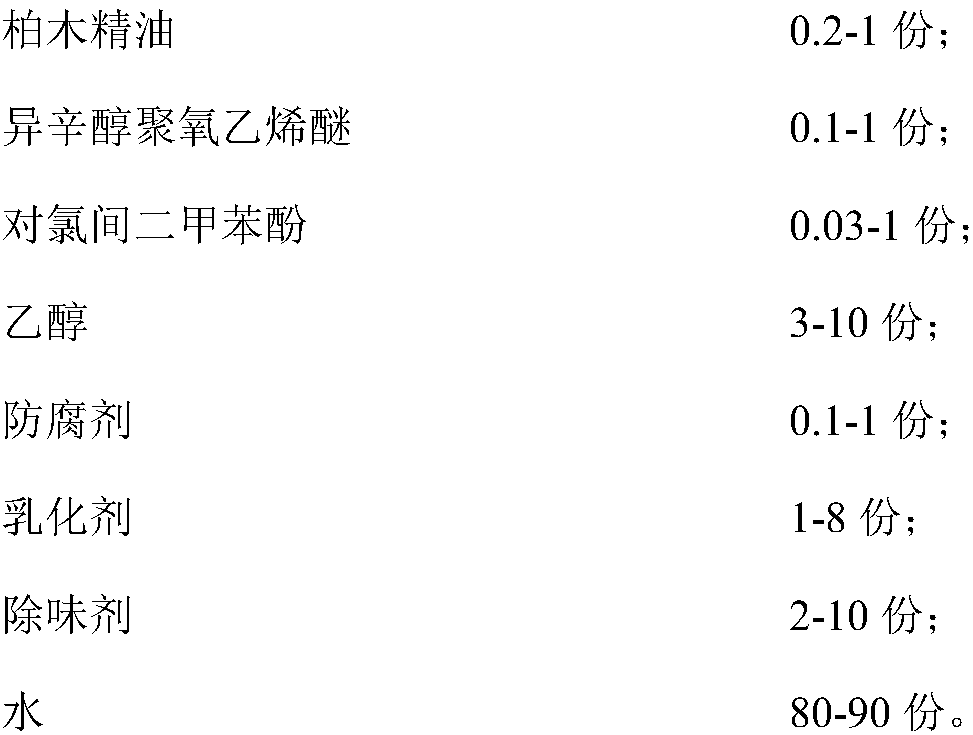

Multifunctional formaldehyde-removing deodorant

ActiveCN108434954ASimple ingredientsFew ingredientsGas treatmentDispersed particle separationIsooctyl alcoholPreservative

The invention provides a multifunctional formaldehyde-removing deodorant. Preparative raw materials of the multifunctional formaldehyde-removing deodorant at least comprise cedar-wood essential oil, isooctyl alcohol polyoxyethylene ether, parachlormetaxylenol, ethanol, a preservative, an emulsifier, a deodorant and water. The multifunctional formaldehyde-removing deodorant provided by the invention is simple in raw materials, low in cost and simple in preparation process; incompatibility of the compounded raw materials can be effectively solved, and effects of removing odor, killing bacteria and removing formaldehyde can be achieved at the highest efficiency.

Owner:浙江施维康生物医学材料有限公司 +1

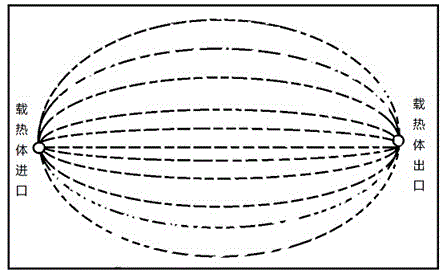

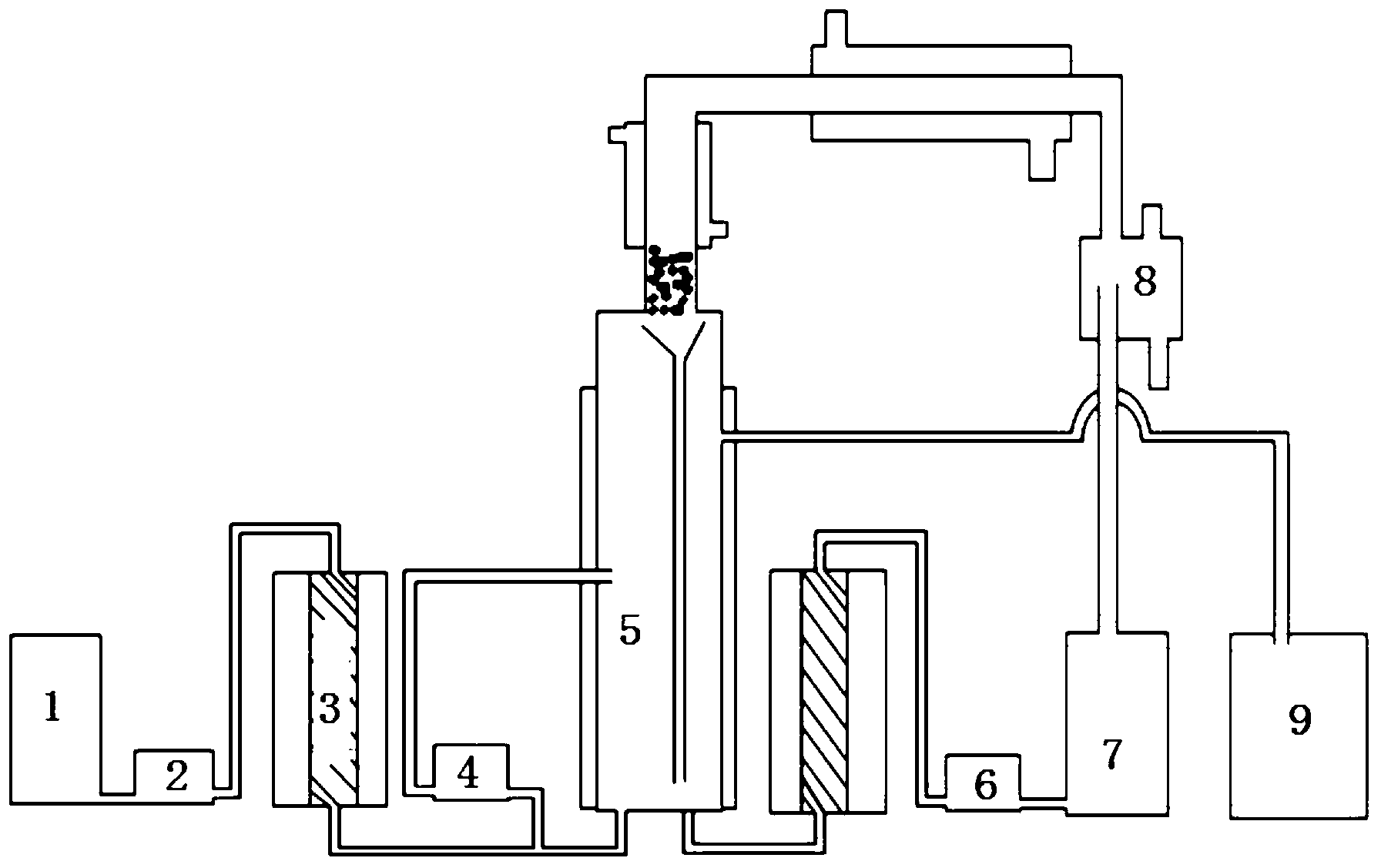

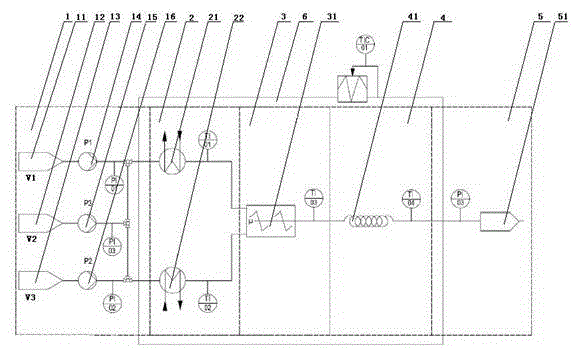

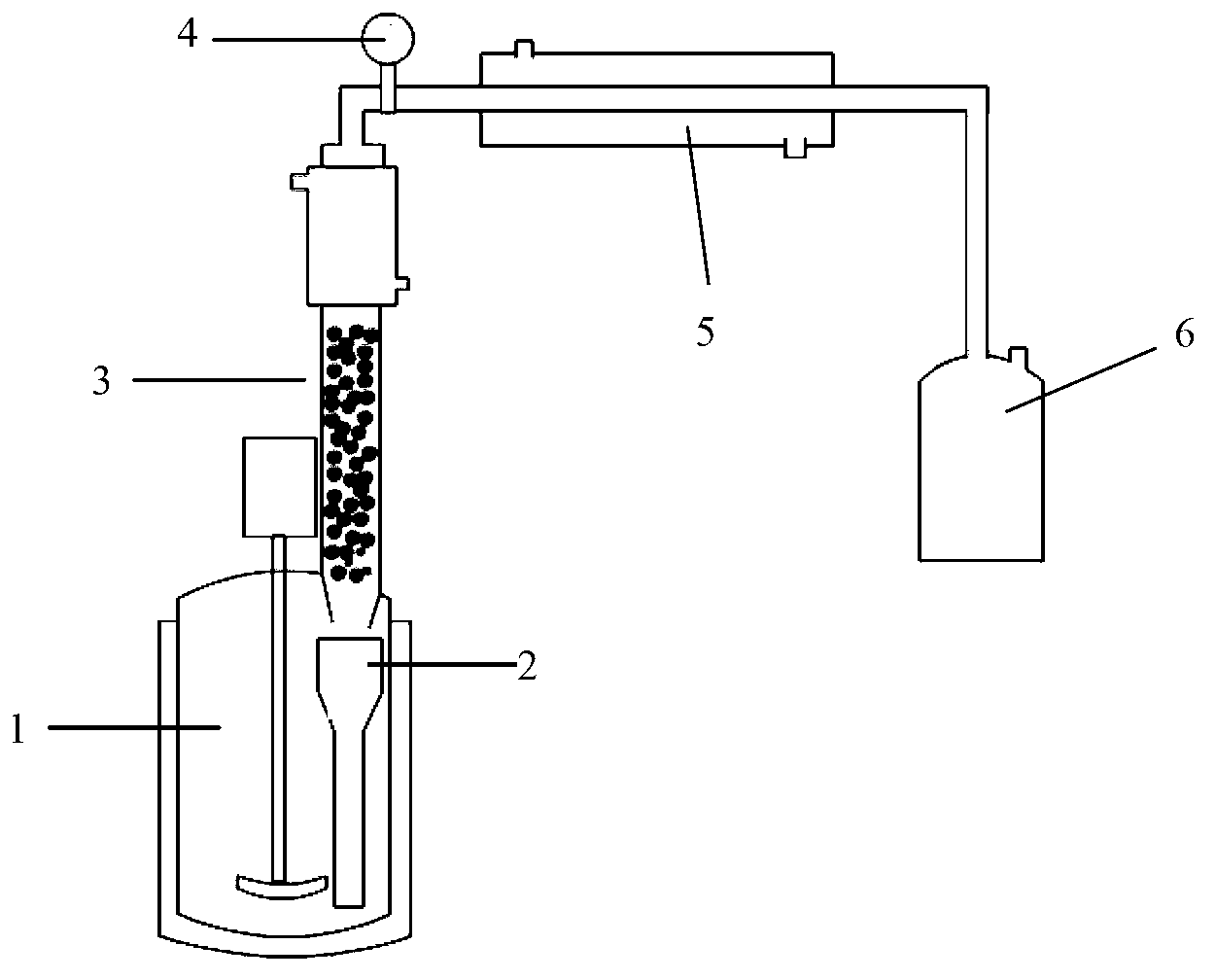

Device and process method for producing isooctyl nitrate

ActiveCN104557556ARealize industrial mass productionAvoid security risksChemical industryMixersIsooctyl alcoholProcess engineering

The invention discloses a device for producing isooctyl nitrate and a process method for producing isooctyl nitrate by using the device. The device comprises a feed system, a precooling system, a mixing system, a reaction system, a receiving system and a circulating bath system, and particularly is an industrial device capable of being used for efficiently and safely producing isooctyl nitrate. The invention mainly aims to solve the problems of potential safety hazards and low production efficiency of the prior art, a connecting device for a micro mixer and an alloy tube array reactor is adopted, and the characteristics of efficient heat and mass transferring capacity and easiness for direct amplification of the device are utilized to ensure that the conversion rate of isooctyl alcohol reaches more than or equal to 99% and the yield of isooctyl nitrate reaches more than or equal to 98%. The device and the method disclosed by the invention have relatively high operational safety and reaction selectivity, can be used for realizing continuous reaction, and are of great significance for strengthening and guaranteeing efficient and safe production of isooctyl nitrate.

Owner:大连微凯化学有限公司

Compound defoaming agent

InactiveCN106731034AFast defoamingLong foam suppression timeWater/sewage treatment by degassingFoam dispersion/preventionIsooctyl alcoholGlycol ethers

The invention discloses a compound defoaming agent which comprises the following ingredients: 20-25 parts of polyoxyethylene polyoxypropylene glycol ether, 20-25 parts of dimethicone, 15-20 parts of polyether modified siloxane, 15-20 parts of glycerol tristearate, 5-10 parts of sodium dodecyl sulfate and 5-10 parts of isooctyl alcohol. The compound defoaming agent has the characteristics of quick defoaming, long foam inhibition time, alkali resistance, acid resistance, high-temperature resistance and good compatibility, and can be widely used for removing harmful foam in industrial production.

Owner:新疆水处理工程技术研究中心有限公司

Method and device for synthesizing plasticizer by regulating pressure

InactiveCN103319346AGood colorFast heating rateOrganic compound preparationCarboxylic acid esters preparationIsooctyl alcoholPlasticizer

The invention provides a method and a device for synthesizing a plasticizer by regulating pressure, using terephthalic acid, isooctyl alcohol and a catalyst as raw materials, wherein a mol ratio of isooctyl alcohol to terephthalic acid is 2.0-3.2:1, weight of the catalyst is 0.1-2% of that of a reaction system. The method comprises: adding the raw materials into a pressure resistant kettle, raising the temperature to 200-240 DEG C, maintaining the reaction pressure at 0-0.4MPa, discharging moisture generated in the reaction by a decompression valve when pressure is raised over 0.3-0.4MPa, and decompressing after 0.5-3h to normal pressure; and raising the temperature to 200-230 DEG C in 1-4h, then regulating negative pressure to -0.1-0MPa in 1-2h, and reaching a reaction endpoint until an acid value is less than 1mgKOH / g, wherein isooctyl alcohol in gaseous state flows back by a rectifying tower in the reaction process, and enters from a kettle bottom by a funnel tube. The method and the device provided in the invention can rapidly synthesize DOTP by regulating pressure, time is shortened, and energy consumption is reduced.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

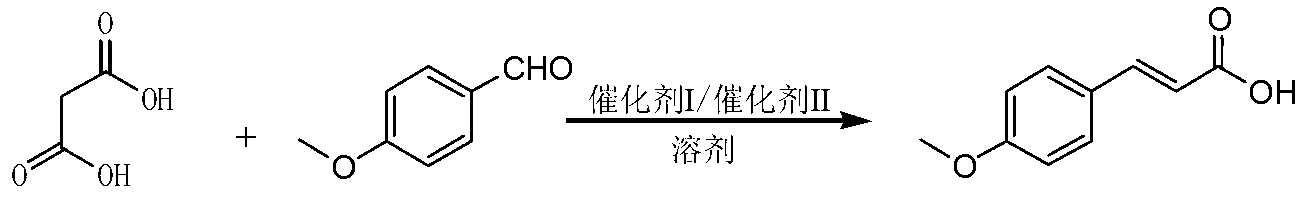

Preparation method of sun-screening agent iso-octyl p-methoxycinnamate

ActiveCN103242163AAchieve separationIncrease profitOrganic compound preparationCarboxylic acid esters preparationWater insolubleSolvent

The invention relates to a preparation method of a sun-screening agent OMC (iso-octyl P-Methoxycinnamate). The preparation method comprises the following steps of: 1, adding p-anisaldehyde, malonic acid, a catalyst I organic secondary amine substance, a catalyst II organic acid substance and a water-insoluble organic aromatic hydrocarbon solvent to a condensation reaction kettle, and carrying out reflux water diversion reaction for 4-5 hours; 2, after condensation reaction is finished, cooling to 5-15 DEG C, filtering to obtain a p-methoxycinnamic acid crude product, directly applying filter liquor to next reaction, and optionally supplementing a small quantity of catalysts and solvents to the filter liquor; 3, adding catalyst III macroporous type storng acid cation exchange resin, isooctyl alcohol, the p-methoxycinnamic acid crude product and an aromatic hydrocarbon or aliphatic hydrocarbon solvent to an esterifying reaction kettle, and carrying out reflux water diversion reaction for 2-3 hours; and 4, after esterifying reaction is finished, cooling to 65 DEG C, filtering and recovering the catalysts for mechanical application, washing the filter liquor to neutrality through a 5% sodium carbonate water solution, desolventizing, and rectifying to obtain the final product isooctyl p-methoxycinnamate. The method disclosed by the invention has the characteristics of easiness, convenience, easiness in control, industrial production, low environment pollution, low energy consumption, material recycling, high product purity, and the like.

Owner:ANHUI SHENGNUOBEI CHEM TECH

Method for catalytically synthesizing diisooctyl dodecanedioate base oil by solid superacid

InactiveCN103274938AHigh activityEasy to separatePhysical/chemical process catalystsOrganic compound preparationIsooctyl alcoholPtru catalyst

The invention discloses a method for obtaining high-purity diisooctyl dodecanedioate base oil by synthesizing solid superacid SO4<2-> / ZrO2-TiO2 catalyst with a precipitation-impregnation method, catalytically synthesizing diisooctyl dodecanedioate by dodecanedioic acid and isooctanol, and subjecting to separation and purification. The synthesized catalyst has the advantages of high activity, easiness in separation, capacity of recycling, good stability, high product yield and the like. The synthesized ester base oil has the advantages of high viscosity index and open cup flash point, low pour point and toxicity, good low temperature fluidity, wider operating temperature range, and excellent lubrication, environmental protection and biodegradation properties.

Owner:NANTONG ZHONGCHENG BIOTECH

Preparation method of low-thorium lutetium oxide

ActiveCN101748275AEasy to separateThe separation effect is achievedRare earth metal compoundsProcess efficiency improvementIsooctyl alcoholLutetium

The invention relates to a preparation method of low-thorium lutetium oxide, comprising the following steps of: firstly carrying out 3-10 level of primary countercurrent extraction on lutetium oxide extracted from a solvent as a raw material by adopting an isooctanol or kerosene solution of 0.5-2.0mol / L of N235 extracting agent, and then carrying out 3-10 level of countercurrent washing selective backextraction on organic phases of extracted thorium by adopting 0.1-2mol / L of alkali abluent solution; then separating the low-thorium lutetium oxide by a kerosene solution of 0.1-1.0mol / L of another extracting agent, carrying out 3-10 level of countercurrent washing selective backextraction on the organic phases of the extracted thorium by adopting 0.5-2mol / L of acidic abluent solution, carrying out oxalic precipitation, washing and dehydration on aqueous-phase lutetium oxide after thorium removal, and burning at the condition of 750-1000 DEG C to obtain a product, namely, the low-thorium lutetium oxide. In the method, rare earth and thorium are thoroughly separated, and the organic extracting agent is low in price.

Owner:江阴加华新材料资源有限公司

Delayed coking defoaming agent and preparation method and application thereof

ActiveCN102764521AGood defoamingAdd lessThermal non-catalytic crackingFoam dispersion/preventionPhosphateEther

The invention relates to a delayed coking defoaming agent and a preparation method and application thereof. The defoaming agent comprises the following components in percentage by weight: 5 to 15 percent of isooctanol, 15 to 30 percent of polyether modified silicon oil, 5 to 15 percent of decyne diol, 1 to 10 percent of nonyl phenol (n=10) ether phosphate, and 30 to 70 percent of No.200 solvent oil. The sum of the weight percentages of the components is 100 percent. The silicon content of the defoaming agent is less than 3 percent; the defoaming agent is used for a delayed coking technology; under the condition that the adding quantity of the defoaming agent is 15 to 40ppm, the height of a foam layer can be effectively reduced by 2.5 to 3 meters; and the defoaming agent has an excellent foam inhibiting effect, so that the adding quantity of the defoaming agent is reduced, and the coking cycle of a coke tower is prolonged.

Owner:天津市瑞德赛恩新材料开发有限公司

Production method of isooctyl nitrate

PendingCN107935857AIncrease the nitrification reaction timeEfficient nitrification reactionTransportation and packagingMixersNitrationMixed materials

The invention provides a production method of isooctyl nitrate. The method mainly comprises the following steps that metered conveyance of nitro-sulfuric acid and isooctanol raw materials is performedthrough reliable and stable feeding equipment; the two strands of raw materials are mixed for reaction in a micro mixer; the mixed materials are subjected to heat exchange in a micro heat exchanger and enter a single pipe reactor for further reaction; acidic isooctyl nitrate and waste acid are separated out from a reaction product in an automatic separator; the acidic isooctyl nitrate is fast treated by a conventional water washing, alkali washing and water washing process in a series of micro mixers, and is finally dried or subjected to still standing to remove moisture to obtain a product of isooctyl nitrate. The method has the advantages that the nitration process is safe and efficient; the raw material isooctanol conversion rate and the product selectivity are higher than 99.5 percent; the product acidity value can reach 0.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Environmental-friendly shield tail seal grease and preparation method thereof

The invention provides an environmental-friendly shield tail seal grease and a preparation method thereof. The environmental-friendly shield tail seal grease is prepared from combining the following raw materials in parts by weight: 20 to 35 parts of base oil composition, 6 to 15 parts of viscosity index modifier, 30 to 55 parts of waterproof sealing material, 2 to 5 parts of lubricating agent, and 5 to 25 parts of complex fiber, wherein the base oil composition is prepared from mixing isooctyl alcohol modified colleseed oil and soybean oil or biodiesel according to the mass ratio being 1 to 4:1; the complex fiber is prepared from mixing a mineral fiber and a plant fiber according to the mass ratio being 1 to 4.5:1. The base oil composition is prepared from mixing the isooctyl alcohol modified colleseed oil and the soybean oil or the biodiesel, has excellent abrasion resistance and oxidation resistance, and no harm on soil and underground water, can be degraded within a short term in the underground environment, and solves the problem that a shield tail seal grease has severe pollution on the underground environment during the shield process on the basis of ensuring a better sealing performance.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com