Device and process method for producing isooctyl nitrate

A technology of isooctyl nitrate and isooctyl alcohol, which is applied in the field of microreactor devices, can solve problems such as potential safety hazards and low production efficiency, and achieve cost saving of raw materials, avoiding potential safety hazards, high operational safety and selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

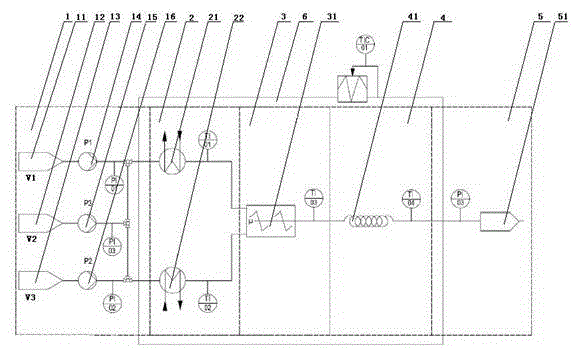

[0043] use figure 1 The micro-reactor device, the mixed acid of fuming nitric acid and concentrated sulfuric acid is added to the raw material storage tank V1, and iso-octanol is added to the raw material storage tank V2, the volume flow ratio of the mixed acid and iso-octanol is adjusted, and the fuming nitric acid and iso-octanol are controlled. The molar ratio of octanol is 1.1, and the molar ratio of concentrated sulfuric acid and fuming nitric acid is 1.1, which are fed by feed pump P1 and feed pump P2 respectively. The total flow rate of feed is 20L / h, and the constant temperature cooling bath is set to 0~ 10 o C. The two feed liquids enter the micro-mixer A to mix and further react in the tube reactor. The reaction liquid enters the receiving storage tank, stands for stratification, separates the acid liquid, washes the ester layer with water, alkali washes and then washes with water. to neutral. The purity of product isooctyl nitrate is 99.6%, and the yield is 98.4%....

Embodiment 2

[0045] The process is the same as in Example 1, only the total flow rate of the feed is changed to 2.0 L / h, and the micro-mixer B is used. The purity of the product isooctyl nitrate is 99.7%, and the yield is 99%.

Embodiment 3

[0047] The process is the same as in Example 1, except that the total flow rate of the feed is changed to 80 L / h, and the micro-mixer C is used. The purity of product isooctyl nitrate is 99.2%, yield 98.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com