Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

233results about How to "Reduce the difficulty of recycling" patented technology

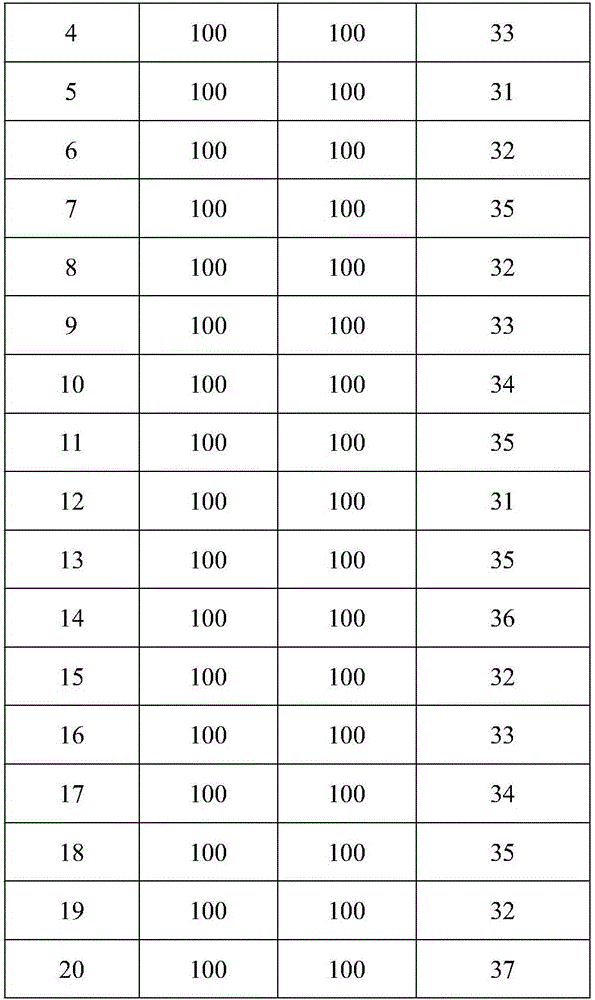

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

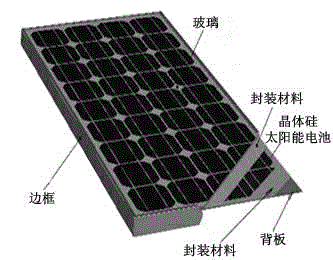

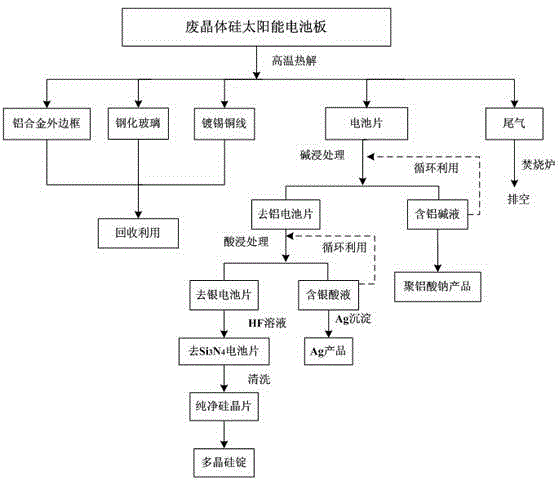

Waste crystalline silicon solar cell panel disassembling and recovering method

ActiveCN103978021AIncrease added valueRealize sorting and recyclingWaste processingSolid waste disposalWaferingPhysical chemistry

The invention discloses a waste crystalline silicon solar cell panel disassembling and recovering method. The method can realize the classification recovery of aluminum frames, toughened glass, silicon wafers, aluminum, silver and copper of waste crystalline silicon solar cell panels. The method adopts a heat treatment technology and a chemical technology combination technique to realize the frame and glass recovery of the waste crystalline silicon solar cell panels, the silicon wafer separation, and the valuable metal and silicon wafer recovery. The method has the advantages of recovery treatment difficulty reduction, tail gas harmlessness realization, secondary pollution control and environment protection; and an alkali dipping treatment and acid dipping treatment solution can be recycled, so the reagent consumption is reduced, the waste acid and waste alkali generation amount is reduced, and the final waste treatment cost is reduced.

Owner:刘景洋

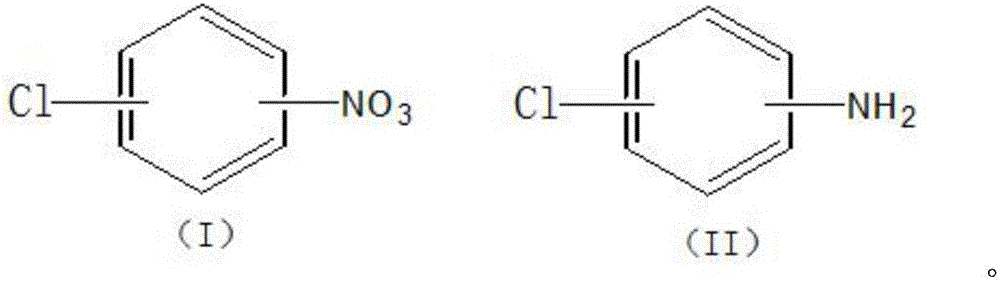

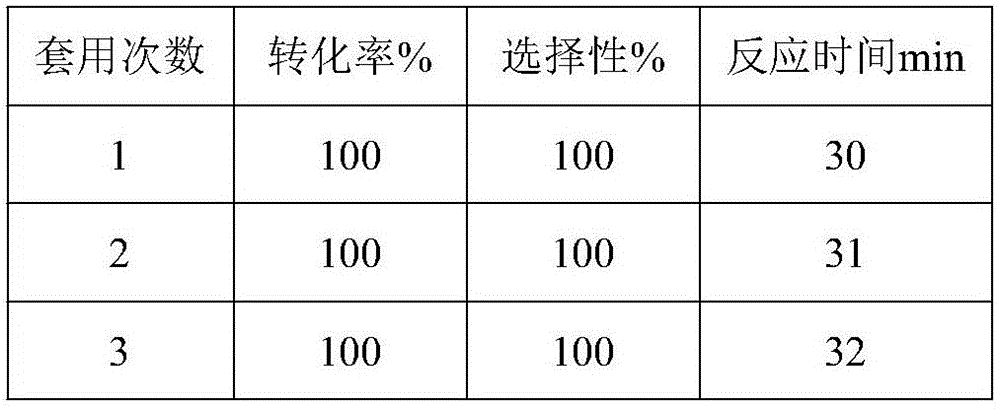

Porous carbon-loaded composite material catalyst as well as preparation method and application thereof

ActiveCN106732549AImprove transfer abilityModulation distribution characteristicsOrganic compound preparationAmino compound preparationIridiumPorous carbon

The invention discloses a porous carbon-loaded composite material catalyst as well as a preparation method and application thereof. The catalyst consists of a carrier, an active component and a carbon quantum dot, wherein the active component and the carbon quantum dot are loaded on the carrier; the size of the carbon quantum dot is not more than 10 nm; the carrier is porous activated carbon; the active component is one of or a combination of several of platinum, palladium, iridium, ruthenium and rhodium; based on the mass of the carrier, the loading quantity of various metals in the active component is shown as follows: the platinum is 0-10.0 percent by weight, the palladium is 0-10.0 percent by weight, the iridium is 0-10.0 percent by weight, the ruthenium is 0-10.0 percent by weight, and the rhodium is 0-5.0 percent by weight; the loading quantity of the platinum, the rhodium and the palladium is not 0; the total loading quantity of the active component is more than 0.5 percent by weight and is not more than 20 percent by weight; based on the mass of the carrier, the loading quantity of the carbon quantum dot is not more than 15.0 percent by weight. The invention further provides application of the porous carbon-loaded composite material catalyst to the reaction of synthesis of chloroaniline by selective catalytic hydrogenation of chloro-nitrobenzene. The catalyst has the characteristics of being high in conversion rate, high in catalytic activity and high in stability.

Owner:ZHEJIANG UNIV OF TECH

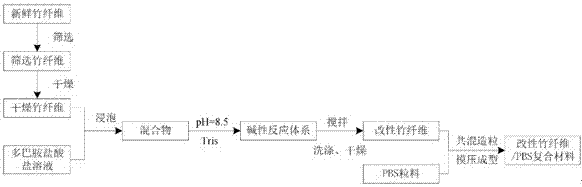

Technique for improving interfacial compatibility of bamboo fiber and polybutylene succinate based on polydopamine bionic interfacial modification modifier

InactiveCN107459830ALow priceGood dimensional stabilityBiocompatibility TestingPoly(butylene succinate)

The invention discloses a method for preparing a bionic modified bamboo fiber reinforced polybutylene succinate (PBS) composite material. The method comprises the following steps: (1) screening a bamboo fiber, keeping the length less than 380mu m, and performing soaking treatment with a dopamine hydrochloride solution; 2) putting trismetyl aminomethane (Tris) into the soaked mixed system to adjust the pH value to alkalescence, stirring at normal temperature and normal pressure, filtering, and drying so as to obtain a polydopamine modified bamboo fiber of which the water content is less than 1%; and 3) uniformly mixing the modified bamboo fiber with PBS granules in a mass ratio of 1:1 in a high-speed mixing machine, pelletizing in a double-screw extruder, performing compression molding on mixed granules in a hot press, naturally cooling in a cold press, and demolding, thereby obtaining a modified bamboo fiber / PBS composite material. According to the method disclosed by the invention, dopamine has biocompatibility, the fiber is slightly damaged, no complex container is needed in the modification process, the production method is simple and convenient and safe and environmentally friendly, and the mechanical properties of the composite material are remarkably improved.

Owner:BEIJING FORESTRY UNIVERSITY

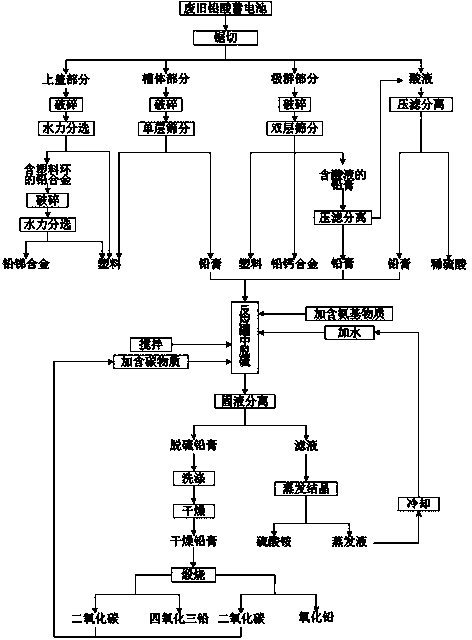

Method for recycling used lead-acid batteries in full circulation mode

InactiveCN103794834AAchieve separationGuaranteed normal processingMetal sawing devicesWaste accumulators reclaimingLEAD TETROXIDELead oxide

The invention relates to a method for recycling used lead-acid batteries in a full circulation mode. According to the technical scheme, a band sawing machine for cutting the used lead-acid batteries is used for sawing and cutting a used lead-acid battery into an upper cover, a groove body, an electrode set and acid liquid, and the upper cover, the groove body, the electrode set and the acid liquid are respectively processed to obtain lead-antimony alloy, plastic, lead plaster, lead-calcium alloy and dilute sulphuric acid. Then, the lead plaster is added into a reaction tank, amidogen-contained substances are added to the lead plaster, stirring is conducted, desulfurization is conducted after carbon-contained substances are added, solid-liquid separation is conducted, and therefore desulfurated lead plaster and filter liquid are obtained. Then, the filter liquid is evaporated and crystallized to obtain ammonium sulfate, and liquid evaporated in the evaporation and crystallization process is cooled to the room temperature and recycled. The washed desulfurated lead plaster is dried, and the dried desulfurated lead plaster is roasted at the temperature larger than 400 DEG C and smaller than or equal to 500 DEG C or at the temperature larger than 500 DEG C and smaller than or equal to 650 DEG C to obtain lead tetroxide or lead oxide. The method has the advantages of being simple in process, low in recycling cost, high in recycling rate, high in product purity and environmentally friendly.

Owner:襄阳远锐资源工程技术有限公司 +1

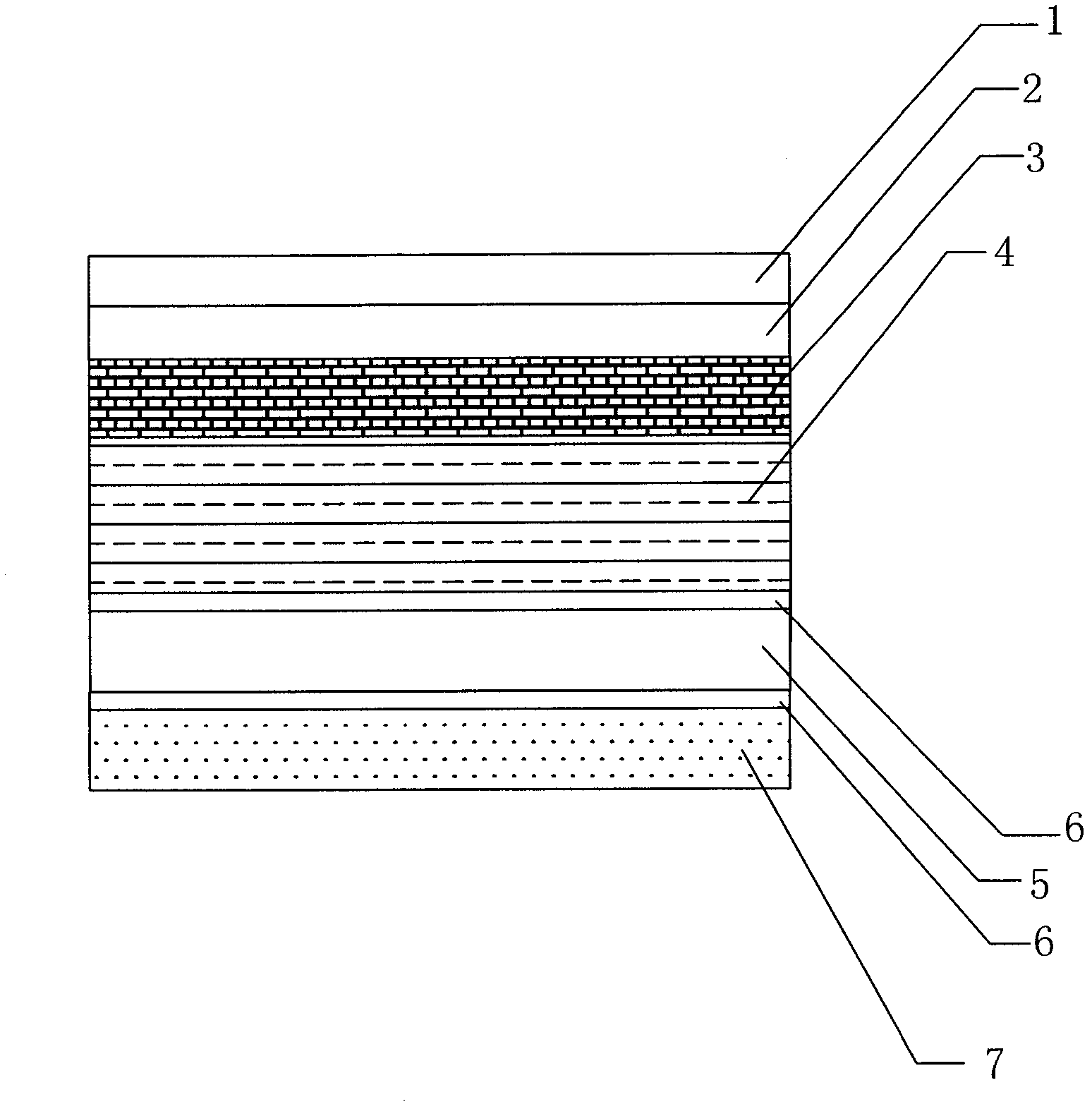

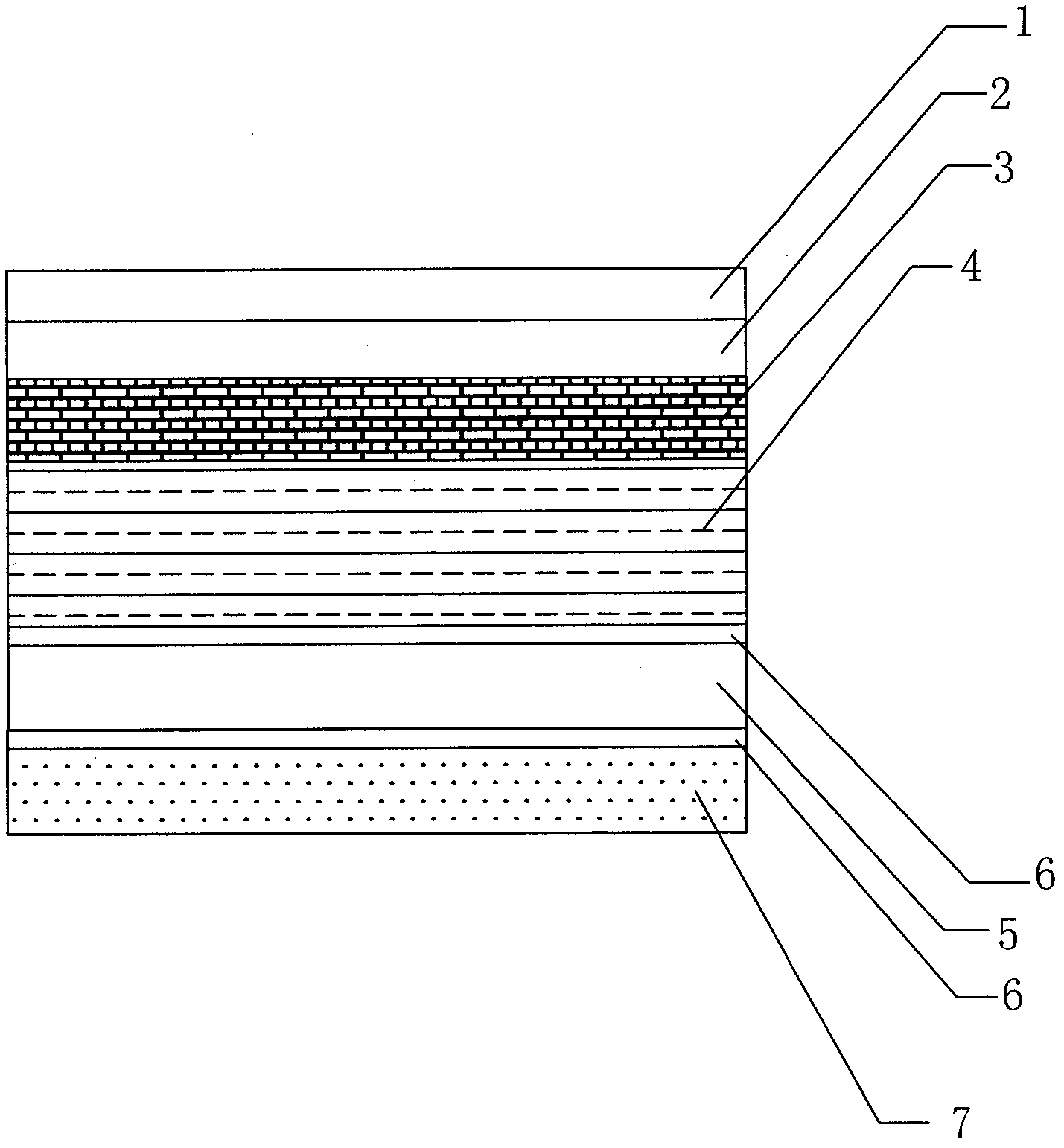

Preparation method for lamination blocking type package materials

ActiveCN102380989AAvoid damageLower surface statePackage recyclingFlexible coversCardboardImage resolution

The invention relates to a preparation method for lamination blocking type package materials, which comprises the steps that: a laminated film is extruded at least one side surface of a support layer base material, simultaneously, the surface treatment is carried out on the laminated support layer base material, blocking type coating liquid is coated onto the surface of the laminated film, a blocking layer is prepared through baking, a composite hot sealing layer is extruded on the outer surface of the prepared blocking layer, a light shading layer is compounded on one side surface of the support layer base material, in addition, the surface tension reaches higher than 38 dynes through pretreatment, in addition, printing layer coating liquid is coated on the outer side surface of the light shading layer, a printing layer is obtained after baking, and a protection layer is extruded on the outer side surface of the printing layer, so the printing layer and the protection layer are compounded. The light shading layer and the printing layer are compounded on the support layer, the requirement on paper boards by printing is reduced, the resolution ratio of images can be greatly improved, simultaneously, the cost is reduced, in addition, an oxide coating is used for replacing an aluminum foil to be used as the blocking layer, the problems of difficult recovery and difficult degradation caused by aluminum foil discharge are reduced, and simultaneously, high oxygen blocking performance is provided.

Owner:GREATVIEW BEIJING TRADING CO LTD

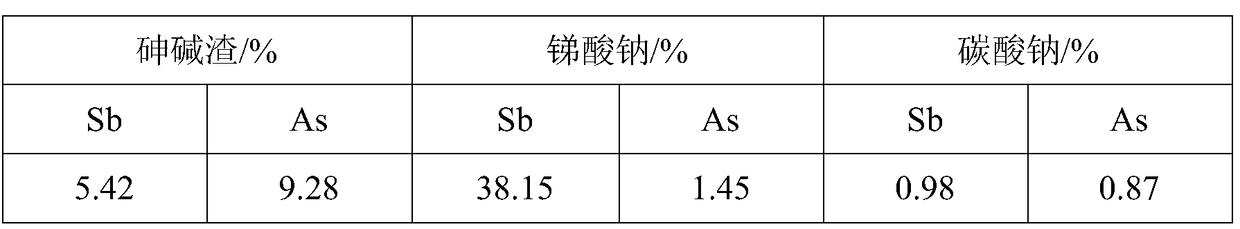

Method for achieving efficient and comprehensive resource utilization of arsenic-alkali residues

ActiveCN108611494AReduce the difficulty of recyclingHigh crystallinityProcess efficiency improvementSodium bicarbonateResource utilization

The invention discloses a method for achieving efficient and comprehensive resource utilization of arsenic-alkali residues. The method comprises the steps that after oxidation and water logging are conducted on the arsenic-alkali residues, solid-liquid separation is conducted, so that leachate and antimony-enriched residues are obtained; an ammonium-source solution is made to react with metallic oxide, so that a metallic ammonium complex ion solution is obtained; the metallic ammonium complex ion solution and a crystal growth accelerant are added to the leachate for a reaction, a mixed solution obtained after the reaction is sequentially subjected to aging, crystallization, precipitation and solid-liquid separation, and an obtained solid phase is an ammonium arsenate metallic salt product;and firstly, treatment of heating for ammonium removal is conducted on a liquid phase, then, carbon dioxide is introduced for a reaction, so that sodium bicarbonate crystals are separated out, and thermal decomposition is conducted on the sodium bicarbonate crystals, so that a sodium carbonate product is obtained. By means of the method, antimony, alkali and arsenic can be rapidly and efficientlyseparated out of the arsenic-alkali residues; the effect that the arsenic is efficiently separated from the alkali is achieved; and in addition, the method is low in cost, simple in process and convenient to operate, and the requirement of industrialized production is met.

Owner:CENT SOUTH UNIV

Method for extracting microbial oil

InactiveCN104479862AReduce adverse reactionsAvoid regulationsFatty-oils/fats productionMicrobial oilOil and grease

The invention provides a method for extracting microbial oil. The method comprises the following steps: oil-producing microorganisms are inoculated and fermented; a fermentation liquor obtained after fermentation is further smashed and dried through a separating system, and dry biomasses with the water content not higher than 20 percent is obtained; after even mixing, physical wall breaking is performed on the dry biomasses and an organic solvent for extraction until the volume average diameter of thallus particles are smaller than 600 mum; an oil mixture is obtained through solid-liquid separation to a mixed solution after physical wall breaking; the microbial oil is obtained through desolvation to the oil mixture. According to the method for extracting microbial oil, provided by the invention, adding enzyme for wall breaking is not required, risks, caused by enzyme residue, on aspects of laws and regulations and food security, can be avoided, more deterioration reactions of oil under high temperature can be reduced greatly, and energy consumption is reduced.

Owner:CABIO BIOTECH WUHAN CO LTD

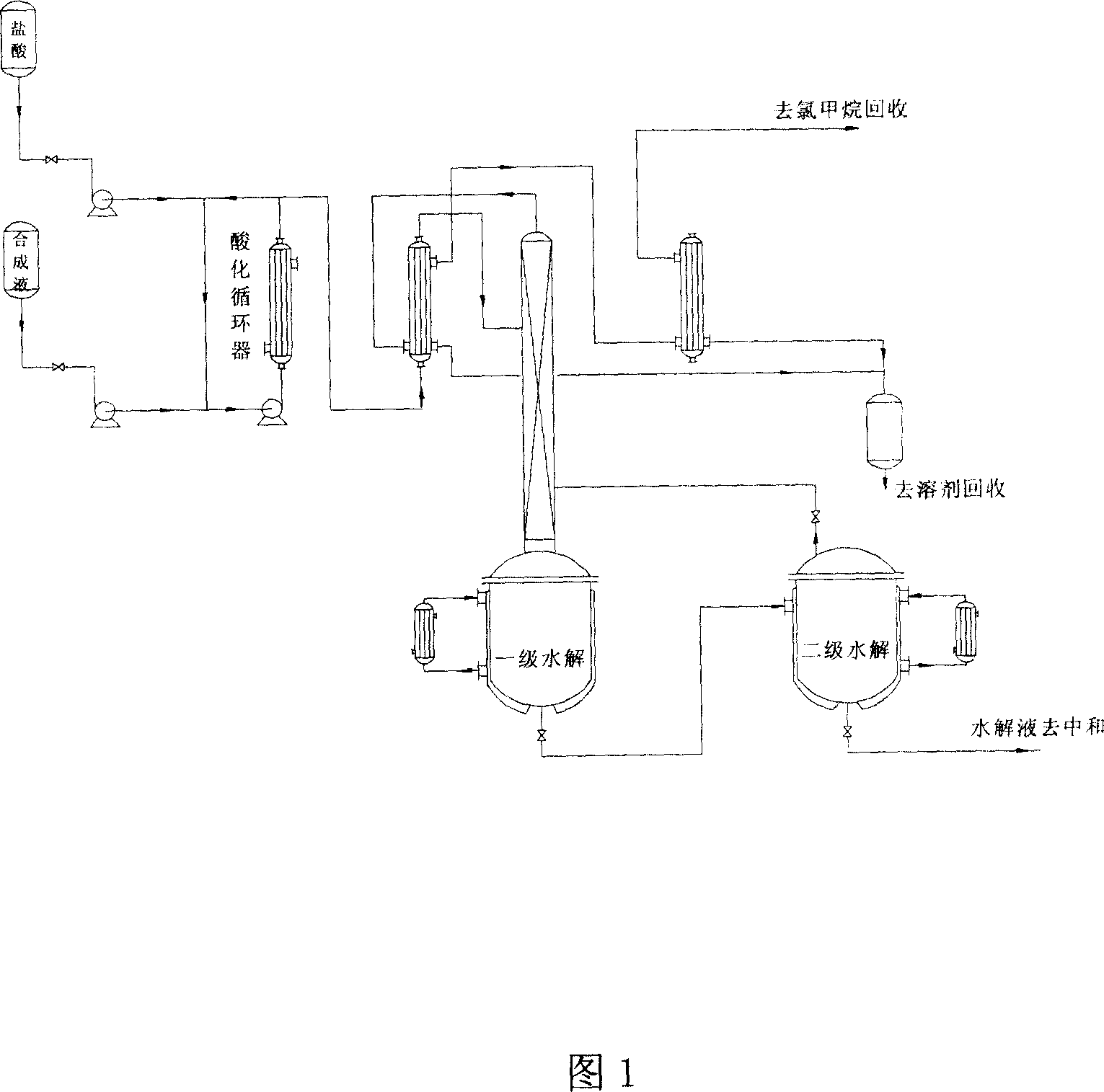

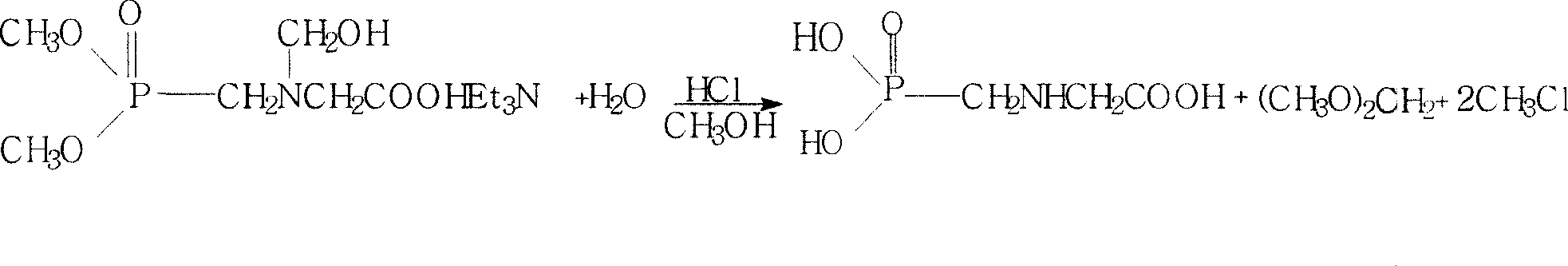

Continuous synthesis of glyphosate by dimethyl ester

Continuous synthesis of glyphosate by dimethyl ester is carried out by taking paraformaldehyde, amino acetic acid and dimethyl ester as raw materials to obtain synthetic liquid, acidizing it with hydrochloric acid, mixing, entering into hydrolytic reactive zone, reacting in hydrolytic reactor continuously, acidizing synthetic liquid, hydrolyzing in hydrolytic reactive zone continuously, forming into glyphosate salt, batching continuously and neutralization crystallizing to obtain the final product. It realizes continuous hydrolysis and simplifies process and can be used in large-scale production.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Recovery method of waste lithium ion battery negative electrode material

ActiveCN111430831AHigh recovery rateHigh lithium contentCarbon compoundsNegative electrodesMetal leachingElectrical battery

The invention discloses a recovery method of a waste lithium ion battery negative electrode material. The method comprises the following basic steps of 1) mixing the waste lithium ion battery negativeelectrode powder with molten salt; 2) carrying out heat treatment on the mixed powder at a temperature not lower than the melting point of molten salt; and 3) soaking the material subjected to heat treatment in water, uniformly stirring, carrying out solid-liquid separation, recovering lithium and other valuable metals by using the liquid phase, and drying the solid phase to obtain the regenerated negative electrode material. According to the invention, the purification and structure repair of the negative electrode material in the waste lithium ion battery negative electrode material and therecovery of valuable metals are realized. The method has the advantages of short treatment flow and low cost, and the obtained regenerated negative electrode material is high in purity, good in crystallinity and high in valuable metal leaching rate and is suitable for the large-scale production.

Owner:湖南烯富环保科技有限公司

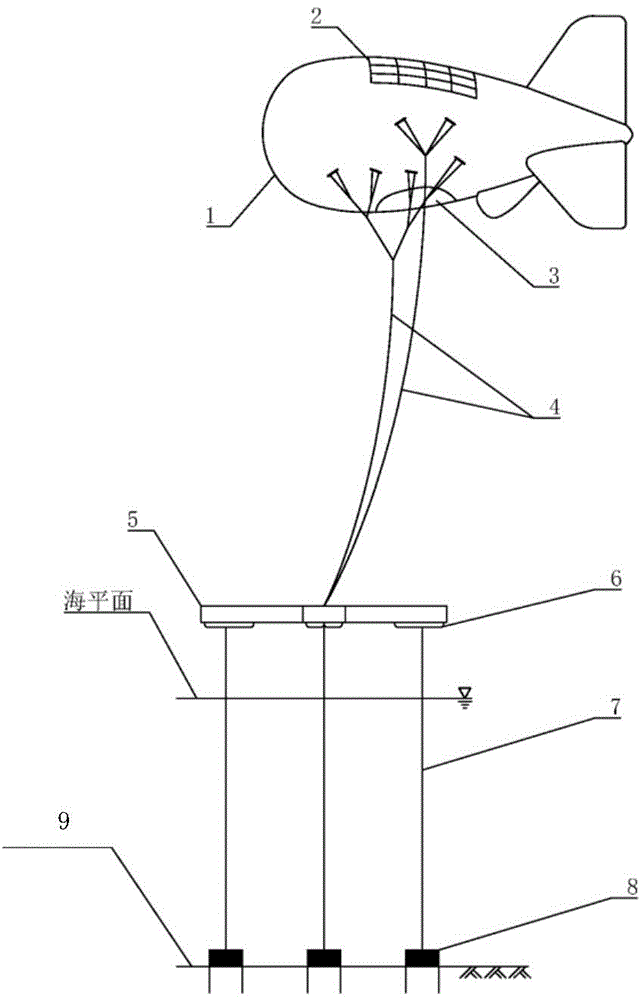

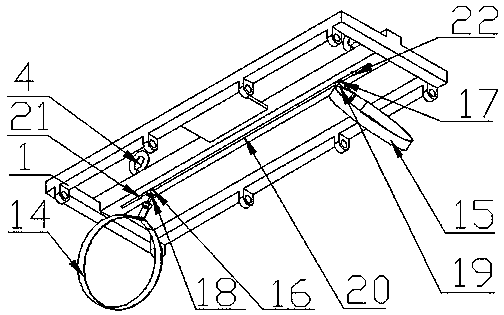

Tethered balloon system used for marine environmental monitoring

InactiveCN104787297AReduce the stress areaReduce the impactBalloon aircraftsFloating buildingsEnvironmental monitoringTension-leg platform

The invention discloses a tethered balloon system used for marine environmental monitoring. The tethered balloon system can fixedly float in the sea to achieve monitoring and is good in stability performance and easy to transport, install and recycle in the sea. Floating of a tethered balloon is limited within a certain range through a tension leg platform. When the tethered balloon does not rise to a predetermined height yet, buoyancy force produced by gas stored in a compressed gas bag can guarantee normal working of the tension leg platform. When the tethered balloon rises to the predetermined height and starts to perform monitoring, lift force of the tethered balloon provides tension required by stabilization of the tension leg platform, and therefore the design of a pontoon is omitted. Meanwhile, upward traction borne by the tension leg platform can relieve the influence on a bearing platform by a transverse wave load, and therefore the stability of the bearing platform is improved. Besides, the compressed gas bag can be used for storing a certain amount of helium gas, so the height of the tethered balloon is reduced, the tethered balloon is convenient to maintain and recycle, maintenance difficulty and recycling difficulty are lowered, and the helium gas in the tethered balloon can be recycled.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

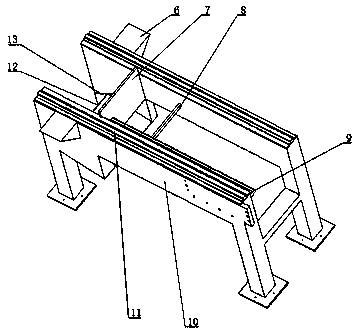

Automatic spraying device, spraying production equipment and automatic spraying method for floor side

InactiveCN101733224AUniform amount of sprayingIncrease profitSpraying apparatusPretreated surfacesEngineeringContinuous operation

The invention relates to a processing technology of floors. An automatic spraying device for a floor side comprises a containing slot, wherein the containing slot can be used for containing the floor side, the containing slot is provided with a spray head and a paint recovering opening, the spray head is connected with a paint transmission pipeline, and the paint recovering opening is connected with a paint recovering pipeline. Automatic spraying production equipment for the floor side comprises a floor feeding device, an automatic spraying device, a drying device and a polishing device, wherein the automatic spraying device comprises the containing slot which can be used for containing the floor side, the containing slot is provided with the spray head and the paint recovering opening, the spray head is connected with the paint transmission pipeline, and the paint recovering opening is connected with the paint recovering pipeline. The automatic spraying device for the floor side is used for spraying, the automation degree is high, and both sides of the floor have uniform spray amount and uniform color, thereby solving the problem of a manually operated original method, lowering the labor intensity of workers and realizing continuous operation; and the paint recovering opening is arranged, thereby improving the utilization ratio of paint and greatly lowering the production cost.

Owner:GUANGDONG YINGRAN WOOD IND

Regeneration method for alkali metal poisoned denitration catalyst

InactiveCN106179528AEfficient removalAvoid churnCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsRegenerative processActive component

The invention discloses a regeneration method for an alkali metal poisoned denitration catalyst. After ash removal is carried out, the alkali metal poisoned denitration catalyst is dipped in an ammonium salt aqueous solution; and then a mixed solution is transferred to a microwave reactor to carry out microwave treatment, and filtered, dried and roasted to obtain a regenerated denitration catalyst. The regeneration method for the alkali metal poisoned denitration catalyst disclosed by the invention is simple to operate, short in processing time and better in removal effect for alkali metals on the surface of an inactivated denitration catalyst, and further can remove most of calcium compounds on the catalyst. Furthermore, active components of the denitration catalyst are not lost greatly in the regenerative process.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

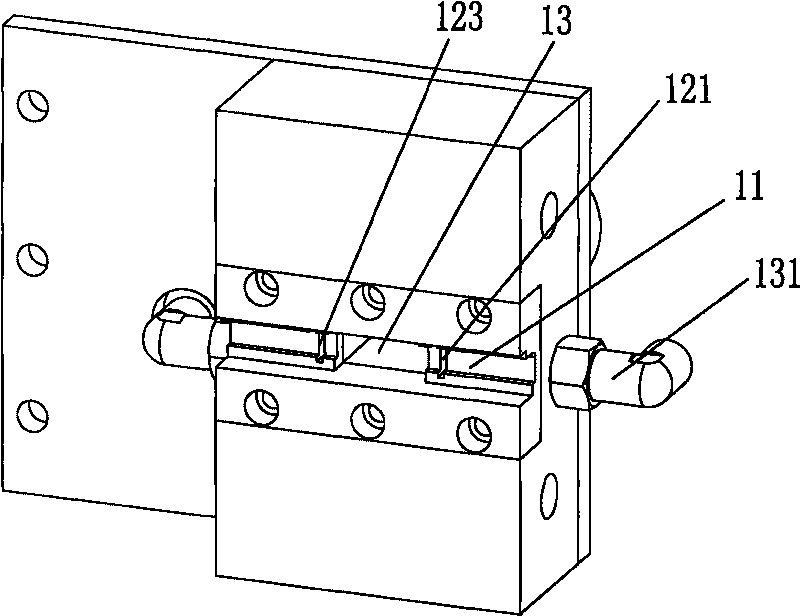

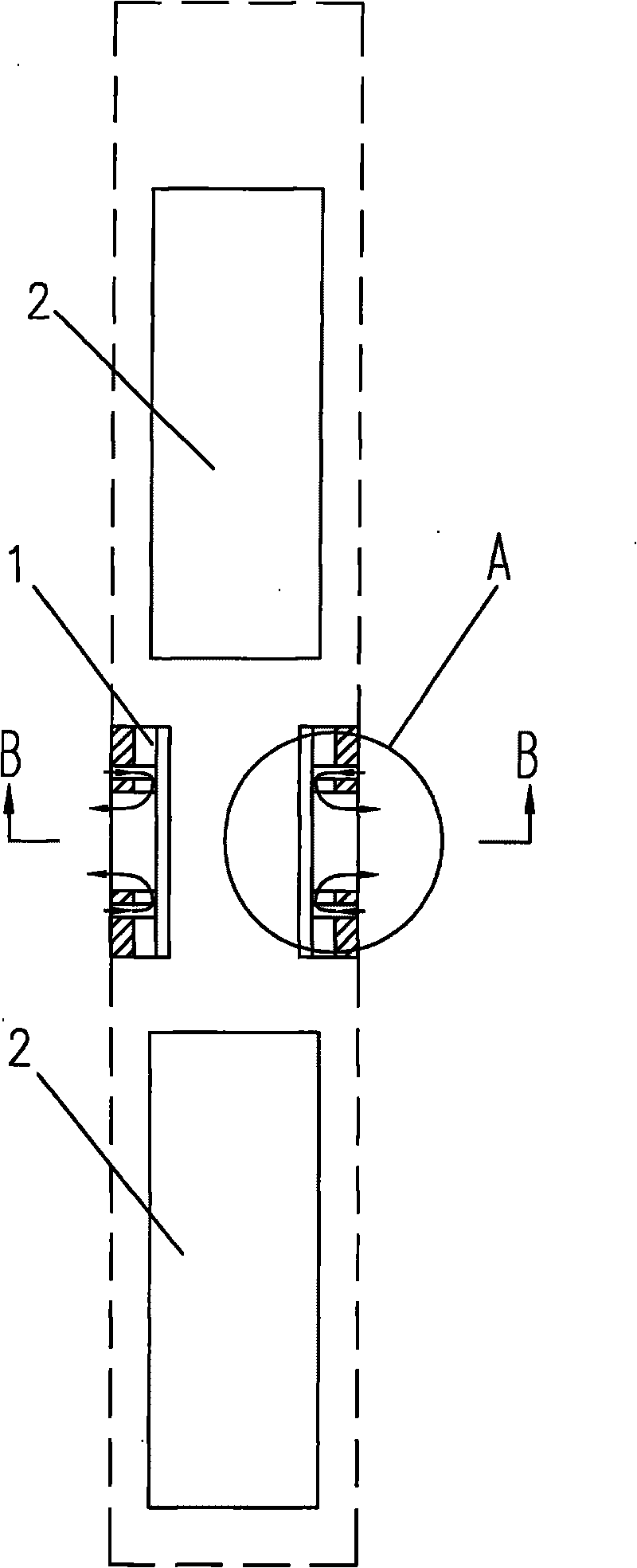

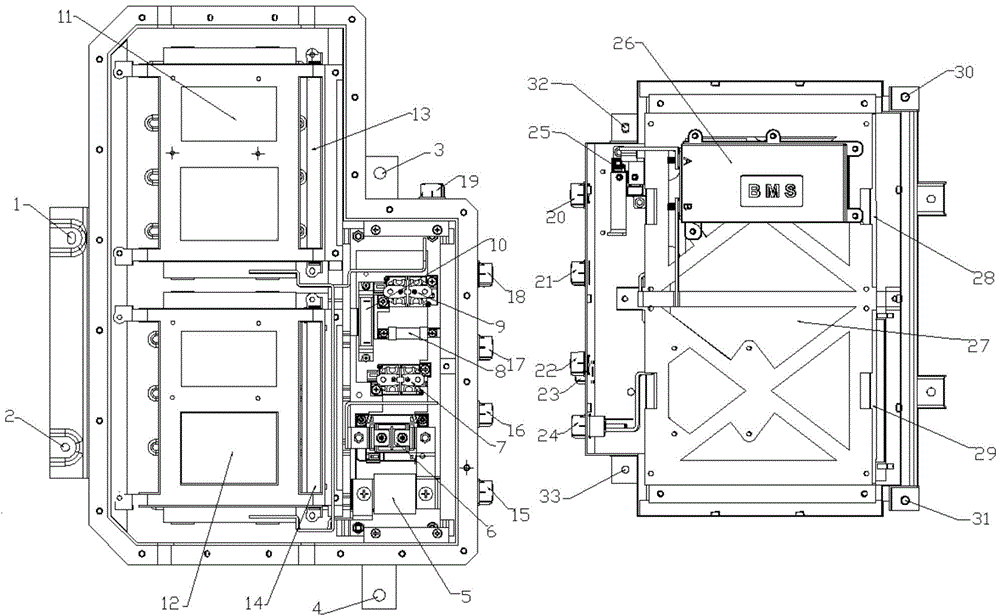

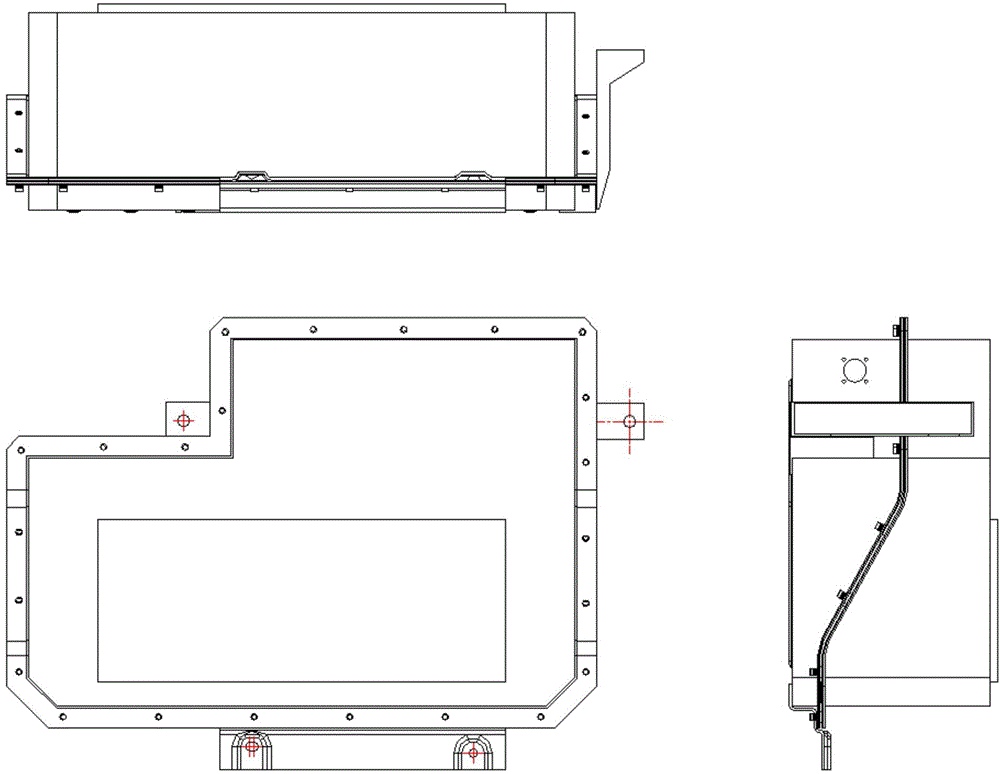

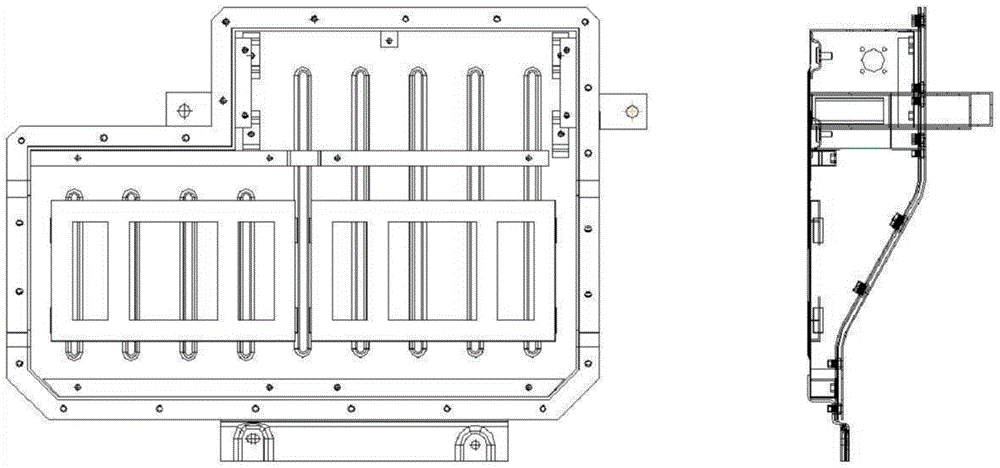

Lithium battery system capable of replacing lead-acid electric vehicle battery system and manufacturing method thereof

ActiveCN104868198AReduce usageReduce the risk of contaminationSecondary cellsCell component detailsElectrical batteryAutomotive battery

The invention relates to a lithium battery system capable of replacing a lead-acid electric vehicle battery system and a manufacturing method thereof. The lithium battery system comprises a battery pack shell, a battery module, a support, a battery management system (BMS) and electric parts, wherein the battery pack shell comprises an upper shell and a lower shell, and the upper shell and the lower shell are connected in a closable manner; the battery module is assembled and formed by connecting lithium batteries in a series-parallel manner, and is fixed to the lower battery pack shell through the support; the BMS is mounted on the support; and the electric parts are mounted at corresponding design positions of the battery pack shell. The manufacturing method comprises the following steps: (1) processing the battery pack shell and the internal support; (2) connecting the lithium batteries in the series-parallel manner to assemble and form the module by using connecting cables and connecting copper bars; (3) putting the module into the lower battery pack shell, and mounting the support to fix the module; (4) mounting the related electric parts at the design positions of the battery shell; (5) mounting the BMS on the support; and (6) closing the upper battery pack shell. Through the replacement scheme, the usage of lead-acid batteries can be reduced, and the risks of environmental pollution are reduced; the lithium batteries are used for replacing the lead-acid batteries, and a low-temperature charging heating system is added, so that the low-temperature discharge capacity and the low-temperature charge performance of the battery system are improved.

Owner:奇瑞新能源汽车股份有限公司

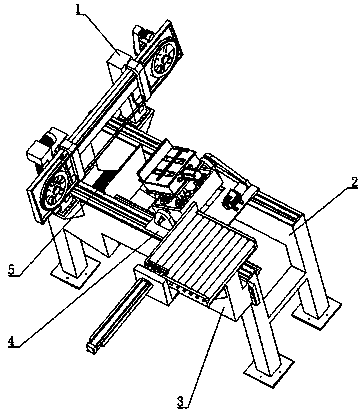

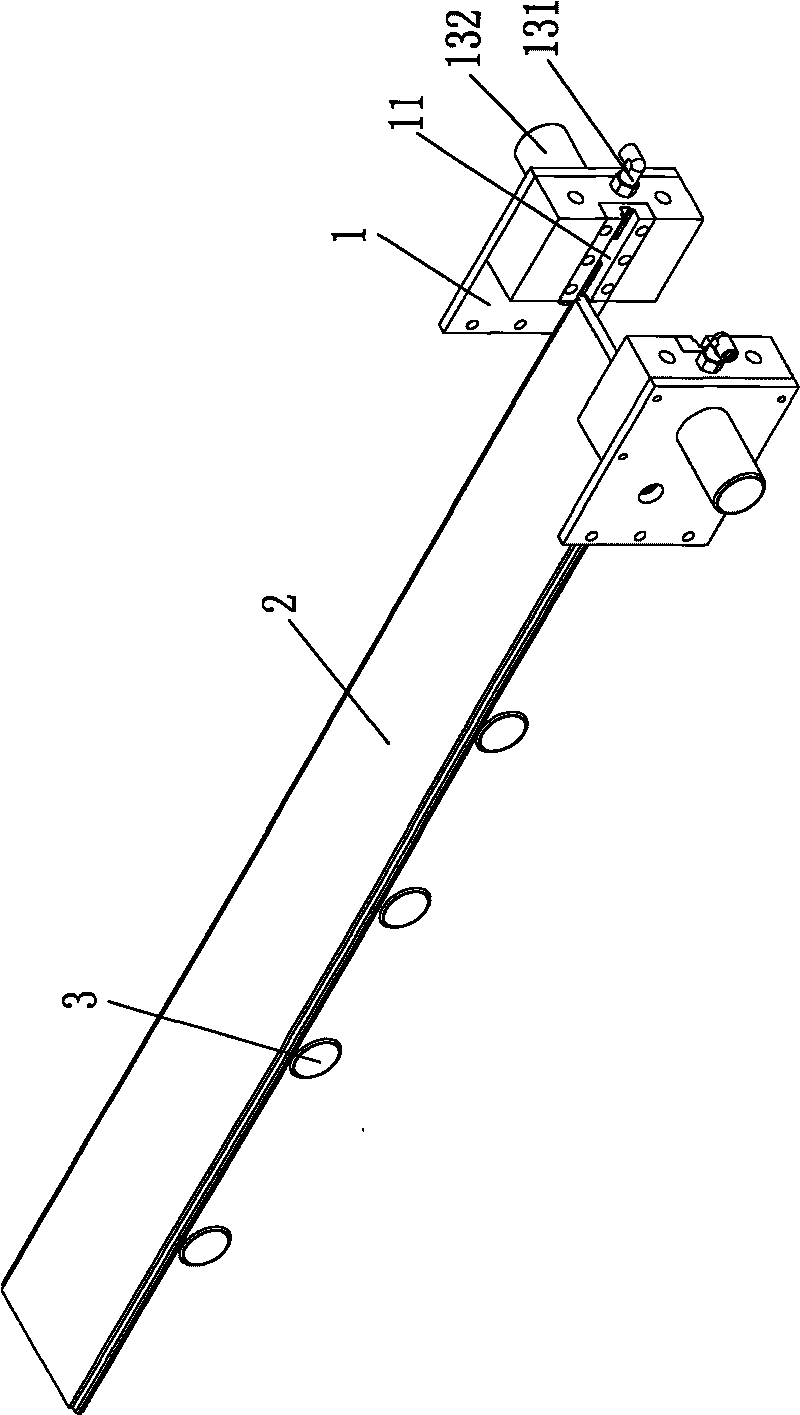

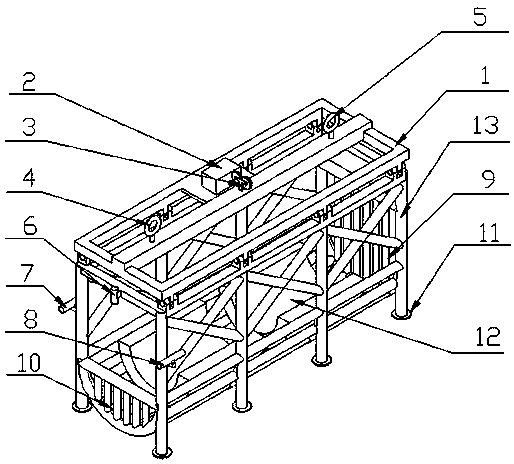

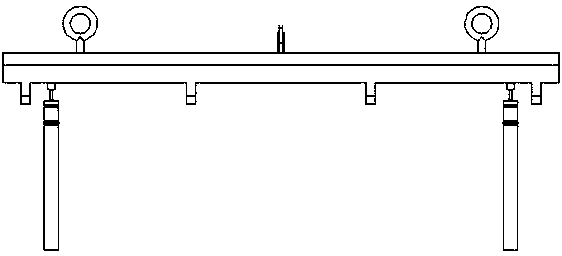

Universal unmanned underwater vehicle recovery device and recovery method

ActiveCN110816794AImprove work efficiencySolve the dangerHoisting/lowering gearUnderwater equipmentMarine engineeringPulley

The invention discloses a universal unmanned underwater vehicle recovery device and recovery method, and relates to the technical field of underwater robot recovery. The device comprises a cage and atop cross beam. A first lifting lug, a second lifting lug, a guide cable pulley and a camera cable storage box are mounted on the top cross beam, and the top cross beam and the cage are fixedly connected to form a recovery lifting cage. A front fence and a rear fence are arranged at the two ends of the cage correspondingly. A left eye camera and a right eye camera are mounted on the two sides of an inlet of the cage. A top camera is mounted at the top of the inlet of the cage. A T-shaped groove is formed in the bottom of a middle cross beam of the top cross beam. A spherical hinge structure isin sliding connection in the T-shaped groove. The top cross beam is connected with hose clamps through the spherical hinge structure. The universal unmanned underwater vehicle recovery device and recovery method have the advantages that the two work modes of water recovery and underwater recovery are achieved, the proper work modes can be selected according to different work sea conditions, and work efficiency is improved; and the problem of high danger of release and recovery work of unmanned underwater vehicles can be solved.

Owner:JIANGSU UNIV OF SCI & TECH +1

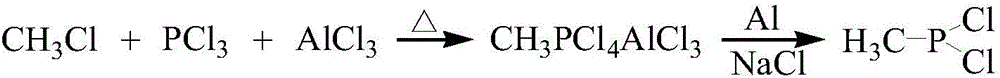

Synthesis method of glufosinate-ammonium intermediate methylphosphorus dichloride

InactiveCN106046052AReduce the difficulty of recyclingReduce recycling costsGroup 5/15 element organic compoundsAluminum trichlorideSolvent

The invention discloses a synthesis method of glufosinate-ammonium intermediate methylphosphorus dichloride, belonging to the technical field of synthesis of a glufosinate-ammonium intermediate. The synthesis method comprises the following steps: by using methyl chloride, aluminum trichloride and phosphorus trichloride as raw materials, carrying out reaction under the pressure of 0.5-3.0 MPa for 6.5-10 hours to obtain a ternary complex, adding aluminum powder and sodium chloride, and carrying out reaction at a certain temperature to obtain the methylphosphorus dichloride. According to the method, the phosphorus trichloride is simultaneously used as the reactant and solvent; and the reaction pressure is enhanced, so that the methyl chloride gas sufficiently reacts with the solid and liquid phases without adding any other solvent, thereby enhancing the product purity, avoiding the problems of solvent separation, recovery and the like, reducing the phosphorus trichloride recovery difficulty, and greatly lowering the production cost.

Owner:ANHUI COSTAR BIOCHEM CO LTD

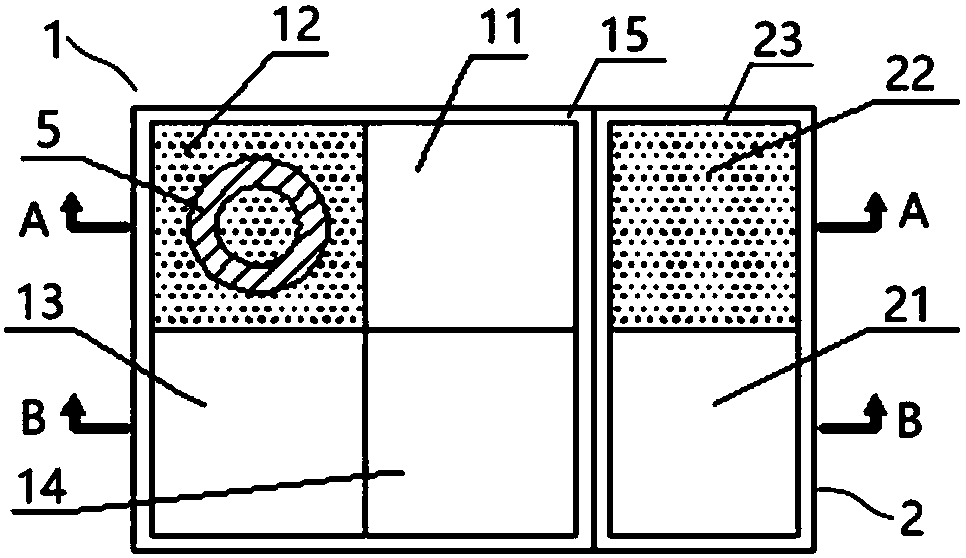

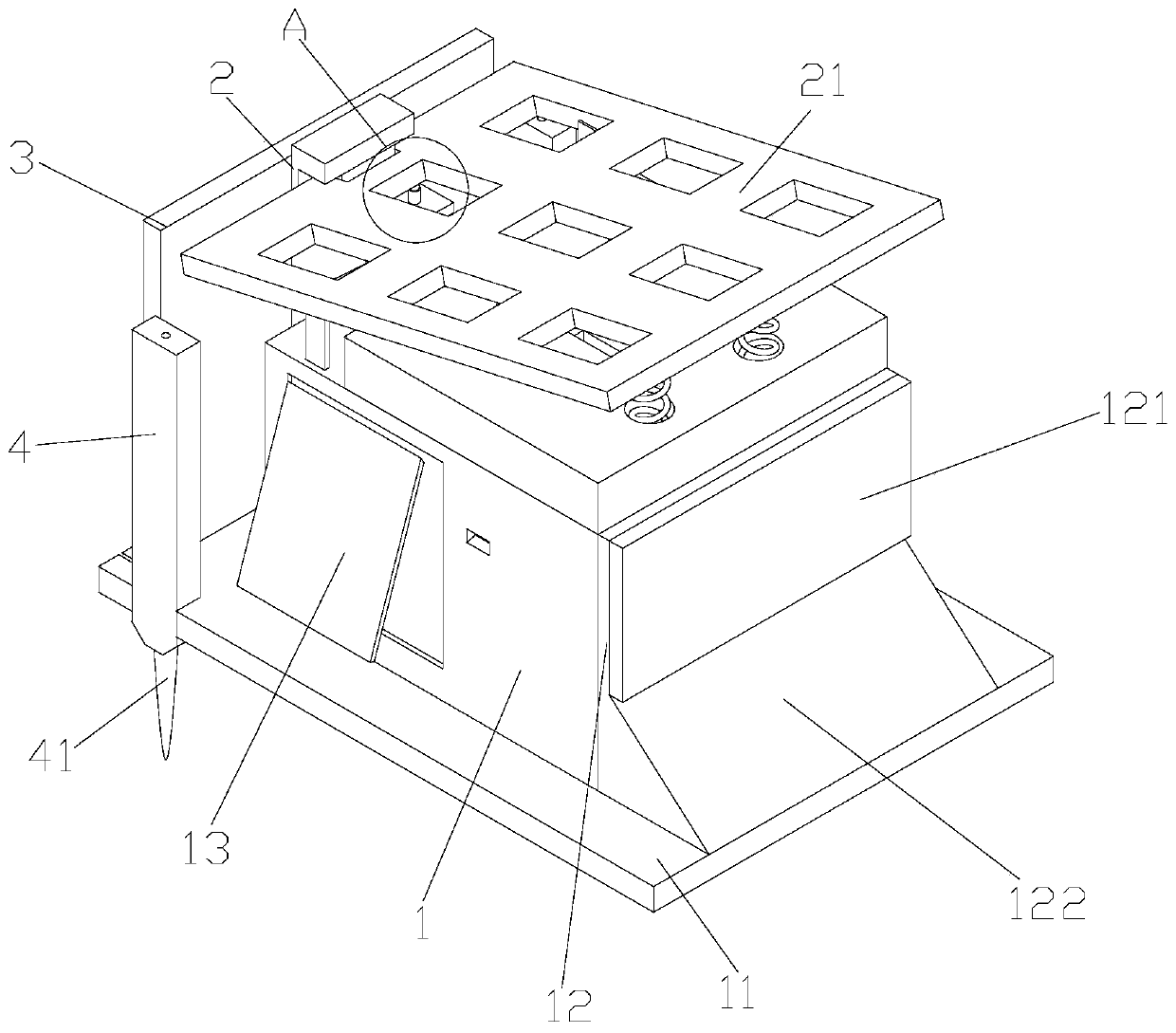

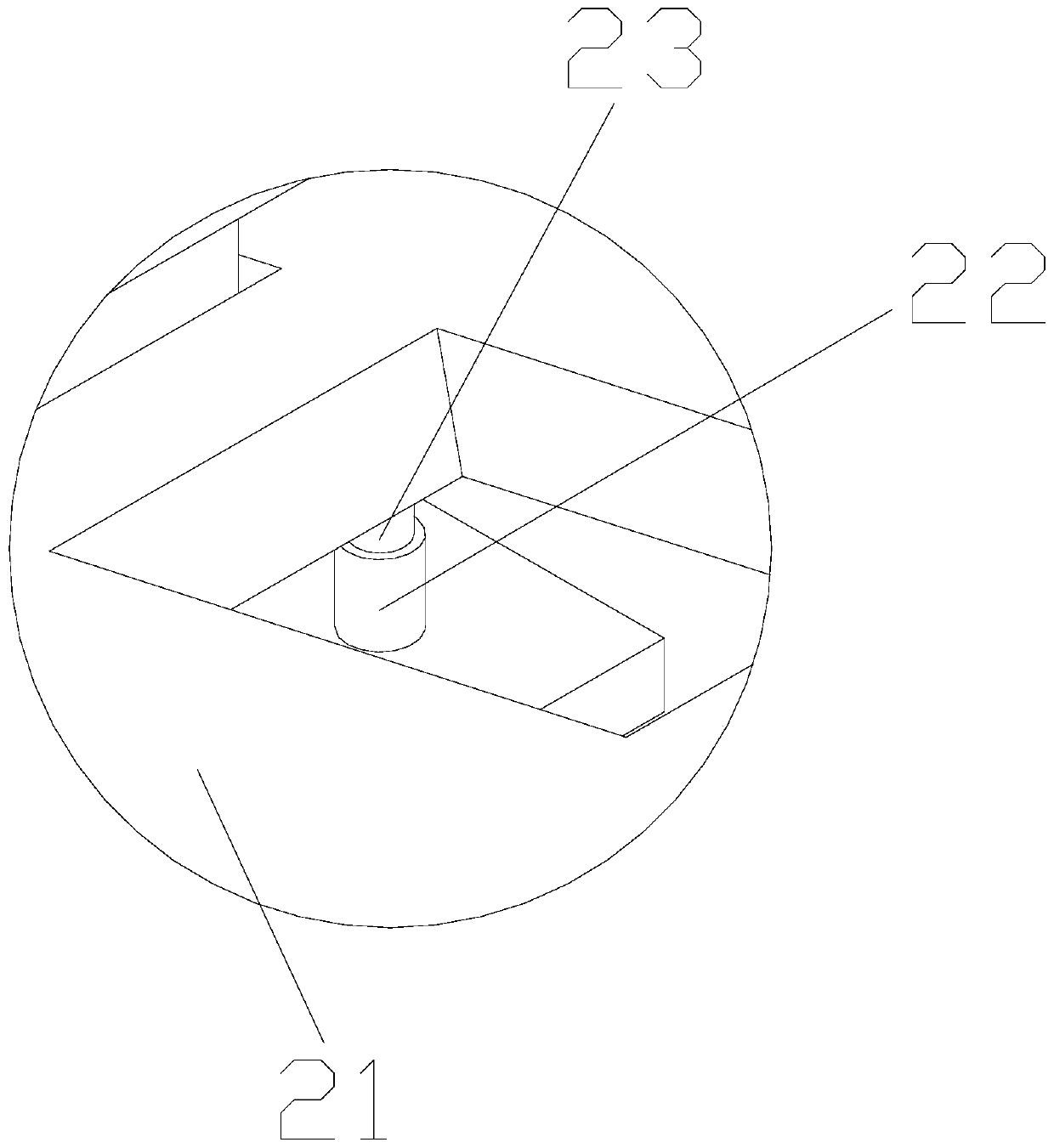

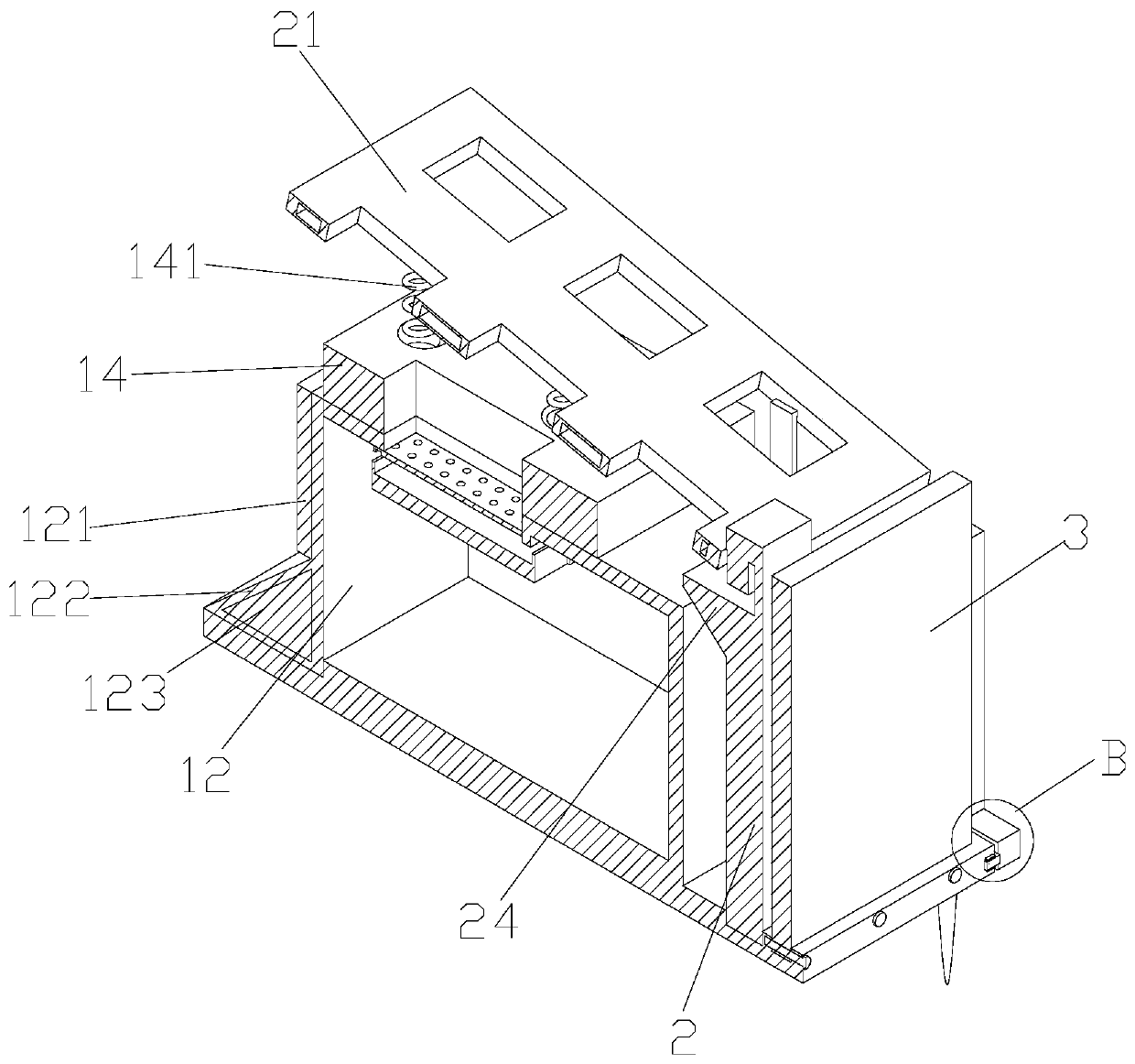

Additive manufacturing selective forming device and forming method

ActiveCN108620583AReduce usageIncrease profitAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringAdditive layer manufacturing

The invention relates to an additive manufacturing selective forming device and a forming method. The additive manufacturing selective forming device comprises a forming cylinder (1), the forming cylinder (1) comprising a plurality of sub-forming cylinders arranged in a geometrical shape array mode, and each sub-forming cylinder can be used independently or in combination according to the size shape of a to-be-formed part. According to the device and the method, the additive manufacturing selective forming device can be flexibly applied to manufacturing of various different parts, the powder can only be fully laid in the area needing to be formed so that the powder can be locally laid on a working table of the forming cylinder, the use amount of the powder can be reduced, and the powder utilization rate can be improved; and meanwhile, the powder pollution caused by sintering can be further reduced, the quality of the recovered powder is improved, and the recovery difficulty of the powder is reduced.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Chlorination method for industrial production of sucralose-6-acetate

InactiveCN102964397AReduce the difficulty of recyclingFacilitated releaseEsterified saccharide compoundsSugar derivativesOrganic solventSucrose

A chlorination method for industrial production of sucralose-6-acetate. The method comprises steps of: (a) adding thionyl chloride into an organic solvent below 30 DEG C to form a mixed solution, with a molar ratio of the organic solvent to thionyl chloride of 3.5-4.6:1; (b) adding sucrose-6-acetate with water content of 0.2%-0.8% into the mixed solution, and stirring, wherein a molar ratio of added sucrose-6-acetate to thionyl chloride is 1:7-9; and (c) slowly heating to 110-113 DEG C in 6-7 h; and after the reaction, subjecting the reaction product to neutralization, solvent removal, decolorization by adding water and crystallization to obtain the sucralose-6-acetate crude product. According to the invention, sucrose-6-acetate containing water is adopted for chlorination, and thionyl chloride is added once without cooling, so as to speed up the process, and reduce energy consumption. The employed solvent is more conducive to release of gas products such as sulfur dioxide generated in the chlorination process and promotion of yield increase, and reduces the generation of the other salts and separation burden.

Owner:LIYANG WEIXIN CHEM

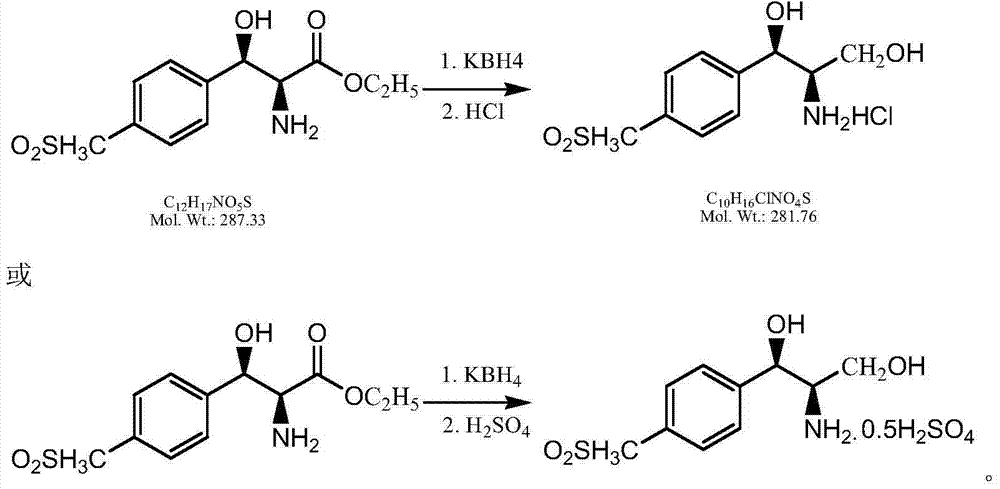

Synthetic method of florfenicol intermediate cyclic product

InactiveCN103570638AReduce the difficulty of recyclingOverall synthesis time reductionOrganic chemistryChemical synthesisPotassium borohydride

The embodiment of the invention provides a synthetic method of a florfenicol intermediate cyclic product and belongs to the technical field of chemical synthesis. The method comprises the following steps of: (1) carrying out reduction reaction on D-4-Methylsulfonylphenyl serine ethyl ester and potassium borohydride in an organic solvent at a temperature of -5 to 100 DEG C in the presence of anhydrous calcium chloride serving as a catalyst to obtain a thiamphenicol amine organic solution; adding hydrochloric acid or sulfuric acid to the thiamphenicol amine organic solution and acidifying; controlling the pH to 2-3; steaming out a part of the organic solvent at a reduced pressure; cooling and crystallizing; and separating to obtain thiamphenicol amine hydrochloride or thiamphenicol amine sulfate; (2) dissolving thiamphenicol amine hydrochloride or thiamphenicol amine sulfate into the organic solvent; adjusting the pH to be 7 to 7.5 through alkali; performing cyclization reaction with dichloroacetonitrile under 30 to 70 DEG C; cooling and crystallizing after the reaction is done; and separating to obtain the florfenicol intermediate cyclic product. The synthetic method provided by the invention enables the production cycle to be reduced greatly; and the synthetic yield of the florfenicol intermediate cyclic product reaches more than 90.5%.

Owner:HUBEI ZHONGMU ANDA PHARMACEUTICAL CO LTD

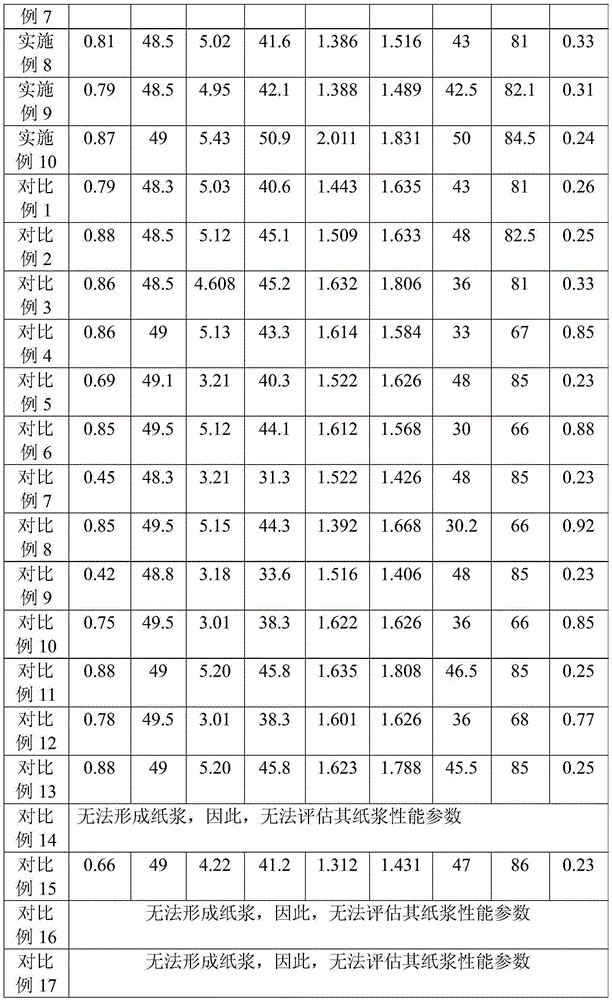

Treatment method of wood fiber raw material

ActiveCN105239435AImprove processing efficiencyIncrease pulp yieldPretreatment with alkaline reacting compoundsPulping with organic solventsOrganic acidFiber

The invention provides a treatment method of wood fiber raw materials, which includes the following steps: (1) pre-impregnation: impregnating the wood fiber raw materials in a Na2CO3 water solution; and (2) steam-boiling: steam-boiling the impregnated wood fiber raw materials with an organic acid water solution as a steam-boiling solvent with addition of an inorganic acid as a catalyst. In the invention, by means of synergistic effect between the pre-impregnation with the Na2CO3 water solution and the steam-boiling of the organic acid water solution and the inorganic acid, yield of paper pulp is increased, ash content is reduced and comprehensive performance of the paper pulp is improved.

Owner:GUANGZHOU YINNOVATOR BIOTECH CO LTD

Low-melting-point scratch-resistant polycarbonate composition and preparing method of low-melting-point scratch-resistant polycarbonate composition

The invention relates to a polycarbonate composition, in particular to a low-melting-point scratch-resistant polycarbonate composition and a preparing method of the low-melting-point scratch-resistant polycarbonate composition. The low-melting-point scratch-resistant polycarbonate composition comprises the following ingredients in parts by weight: 70 to 90 parts of polycarbonate, 10 to 25 parts of polylactic acid, 12 to 20 parts of polytrimethylene terephthalate, 5 to 15 parts of flame retardants, 5 to 15 parts of erucyl amide, 3 to 8 parts of glass fiber, 3 to 10 parts of organic silicon toughening agents, 0.1 to 5 parts of polyethylene wax and 0.2 to 0.8 part of antioxidants. The polycarbonate composition provided by the invention has the advantages that the processing temperature of products extruded through an extruding machine is lowered in the subsequent processing process, so the cost of the subsequent processing is reduced, and the energy source waste is reduced.

Owner:NINGBO BULL ELECTRIC CO LTD

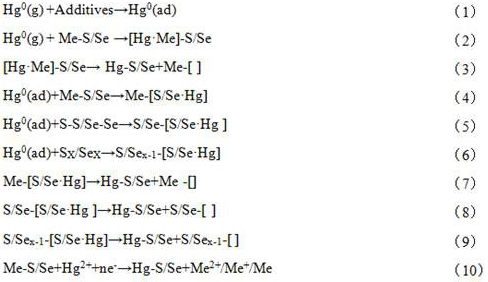

Stable suspension system for removing mercury in flue gas and recovery method of suspension system

ActiveCN112755764AImprove mercury removal efficiencyLarge capacityGas treatmentDispersed particle separationFlue gasControl system

The invention discloses a stable suspension system for removing mercury in flue gas and a recovery method of the suspension system. Metal sulfur, a selenide mercury removal agent and an additive are pretreated to form a stable suspension, the mercury-containing flue gas is in contact with the suspension, gaseous mercury (Hg0) is converted into stable mercuric sulfide or mercury selenide, and efficient removal of gaseous mercury in the flue gas is achieved. According to the method, existing pollutant control systems in various industries can be utilized, and the cost is low; the suspension system is simple to recover and separate and can be recycled; mercury can be recycled as a product; and the market prospect is wide.

Owner:CENT SOUTH UNIV

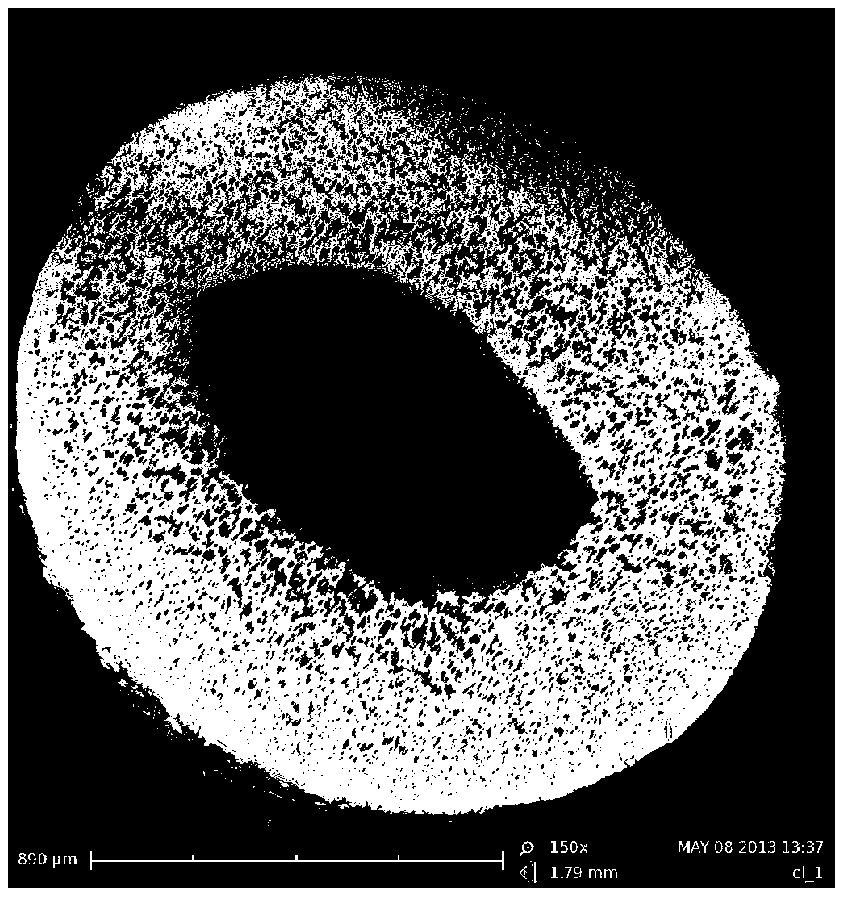

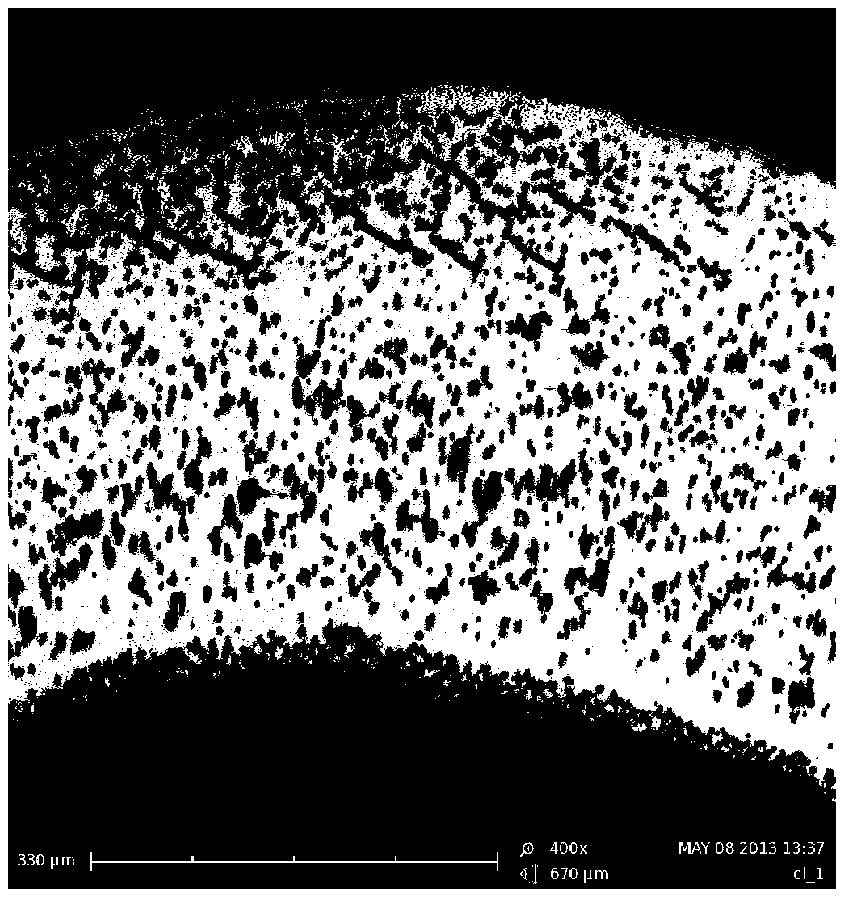

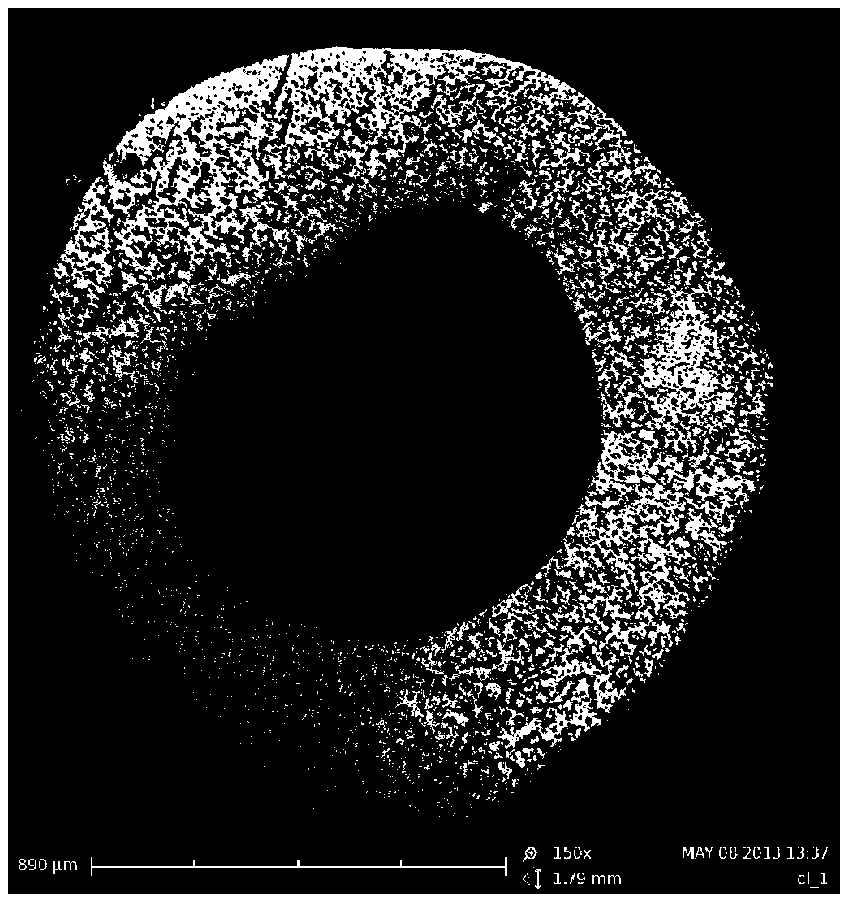

Preparation method of UHMWPE (Ultrahigh Molecular Weight Polyethylene) hollow fiber membrane

InactiveCN103301755AImprove hydrophilicityPrevent shrinkageSemi-permeable membranesFiberPolyethylene glycol

The invention relates to a preparation method of a UHMWPE (Ultrahigh Molecular Weight Polyethylene) hollow fiber membrane. The method comprises the following steps of: based on a developed thermally induced phase method film forming mechanism, mixing and fusing raw materials by adopting a double-screw-rod extruder; metering by a gear pump; extruding by a spinneret plate; and carrying out procedures of cooling, winding, extracting, stretching, sizing and the like to finally prepare the UHMWPE hollow fiber membrane. According to the preparation method disclosed by the invention, high-temperature-resisting amphiphilic copolymers, such as an ethylene-vinyl alcohol copolymer (EVOH), a PE-PEO (Polyethylene-Polyoxyethylene) copolymer, an ethylene-acrylic copolymer (EAA) and an PE-PEG (Polyethylene-Poly Ethylene Glycol) copolymer, are added into the raw materials, so as to realize the permanent hydrophily of a membrane wire; the pollution resistance of the membrane wire is lasting and the service life of the membrane wire is greatly prolonged; and an oil-free and anhydrous air flow is adopted to form an inner cavity of the membrane wire, so that the problems that the recycling load of a solvent is great and the consumed amount of the solvent is great in a production process of the UHMWPE hollow fiber membrane by a thermally induced phase method are solved.

Owner:BEIJING ORIGIN WATER FILM TECH

Escape tower, fairing cover and booster rocket with remote control hang gliders and tail rudder wings

InactiveCN106500550AReduce the difficulty of recyclingReduce recycling costsProjectilesRemote controlTower

The invention relates to the technical field of rockets, in particular to an escape tower, a fairing cover and a booster rocket with remote control hang gliders and tail rudder wings. The escape tower, the fairing cover and the booster rocket are characterized in that the escape tower, the fairing cover and the booster rocket are each provided with one pair of hang gliders and each provided with one vertical tail wing, each vertical tail wing is arranged on the vertical symmetry central plane of the corresponding pair of hang gliders, the tail of one pair of hang gliders is provided with a gliding pose balance wing, the tail of each vertical tail wing is provided with one tail rudder wing, the escape tower, the fairing cover and the booster rocket are each provided with a remote control receiver, a corresponding remote control mechanical driving mechanism and a position signal wireless transmitter, and the escape tower, the fairing cover and the booster rocket can be controlled by a ground control center to land according to a specified site in the falling and gliding process. The recycling difficulty and cost for the remains of the escape tower, the fairing cover and the booster rocket are greatly lowered, and the phenomenon that the danger is brought when remains fall down to villages can be avoided.

Owner:福州幻科机电科技有限公司

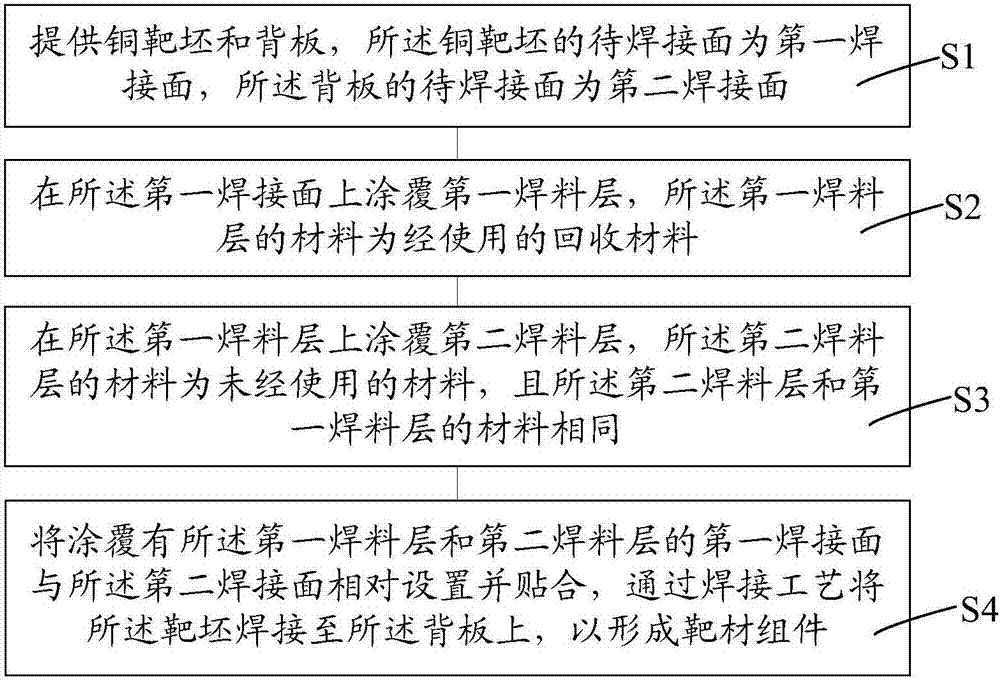

Manufacture method of target material assembly

ActiveCN107570905AImprove solder joint rateImprove wettabilityVacuum evaporation coatingSputtering coatingCopperBackplane

The invention provides a manufacture method of a target material assembly. The method comprises the following steps: providing a copper target blank and a back board, wherein a to-be-welded surface ofthe copper target blank is a first welding surface and a to-be-welded surface of the back board is a second welding surface; coating the first welding surface with a first solder layer, the materialof which is used recovery material; coating the first solder layer with a second solder layer, the material of which is not used, wherein the second solder layer and the first solder layer are the same in material; enabling the first welding surface coated with the first solder layer and the second welding surface coated with the second solder layer to be oppositely arranged and attached with eachother, welding the target blank to the back board by welding technology in order to form the target material assembly. The material of the first solder layer is used recovery material while the material of the second solder layer is not used. Compared with a scheme adopting only one solder layer, welding bonding efficiency of the target blank and the back board can be increased after mutual fusion between the first solder layer and the second solder layer.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

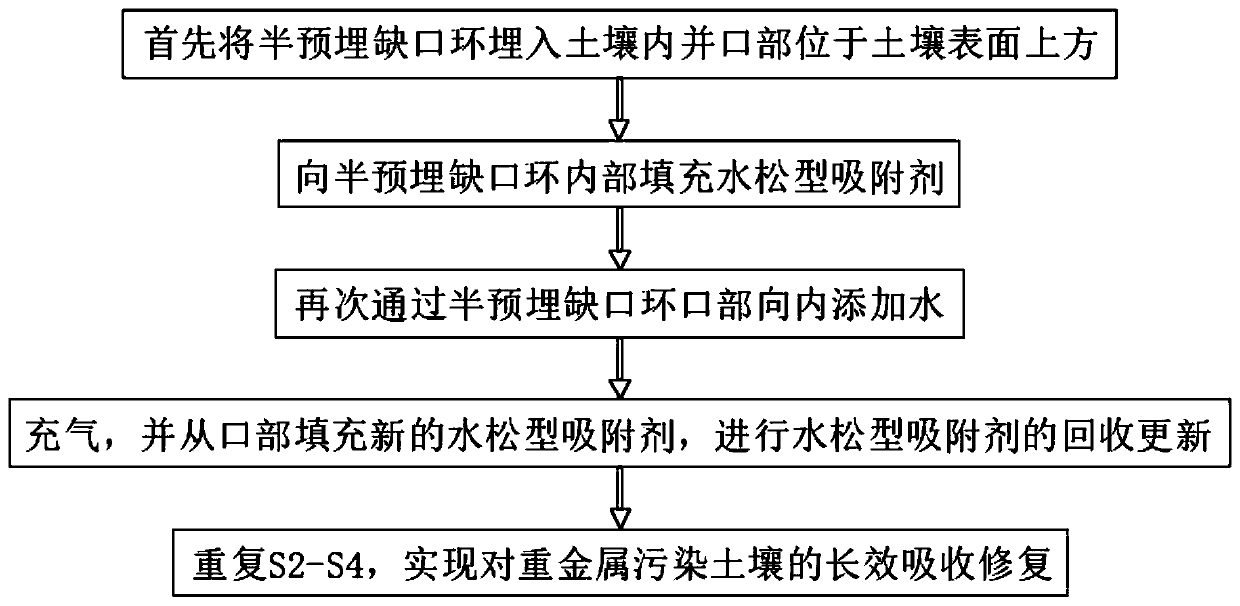

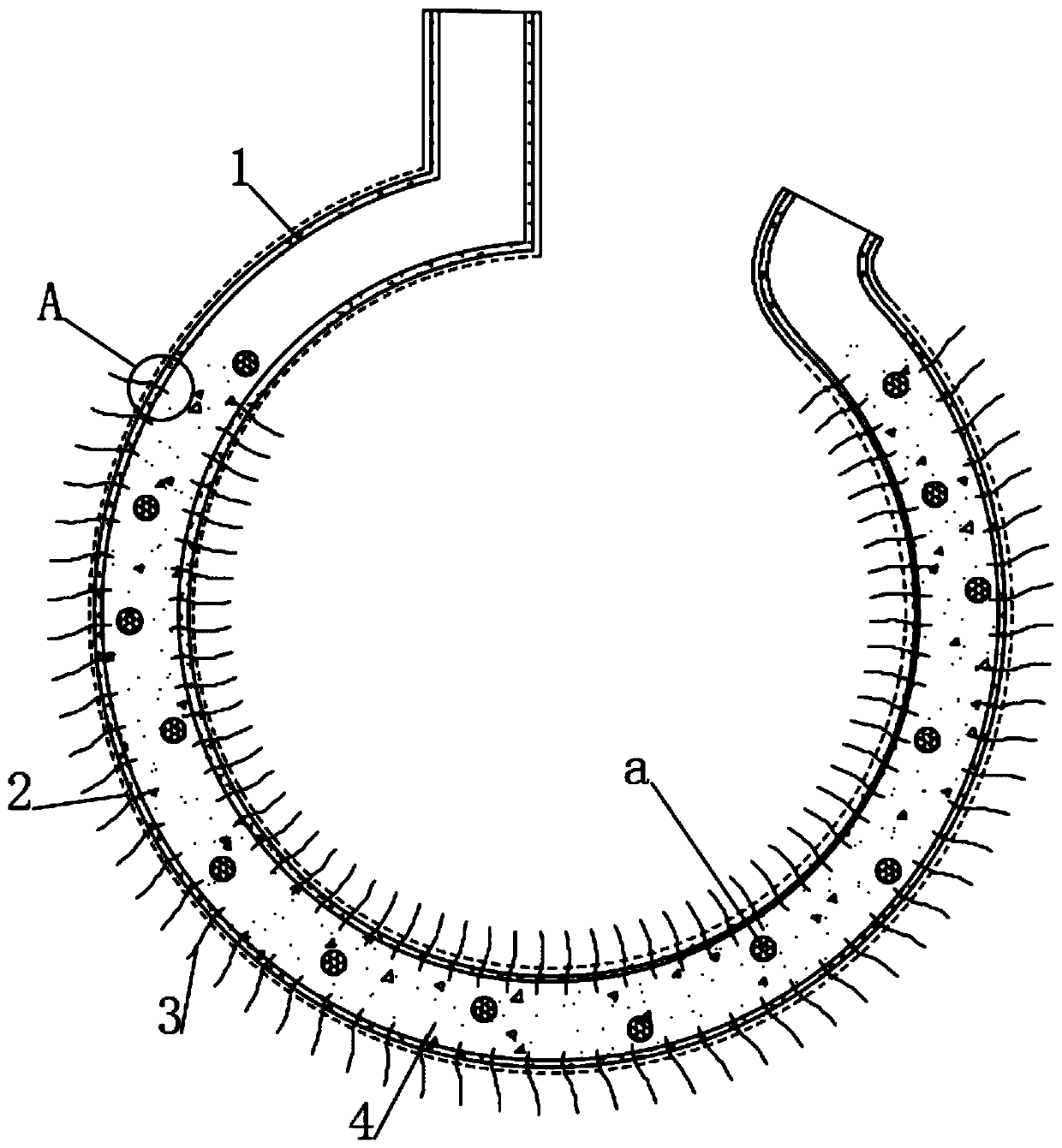

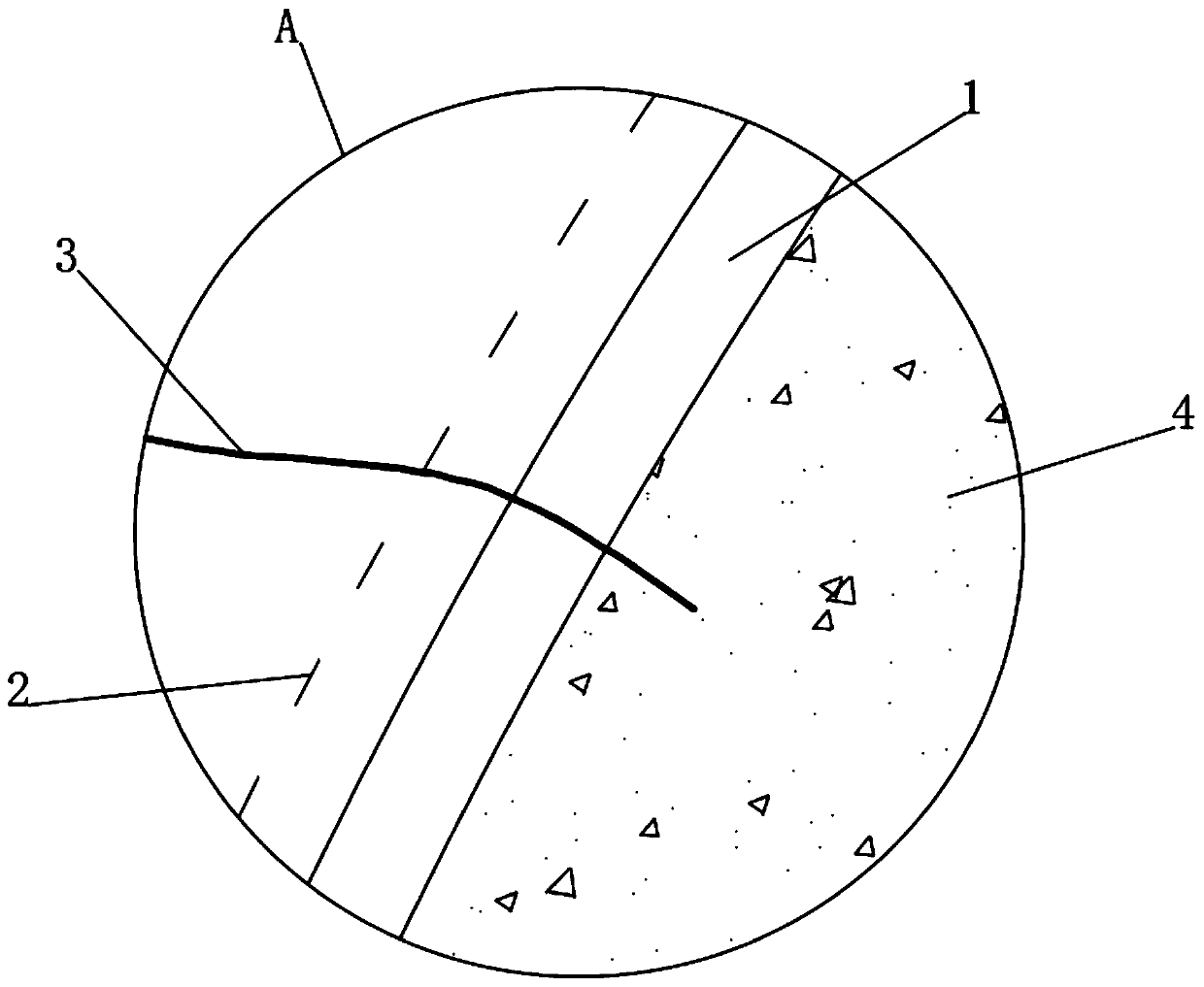

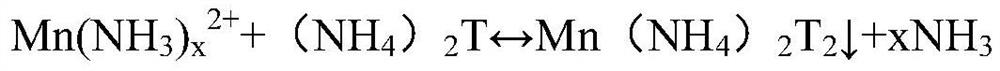

Semi-embedded ring type remediation method for heavy metal contaminated soil

ActiveCN111570500AReduce the difficulty of replacementImprove repair efficiencyContaminated soil reclamationMicroorganismSoil science

The invention discloses a semi-embedded ring type remediation method for heavy metal contaminated soil, and belongs to the field of soil remediation. According to the method, a semi-embedded notch ring is arranged so that the effect that a water-absorbing loosening adsorbent can be supplemented without digging out the embedded part can be achieved, the replacement difficulty of the water-absorbingloosening adsorbent is reduced, and the efficiency of soil remediation is improved; a water-soluble control ball is arranged in the water-absorbing loosening adsorbent, and therefore after the adsorbent adsorbs heavy metal ions, the adsorbent adsorbs a part of water in soil under the action of a transport channel correspondingly, then the water-soluble control ball is dissolved and release air the heavy metal ion adsorbent can be loosened and the compactness of the heavy metal ion adsorbent can be reduced in an outward overflowing process, so that the heavy metal ion adsorbent is effectivelyprevented from caking, the recycling and replacing difficulty of the heavy metal ion adsorbent adsorbing heavy metal ions is reduced, oxygen can be supplied to microorganisms in soil, the activity ofthe heavy metal ion adsorbent is improved, and the remediation of the soil is accelerated.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

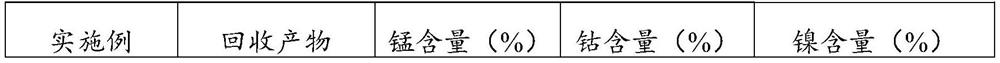

Comprehensive recovery method of waste sodium-ion battery

PendingCN114229875ARapid responseImprove leaching efficiencyAluminium hydroxide preparationWaste accumulators reclaimingPregnant leach solutionAluminium hydroxide

The invention discloses a comprehensive recovery method of waste sodium-ion batteries, which comprises the following steps: mixing and grinding battery black powder and a pre-leaching agent, adding a reducing agent and ammonia liquor for leaching, carrying out solid-liquid separation to obtain a leachate and a solid, adding acid into the solid for dissolving, carrying out solid-liquid separation to obtain carbon residue and filtrate, adding alkali into the filtrate for adjusting pH, and separating to obtain aluminum hydroxide, alkali is continuously added into the filtrate to adjust the pH, manganese hydroxide is obtained through separation, a first oxidizing agent, a chelating agent and alkali are added into the leachate, ammonia distillation and solid-liquid separation are carried out, and a cobalt-containing insoluble substance and a nickel-containing chelate solution are obtained. According to the method, the battery black powder and the pre-leaching agent are subjected to ammonia leaching, Mn and Al in a reaction system are precipitated, Na, Ni and Co are still stored in the leaching agent, the separation and recovery difficulty of valuable metal compounds in the leaching agent can be reduced, the subsequent precipitation and separation procedures are greatly reduced, then a chelating agent and nickel are utilized for generating a chelate, nickel and cobalt in the solution coexist in the form of different substances, and the separation efficiency is improved. Therefore, high-efficiency separation of nickel and cobalt is realized.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

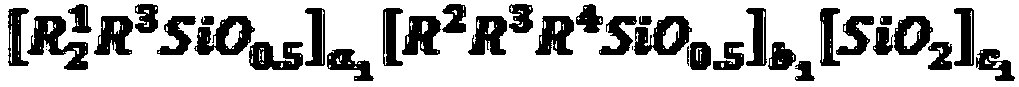

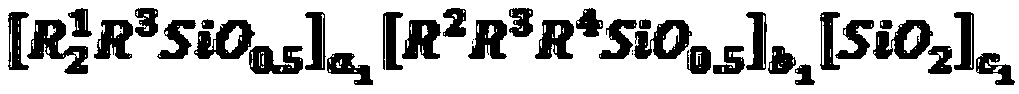

Preparation method of controllable high-molecular-weight MQ silicon resin

The invention discloses a preparation method of controllable high-molecular-weight MQ silicon resin. The preparation method comprises the following steps: (1) uniformly mixing a component A, a solventI and a catalyst to form mixed liquid C, dissolving a component B in a solvent II, and uniformly stirring and mixing to form mixed liquid D; (2) stirring the mixed liquid C at any temperature between30 DEG C and 80 DEG C at constant temperature, slowly dropwise adding the mixed liquid D for 30 to 60 min, and carrying out constant temperature reaction for 2 to 10 h at the end of dropwise adding;(3) adding a reaction inhibitor, stirring for 10 to 50 min, and distilling the mixture in vacuum to remove the solvent, thus obtaining the controllable high-molecular-weight MQ silicon resin. Preparation of the high-molecular-weight MQ silicon resin and control of the molecular weight can be realized only by adjusting a mole ratio of an active group of the component A to an active group of the component B. According to the preparation method, a few of side products are produced, and recycling of acid, byproducts and the like is not considered; the preparation method is short in production period and high in efficiency and can completely realize industrialization. The product disclosed by the invention is completely dissolved into a polarity or low-polarity solvent, so no problems of sediments and gel which are produced by the system are considered.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Landslide monitoring and alarming device based on mountain torrent prevention

ActiveCN110930652AImprove reliabilityGuaranteed reliabilityHuman health protectionAlarmsLandslideStructural engineering

The invention discloses a landslide monitoring and alarming device based on mountain torrent prevention. The device comprises a detection box and an inductor arranged in the detection box, a bottom plate is arranged at the bottom of the detection box, the section of the bottom plate is larger than that of the detection box, a supporting plate is arranged on the bottom plate, a first movable grooveis formed in the supporting plate, a baffle is rotatably connected into the first movable groove, and a supporting assembly is arranged on the supporting plate; a first opening is formed in the bottom plate, a first supporting block is arranged on the inner wall of the first opening, a fixing rod is arranged in the first opening in a penetrating mode, and a positioning needle is arranged at the bottom of the fixing rod. The detection box is protected under the action of the baffle, stones are prevented from directly falling onto the detection box, the detection box is well protected, and theservice life of the detection box is prolonged.

Owner:杭州鲁尔物联科技有限公司

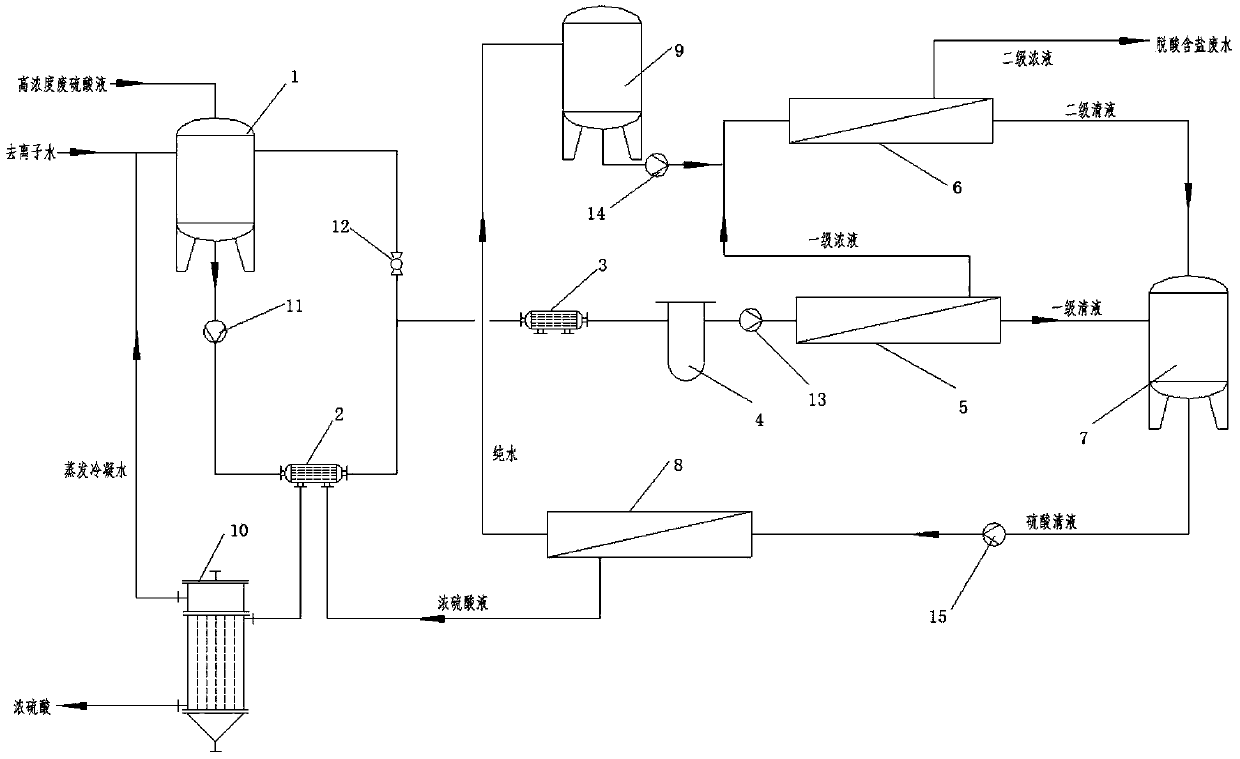

High-concentration waste sulfuric acid treatment method and system

PendingCN111003865AReduce dilutionReduce processing difficultyWater treatment parameter controlSpecific water treatment objectivesFiltrationPhysical chemistry

The invention discloses a high-concentration waste sulfuric acid treatment method which comprises the following steps: (1) diluting high-concentration waste sulfuric acid, and carrying out primary heat exchange on the diluted waste sulfuric acid solution; (2) carrying out heat exchange again on the waste sulfuric acid solution obtained by the primary heat exchange for further cooling; (3) pretreating the waste sulfuric acid solution subjected to heat exchange again, and filtering to remove particle impurities to obtain a primary filtrate; carrying out primary nanofiltration on the primary filtrate, storing a primary clear solution obtained by filtering, carrying out washing filtration on a filtered primary concentrated solution by using a secondary nanofiltration membrane, and mixing a secondary clear solution obtained by washing filtration of the secondary nanofiltration membrane and the primary clear solution into a sulfuric acid clear solution for storage; filtering the sulfuric acid clear solution through a reverse osmosis membrane to obtain concentrated sulfuric acid, and filtering to obtain pure water; and (4) evaporating and concentrating the concentrated sulfuric acid. Theinvention discloses a high-concentration waste sulfuric acid treatment system. According to the method, the early sulfuric acid dilution amount is reduced, the later evaporation amount is reduced, andthe production energy consumption is reduced.

Owner:四川恩特普环保科技有限公司

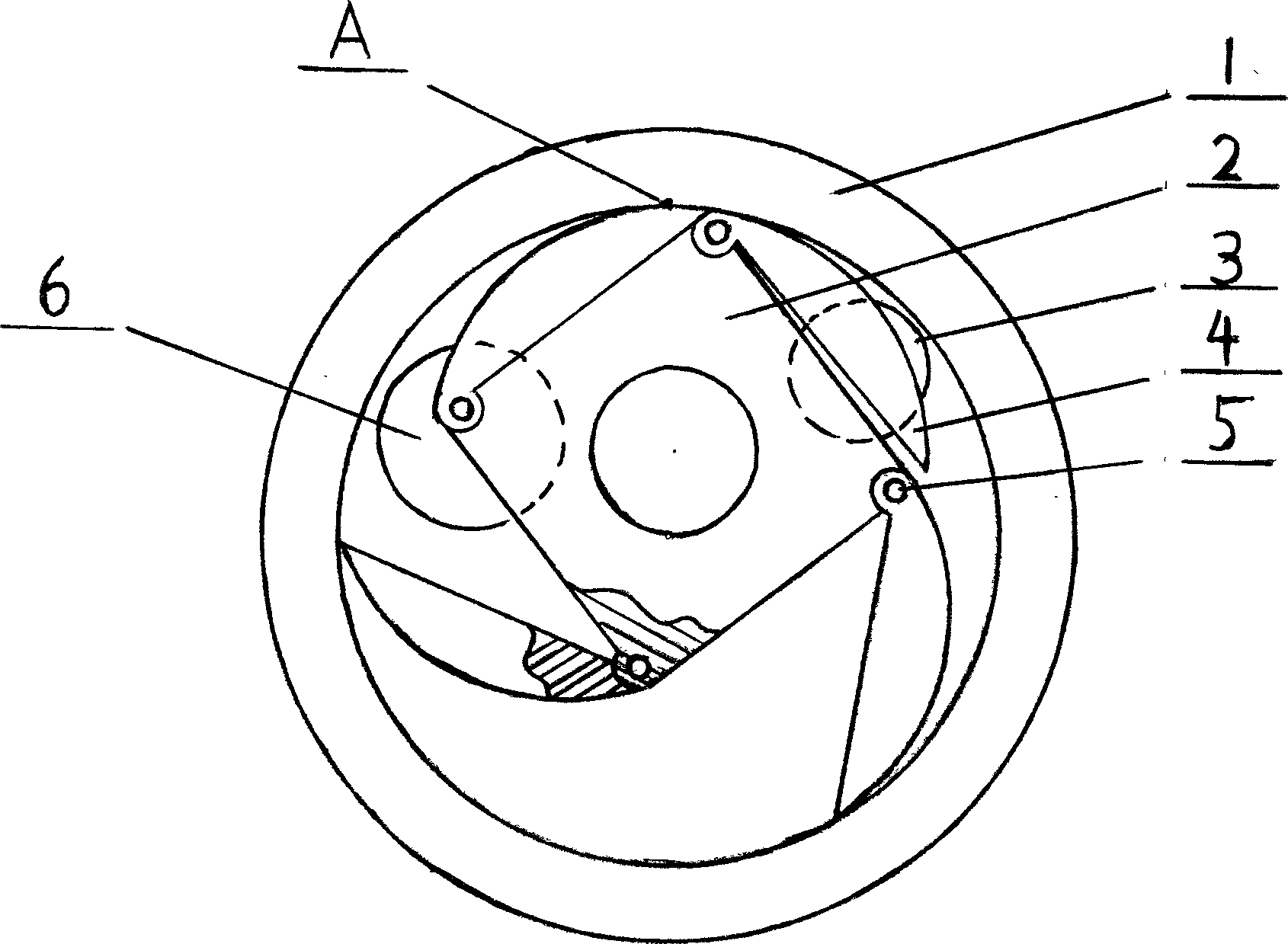

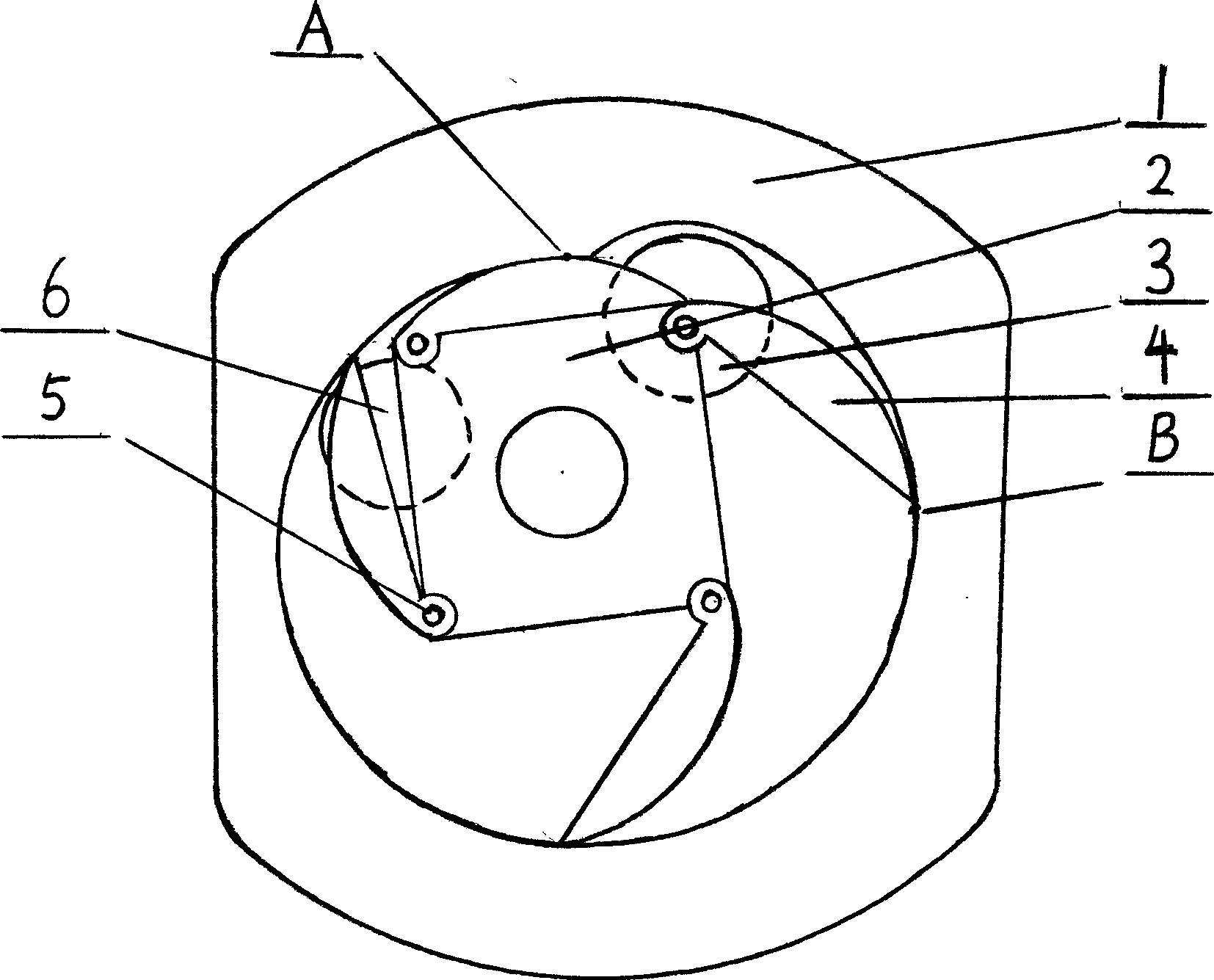

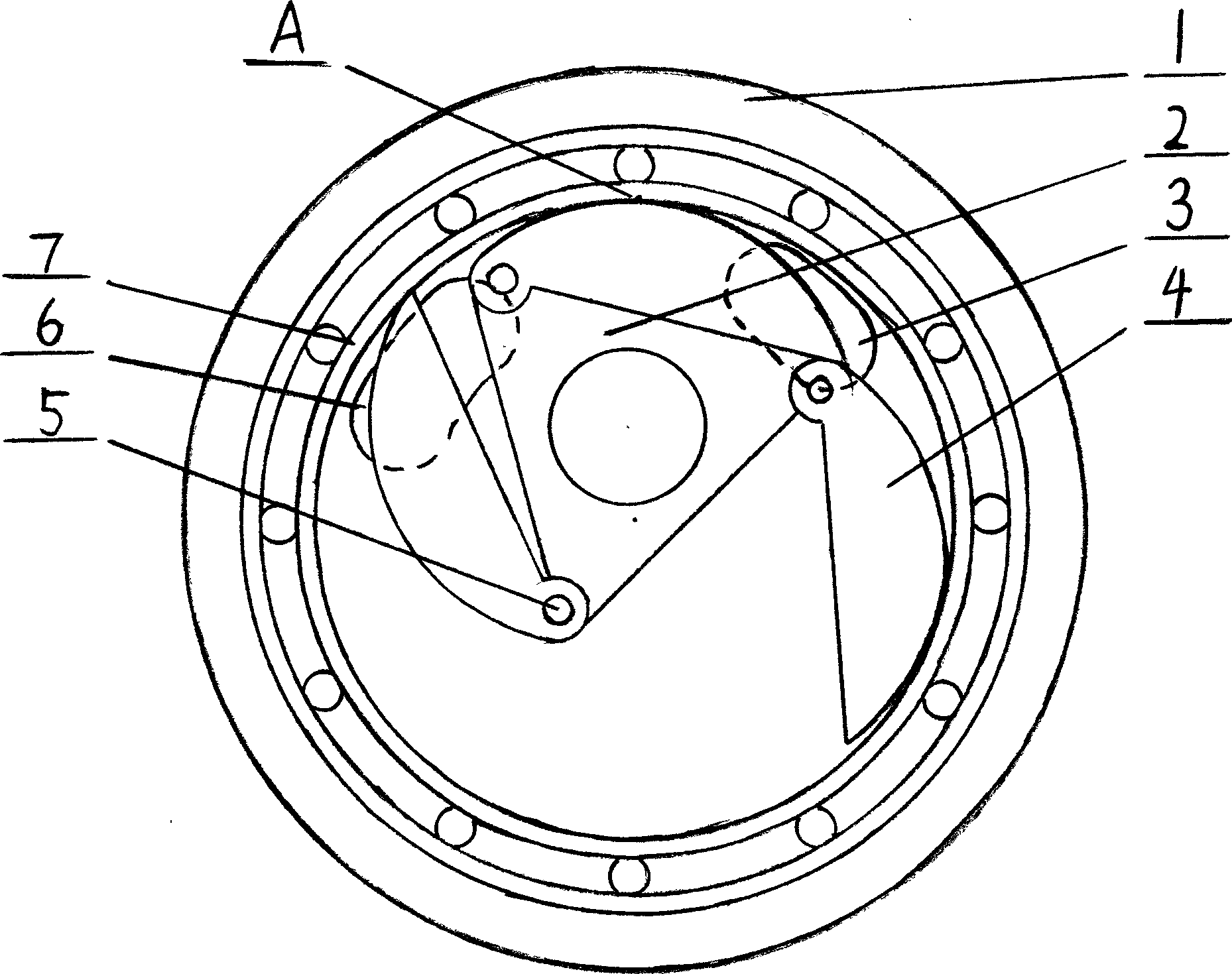

Novel mass flow blade mechanism

InactiveCN101397914AReduce the difficulty of recyclingIncrease frictional resistanceRotary piston pumpsRotary piston liquid enginesContact formationEngineering

The invention relates to a novel large-flow vane pump or motor, which is provided with a stator 1, a rotor 2, an oil inlet 3, a vane 4, an articulated connecting pin 5 and an oil outlet 6. The five angles of the pentagonal rotor are connected with a vane 4-1, a vane 4-2, a vane 4-3 and a vane 4 respectively which are in a small semicircle-shape by the articulated connecting pin 5, form a circle jointly and are arranged in the stator 1. An excircle formed by the rotor 2 and the vane 4 is in contact with a point A at the upper end of the inner wall of the stator 1 and the excircle and the open vane 4 opened by a centrifugal force are in contact with the inner wall of the stator 1 during the compression process to form a closed space. Liquid is adsorbed into the stator 1 by the oil inlet 3; the rotor 2 rotates at a high speed; each vane of the vane 4 is fast opened under the effect of the centrifugal force, drives the liquid in the stator 1 to be discharged from the oil outlet 6; and as one end of the vane 4 is connected with the corner of the excircle of the rotor 4, the distance between the rotor 2 and the inner wall of the stator 1 after the vane 4 is opened is increased, so flow is increased at the same rotating speed.

Owner:陈军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com