Preparation method for lamination blocking type package materials

A packaging material and barrier technology, which is applied in the field of preparation of laminated barrier packaging materials, can solve the problems of high surface state and fiber morphology, and achieve the effect of reducing the difficulty of degradation, lowering requirements, and reducing difficulty in recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of a laminated barrier packaging material, the preparation method is as follows:

[0027] Step 1: Extrude coating on at least one side of the substrate of the support layer, and at the same time perform surface treatment on the substrate of the substrate after coating;

[0028] Step 2: Coating the barrier coating solution on the surface of the film in step 1, and drying to obtain a barrier layer;

[0029] Step 3: extruding a composite heat-sealing layer on the outer surface of the prepared barrier layer;

[0030] Step 4: compound a light-shielding layer on one side of the support layer base material in step 1, and make the surface tension reach more than 38 dynes after pretreatment;

[0031] Step 5: Coating the printing layer coating solution on the outer surface of the prepared light-shielding layer, and drying to obtain the printing layer;

[0032] Step 6: extruding the protective layer on the outer surface of the printing layer to compound the ...

Embodiment 1

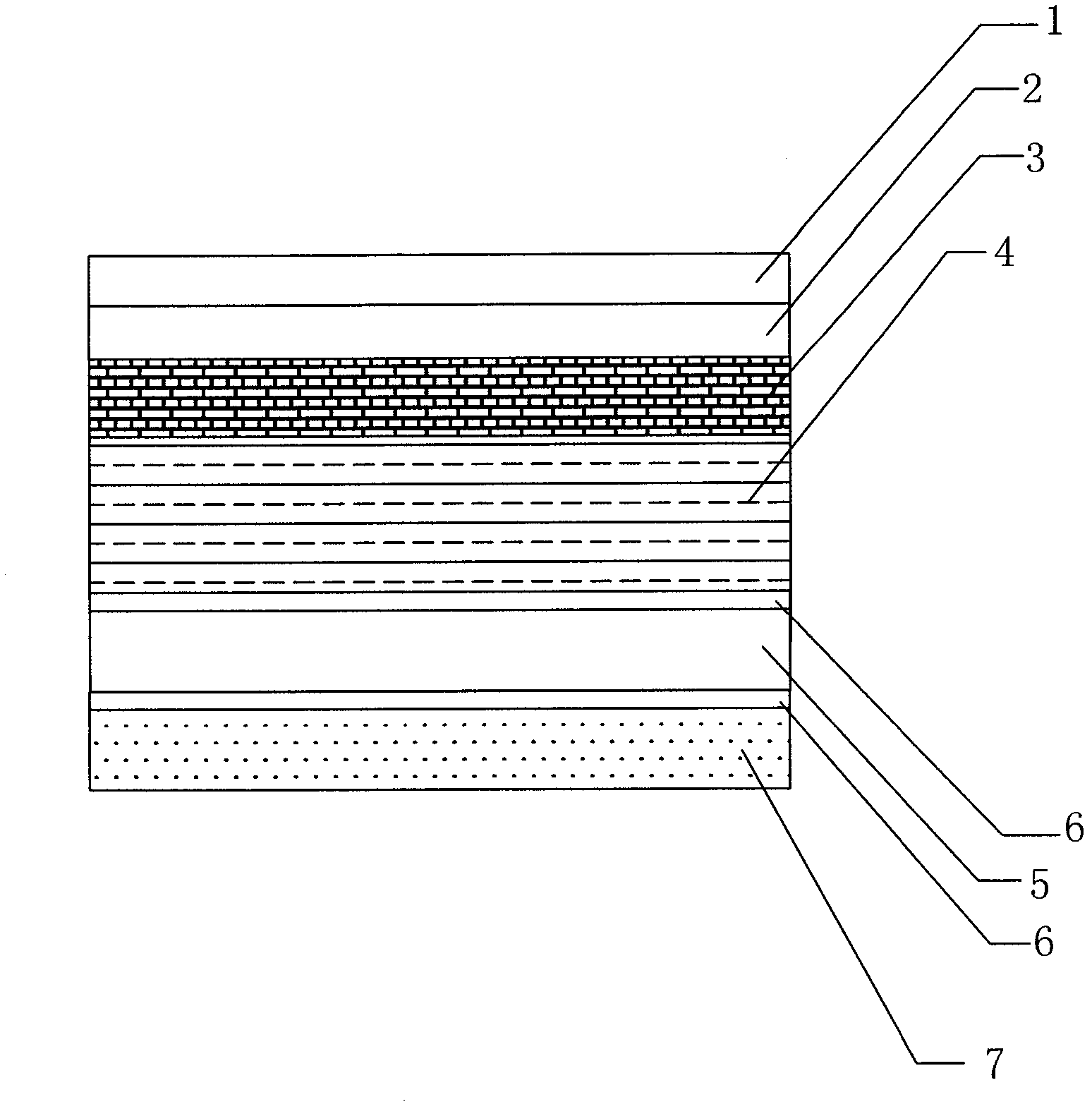

[0051] like figure 1 As shown, it includes a heat-sealing layer 8, an adhesive layer 5 tightly compounded on the heat-sealing layer 8 from bottom to top, a barrier layer, an adhesive layer 5, and a support layer 4, and the upper side of the support layer 4 is from bottom to top Covered with a light-shielding layer 3, a printing layer 2 and a protective layer 1 in sequence, wherein the printing layer 2 is a mixture of nano-alumina and polyvinyl alcohol, the weight ratio of nano-silicon oxide and polyvinyl alcohol is 1:5, and the weight ratio of nano-silicon oxide The specific surface area is 220m 2 / g, the degree of polymerization of polyvinyl alcohol is 3000, its degree of alcoholysis is 87%, the thickness of the printing layer 2 is 10um; the protective layer 1 is a polypropylene layer, the purpose is to protect the printing layer 2 from being scratched and damaged, the protective layer 1 has a thickness of 10um, and the light-shielding layer 3 includes a mixture of polyolefi...

Embodiment 2

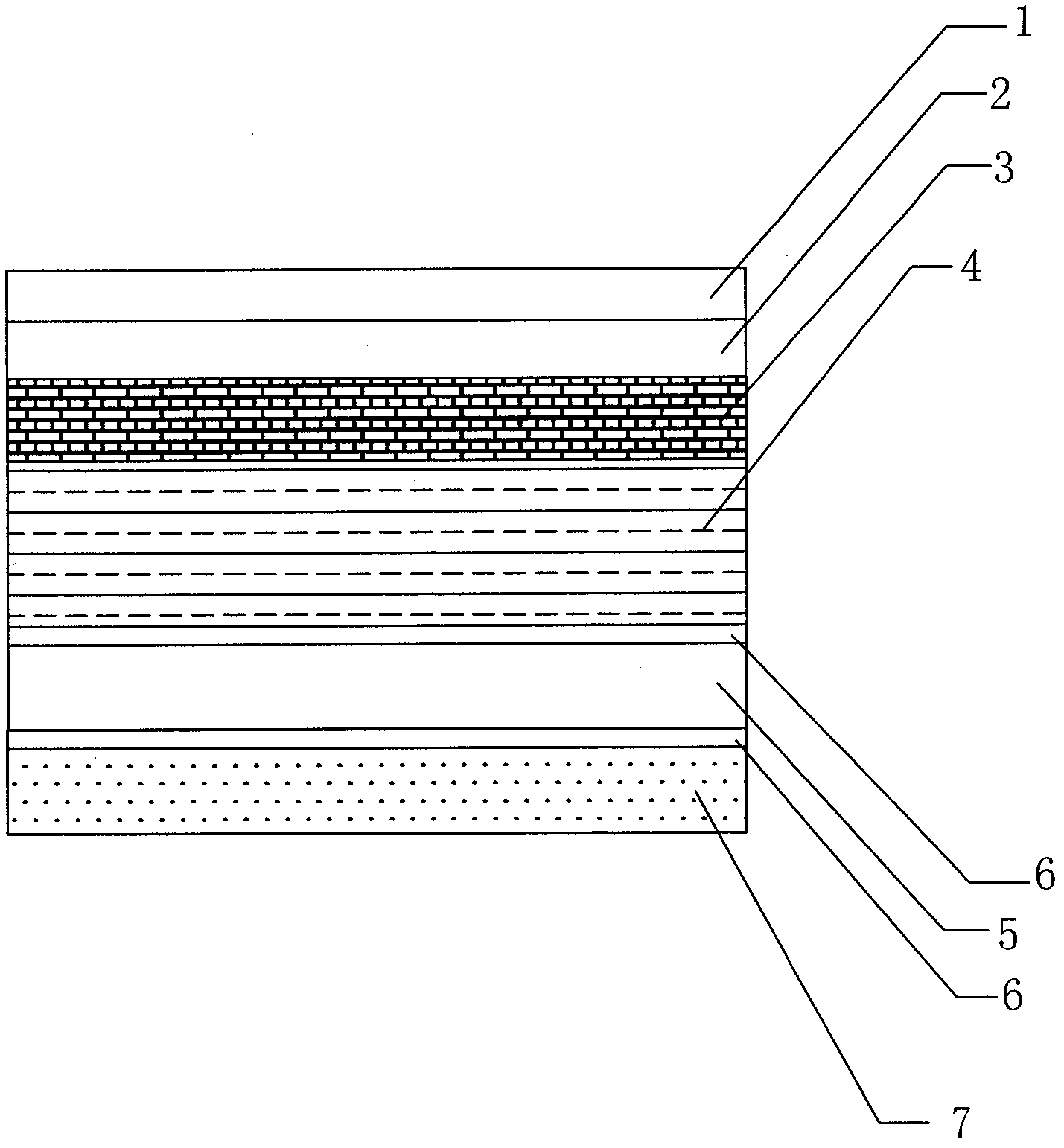

[0053] structured as figure 1 Shown, wherein the difference with embodiment 1 is:

[0054] The protective layer 1 is a polyethylene layer, and the thickness of the protective layer 1 is 20um;

[0055] The printing layer 2 is a mixture of nano-silicon oxide and poly(meth)acrylic acid, the weight ratio of nano-silicon oxide and poly(meth)acrylic acid is 2:1, and the specific surface area of nano-silicon oxide is 175m 2 / g, wherein the thickness of the printing layer 2 is 15um;

[0056] The light-shielding layer 3 includes polyolefin resin, carbon black and titanium dioxide, wherein carbon black is 10% of the light-shielding layer, titanium dioxide is 20% of the light-shielding layer, and the balance is polyolefin. Carbon black and titanium dioxide are mixed and co-extruded respectively. The thickness is 30um;

[0057] The support layer 4 is a biaxially stretched foamed polyester material, and the thickness of the support layer is 40um;

[0058] The thickness of the bonding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com