Treatment method of wood fiber raw material

A technology of lignocellulosic raw materials and processing methods, which is applied in the directions of fiber raw material processing, cellulose raw material pulping, pretreatment with alkaline compounds, etc., and can solve problems such as difficult industrialization, very high requirements for equipment and processes, and high requirements for equipment , to increase the strength and pulp yield, shorten the cooking time, and improve the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

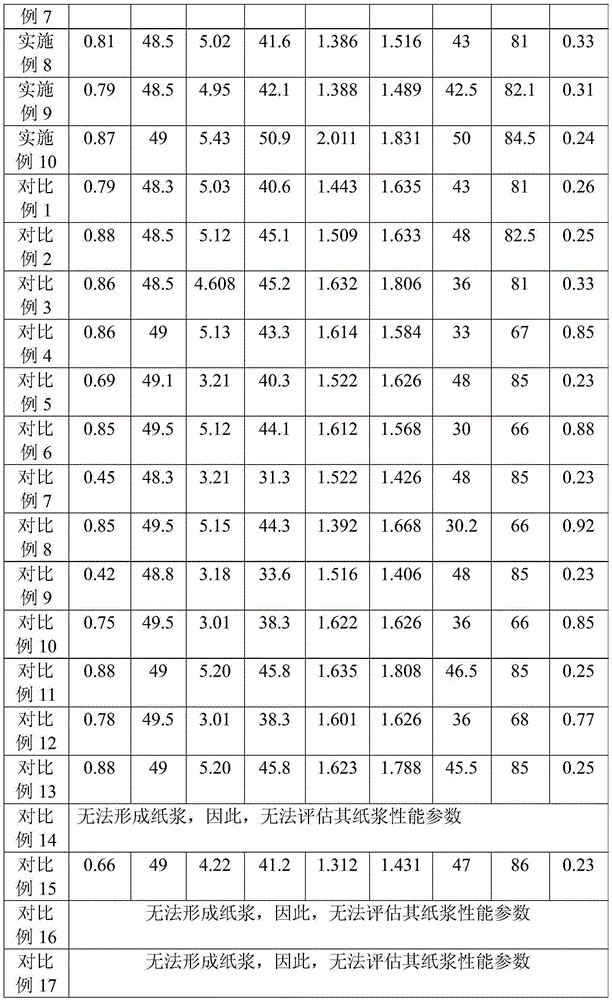

Examples

Embodiment 1

[0055] Bagasse (moisture content 8%) is chopped, take by weighing the bagasse raw material 50g that particle diameter is greater than 60 mesh sieve apertures and put into pressure vessel, measure Na by liquid-solid mass ratio 8:1 2 CO 3 aqueous solution for pre-dipping, where Na 2 CO 3 Na in aqueous solution 2 CO 3 The concentration is 20%. After fully stirring, react at 120°C for 30 minutes. After the pre-impregnation, collect the pre-impregnation liquid, and clean the fibers with clean water to collect the cleaning liquid;

[0056] Measure the acetic acid solution according to the liquid-solid mass ratio of 12:1, wherein the concentration of the acetic acid solution is 90%, add 1g of hydrochloric acid in the acetic acid solution, put it into a pressure vessel after fully stirring, and react at 120°C for 180min. Filtrate the fiber, and wash the fiber with acetic acid, wash it with clear water in the same way after the acetic acid wash, and collect the washing liquid produ...

Embodiment 2

[0061] Bagasse (moisture content 8%) is chopped, take by weighing the bagasse raw material 50g that particle diameter is greater than 60 mesh sieve apertures and put into pressure vessel, measure Na by liquid-solid mass ratio 8:1 2 CO 3 aqueous solution for pre-dipping, where Na 2 CO 3 Na in aqueous solution 2 CO 3 The concentration is 20%. After fully stirring, react at 120°C for 60 minutes. After the pre-impregnation, collect the pre-impregnation liquid, and clean the fibers with clean water to collect the cleaning liquid;

[0062] Measure the acetic acid solution according to the liquid-solid mass ratio of 8:1, wherein the concentration of the acetic acid solution is 95%, add 1g of hydrochloric acid in the acetic acid solution, put it into a pressure vessel after fully stirring, and react at 120°C for 120min. Filtrate the fiber, and wash the fiber with acetic acid, wash it with clear water in the same way after the acetic acid wash, and collect the washing liquid produc...

Embodiment 3

[0067] All the other are identical with embodiment 1, except cooking solvent is formic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com