Novel mass flow blade mechanism

A large flow and vane technology, applied in the field of new structure, can solve the problems of increased volume, increased cost, high pressure, etc., and achieve the effects of small frictional resistance, easy low-speed work, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

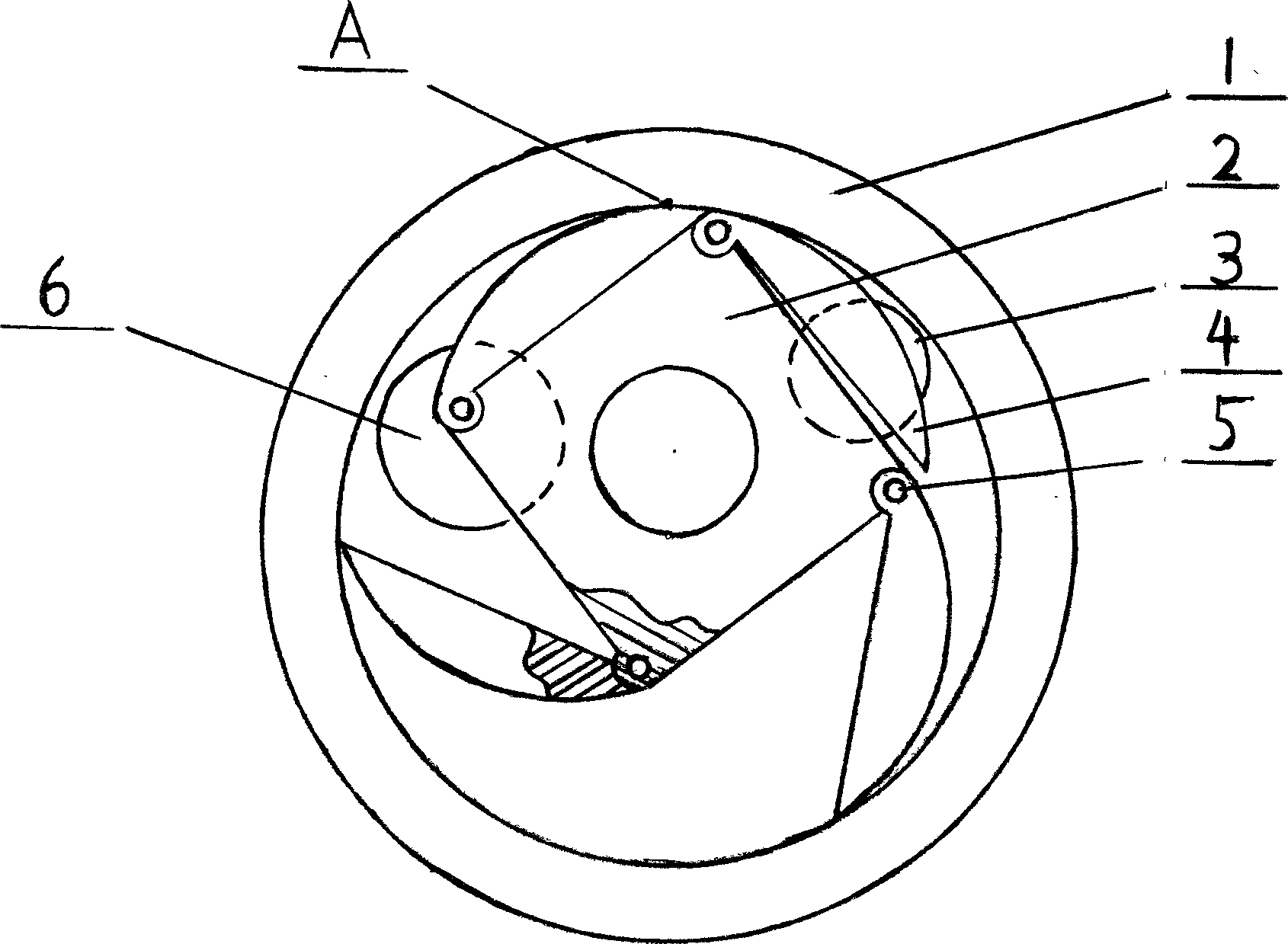

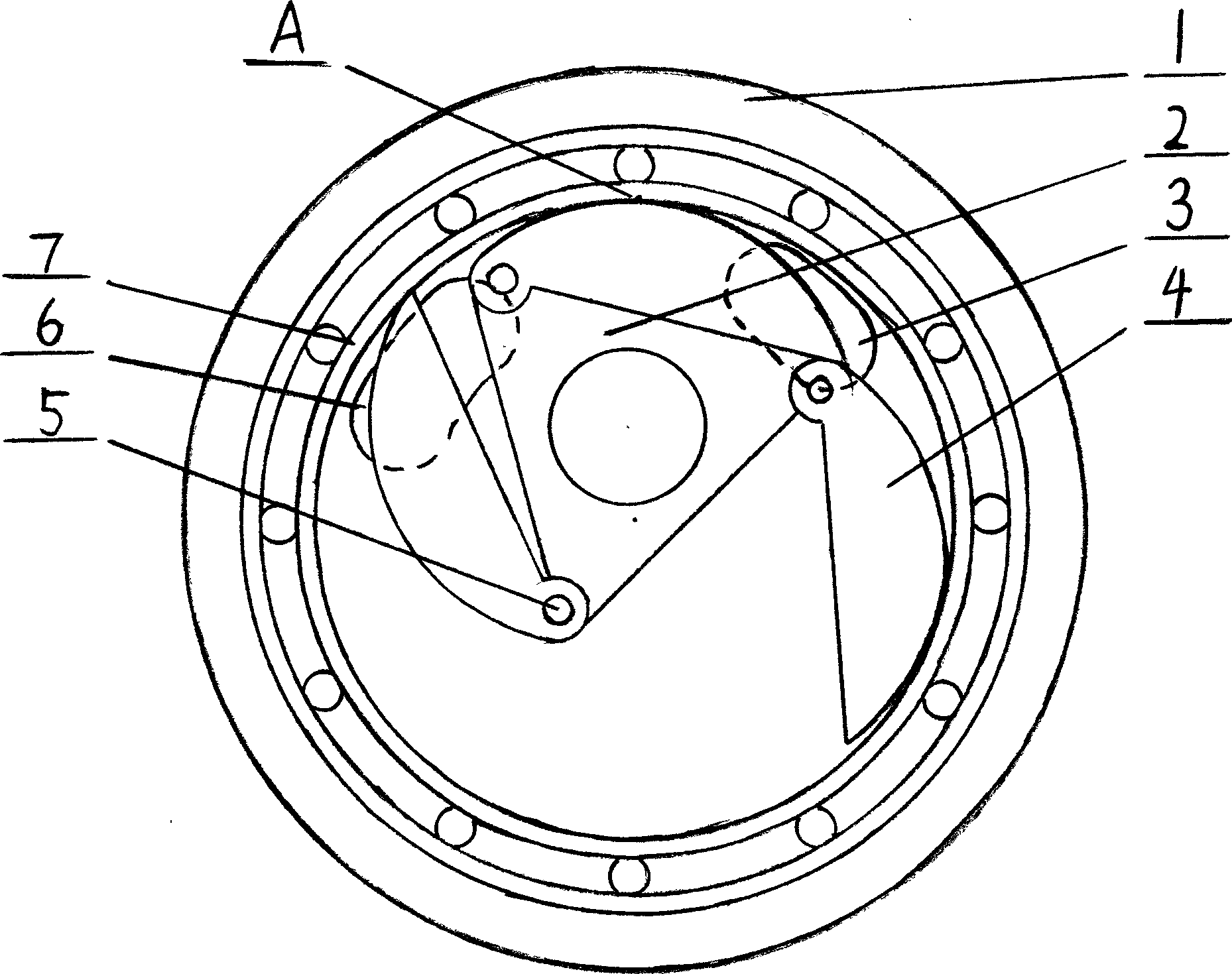

[0013] Such as figure 1 As shown, the novel high-flow vane mechanism provided by the present invention has a stator 1, a rotor 2, an oil inlet 3, a vane 4, a hinged connecting pin 5, and an oil outlet 6. The four corners of the square rotor 2 are respectively hinged with small semicircular blades 4-1, 4-2, 4-3, and 4-4 through pins 5, which are combined into a circle and installed in the stator 1. . The outer circle formed by the rotor 2 and the vanes 4 is in contact with the inner wall of the stator 1 at point A on the upper end, and the vanes 4 opened with the hinged connecting pin 5 at the corner of the rotor 2 as the center of the circle are in contact with the inner wall of the stator 1 during the compression process to form a closed space .

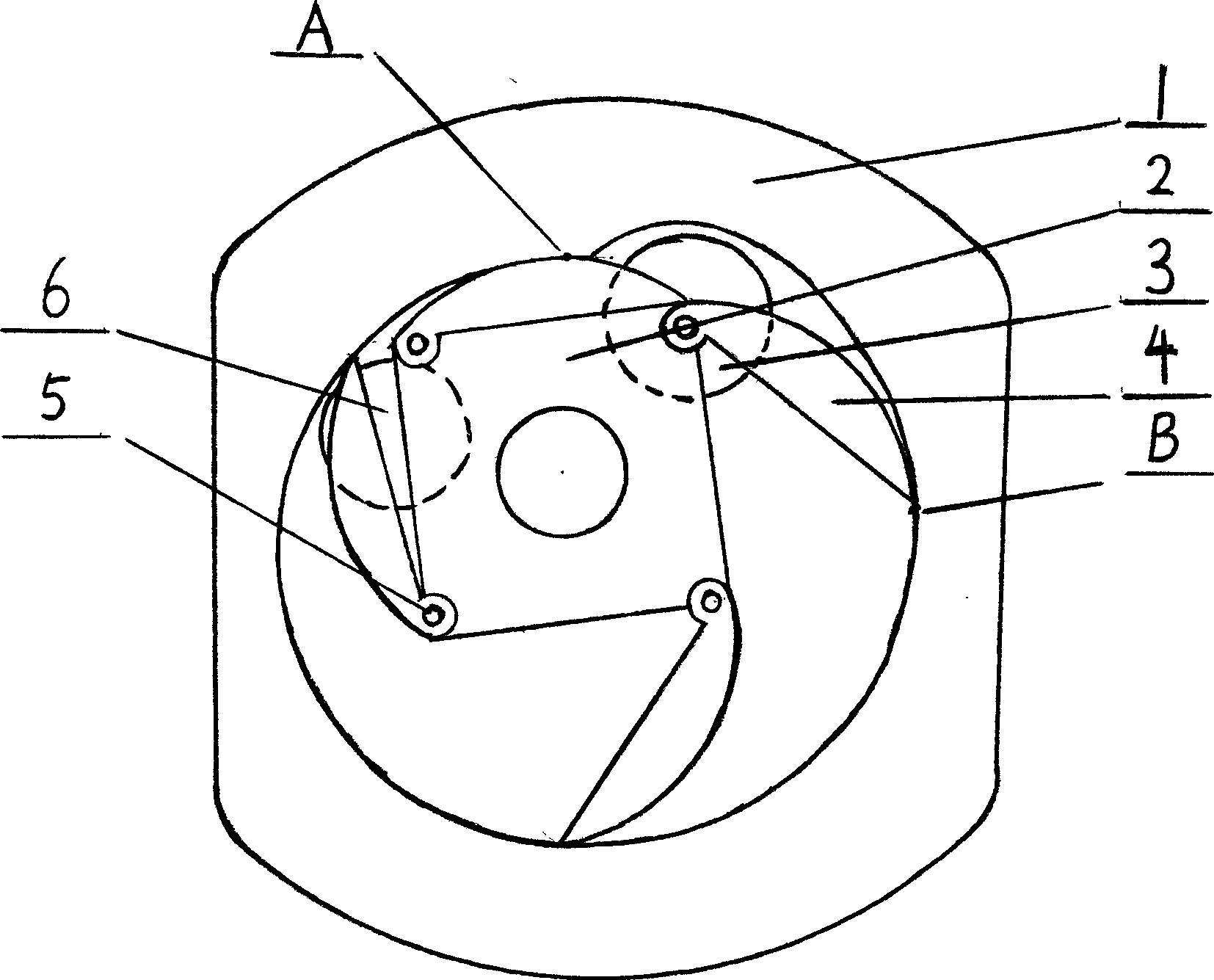

[0014] Such as figure 2 As shown, the arc radius of the point B on the inner wall of the stator 1 in the oil inlet 3 is increased, and the volume of the oil inlet 3 and the capacity between the blades 4 are increased. And lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com