Preparation method of controllable high-molecular-weight MQ silicon resin

A MQ silicone resin, high molecular weight technology, applied in the field of additives, can solve the problems of easy to produce white precipitation, low molecular weight, easy gelation of the system, etc., and achieve the effects of easy molecular weight control, mature technology and fewer reaction by-products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A preparation method of controllable high molecular weight MQ silicone resin, comprising the following steps:

[0046] (1) Add component A, solvent 1 and catalyst into the reactor, and mix uniformly to form mixed solution C; dissolve component B in solvent 2, stir and mix evenly to form mixed solution D;

[0047](2) Stir the mixed solution C at a constant temperature at any temperature in the range of 30-80°C, with a rotation speed of 200-3000rpm; slowly add the mixed solution D dropwise, and complete the dropwise addition in 30-60 minutes, and then react at a constant temperature for 2-10 hours after the dropwise addition;

[0048] (3) Add reaction inhibitor, stir for 10-50min, remove solvent by vacuum distillation, and obtain MQ silicone resin with controllable high molecular weight;

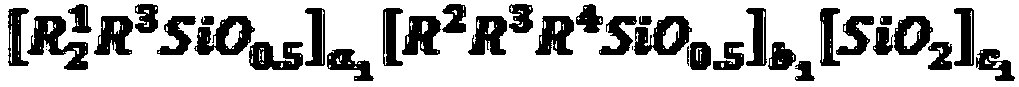

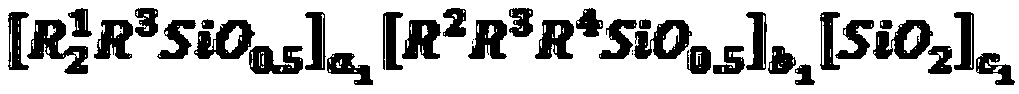

[0049] The general formula of the component A is:

[0050]

[0051] where: R 1 for C 1 ~C 4 the alkyl group, R 3 and R 4 is aryl, alkyl or arylalkyl; (a 1 +b 1 ) / c 1 The rat...

Embodiment 1

[0073] Add 27.00 g of Component A (see Table 1), 10.80 g of toluene, and 29,000 ppm of Pt catalyst to a 500 ml three-necked flask equipped with a reflux device, an electric heating mantle, a mechanical stirrer, and a dropping funnel, raise the temperature to 50° C., and stir at 300 rpm. 10min; move the mixed solution equipped with 2.00g of component B (see Table 2) and 0.80g of toluene to the dropping funnel, increase the speed of the mixer to 2000rpm and stir at a constant temperature, and add it dropwise to the mixed solution of component A. The dropwise addition was completed in 30 minutes. After the dropwise addition was completed, the reaction was carried out at a constant temperature for 7 hours; then 0.013 g of ethynylcyclohexanol was added and stirred for 20 minutes. After the reaction, the toluene was distilled off under vacuum at 100°C and 0.9MPa, the product was recovered, and dried at 100°C for 2 hours to obtain the MQ silicone resin product. Carry out GPC test to ...

Embodiment 2

[0079] As shown in Group 1 in Table 4, add Component A (see Table 1) 10.00g, toluene 4.00g, Pt catalyst 12000ppm into a 500ml three-necked flask equipped with a reflux device, electric heating mantle, mechanical stirring and dropping funnel , heated up to 50°C, and stirred at 300rpm for 10min; moved the mixed solution equipped with 2.00g of component B (see Table 2) and 0.80g of toluene to the dropping funnel, increased the speed of the mixer to 2000rpm, stirred at a constant temperature, and dropped Add it to the mixed solution of component A, drop it in 30 minutes, and react at constant temperature for 7 hours after the dropwise addition; then add 0.012 g of ethynylcyclohexanol, and stir for 20 minutes. After the reaction was completed, toluene and small molecules were removed by vacuum distillation at 100°C and 0.9 MPa, the product was recovered, and dried at 100°C for 2 hours to obtain the MQ silicone resin product. Carry out GPC test to the product, measure the Mw of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com