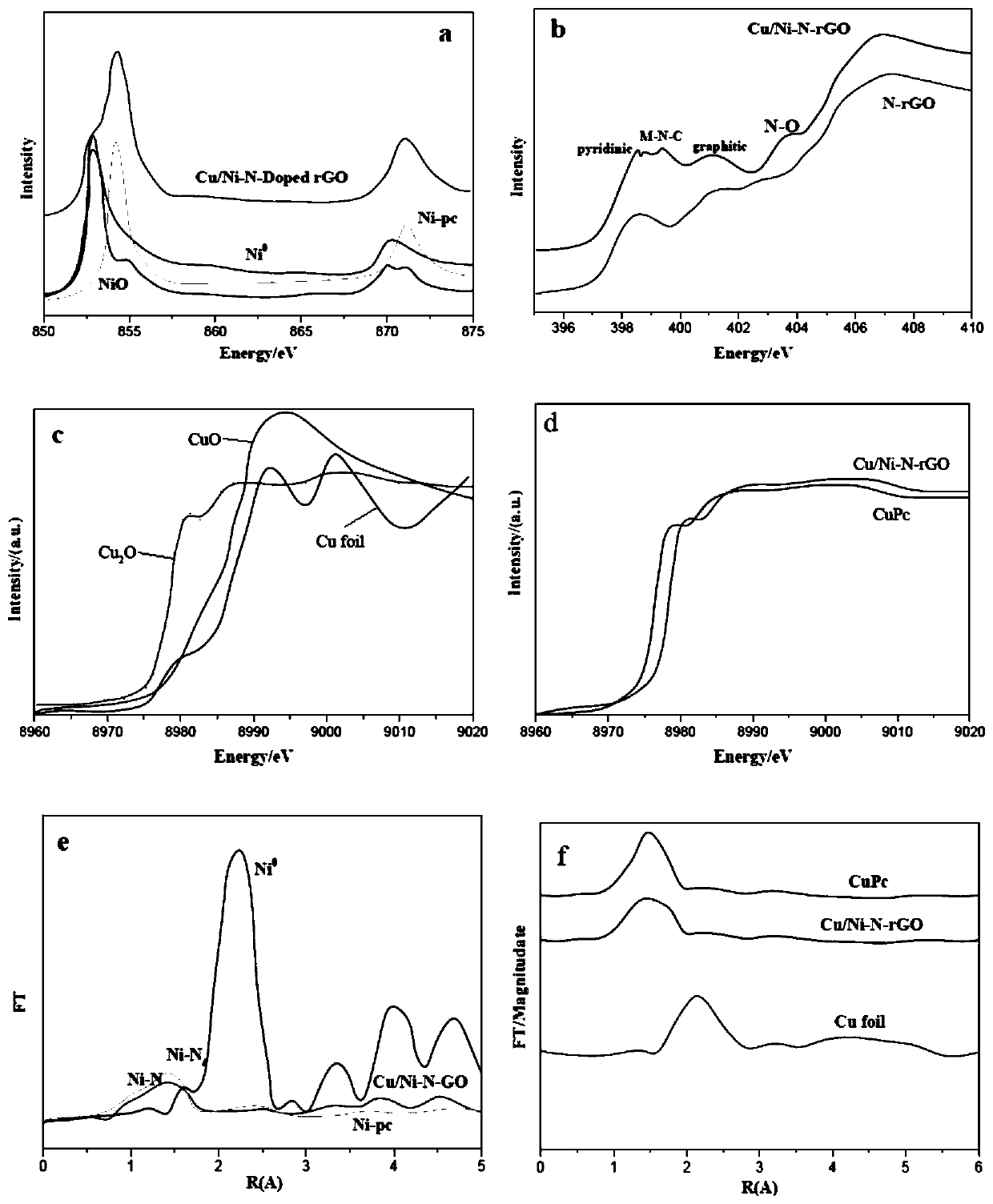

N-rGO loaded copper-nickel bimetallic monatomic catalyst as well as preparation and application thereof

A catalyst and bimetallic technology, which is applied in the field of copper-nickel bimetallic single-atom catalysts, can solve problems such as few researches, and achieve the effects of safe and easy-to-obtain raw materials, simple preparation process, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A copper-nickel bimetallic single-atom catalyst supported by N-rGO is prepared by the following method:

[0056] Weigh 0.3g of graphene and mix it with 70mL (0.5mol / L) hydrochloric acid, sonicate in an ice bath for 1.5 hours, drop 300 μL of aniline into the suspension and stir for 0.3 hours to obtain the first suspension;

[0057] Slowly add 2.0mL (1.5mol / L) of (NH 4 ) 2 S 2 o 8 And stirred in ice bath for 8 hours, filtered and washed 3 times, and dried under vacuum at 363K for 4 hours. The obtained composite was heated to 973K in an Ar atmosphere at a heating rate of 3.2K / min in a tube furnace and calcined at a constant temperature for 1 hour to obtain N-rGO;

[0058] Disperse 100 mg of N-rGO in 50 mL of water and sonicate for 1 h to obtain a homogeneous suspension. Then, by dropwise adding Na 2 CO 3 (0.5mol / L) solution adjusts solution pH to 9.5, is recorded as the second suspension;

[0059] Polyvinyl alcohol was dissolved in 200mL water to obtain an aqueous ...

Embodiment 2

[0064] Weigh 0.3g of graphene and mix it with 70mL (0.5mol / L) hydrochloric acid, sonicate in an ice bath for 1.5 hours, drop 300 μL of aniline into the suspension and stir for 0.3 hours to obtain the first suspension;

[0065] Slowly add 2.2mL (1.5mol / L) of (NH 4 ) 2 S 2 o 8 And stirred in ice bath for 10 hours, filtered and washed 3 times, and dried under vacuum at 363K for 5 hours. The obtained composite was heated to 973K at a heating rate of 3.2K / min in an Ar atmosphere in a tube furnace and calcined at a constant temperature for 2 hours to obtain N-rGO;

[0066] Disperse 102 mg of N-rGO in 50 mL of water and sonicate for 1 h to obtain a homogeneous suspension. Then, by dropwise adding Na 2 CO 3 (0.5mol / L) solution adjusts solution pH to 10.0, is recorded as the second suspension;

[0067] Polyvinyl alcohol was dissolved in 200mL water to obtain an aqueous solution of polyvinyl alcohol containing 0.3vol% polyvinyl alcohol;

[0068] Dissolve copper nitrate and nicke...

Embodiment 3

[0071] The activity experiment of the catalyst was carried out in the reactor, with 20mg of the catalyst obtained in Example 1——Cu / Ni-N-rGO with a Cu / Ni loading of 0.8wt% (wherein 0.4wt% Cu, 0.4wt% Ni) catalyzed Cleaves the C-S bond in 4,6-DMDBT. Before the desulfurization reaction, the prepared samples were heated at 523K in H 2 (18mol%H in the mixed gas 2 , flow rate: 26mL / min) for 1 hour reduction. After cooling to room temperature, add 1% methanol, 1% O 2 , a gas mixture of 5% 4,6-DMDBT and the balance He (flow rate 40mL / min), then heated to 393K, and stabilized at the reaction temperature for 45 minutes.

[0072] Experiments have found that when the reaction temperature is 393K, the desulfurization rate of 4,6-DMDBT and the selectivity to sulfone respectively reach 100%, which proves that the catalytic system is an ideal deep desulfurization catalytic system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com