Turbine system having more failure resistant rotors and repair welding of low alloy ferrous turbine components by controlled weld build-up

a technology of ferrous turbine components and turbine systems, which is applied in the direction of parallel air flow wind motors, wind turbines with perpendicular air flow, electric beam welding apparatus, etc., can solve problems such as loss of strength, reduce failure risk, reduce weld stress and cracking, and improve weld integrity. , the effect of reducing the risk of failur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

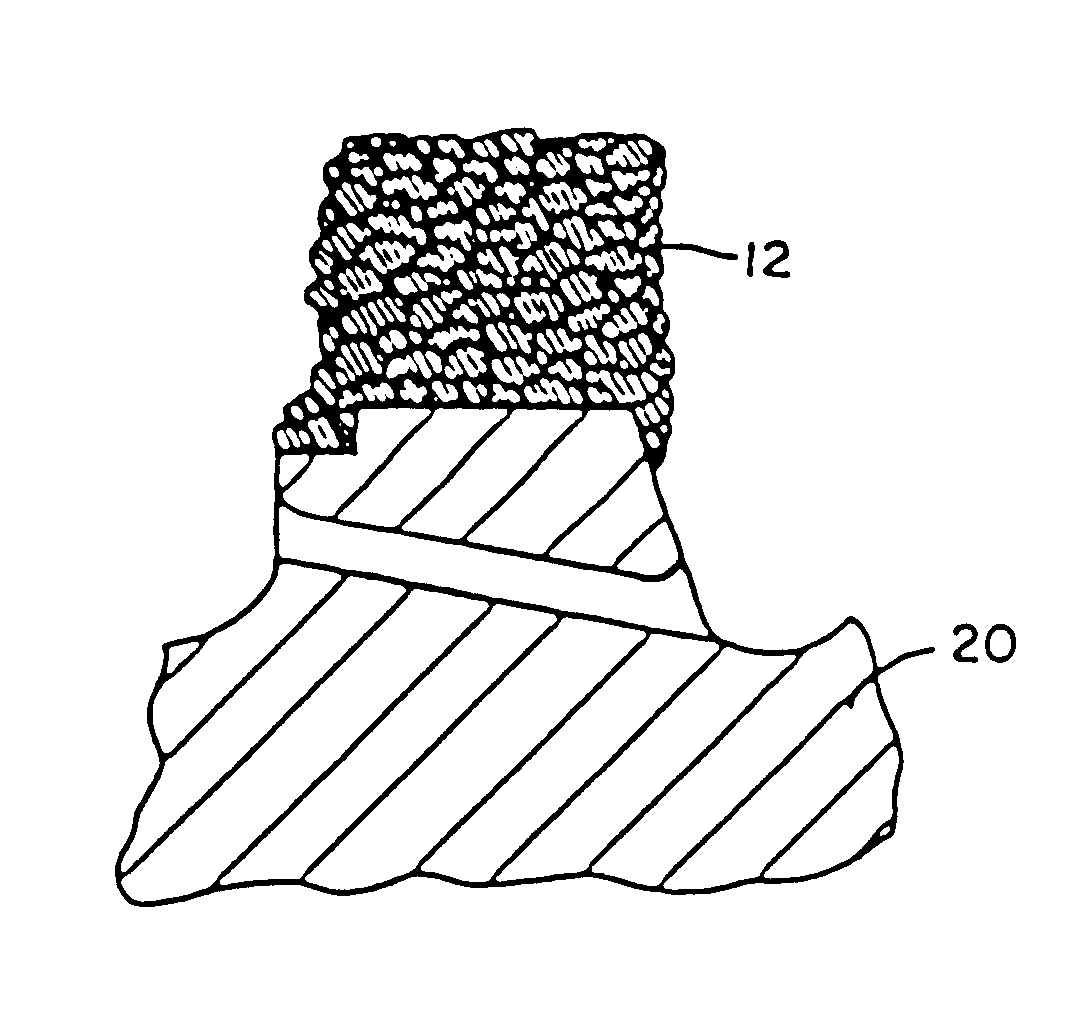

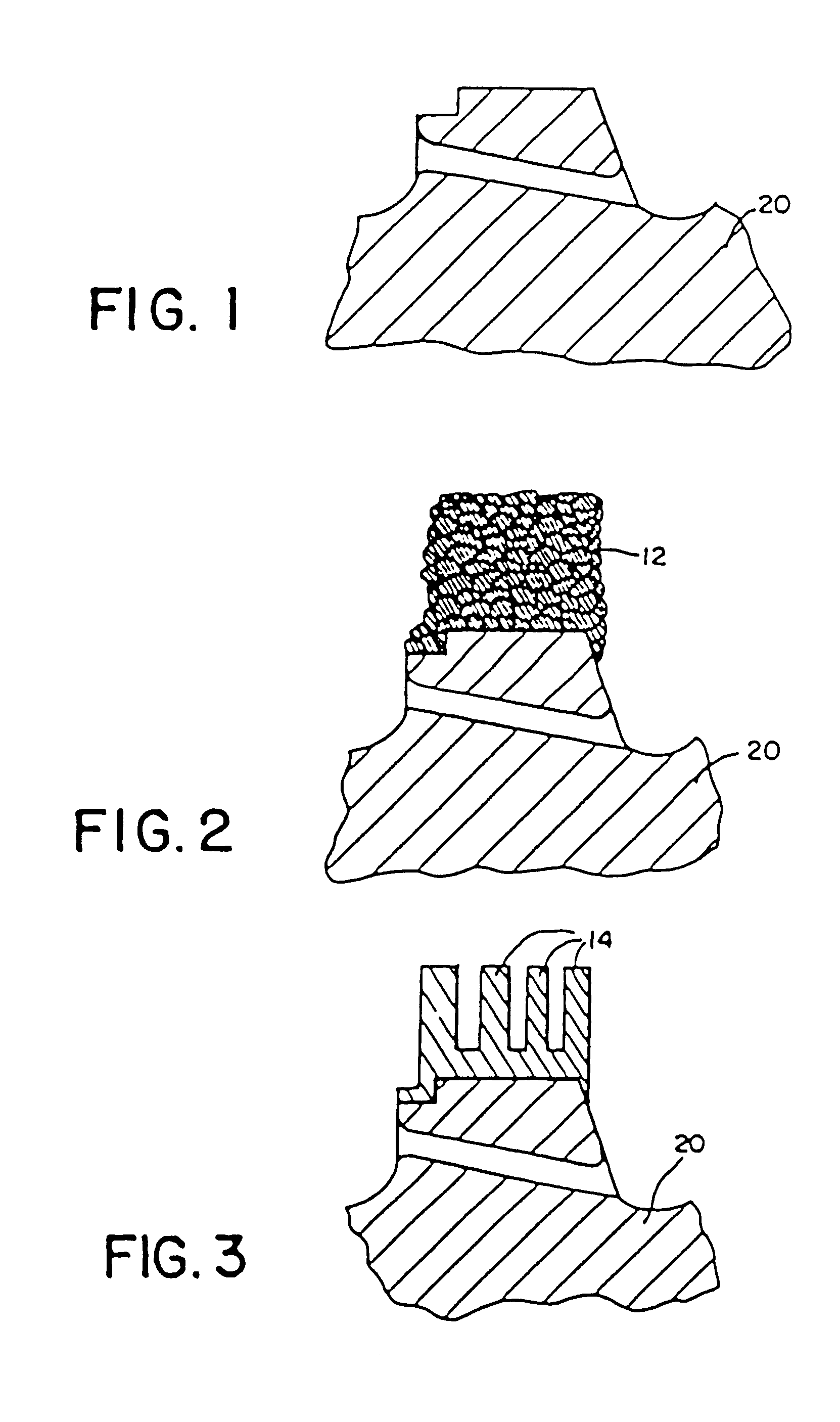

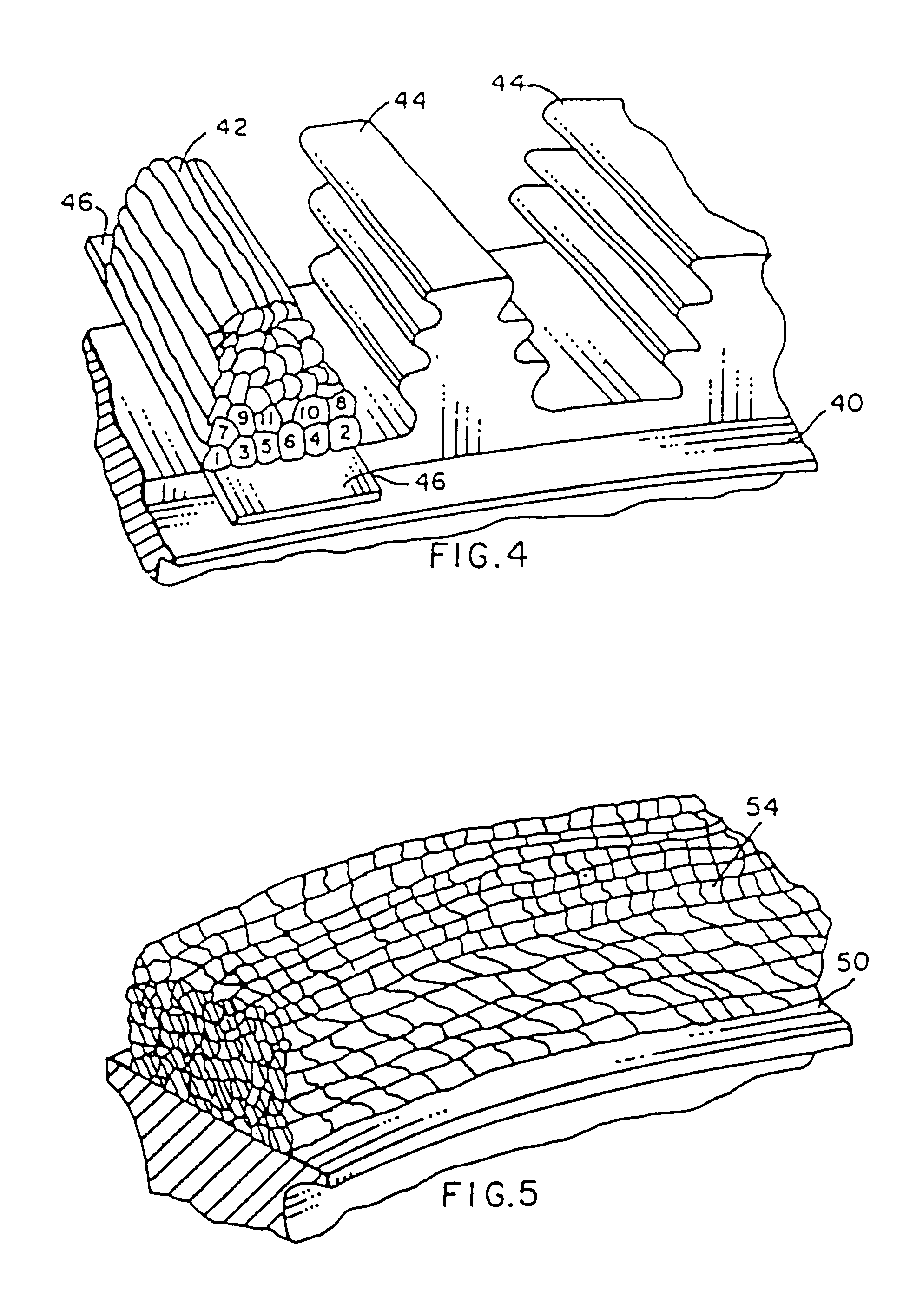

The novel methods of repairing worn surfaces of ferrous turbine components of this invention include providing a ferrous turbine component 20, 40, or 50 having Cr, Mo and V alloying ingredients. These turbine components 20, 40, or 50 include worn surfaces, however it is expected that new components can be manufactured using the methods disclosed herein. The repairing procedure includes depositing a first layer of weld metal the worn surface of the component thereby producing a heat-affected zone in that component. The procedure next deposits a second layer of weld metal on top of the first layer. This second layer is deposited with a greater amount of heat than the depositing of the first layer for tempering at least a portion of the heat affected zone produced by the first depositing step. As used herein, the term "tempering" refers to the process wherein the heat-affected zone of the base metal is re-heated and then cooled to relieve internal stress and reduce its hardness.

By care...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature Charpy toughness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com