Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

346 results about "Aluminium nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium nitrate is a white, water-soluble salt of aluminium and nitric acid, most commonly existing as the crystalline hydrate, aluminium nitrate nonahydrate, Al(NO₃)₃·9H₂O.

Method for preparing aluminium nitride powder

A process for preparing superfine aluminium nitride powder includes proportioning aluminium nitrate as Al source, urea, and water-soluble organic carbon source (glucose, cane sugar, citric acid, or soluble starch), mixing, preparing solution of mixture, thermal drying at 100-400 deg.C to obtain powder, reductive nitrifying reaction at 1200-1600 deg.C in N2 for 1-24 hr, and calcining at 600-700 deg.C for 1-7 hr.

Owner:苏州创基精密制造有限公司

Porous material and its synthesis method

ActiveCN1751994AHas a compound pore structureMolecular sieve catalystsCrystalline aluminosilicate zeolitesSynthesis methodsAluminium hydroxide

A process material with compound artery is prepared from the Si source chosen from amorphous SiO2, si sol, silicon oxide solid, silicon gel, diatomite and water glass, the Al source chosen from sodium aluminate, sodium metaaluminate, aluminium sulfate, aluminium nitrate, etc, at least one of lithium hydroxide, sodium hydroxide, potassium hydroxide, rubidium hydroxide and cesium hydroxide, and template agent through proportional mixing, reaction, ageing and crystallizing.

Owner:CHINA PETROLEUM & CHEM CORP +1

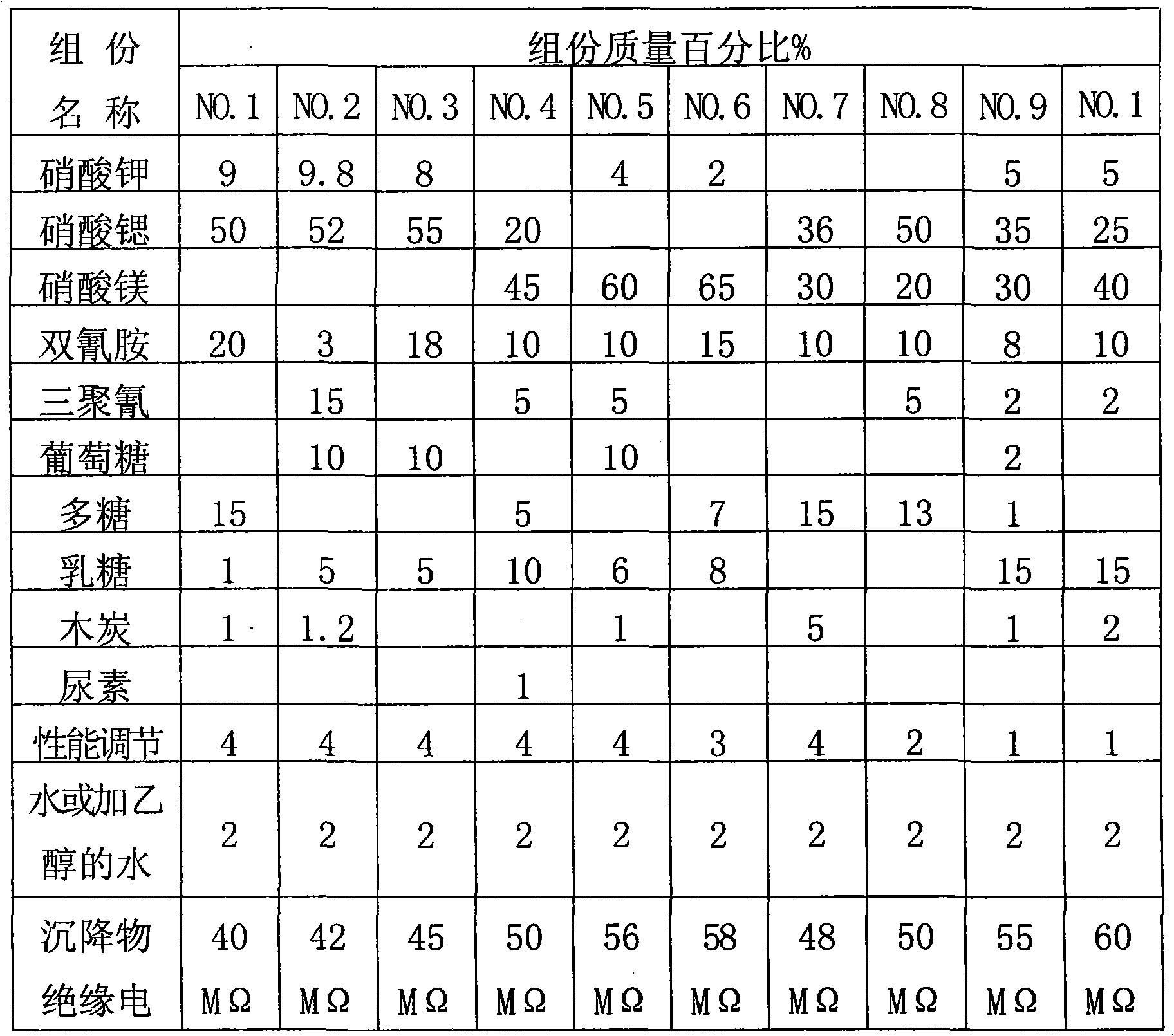

Compound type aerosol extinguishing agent

InactiveCN101862517ALow fire extinguishing concentrationImprove corrosion resistanceFire extinguisherSucroseNuclear chemistry

The invention discloses a compound type aerosol extinguishing agent comprising the following components in percentage by weight: 30-75 percent of oxidizing agent, 20-50 percent of reducing agent, 2-15 percent of performance regulating agent and no more than 2 percent of binding agent. The oxidizing agent is prepared by matching any two or three matched components selected from potassium nitrate, strontium nitrate and magnesium nitrate; the reducing agent is prepared by matching two or more components selected from polyhexose, glucose, starch, sorbitol, xylitol, lactose, dicyandiamide, melamine, carbamide and sucrose; the performance regulating agent is prepared by matching one or more component selected from carbon powder, light magnesium carbonate, magnesium stearate, aluminium nitrate, hexamethylenetetramine, aluminium oxide, magnesium oxide and light metal oxide; and the binding agent is prepared by matching water or 20-30 percent of ethanol added into the water. In the invention, production raw materials have a wide source and low cost, can be constantly obtained and are safe and reliable, and burnt residues have no toxicity and good environmental protection performance.

Owner:湖南省金鼎消防器材有限公司

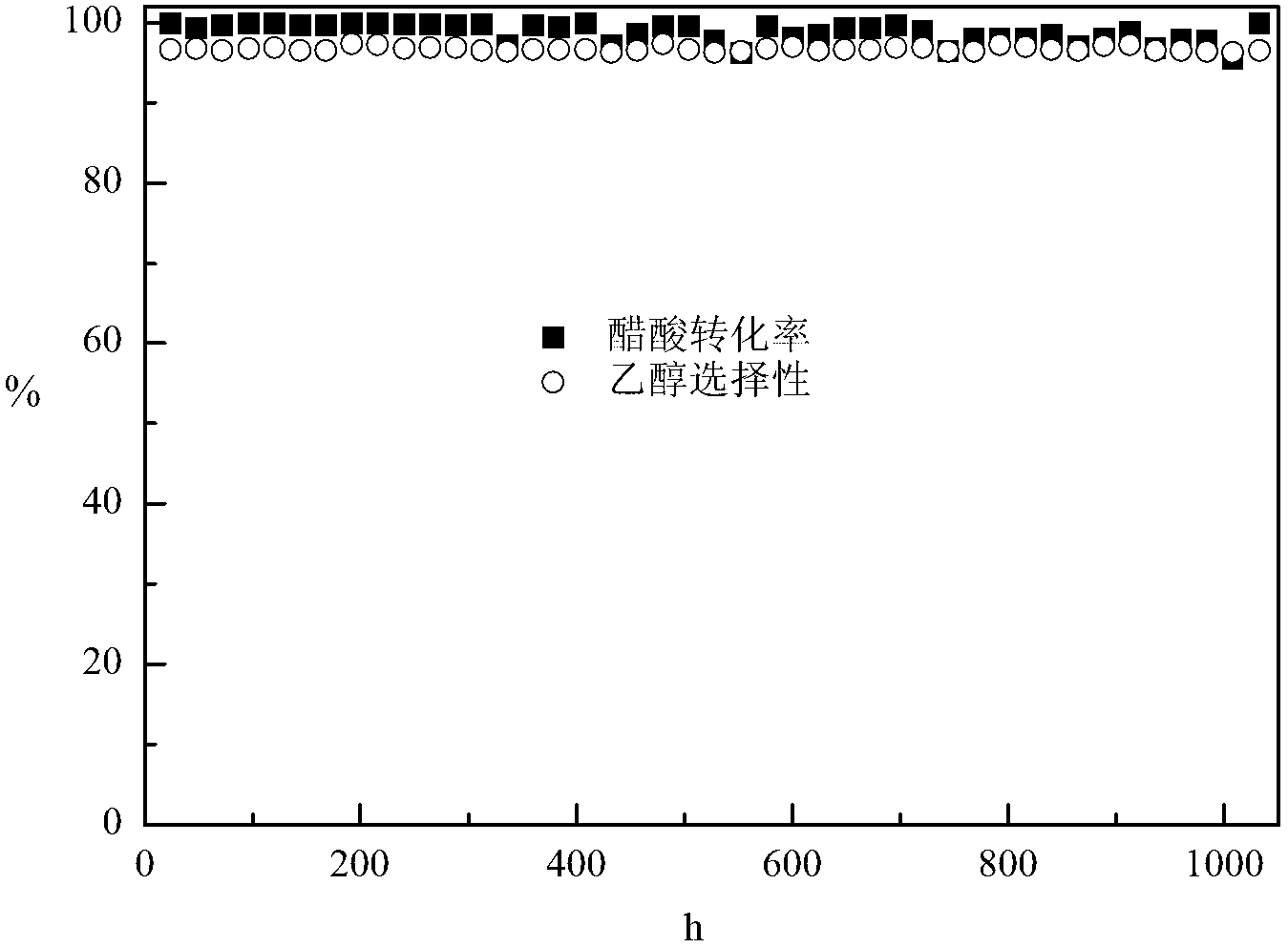

Catalyst for producing ethanol and preparation method thereof

ActiveCN103170337AImprove thermal stabilityAvoid inactivationOrganic compound preparationHydroxy compound preparationHydrogen pressureReaction temperature

The invention relates to a catalyst for producing ethanol and a preparation method thereof. The weight ratio of reactive metal to aid to a protective agent to a carrier in components of the catalyst is (5-30):(0-20):10:100, wherein the reactive metal is any one of nickel, cobalt, copper and manganese; the aid is any one of iron, molybdenum, cerium, barium, zinc and tin; the protective agent is aluminium nitrate or silica sol; and the carrier is carbon nano tube or silica. By taking glacial acetic acid hydrogenation ethanol production reaction as an example, the acetic acid conversion rate is more than 99 percent, the ethanol selectivity is more than 95 percent, the service life of the catalyst exceeds 1000 hours, and the space time yield of the ethanol is more than 1000mg / g-cat. / h under the conditions of the reaction temperature of 225 DEG C and the hydrogen pressure of 2.5MPa. According to introduction of the protective agent, the heat stability of the catalyst is greatly improved, and the series of catalysts are low in cost, simple in preparation, excellent in performance and high in stability and have good industrial application prospects.

Owner:XIAMEN UNIV +1

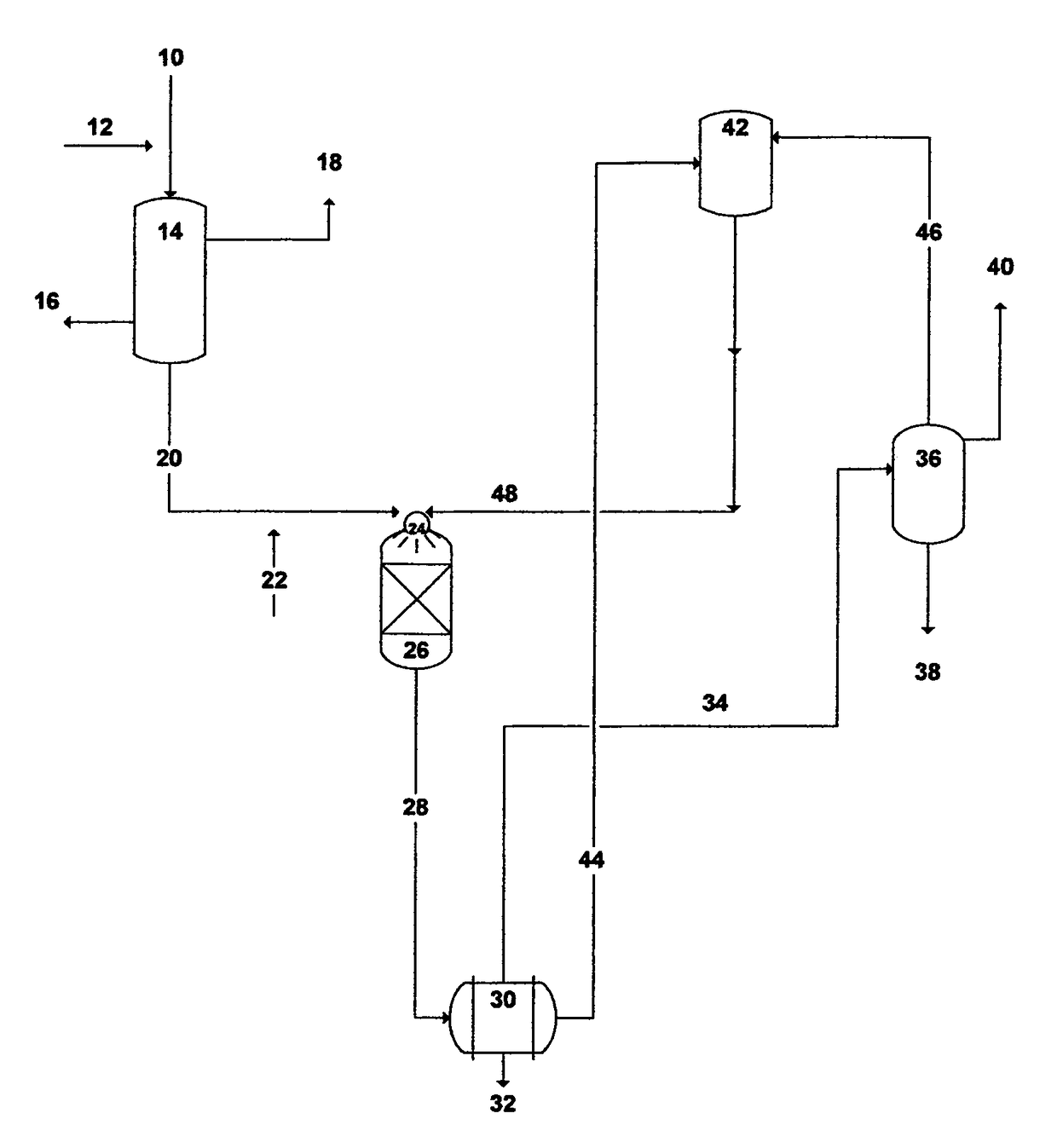

Methods to treat source water for oil-fields heavy oil and other applications

ActiveUS9701558B1Avoid pollutionSpecific water treatment objectivesTreatment involving filtrationNitrateFuel oil

There is provided herein a system and method for treating source water to remove contaminants such as oil from oil-fields produced water. In some embodiments, source water containing CO2, endotoxins, foulants, sulfate, and oxygen will be treated with aluminum nitrate or iron nitrate, separating the CO2 and endotoxins from the treated water, removing the foulants by mixing hydrated lime and an amine solvent with the treated water, and separating the dissolved oxygen and recovering the amine solvent using a hydrophobic membrane.

Owner:BADER MANSOUR S

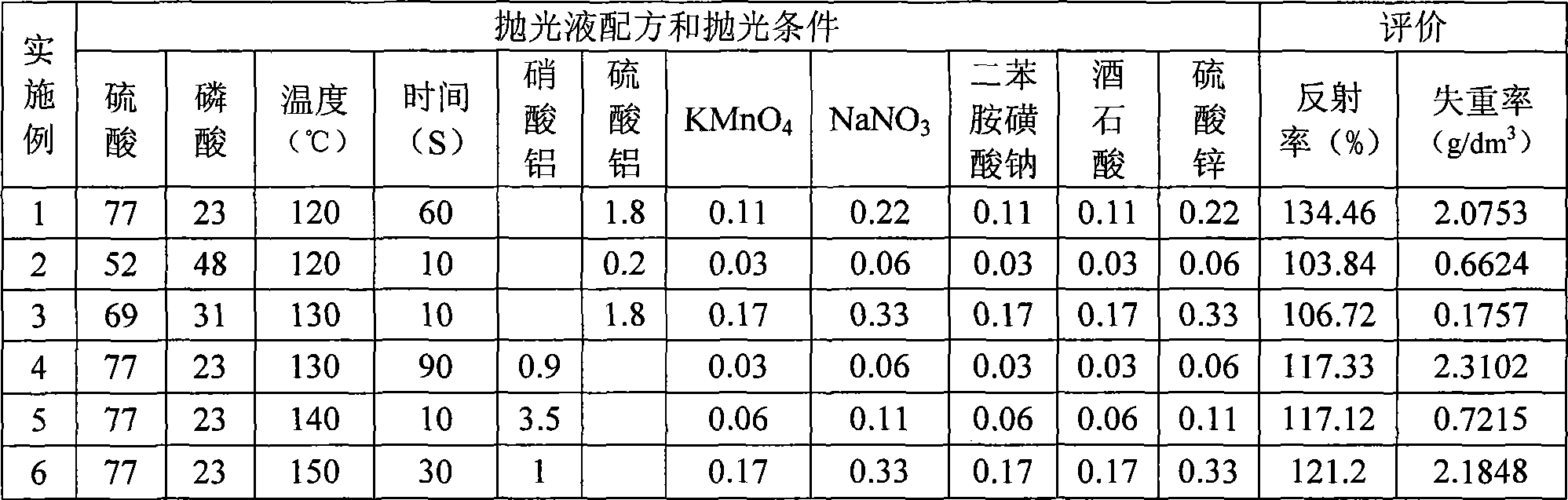

Aluminum product chemical polishing solution and polishing method thereof

InactiveCN101476126AEasy to cleanReduce corrosion pointsPhosphoric acidSodium diphenylamine sulfonate

The invention discloses an aluminium product chemical polishing solution composition with nitric acid free. The composition uses sulfuric acid and phosphoric acid as a basic solution, an additive is composed of aluminium sulphate (or aluminium nitrate), potassium permanganate, sodium nitrate, diphenylamine sulfonic acid sodium salt, tartaric acid and zinc sulfate. Polishing temperature is 110-150 DEG C, polishing time is 10s-120s when the polishing solution is used for polishing. The composition can ensure no nitrogen oxide yellow smoke harm, at the same time ensure the aluminium product having better polishing blare effect for reaching mirror surface brightness, and having little rate of weight loss.

Owner:SHANXI UNIV

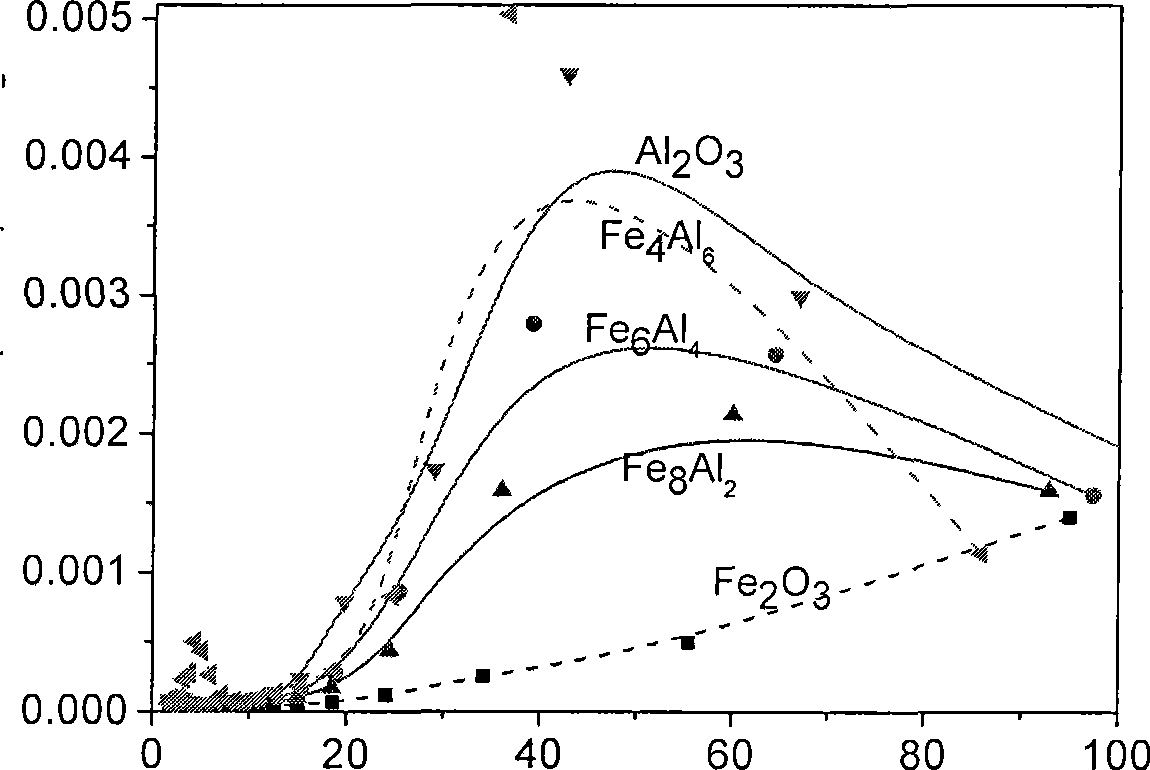

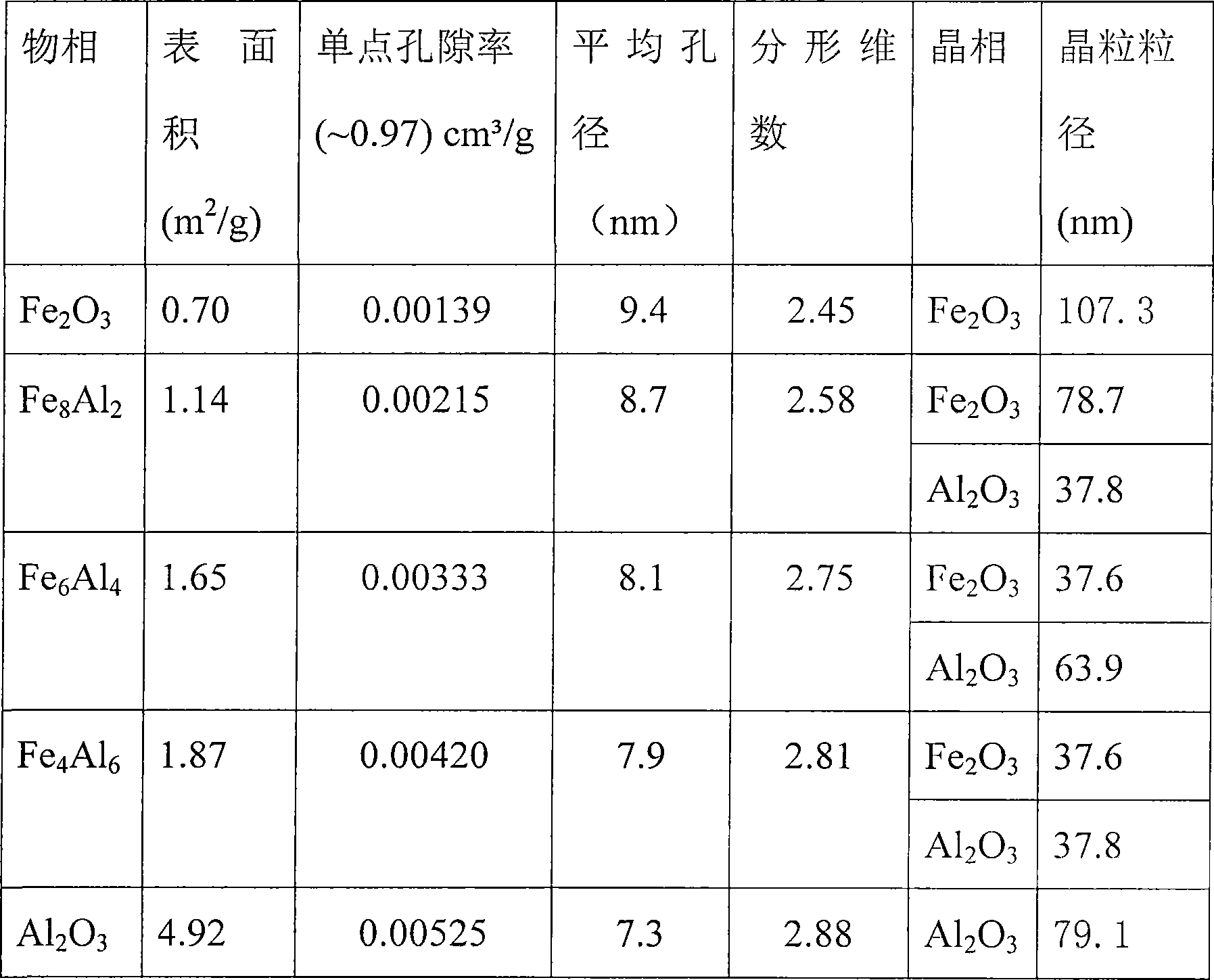

Process for preparing iron based oxygen carrier

InactiveCN101486941AOvercome the disadvantage of long preparation timeMake up granularityFerric oxidesFuel additivesSelf maintenanceAluminium nitrate

The invention provides an iron-based oxygen carrier preparation method which takes iron and aluminium nitrate as raw materials and urea as fuel, and combines the sol-gel method organically with combustion compound method to prepare nanometer-class Fe2O3 / Al2O3 oxygen carrier with excellent anti-sintering performance. The iron-based oxygen carrier preparation method fully uses the mixing evenness between a plurality of components in the sol-gel method and the reaction process self-maintenance, quickness and low energy-consumption characteristics in the combustion compound method, easily obtains the used oxygen carrier preparation raw material, has the advantages of low price, simple preparation technology and easy operation, and is suitable for scaled mass production of the oxygen carrier.

Owner:HUAZHONG UNIV OF SCI & TECH

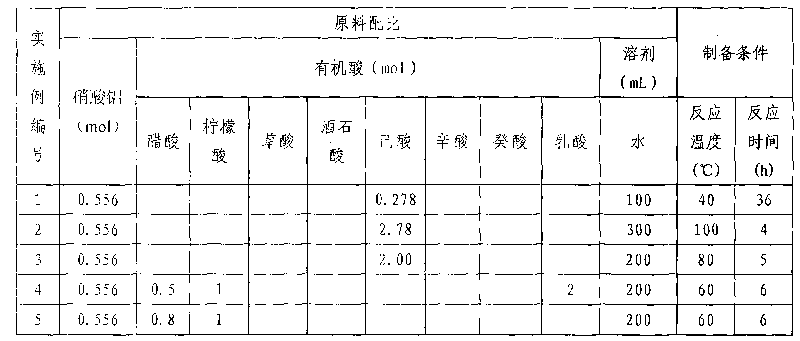

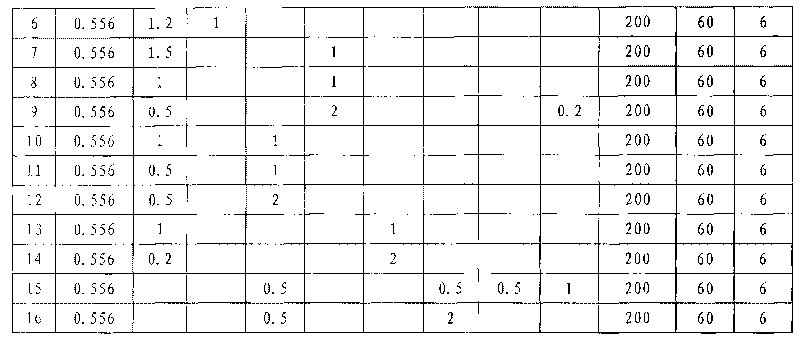

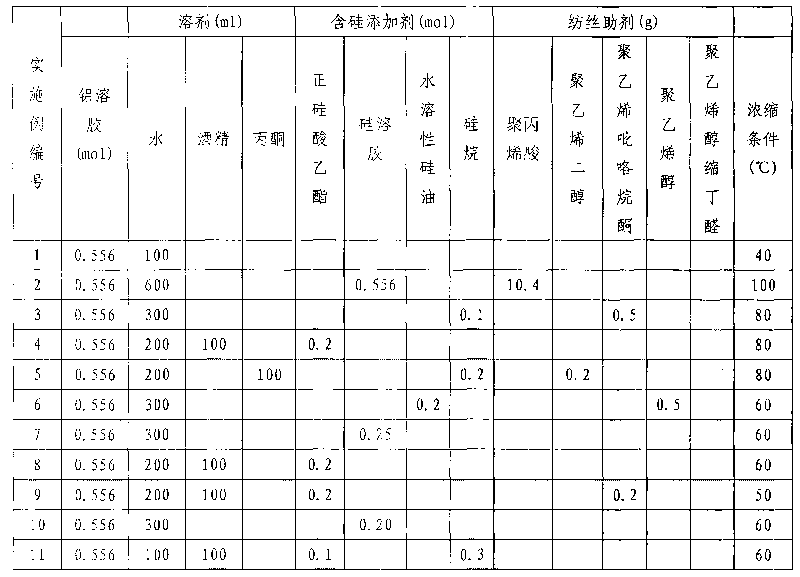

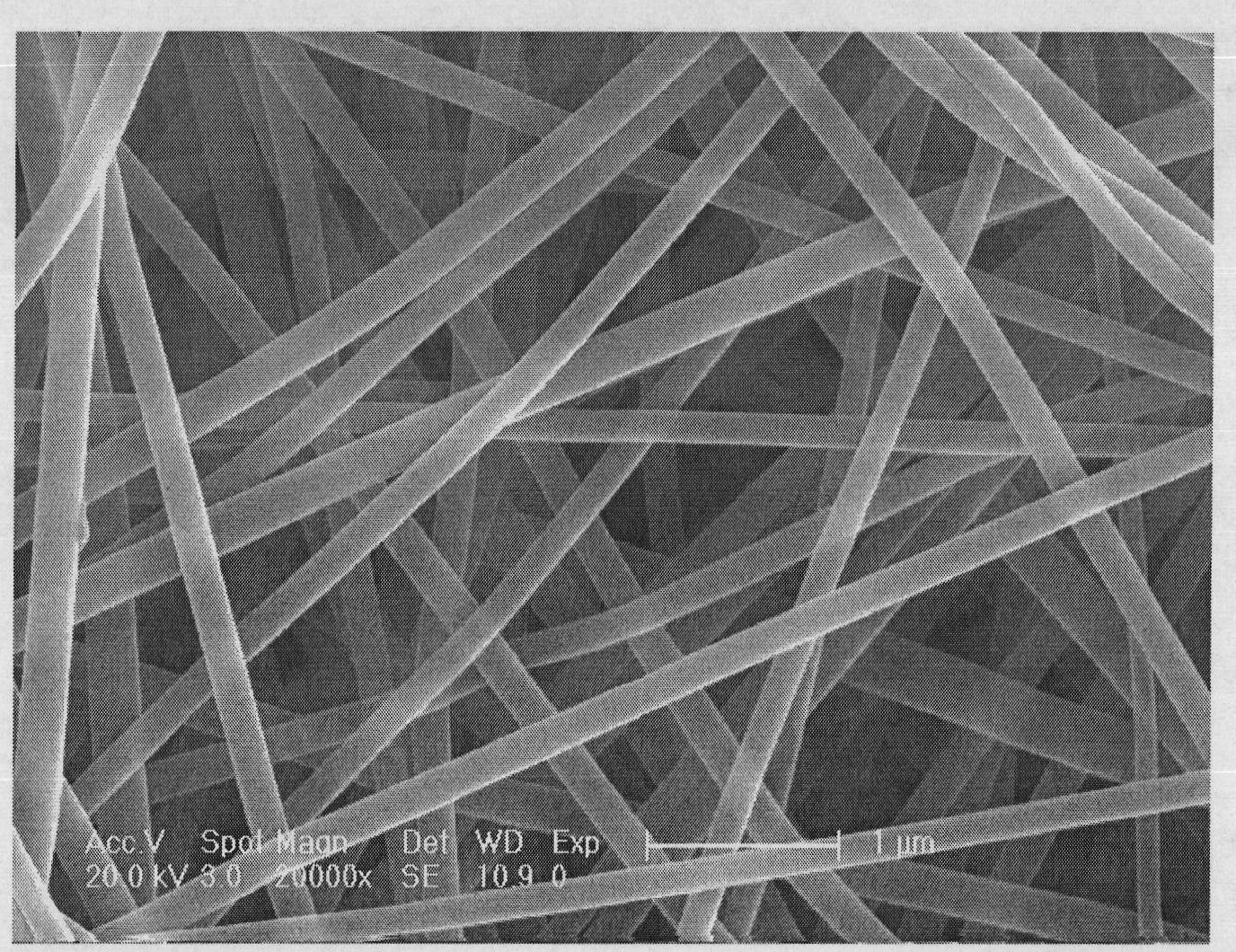

Process for preparing alumina-based continuous fiber with sol-gel method

The invention discloses a process for preparing alumina-based continuous fiber with a sol-gel method. The process comprises the following steps of: adding aluminium nitrate and one or a plurality of kinds of carboxylic acids with the carbon number of 2 to 24 to distilled water; ensuring the mixture to react in the condition of continuous stirring under a certain temperature to obtain transparent carboxylate aluminium gel; adding a certain amount of solvent to the carboxylate aluminium gel, and adding a certain amount of silicon-contained additives and superpolymer spinning additives to obtain an alumina-based fiber precursor solution; concentrating the solution to obtain spinnable alumina-based fiber precursor sol; placing the concentrated sol to a liquid storage tank with a spray head, and spinning by adopting a dry method or a wet method to obtain alumina-based continuous fiber protofilament containing organic matters; and drying and sintering the protofilament to obtain the alumina-based continuous fiber. The alumina-based continuous fiber obtained by adopting the invention can be used for reinforcement of composite materials so as to further enhance the strength and toughness of the materials and improve the heat resistance of the materials, and is widely applied in the fields of aerospace, automobiles, and the like.

Owner:XI AN JIAOTONG UNIV

Low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3, and preparation method and application thereof

InactiveCN103433033AHigh activityImprove operating economyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAluminium nitrateCerium nitrate

The invention discloses a low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3, and a preparation method and an application thereof. The low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is composed of carriers and active components, wherein the carriers are TiO2 and Al2O3 and the active components are MnOx and CeO2. The molar ratio of Ce:Ti:Al:Mn in the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is 0.2-0.4:1:1:0.4-1.2. The preparation method is that: the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is prepared by taking titanium sulfate, aluminium nitrate, manganous nitrate and cerium nitrate as precursors and employing a coprecipitation method. The preparation cost is low, and the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 has better denitration effect in a flue gas at a temperature of 150-300 DEG C.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Process for preparing alumina powder with high sinter activity

InactiveCN1369434AImprove sintering performanceLow costAluminium hydroxide preparationAluminium chlorideInorganic salts

A process for preparing alumine powder with high sinter activity includes reaction of Al-contained inorganic salt chosen from aluminium nitrate, aluminium chloride and aluminium ammonium sulfate on ammonium bicarbonate at 5-50 deg.C to generate NH4Al(OH)2CO3, depositing and ageing for 2-24 hrs, washing with deionized water, baking at 50-150 deg.C and sintering at 1100-1200 deg.C to obtain alpha-Al2O3 particles less than 400 nm.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

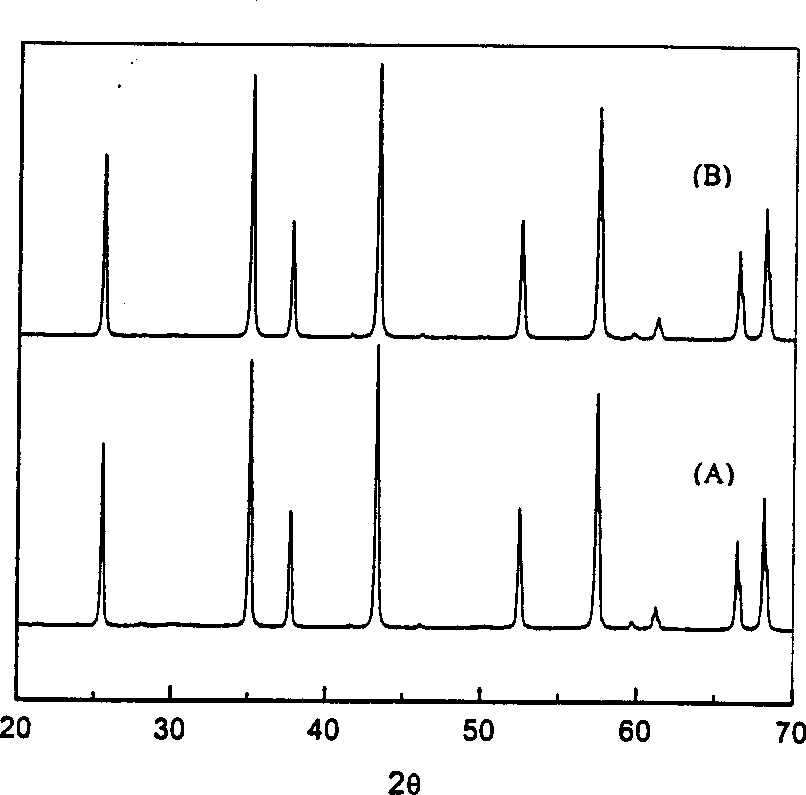

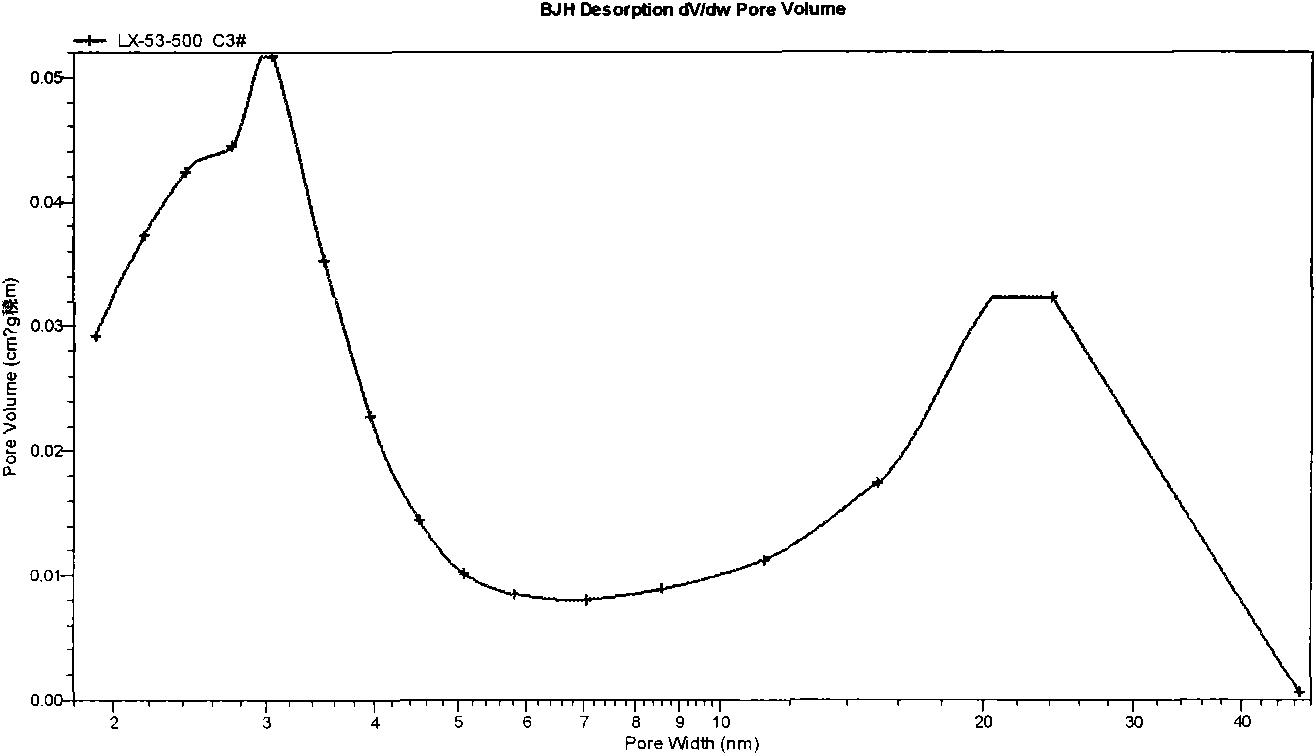

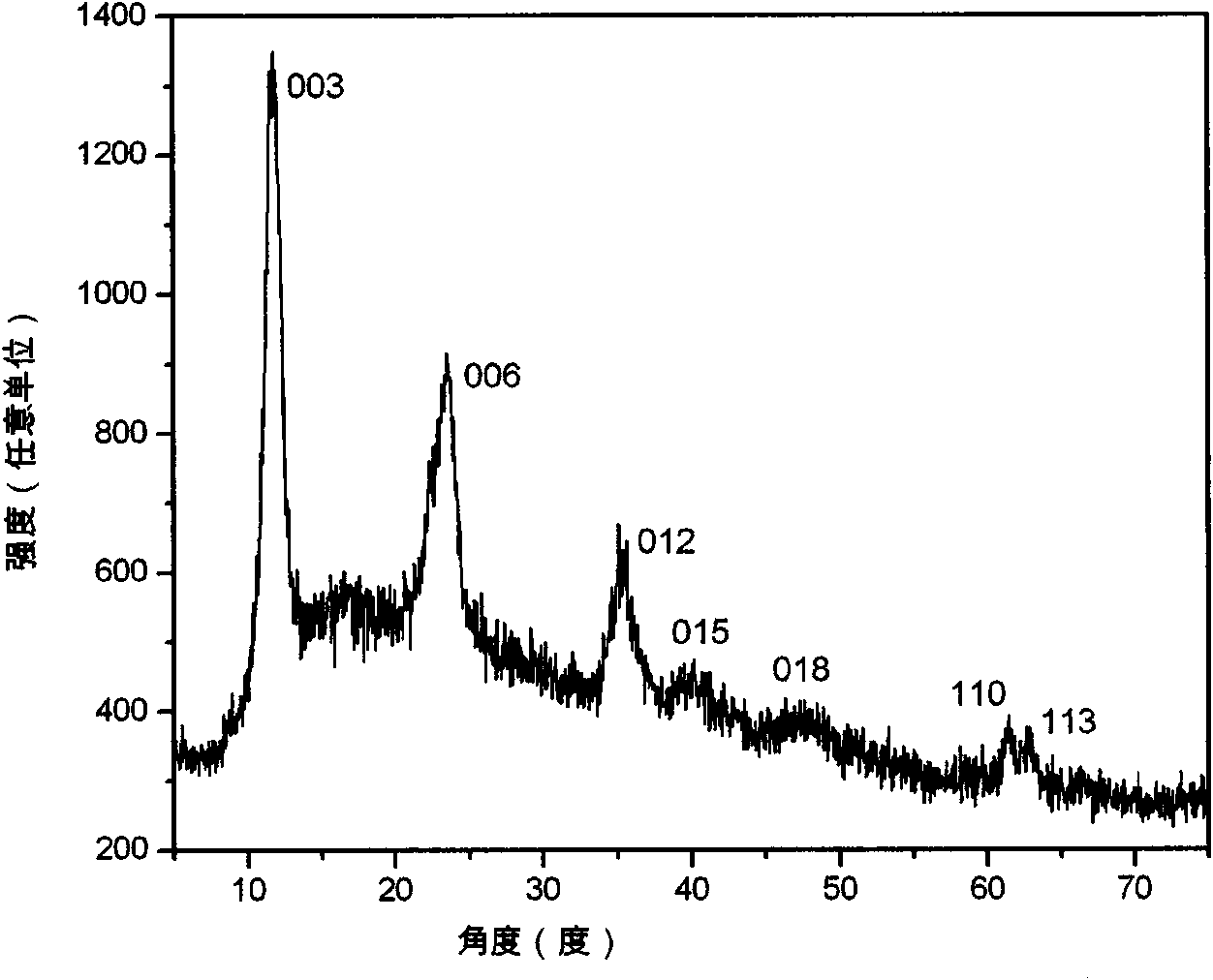

Preparation method for hierarchically mesoporous gamma-Al2O3 nanorods

ActiveCN101880049ALarge specific surface areaLarge hole volumeAluminium compoundsNanostructure manufactureAluminium nitrateSucrose

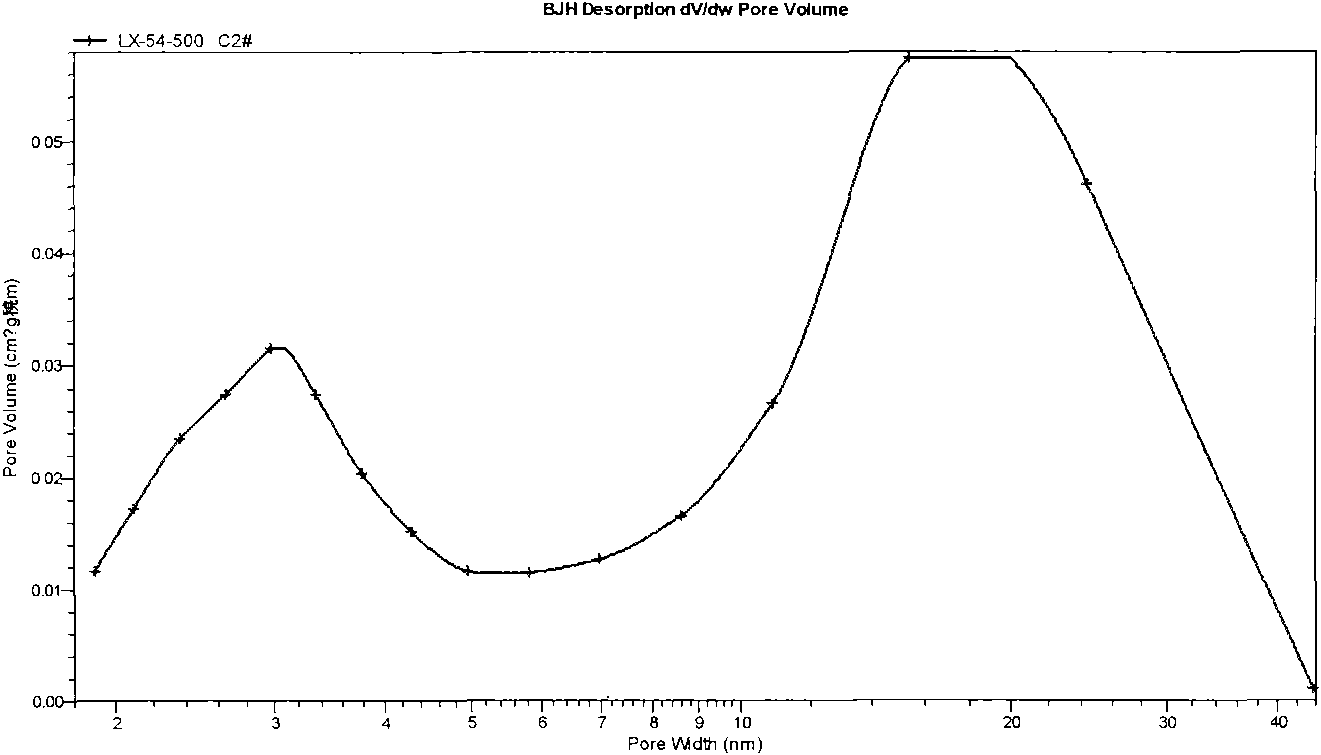

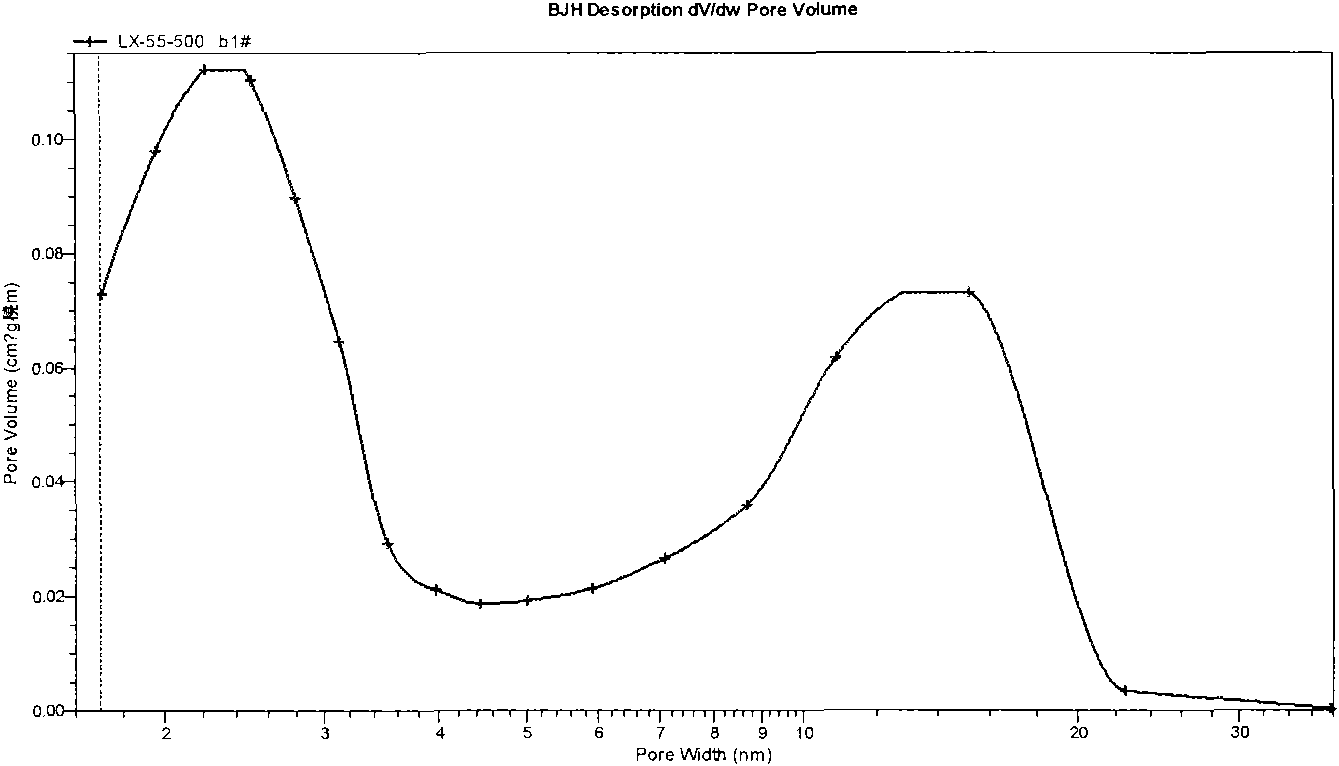

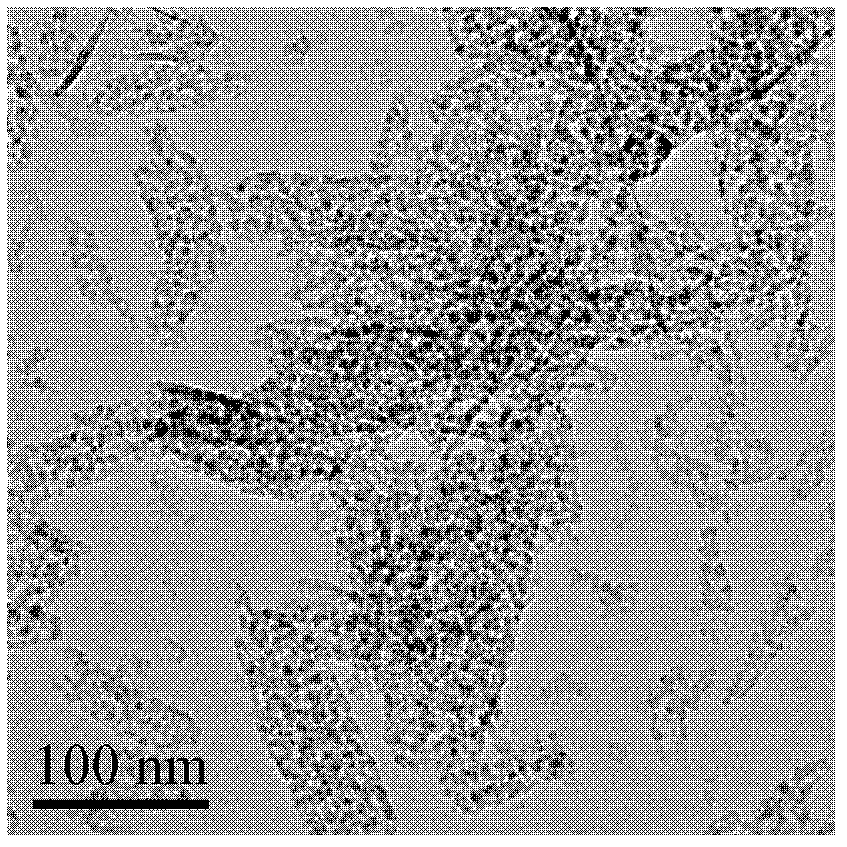

The invention discloses a preparation method for pore canal aluminium oxide nanorods with hierarchical mesopores. The hierarchically mesoporous aluminium oxide nanorods with high specific surface area and large pore volume are synthesized by a hydrothermal crystallization method by taking aluminium nitrate as a precursor and ammonium carbonate or ammonium bicarbonate as a precipitate under the combined action of biological micromolecules such as sucrose and the like and macromolecules such as polyalcohol and the like. The small mesopores of the aluminium oxide obtained by the method are concentrated on about 3nm; the large mesopores can be adjusted and controlled within the range from 10 to 30nm; the length-diameter ratio of the nanorods is less than 50; and the specific surface reaches 500sq.m / g. The method has the advantages of overcoming the disadvantages of limitation of complex process route and high cost existing in a conventional synthetic mesoporous material. The obtained material has significant application value during the hydrotreating process of heavy distillate oil.

Owner:PETROCHINA CO LTD +1

A kind of preparation method and application of nano-alumina

ActiveCN102275962ASave raw materialsSimple processPhysical/chemical process catalystsNanotechnologyPore distributionFiltration

The invention belongs to the technical field of inorganic nano-material preparation, and particularly discloses a preparation method of nano-alumina; the method comprises the following steps: preparing a aluminium nitrate alcoholic solution A with a concentration of 0.10-0.50 g / ml; preparing an ammonium carbonate or ammonium bicarbonate aqueous solution B with a NH4 concentration of 1-4 mol / L; adding a proper amount of organic acids into the solution A under stirring at 60-80 DEG C, adding the solution B into the solution A under stirring, stopping adding the solution B till the pH of the reaction system reaches a target pH value, uniformly stirring to obtain a sol C; continuing stirring the sol C for 2-15 hours, aging at 60-80 DEG C for 15-60 hours; filtering the aged sol C, drying and roasting the solid obtained after filtration so as to obtain the product. The morphology of the product can be controlled by the pH value of the reaction system, and the pore distribution is adjustable; therefore the product is especially suitable to be used as a carrier of a Fischer-Tropsch synthesis catalyst.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

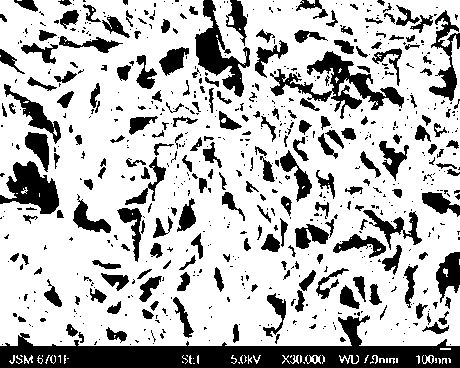

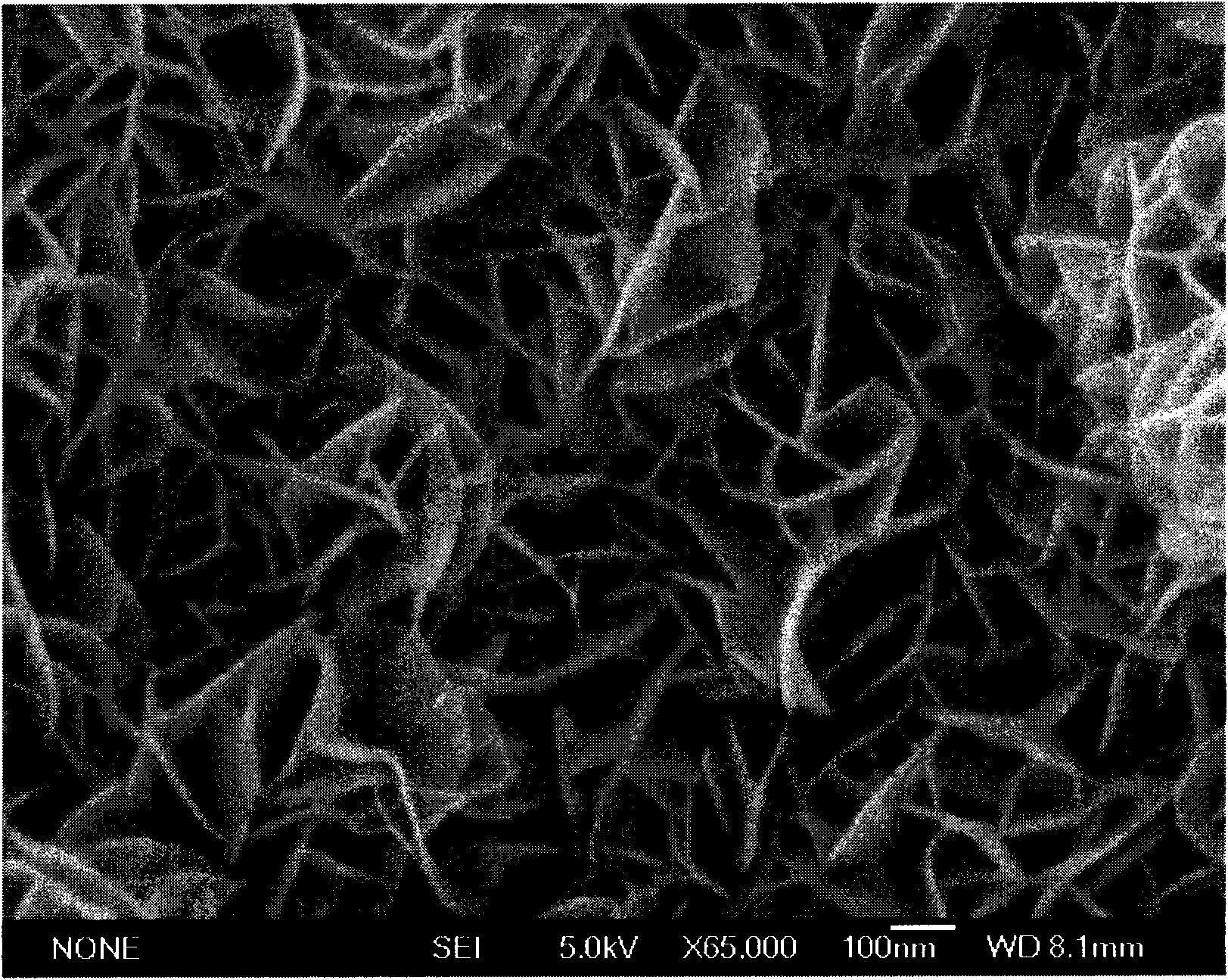

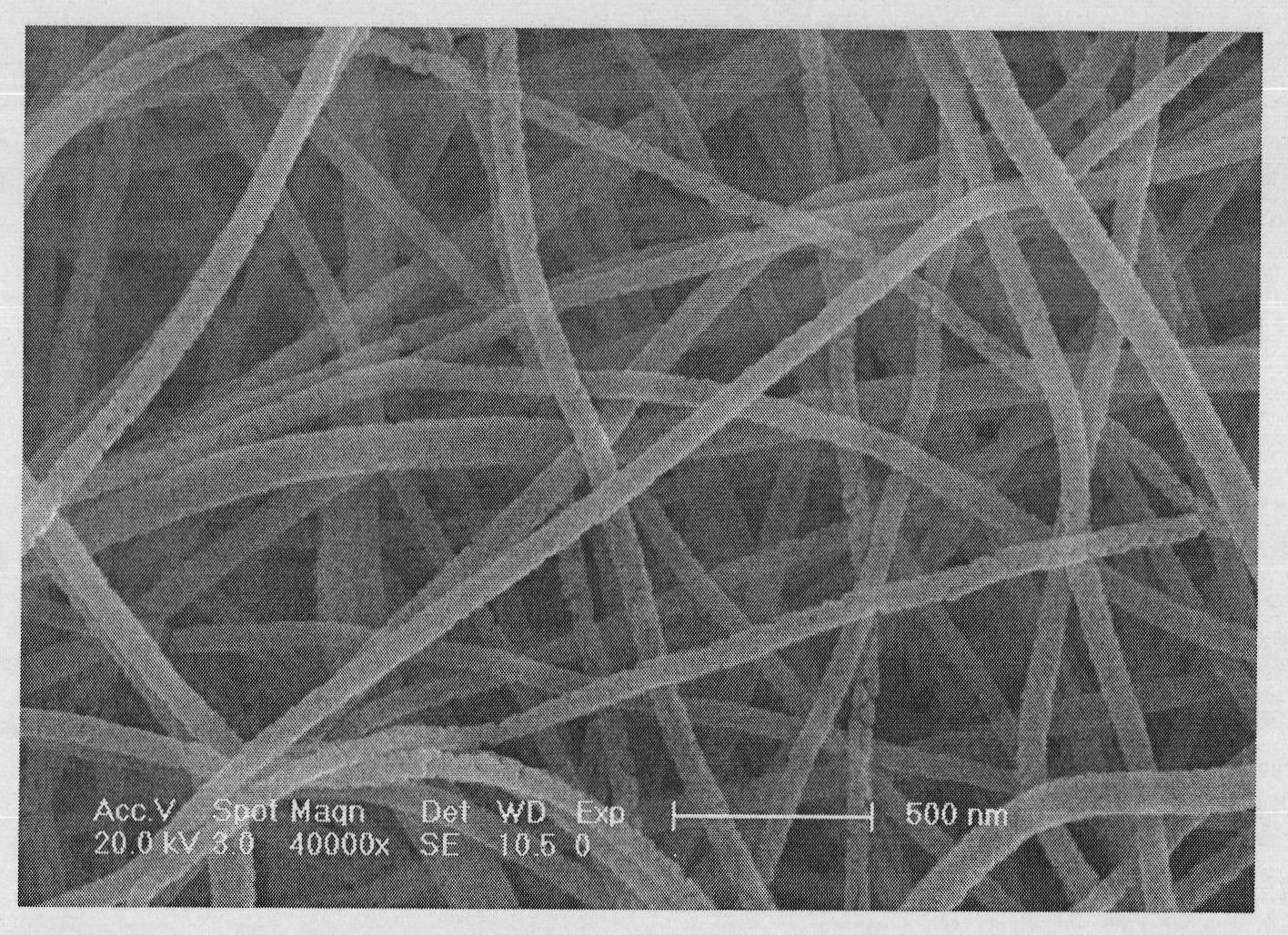

Fibrous mesoporous alumina and preparation method thereof

InactiveCN102153119ASimple processOperational securityAluminium oxides/hydroxidesAluminium nitrateAmmonium carbonate

The invention discloses fibrous mesoporous alumina and a preparation method thereof. At a medium / low temperature, inorganic aluminum salt is used as aluminum source and ammonium salt is used as precipitant to prepare fibrous mesoporous alumina through the precipitation method, wherein inorganic aluminum salt is aluminum nitrate and ammonium salt is ammonium carbonate; the traditional precipitation method is adopted to drop ammonium carbonate solution in aluminum nitrate solution and obtain precipitate; and the precipitate is aged, washed, filtered and dried to obtain fibrous precursor powder, and the obtained fibrous precursor powder is calcined to obtain fibrous mesoporous alumina. The preparation method has simple technology and safe operations and is suitable for large-scale mass production. By using inorganic aluminum salt as aluminum source and ammonium carbonate as precipitant, the production cost is low. The prepared mesoporous alumina is fibrous, the diameter is 70-500nm and the length is 2-3mu m. The fibrous mesoporous alumina has larger specific surface area and bore diameter which are separately 290-380m<2> / g and 3.8-6.5nm and can be widely used in the fields such as adsorption and catalysis, thus the fibrous mesoporous alumina has important and practical application value.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Preparation method of octylene aldehyde gas phase hydrogenation catalyst for octanol production

InactiveCN102407122AImprove hydrogenation activityLarge specific surface areaOrganic compound preparationHydroxy compound preparationAluminium nitrateGas phase

The invention discloses a preparation method of octylene aldehyde gas phase hydrogenation catalyst for octanol production. The method comprises: firstly, adopting coprecipitation to add mixed aqueous solution of copper nitrate and zinc nitrate and aqueous solution of precipitator into a reactor for neutralization, obtaining copper and zinc precipitate; secondly, adopting cocurrent coprecipitationadd mixed aqueous solution of zinc nitrate and aluminium nitrate and aqueous solution of precipitator into a reactor for neutralization, obtaining copper, zinc and aluminum precipitate; thirdly, ageing the precipitate, washing, filtering, drying, pelletizing and roasting to obtain powder material; fourthly, adding graphite and deionized water to the powder material and tabletting to obtain the catalyst. The invention adopts fractional continuous coprecipitation method to effectively increase specific surface area of the catalyst, to increase hydrogenation activity of the catalyst and to improve thermal stability of the catalyst. Furthermore, the coprecipitation is finished in the same rector to simplify the technical process, to save the equipment investment, to reduce the production costand to realize industrialized production more easily.

Owner:THE NORTHWEST RES INST OF CHEM IND

Method for preparing hydrotalcite like compound/attapulgite composite material

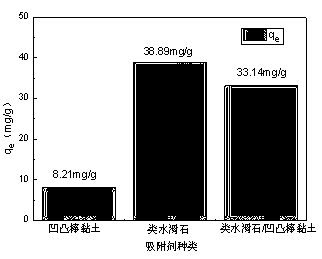

InactiveCN103301804AIncrease profitGive full play to the adsorptionOther chemical processesWater/sewage treatment by sorptionAluminium nitrateActive agent

The invention discloses a method for preparing a hydrotalcite like compound / attapulgite composite material. The method comprises the steps of: (1) adding distilled water to attapulgite clay, agitating and dispersing for 0.5 hour to obtain 0.01-0.03% supernatant solution; (2) sequentially adding a surfactant, magnesium nitrate and aluminium nitrate, agitating for 0.5 hour; (3) slowly dropwise adding a mixed solution containing alkali and sodium carbonate while agitating, continuing agitating for 1 hour after dropwise adding is finished; (4) standing and aging for 1 hour after agitation is finished; and (5) carrying out suction filtration to neutral property, and drying at 60 DEG C, so as to obtain a white composite material product.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

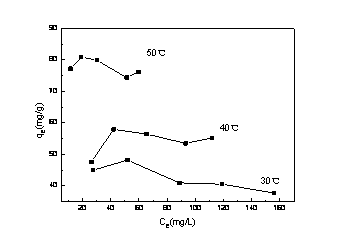

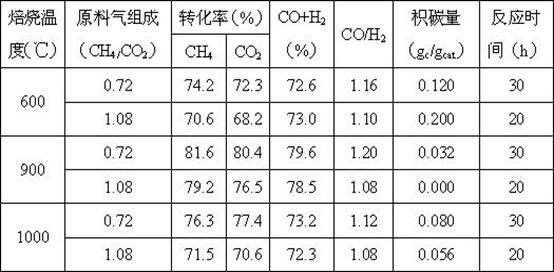

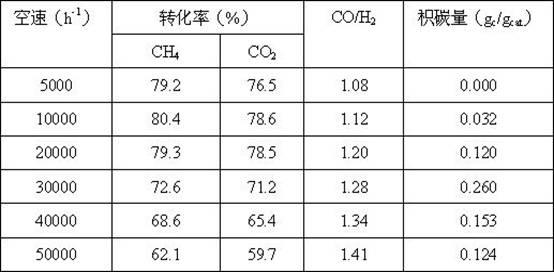

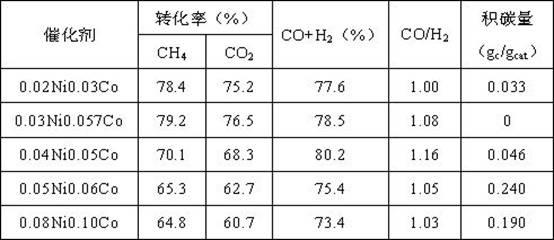

Cordierite matrix catalyst used for preparing synthesis gas by reforming methane and carbon dioxide and preparation method thereof

InactiveCN102407119AUniform growthImprove bindingHydrogenMetal/metal-oxides/metal-hydroxide catalystsSynthesis methodsCordierite

The invention relates to a cordierite matrix catalyst used for preparing synthesis gas by reforming methane and carbon dioxide and a preparation method thereof. In the method, cellular cordierite is taken as the matrix of the catalyst, and the mixture of metallic oxide sosoloid NixMg(1-x)Al2O4 and CoxMg(1-x)Al2O4 is taken as active components and a carrier. The preparation method comprises the following steps of: processing the cellular cordierite in a salpeter solution, then washing and drying to obtain a cordierite matrix; preparing the cobalt nitrate, nickel nitrate, magnesium nitrate and aluminium nitrate into a solution according to the different contents of the catalyst, dropwise adding ammonia, and stirring to form a precipitation solution; and finally placing the cordierite and precipitation solution together into an autoclave and then placing the autoclave in a muffle furnace, then carrying out crystallization, drying and roasting to obtain the cordierite matrix catalyst. In the invention, an in-situ synthesis method is used, and the preparation process is simple; the prepared catalyst has a coating layer which is firmly combined with the matrix, and is applied to carbonyl synthesis; and in the synthesis chemical process of F-T, the catalyst has low bed pressure and good thermostability and the active component Ni is dispersed highly and has small possibility of sintering.

Owner:TAIYUAN UNIV OF TECH

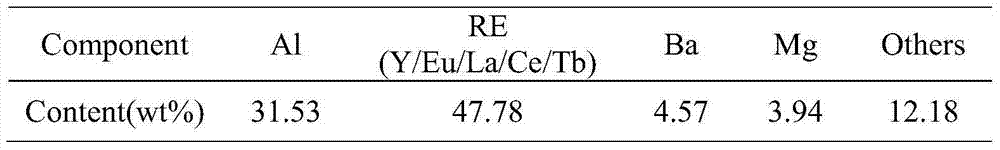

Method for recovering valuable metal element in waste phosphor by using phosphonium ionic liquid

InactiveCN103924084AImprove use valueReduce acid consumptionProcess efficiency improvementRare-earth elementPhosphonium

The invention relates to a method for recovering a valuable metal element in waste phosphor by using phosphonium ionic liquid. The method comprises the following steps: collecting phosphor in a waste fluorescent lamp and taking as an initial raw material, using a strong alkaline compound for high temperature roasting to prepare an alkali fusion object, directly using nitric acid for leaching to obtain an insoluble substance leached by water and an acidic material liquid, wherein acidity of the material liquid is 0.1-3.0mol / L, a difunctional ionic liquid extractant [P6,6,6,14][P204] or [P6,6,6,14][P507] as an extractant, isooctyl alcohol is taken as an additive, a diluent selects n-heptane or kerosene, under condition of weak acid, using coexisted mass aluminium nitrate salt as a salting-out agent, extracting and recovering the rare earth element in a phosphor leachate, and then acquiring an organic extract loaded with rare earth ions and a raffinate aqueous solution with rich aluminium nitrate salt. According to the invention, valuable metals in the waste fluorescent lamp can be recovered and used, the process flow is simple, and the method has the advantages of and friendly environment.

Owner:NANTONG UNIVERSITY

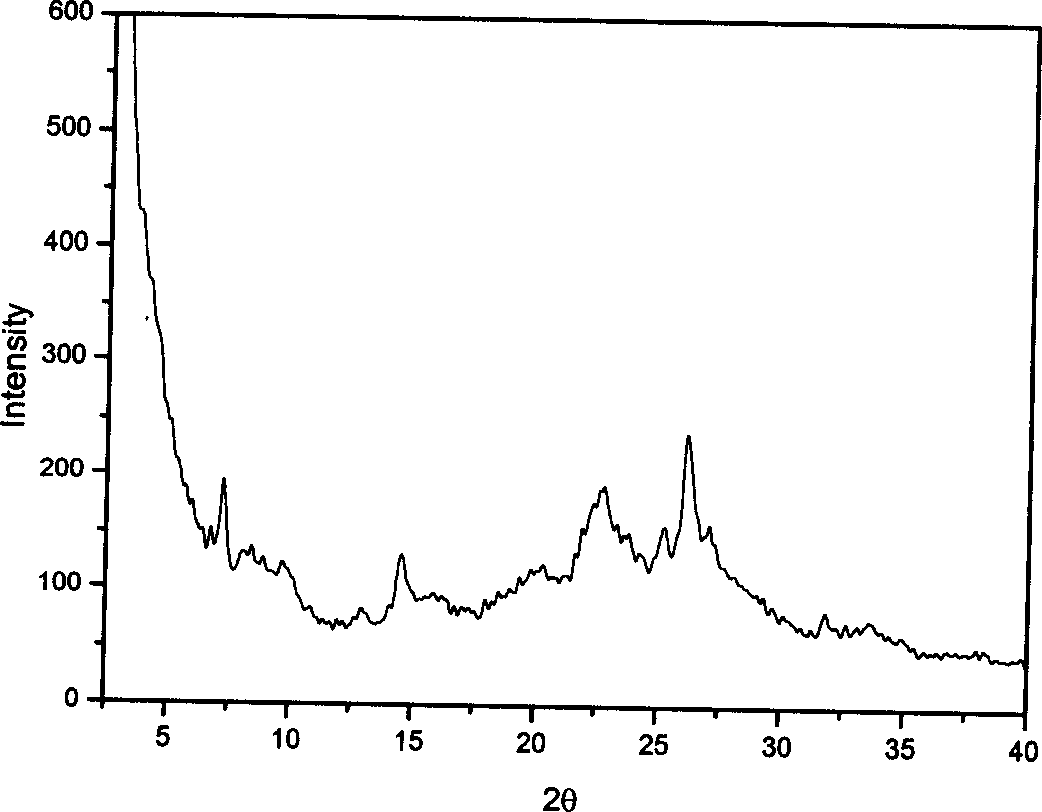

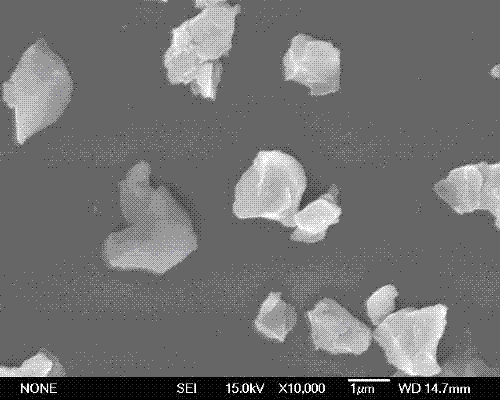

Process for preparing gamma-AlON powder by chemical coprecipitation and carbothermal reduction method

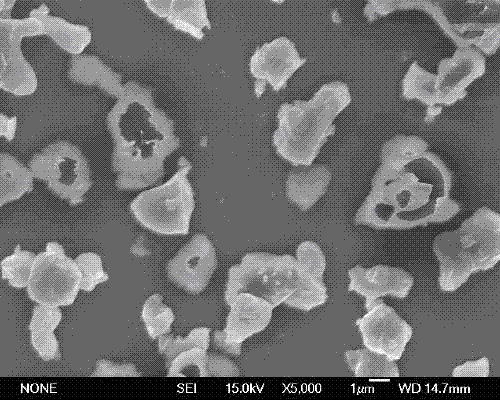

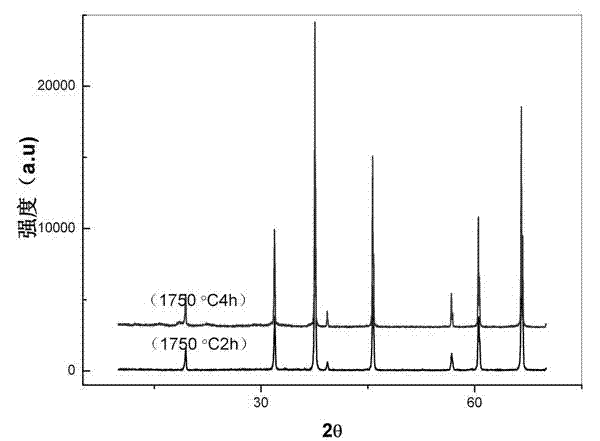

The invention relates to a process for preparing gamma-AlON powder by chemical coprecipitation and a carbothermal reduction method, belonging to the synthesis and processing field of ceramic material powder. The process is characterized by comprising the following steps: carrying out precipitation reaction based on aluminium nitrate, urea and nano carbon black as raw materials, polyethylene glycol (PEG) as a dispersing agent and ammonium bicarbonate as a precipitator so as to obtain a precursor; precipitating and washing the precursor, drying and then grinding, and processing for 2-4 hours under the protective condition of nitrogen with 700 DEG C; insulating for 2-4 hours at the temperature of 1750 DGE C under the condition that the flow of nitrogen is 0.5L / min; and naturally cooling in air, then decarbonizing at the temperature of 700 DEG C so as to finally obtain the pure AlON powder with a particle size of 1-4 mu m and the grain size of the powder is uniform.

Owner:SHANGHAI UNIV

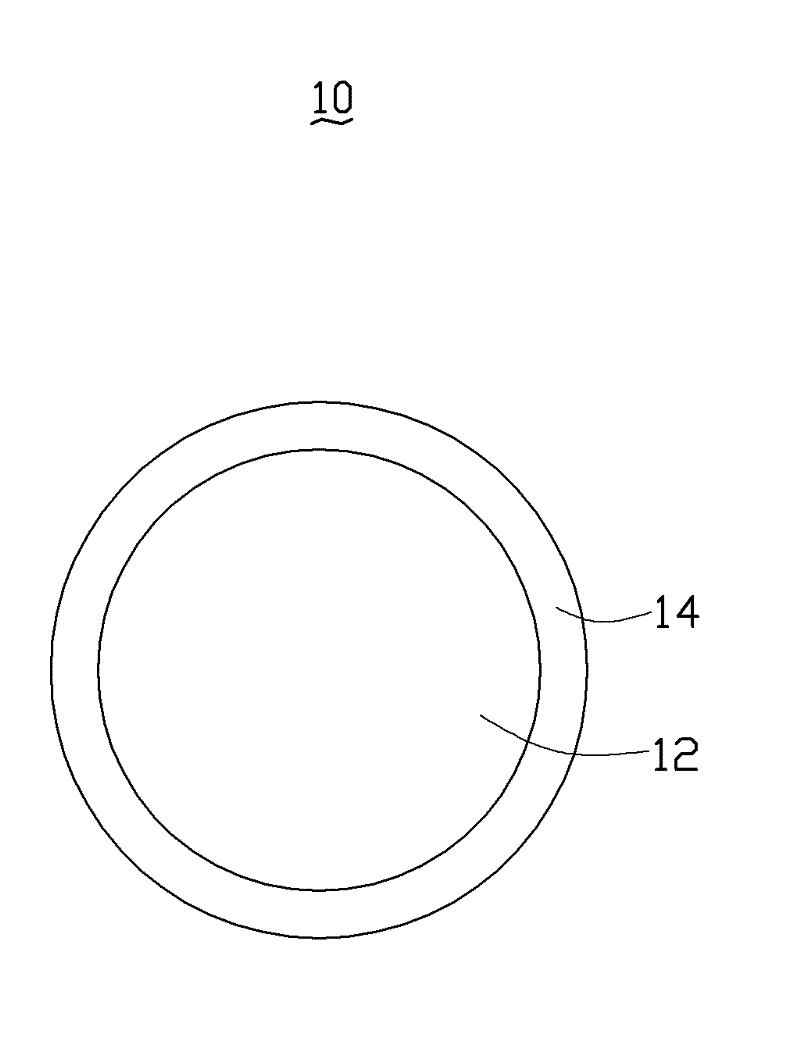

Anode composite material particle of lithium ion battery and preparation method thereof

ActiveCN102347473AAvoid uneven coverageSuitable for large-scale industrial applicationsCell electrodesAluminium nitratePhosphate

The invention relates to an anode composite material particle of a lithium ion battery and a preparation method thereof. The composite material particle comprises anode active substance particles and an aluminium phosphate layer cladded thereon. The invention also relates to the preparation method of the anode composite material particle of a lithium ion battery. The method comprises steps of: providing an aluminium nitrate solution; adding anode active substance particles to be cladded in the aluminium nitrate solution, controlling an addition of the anode active substance and forming a mixture; adding a phosphate solution into the mixture for reaction to form an aluminium phosphate layer on the anode active substance particle surfaces; and carrying out heat treatment on anode active substance particle with the aluminium phosphate layer to obtain the anode composite material particles.

Owner:TSINGHUA UNIV +1

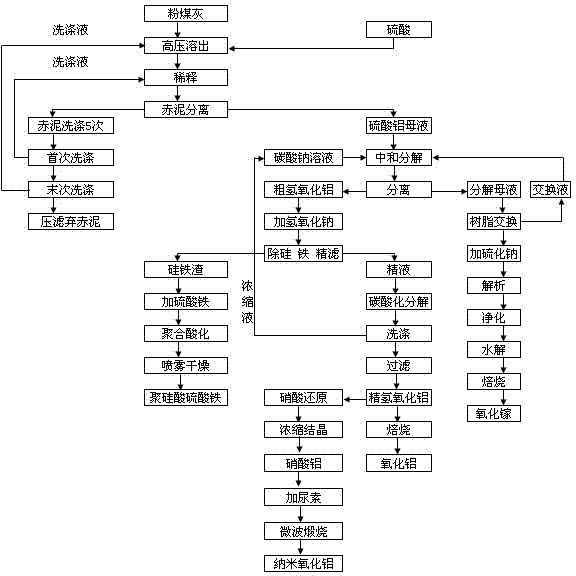

Method for extracting alumina and gallium oxide from pulverized fuel ash to prepare aluminum oxide nanometer and polymeric ferric silicate sulfate

InactiveCN102515220AImprove use valueReduce manufacturing costSolid waste disposalGallium/indium/thallium compoundsSlurryMaterials science

Provided is a method for extracting alumina and gallium oxide from pulverized fuel ash to prepare aluminum oxide nanometer and polymeric ferric silicate sulfate. Pulverized fuel ash and sulfuric acid are sent to a high-pressure autoclave to react by heating and pressurizing so as to generate slurry, and after dilution separation, neutralization desilicication of iron, carbonation decomposition, washing and dehydration and roasting, aluminum oxide is obtained. Nitric acid is added to the prepared aluminium hydroxide for reduction to prepare aluminium nitrate. The aluminium nitrate is added with carbamide and enters a microwave oven to be roasted to ashes, and aluminum oxide nanometer is obtained. Aluminum sulfate solution which has subjected to separation is added to sodium carbonate for neutralization and decomposition, and filtrated stock is sent to an ion resin exchange column to extract gallium oxide. Aluminum hydroxide is added to sodium hydroxide, and then silicon iron filter residue is obtained by filtering. Ferric sulfate is added for polymerization reaction to obtain polymeric ferric silicate sulfate. By adopting the technique of decomposing pulverized fuel ash with sulfuric acid in a high-temperature high-pressure mode, a plurality of industrial products are can be obtained respectively. Compared with an existing hydrochloric acid decomposition method, the method for extracting alumina and gallium oxide from pulverized fuel ash to prepare aluminum oxide nanometer and polymeric ferric silicate sulfate increases comprehensive utilization value of pulverized fuel ashand has great economic benefits.

Owner:潘安标

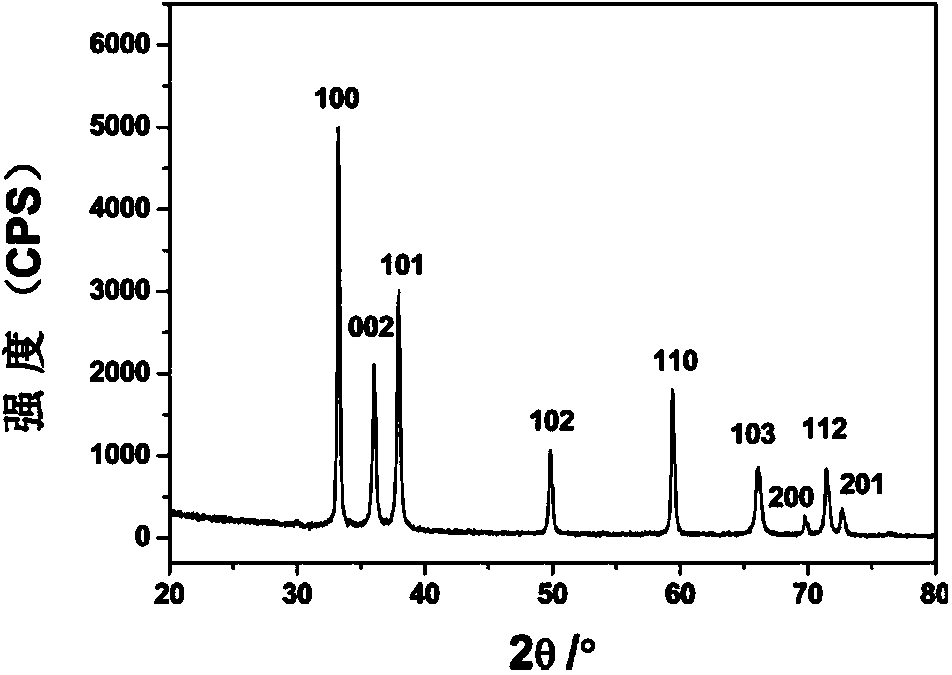

Synthetic method of aluminium nitride nanoparticles

ActiveCN103539088AEvenly dispersedLarge specific surface areaNitrogen compoundsWater bathsFiltration

The invention discloses a synthetic method of aluminium nitride nanoparticles. According to the method, aluminium nitrate nonahydrate and melamine are adopted as raw materials for the first time and the synthetic method of the aluminium nitride nanoparticles comprises the following two steps of: 1, dissolving a mixture of the aluminium nitrate nonahydrate and the melamine in water (heated in a water bath kettle) at the temperature of 95 DEG C to obtain a settled solution, naturally cooling the settled solution, carrying out pumping filtration to obtain a white intermediate product and drying the intermediate product at the temperature of 80 DEG C to obtain a precursor; and 2, placing the synthetic precursor in an aluminium oxide tube furnace, carrying out high temperature reaction in an ammonia atmosphere and finally obtaining the aluminium nitride nanoparticle product. The method is simple, low in cost and high in product crystallinity and purity.

Owner:HEBEI UNIV OF TECH

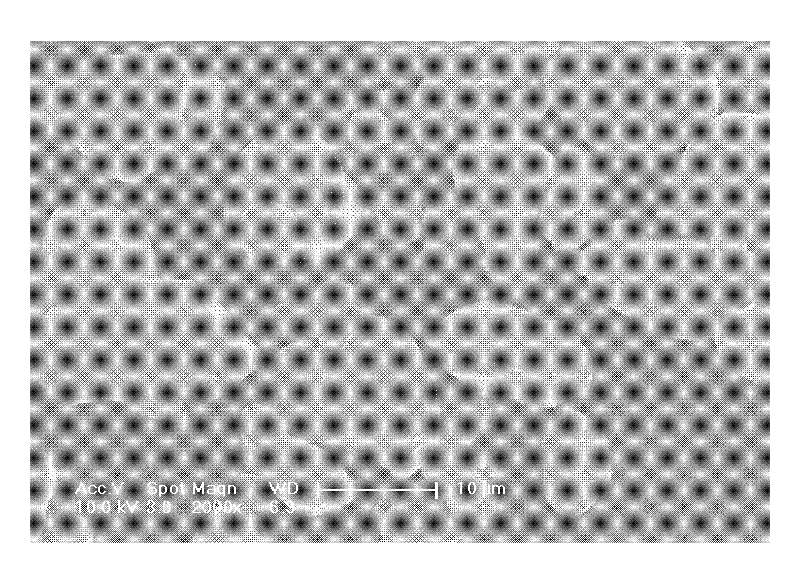

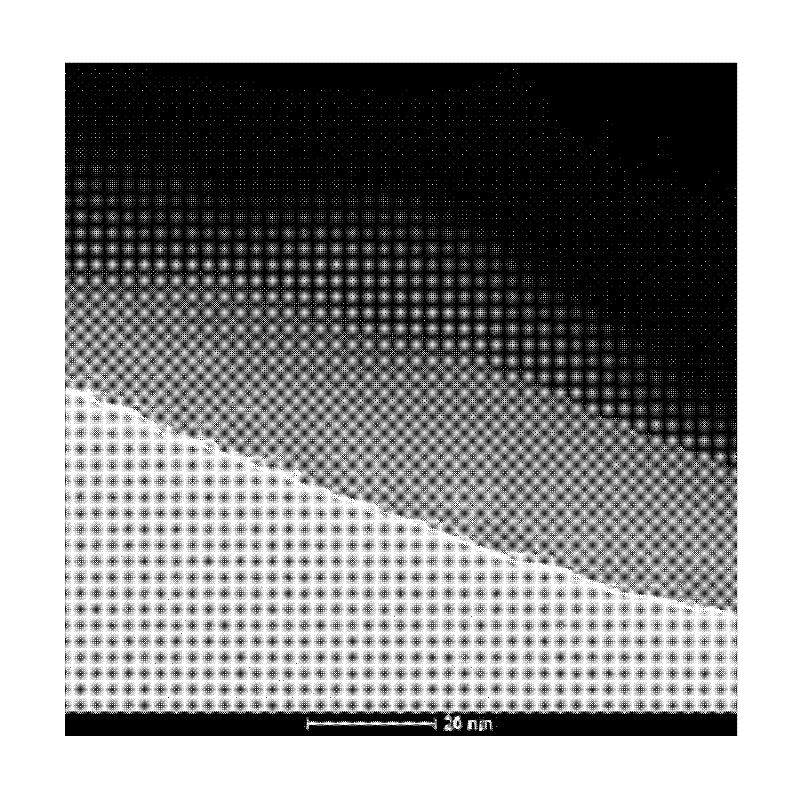

Preparation method of CNT (carbon nano tube) reinforced aluminum composite

The invention provides a simple preparation method of a CNT (carbon nano tube) reinforced aluminum composite. The method comprises the following steps: firstly, CNTs are subjected to acidification pretreatment for 2-4 h; then the CNTs are dispersed in a mixed organic solution formed by ethanol and acetone, aluminium nitrate is added for ultrasonic processing, and a uniformly dispersed CNT electroplating solution is obtained; then, electrophoretic deposition is performed with aluminum foil serving as an electroplating cathode and a stainless steel sheet serving as an electroplating anode, an aluminum foil laminate obtained through electrophoretic deposition is subjected to SPS (spark plasma sintering) and room-temperature rolling, and the CNT reinforced aluminum composite is obtained. The CNT reinforced aluminum composite prepared with the process not only has high tensile strength, but also has improved work hardening rate and uniform deformability while keeping better elongation, is simple to operate and low in cost, and has good generalizability.

Owner:FUZHOU UNIV

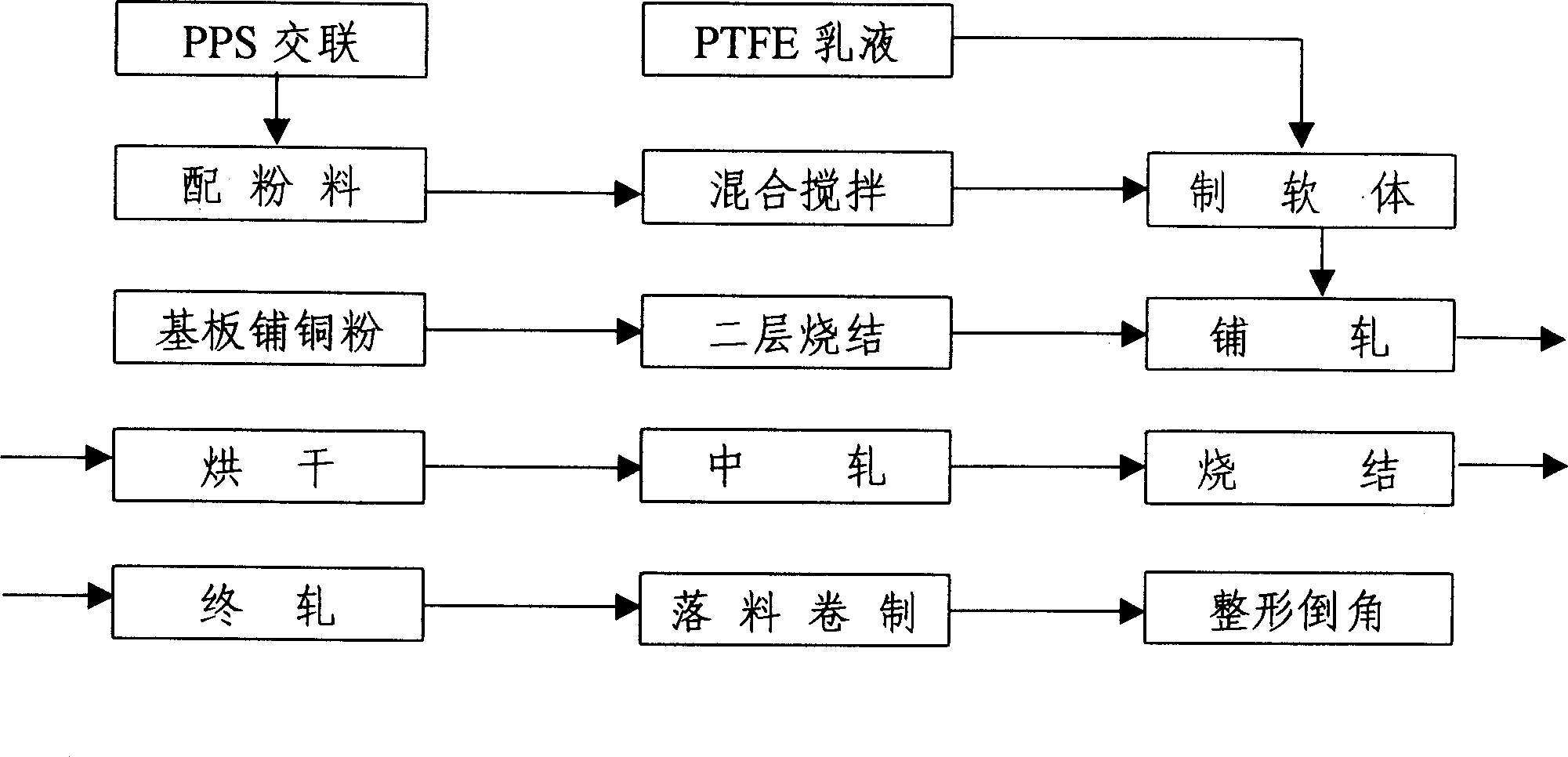

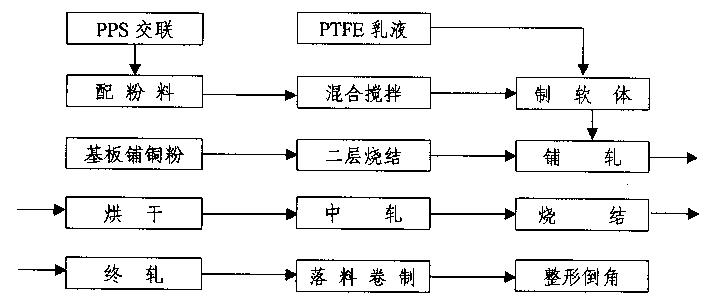

Self-bubricating lead-free bearing and manufacture method thereof

InactiveCN1488865AExcellent PV valueBearing componentsRolling resistance optimizationFiberAluminium nitrate

The present invention relates to a self-lubricating lead-free bearing, including metal base plate, head-free copper powder layer and antifriction wear-resisting layer, finally they are rolled into the form of shaft sleeve. At the same time said invention also discloses its production method. Its antifriction wear-resisting layer material is PTFE, EKONOL, PPS and MoS2, and its technological process does not use toluene or aluminium nitrate.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

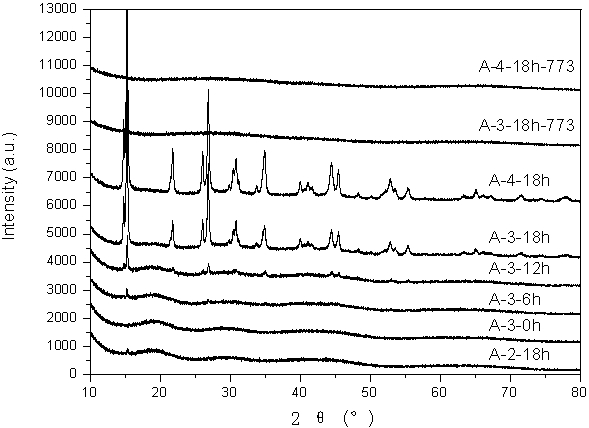

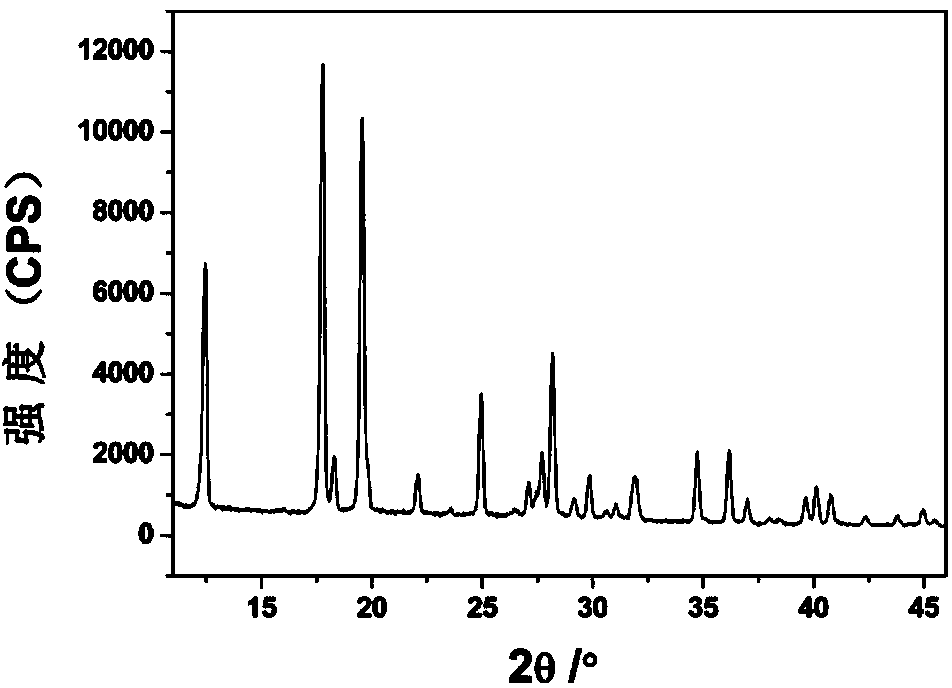

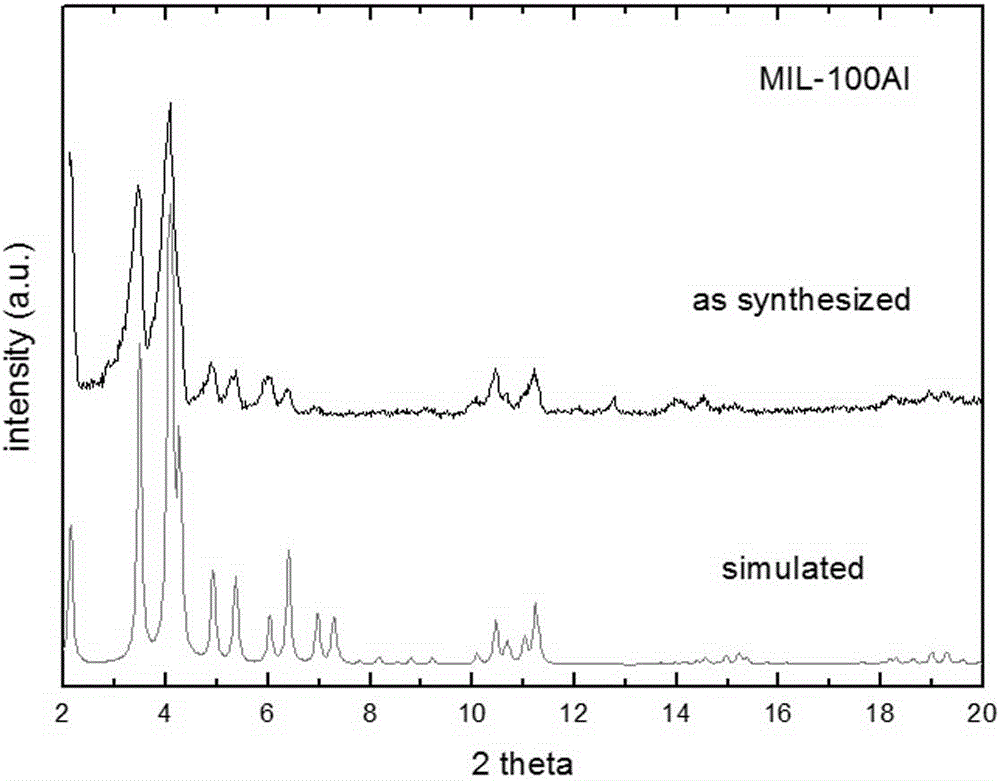

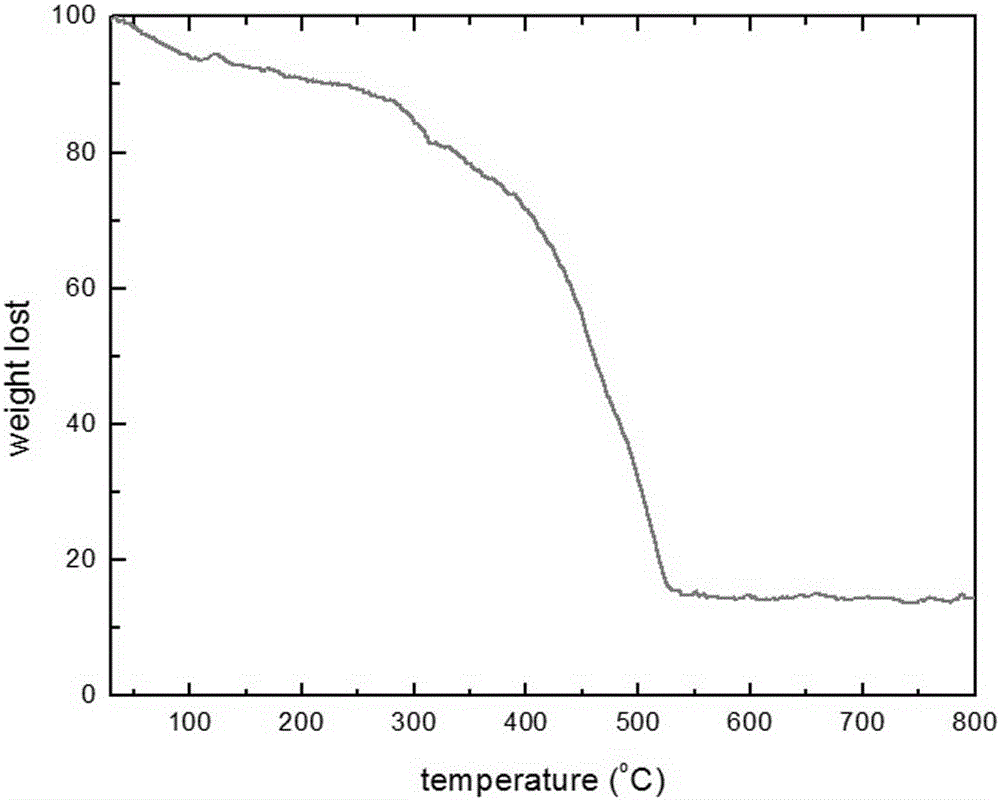

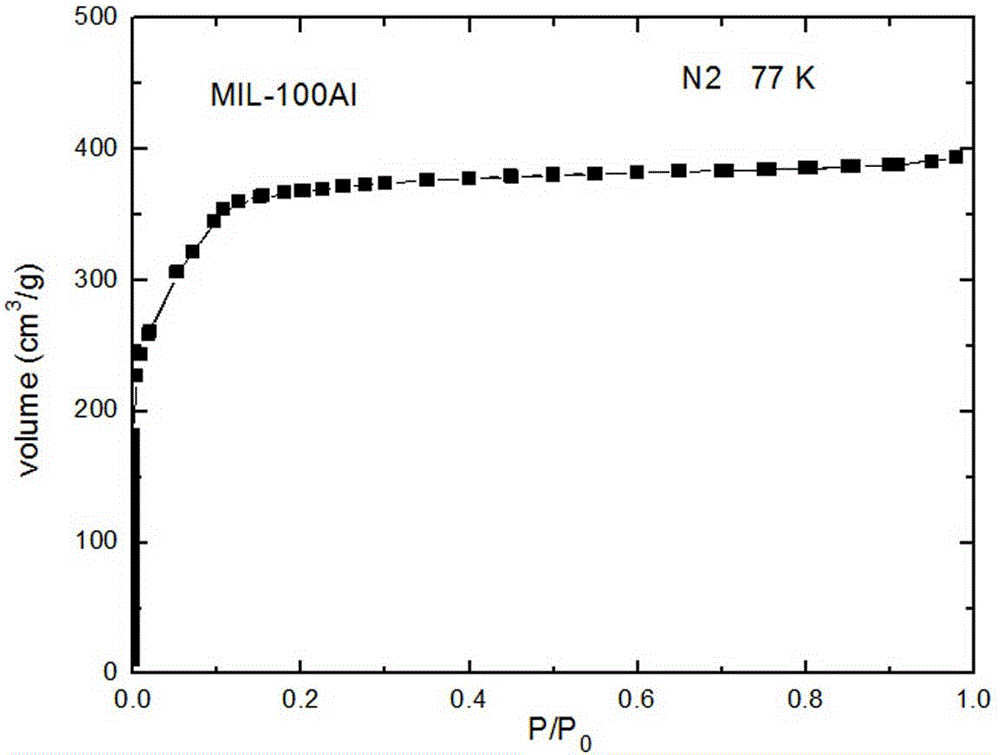

Method for directly compounding metal-organic framework material MIL-100A1 by using trimesic acid

ActiveCN105061482ANo pollutionAccurate and informative dataOrganic chemistry methodsGroup 3/13 element organic compoundsN dimethylformamideFiltration

The invention relates to the field of preparation of a metal-organic framework material MIL-100A1, particularly to a method for directly compounding the metal-organic framework material MIL-100A1 by using trimesic acid. The method comprises the following steps: mixing aluminium nitrate, trimesic acid and N,N-dimethylformamide with the molar ratio of 1:0.87:0.69; adding deionized water; uniformly stirring; dropwise adding a dilute nitric acid solution to regulate the pH of the mixed reaction solution to 1.6-1.7; sealing a polytetrafluoroethylene container in which the mixed reaction solution is accommodated in a stainless steel reaction kettle; carrying out constant-temperature crystallization reaction for 6 h at the temperature of 200 DEG C; naturally cooling to room temperature; carrying out suction filtration; adding deionized water for washing; repeatedly carrying out suction filtration for three times; drying for 15 min at the temperature of 85 DEG C and the vacuum degree of 50 Pa, so as to obtain the metal-organic framework material MIL-100A1. According to the method, aluminium nitrate is adopted as a metal source, ordinary trimesic acid is adopted as an organic ligand, and a trace amount of N,N-dimethylformamide is adopted as an additive, so that the preparation method is economic in raw material selection and free of environmental pollution.

Owner:TAIYUAN UNIV OF TECH

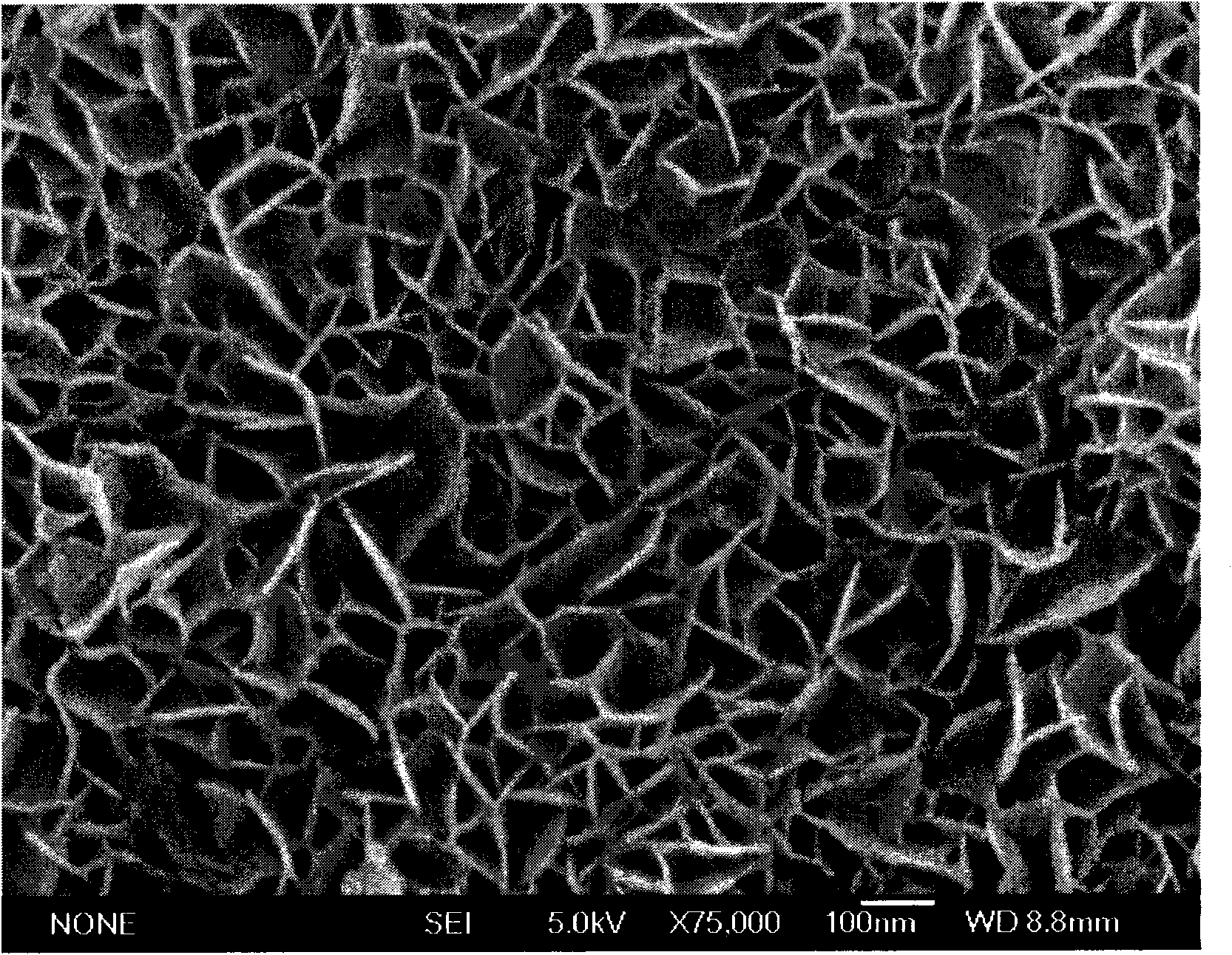

Glucose sensor electrode without enzyme with nickel-aluminium-hydrotalcite nano-chip arrays on substrate of titanium

InactiveCN101598697AGuaranteed stabilityEasy to storeMaterial electrochemical variablesGlucose sensorsTitanium metal

A glucose sensor electrode without enzyme with nickel-aluminium-hydrotalcite nano-chip arrays on a substrate of titanium is composed of the nickel-aluminium-hydrotalcite nano-chip arrays on the substrate of the titanium, the thickness of the single nickel- aluminium-hydrotalcite nano-chip is 20-40nm, and the diameter thereof is 200-400nm; the nickel-aluminium-hydrotalcite nano-chip arrays are distributed on the surface of the titanium metal vertically, evenly and densely in an arrayed manner. The preparation method is as follows: the titanium metal is soaked in hydrofluoric acid solution, and is placed into aqueous solution prepared by nickel nitrate hexahydrate, aluminum nitrate nonahydrate and carbamide after being washed by clean water; and then the titanium metal is sealed in a polytetrafluoroethylene liner in an autoclave and heated to over 70 DEG C for more than 36 hours; the titanium metal is taken out after being cooled naturally to obtain an electrode sample, wherein, the concentration of the nickel nitrate hexahydrate is 2.036g / 70-140ml of water, the concentration of the aluminum nitrate nonahydrate is 1.313g / 70-140ml of water and the concentration of the carbamide is 4.200g / 70-140ml of water. The electrode is applicable to the products in the fields such as biology, medicine, electronic instruments and the like. The glucose sensor electrode has high sensitivity to glucose detection, low detection limit, fast response, large linear range, stable work performance.

Owner:HUAZHONG NORMAL UNIV

Nano-copper base catalyst used for methanol aqueous vapour reforming hydrogen producing and its preparation method

InactiveCN1785513AEasy to manufactureAvoid pollutionHydrogenMetal/metal-oxides/metal-hydroxide catalystsNano catalystWater vapor

A Cu-based nano-catalyst for preparing H2 by reforming the vapor of methanol contains CuO (30-70 mole %), ZnO (20-60), and Al2O3 (0-15). It is proportionally prepared from copper nitrate, zinc nitrate, aluminium nitrate and oxalic acid through grinding, drying and calcining. Its advantages are high low-temp activity, high stability and high selectivity to H2.

Owner:FUDAN UNIV

Polycrystalline nano-fiber with europium ion doped with lanthanum aluminate and preparation method thereof

The invention relates to polycrystalline nano-fiber with europium ion doped with lanthanum aluminate and a preparation method thereof, which belongs to the technical field of nano-material preparation. The invention comprises three steps of: (1) preparation of spinning solution; dissolving lanthanum nitrate, europium nitrate, aluminium nitrate and PVP in DMF to form the spinning solution. (2) preparing PVP / metal nitrate composite nano-fiber with the electrospinning technology, 17-20kV of voltage , 16-20 cm of solidification distance , room temperature in 18-28 degrees C., and 40-50 percent of relative humidity. (3) preparing La1-xEuxAlO3 (x = 0-0.1) nano-fiber: heat-processing the PVP / metal nitrate composite nano-fiber to obtain La1-xEuxAlO3 (x = 0-0.1) polycrystalline nano-fiber; the nano-fiber is composed of nano-particles, has the diameter of 75-100 nm and the length of more than 300 Mum, has good crystallinity, and belongs to the rhombohedral crystal system.

Owner:CHANGCHUN UNIV OF SCI & TECH

Method of preparing cerium activated yttrium aluminium garnet ultrafine fluorescent powder using coprecipitation

InactiveCN1718669AHigh luminous intensityIncrease brightnessLuminescent compositionsDicarbonateElemental composition

A process for preparing the superfine fluorescent powder of Ce activated YAG by codeposition includes such steps as dissolving aluminium nitrate in deionized water, dissolving RE oxide in nitric acid, proportional mixing to obtain mother salt solution, preparing the solution of composite precipitant from ammonia water and ammonium dicarbonate, dripping the mixed solution to the solution of composite precipitant, depositing, ageing, filter, washing with deionized water, dewatering by absolute alcohol, baking to obtain precursor, pulverizing, and calcining in weak reducing gas.

Owner:SHANGHAI JIAO TONG UNIV

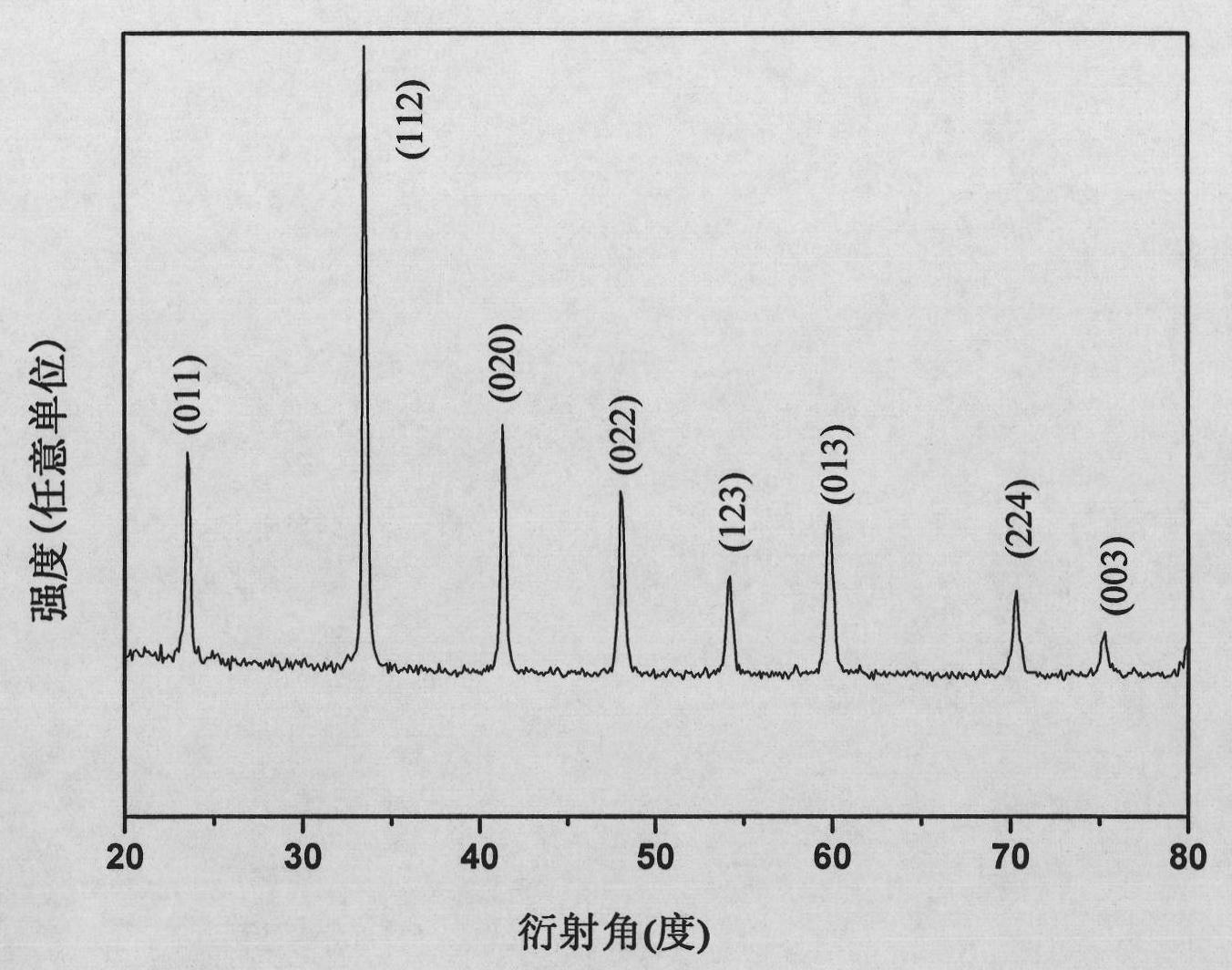

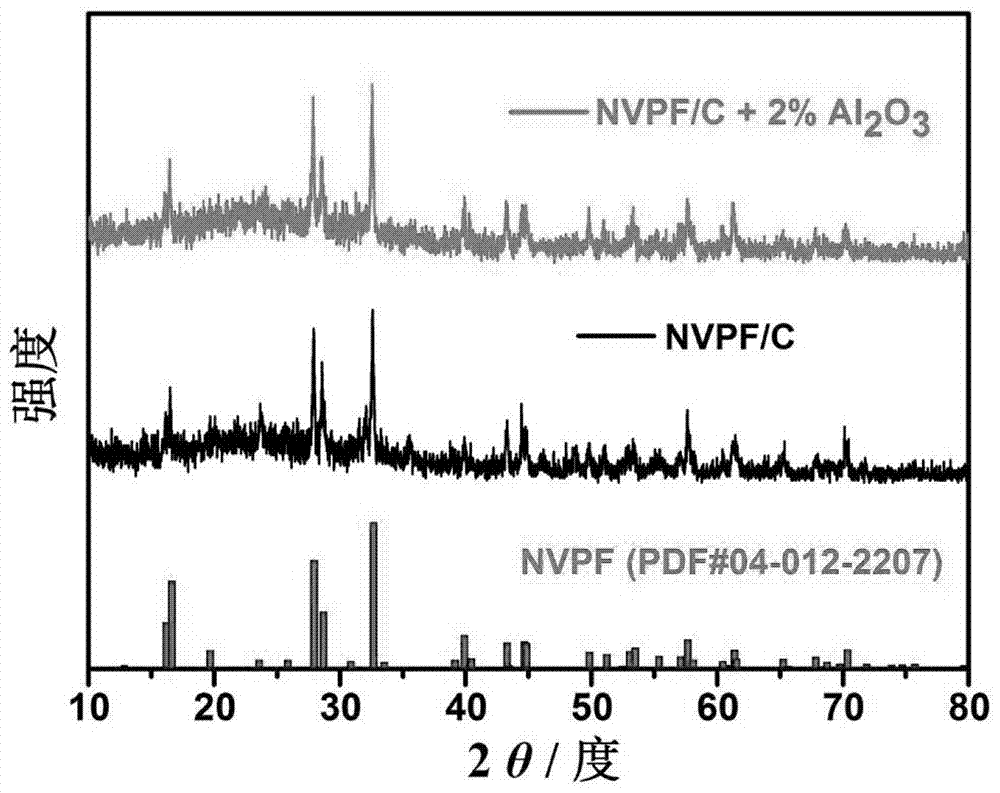

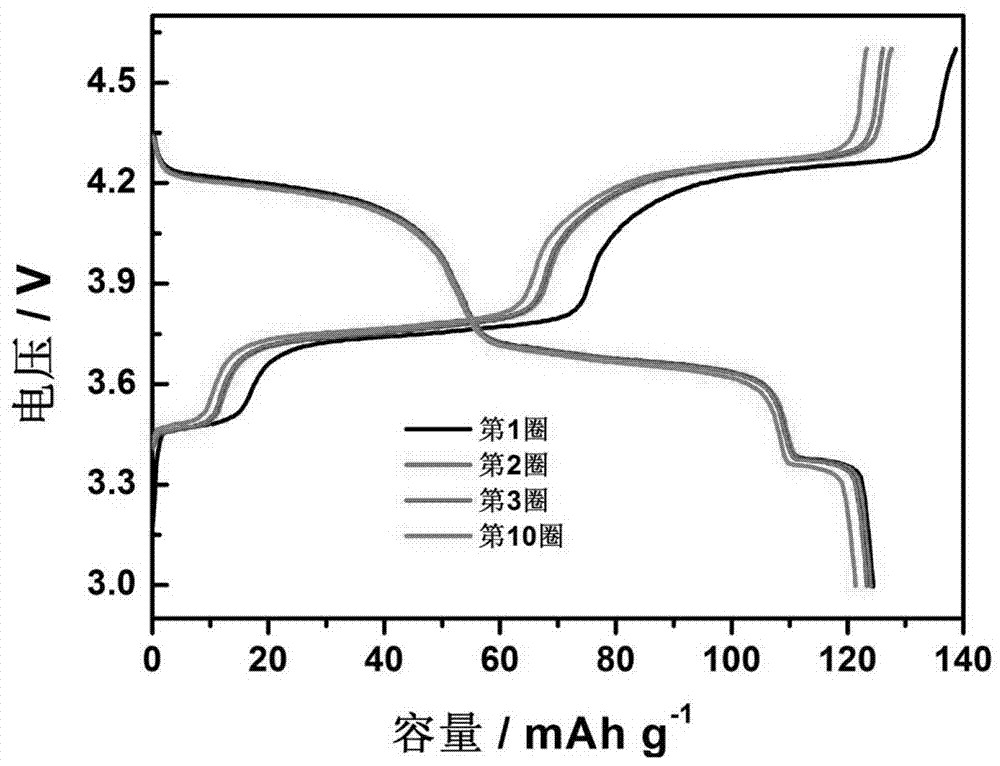

Preparation method for aluminum oxide and carbon composite coated sodium vanadium fluorophosphate positive electrode material

ActiveCN106920946ASimple processImprove cycle performanceCell electrodesSecondary cellsCarbon compositesFiltration

The invention provides an aluminum oxide and carbon composite coated sodium vanadium fluorophosphate positive electrode material and a preparation method therefor. The preparation method comprises the steps of dissolving oxalic acid H<2>C<2>O<4>, sodium fluoride NaF, a vanadium source and a phosphorus source into deionized water, and stirring at a temperature of 60 DEG C to form gel, and performing pre-calcining on the obtained powder after drying in a tubular furnace to obtain a precursor; and adding a carbon source to the precursor, performing ball milling and drying and then performing calcining in the tubular furnace in nitrogen atmosphere, and then sieving to obtain carbon-coated sodium vanadium fluorophosphate positive electrode material, performing uniform ultrasonic dispersion on the carbon-coated sodium vanadium fluorophosphate in deionized water, then adding aluminium nitrate nonahydrate Al(NO<3>)<3>.9H<2>O and performing ultrasonic processing for 20min and then stirring for 30min, next, adding ammonium hydroxide NH<3>.H<2>O, continuously stirring at a temperature of 60 DEG C for 1.5h and then performing suction filtration, washing by deionized water for multiple times and drying, and finally performing final calcining in the tubular furnace, and cooling and then sieving to obtain the aluminum oxide and carbon composite coated sodium vanadium fluorophosphate positive electrode material.

Owner:CHINA THREE GORGES UNIV

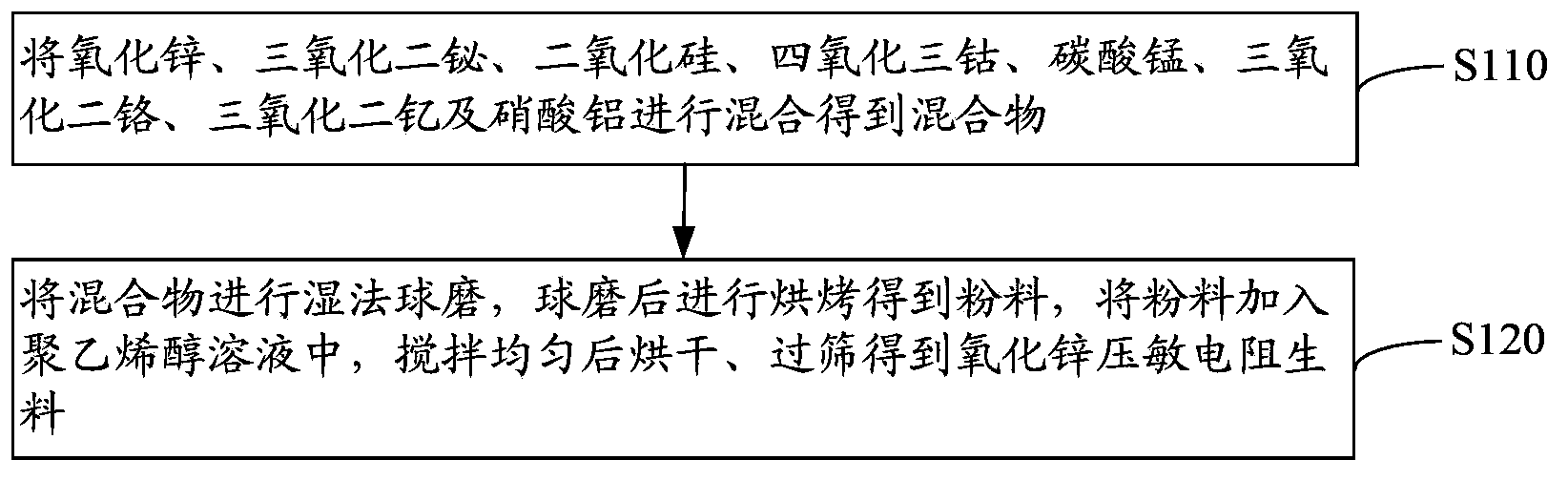

Zinc-oxide piezoresistor raw material, preparation method thereof and piezoresistor

ActiveCN103396116AImprove uniformityIncreased surface state densityVaristor coresOvervoltage protection resistorsManganeseVoltage gradient

The invention relates to a zinc-oxide piezoresistor raw material, a preparation method thereof and a piezoresistor. The zinc-oxide piezoresistor raw material comprises the following components by mole percent: 91.48-98.03% of zinc oxide, 0.5-2.0% of bismuth trioxide, 0.5-2.5% of silicon dioxide, 0.35-1.5% of cobaltosic oxide, 0.5-1.0% of manganese carbonate, 0.1-0.5% of chromium oxide, 0.01-2.0% of yttria and 0.0001-0.001% of aluminium nitrate. The zinc-oxide piezoresistor raw material does not antimony, and due to the silicon dioxide, the characteristic of the piezoresistor is improved, the surface state density is increased, the voltage gradient, the barrier height and the nonlinear coefficient are improved, the leakage current is reduced and the current impact resistance is enhanced; due to the yttria, the conductivity, the current impact resistance, the nonlinear coefficient and the voltage gradient are improved, the limiting voltage rate and the leakage current are reduced, the grain growth is inhibited and the zinc-oxide piezoresistor has higher voltage gradient and excellent electrical property.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com