Porous material and its synthesis method

A technology of porous materials and synthesis methods, which can be used in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., and can solve problems such as porous materials that do not involve micro-scale macropores and nano-scale micropores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Sodium aluminate (Al 2 o 3 42.0% by weight) 16.0 grams are dissolved in 180 grams of water, add 8.0 grams of sodium hydroxide and make it dissolve, then add n-hexadecylamine R under the condition of stirring 1 120.5 g, tetrapropylammonium hydroxide R 2 40 g and cetyltrimethylammonium bromide R 3 7.3 grams, then add silica sol (SiO 2 40% by weight) 300 grams, after stirring evenly, aging at 40°C for 72 hours. The reactant mixture is in molar ratio: SiO 2 / Al 2 o 3 =30,OH - / SiO 2 = 0.1, R 1 / SiO 2 =0.25,R 2 / SiO 2 =0.10,R 3 / SiO 2 =0.01,H 2 O / SiO 2 =10. Then put it into a stainless steel reaction kettle, and crystallize at 175°C for 5 hours under agitation. After taking out, it is filtered, washed and dried. SiO was obtained by chemical analysis 2 / Al 2 o 3 The molar ratio was 28.6. The specific surface area is 550 meters 2 / gram. In terms of volume percentage, the macropores of 0.1 to 10 microns account for 57.4%, the micropores of 0.4 to 2...

Embodiment 2

[0021] Sodium metaaluminate (Al 2 o 3 40% by weight) 6.07 grams are dissolved in 468 grams of water, add 48 grams of sodium hydroxide and make it dissolve, then add hexamethyleneimine R under stirring condition 4 79.2 g and cetyltrimethylammonium bromide R 3 7.3 grams, then add silica sol (SiO 2 40% by weight) of 300 grams, after stirring evenly, aged at 80° C. for 120 hours. The reactant mixture is in molar ratio: SiO 2 / Al 2 o 3 =80,OH - / SiO 2 =0.6,R 4 / SiO 2 = 0.4, R 3 / SiO 2 =0.01,H 2 O / SiO 2 =18. Then put it into a stainless steel reaction kettle, and crystallize at 150° C. for 50 hours under agitation. After taking out, it is filtered, washed and dried. SiO was obtained by chemical analysis 2 / Al 2 o 3 The molar ratio was 76.6. The specific surface area is 420 meters 2 / gram. In terms of volume percentage, the macropores of 0.1 to 10 microns account for 84.4%, the micropores of 0.4 to 2 nanometers account for 15.6%, and the total pore volume is...

Embodiment 3

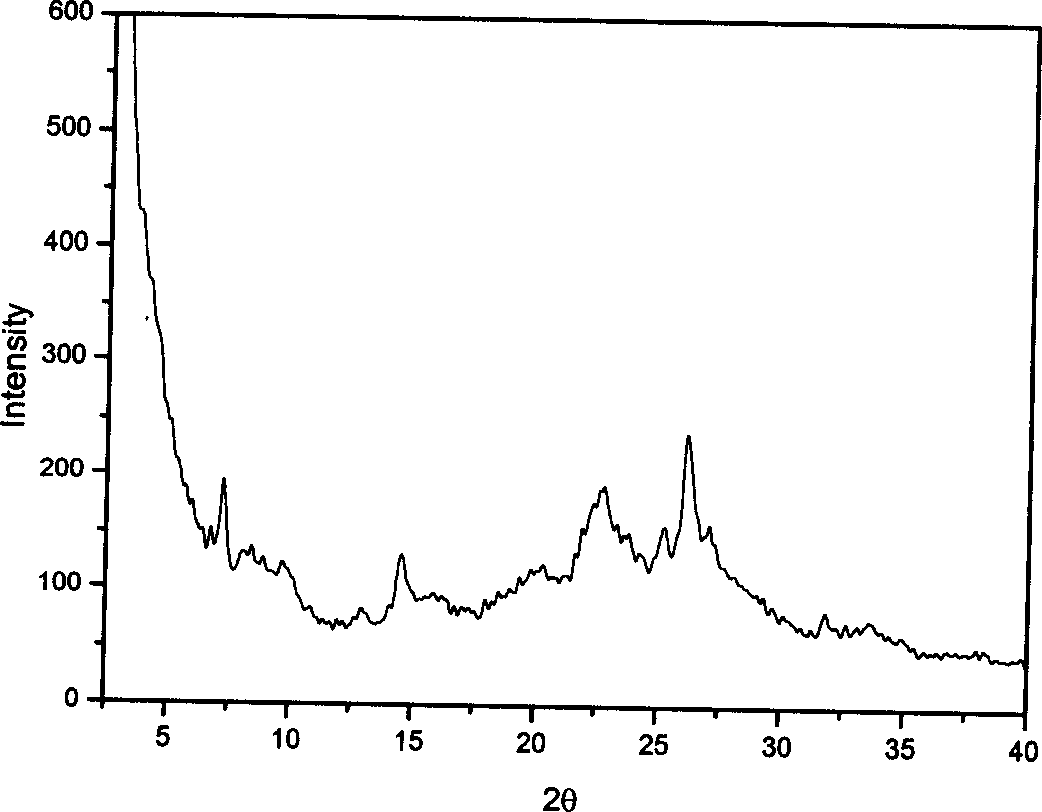

[0023] Dissolve 21.3 grams of aluminum nitrate in 612 grams of water, add 48 grams of sodium hydroxide to dissolve it, and then add hexamethyleneimine R under stirring 4 79.2 g and cetyltrimethylammonium bromide R3 14.6 grams, then add silica sol (SiO 2 40% by weight) 300 grams, 30 grams of seed crystals, after stirring evenly, age at 50° C. for 2 hours. The reactant mixture is in molar ratio: SiO 2 / Al 2 o 3 =40,OH - / SiO 2 =0.6,R 4 / SiO 2 = 0.4, R 3 / SiO 2 =0.02,H 2 O / SiO 2 =22. Then put it into a stainless steel reaction kettle, and crystallize at 160°C for 15 hours under agitation. After taking out, it is filtered, washed and dried. SiO was obtained by chemical analysis 2 / Al 2 o 3 The molar ratio was 42.5. The specific surface area is 435 meters 2 / gram. In terms of volume percentage, the macropores of 0.1-10 micrometers account for 76.0%, and the micropores of 0.4-2 nanometers account for 29.0%. XRD analysis presents a specific zeolite structure. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com