Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

246 results about "Aluminium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium phosphate is a chemical compound. In nature it occurs as the mineral berlinite. Many synthetic forms of aluminium phosphate are known. They have framework structures similar to zeolites and some are used as catalysts, ion-exchangers or molecular sieves. Commercial aluminium phosphate gel is available.

Lithium titanate composite electrode material with surface coating layer

InactiveCN101764209AChange physical propertiesChange chemical propertiesCell electrodesMagnesium phosphateMagnesium orthophosphate

The invention relates to a battery electrode material, in particular to a lithium titanate composite electrode material with surface coating layer; in the lithium titanate composite electrode material with surface coating layer, the electrode material is composed of lithium titanate particles and a coating layer coated with the surface of the lithium titanate particles; the particle size of the lithium titanate particles is 100nm-95mum, the average thickness of the surface coating layer is 0.2nm-5m, and the particle diameter of the composite electrode material is 0.1-100mum; the material of the surface coating layer is one or mixture of more than one kind of insulation oxide, insulation composite oxide, aluminium phosphate, magnesium phosphate, lithium fluoride, lithium phosphate or LiMPO4, wherein M is magnesium, ferrum, cobalt, nickel, chromium, titanium or vanadium; in the invention, by carrying out surface coating treatment to the surfaces of the existing lithium titanate particles, a layer of protective film is formed on the surface, so as to change the physical and chemical characteristics of the surface of the lithium titanate active material, the surface can not be reacted with electrolyte even if under overpotential condition, so as to avoid ballooning and ensure the capacity and the circularity of the battery not to be reduced.

Owner:SUZHOU PHYLION BATTERY

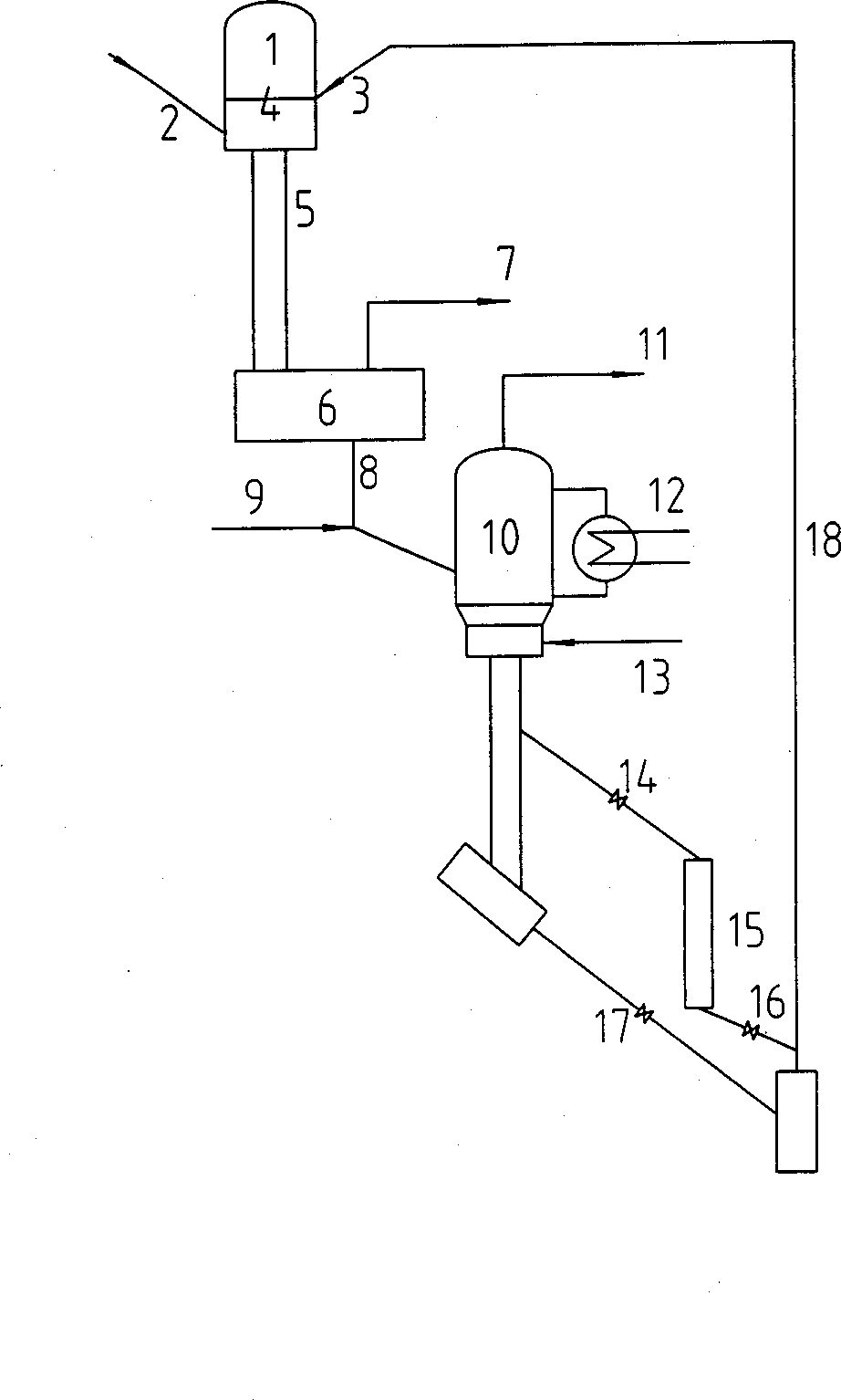

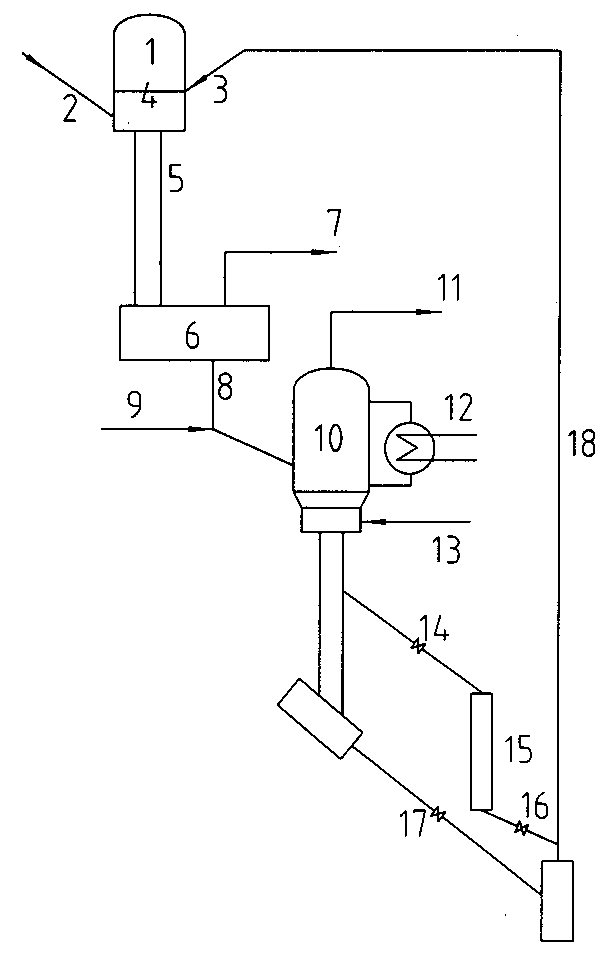

Process and system for preparing low-carbon olefin from methanol or dimethylether

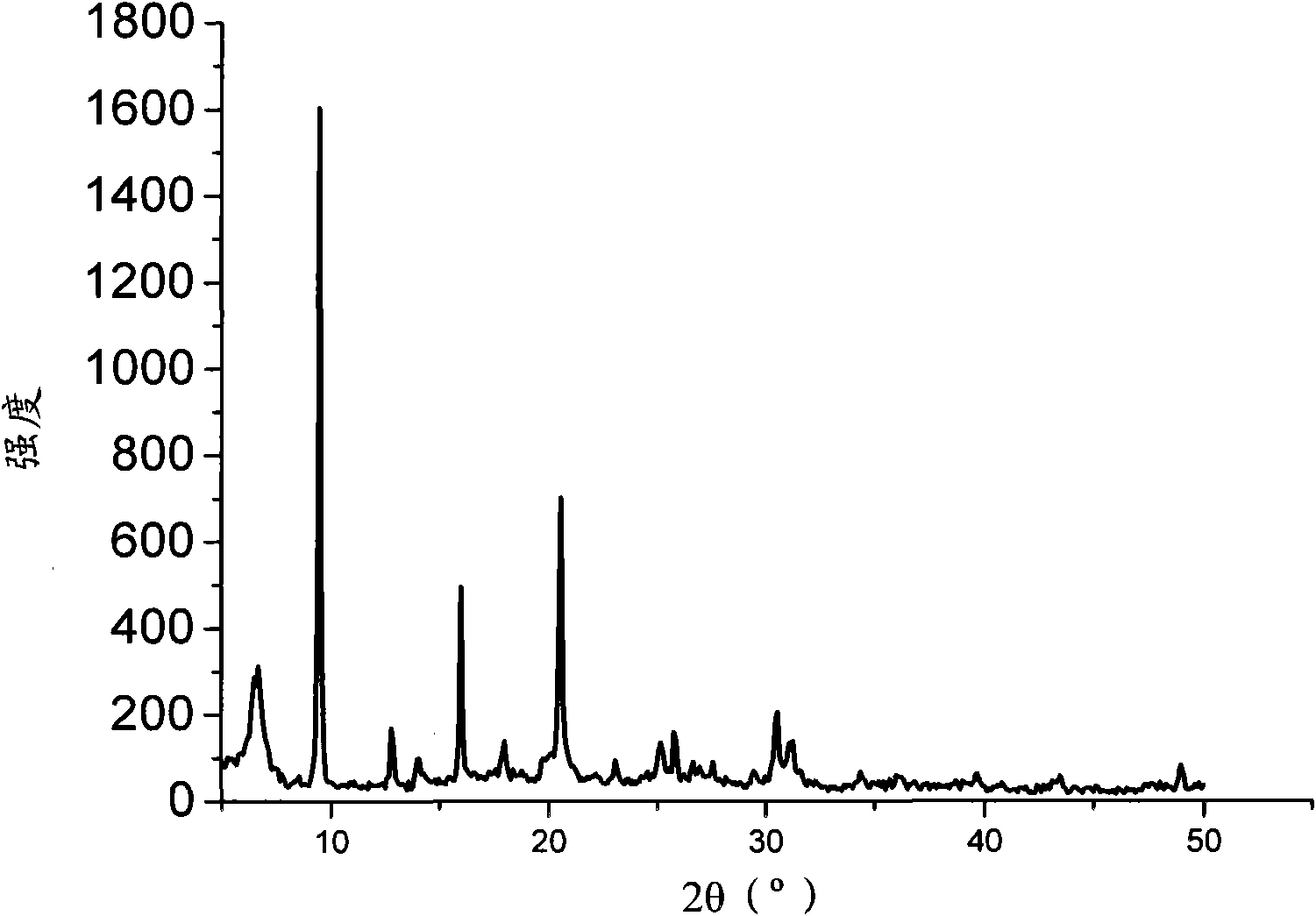

InactiveCN1356299AReduce wearReduce aggregationHydrocarbon from oxygen organic compoundsChemical recyclingAlkaneGas solid

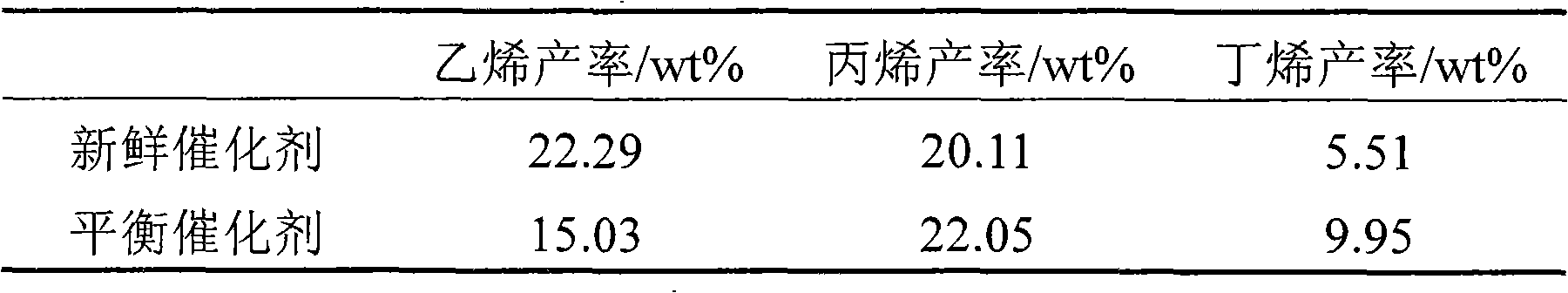

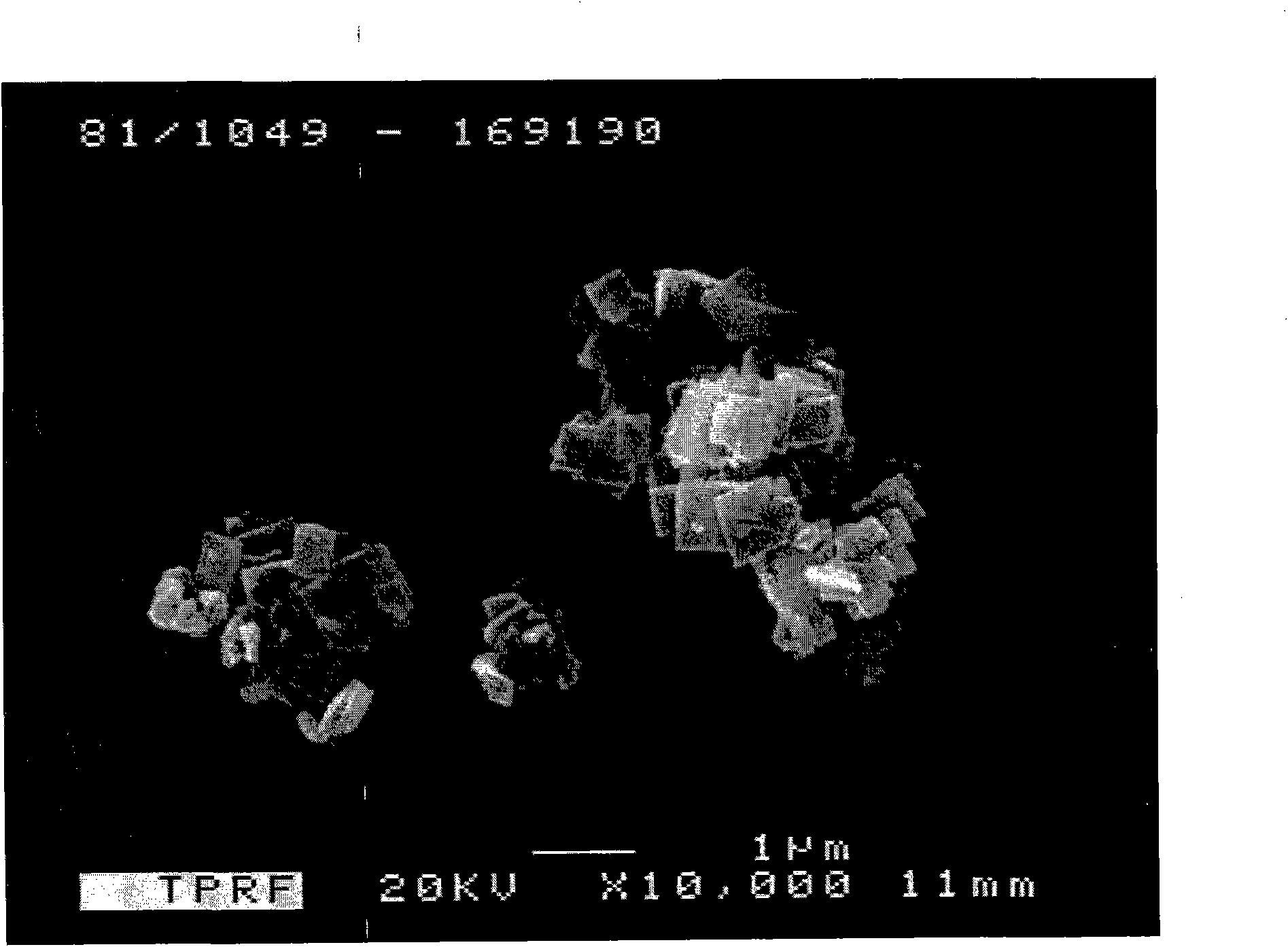

A process for preparing low-carbon olefin from methanol or dimethyl ether includes loading its raw material and silicon aluminium phosphate (SAPO34) molecular sieve as catalyst into gas-solid parallel down-flowing fluidized bed reactor, super-short contact, reaction, fast gas-solid separation to separating resultant from catalyst to prevent secondary reaction, and regerating catalyst for cyclic use. Its advantages include high output rate (93%), high conversion rate of raw material, and less by-product.

Owner:TSINGHUA UNIV

Nano ceramic coating with high emissivity

The invention discloses a nano ceramic coating with high emissivity, which is prepared from a high temperature resistant basic material, an additive with high emissivity, a binder, a stabilizing agent and a solvent. The high temperature resistant basic material and the additive with high emissivity are one or several of alumina, silicon oxide, boron nitride, silicon carbide, ferric oxide and cerium oxide. The binder is one or several of silica gel, potassium silicate solution, aluminium phosphate solution, silicon oxide hydrate, ethanol and water. By weight percentage, the high temperature resistant basic material and the additive with high emissivity account for 5-78%, the binder accounts for 5-30%, the stabilizing agent accounts for 0.5-3% and the balance of solvent is water. The coating which can be used above 1300 DEG C has the advantages of being wide in work temperature range with the maximum service temperature close to 2000 DEG C, applicable to various base materials, strong in adhesive force to the base materials, applicable to reaction atmosphere, good in long-time durability and strong in heat shock endurance, improving thermal efficiency, lowering temperature of the base materials, and being excellent in abrasion and corrosion resistance, less in impact on environment, convenient to use and the like.

Owner:赵凯

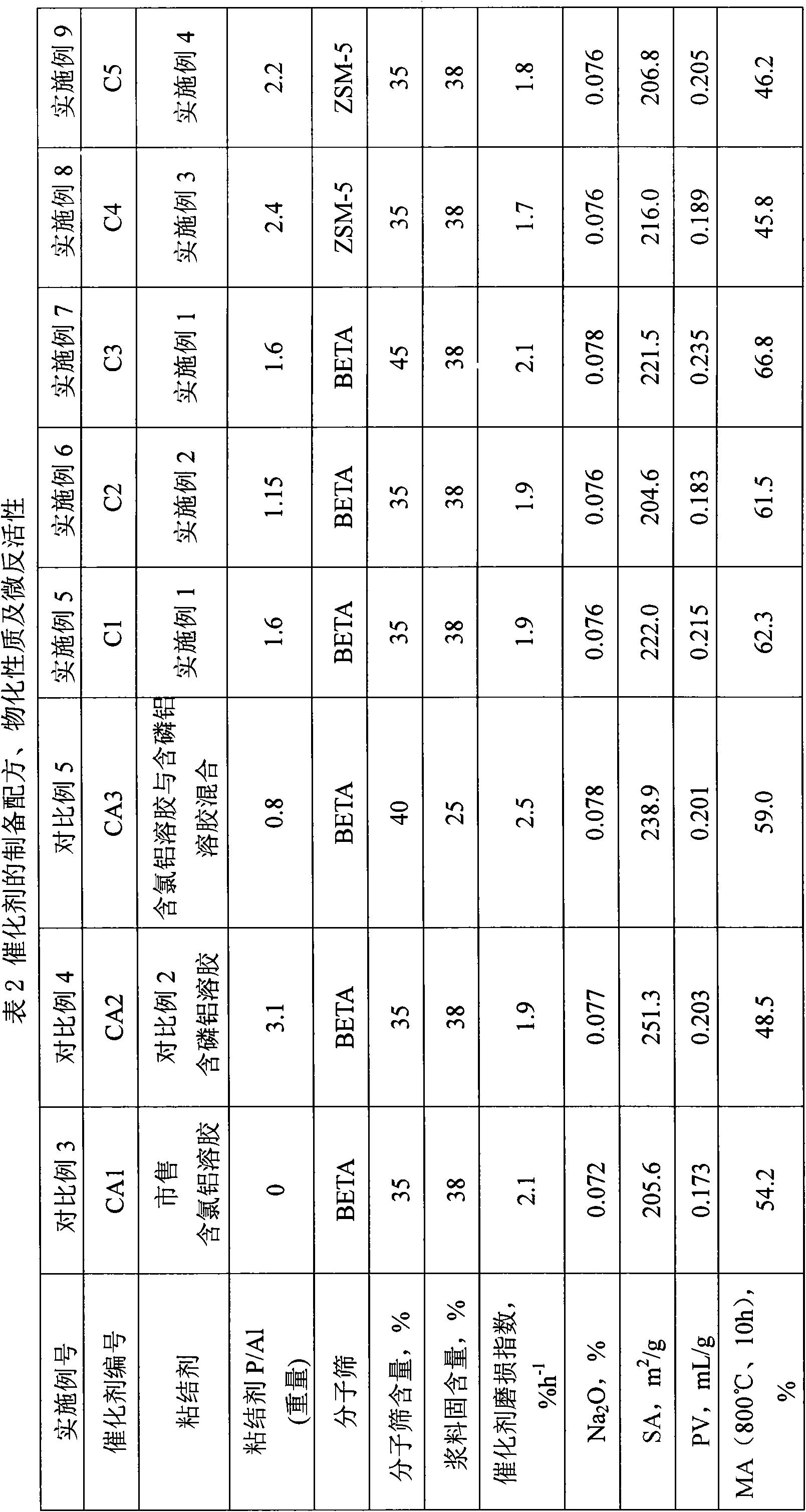

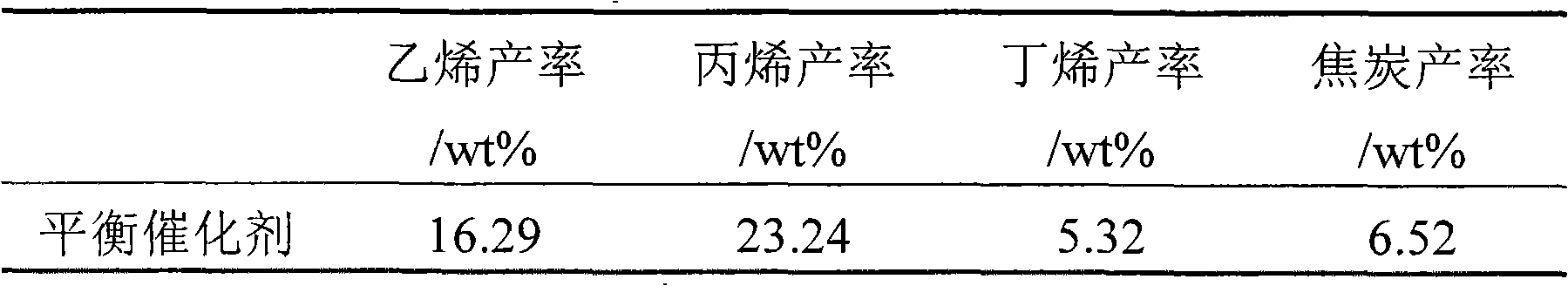

Aluminium phosphate sol used for catalyst and preparation method thereof

ActiveCN102050434AHigh activityHigh yieldPhysical/chemical process catalystsCatalytic crackingHydrogen NitratePhosphoric acid

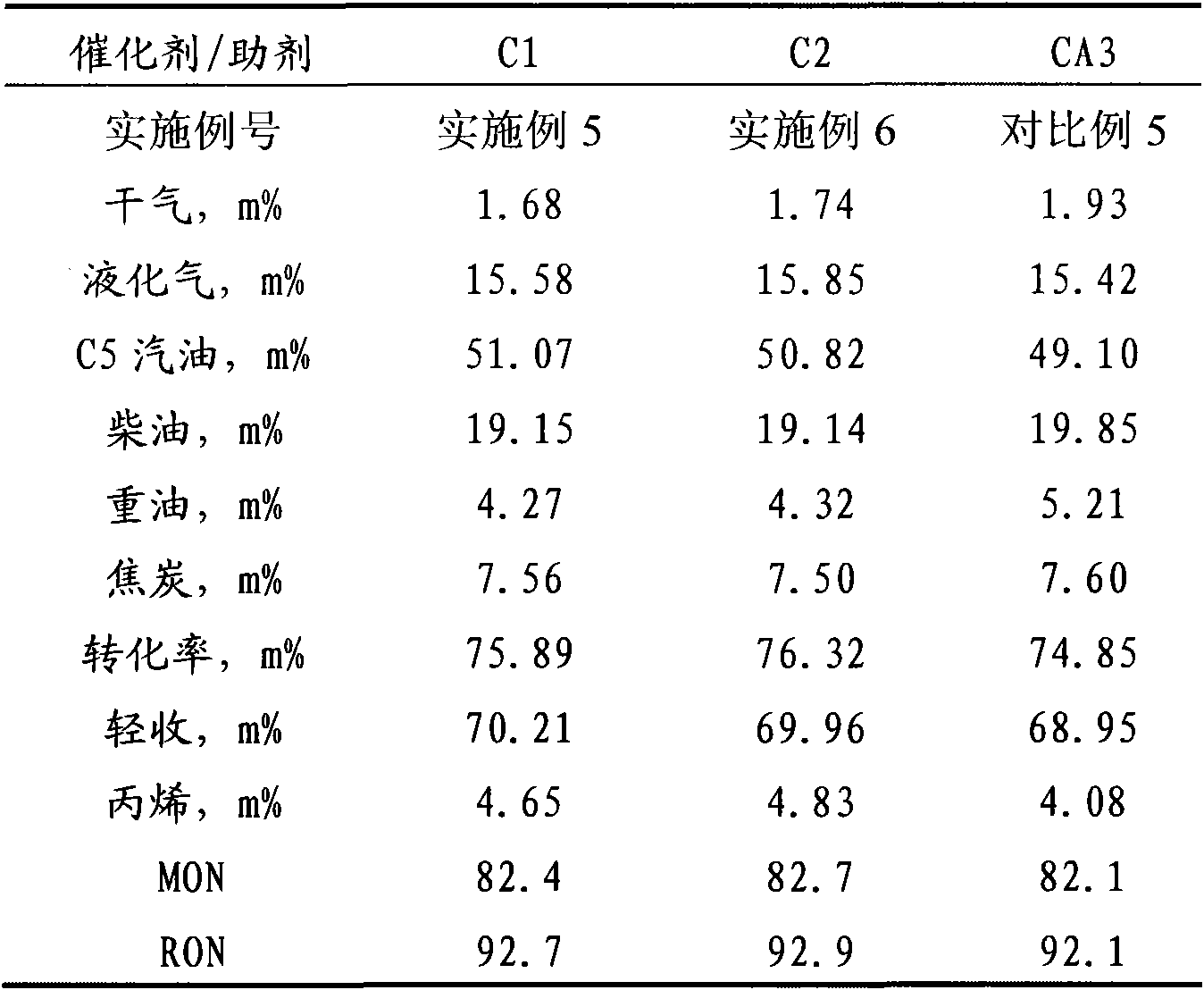

The invention relates to a preparation method of aluminium phosphate sol used for a petroleum hydrocarbon cracking catalyst, which is characterized by comprising the steps of: mashing and dispersing an acid soluble aluminum precursor and decationed water into serous liquid with solid content of 15-35 percent, slowly adding phosphoric acid with concentration of 60-98 percent into the serous liquidunder the stirring according to the weight proportion of P / Al=1.0-2.5; then adding hydrogen nitrate with concentration of 40-98 percent according to the weight proportion of HNO3 / Al2O3=0.2-2.0, rapidly reacting and releasing a large quantity of heat; and generating colorless transparent thick liquid after the reaction. The microactivity of the catalytic cracking catalyst prepared by adopting the aluminium phosphate sol bonder provided by the invention is remarkably improved. The selectivity of the aluminium phosphate sol is improved, the yields of gas and coke are remarkably reduced, and the yields of light oil and propylene are improved.

Owner:PETROCHINA CO LTD

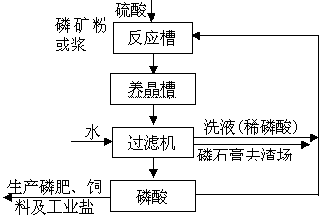

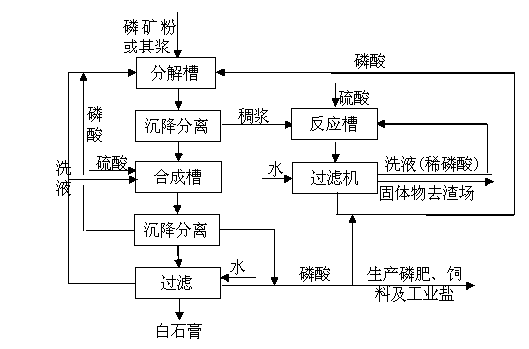

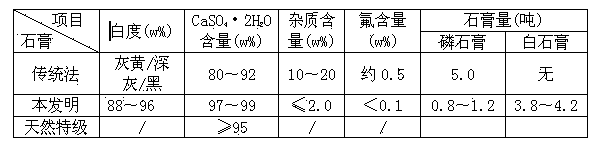

Method for wet production of phosphoric acid and byproduct, namely white gypsum

InactiveCN103626143AReduce long-term pollutionGood environmental benefitsCalcium/strontium/barium sulfatesPhosphorus compoundsChemical industryO-Phosphoric Acid

The invention discloses a method for wet production of phosphoric acid and a byproduct, namely white gypsum, relating to the technical field of phosphorus chemical industry. The method is mainly used for solving the problems in the traditional wet production of phosphoric acid that the byproduct, namely phosphogypsum is high in impurity content, poor in quality and yellow grey, dark grey and black in appearance, can be stacked only as waste and pollutes the environment. The method comprises the steps of firstly, reacting phosphorite powder (slurry) (the content of phosphorus pentoxide in phosphorite is 18-35%) and phosphoric acid of a volume, which is 16-32w% of the weight of phosphorus pentoxide, for 15-60 minutes at the temperature of 45-70 DEG C while stirring, so as to produce mixed slurry containing phosphoric acid, a calcium phosphate solution, phosphorite carrying acid insoluble matters and a small amount of produced calcium fluoride, ferric phosphate and aluminum phosphate solid impurities; continuously or intermittently precipitating the mixed slurry for 1.0-3.5 hours, and carrying out layered separation, so as to obtain a phosphoric acid and calcium phosphate mixed solution and thick slurry containing solid impurities; adding 40-98w% sulfuric acid while stirring, reacting sulfuric acid and the phosphoric acid and calcium phosphate mixed solution for 10-40 minutes, precipitating for layering, and separating, thereby obtaining phosphoric acid and white gypsum. The method has the advantage that the pollution to atmosphere, soil and groundwater due to phosphogypsum stacking is reduced.

Owner:晏明朗

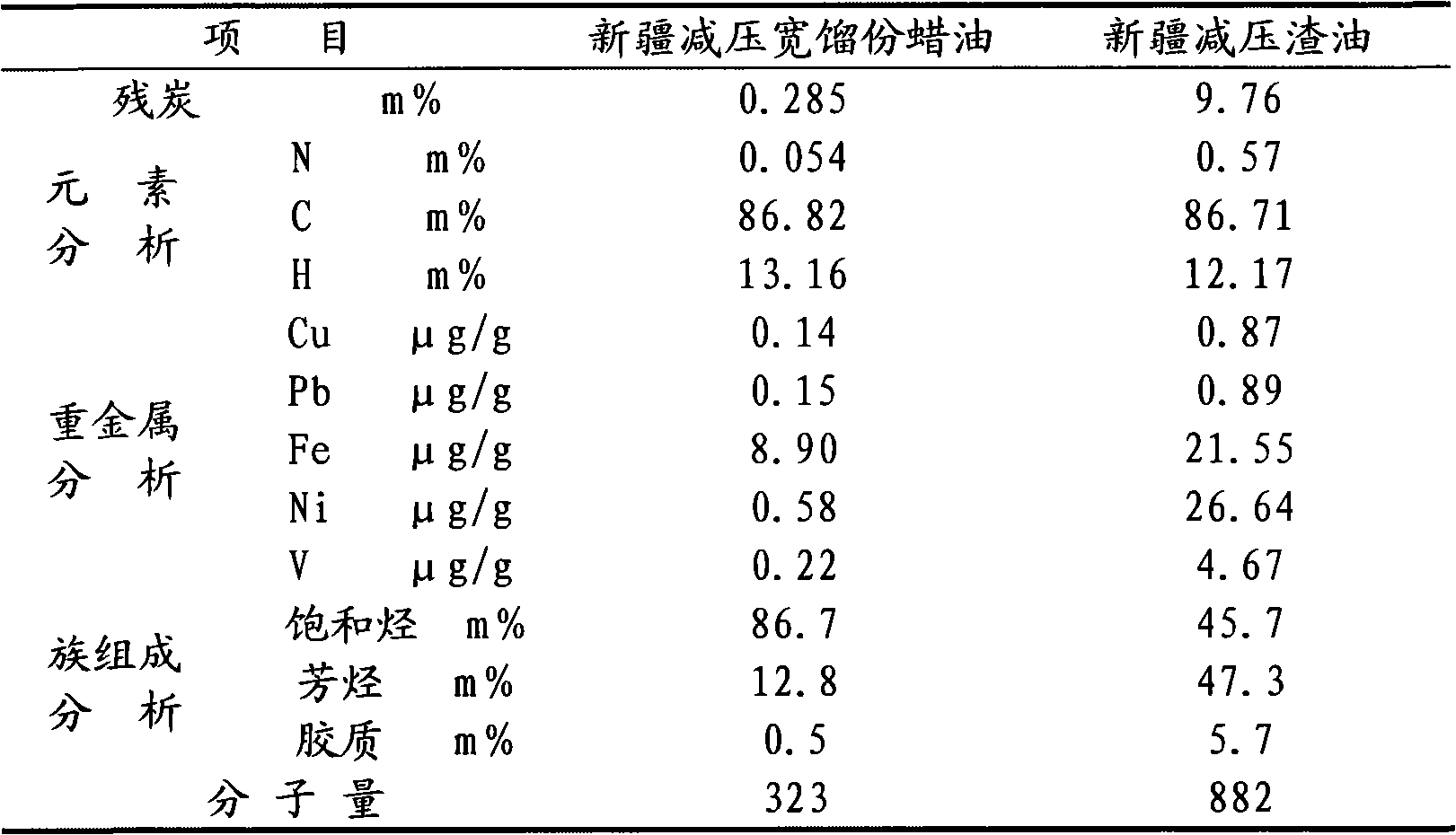

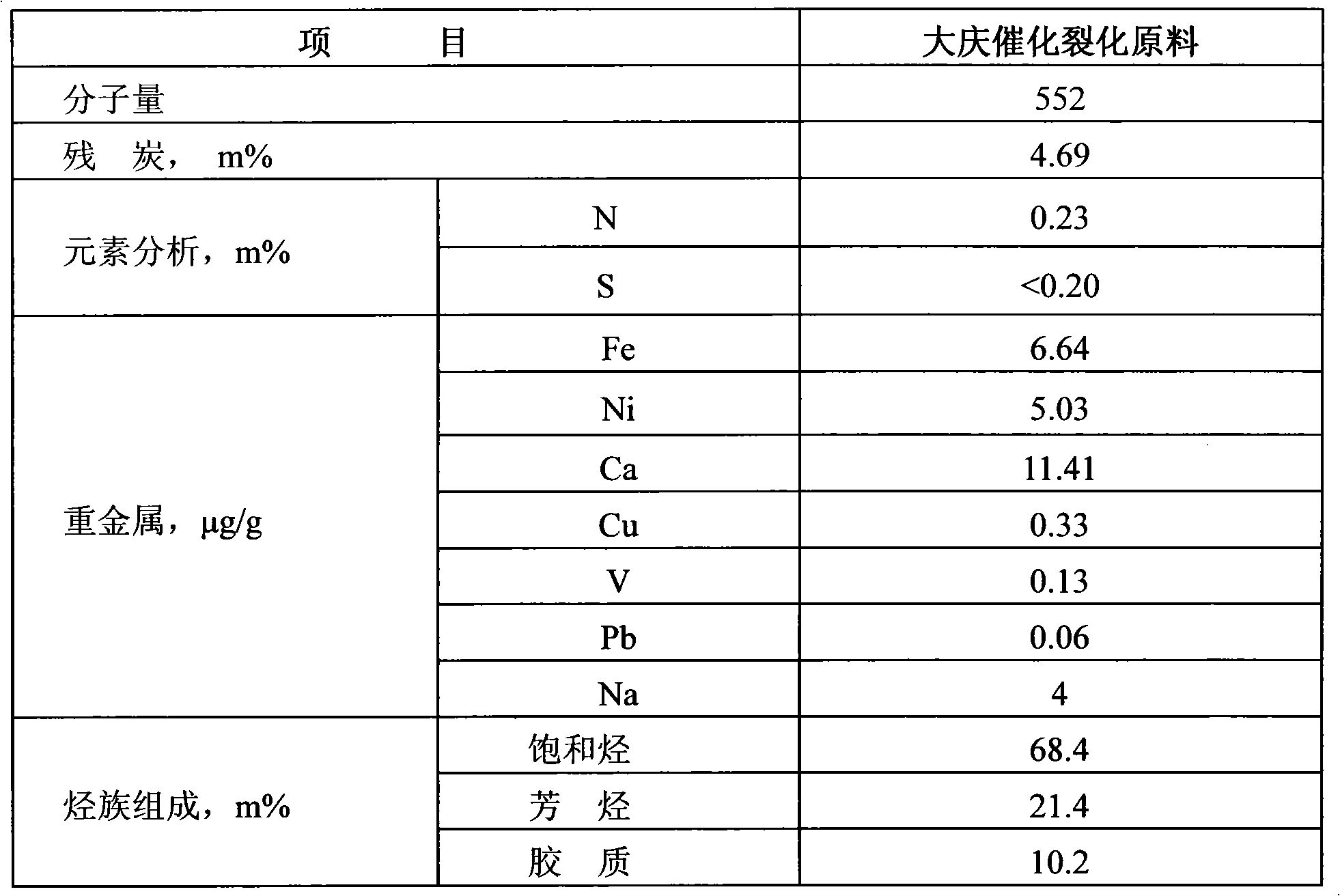

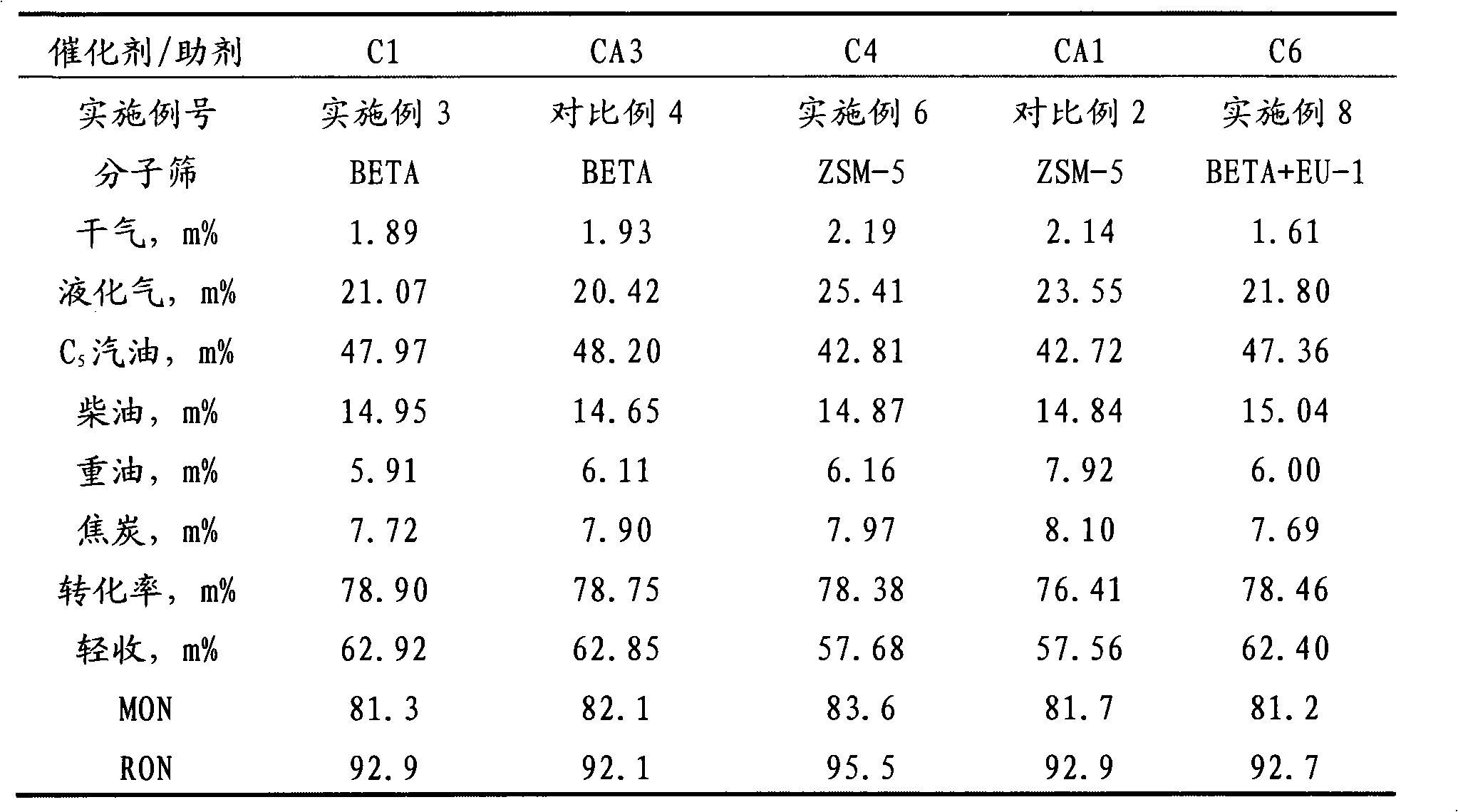

Hydrocarbon catalytic cracking catalyst and preparation method thereof

ActiveCN102049291AReduce dosageReduce manufacturing costCatalytic crackingMolecular sieve catalystsMolecular sieveAluminium phosphate

A hydrocarbon catalytic cracking catalyst is characterized in that in terms of 100wt% of the catalyst, the catalyst comprises 30-80wt% of molecular sieve and 10-65wt% clay; the catalyst comprises 5.0-20.0wt% of P calculated in the form of P2O5, and 0-1.0wt% of La2O3; P in the catalyst is provided by aluminium phosphate sol; and the aluminium phosphate sol adopted by the catalyst comprises 2-10wt%of AI and 5-15wt% of P, wherein the pH of the aluminium phosphate sol is 1.0-2.5, and the aluminium phosphate sol comprises 2-20wt% of P calculated in the form of HNO3. The prepared hydrocarbon catalytic cracking catalyst has great strength and high activity, can be used as an auxiliary to be mixed with a main catalyst, hardly reduces the activity of the main catalyst, can improve product distribution, has excellent selectivity for dry gas and coke, and meanwhile can improve the yield of light oil.

Owner:PETROCHINA CO LTD

Electrolyte of lead-acid accumulator and preparation method thereof

InactiveCN101882694AExtended service lifeEnhanced cryogenic performanceFinal product manufactureLead-acid accumulators constructionLithium chlorideGas phase

The invention discloses an electrolyte of a lead-acid accumulator and a preparation method thereof. The electrolyte comprises the following raw materials in part by weight: 25 to 45 parts of deionized water, 60 to 70 parts of dilute sulfuric acid solution, 1.8 to 2.8 parts of gas-phase nanometer silicon dioxide and 2.5 to 3 parts of electrolyte activating agent, wherein the electrolyte activating agent is prepared from the following raw materials in part by weight: 1,000 parts of deionized water, 2 parts of nickel sulfate, 2 parts of cobalt sulfate, 25 parts of aluminum sulfate, 15 parts of sodium sulfate, 25 parts of magnesium sulfate, 20 parts of aluminium phosphate, 5 parts of lithium iodide, 5 parts of lithium chloride and 20 parts of lithium carbonate. Because the nickel sulfate, the cobalt sulfate, the lithium chloride and the lithium carbonate are added into the electrolyte activating agent, the large current charge and discharge and the ultra-low temperature performance of the accumulator are increased by 25 to 30 percent, and the service life of the accumulator is prolonged by 25 to 30 percent compared with the traditional accumulator with the traditional electrolyte. Because of the adoption of the nanometer silicon dioxide and the adoption of high-speed shearing way in the preparation method, the prepared electrolyte does not settle down within 30 days.

Owner:冯家齐

Method for producing artificial sandstone for tertiary oil production in oil field

InactiveCN1587960ATrue PenetrationPreparing sample for investigationCeramic shaping apparatusAluminium hydroxideOil field

The invention relates to an artificial sandstone manufacture method of oil field tertiary oil recovery, basically including the following steps that firstly using aluminium phosphate to cement quartz sand having different particle diameter, which is then to be pressed by sixty t hydraulic press, dried wet core to increase temperature gradient warm up from 150 deg. to 960 deg. Under which the substance needed is produced. Preparation of cementitious agent includes the water is added after match of aluminium hydroxide and phosphoric acid, which is heated on electric furnace to boil then moved away and then heated to boil again, lasting ten minutes. Artificial anisotropic core created by the invention can practically express practical coefficient of permeability of underground rock, simulate practical condition of underground oil layer and do physical simulation experiment of core edge-water encroachment in doors.

Owner:中国石油大港油田油气勘探开发技术研究中心

Method for synthesizing silicoaluminophosphate molecular sieve SAPO-11 at normal pressure

InactiveCN102786063AEasy to separateMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveOrganic acid

The invention provides a method for synthesizing a silicoaluminophosphate molecular sieve SAPO-11 at normal pressure. The method is characterized in that the main process comprises the following steps of 1) preparation of eutectic mixture: fully grinding and mixing quaternary ammonium salt and organic acid or organic alcohol in a mortar with a mol ratio of 0.1 to 1.0; placing the mixture in a beaker, heating the beaker at a temperature of 80-180 DEG C to melt the mixture into transparent liquid, so as to obtain the eutectic mixture; 2) preparation of crystallization reaction mixture: adding phosphorus source, silicon source, mineralizing agent, template agent and aluminum source into the molten eutectic mixture in sequence, uniformly stirring the mixture at a mixing temperature range from 80 to 150 DEG C to form a reaction mixture; 3) crystallizing the reaction mixture prepared by step 2); and 4) water cooling the reactant reacted in step 3) to a room temperature, washing and separating the mixture, and drying and baking the washed and separated mixture, wherein the washed filtrate is recovered after rotary evaporation.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Fire-resistant rubber

Owner:山东中一橡胶有限公司

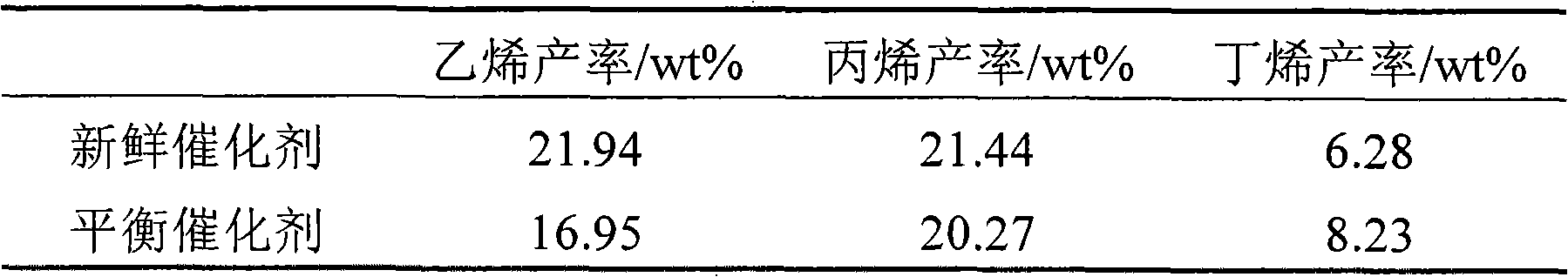

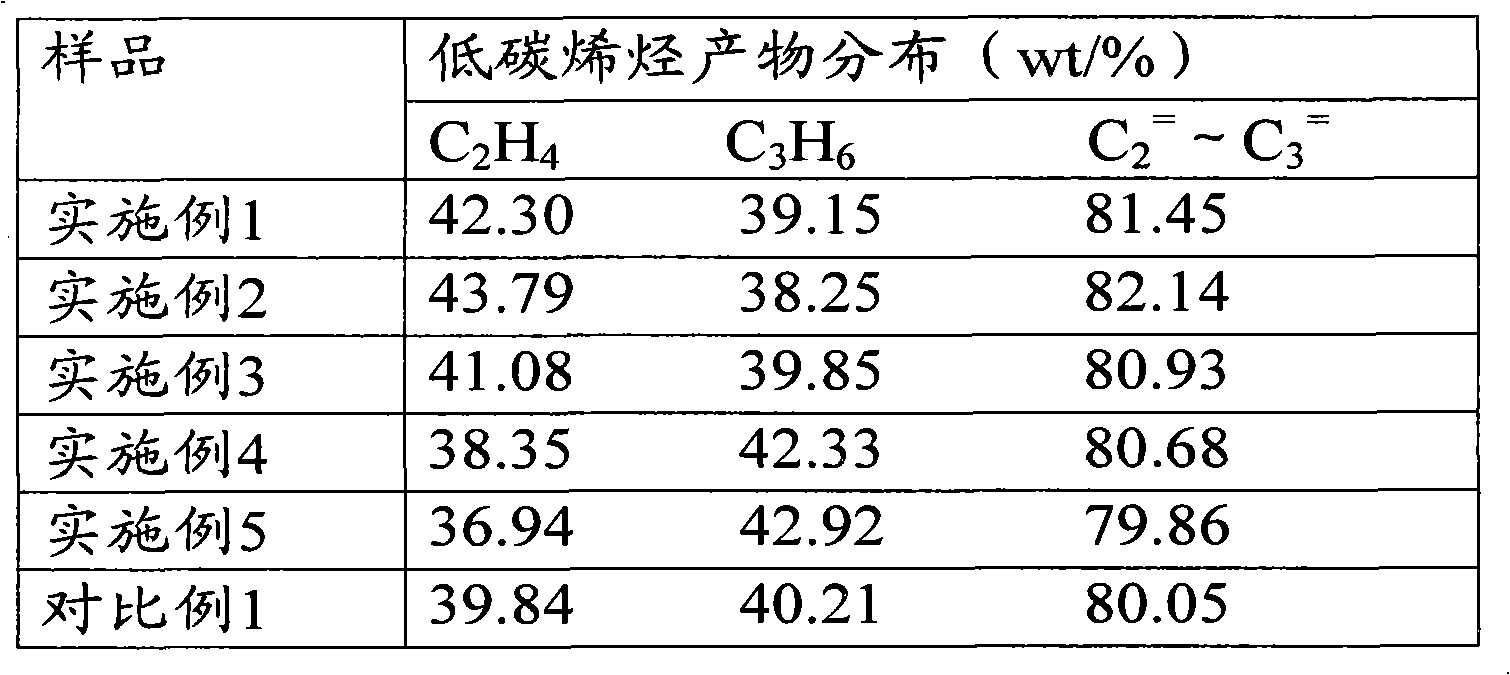

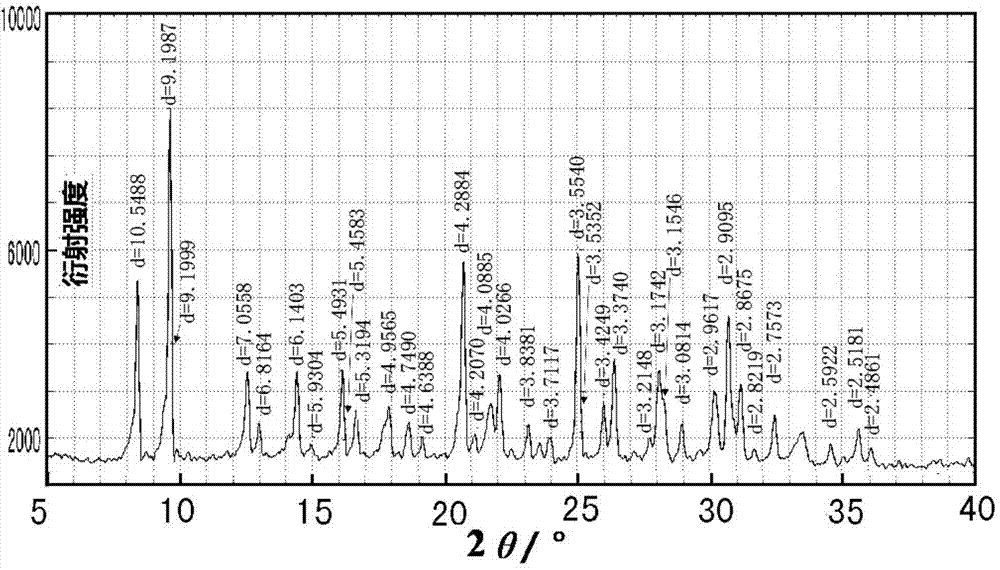

Catalyst for preparing low-carbon olefine by catalytic cracking using fluidized-bed and preparation method and use thereof

ActiveCN101337190AGood hydrothermal stabilityIncrease olefin yieldOrganic chemistryMolecular sieve catalystsMolecular sieveFluid catalytic cracking

The invention discloses a catalyst used for preparing lower olefins through the catalytic cracking process of a fluidized bed, and the catalyst comprises an active component molecular sieve and a matrix, wherein, the matrix is nonstoichiometric aluminium phosphate or the nonstoichiometric aluminium phosphate doped with a silicon-containing compound; the chemical composition of the matrix is as follows: P / Al is equal to 0.01-0.9, and Si / Al is equal to 0-50. The molecular sieve and the matrix are mixed for beating; then residual oil, animal and vegetable oil as well as naphtha can be made through spray drying and calcination; and the catalytic pyrolysis is carried out to prepare the lower olefins catalyst. The catalyst of the invention takes the residual oil, the animal and vegetable oil aswell as the naphtha as the raw materials, and uses the catalytic pyrolysis process to prepare the lower olefins, thereby opening up the new material source and the technological line for producing olefin, and having higher economic benefits.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ferrite catalyst and preparation method thereof

ActiveUS20140141965A1Increase conversionsHigh selectivityHeterogenous catalyst chemical elementsCatalystsCalcium biphosphateZinc phosphate

Disclosed are a ferrite catalyst and preparation methods thereof. The catalyst is provided with a formula below, wherein A is Mg atom, Zn atom or a mixture of both atoms at any ratio; D is one or more atoms selected from the group consisting of Ni, Co, W, Mn, Ca, Mo or V atom; Z is a catalyst carrier, which is one or more selected from the group consisting of calcium phosphate, calcium dihydrogen phosphate, aluminium phosphate, aluminium dihydrogen phosphate, ferric phosphate, magnesium phosphate, zinc phosphate, Mg—Al hydrotalcite, calcium carbonate, magnesium carbonate; a=0.01-0.6; b=0-0.30; c is a number balancing each valence; x, y represent the amounts of principal catalyst and carrier Z respectively, wherein the weight ratio y / x=0.5:1-7:1.x(FeAaDbOc) / yZ

Owner:SHANGHAI HUAYI ACRYLIC-ACID CO LTD

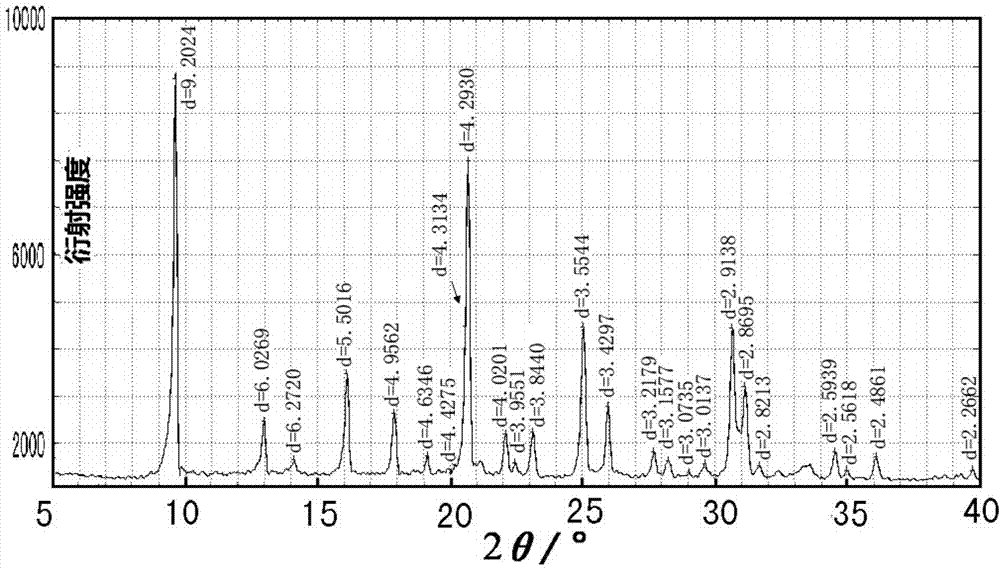

Method for preparing silicoaluminophosphate (SAPO)-34 molecular sieve molded catalyst, product prepared by method and application of product

ActiveCN101884936AFacilitated DiffusionReduced Diffusion ResistanceMolecular sieve catalystsCatalyst activation/preparationMolecular sievePolymer science

The invention relates to a method for preparing an SAPO-34 molecular sieve molded catalyst, a molded catalyst prepared by the method and application of the molded catalyst. The method comprises the following steps of: activating montmorillonoid by using aqueous alkali; mixing the activated montmorillonoid and an aluminum source, a phosphorus source, a template agent and de-ionized water and then performing a hydrothermal crystallization reaction at a high temperature; and mixing and molding a montmorillonoid-contained base material, crystallization liquid of a silicoaluminophosphate molecular sieve and a binder to obtain the SAPO-34 molecular sieve molded catalyst. In the invention, the SAPO-34 molecular sieve molded catalyst is prepared by taking the montmorillonoid as a raw material, and the non-converted montmorillonoid in the crystallization liquid is used as a carrier material when the catalyst is molded, so that a carrier can be avoided or a smaller amount of the carrier is used during molding; and due to a layer structure of the montmorillonoid, a mesoporous or macropore structure can be formed when the catalyst is molded, and a pore-forming agent is not required to be added into the molding liquid, so that resources are saved and cost is reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

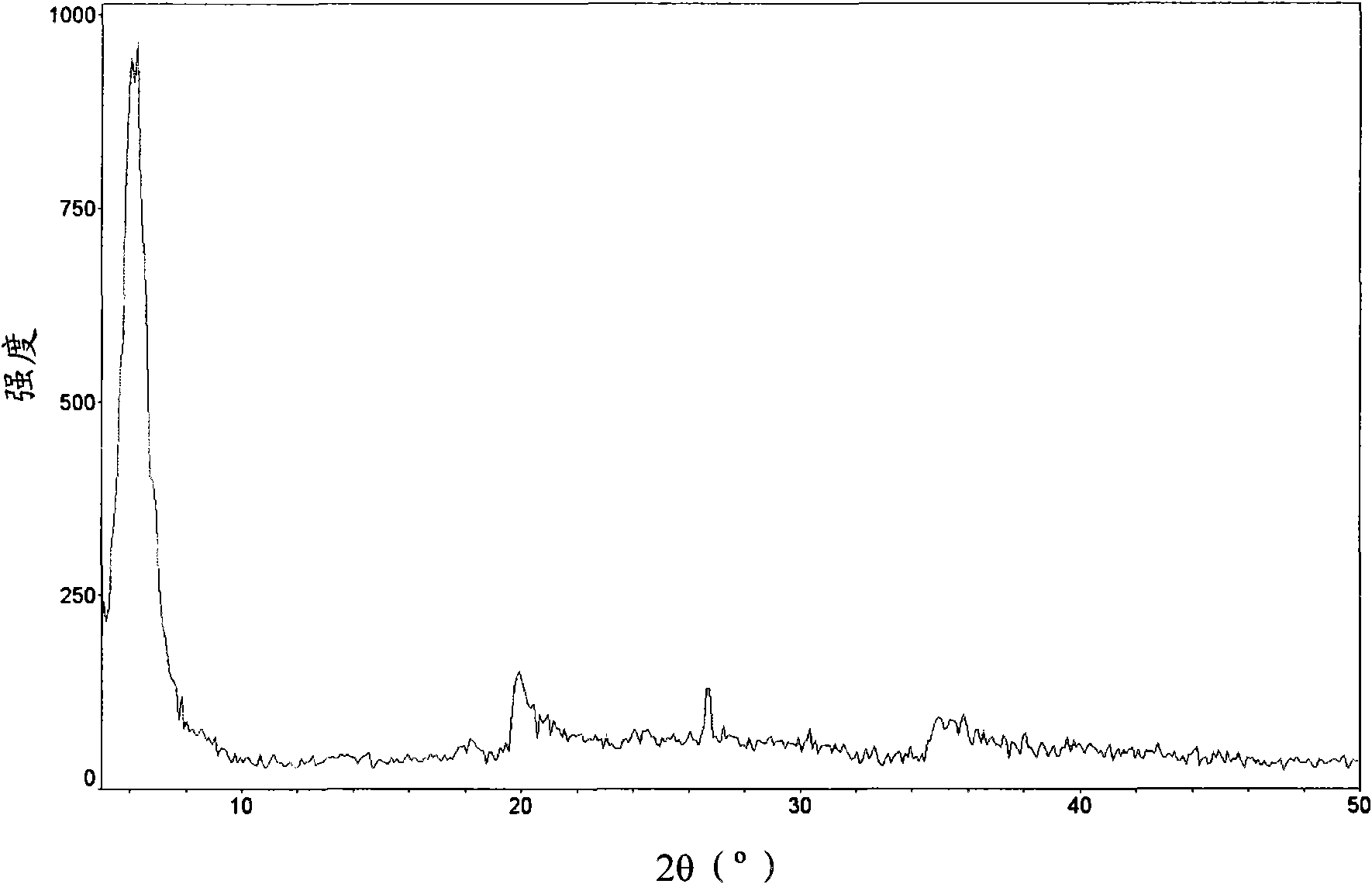

Nano-polycrystalline SAPO molecular sieve with high specific surface area, and preparation method and application thereof

InactiveCN104760975AImprove performanceNew structureMolecular sieve catalystsOther chemical processesPhosphoric acidAluminium phosphate

The invention belongs to the technical field of zeolite molecular sieve materials, and concretely relates to a nano-polycrystalline SAPO molecular sieve with a high specific surface area, and a preparation method and an application thereof. The nano-polycrystalline SAPO molecular sieve with a high specific surface area is a CHA structure type or RHO structure type or CHA structure and RHO structure eutectic silicoaluminophosphate (SAPO) molecular sieve, is synthesized through a gas and solid phase crystal transformation reaction of a amorphous silica alumina phosphorus oxide dry glue in steam of a water and diethylamine mixed template, and is especially suitable for catalyzing adsorbing separation of micro-molecular gases from low carbon olefins prepared from methanol.

Owner:SHANGHAI FUYU NEW MATERIAL TECH

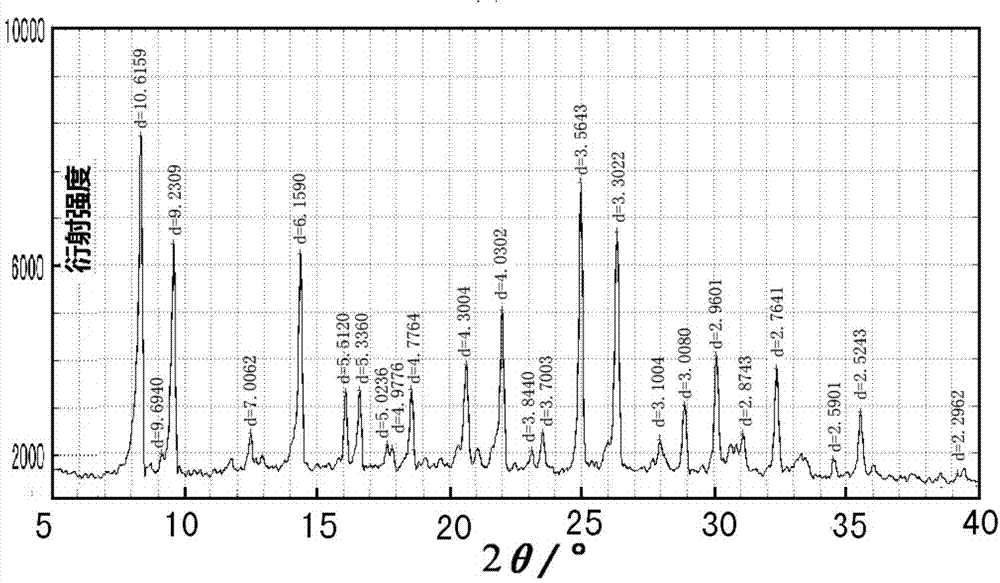

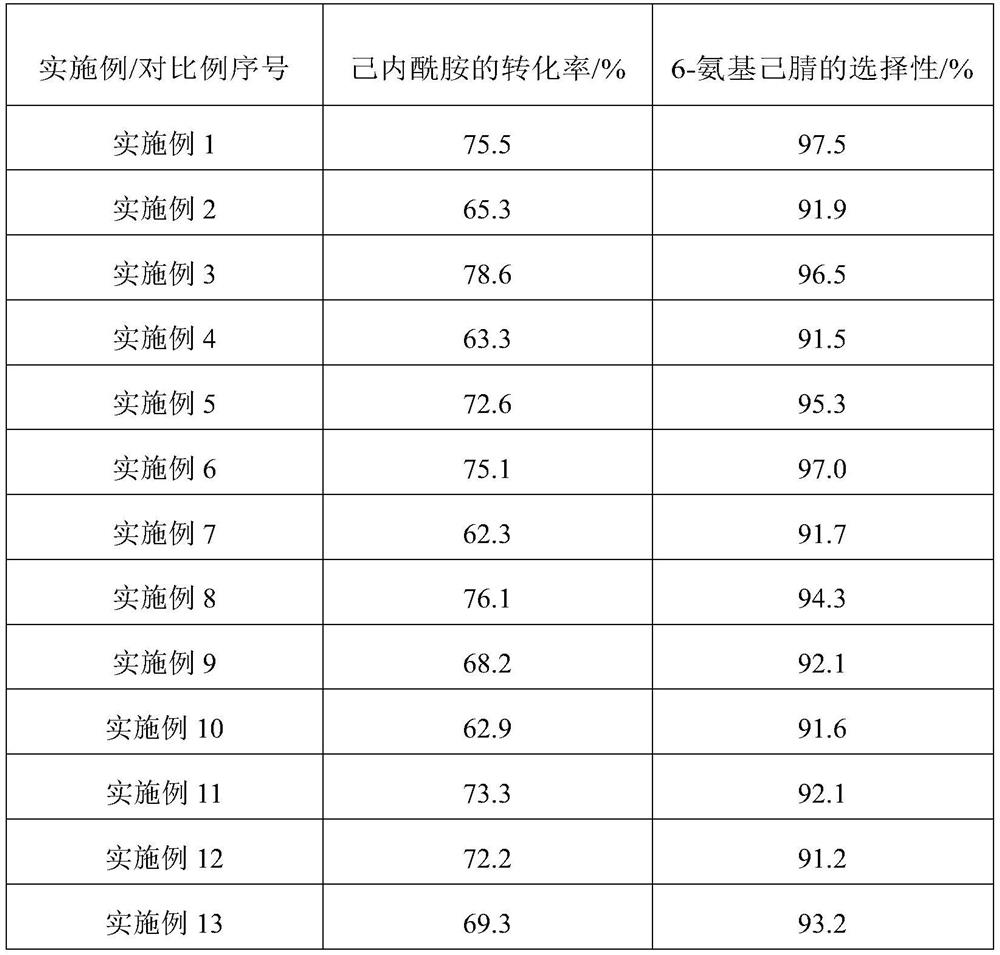

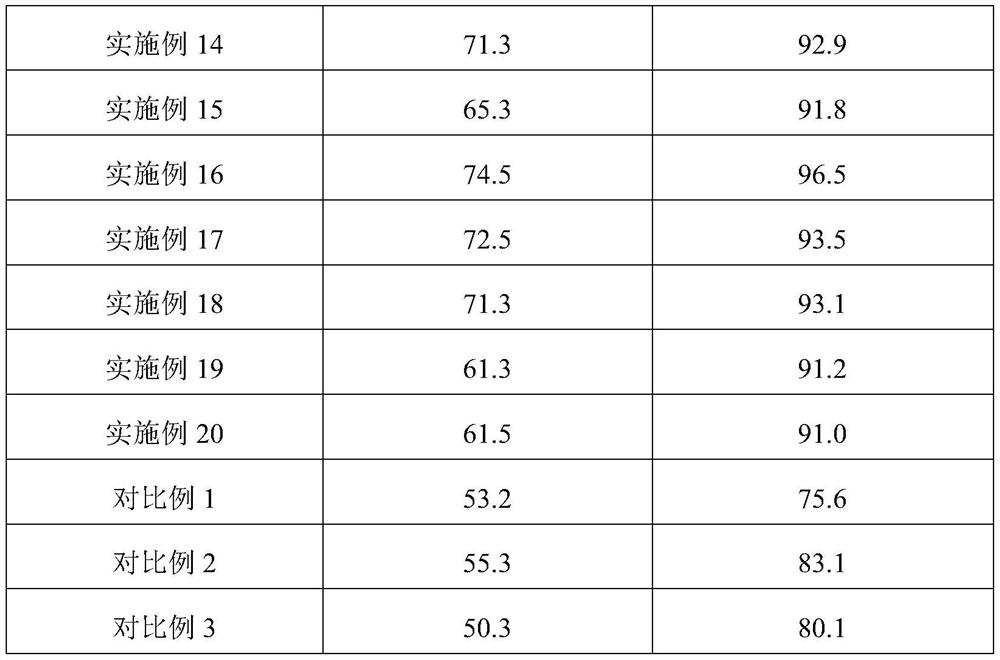

Preparation method of catalyst for synthesizing hexamethylenediamine intermediate 6-aminocapronitrile and synthesis method of 6-aminocapronitrile

ActiveCN111672526AHigh strengthHigh activityPhysical/chemical process catalystsCarboxylic acid nitrile preparationPhosphorous acidMagnesium phosphate

The invention provides a preparation method of a catalyst for synthesizing a hexamethylenediamine intermediate 6-aminocapronitrile and a synthesis method of the 6-aminocapronitrile. The preparation method comprises the following steps: S1, mixing a carrier, a binder, water and a peptizing agent to obtain a mixture; S2, molding the mixture to obtain a molded carrier; and S3, modifying the molded carrier in a modifier acidic solution to obtain the catalyst for synthesizing the hexamethylenediamine intermediate 6-aminocapronitrile, wherein the mass ratio of the modifier to the molded carrier is (0.1-1): 1, and the modifier is selected from one or more of calcium phosphate, magnesium phosphate, aluminum phosphate, calcium metaphosphate, magnesium metaphosphate, aluminum metaphosphate and aluminum phosphite. Therefore, the catalyst has better strength, activity and selectivity. The preparation method is simple, wide in raw material source and relatively low in cost.

Owner:JIANGSU YANGNONG CHEM GROUP +3

High temperature resistant inorganic adhesive

InactiveCN101307212AEasy to operateSmall coefficient of thermal expansionInorganic adhesivesSoluble glassHeat resistance

The invention provides a high temeperature resistant inorganic cementing compound, relating to an inorganic cementing compound. The invention overcomes the disadvantages that the prior cementing compound has poor heat resistance and low connecting intensity of a glued joint metal material and a composite material. The high temperature resistant inorganic cementing compound consists of an inorganic solvent and a curing toughening agent which are mixed according to a mass ratio of 1 to 0.7-1.5, wherein, the inorganic solvent is a reaction solution of aluminium phosphate and cupric oxide, soluble glass or a aluminium phosphate solution; the curing toughening agent consists of 50 to 95 portions of inorganic solidified agent and 5 to 50 portions of toughening strengthening agent by weight portion. The high temperature resistant inorganic cementing compound has good heat resistance and high connecting intensity of the glued joint metal material and the composite material.

Owner:HARBIN INST OF TECH

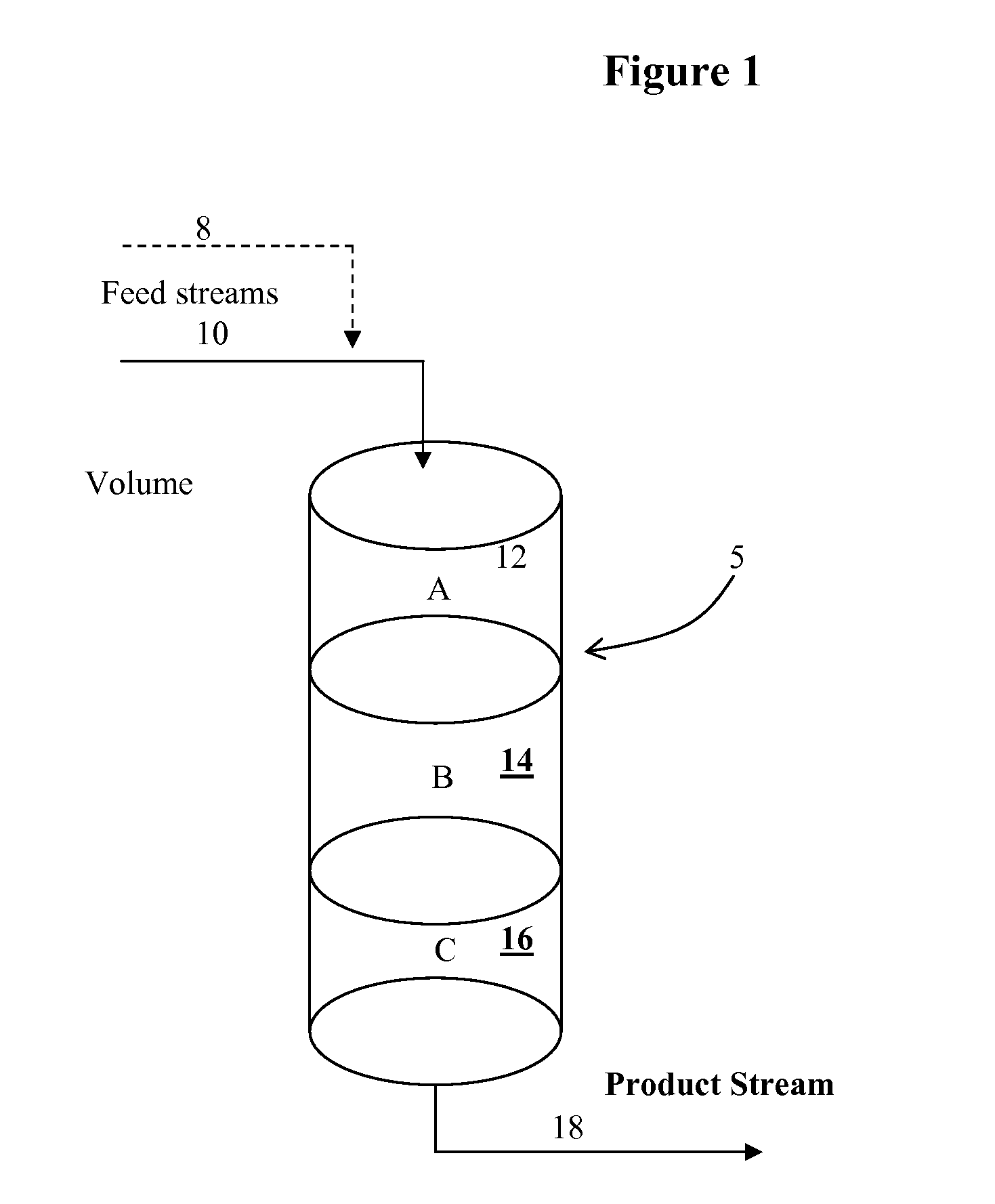

Graded catalyst bed for methyl mercaptan synthesis

A process and graded catalyst bed for selectively producing methyl mercaptan from methanol. The methanol is reacted with hydrogen sulfide, in the presence of a graded catalyst bed containing at least three types of nickel or cobalt molybdenum alumina catalysts to convert the methanol to methyl mercaptan in one-pass. At least one of the hydrotreating catalysts can contain aluminium phosphate. Use of the graded catalyst bed prevents the formation of a hot spot within the graded catalyst bed. The methyl mercaptan having less than about 30 wt. % unreacted methanol contained therein.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Method for making man-made rock core target

InactiveCN101435330AMeet the needs of the siteFluid removalStructural/machines measurementRock coreOil field

The invention relates to a manufacturing method of an artificial rock core barn used for evaluation articles of an oil field oil gas water well perforator, which comprises fives procedures of screening quartz sand, manufacturing a standard test rock core, preparing an aluminium phosphate cementing agent, manufacturing the rock core by pressing and drying and sintering. The manufacturing method is easy to be implanted, the one-time success rate of quartz sand matching of different particles can be improved when a large size rock core is manufactured by the method, and the artificial rock core barn which can meet the on-site requirement and can be used in the evaluation on the perforator in high pressure seepage flow performance test is manufactured.

Owner:CNPC GREATWALL DRILLING ENG

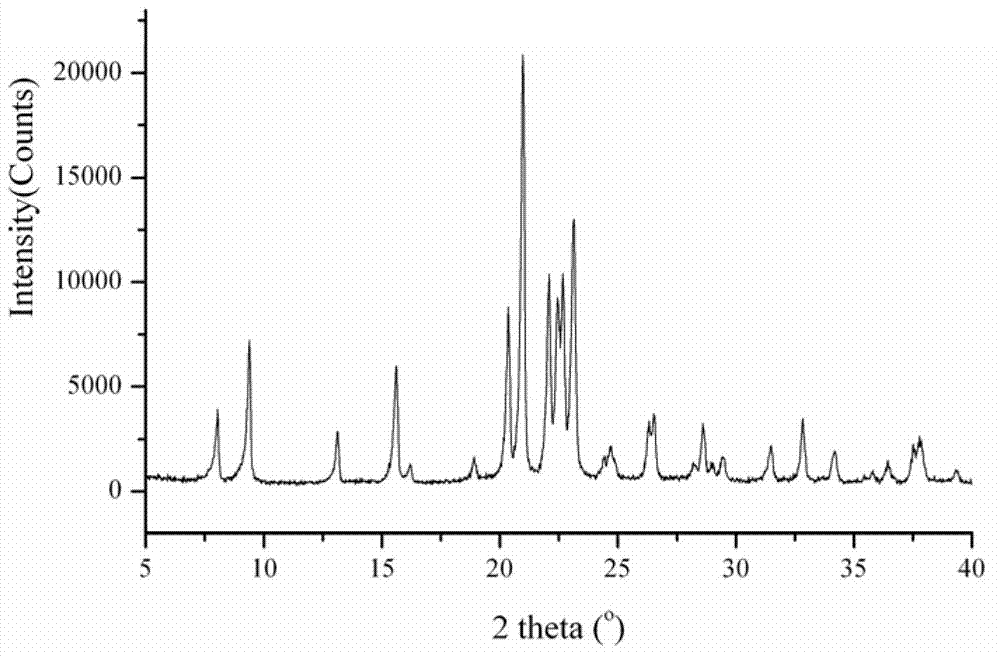

AFO structured silicon-aluminium phosphate molecular sieve and synthetic method therefor

InactiveCN1541942AMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sievePropylamine

The present invention discloses one kind of silicon aluminum phosphate molecular sieve in AFO structure. It has molar composition in oxide form of Al2O3:yP2O5:zSiO2, where y is 0.60-1.20 and z is 0.05-1.3. It features that the molar composition before roasting to eliminate templating agent is (x1R1+x2R2):Al2O3:yP2O5:zSiO2, where R1 and R2 are templating agent in crystal pores of molecular sieve, R1 is diethylamine, R2 is di-n-propylamine, x1+x2 is 0.01-0.35, and neither x1 nor x2 is zero. The molecular sieve is synthesized with double templating agent and crystal seed and through high temperature synthesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

Castable used for electric furnace slag/iron notch as well as method for pouring electric furnace slag/iron notch

The invention provides a castable used for electric furnace slag / iron notch and a method for pouring the electric furnace slag / iron notch. The castable used for the electric furnace slag and the iron notch comprises the following components by weight percent: 50-60wt% of carborundum grains, 12-16wt% of silicon carbide fine powder, 0-8wt% of Al203 micro powder, 0-5wt% of silicon micro powder, 0-5wt% of additive, 5-9wt% of binding agent, additionally added 5-9wt% of binding agent and 1-4wt% of coagulant, wherein the carborundum grains, the carborundum fine powder, the Al203 micro powder, the silicon micro powder and the additive are mixed on a mixing mill after being blended; adding the binding agent, milling and souring. When the castable is poured on site, the binding agent and the coagulant are additionally added and evenly stirred to obtain the castable used for the electric furnace slag and the iron notch, wherein the additive is at least one of sodium hexametaphosphate, sodium tripolyphosphate, carboxymethylcellulose and calcium lignosulphonate; and the binding agent is at least one of the sodium hexametaphosphate, phosphoric acid and aluminium phosphate.

Owner:PANZHIHUA WANTENG REFRACTORY MATERIALS

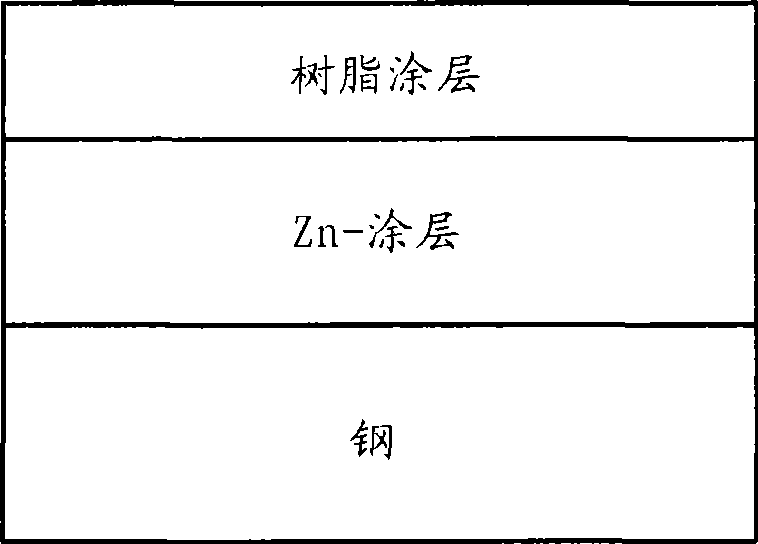

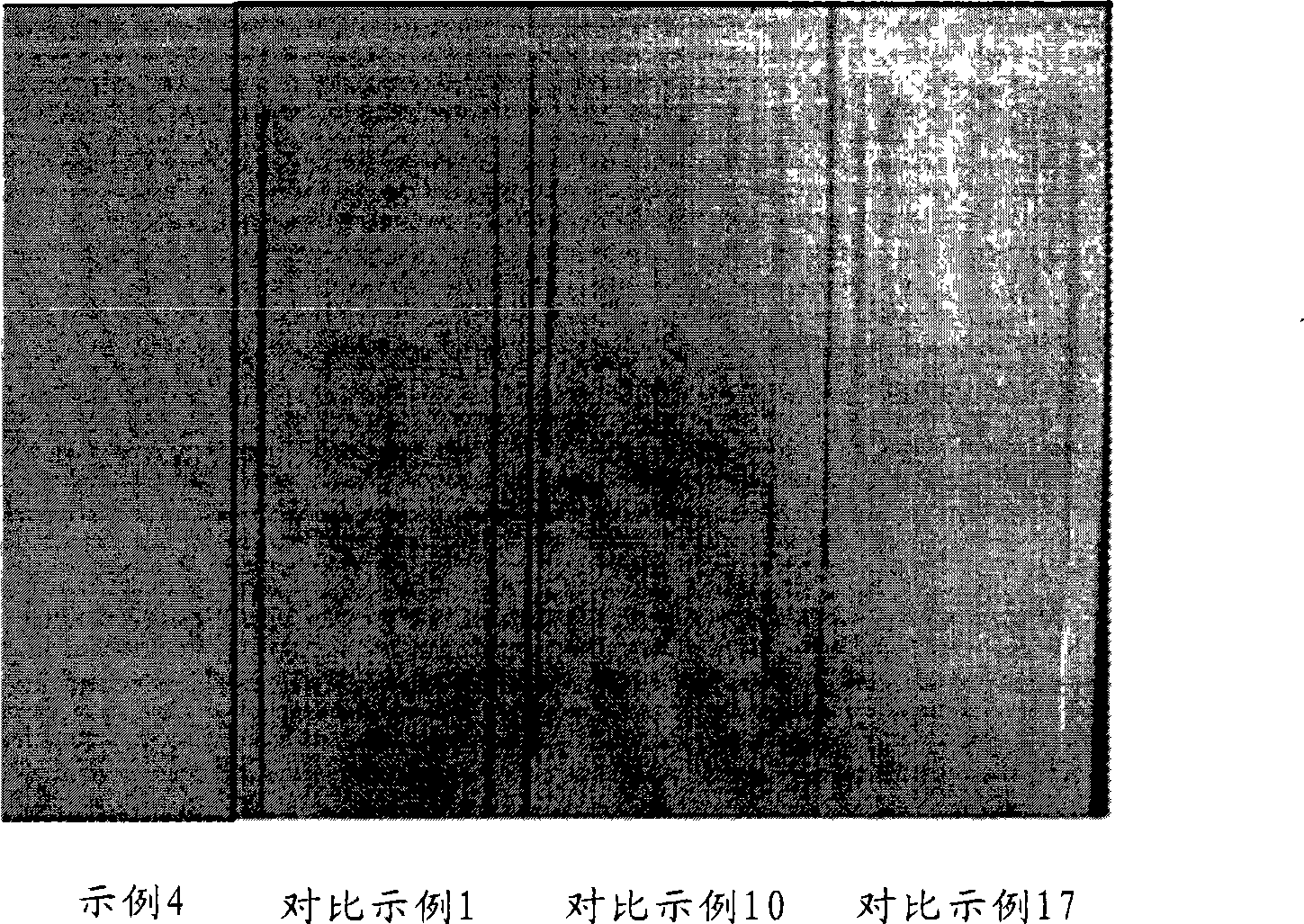

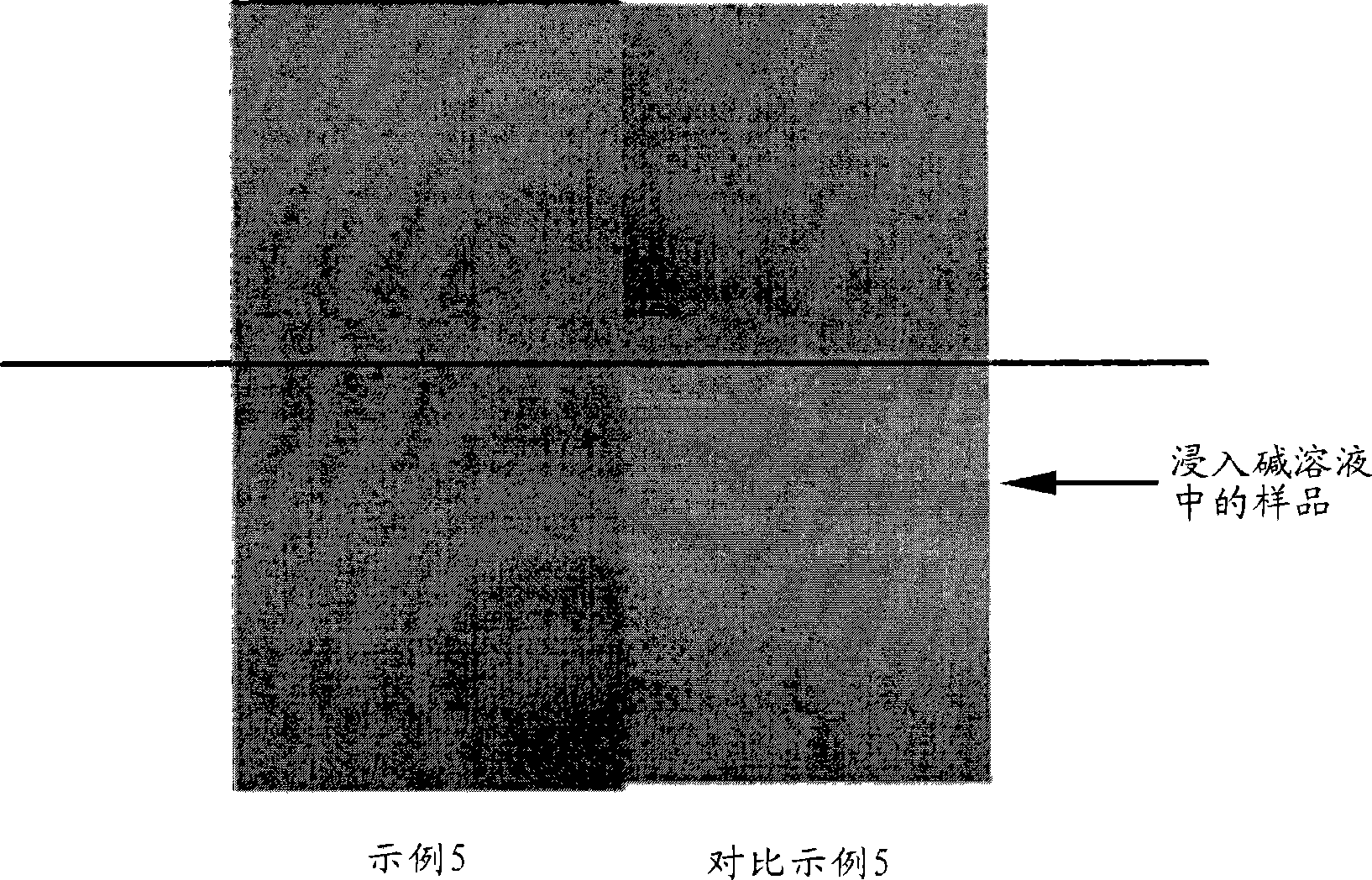

Non-chrome resin composition, method for processing steel plate surface and steel plate

ActiveCN101435078AProcessableConductiveAnti-corrosive paintsPolyurea/polyurethane coatingsSheet steelOrganic Oxide

The invention provides a chromium-free resin constituent with excellent corrosion resistance, alkali resistance, processability, electroconductibility, and chemical resistance, a method for carrying out a surface treatment on a steel plate, and a steel plate manufactured according to the method. The surface treatment steel plate is prepared through coating the steel plate by the resin constitute; after the steel plate is dry, the quantity of resin mixture adhered to the steel plate is in the scope of 300 to 1800mg / m<2>, wherein, based on the overall solid content of the resin constituent, the resin constituent consists of: mixture of hard urethane resin and 10-90 weight percent of soft urethane resin; based on the overall solid content of the mixture, the mixture contains 5-95 weight percent of soft urethane resin and 5-95 weight percent of hard urethane resin; 1-20 weight percent of Ti or Zr and the like organic oxide; 0.1-10.0 weight percent of at least one of compounds selected from a group composed of aluminium phosphate, aluminium dihydrogen phosphate, phosphate monozinc and hydrated manganese phosphate; solvent.

Owner:浦项股份有限公司

Firm can plastic and preparation method thereof

Owner:宜兴市炉顶密封工程有限公司

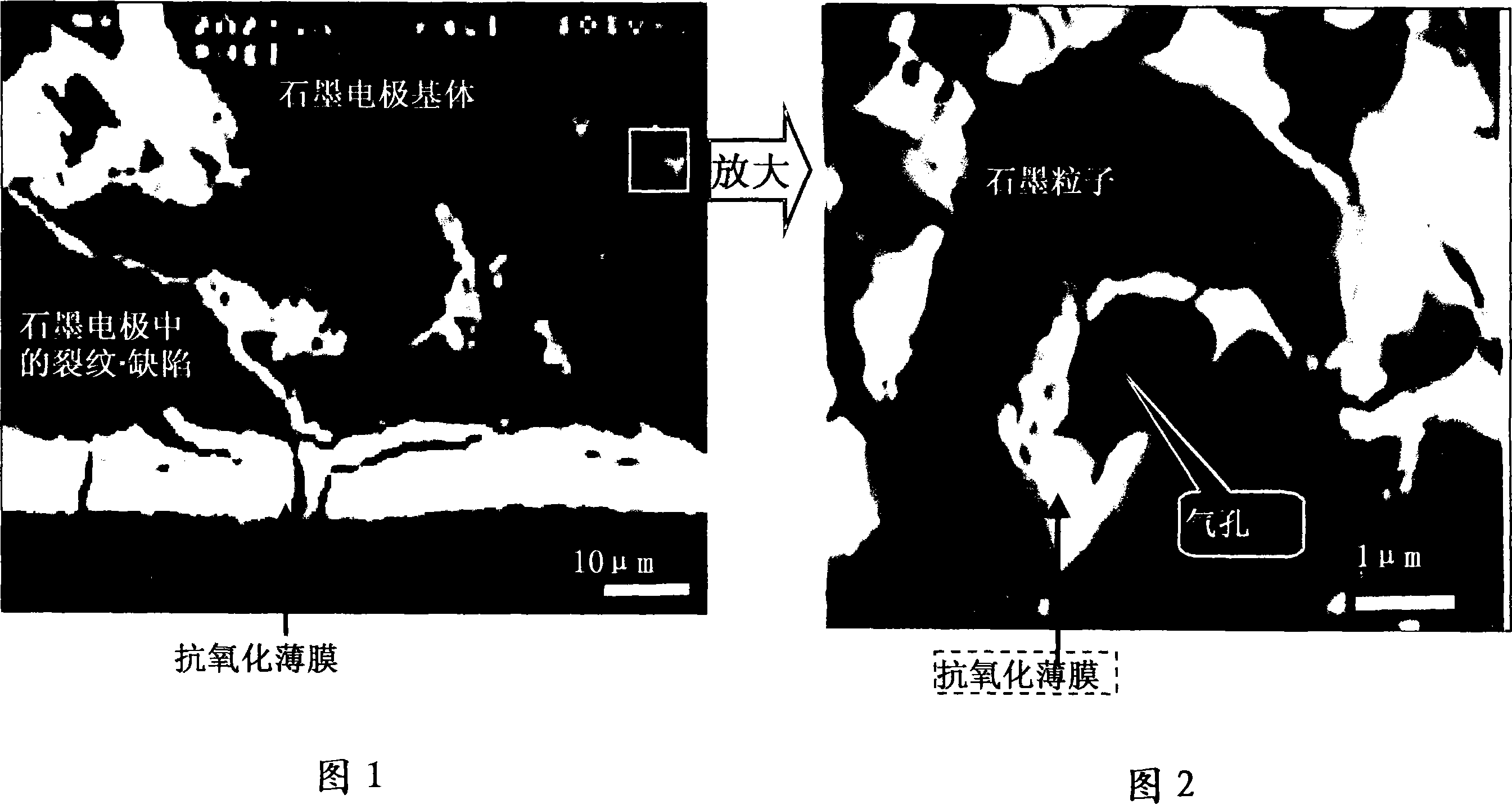

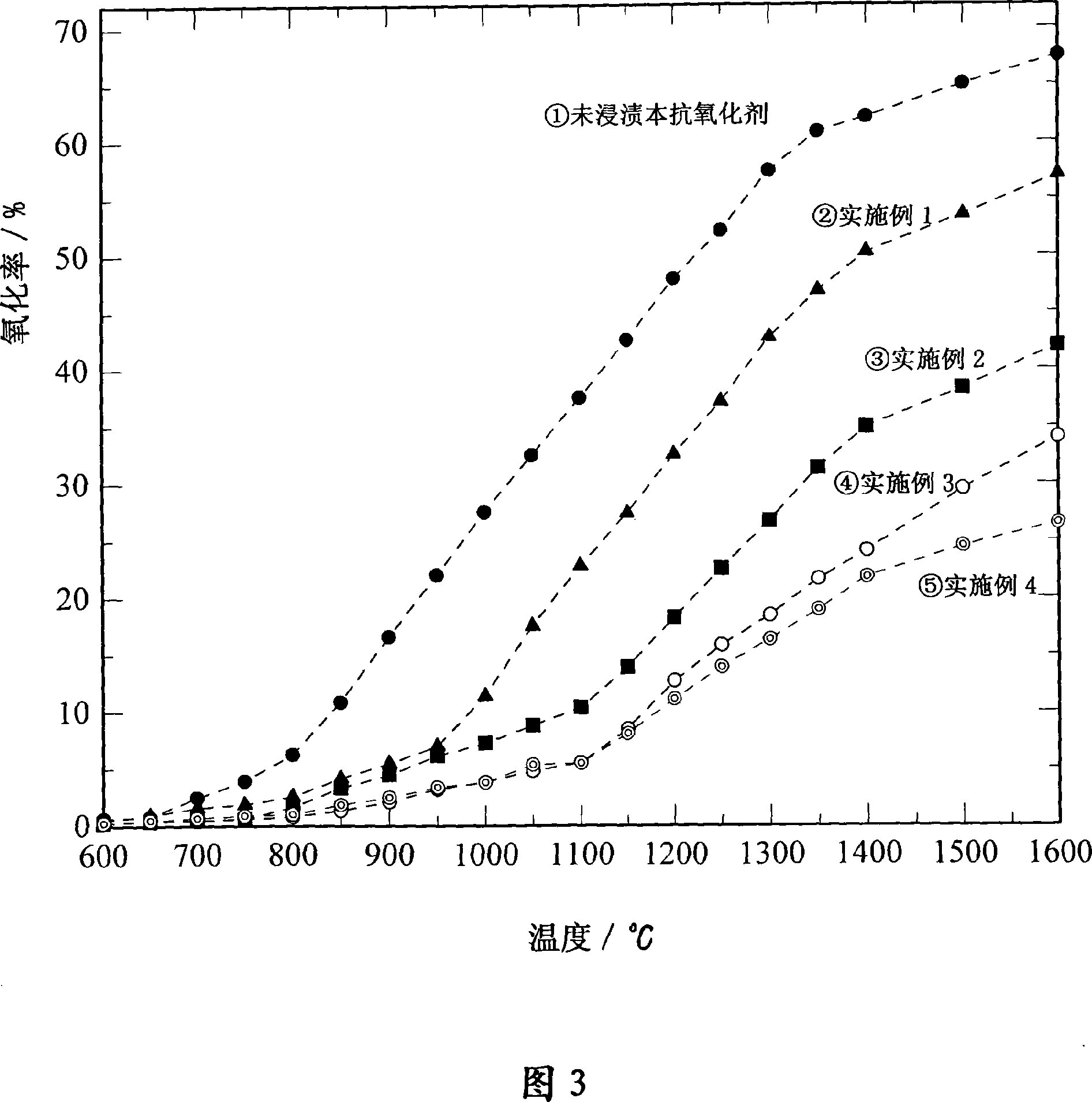

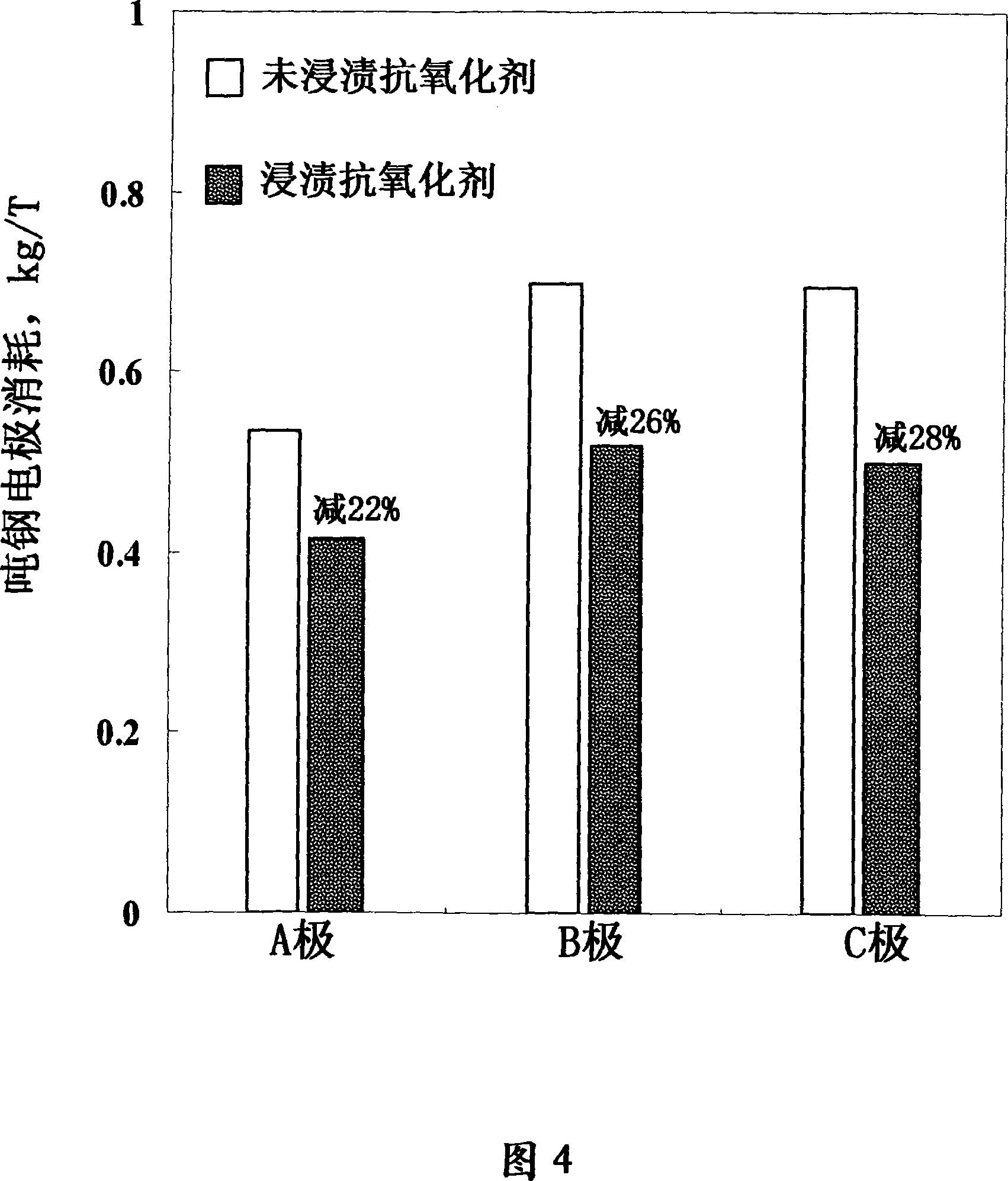

Dipping type anti-oxidant for improving graphite electrode performance of electric arc steelmaking

InactiveCN101052251AImprove stabilityImprove antioxidant capacityElectric discharge heatingSteelmakingOxidation resistant

The invention comprises: solid constituent aluminium phosphate, silicon dioxide, alumina and aqueous solution. The grain size of said solid constituent is 0.01-1 mu m oxide particle stably dispersed in the aqueous solution to form multi phase suspended liquid. Calculated based on the 100% of solid constituent weight, wherein, the aluminium phosphate is 40wt%-64wt%, the silicon dioxide is 30wt%-57wt%; the alumina is 1wt%-6wt%; the heat-resistance of oxidation resistance ceramic film formed using the invention can reach 1400 deg.c The fluid graphite electrode is dipped in the invention, and after drying, an oxidation resistance ceramic film is formed on the graphite electrode.

Owner:王玉凡

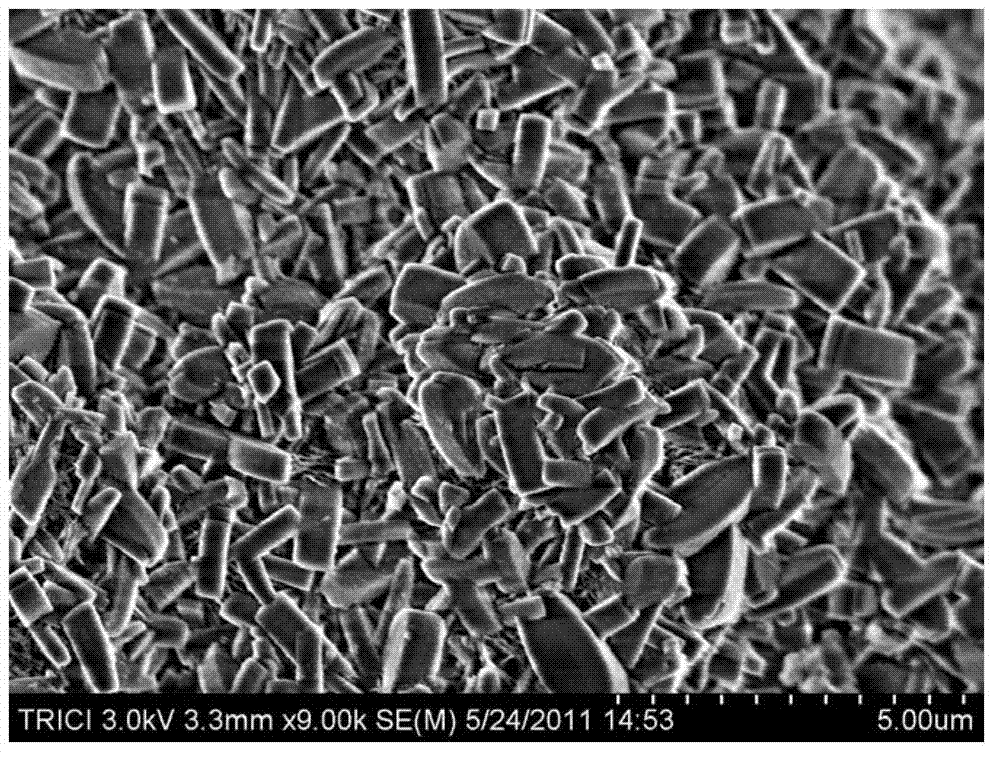

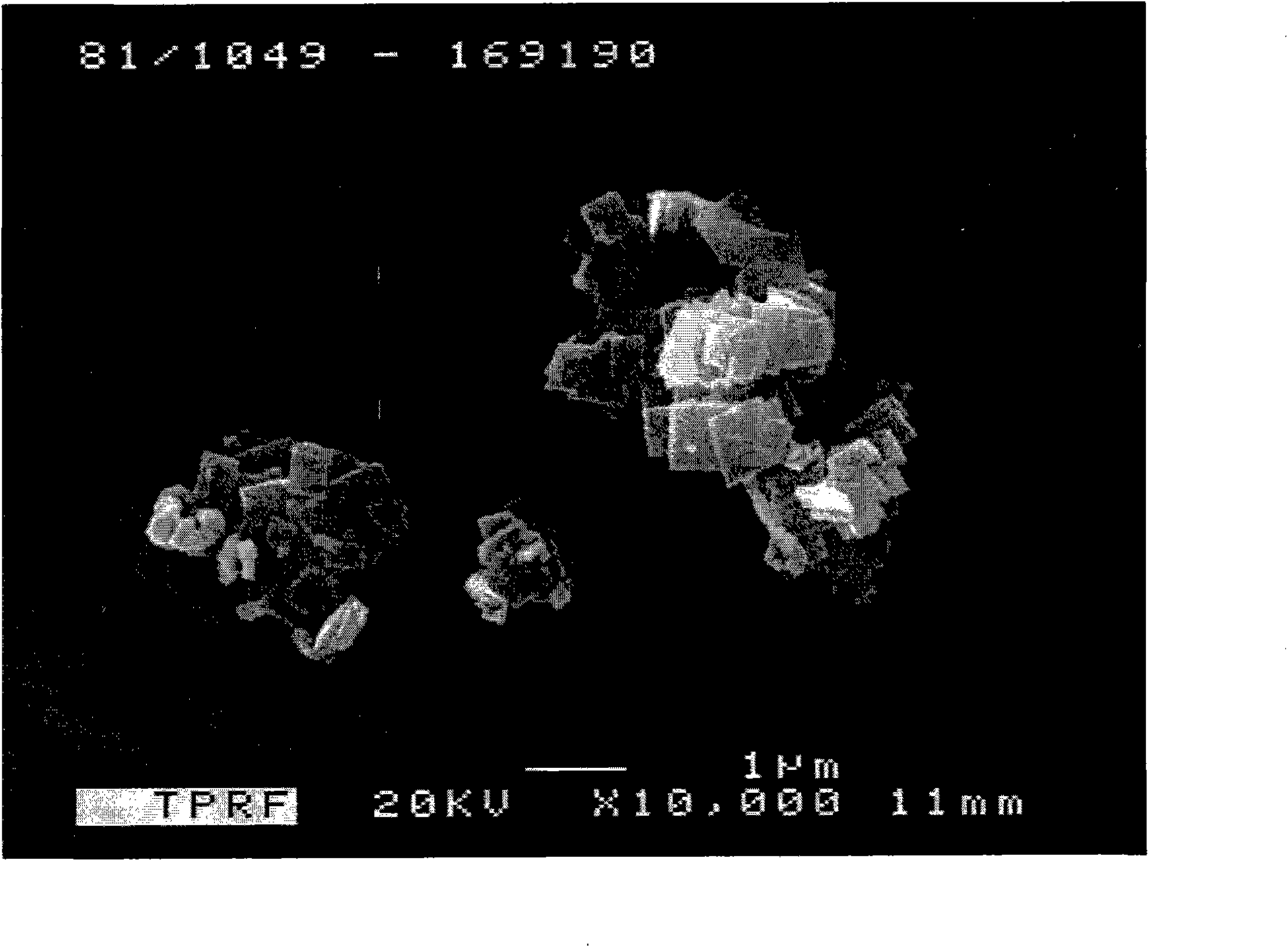

Method for preparing metalloaluminophosphate (MEAPO) molecular sieve

InactiveCN101679054AIncrease productionIncrease flexibilityMolecular sieve catalystsMolecular sieve catalystLamellar crystalsCrystal morphology

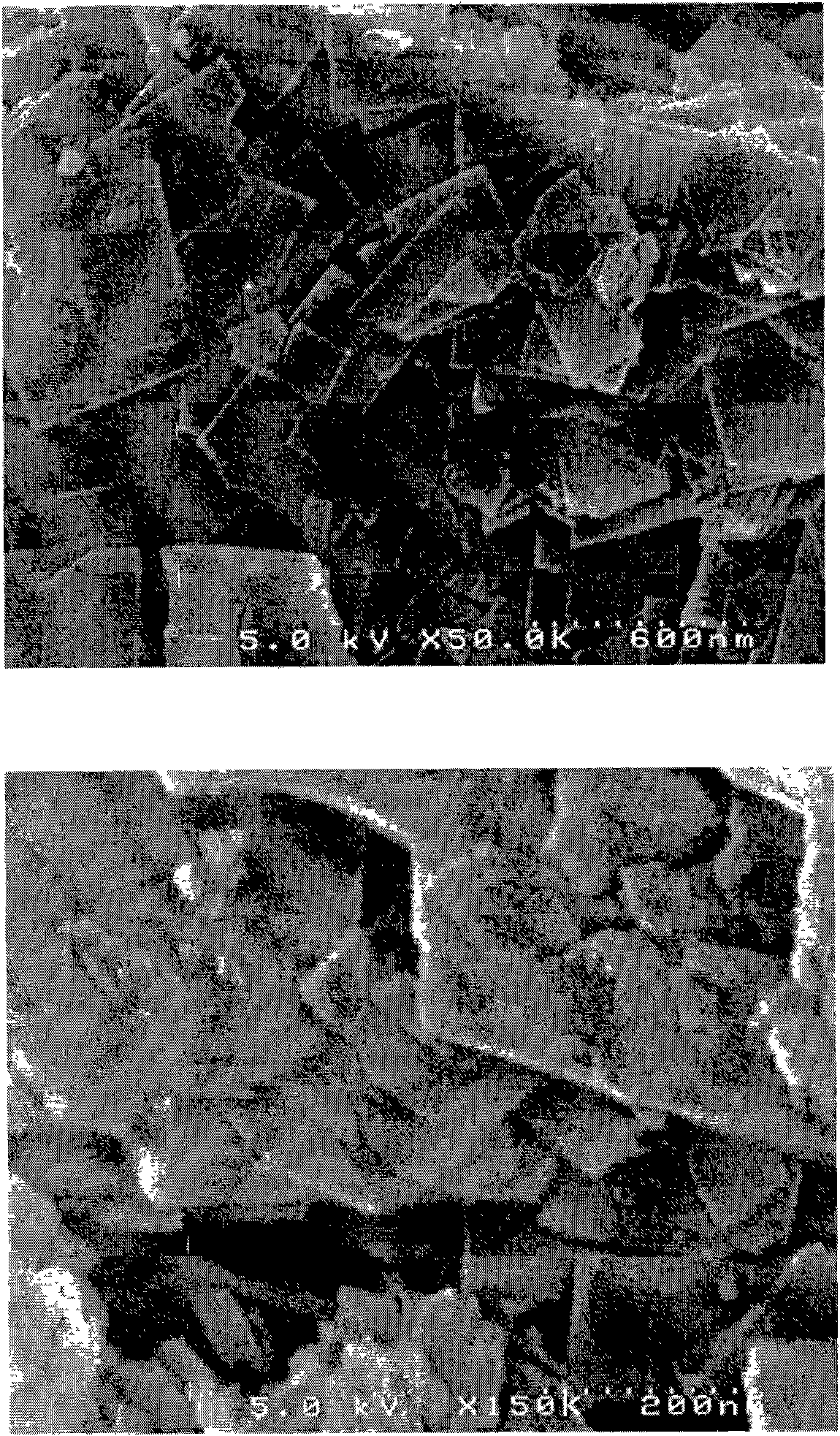

The present invention also relates to a method for preparing metalloaluminophosphate (MeAPO) molecular sieve said method comprising : a) forming a reaction mixture containing a texture influencing agent (TIA), an organic templating agent (TEMP), at least a reactive inorganic source of MeO2 insoluble in the TIA, reactive sources of Al2O 3 and P2O5, b) crystallizing the above reaction mixture thus formed until crystals of the metalloaluminophosphate are formed, c) recovering a solid reaction product, d) washing it with water to remove the TIA and e) calcinating it to remove the organic template.In a usual embodiment said reaction mixture has a composition expressed in terms of molar oxide ratios of: TEMP / Al2O3=0.3-5, more desirable 0.5-2 MeO2 / Al2O3= 0.005-2.0, more desirable 0.022-0.8 P2O5 / Al2O3=0.5-2, more desirable 0.8-1.2 TIA / Al2O3=3-30, more desirable 6-20. In a usual embodiment the metalloaluminophosphate (MeAPO) molecular sieves made with the above method have a lamellar crystal morphology having an empirical chemical composition on an anhydrous basis, after synthesis and calcination, expressed by the formula HxMeyAlzPkO2 wherein, y+z+k=1, x<=y, y has a value ranging from 0.0008 to 0.4 and more desirable from 0.005 to 0.18, z has a value ranging from 0.25 to 0.67 and more desirable from 0.38 to 0.55, k has a value ranging from 0.2 to 0.67 and more desirable from 0.36 to 0.54, said molecular sieve having predominantly a plate crystal morphology. In an advantageous embodiment the MeAPO made by the method of the invention have essentially a structure CHA or AEI or a mixture thereof. Preferably they have essentially the structure SAPO 18 or SAPO 34 or a mixture thereof. The present invention also relates to catalysts consisting of the above MeAPO molecular sieves madeby the method of the invention or comprising the above MeAPO molecular sieves made by the method of the invention.

Owner:TOTAL RES & TECH FELUY +1

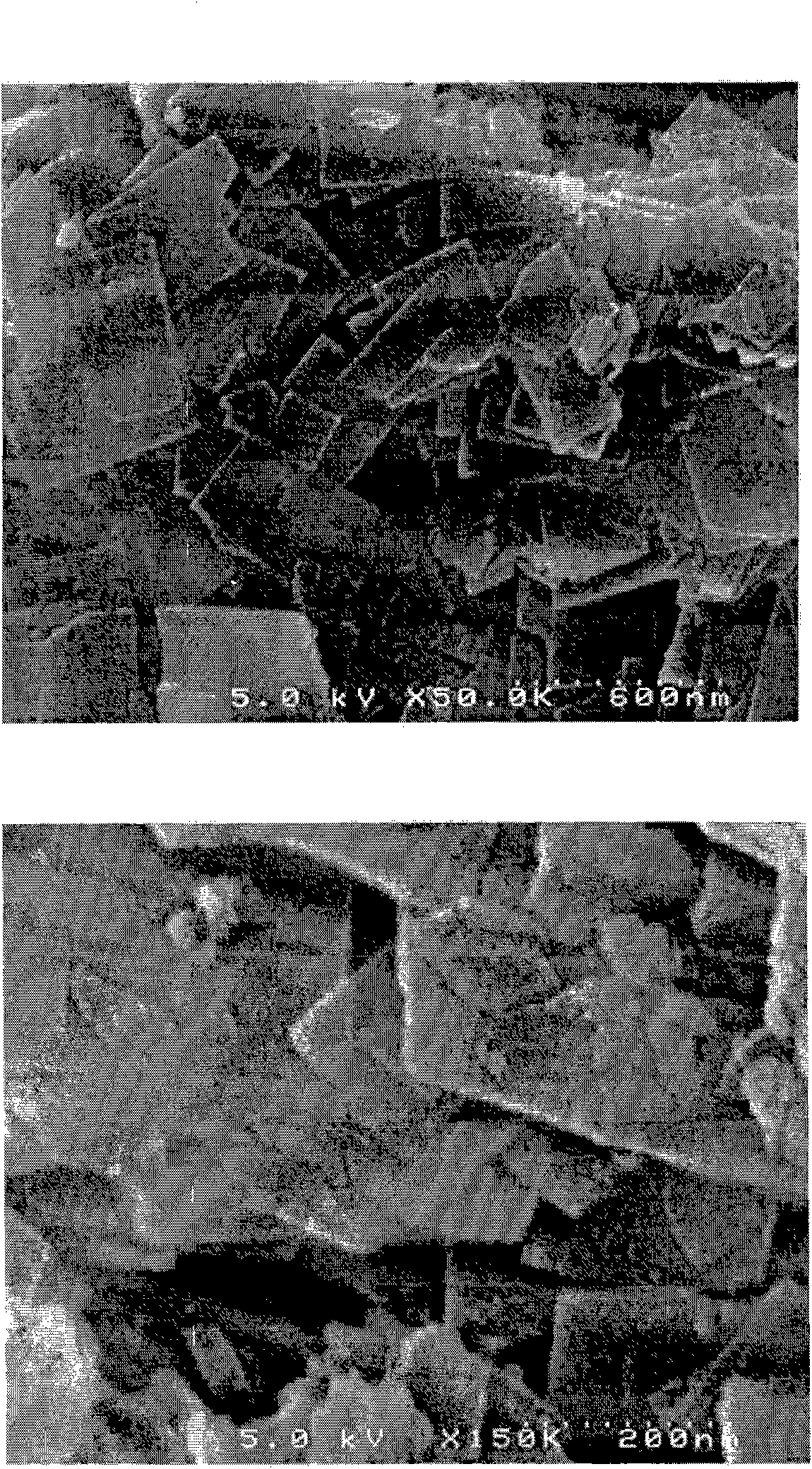

Metalloaluminophosphate molecular sieves with lamellar crystal morphology and their preparation

InactiveCN101679053AIncrease productionIncrease flexibilityMolecular sieve catalystsMolecular sieve catalystCrystal morphologyPhosphoric acid

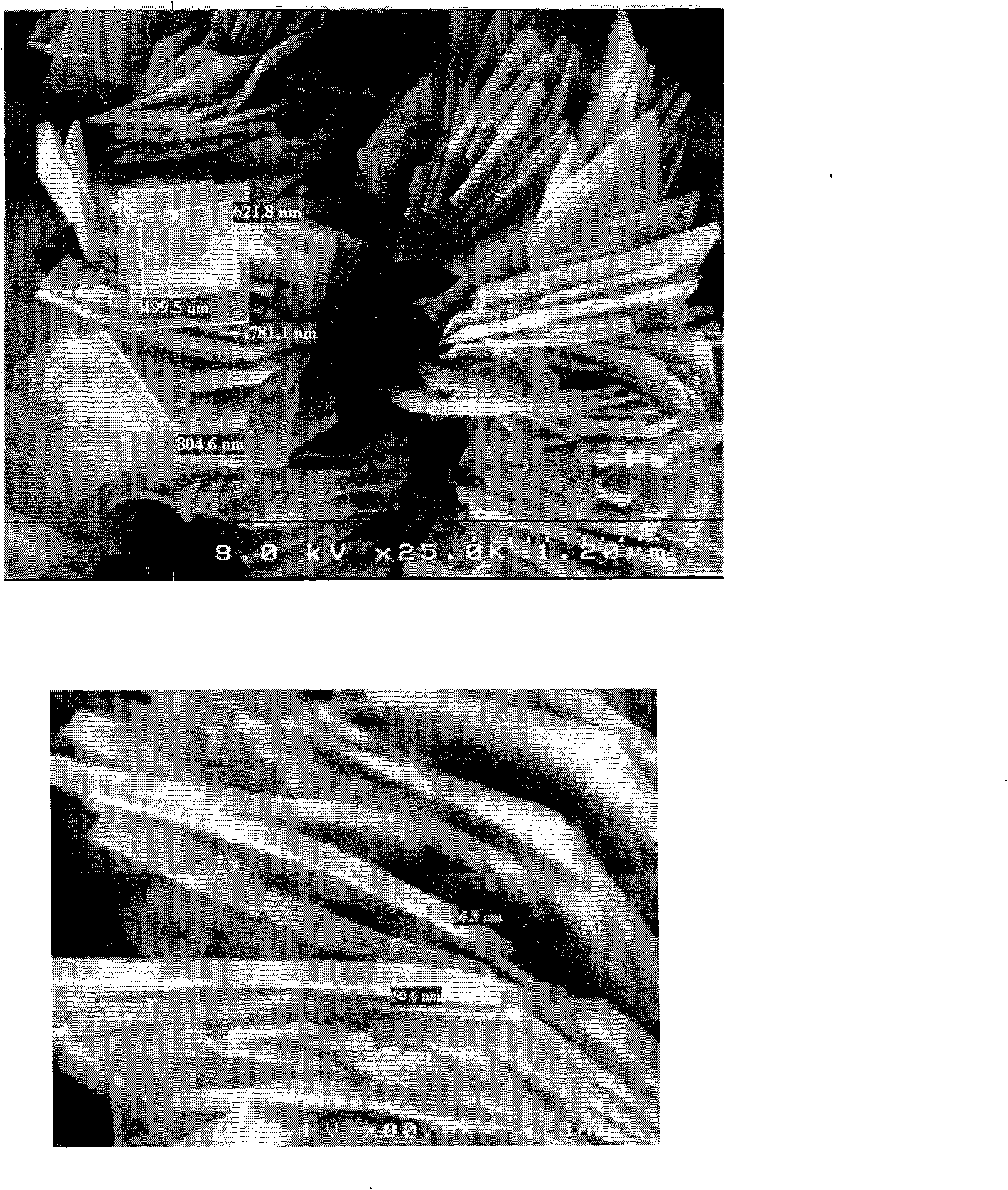

The present invention relates to metalloaluminophosphate (MeAPO) molecular sieve with lamellar crystal morphology having an empirical chemical composition on an anhydrous basis, after synthesis and calcination, expressed by the formula HxMeyAlzPkO2 wherein, y+z+k=1 and x<=y, said molecular sieve having predominantly a plate crystal morphology in which the width (W) and the thickness (T) are such as : W / T is >= 10 and advantageously ranges from 10 to 100. In a preferred embodiment T is <= 0.15 mum, more desirably <=0.10 mum, more desirably <=0.08 mum, advantageously ranges from 0.01 to 0.07 mumand preferably from 0.04 to 0.07 mum. The above metalloaluminophosphate (MeAPO) molecular sieve can be made by a method which comprises : a) forming a reaction mixture containing a texture influencing agent (TIA), an organic templating agent (TEMP), at least a reactive inorganic source of MeO2 insoluble in the TIA, reactive sources of Al2O3 and P2O5, b) crystallizing the above reaction mixture thus formed until crystals of the metalloaluminophosphate are formed, c) recovering a solid reaction product, d) washing it with water to remove the TIA and e) calcinating it to remove the organic template. In an advantageous embodiment the MeAPO of the invention have essentially a structure CHA or AEI or a mixture thereof. Preferably they have essentially the structure SAPO 18 or SAPO 34 or a mixture thereof. The present invention also relates to catalysts consisting of the above MeAPO molecular sieves or comprising the above MeAPO molecular sieves. The present invention also relates to a process for making an olefin product from an oxygen-containing, halogenide-containing or sulphur-containing feedstock wherein said oxygen-containing, halogenide-containing or sulphur-containing feedstock is contacted with the above catalyst under conditions effective to convert the oxygen-containing, halogenide-containing or sulphur-containing feedstock to olefin products.

Owner:TOTAL RES & TECH FELUY +1

Water phosphorus control technology and phosphorus locking agent

The invention discloses water phosphorus control technology and a phosphorus locking agent, and relates to the environment-friendly field of water pollution control and ecological restoration technology. Inorganic salt and hydrolysate thereof capable of releasing aluminum ions and the phosphorus locking agent for other aluminum-containing active sludge are thrown into the water, the phosphorus locking agent can slowly release the aluminum ions, and the aluminum ions are combined with phosphorus dissolved in the water and released in the bottom mud to generate more insoluble aluminium phosphate to permanently lock the active phosphorus in the natural water bottom so that the active phosphorus cannot be utilized by algae and aquatic animals and plants and the aim of permanently eliminating eutrophication is achieved. The water phosphorus control technology of the invention has the advantages of simple operation, quick response, little sludge, stable and durable effect and broad application. The phosphorus locking agent of the invention has the advantages of cheap, broad and readily available raw materials and medicaments, low cost, and safety, has no toxicity or pollution, also can be used for treating pollution by using waste, and is convenient for popularization and application.

Owner:路林茫

Preparation method for magnesium alloy cast paint

InactiveCN101342570AReduced hot cracking tendencyImprove insulation effectFoundry mouldsFoundry coresWrinkle skinPhosphoric acid

The present invention relates to a method for preparing magnesium casting coating; 0.7 percent of paligorskite clay that is configured with 17 percent of water is milled for 3 hours to be made into solution A; secondly 5 percent of talcum powder, 3 percent of diatomite, 0.5 percent of KBF4 and 1 percent of aluminium phosphate are put into a spherical mill, and is respectively mixed with solution A, 3 percent of silica sol and 67.6 percent of water to be milled for 3 hours to obtain the magnesium alloy metal-typed casting coating; metal mould is heated to be about 200 DEG C, and then is sprayed with a layer of magnesium alloy casting coating on the surface, and is dried finally. The method of the present invention has the advantages of strong heat preservation, flame retardant performance, sticking performance and coating performance, favorable suspension performance and less heat fracture of the casting piece. Oxidation is prevented, so the surface is bright and smooth and is free from oxidized wrinkle.

Owner:ZHONGHONG (TIANJIN) IND CO LTD

Nanometer material modified bi-component aqueous epoxy anticorrosive paint and manufacturing method thereof

InactiveCN101921532AStrong adhesionReduce adhesionAnti-corrosive paintsEpoxy resin coatingsPolymer scienceFirming agent

Owner:HUIZHOU LIDE TECH CO LTD

Nano-class film-wrapped powder and preparation method thereof

InactiveCN1876728AGood dispersionGood weather resistanceInorganic pigment treatmentAluminium phosphateNanometre

The invention provides the nanometer integument powder which is made at the machinery-chemical action. It has inner core and integument, or inner, shell and integument. The inner core is composed by oxide compound or inorganic oxy salt, shell is composed by inorganic oxy salt, and the integument is composed by aluminum orthophosphate. The powder surface can be carried out anchorage solvating chain segment. The invention also provides the preparing method. The integument powder can be used as coloring agent, strengthening agent, powdered material to be used in coating mixture, rubber, plastic, admixture, ceramics, paper and magnetic material.

Owner:张义纲 +1

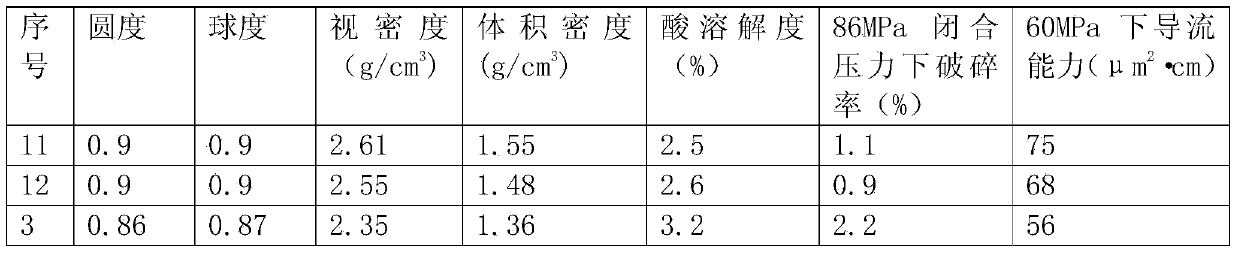

Petroleum fracturing proppant and preparation method thereof

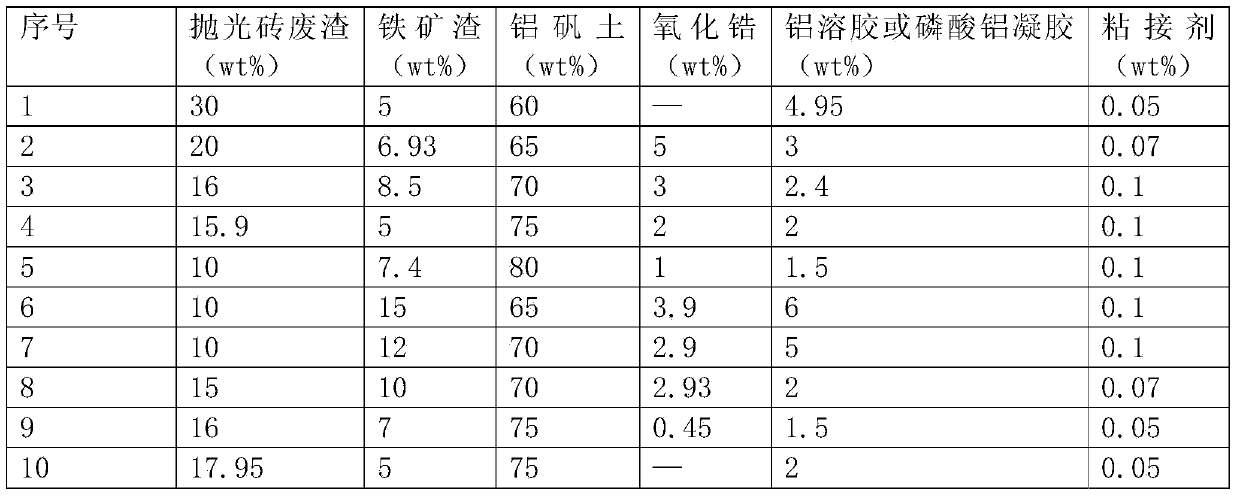

The invention relates to a petroleum fracturing proppant and a preparation method thereof. The petroleum fracturing proppant is prepared from the following components by weight percent: 60-80% of bauxite, 10-30% of polished tile waste residues, 5-15% of iron ore slag, 0-5% of zirconia, 1.5-6% of aluminium sol or aluminium phosphate gel and 0.05-0.1% of adhesives. Tests show that the volume density of the petroleum fracturing proppant provided by the invention is 1.26-1.69g / cm<3>, the apparent density is 2.07-2.96g / cm<3>, and the crushing rate under the closure pressure of 86MPa is less than 5%. The petroleum fracturing proppant has the excellent characteristics of low and medium density, high strength and the like. Plenty of polished tile waste residues and iron ore slag are utilized in the raw materials, thus being favorable for reducing pollution and reducing the pressure of the waste residues of waste materials on the environment. Besides, the mineral components in the polished tile waste residues and the iron ore slag can serve as mineralizers in a calcining preparation process, thus reducing the production energy consumption while promoting the product performance.

Owner:FOSHAN DONGPENG CERAMIC +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com