Preparation method for hierarchically mesoporous gamma-Al2O3 nanorods

A nanorod, grade technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of high cost, difficult to realize industrialization, difficult to control process conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Take 80ml of the prepared aluminum nitrate solution with a concentration of 1mol / L, add 27.4g of sucrose and 16g of PEG2W, stir to dissolve, and call it solution A1. Take 80ml of prepared ammonium carbonate solution with a concentration of 1.2mol / L, which is called solution B1.

[0023] (2) Under the condition of stirring, the solution A1 and the solution B1 are simultaneously added into a 200ml beaker for reaction in a co-current manner, and the reaction temperature is room temperature.

[0024] (3) Add 20ml of ammonia water with a concentration of 25% to the mixed solution obtained in (2), and adjust the p hour value of the system to 9.5.

[0025] (4) After aging the mixed solution obtained in (3) for 24 hours at room temperature, put it into a 200ml reactor, and conduct a hydrothermal reaction at 100°C for 24 hours;

[0026] (5) Filter the product obtained in (4), wash the filter cake with distilled water until the pH is 7-8, dry at 80°C for 48 hours; finally ro...

Embodiment 2

[0029] The preparation steps of this example are the same as Example 1, and the difference from Example 1 is that the PEG2W in Step 1 is changed from 16g in Example 1 to 24g.

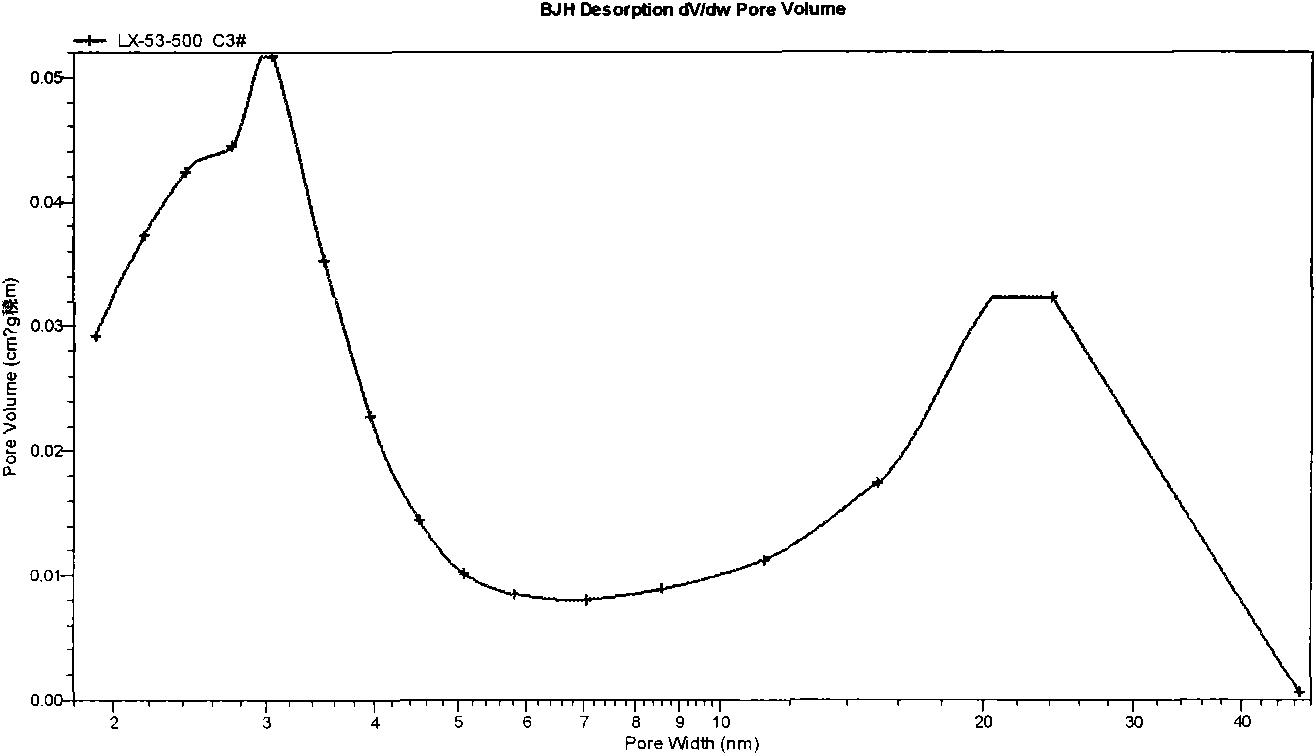

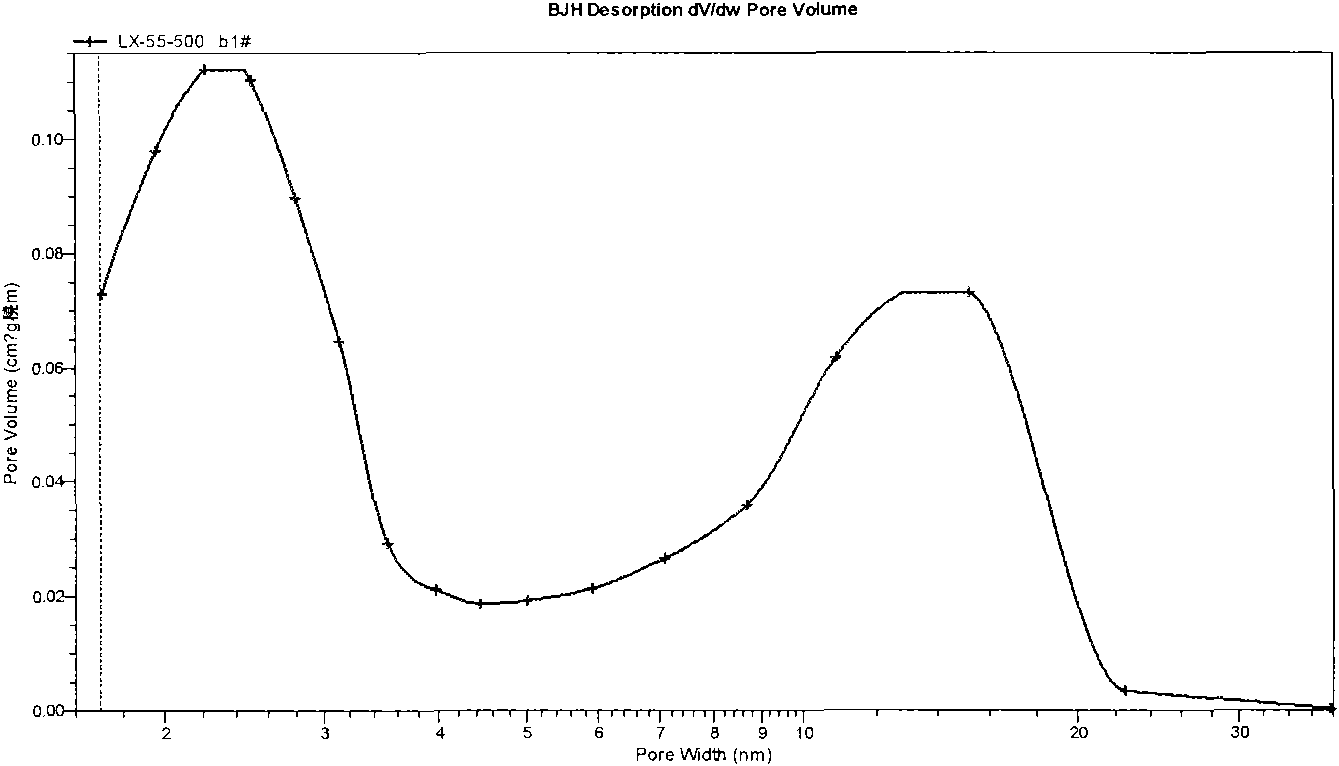

[0030] The main physical and chemical properties of alumina: the specific surface area is 343.2m 2 / g, the pore volume is 1.54cm 3 / g, the pore size distribution is as figure 1 Shown: Double peaks appear at 3nm and 18nm, and the average pore diameter is 17.91nm.

Embodiment 3

[0032] The preparation steps of this example are the same as Example 1, and the difference with Example 1 is only that the concentration of the ammonium carbonate solution in Step 2 is changed from 1.2M in Example 1 to 5M.

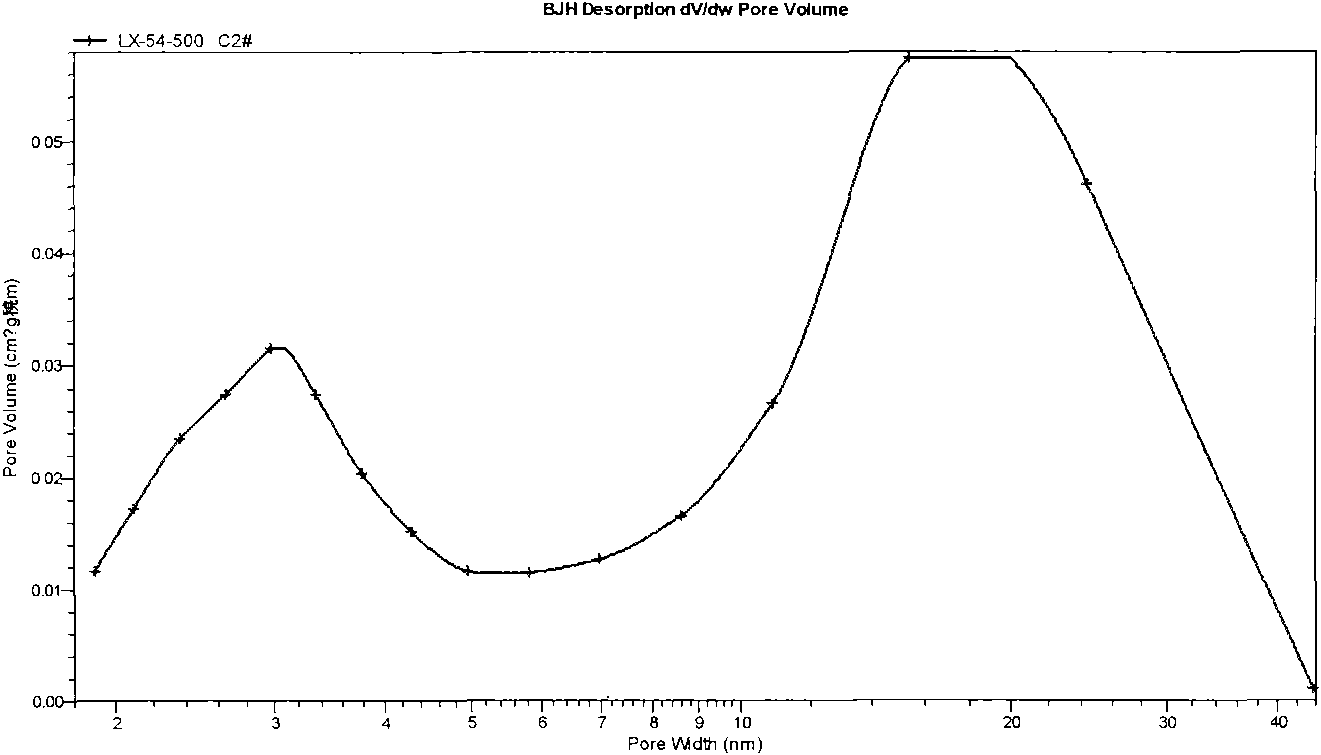

[0033] The main physical and chemical properties of alumina: the specific surface area is 493.5m 2 / g, the pore volume is 1.07cm 3 / g, the pore size distribution is as figure 1 Shown: Double peaks appear at 2.4nm and 14.2nm, with an average pore size of 8.70nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com