Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

700results about "Varistor cores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

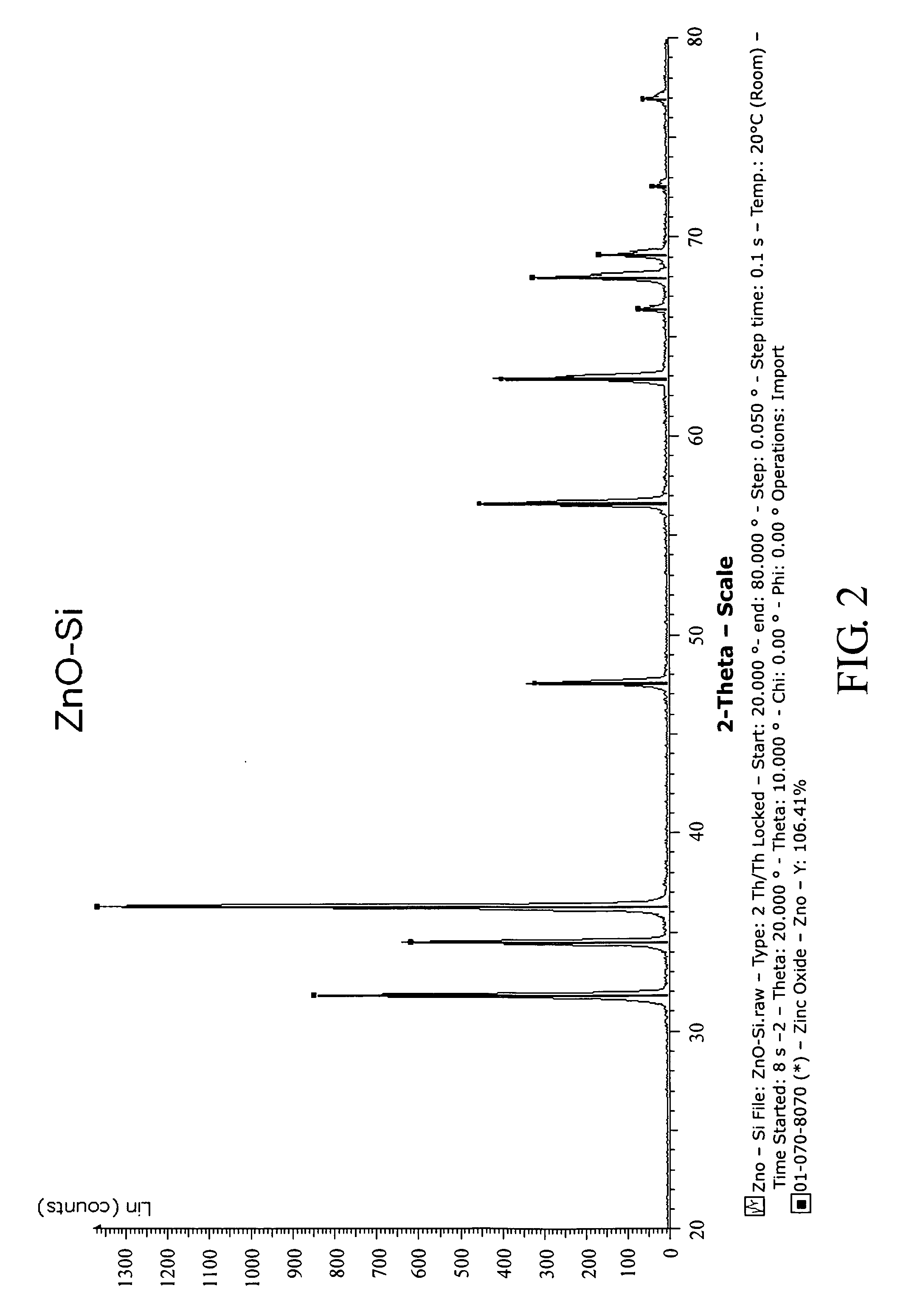

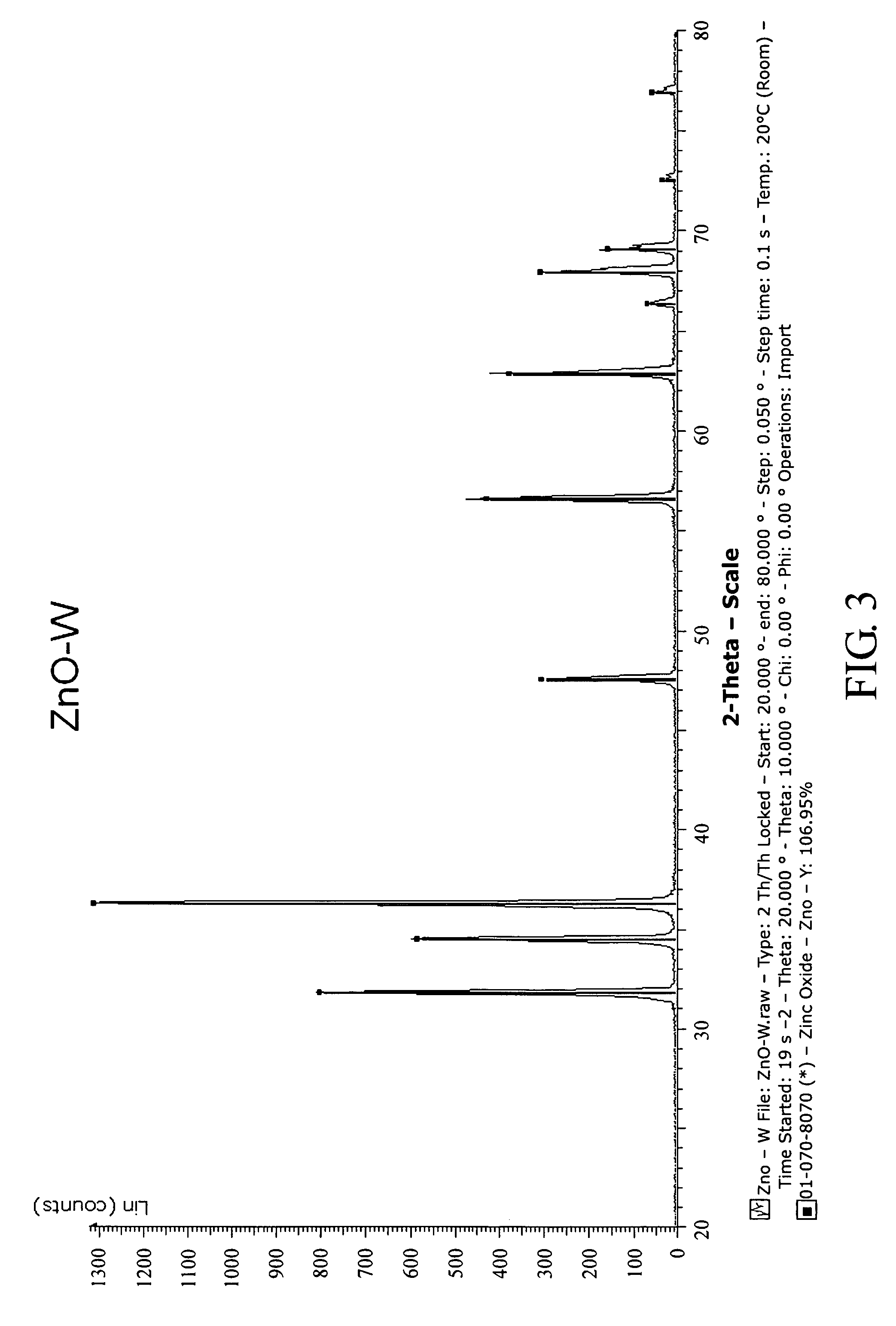

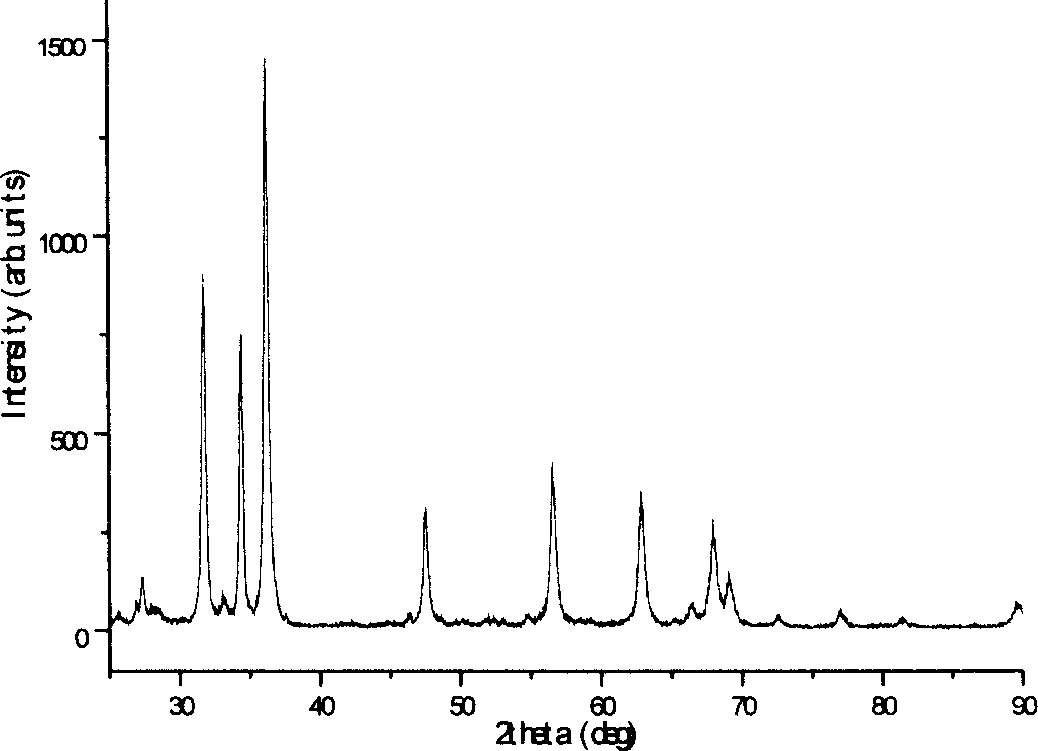

Varistors based on nanocrystalline powders produced by mechanical grinding

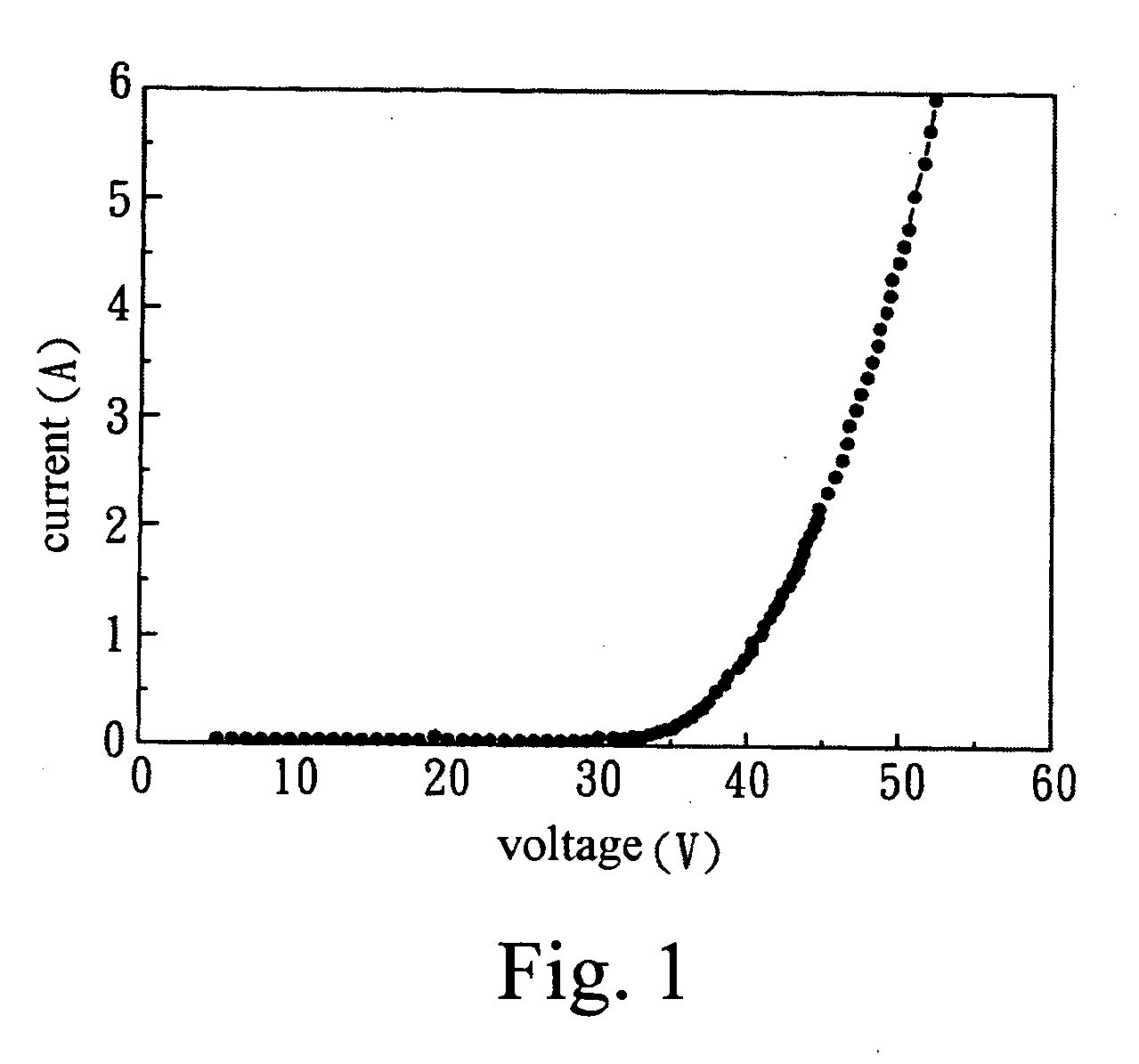

InactiveUS6620346B1Lower breakdown voltageImprove breakdown voltageMaterial nanotechnologyConductive materialGrain boundaryBreakdown voltage

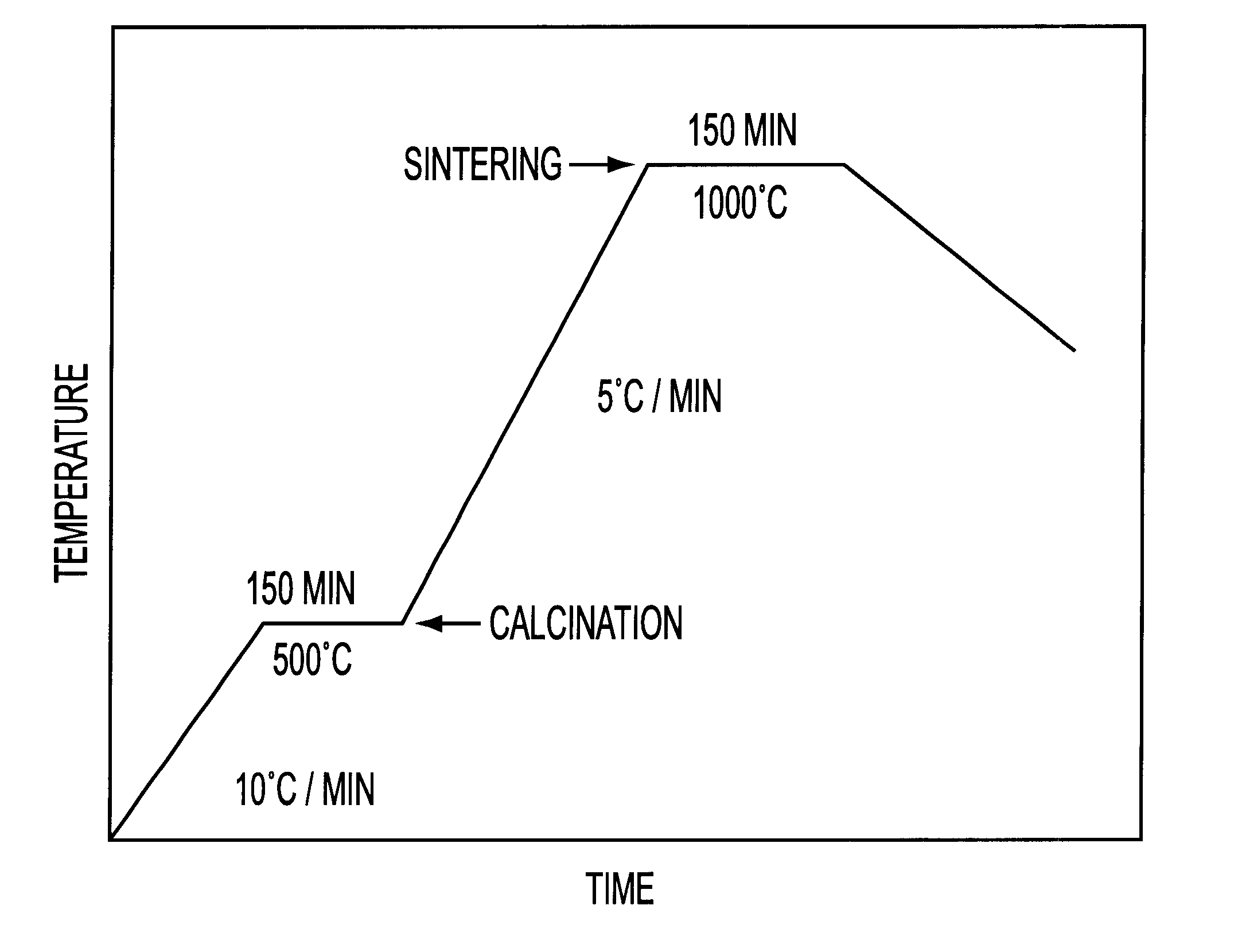

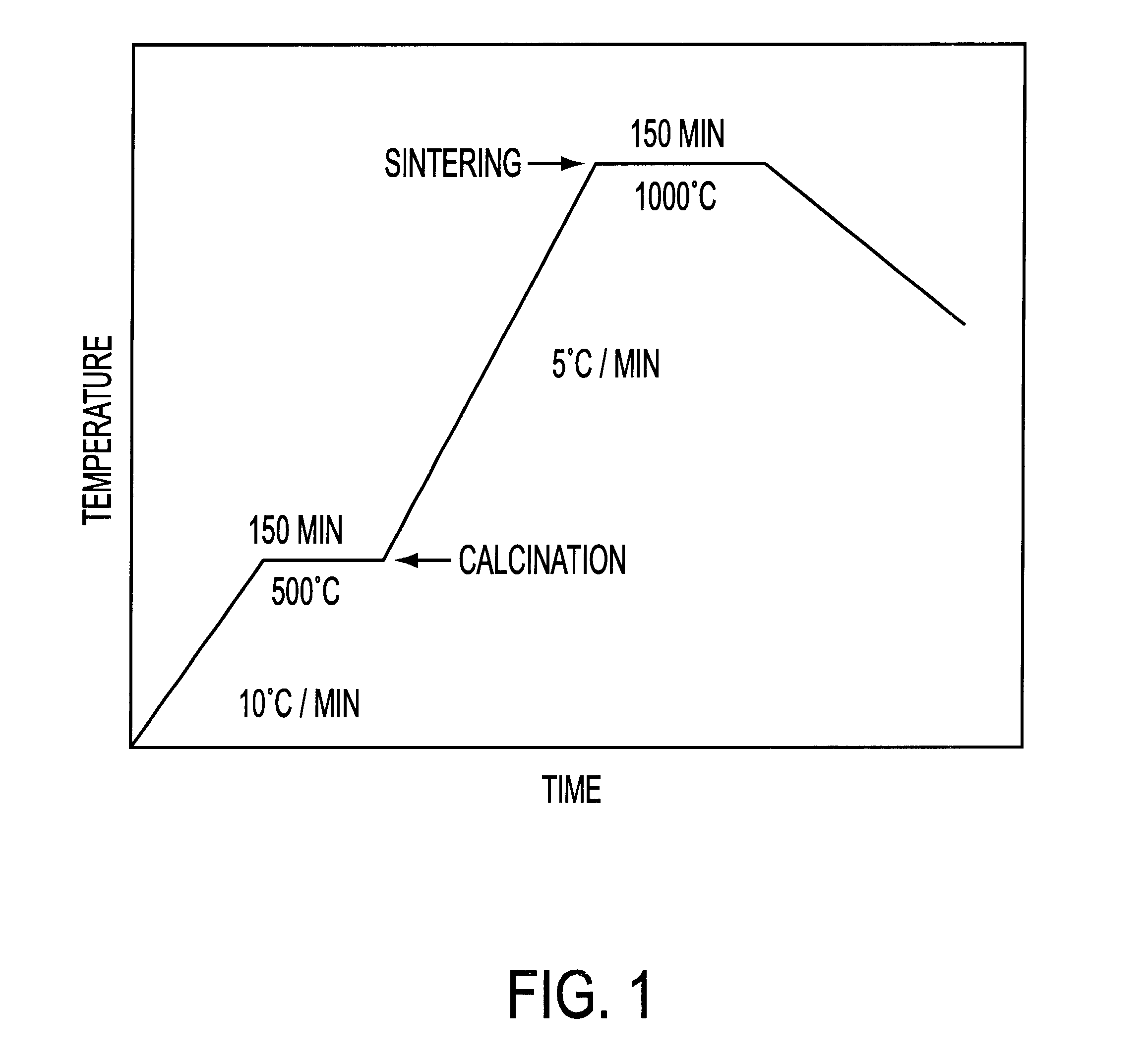

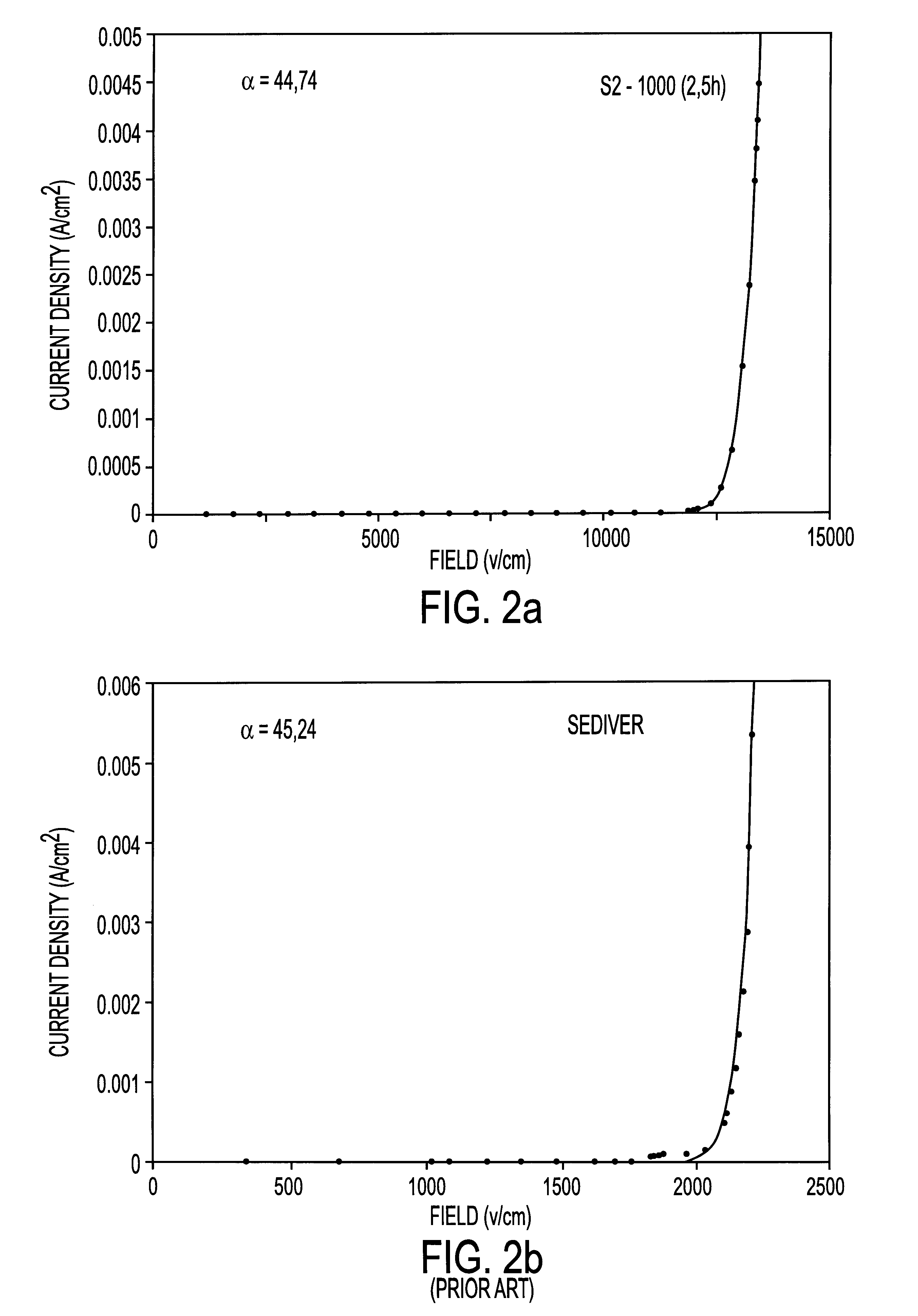

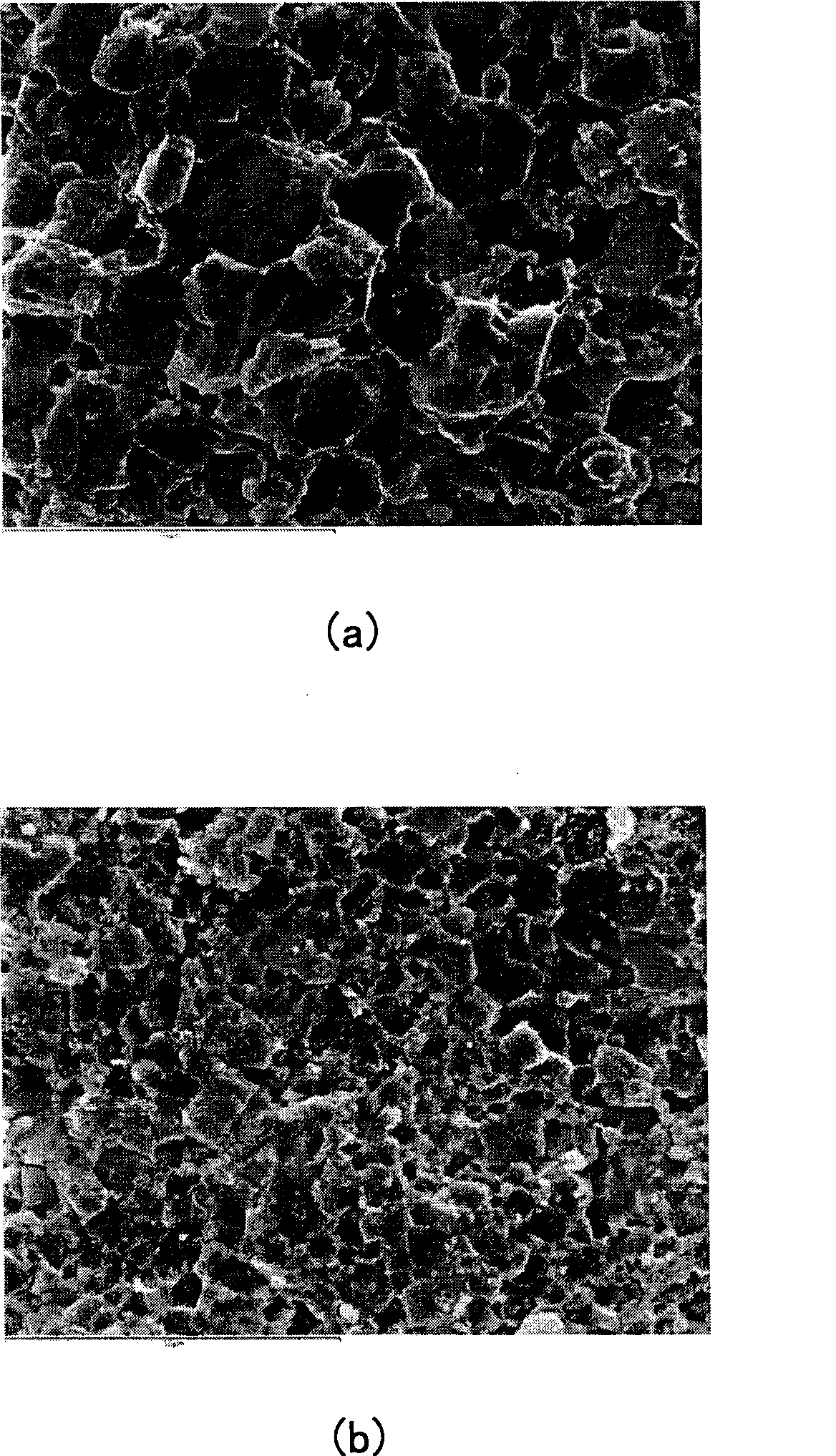

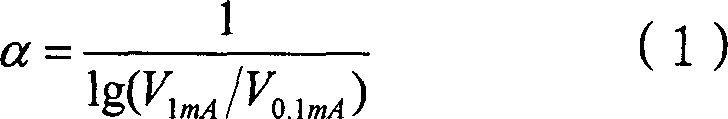

The invention concerns novel varistors based on zinc oxide and a method for making same, which consists in using as base products nanocrystalline powders obtained by high-intensity mechanical grinding and in subjecting the mixture resulting from said nanocrystalline powders a consolidating treatment such as sintering, in suitably selected temperature and time conditions so as to retain the smallest possible grain size of ZnO. The resulting varistors have a very fine homogeneous microstructure and an average grain size characteristically not more than 3pm, i.e. five times smaller than standard materials. Said novel varistors have a larger number of grain boundaries per unit length unit and therefore a much higher breakdown voltage. Said voltage is characteristically higher than 10 kV / cm and can reach 17 kV / cm which is almost one order of magnitude above the breakdown voltage of standard varistors. The non-linearity coefficient of the current-voltage curve is also improved, and is greater than 20 and can reach values as high as 60. Moreover, the leakage currents below the breakdown voltage of said varistors, are much lower.

Owner:HYDRO QUEBEC CORP

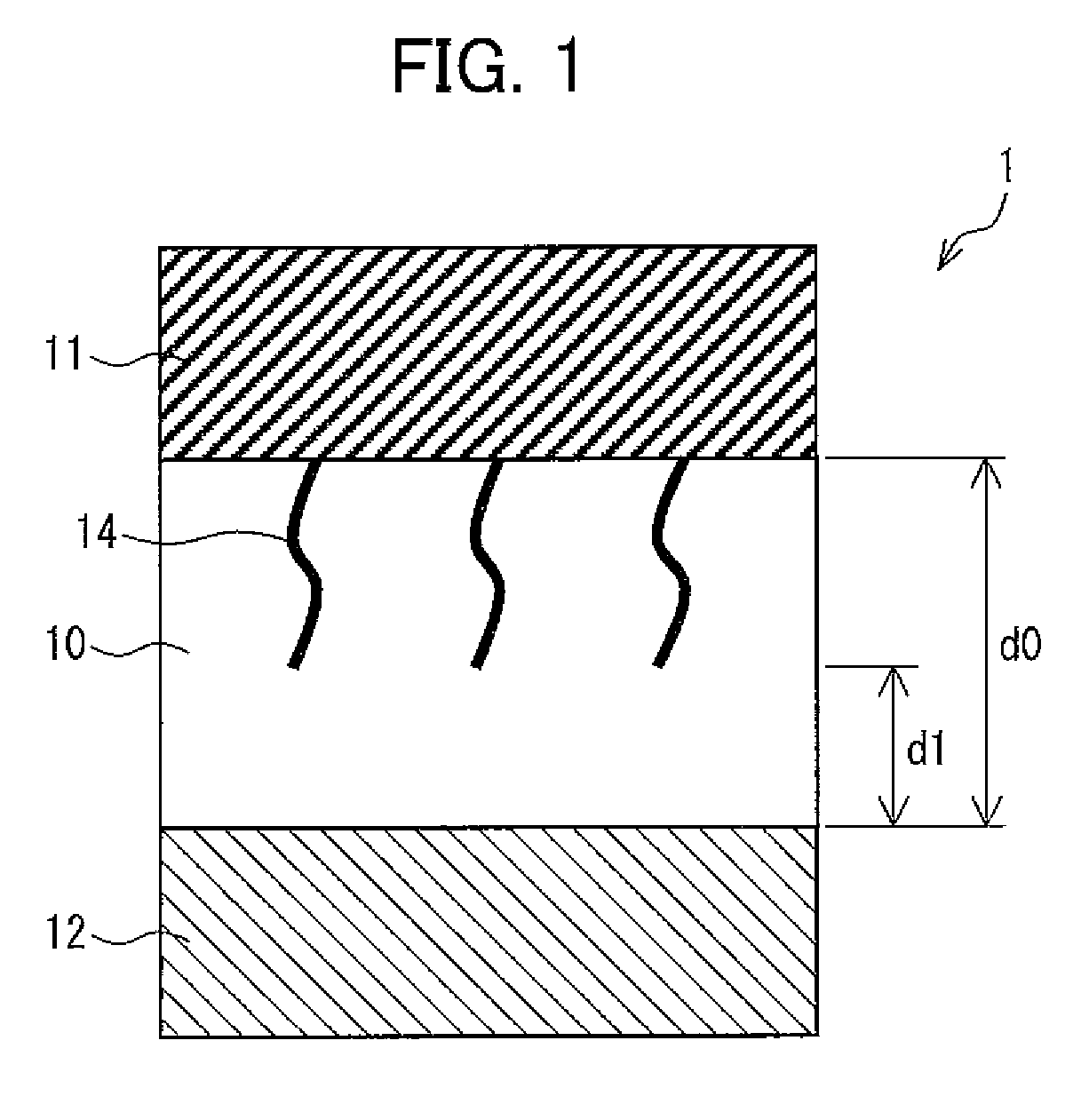

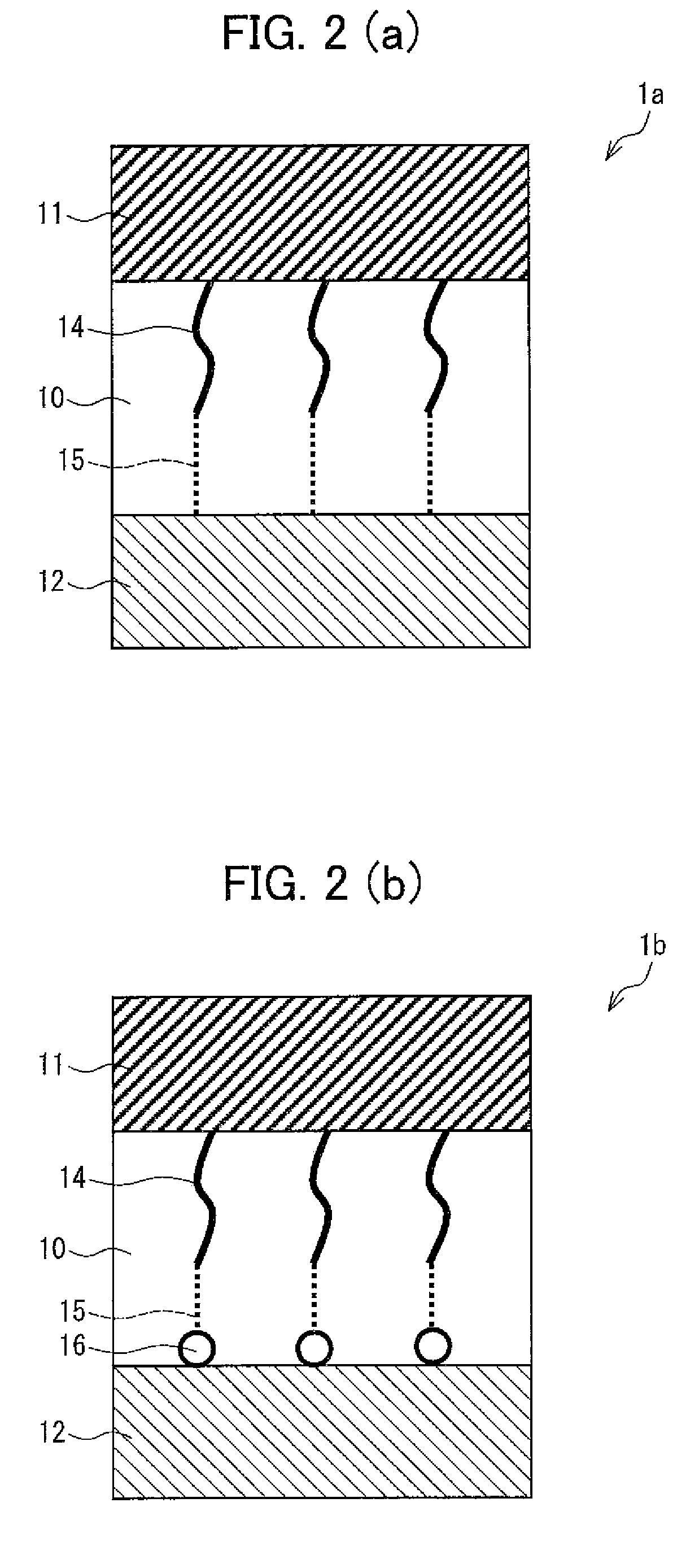

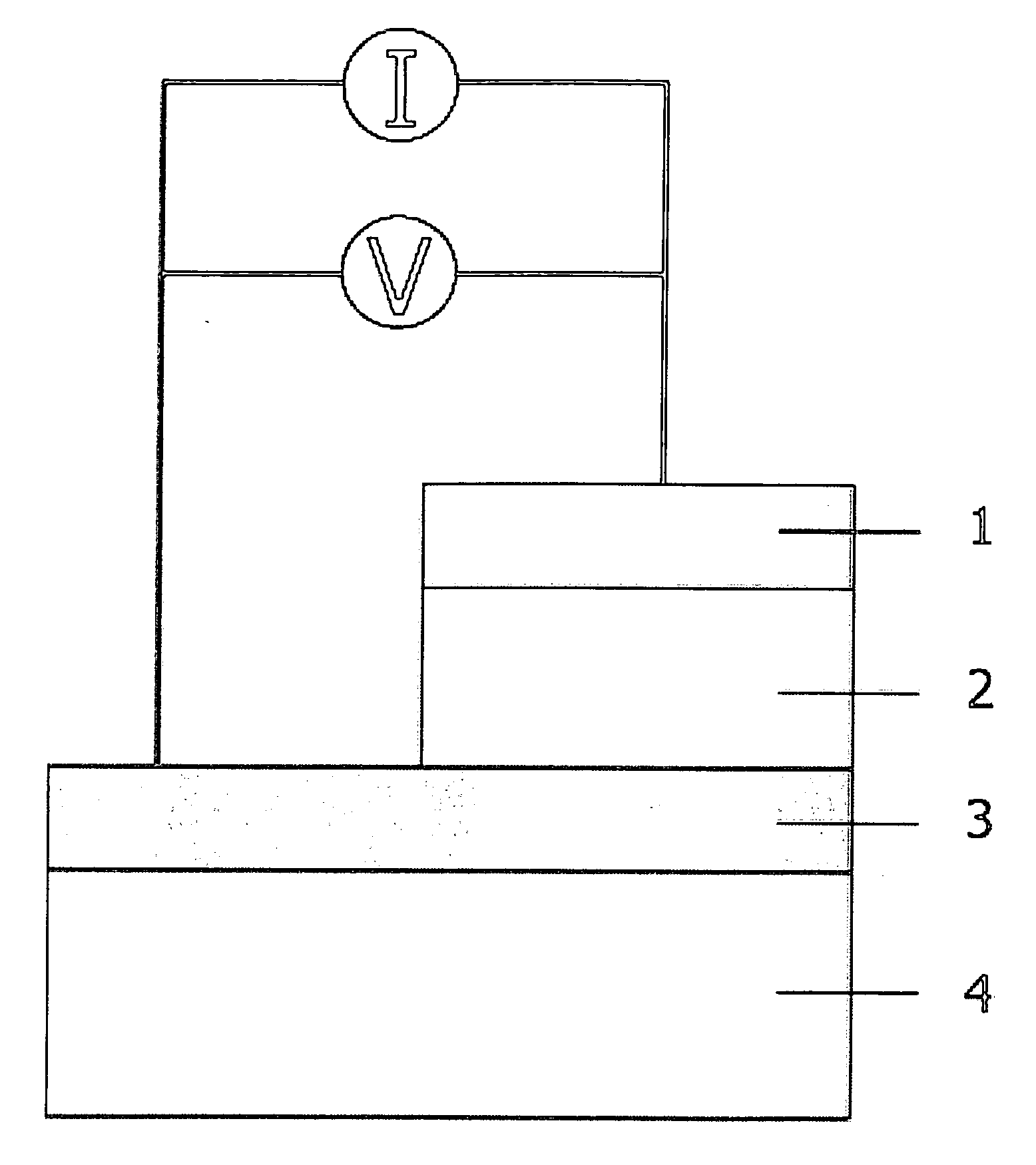

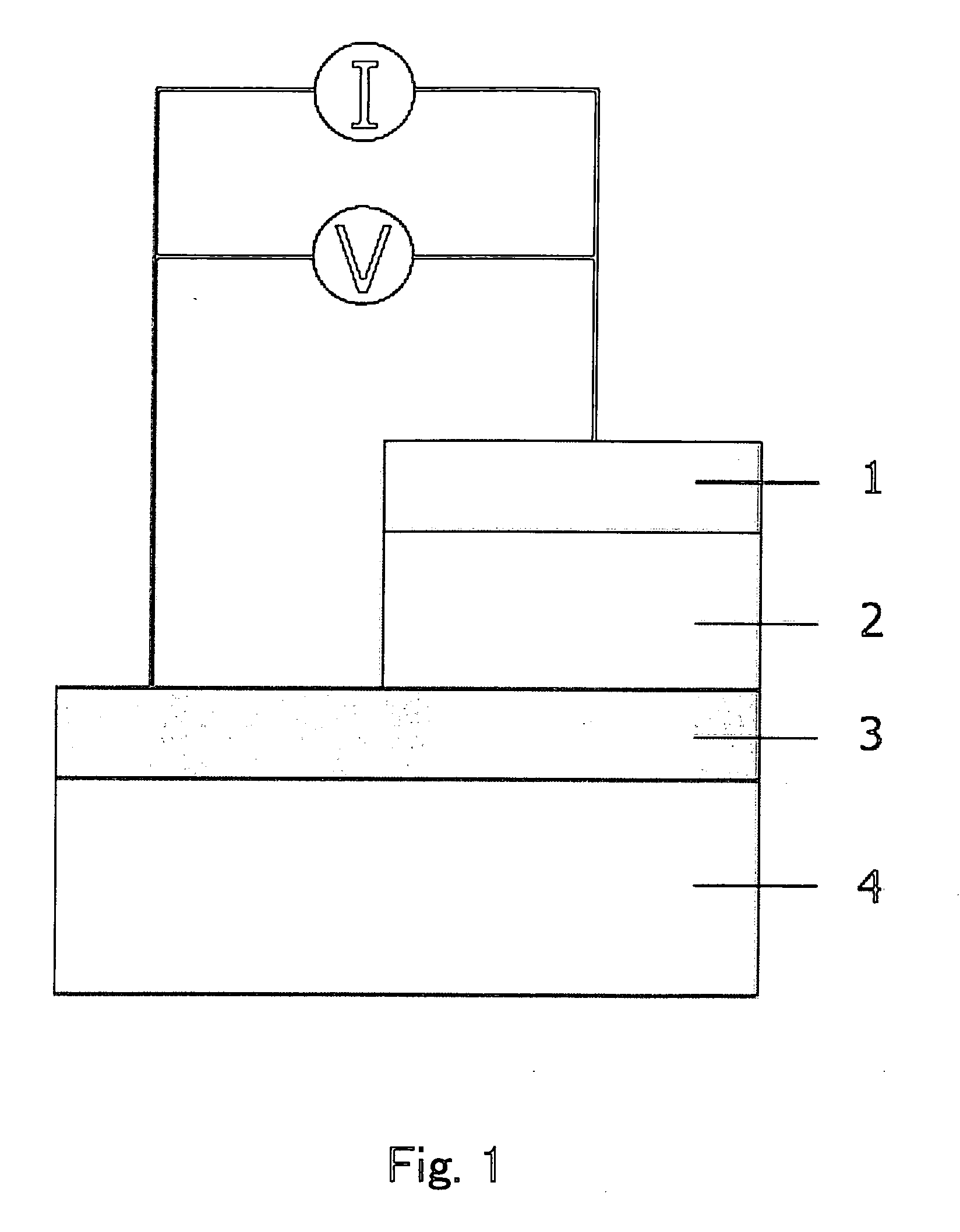

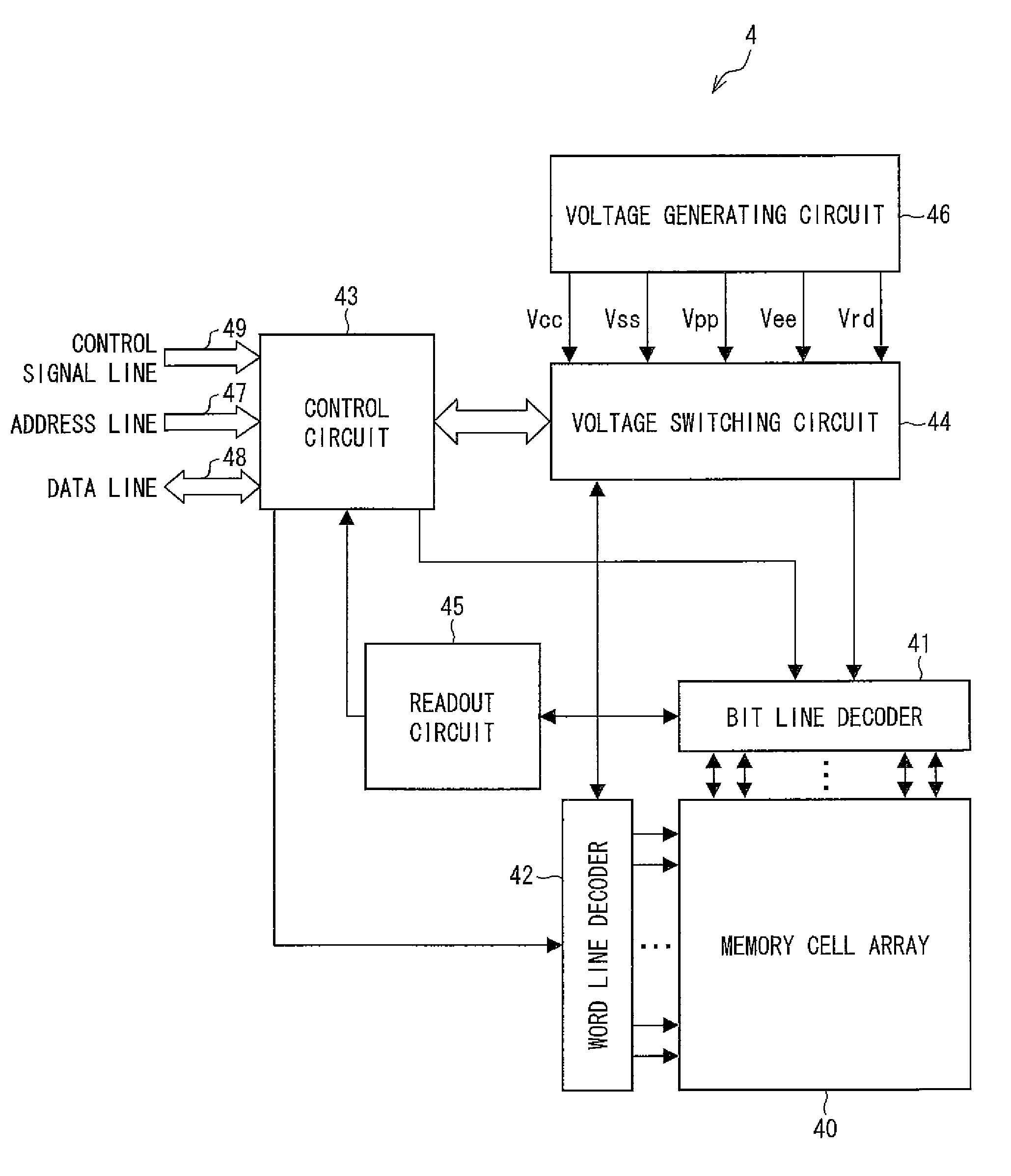

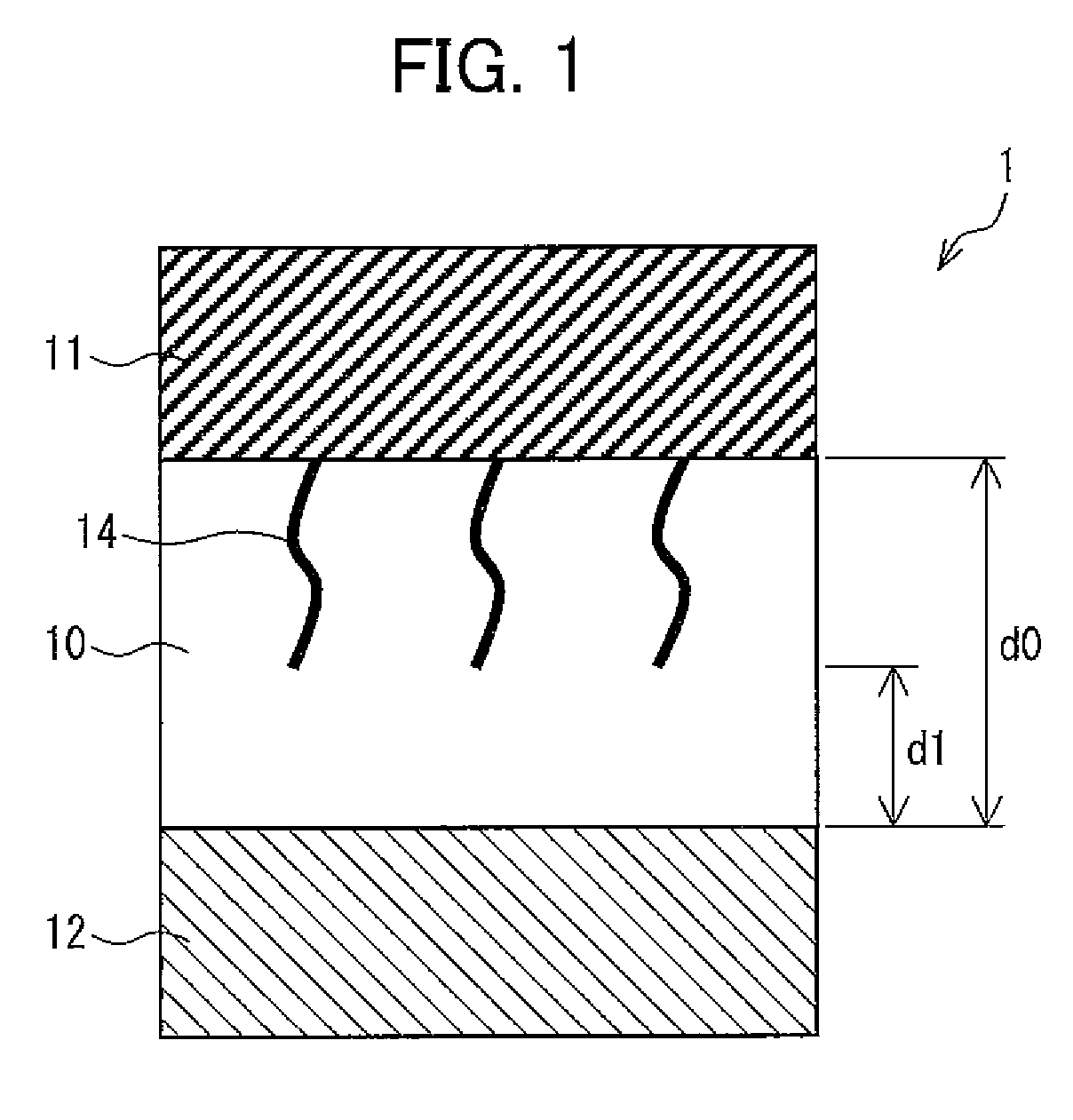

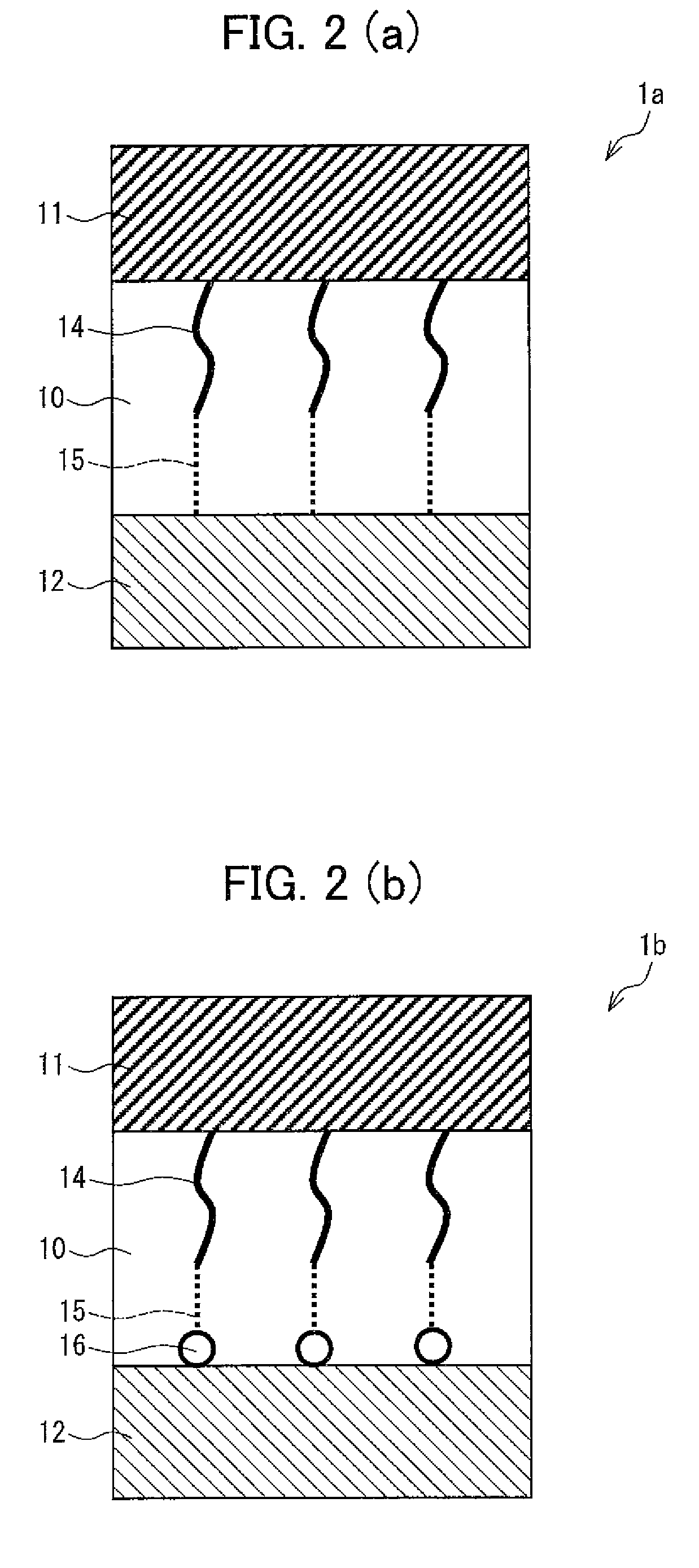

Variable resistance element, method for producing the same, and nonvolatile semiconductor storage device

InactiveUS20090147558A1Forming voltage can be reducedReduce voltageCurrent responsive resistorsDigital storageElectrical resistance and conductanceSemiconductor storage devices

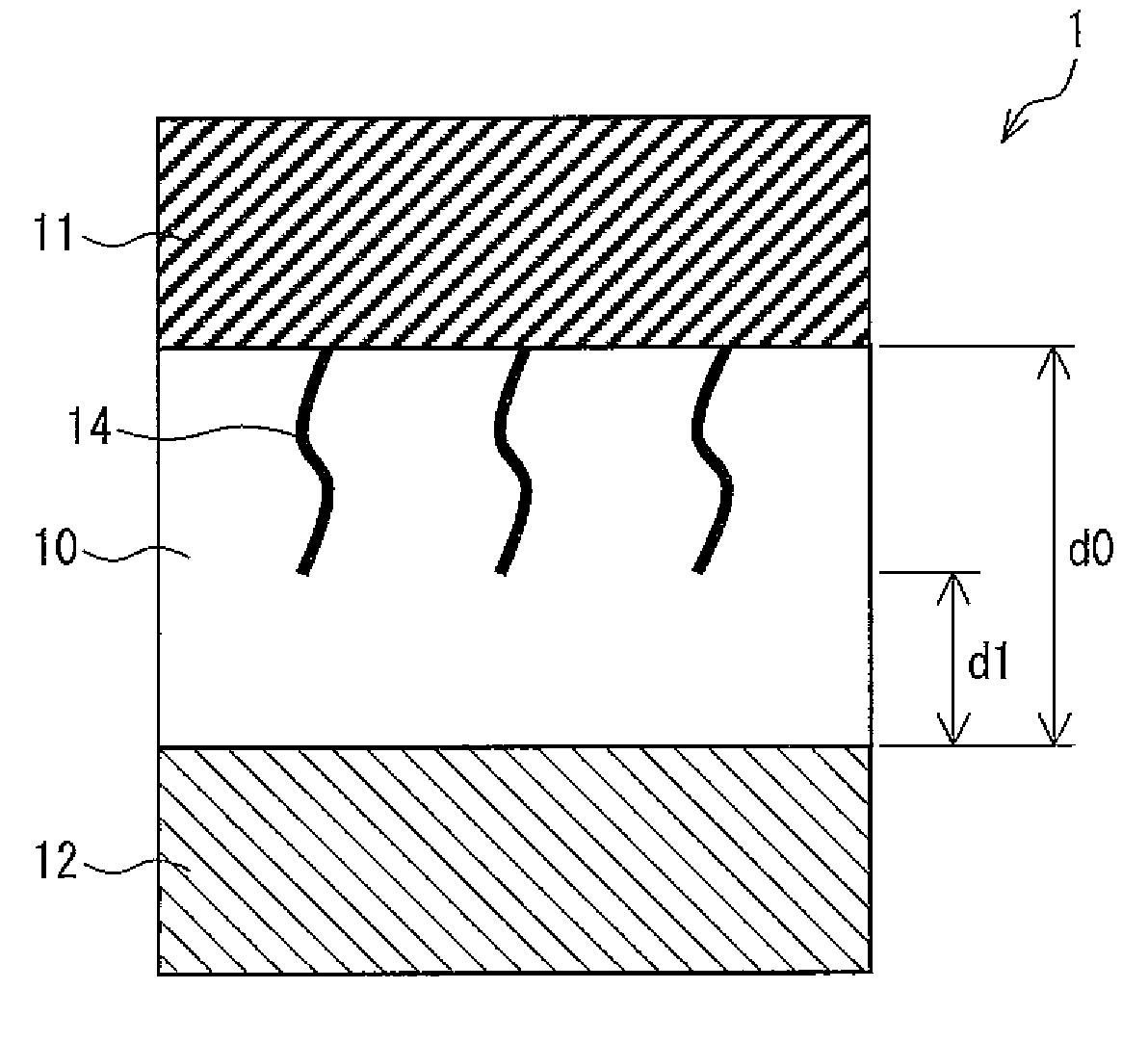

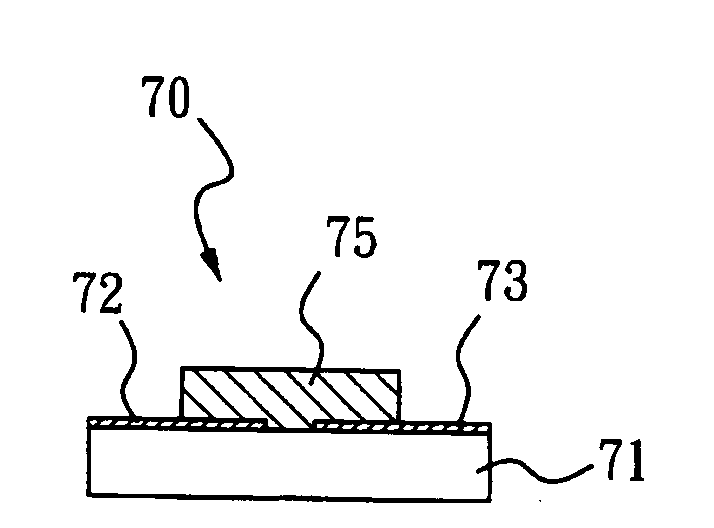

The variable resistance element of the present invention is a variable resistance element having an electrode, the other electrode, and a metal oxide material sandwiched between the electrodes and having an electrical resistance, between the electrodes, changing reversibly in response to a voltage applied between the electrodes. The variable resistance element further includes, inside the metal oxide material, a low resistance material having a lower electrical resistance than the metal oxide material and being out of contact with at least either one of the electrodes. This makes it possible to reduce a forming voltage for providing a conductive section inside the metal oxide material, without causing a leakage current to increase.

Owner:SHARP KK +1

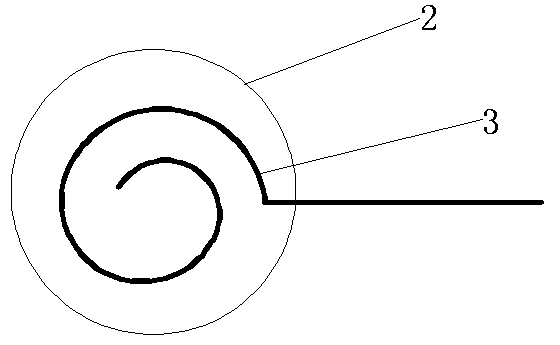

Nanomaterials for quantum tunneling varistors

ActiveUS7132697B2Easy to manufactureMaterial nanotechnologySemiconductor/solid-state device detailsConductive coatingAtomic layer deposition

So-called quantum tunneling varistors are made with a matrix of particles having a nonconductive coating that is deposited on core conductive particles using atomic layer deposition methods. The resulting coated particles have highly uniform, adherent coatings that allow easier production of good quality quantum tunneling varistor devices.

Owner:UNIV OF COLORADO THE REGENTS OF

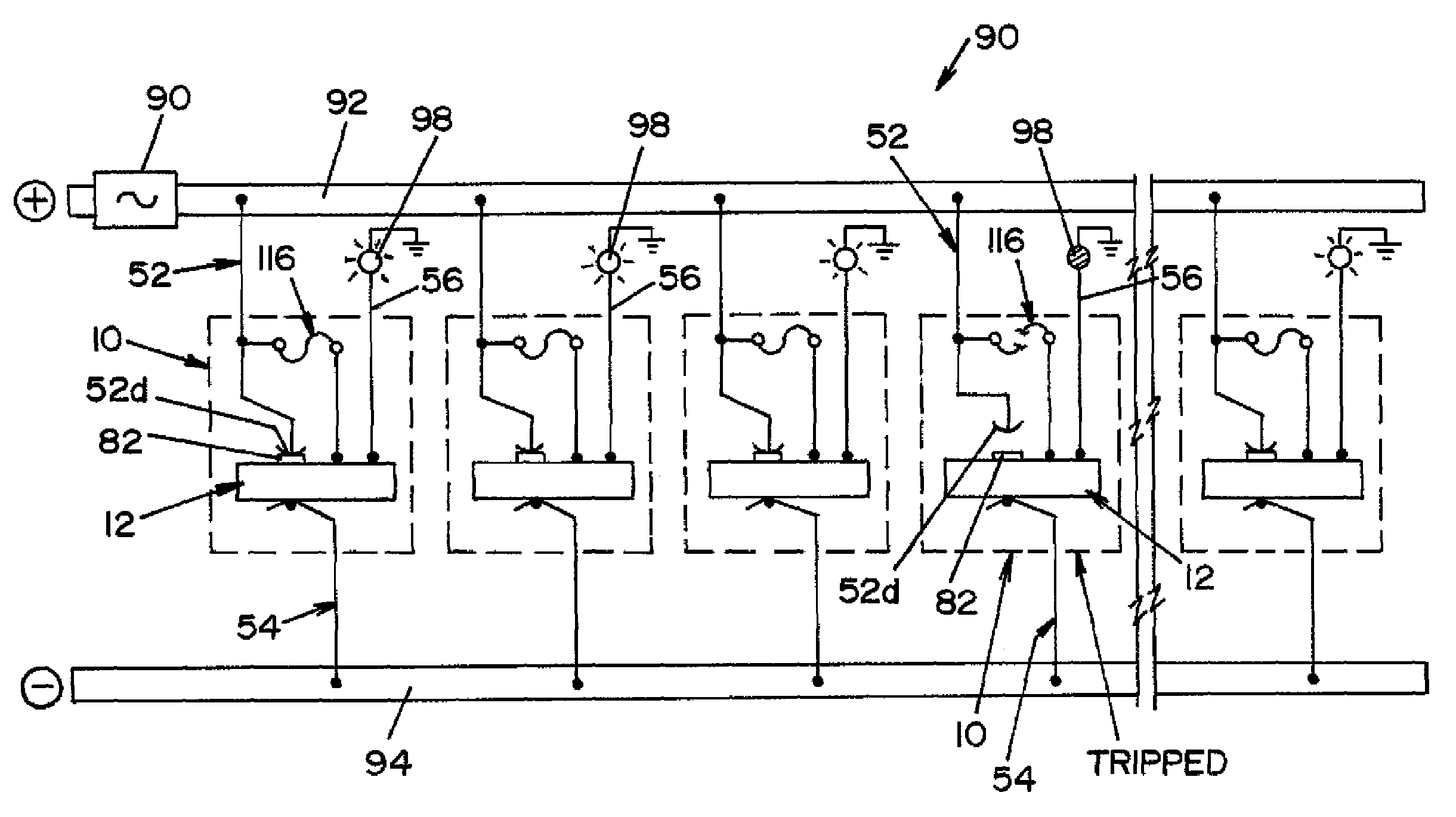

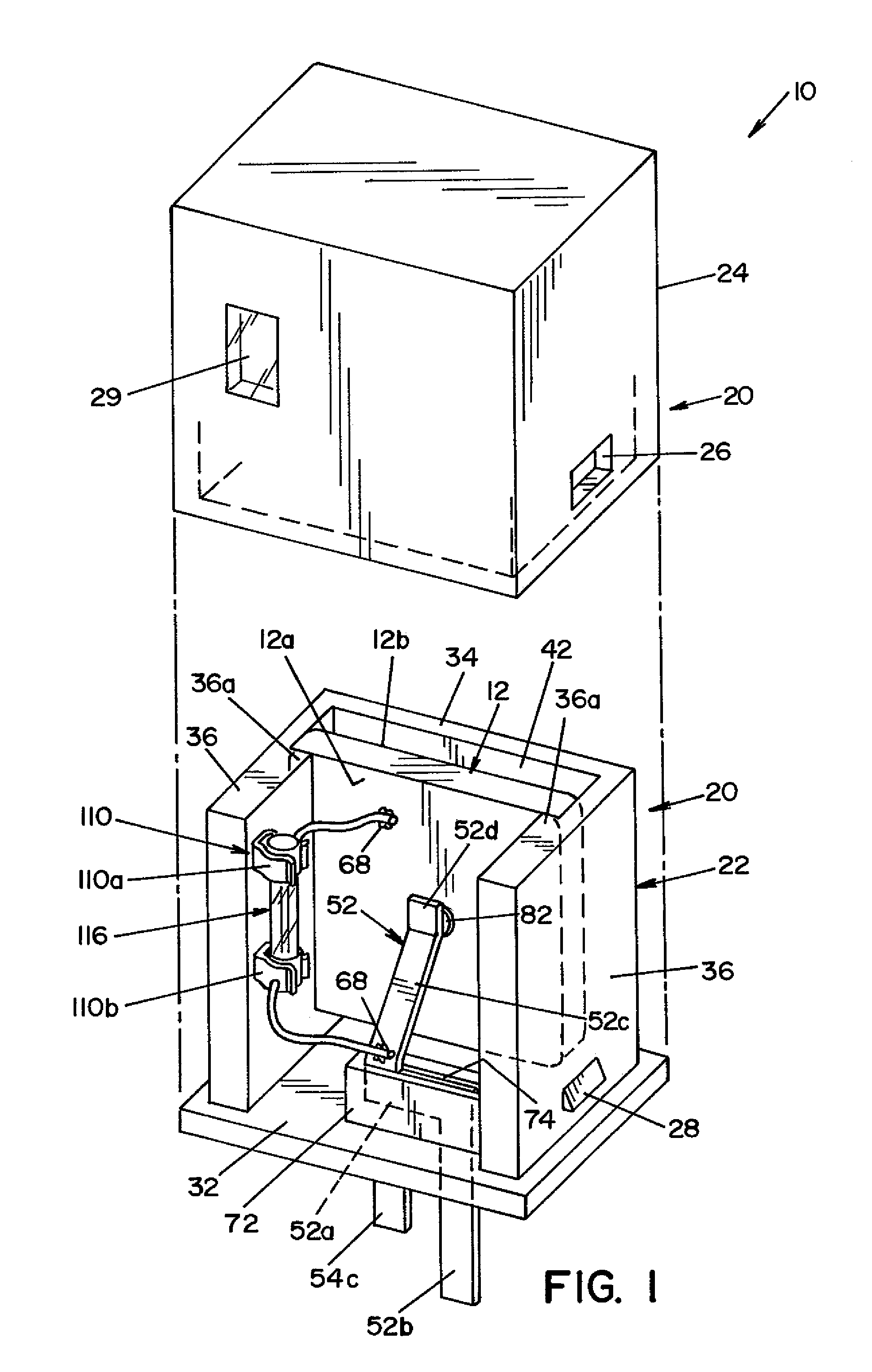

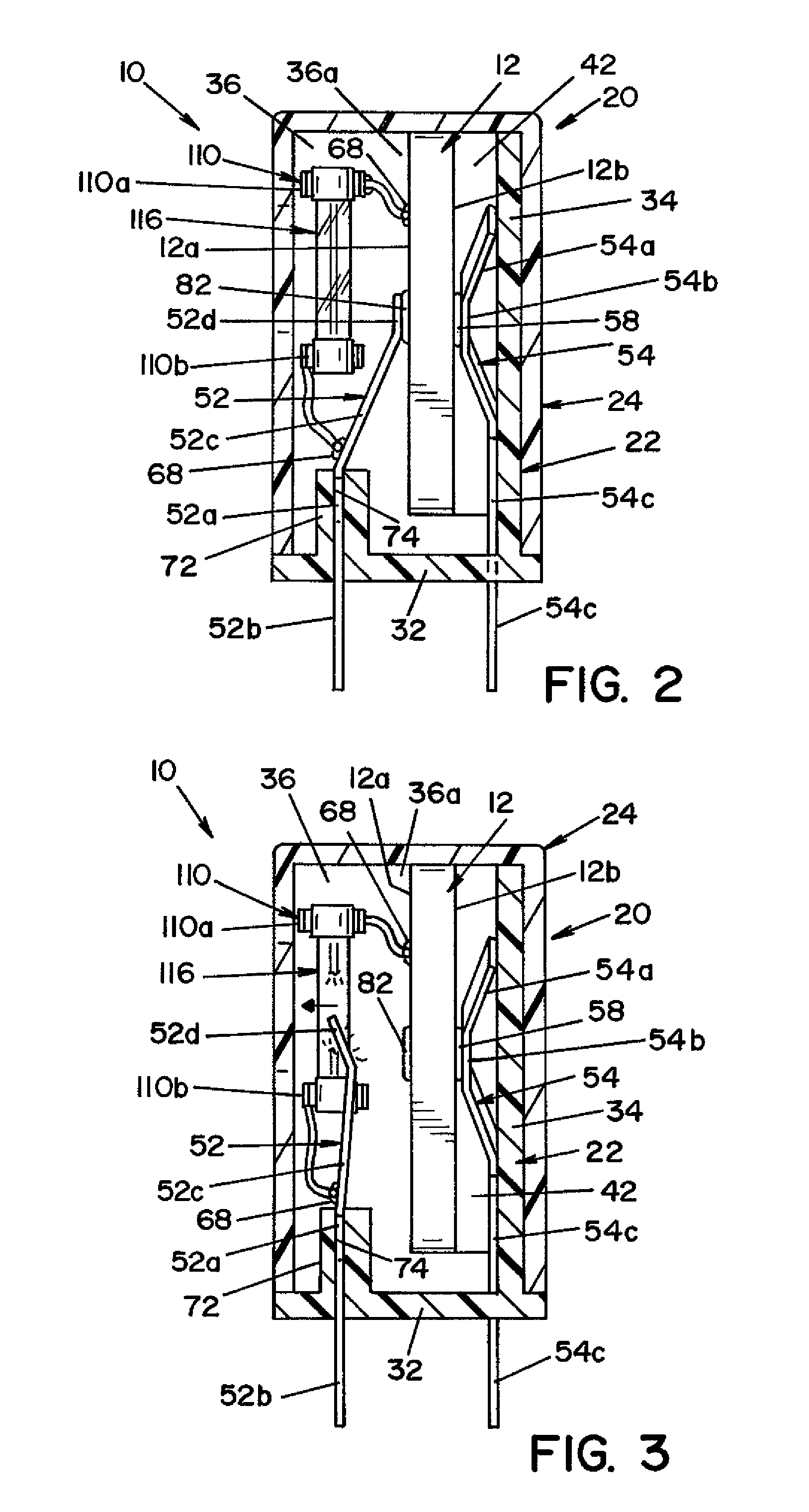

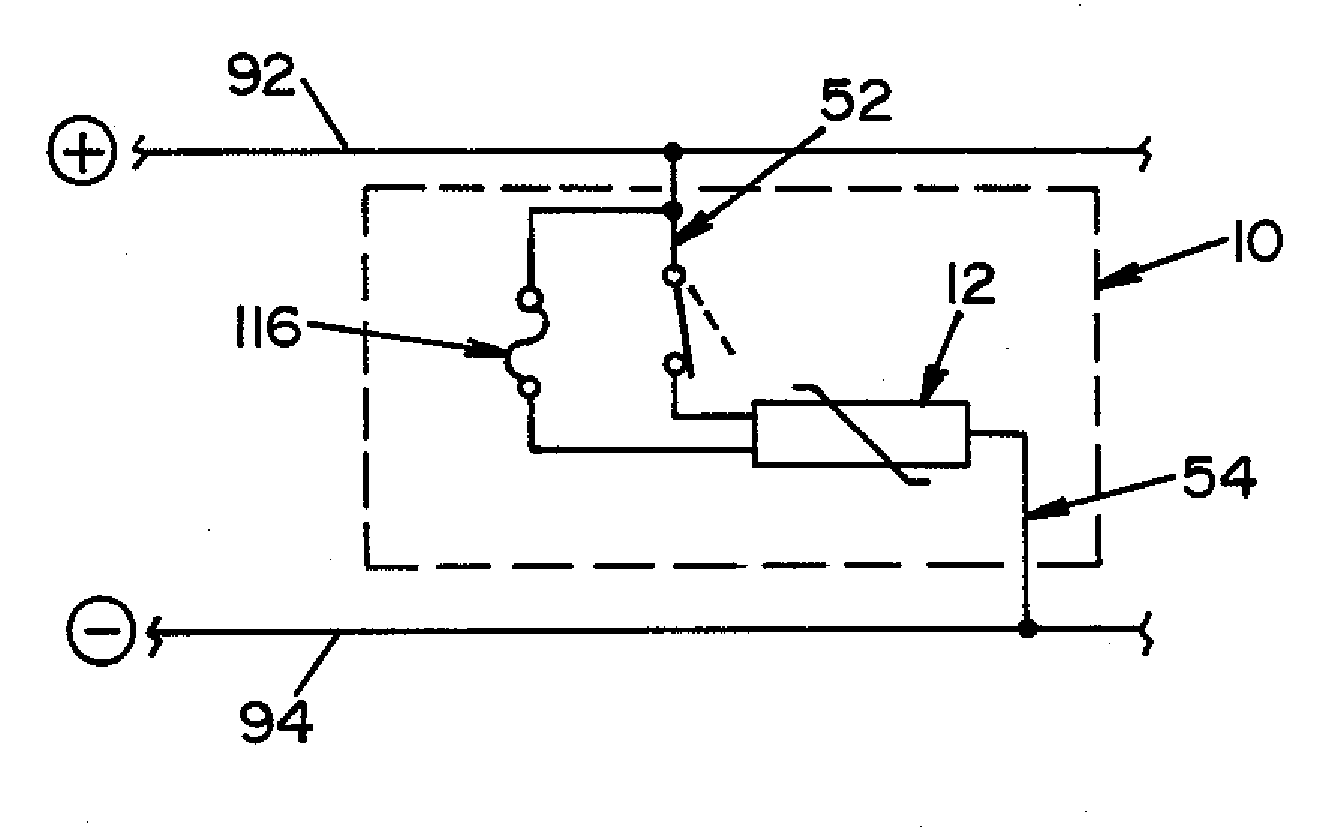

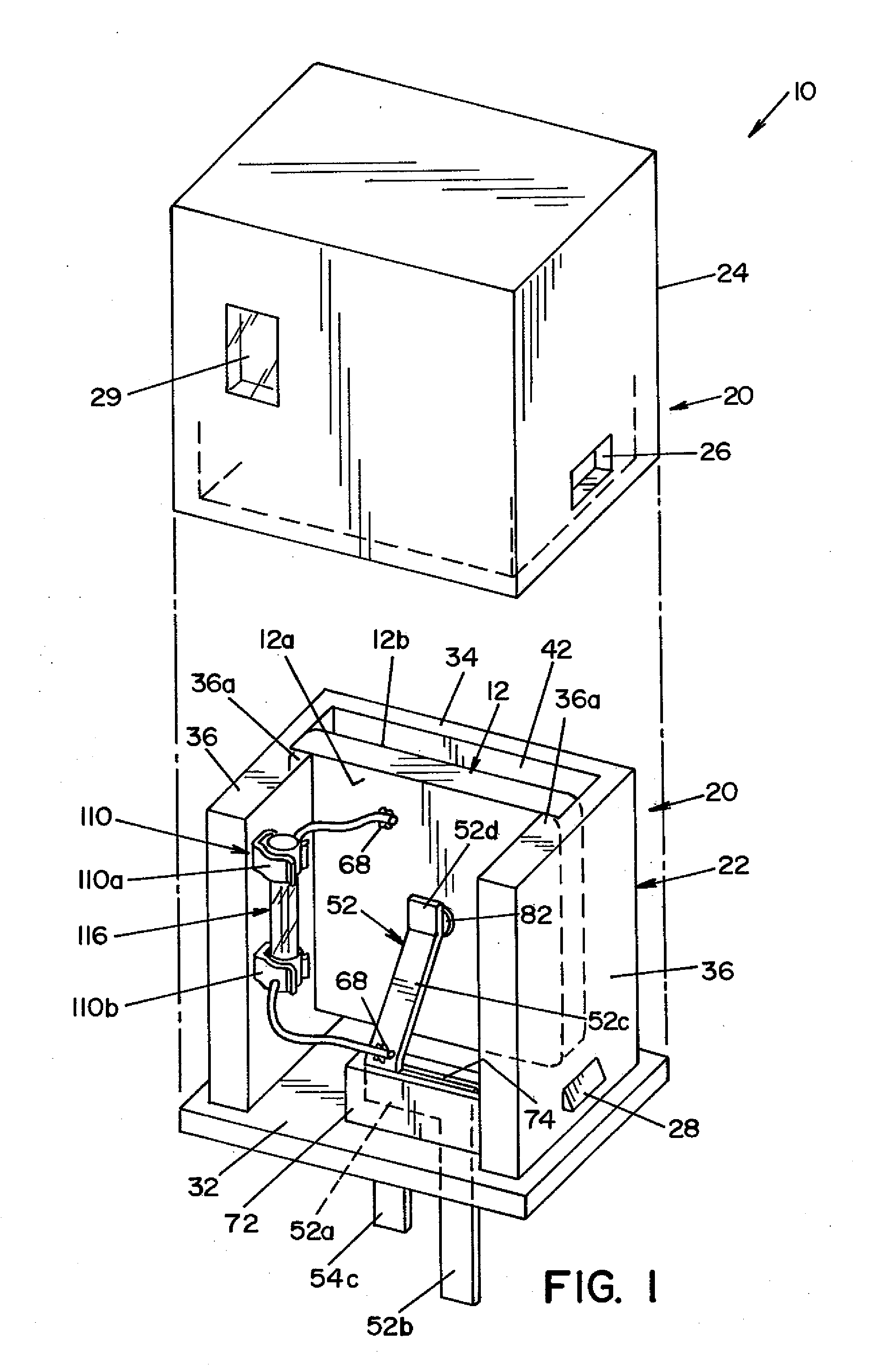

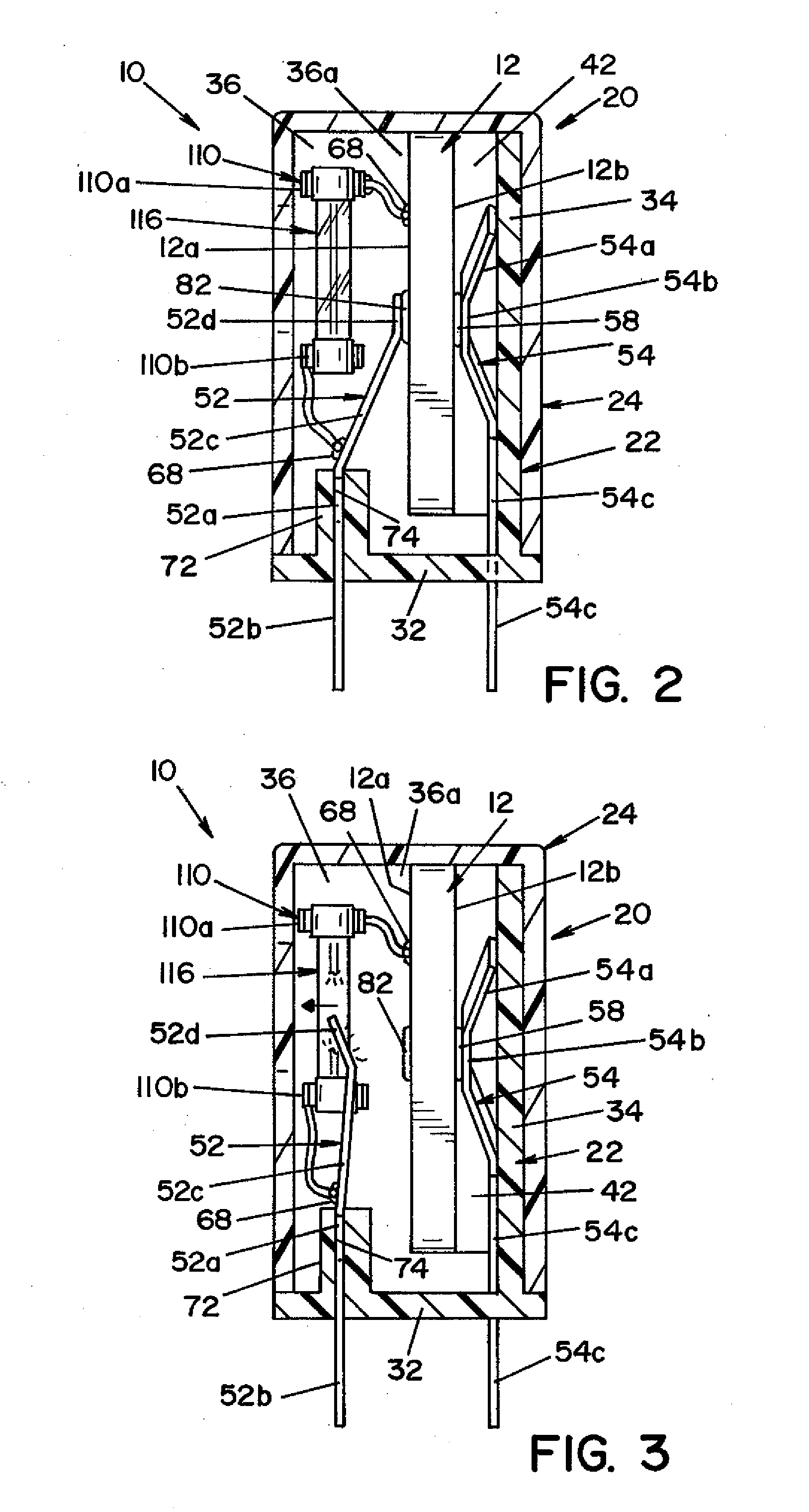

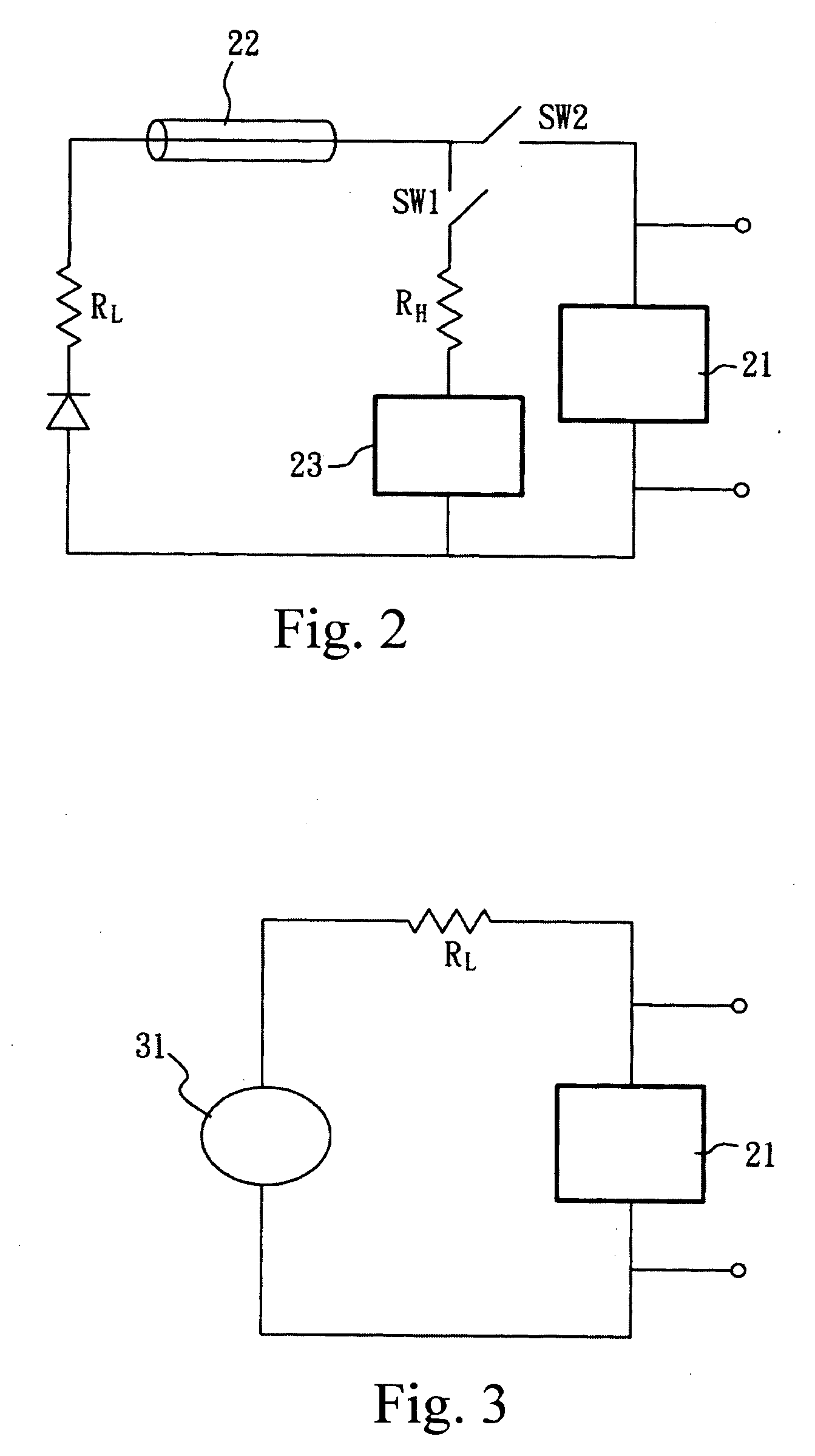

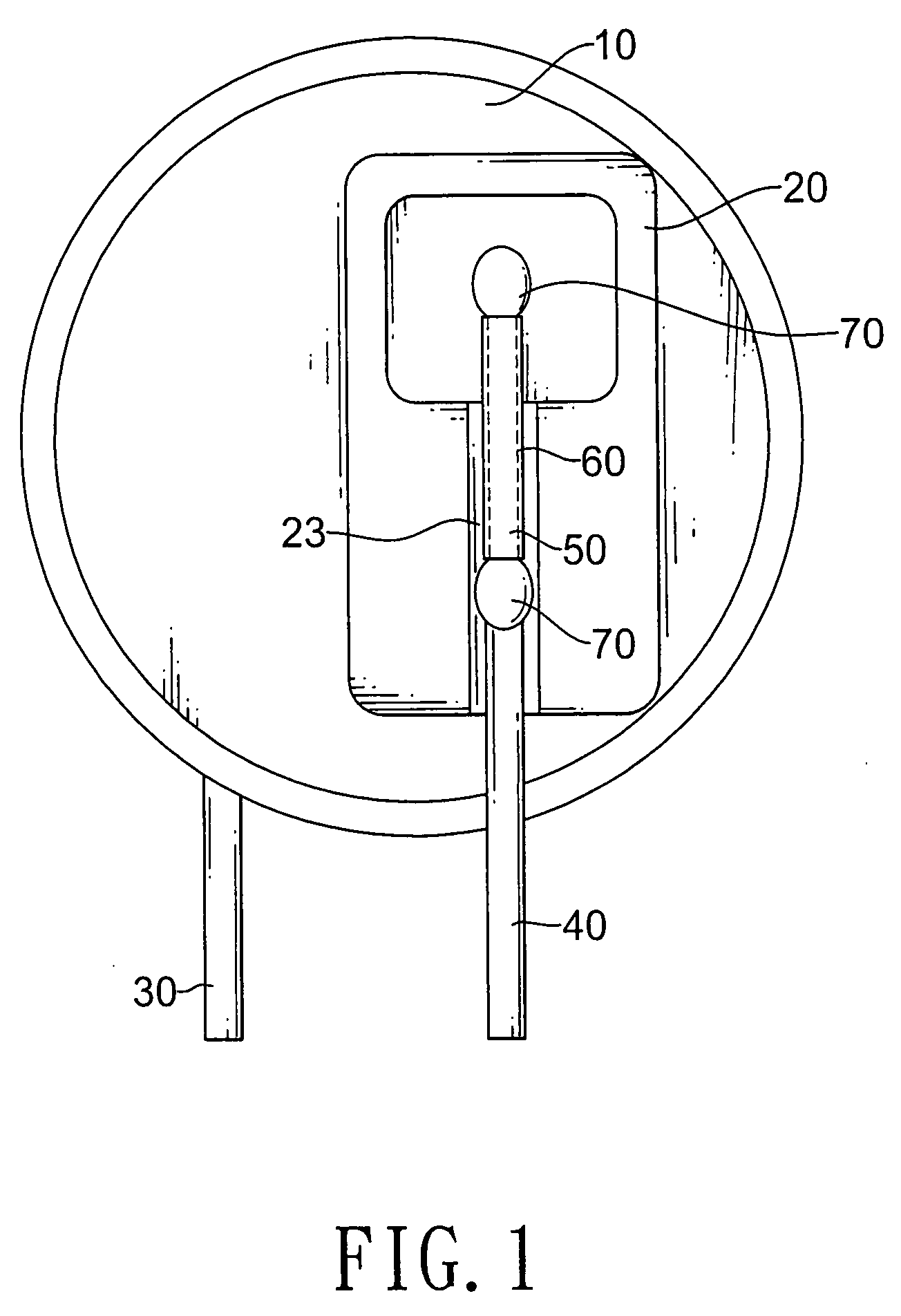

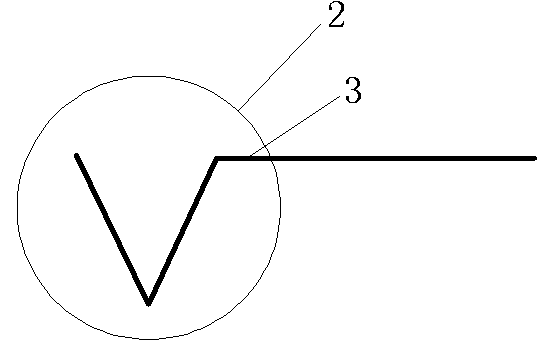

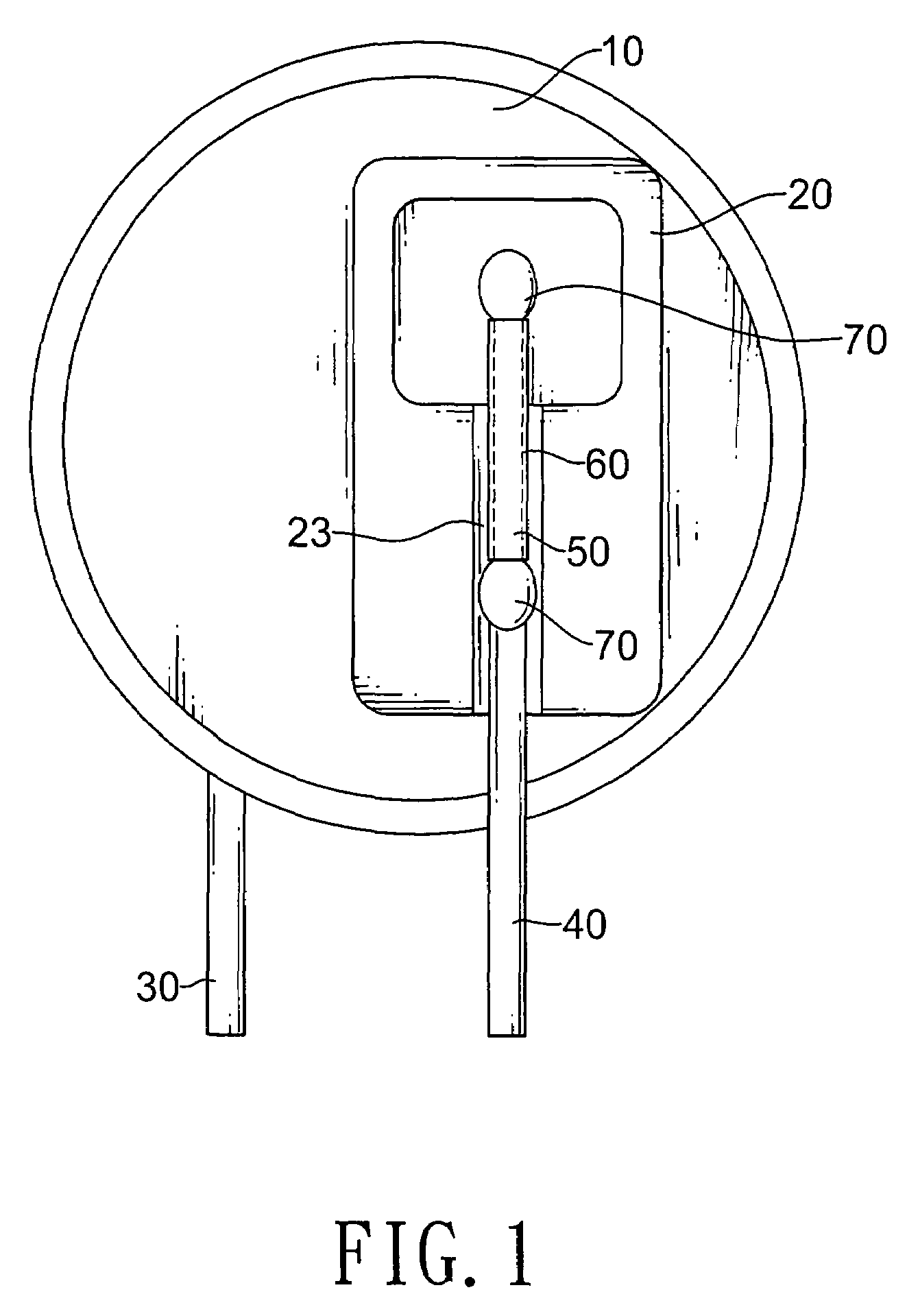

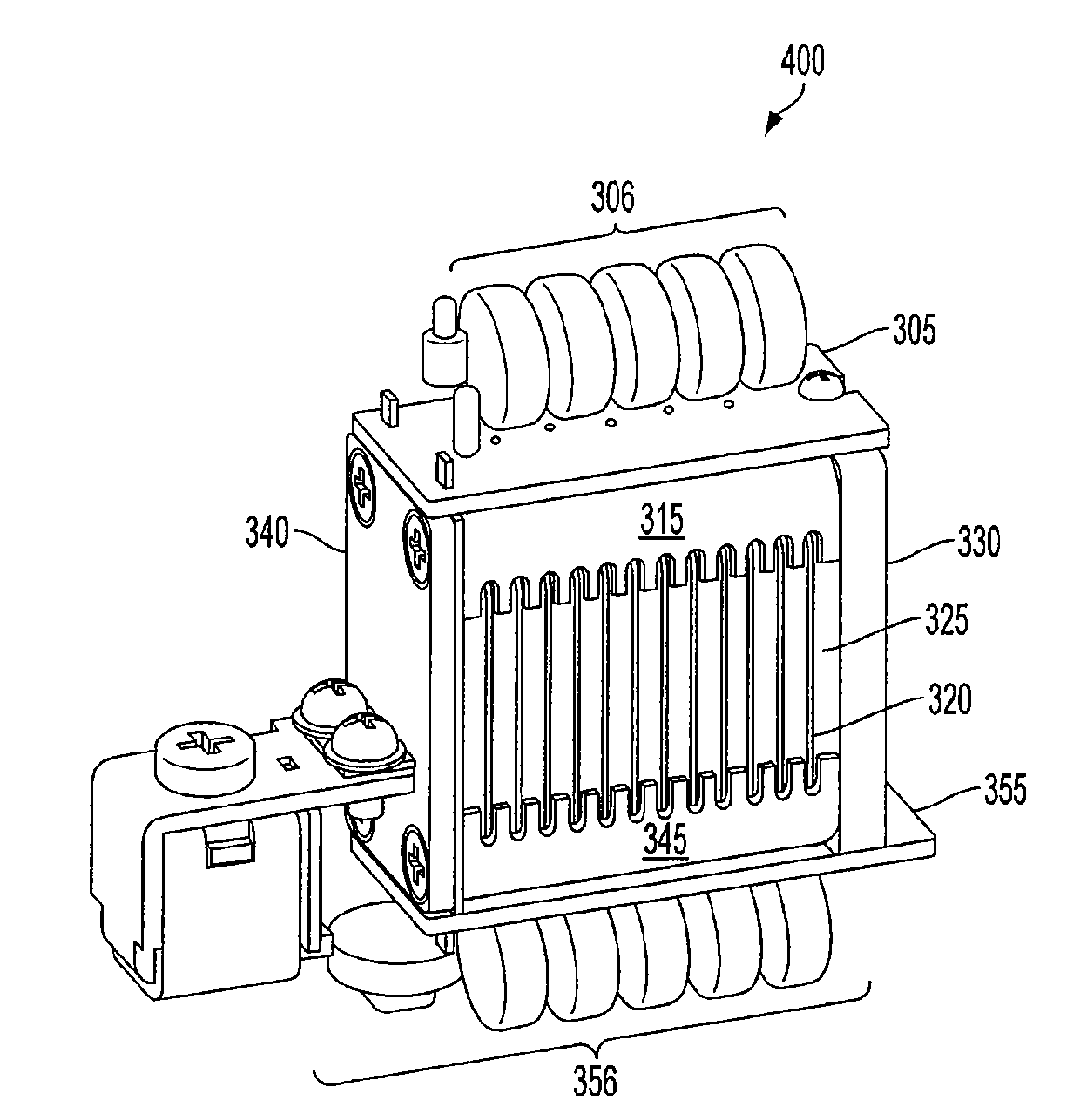

Circuit protection device

ActiveUS7483252B2Modular designEasy to replaceSpark gap detailsEmergency protective arrangement detailsElectricityEngineering

A voltage suppression device for suppressing voltage surges in an electrical circuit, comprised of a voltage sensitive element having a predetermined voltage rating, the voltage sensitive element increasing in temperature as voltage applied across the voltage sensitive element exceeds the voltage rating. Terminals are provided for electrically connecting the voltage sensitive element between a power line of an electrical circuit and a ground or neutral line of the electrical circuit. A normally closed, thermal switch is electrically connected in series with the voltage sensitive element between one line of the electrical circuit and the voltage sensitive element, the thermal switch being thermally coupled to the voltage sensitive element wherein the thermal switch moves from a normally closed position to an open position to form a gap between the thermal switch and the voltage sensitive element when the temperature of the voltage sensitive element reaches a level indicating an over-voltage condition. When the thermal switch moves to the open position, residual follow on current is shunted by a fuse element connected in parallel with the thermal switch. Current flows through the fuse element until the fuse element melts. Electrical arcing is contained inside the fuse until extinguished.

Owner:FERRAZ SHAWMUT

Circuit protection device

ActiveUS20080130180A1Modular designEasy to replaceSpark gap detailsEmergency protective arrangement detailsElectricityEngineering

A voltage suppression device for suppressing voltage surges in an electrical circuit, comprised of a voltage sensitive element having a predetermined voltage rating, the voltage sensitive element increasing in temperature as voltage applied across the voltage sensitive element exceeds the voltage rating. Terminals are provided for electrically connecting the voltage sensitive element between a power line of an electrical circuit and a ground or neutral line of the electrical circuit. A normally closed, thermal switch is electrically connected in series with the voltage sensitive element between one line of the electrical circuit and the voltage sensitive element, the thermal switch being thermally coupled to the voltage sensitive element wherein the thermal switch moves from a normally closed position to an open position to form a gap between the thermal switch and the voltage sensitive element when the temperature of the voltage sensitive element reaches a level indicating an over-voltage condition. When the thermal switch moves to the open position, residual follow on current is shunted by a fuse element connected in parallel with the thermal switch. Current flows through the fuse element until the fuse element melts. Electrical arcing is contained inside the fuse until extinguished.

Owner:FERRAZ SHAWMUT

Material of over voltage protection device, over voltage protection device and manufacturing method thereof

InactiveUS20080079533A1Lower the trigger voltageEasy to useCurrent responsive resistorsVaristor coresAdhesiveEngineering

The present invention relates to a material of an over voltage protection device and an over voltage protection device manufactured by the material. The material comprises a non-conductive powder, a metal conductive powder, and an adhesive. The over voltage protection device comprises a first electrode, a second electrode, and a porous structure connected between the first electrode and the second electrode. The present invention also relates to a method for manufacturing the over voltage protection device. The present invention also relates to a method of adjusting the breakdown voltage of an over voltage protection device.

Owner:INPAQ TECH

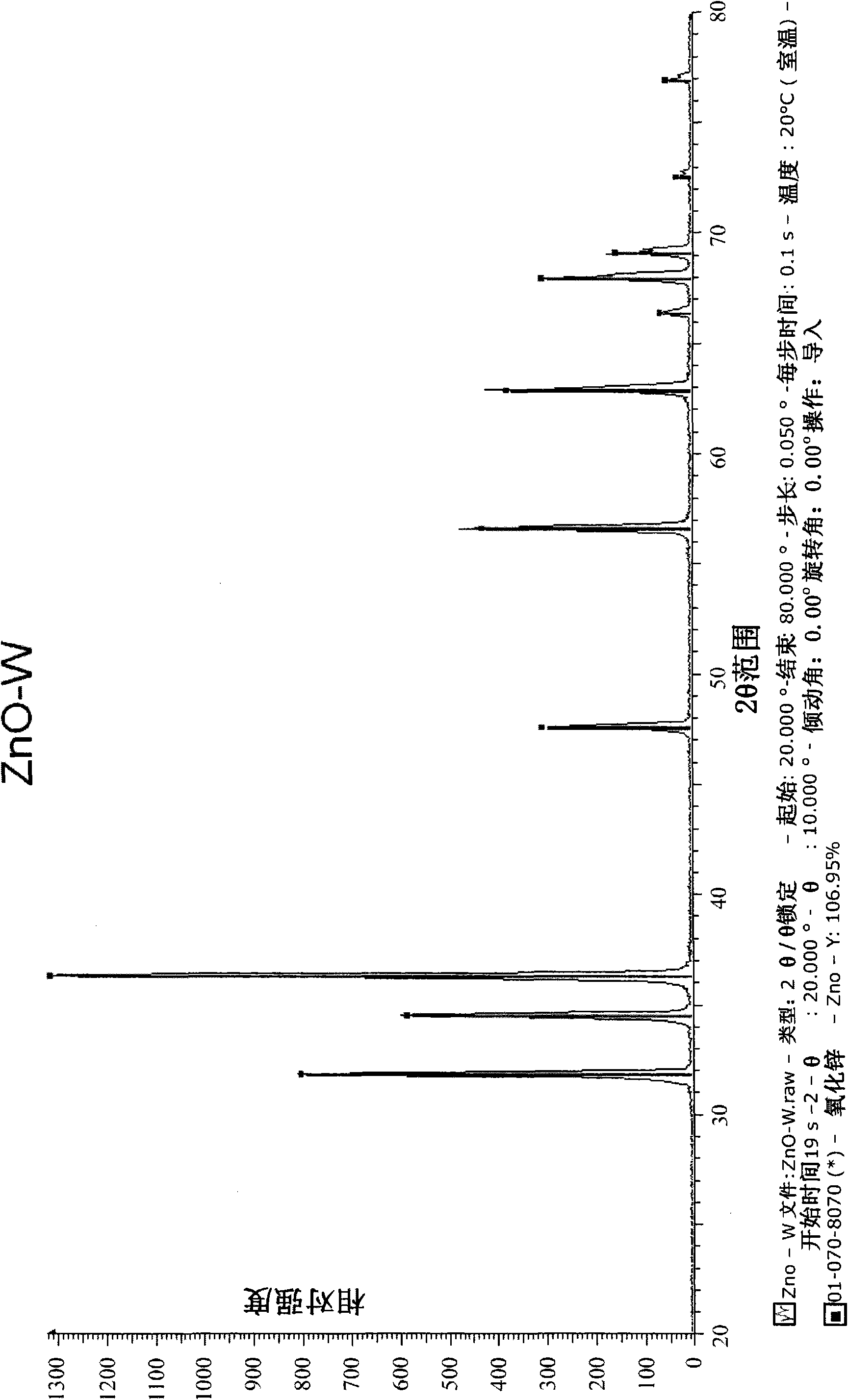

Preparation method of zinc oxide varister

ActiveCN101630553ARegulatory performanceMeet different usage needsResistor manufactureVaristor coresCapacitanceIon

The invention relates to a preparation method of a zinc oxide varister, comprising two independent steps: preparing zinc oxide granules with doping ion components; and preparing a sintering material for coating the zinc oxide granules. According to the performance requirement of the varister, the doping components of the zinc oxide granules, the components of the high-impedance sintering material and preparation conditions are prepared in advance; finally, the zinc oxide granules and the high-impedance sintering material are evenly mixed according to a certain proportion, and the zinc oxide varister is prepared according to the conventional technology. The zinc oxide varister prepared by the preparation method not only has voltage-sensitive performance, but also has one or more functions of heat sensitivity, capacitance, inductance, piezoelectricity or magnetic characteristic, and the like, can sinter at low temperature (lower than 900 DEG C) and can use fine silver as an inner electrode.

Owner:SFI ELECTRONICS TECH

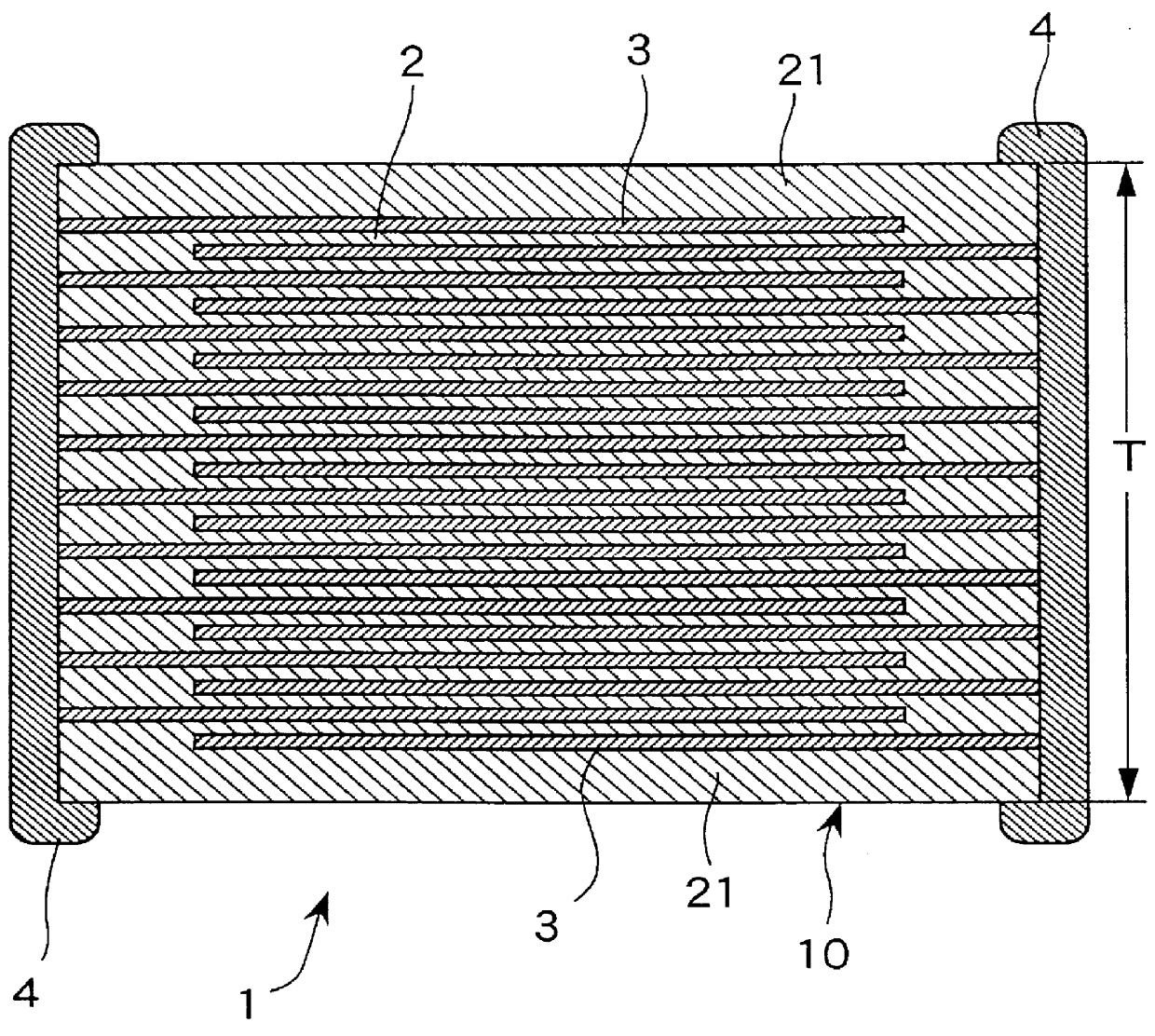

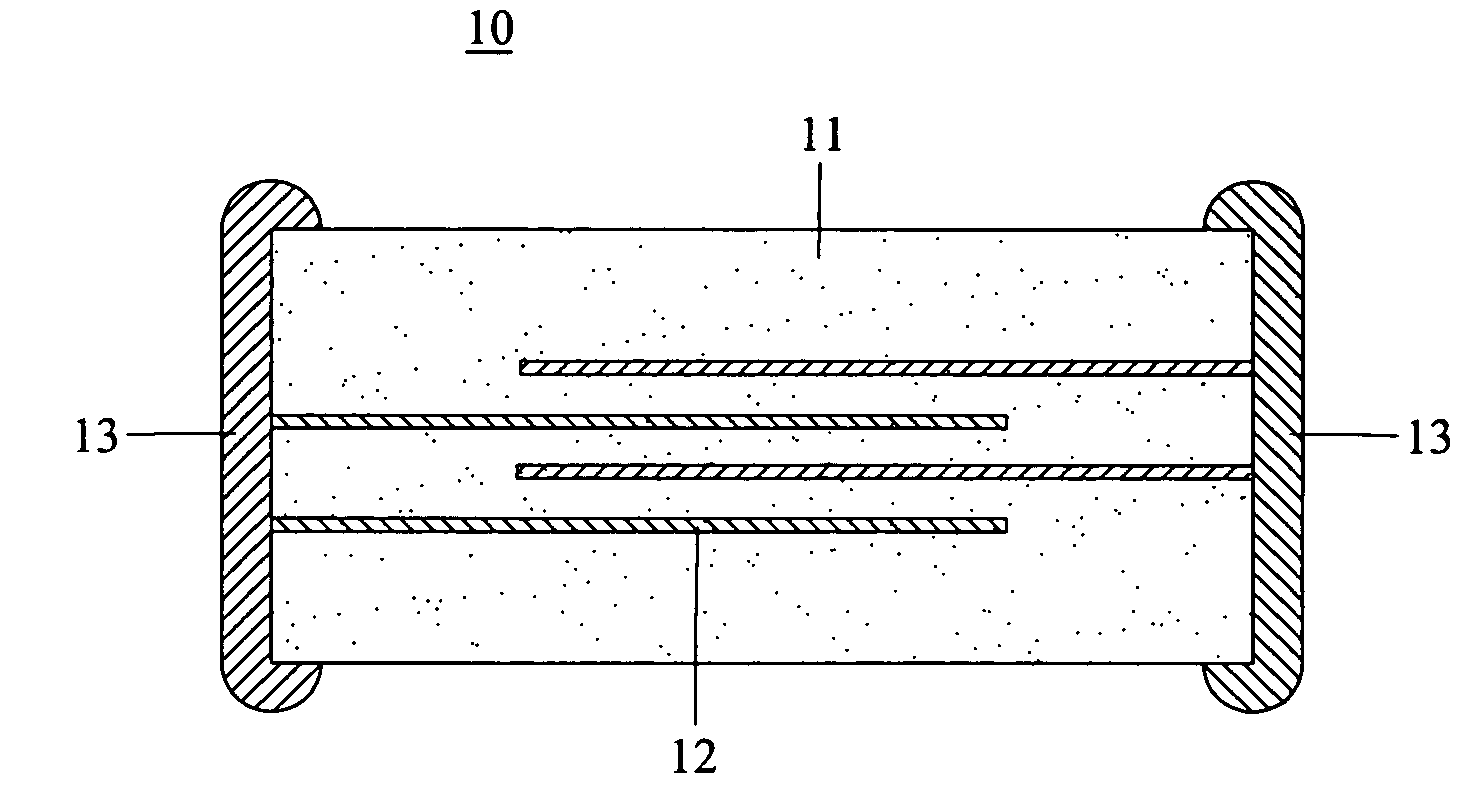

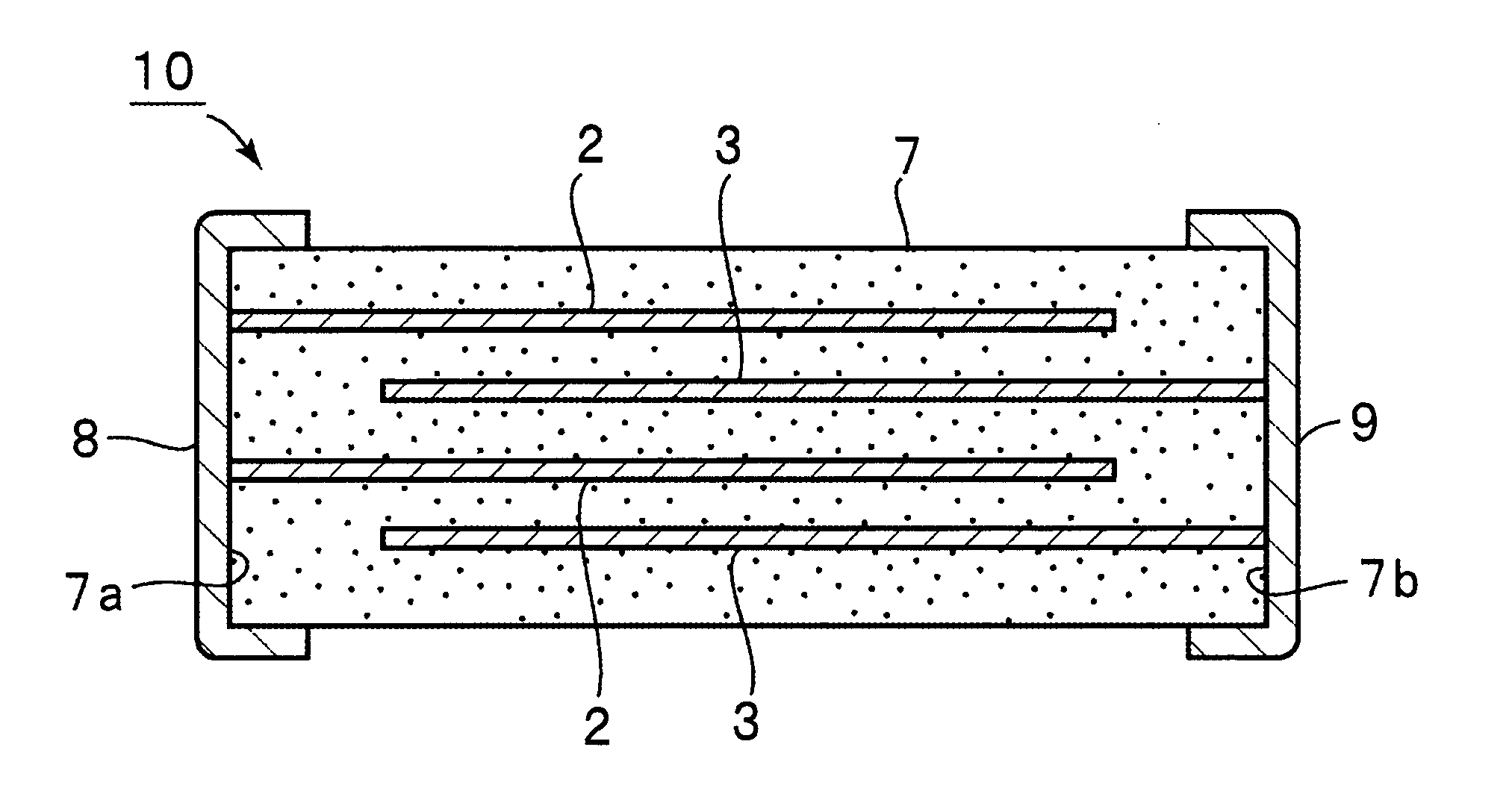

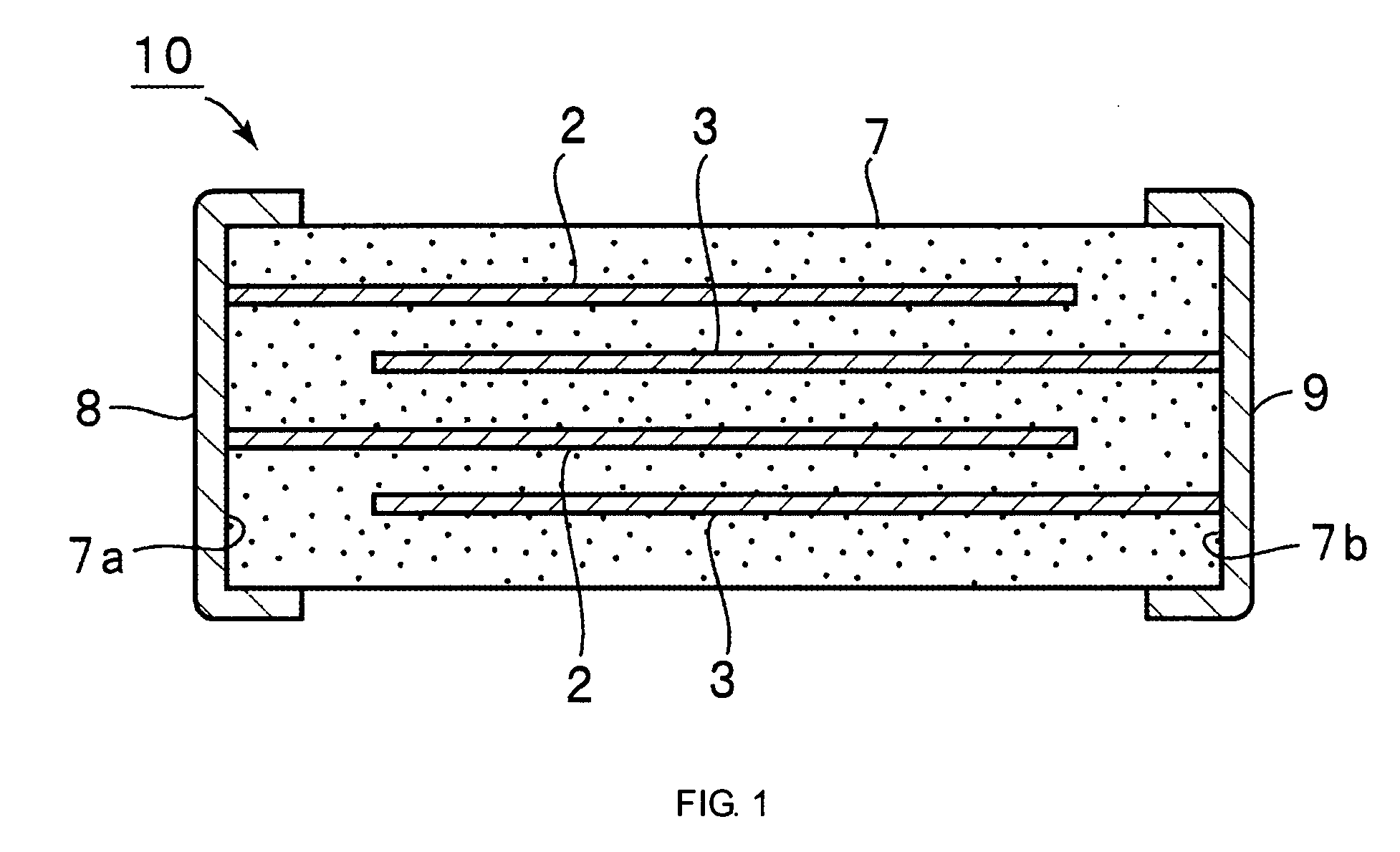

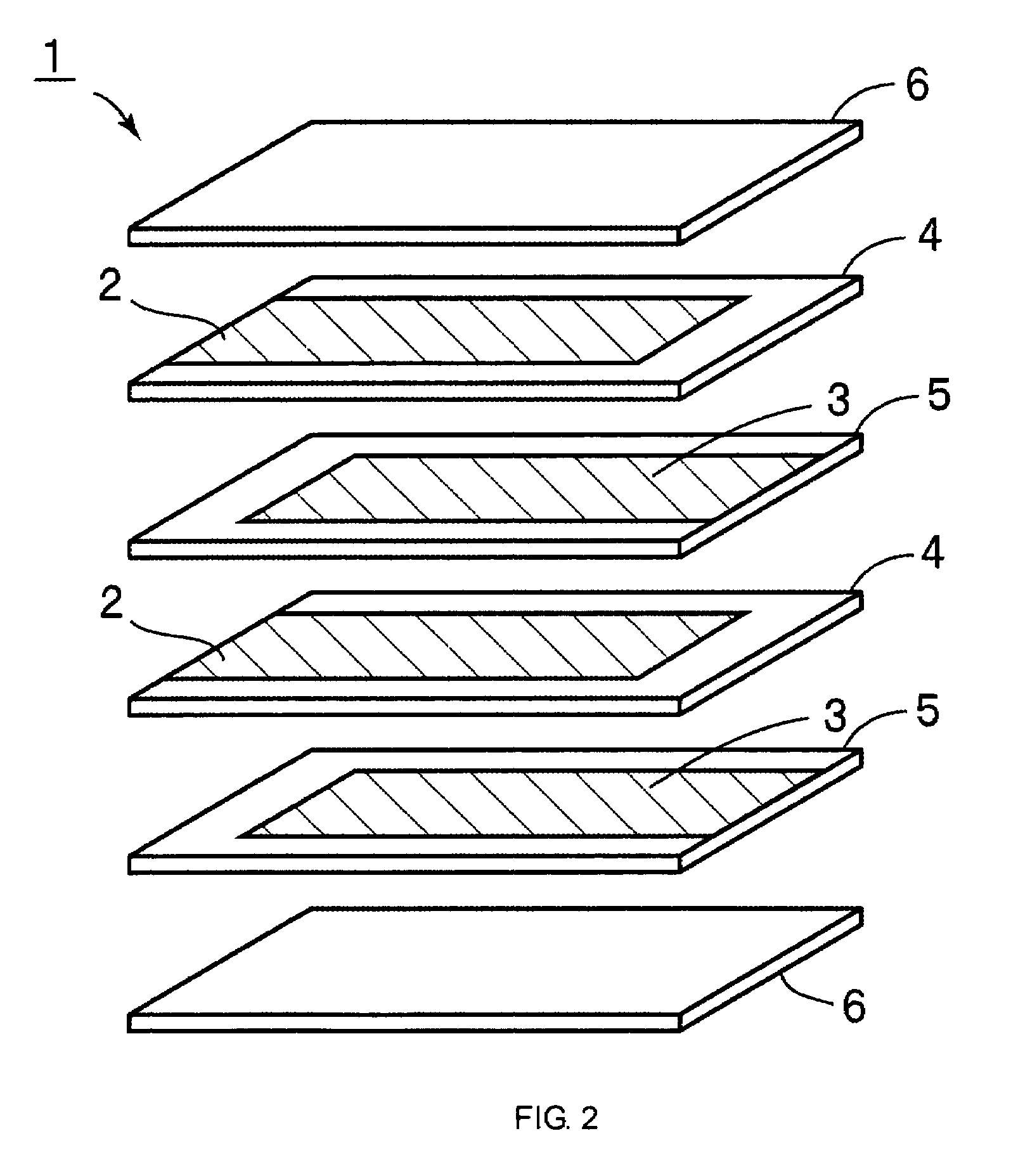

Multilayer varistor

A multilayer varistor comprising a varistor chip body having alternately stacked ceramic layers and internal electrode layers is provided. The ceramic layer is composed of a composite oxide containing Ti and / or Zr and Ba as a main component and Si and / or Al as a subordinate component, substantially free of Cr, and has a perovskite phase. The internal electrode layer is composed of a conductor containing a base metal such as Ni or Ni alloy as a main component. The varistor is used in an electric circuit for suppressing noise.

Owner:TDK CORPARATION

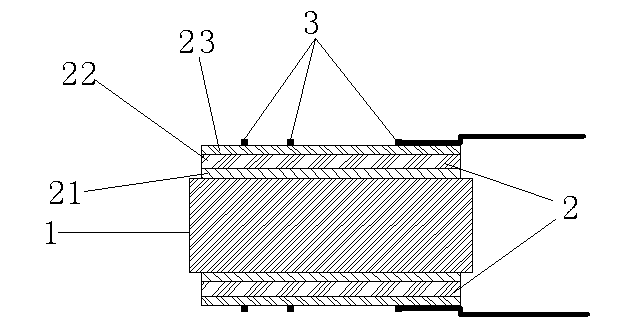

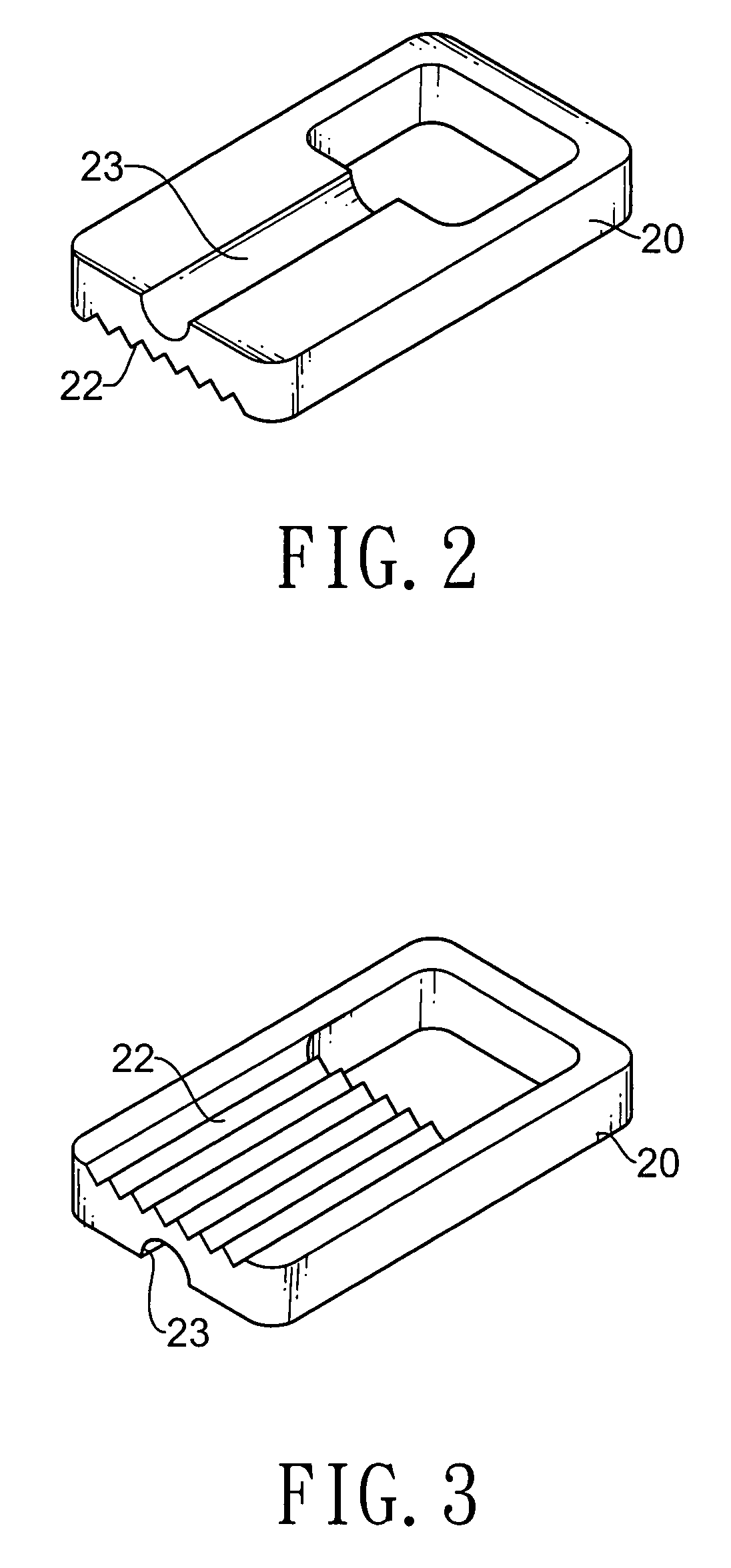

Metal oxide varistor with a heat protection

InactiveUS20080129440A1Go fastFacilitate speed of actionCurrent responsive resistorsResistor cooling/heating/ventillationElectrical resistance and conductanceEngineering

A metal oxide varistor integrally formed with a heat protection structure that will automatically go to open circuit in conditions of overheating due to sustained over-voltages. The metal oxide varistor integrally formed with a heat protection structure has a body, an insulation bracket, a number of terminals and a fuse. The insulation bracket is deposited on the body and has a number of slots. The fuse connects to the body and one of the terminals. The fuse is mounted one of the slots of the insulation bracket. The fuse reacts to the overheating timely and the melting fuse spreads quickly with the assistance of capillary action evolved by the slots of the insulation bracket to speed up the action to go to open circuit in against damage due to sustained over-voltages.

Owner:THINKING ELECTRONICS INDAL

Zinc oxide piezoresistor material and preparing method thereof

The present invention discloses a zinc oxide piezoresistor material comprising the following raw materials: ZnO, Bi2O3, Sb2O3, Co2O3, Cr2O3, MnCO3, NiO, Al2O3 and oxides of boron, wherein, calculating according to B2O3, the weight ratio of the oxide of boron to ZnO is 2.1-20:100; the percentages by mole of ZnO, Bi2O3, Sb2O3, Co2O3, Cr2O3, MnCO3, NiO and Al2O3 are respectively 90.5%-96.5%, 0.3%-5%, 0.1%-3%, 0.1-2%, 0.1%-1%, 0.2%-2%, 0.1%-1% and 0.005%-0.05%; and voltage-dependent combination performance of the material is good. The present invention further discloses a preparing method of the material; the method has the advantages of simple technology and low cost, and the method is suitable for industrialized production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High potential gradient zinc oxide pressure-sensitive resistor material and preparation process thereof

InactiveCN102515742AExtended service lifeReduce energy consumptionVaristor coresHigh energyElectric power system

The invention relates to a high potential gradient zinc oxide pressure-sensitive resistor material and a preparation process thereof. The high potential gradient zinc oxide pressure-sensitive resistor material with uniform particle sizes is obtained by weighing a main material ZnO, a doping oxide, and a product rare earth oxide obtained by carrying out thermal decomposition on a rare earth oxalate or / and carbonate or / and hydroxide according to proportions, carrying out high energy wet grinding, drying, presintering at 200-800DEG C, carrying out high energy dry grinding, and sintering at 800-1100DEG C. The preparation process of the invention has the advantages of simplicity, low cost, environmental protection and low energy consumption, and the prepared zinc oxide pressure-sensitive resistor material can be used for preparing high quality lightning arrester products for ultrahigh electric power systems.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

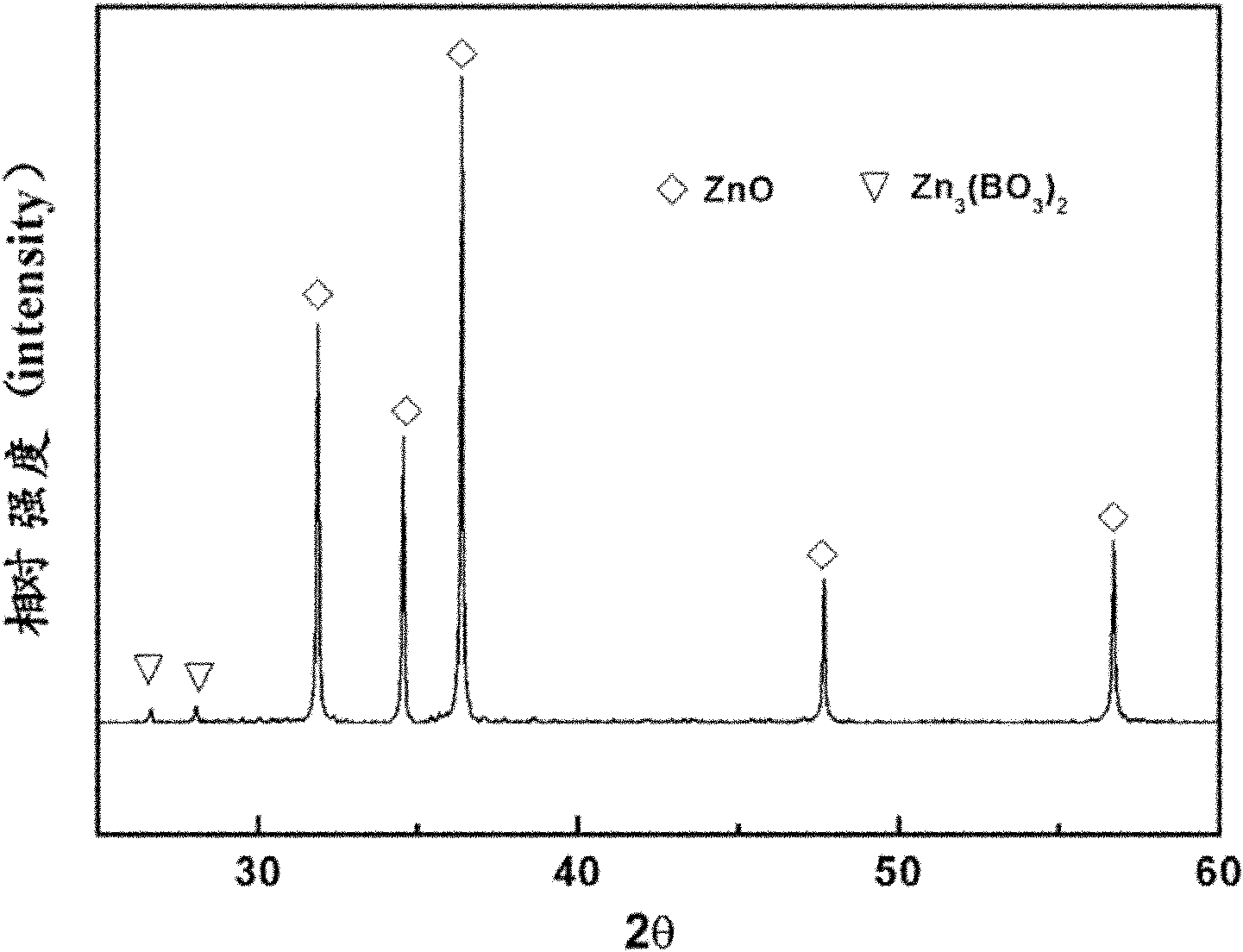

Multilayer zinc oxide varistor

InactiveUS20070273469A1Increase ESD withstanding capabilityMitigate the above drawbacksFixed capacitor dielectricCurrent responsive resistorsRare-earth elementAlkaline earth metal

A multilayer zinc oxide varistor without bismuth oxide system ingredients, and having variable breakdown voltages by controlling the thickness of the ceramic material; the varistor is bismuth-free and composed of zinc oxide as the primary constituent with alkaline earth element (Ba) as first additive, at least one of transition elements of Mn, Co, Cr, or Ni as second additives, at least one of rare earth elements of Pr, La, Ce, Nd or Tb as third additives and at least one of B, Si, Se, Al, Ti, W, Sn, Sb, Na, or K as rest additives, and the bismuth-free and zinc oxide based varistor exhibits an excellent ESD (Electro-Static Discharge) withstanding characteristic.

Owner:SFI ELECTRONICS TECH

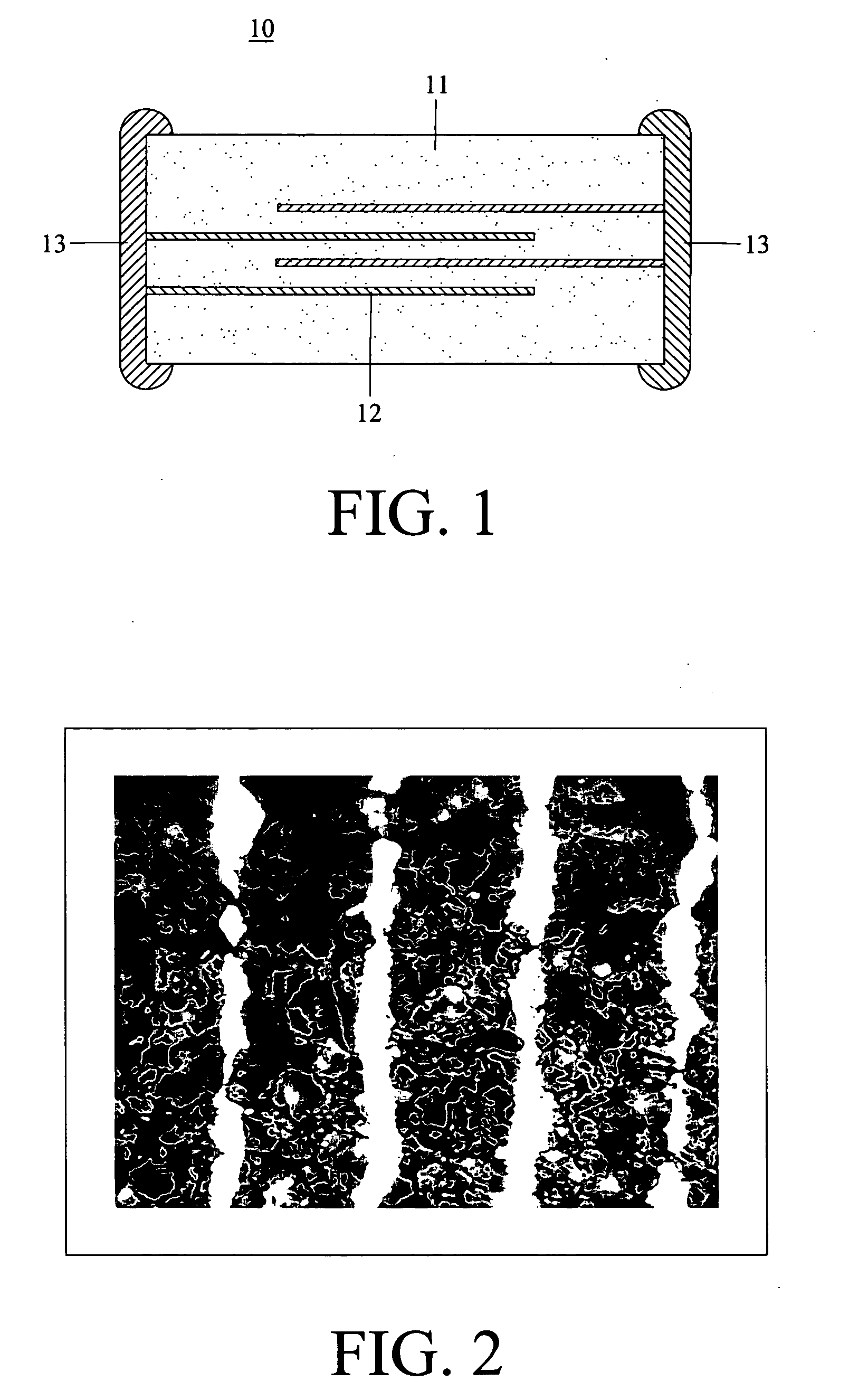

Zinc oxide pressure-sensitive resistor and preparation method thereof

ActiveCN103400675AReduce consumptionReduce energy consumptionVaristor coresResistors adapted for applying terminalsZincTransition layer

The invention discloses a zinc oxide pressure-sensitive resistor. The zinc oxide pressure-sensitive resistor comprises a zinc oxide pressure-sensitive ceramic substrate, electrode layers and electrode leads, wherein the electrode layers are arranged on the upper surface and the lower surface of the zinc oxide pressure-sensitive ceramic substrate respectively; the electrode leads are arranged on the electrode layers respectively. The zinc oxide pressure-sensitive resistor is characterized in that each electrode layer comprises a bottom transition layer which is used for improving bonding force between the zinc oxide pressure-sensitive ceramic substrate and the corresponding electrode layer and reducing contact resistance. Therefore, the electrode layers and the zinc oxide pressure-sensitive ceramic substrate are firmly bonded, and the self through-current capability of the electrode layers is improved. Furthermore, the curved electrode leads are capable of uniformly distributing current on the electrode layers. The surge impact resistance capacity of the zinc oxide pressure-sensitive resistor is improved. The whole preparation process has an environment protection effect, and can reduce over 45 percent of consumed energy and save over 60 percent of production costs compared with the prior art.

Owner:杭州比凡科电子科技有限公司

Variable resistor element and its manufacturing method

InactiveUS20090231083A1Large resistance ratioCurrent responsive resistorsDigital storageHigh resistanceElectrical resistance and conductance

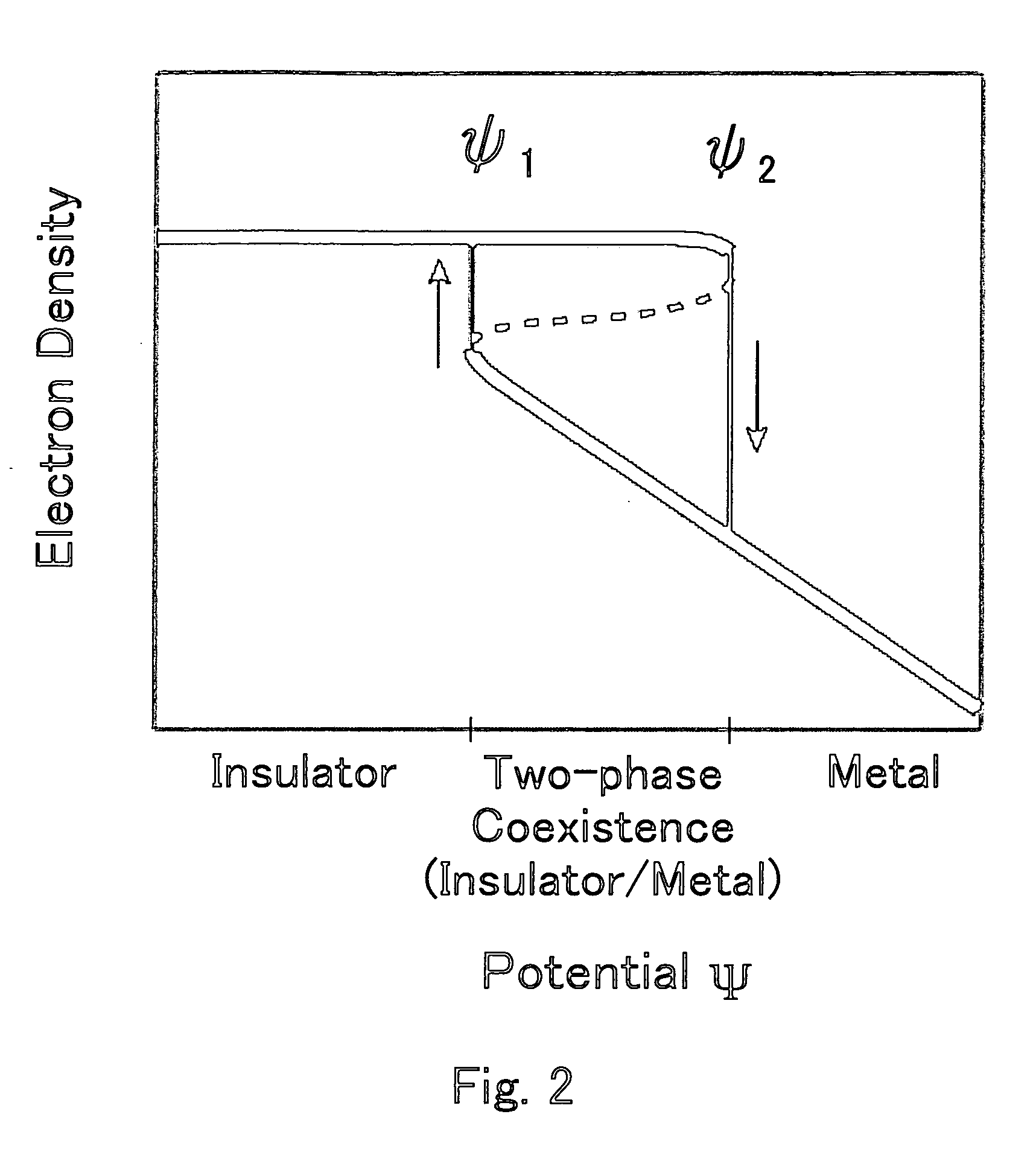

A variable resistance element comprises a variable resistor of strongly-correlated material sandwiched between two metal electrodes, and the electric resistance between the metal electrodes varies when a voltage pulse is applied between the metal electrodes. Such a switching operation as the ratio of electric resistance between low and high resistance states is high can be attained by designing the metal electrodes and variable resistor appropriately based on a definite switching operation principle. Material and composition of the first electrode and variable resistor are set such that metal insulator transition takes place on the interface of the first electrode in any one of two metal electrodes and the variable resistor by applying a voltage pulse. Two-phase coexisting phase of metal and insulator phases can be formed in the vicinity of the interface between the variable resistor and first electrode by the work function difference between the first electrode and variable resistor.

Owner:SHARP KK +1

Preparation of high voltage gradient zinc oxide varistor valve

ActiveCN101383208AReduce volumeReduce weightResistor manufactureVaristor coresPolyvinyl alcoholEnergy absorption

The invention relates to a method for preparing a high voltage gradient zinc-oxide voltage dependent resistor valve plate, which belongs to the technical field of an electrical material. Firstly, raw materials are compounded according to the molar percentage of the raw materials, deionized water is added into the compounded zinc oxide adulterated raw materials as a dispersing agent, a polyvinyl alcohol water solution is added as a binding agent, the raw materials are ground by grinding balls which are prepared by pure monox, pulp ground by the grinding balls is dried and is stirred to form hydrous granular materials by adding the deionized water, the hydrous granular materials are pressed and molded into a plate, the plate is disintegrated, sintered, ground, cleaned and aluminized, and the upper side surface of the plate is insulated. The voltage-dependent voltage gradient of the valve plate reaches 400 V / mm, and the square wave energy absorption density reaches over 250J / cm<3>. The valve plate can be used in an extra-high voltage GIS can-type arrestor, can effectively simplify the structural design of the extra-high voltage GIS can-type arrestor, reduce the production and manufacture difficulty and the cost of the arrestor, and increase the internal safe reliability of the arrestor at the same time, thus, the method has good social and economic benefits.

Owner:TSINGHUA UNIV

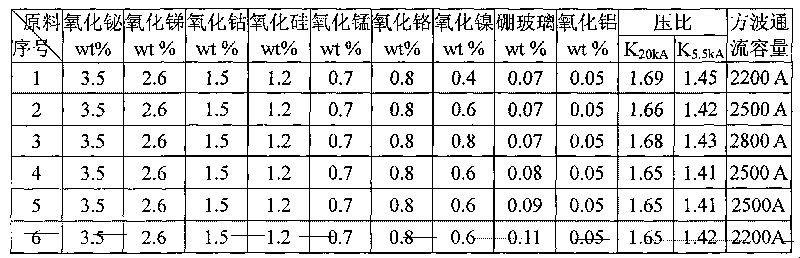

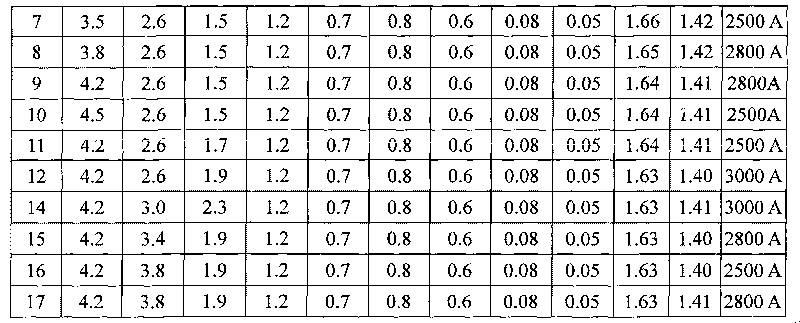

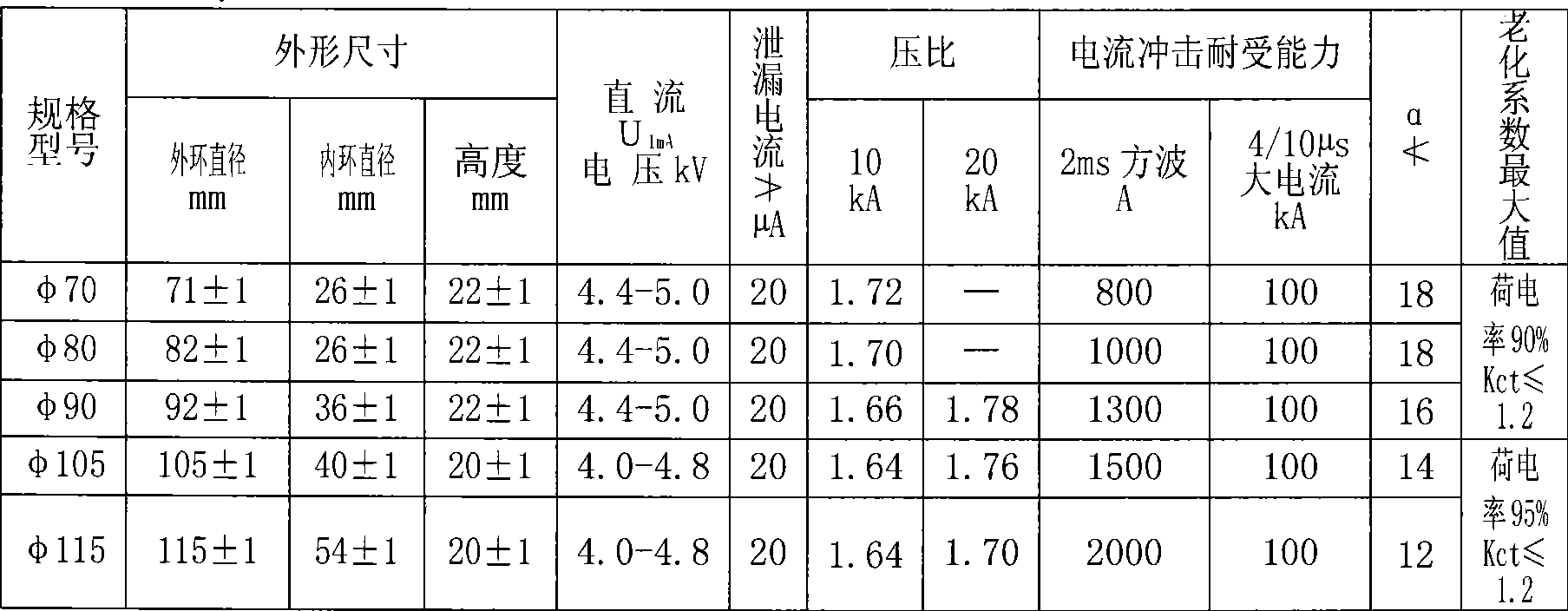

Formula of non-linear resistor for high voltage surge arrester and manufacturing method thereof

ActiveCN101700976AMeet performance requirementsLower pressure ratioResistor manufactureVaristor coresNonlinear resistorUltra high voltage

The invention relates to the field of manufacturing high voltage metal oxide surge arresters and discloses a formula of a non-linear resistor for a high voltage surge arrester and a manufacturing method thereof, which are applicable to the metal oxide surge arresters for protecting high voltage power devices, in particular to the metal oxide surge arresters of ultra-high voltage AC power transmission and transformation systems of 750kV and 1000kV. The formula comprises additives consisting of the following components by weight percent: 3.1-4.8% of bismuth oxide, 2.5-4.6% of antimony oxide, 1.2-2.6% of cobalt oxide, 0.7-1.5% of silicon oxide, 0.5-0.9% of manganese oxide, 0.7-1.3% of chromium oxide, 0.3-0.9% of nickel oxide, 0.04-0.13% of boron glass powder and 0.01-0.06% of aluminum oxide. The balance is a main component-zinc oxide.

Owner:CHINA XD ELECTRIC CO LTD

Process for producing zinc oxide varistor

InactiveUS20100117271A1Improve adjustabilityCeramic shaping apparatusVaristor coresCapacitanceThermistor

A process for producing zinc oxide varistors is to perform the doping of zinc oxide and the sintering of zinc oxide grains with a high-impedance sintering material through two independent procedures, so that the doped zinc oxide and the high-impedance sintering material are well mixed in a predetermined ratio and then used to make the zinc oxide varistors through conventional technology by low-temperature sintering (lower than 900° C.); the resultant zinc oxide varistors may use pure silver as inner electrode and particularly possess one or more of varistor properties, thermistor properties, capacitor properties, inductor properties, piezoelectricity and magnetism.

Owner:SFI ELECTRONICS TECH

Porcelain composition for varistor and varistor

InactiveUS7075404B2Small leak currentIncrease resistanceCurrent responsive resistorsNegative temperature coefficient thermistorsIndiumLow voltage

A varistor is provided which can be driven at a low voltage, has a small leak current, and can realize a high ESD resistance and a high surge resistance. The varistor is formed using a ceramic composition for a varistor which contains zinc oxide as a primary component and sub-components including praseodymium at a content of 0.05 to 3.0 atomic percent of the total, cobalt at a content of 0.5 to 10 atom percent of the total, at least one of potassium, sodium, and lithium at a total content of 0.005 to 0.5 atom percent of the total, at least one of aluminum, gallium, and indium at a total content of 2×10−5 to 0.5 atom percent of the total, and zirconium at a content of 0.005 to 5.0 atom percent of the total.

Owner:MURATA MFG CO LTD

Formula of direct current zinc oxide resistance chip

ActiveCN101503292AUniform and stable structureReduce defect concentrationVaristor coresSesquioxideAntimony trioxide

The invention discloses a formulation of an AC zinc oxide resistance chip. The formulation is characterized by comprising the following additives and a main material ZnO by weight percentage: 4.0 to 4.9 percent of Bi2O3, 3.0 to 4.0 percent of Sb2O3, 0.5 to 1.0 percent of SiO2, 2.0 to 3.0 percent of Co2O3, 0.50 to 0.80 percent of Cr2O3, 0.50 to 0.80 percent of MnCO3, 0.70 to 0.90 percent of NiO, 0.03 to 0.05 percent of aluminum nitrate, 0.10 to 0.20 percent of glass dust, 0.07 to 0.10 percent of B2O3 and 85.0 to 88.0 percent of ZnO. The formulation of the resistance chip has the following characteristics and advantages: the nickel protoxide and the glass dust are introduced into the formulation, so that the stability and the aging performance of the internal structure of the resistance chip is more excellent; and 2, dosage of cobalt sesquioxide, dibismuth trioxide and diantimony trioxide are added in the formulation, the mixture ratio of each composition is more reasonable, and the non-linearity coefficient of the resistance chip can be improved, the pressure ratio is reduced, the circulation capability is improved, and the comprehensive performance is excellent.

Owner:FUSHUN ELECTRIC PORCELAIN MFG CO LTD

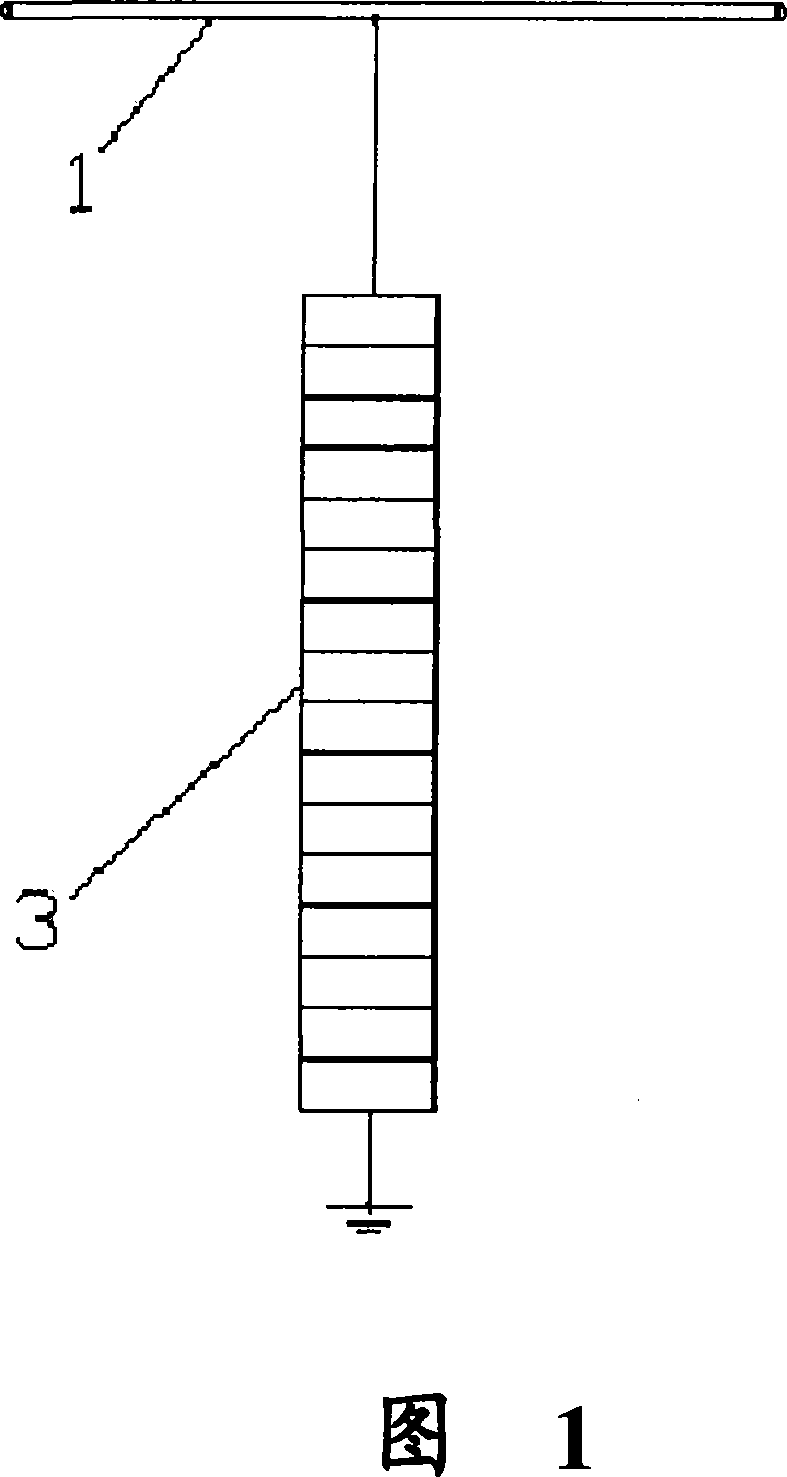

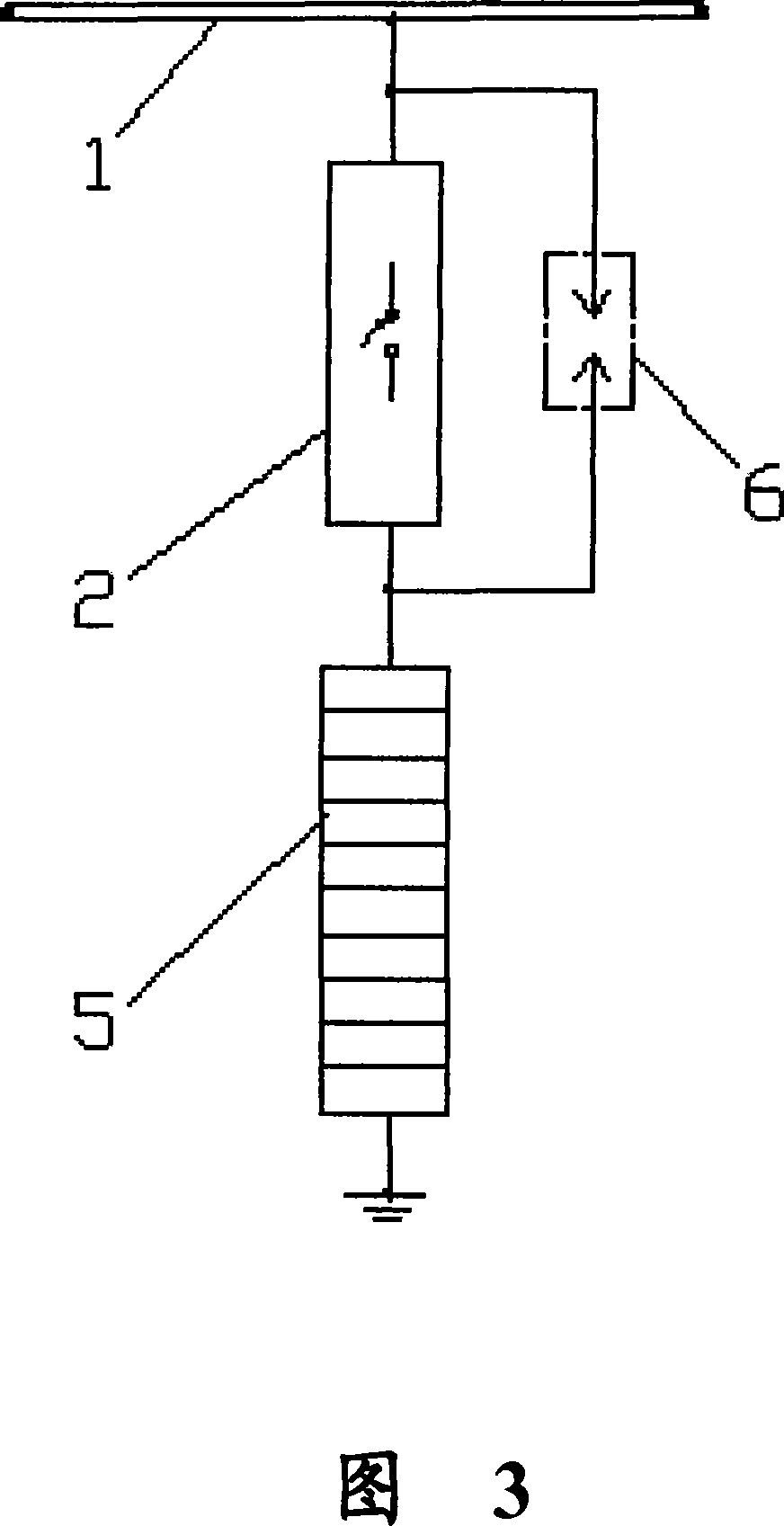

Contrable metal oxide arrester in use for transmission system in supervoltage, extra high voltage

ActiveCN101093742AReduce charge rateImprove operational reliabilityVaristor coresOvervoltage protection resistorsMetal oxide surge arresterHigh pressure

The controllable arrester in metal oxide includes control part and fixed part connected in series. In normal operation of system, the control part and the fixed part together bear system voltage. When amplitude value of system over voltage exceeds prearranged threshold value, the fixed part bears system over voltage. Combining power electronic device in large power with arrester in metal oxide (MO), the invention puts forward concept and designing idea of controllable arrester for aiming at issue of over voltage protection for transmission system in super voltage, extra high voltage. Based on condition of maintaining invariable performance parameters of MO resistance piece, the invention reduces residual voltage of arrester effectively by using characteristics: quick response speed of power electronic device, steady operation, and flexible adjustment so as to raise protection level for arrester.

Owner:CHINA ELECTRIC POWER RES INST

Variable resistance element, method for producing the same, and nonvolatile semiconductor storage device

InactiveUS7894239B2Reduce voltageDigital storageVaristor coresSemiconductor storage devicesDrain current

Owner:SHARP KK +1

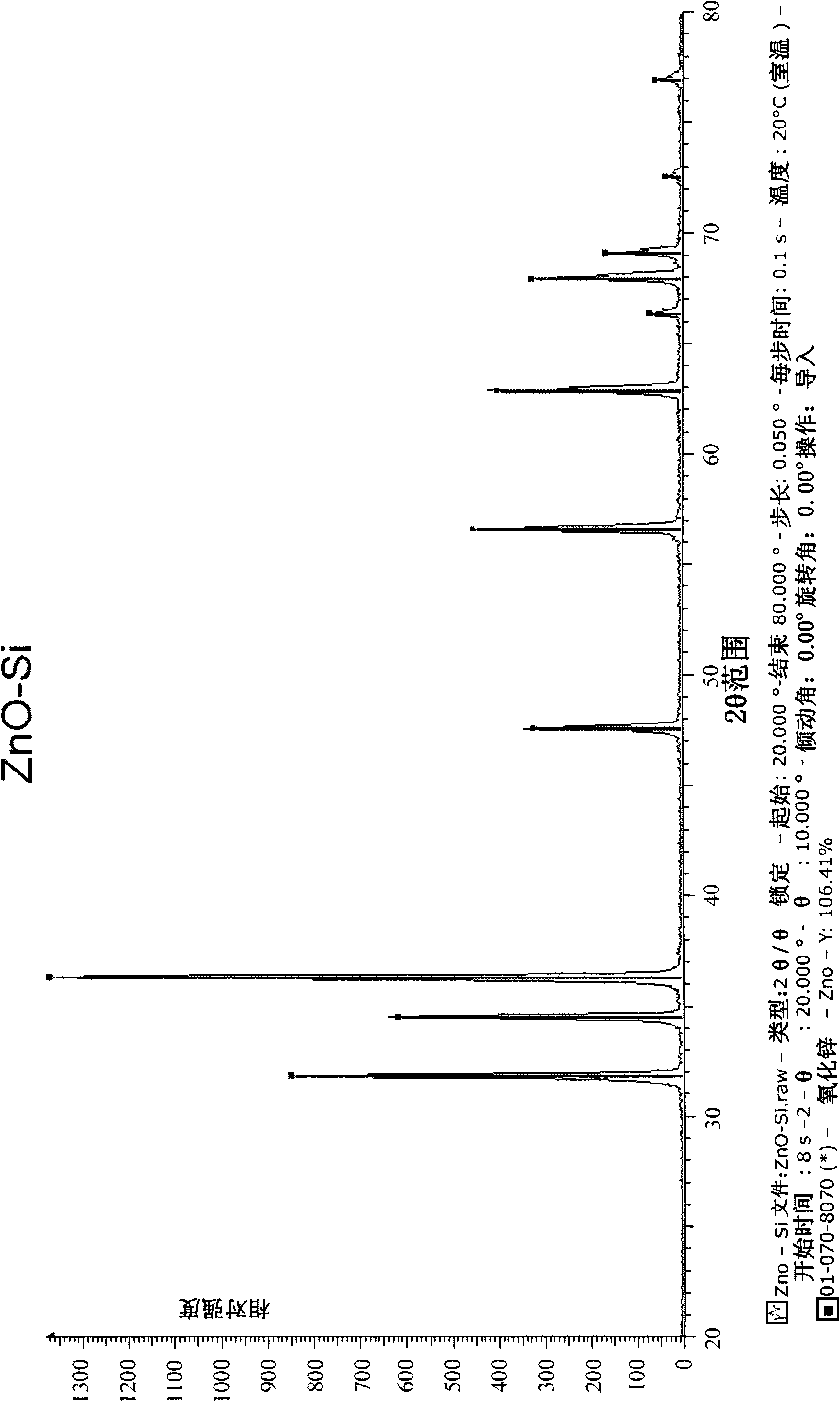

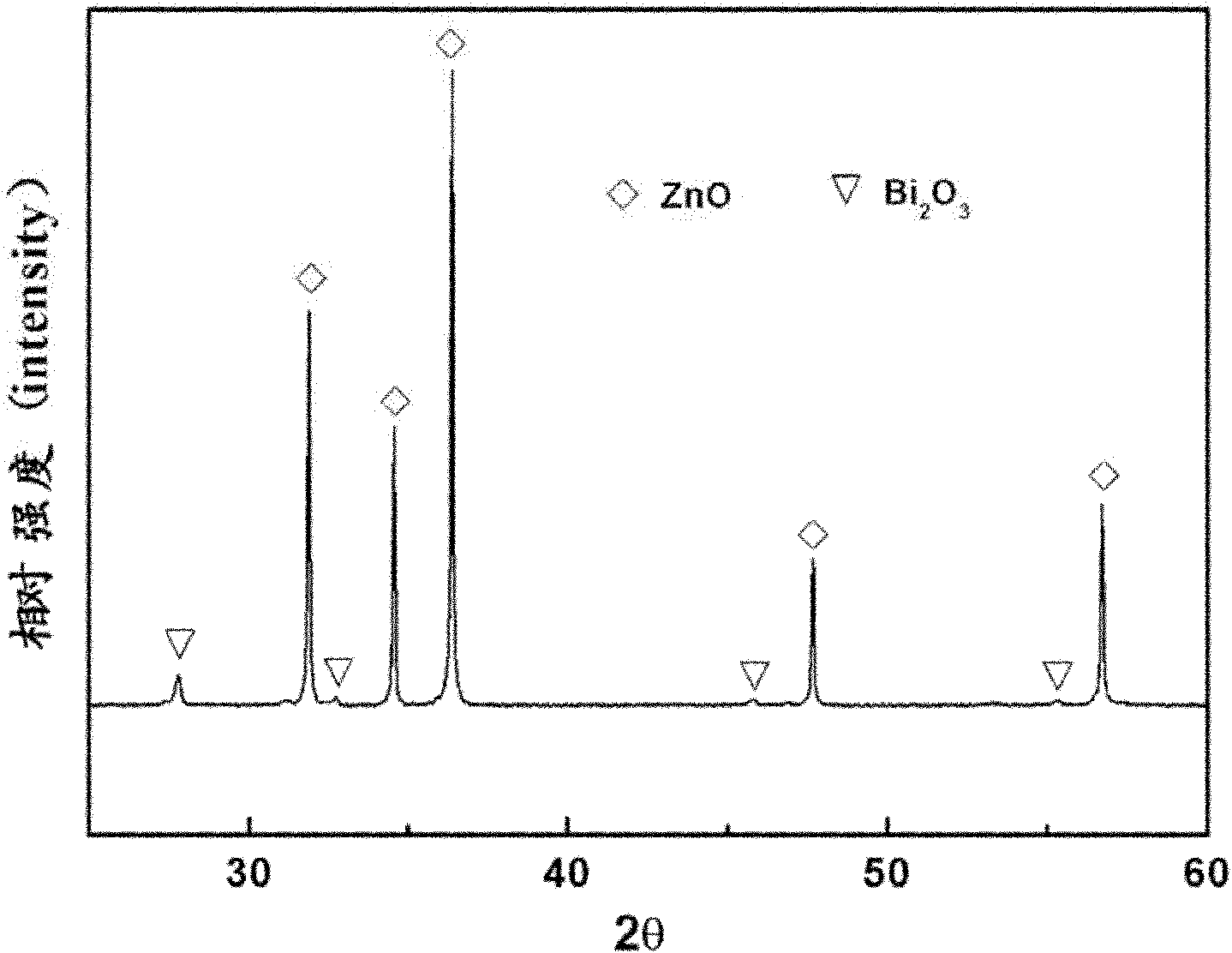

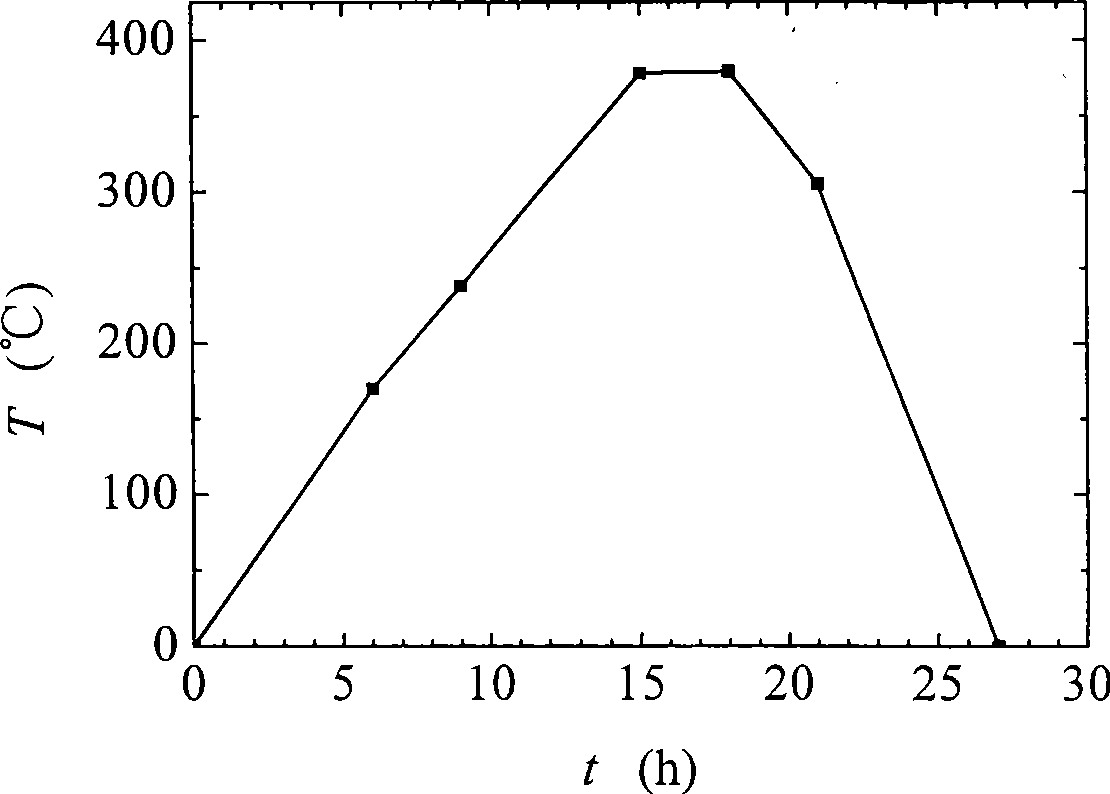

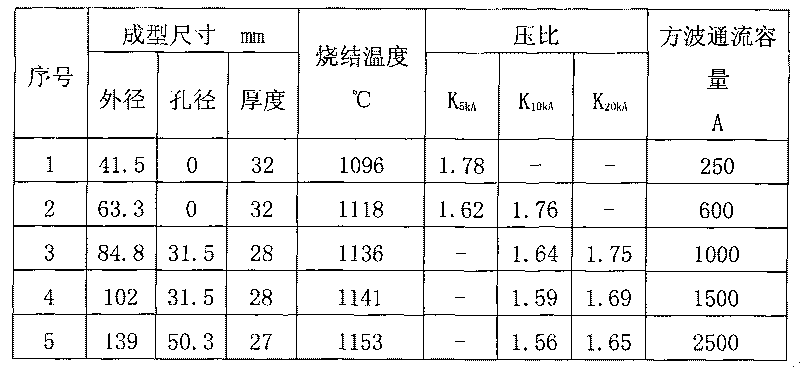

Preparation and application of high-potential gradient zinc oxide piezoresistor material

This invention relates to the preparation and application of a high potential gradient ZnO piezoresistive material including: mixing raw materials in the mol ratio of ZnO: Bi2O3:Sb2O3:Cr2O3:Co2O3:MnO2=96.5:0.7:1.0:0.5:0.8:0.5 to get the product by first and second time powerful fine grindings, low temperature sinter, which is taken as the raw material to be pressed to formation, sintered at low temperature, coated with electrode Ag pulp and welded with electrode lead to get the product of high potential gradient ZnO piezoresistors. This invention greatly refines the metal oxide mixed powder grain size by twice-powerful grindings, the sintered temperature is only 900deg.C and the grain is 1.5-3.5mum.

Owner:EAST CHINA NORMAL UNIVERSITY

Zinc oxide base high potential gradient pressure-sensitive ceramic material and its preparation method and uses

The invention discloses a zinc oxide base high-potential gradient voltage-sensitive ceramic material and preparing method and application, which comprises the following parts: 100mol ZnO as main component, first accessory ingredient within Bi2O3, Co2O3, MnO2, Cr2O3, Ni2O3 with molar quantity at 0.5-1.2mol respectively, second accessory ingredient with 0.8-1.5mol Sb2O3, third accessory ingredient with 0.2-1.2mol Ho2O3 and or Er2O3, forth accessory ingredient with 0.002-0.005mol Al2O3. The preparing method comprises the following steps: blending each component together to make spraying slurry; spraying; drying; graining; proceeding dry pressing; moulding; sintering. The potential gradient of voltage-sensitive ceramic material is 300-500V / mm with non-linear coefficient is more than 50, which can be applied in the electric lightning arrester or other lightning protection overvoltage protection of electric electronic circuit due to strong pulse attack resistance ability.

Owner:山东鸿荣电子有限公司

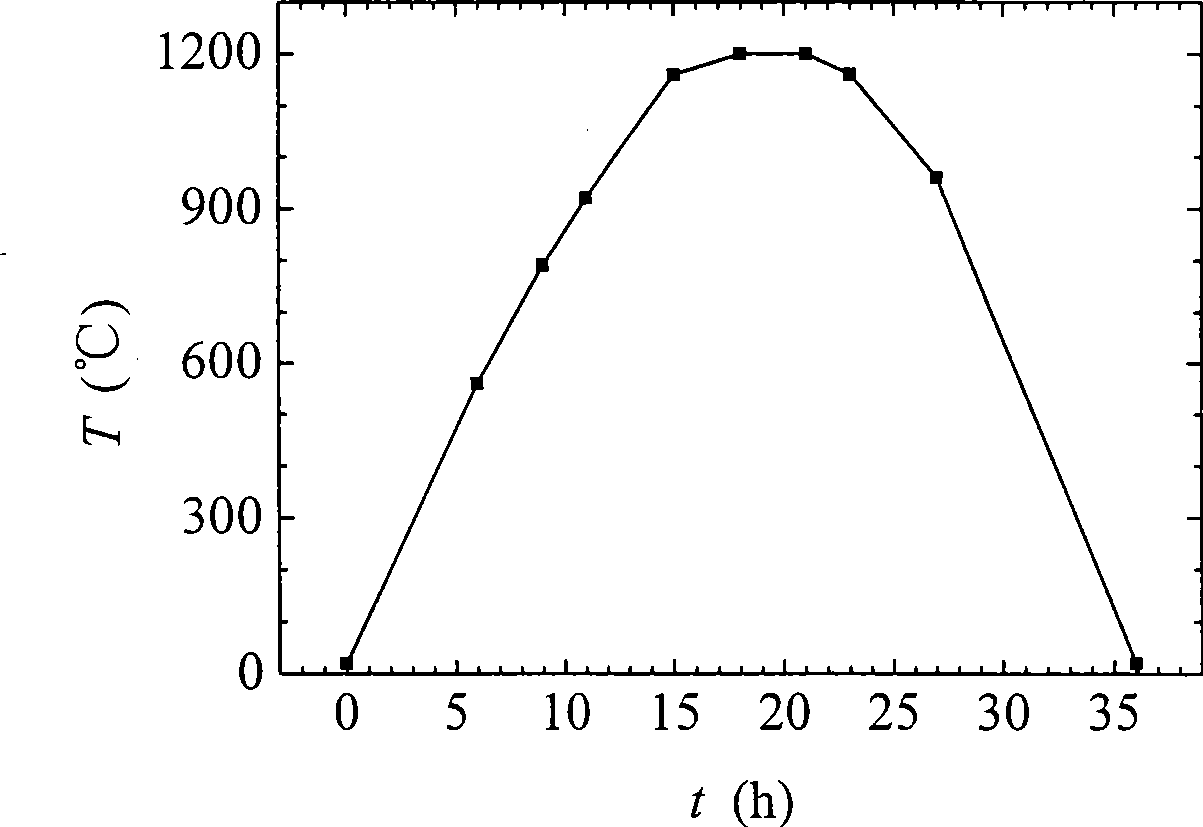

Method for preparing high-potential gradient zinc oxide piezoresistive material by low-temperature sintering

InactiveCN1801409AHigh nonlinear indexRaise the potential gradientResistor manufactureVaristor coresManufacturing technologyHigh energy

The preparation method for high-potential gradient ZnO piezoresistor material comprises: with high-energy ball grinding technology, adding rare earth oxides included Bi2O3, Sb2O3, Cr2O3, Co2O3, MnO2, and Y2O3; sintering at 800Deg, and obtaining the product. The advantages of this invention comprises: simple process technology, low sintering temperature, fit to traditional device, well properties of the product, 5.50~5.64g / cm3 density, 1845.66~2233.33V / mm voltage-sensitive potential gradient, 21.3~25.8 nonlinear index, and 1.55~10.2ª–A drain current (given 0.75V1mA).

Owner:EAST CHINA NORMAL UNIV

Metal oxide varistor with a heat protection

InactiveUS7453681B2Go fastFacilitate speed of actionCurrent responsive resistorsResistor cooling/heating/ventillationElectrical resistance and conductanceEngineering

A metal oxide varistor integrally formed with a heat protection structure that will automatically go to open circuit in conditions of overheating due to sustained over-voltages. The metal oxide varistor integrally formed with a heat protection structure has a body, an insulation bracket, a number of terminals and a fuse. The insulation bracket is deposited on the body and has a number of slots. The fuse connects to the body and one of the terminals. The fuse is mounted one of the slots of the insulation bracket. The fuse reacts to the overheating timely and the melting fuse spreads quickly with the assistance of capillary action evolved by the slots of the insulation bracket to speed up the action to go to open circuit in against damage due to sustained over-voltages.

Owner:THINKING ELECTRONICS INDAL

Zinc oxide piezoresistor material and preparation method

The invention discloses a zinc oxide piezoresistor material which comprises a main material and an additive, wherein the main material comprises 92-97mol% of ZnO; and the additive comprises 0.5-1.5mol% of Bi2O3, 0.1-1.2mol% of Cr2O3, 0.1-1.5mol% of MnCO3, 0.1-1.0mol% of BaCO3, 0.1-1.5mol% of Co3O4, 0.1-1.2mol% of SnO2, 0.1-1.0mol% of SrCO3, 0.1-1.0mol% of V2O5, 0.1-1mol% of H3BO3, and 0.005-0.1mol% of Al2(NO3)3.9H2O. When the zinc oxide piezoresistor material is adopted for preparing a finished product, the sintering temperature can be reduced to 900-940 DEG C while various excellent properties are ensured; when the zinc oxide piezoresistor material is adopted for preparing a sheet zinc oxide piezoresistor, a silver palladium alloy with a silver mass fraction greater than or equal to 85% can be matched as an inner electrode or pure silver can serve as the inner electrode; and the cost is lowered greatly.

Owner:SHENZHEN SUNLORD ELECTRONICS

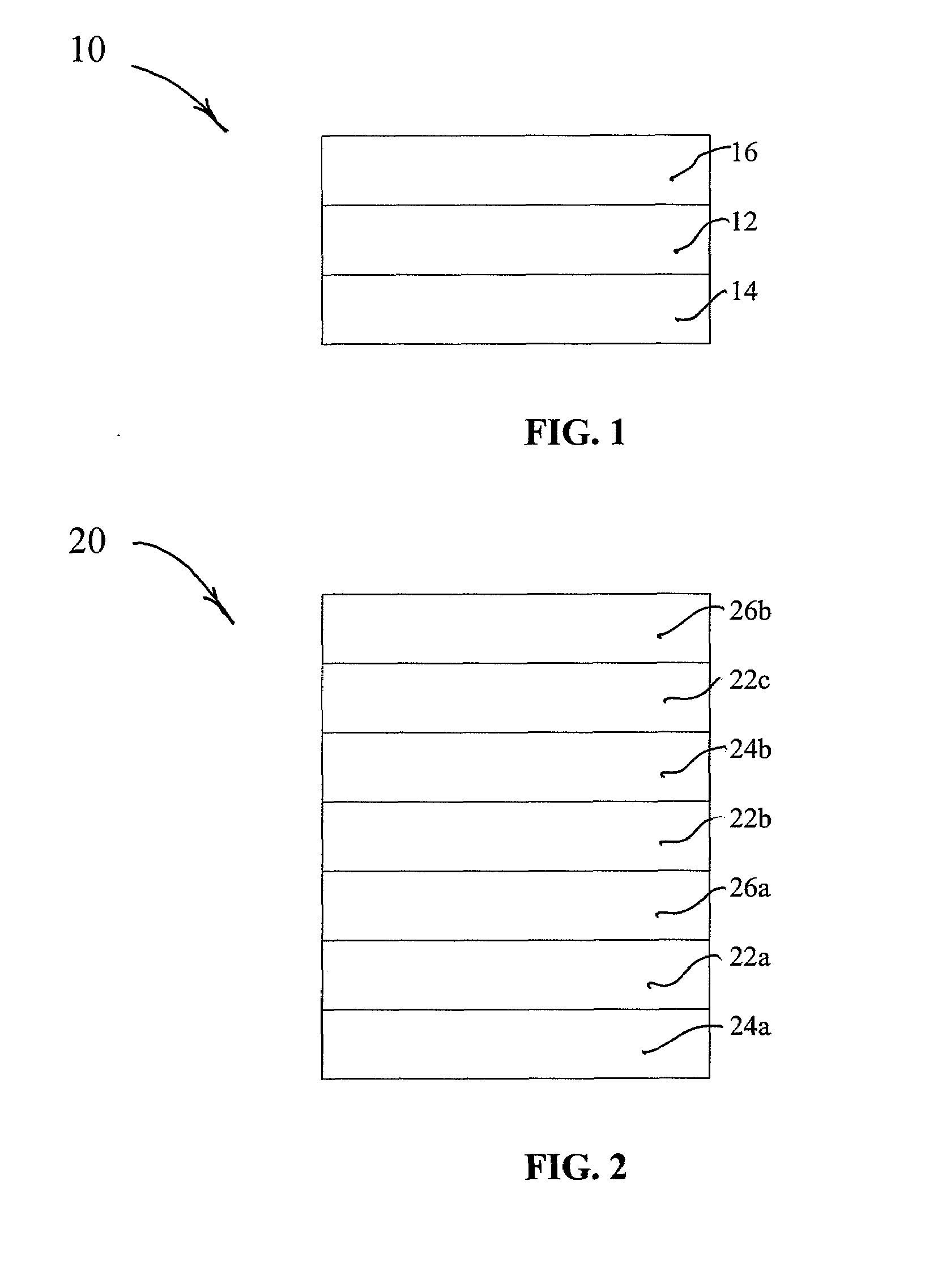

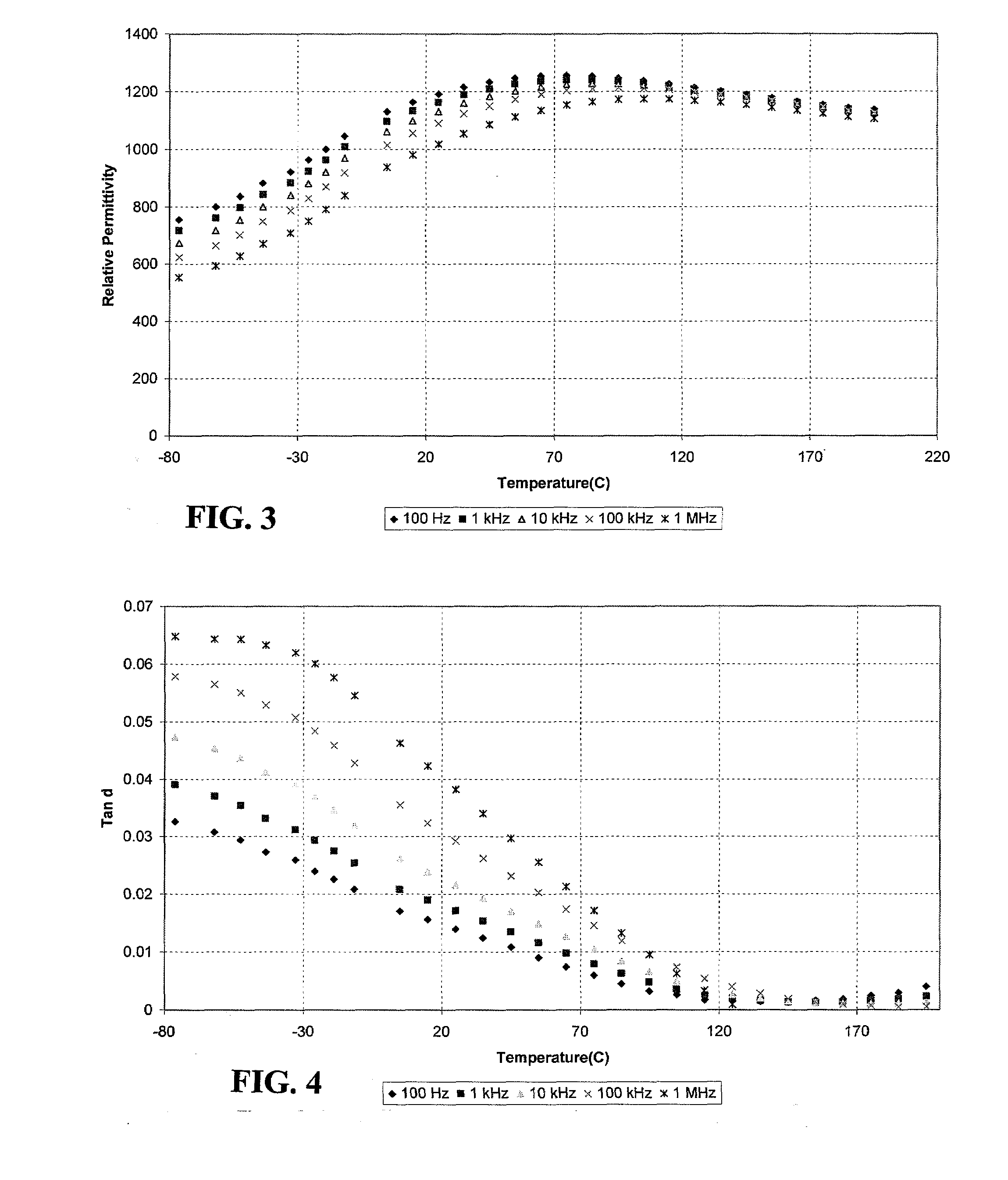

High-Temperature Dielectric Materials and Capacitors Made Therefrom

InactiveUS20080239627A1Reduce lossHigh dielectric constantFixed capacitor dielectricFixed capacitor terminalsCapacitanceLow voltage

A ceramic dielectric composition suitable for preparing capacitors for use in high-temperature service conditions is disclosed. The ceramic material and capacitors made from it exhibit unique and heretofore unrealizable properties including low variation in capacitance with voltage up to high fields, low variation in capacitance with temperature over a broad temperature range, retained high permittivity at temperatures up to 200° C. and beyond, low loss, low field-induced strain and adequate capacitance to retain performance at very low service temperatures. The material is based on sodium bismuth titanate (NBT) with selected additions of substituents and dopants to broaden and flatten its dielectric response, lower loss, lower strain, lower voltage coefficient and increase resistivity.

Owner:ALFRED UNIVERSITY +1

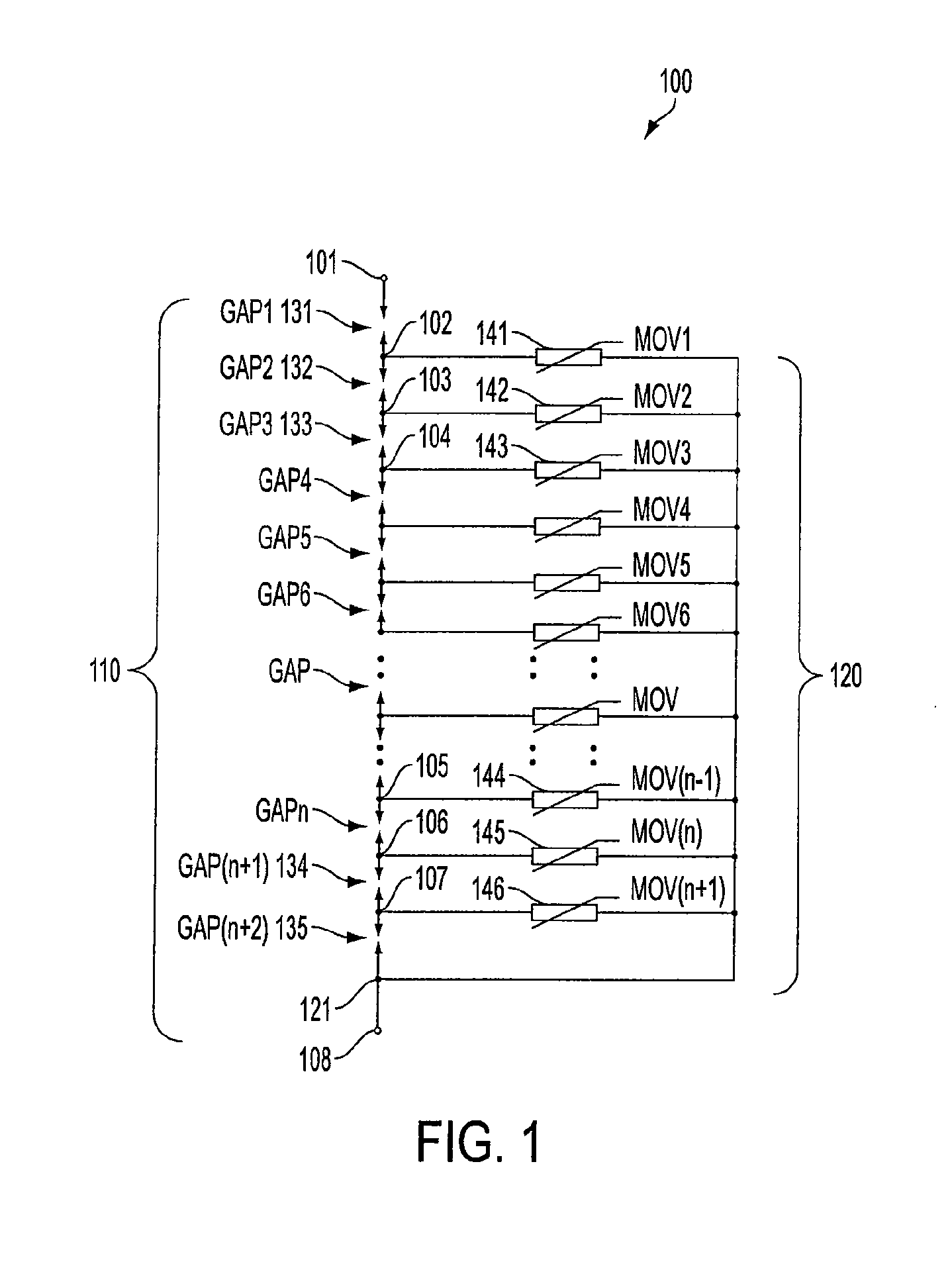

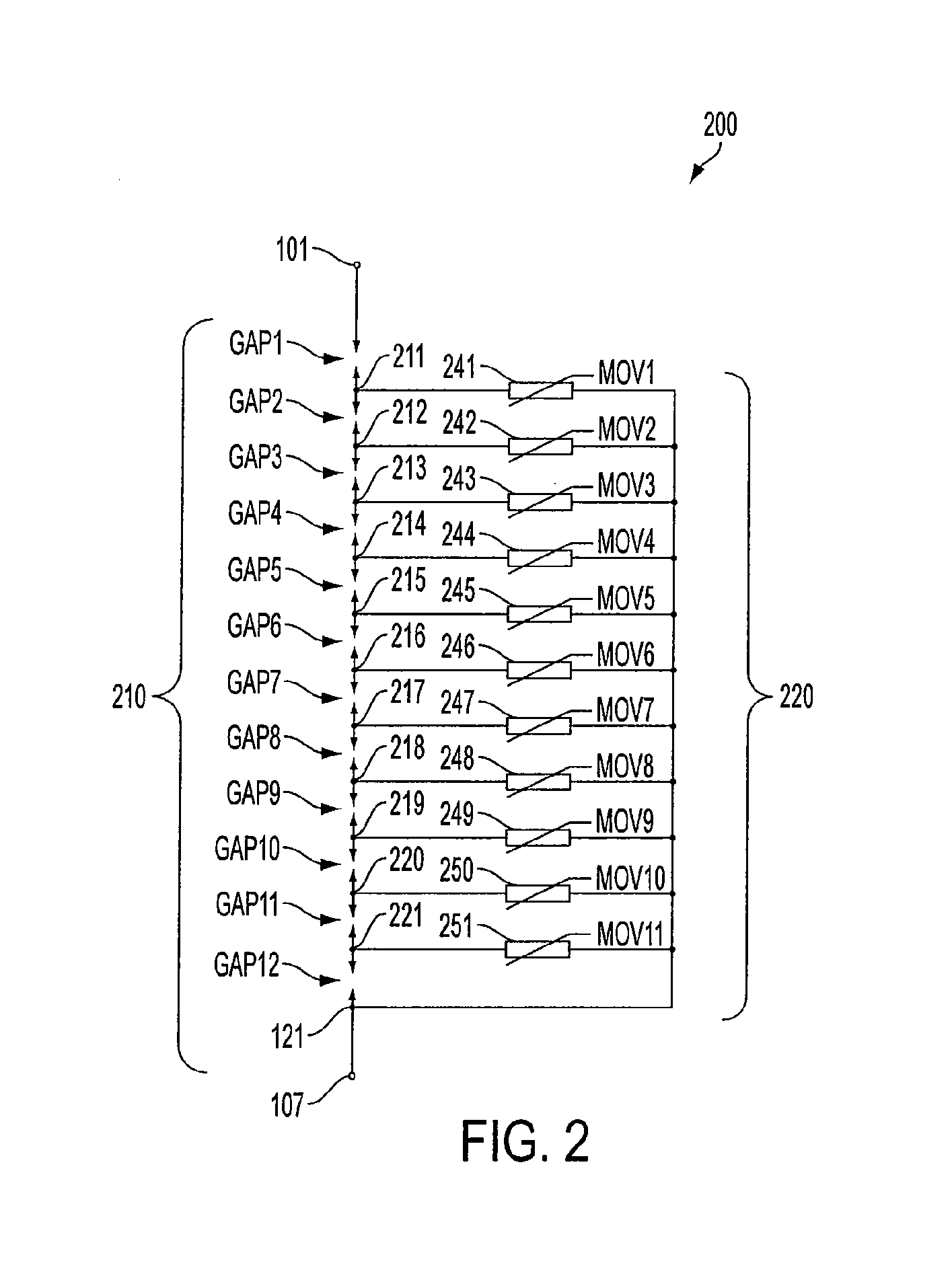

SURGE PROTECTION DEVICE USING METAL OXIDE VARISTORS (MOVs) AS THE ACTIVE ENERGY CONTROL MULTIPLE GAP DISCHARGING CHAIN

InactiveUS20120112872A1Simple designImprove protectionCurrent responsive resistorsVaristor coresEnergy controlSurge voltage

The present invention may provide a surge protection device, which may include a reference node, first, second, and third nodes, a first arcing section (GAP) coupled between the first and second nodes, and configured to receive a surge voltage from the first node, a first metal oxide varistor (MOV) coupled between the second and reference nodes, and configured to reduce the surge voltage to a first sub-surge voltage at the second node, a second arcing section (GAP) coupled between the second and third nodes, and configured to receive the first sub-surge voltage from the second node, and a second metal oxide varistor (MOV) coupled between the third and reference nodes, and configured to reduce the first sub-surge voltage to a second sub-surge voltage at the third node.

Owner:SHENZHEN DOWIN LIGHTNING PROTECTION TECH

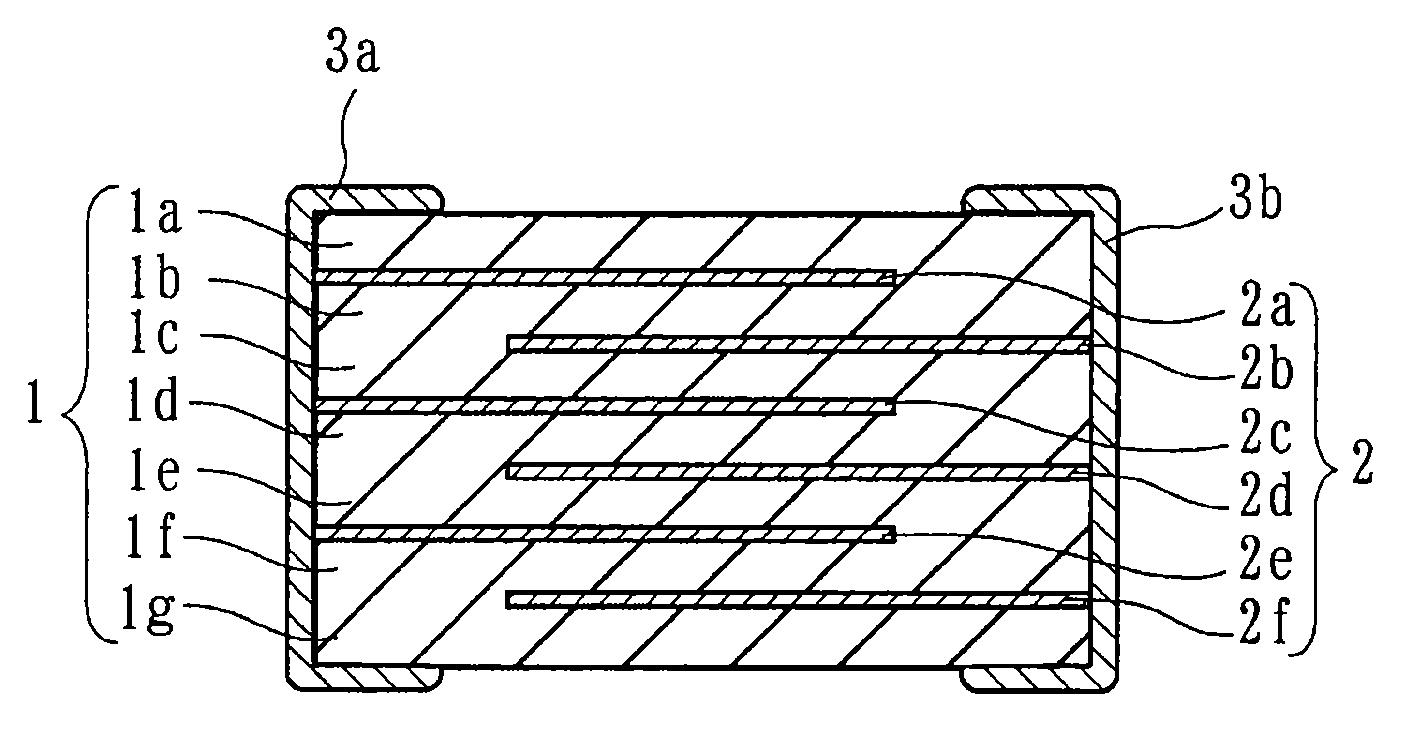

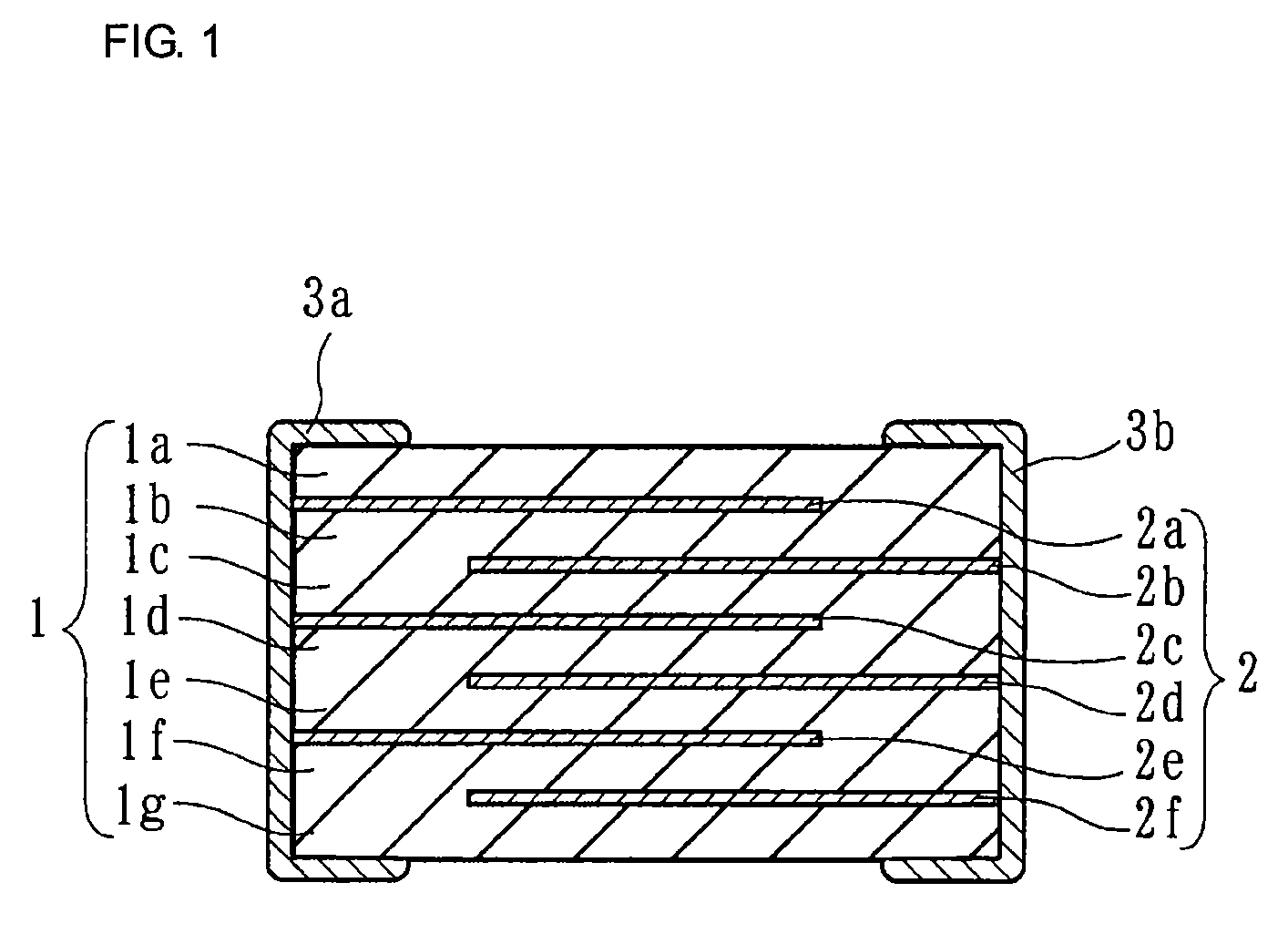

Monolithic semiconductor ceramic capacitor having varistor function and method for manufacturing monolithic semiconductor ceramic capacitor

InactiveUS7583493B2High dielectric strengthReduce capacitanceMaterial nanotechnologyFixed capacitor dielectricCeramic capacitorSolid solution

A monolithic semiconductor ceramic capacitor includes semiconductor ceramic layers made of a semiconductor ceramic having a Sr site and a Ti site. The semiconductor ceramic satisfies the inequality 1.000<m≦1.020, wherein m represents the molar ratio of the Sr site to the Ti site. The semiconductor ceramic contains crystal grains and has grain boundary layers. The crystal grains contain a donor element such as La or Sm in the form of a solid solution. The grain boundary layers contain an acceptor element such as Mn, Co, Ni or Cr. The amount of the acceptor element therein is equal to or less than 0.5 mol (preferably 0.3 to 0.5 mol) per 100 mol of Ti. The crystal grains have an average size of 1.0 μm or less (preferably 0.5 to 0.8 μm). Therefore, the monolithic semiconductor ceramic capacitor has good electrical properties, good resistivity, good dielectric strength, and high reliability and is suitable for thin or compact apparatuses.

Owner:MURATA MFG CO LTD

Porcelain composition for varistor and varistor

InactiveUS20050143262A1Solve the large leakage currentHigh surge resistanceCurrent responsive resistorsConductive materialIndiumLow voltage

A varistor is provided which can be driven at a low voltage, has a small leak current, and can realize a high ESD resistance and a high surge resistance. The varistor is formed using a ceramic composition for a varistor which contains zinc oxide as a primary component and sub-components including praseodymium at a content of 0.05 to 3.0 atomic percent of the total, cobalt at a content of 0.5 to 10 atom percent of the total, at least one of potassium, sodium, and lithium at a total content of 0.005 to 0.5 atom percent of the total, at least one of aluminum, gallium, and indium at a total content of 2×10−5 to 0.5 atom percent of the total, and zirconium at a content of 0.005 to 5.0 atom percent of the total.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com