Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

158results about How to "Go fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

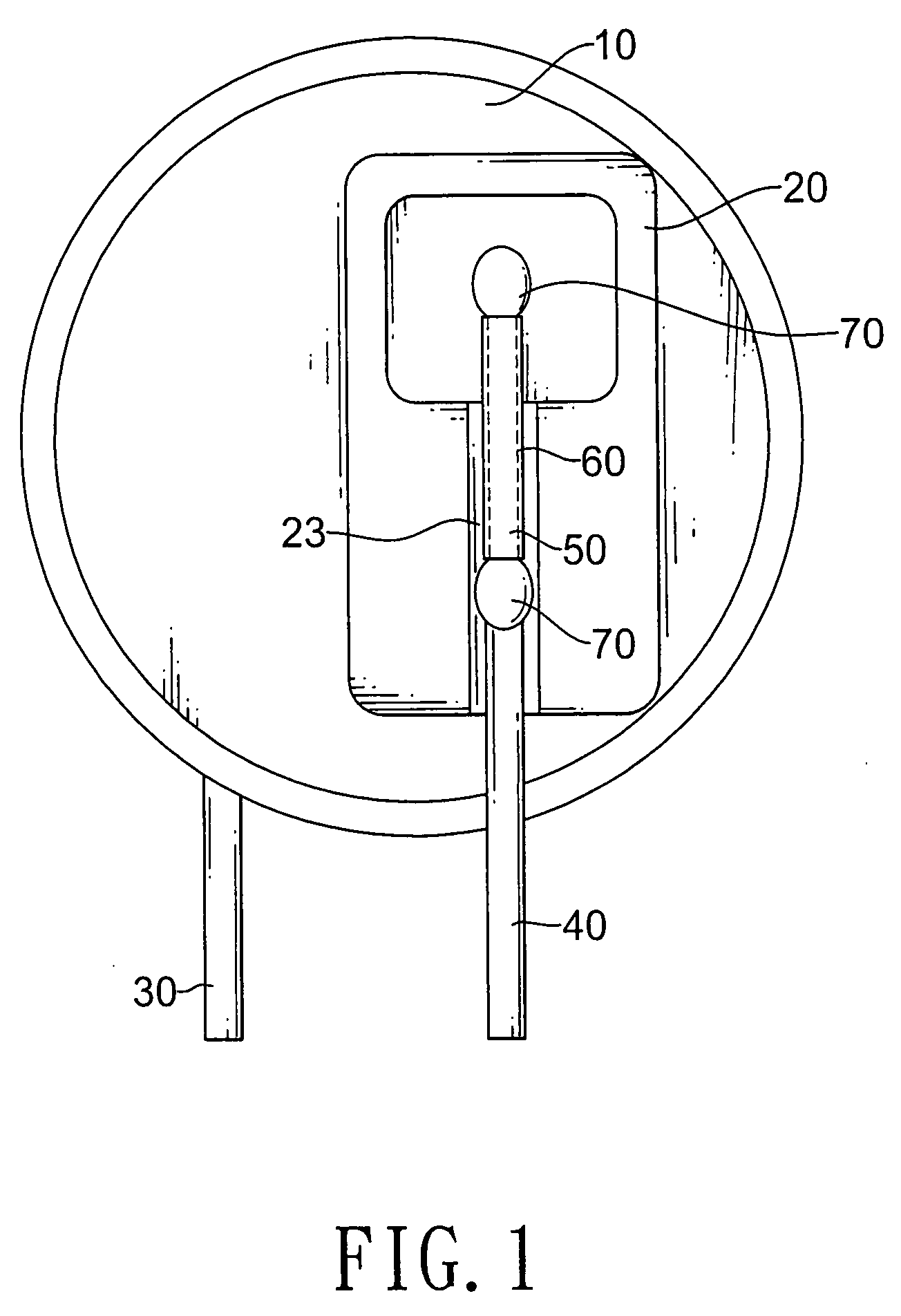

Metal oxide varistor with a heat protection

InactiveUS20080129440A1Go fastFacilitate speed of actionCurrent responsive resistorsResistor cooling/heating/ventillationElectrical resistance and conductanceEngineering

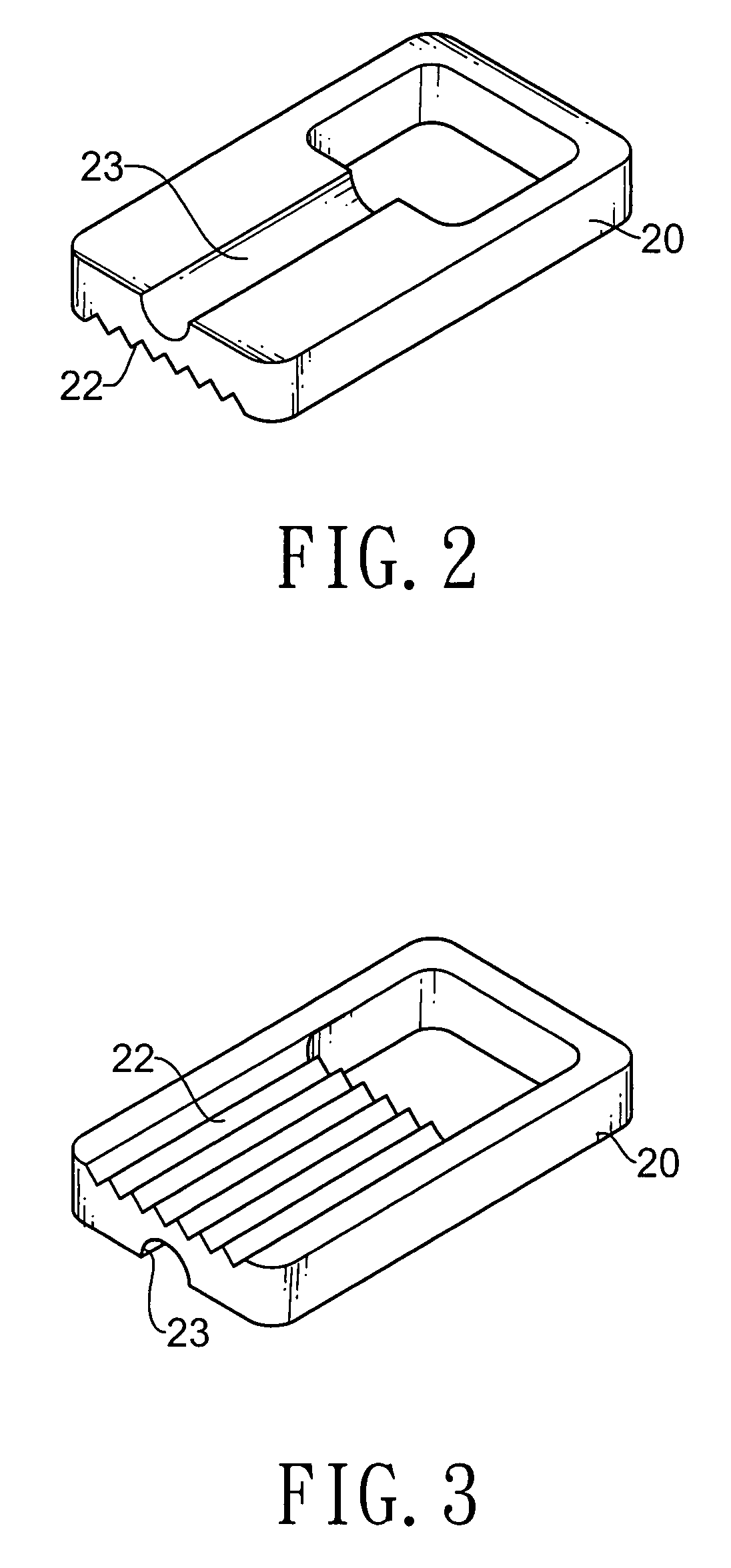

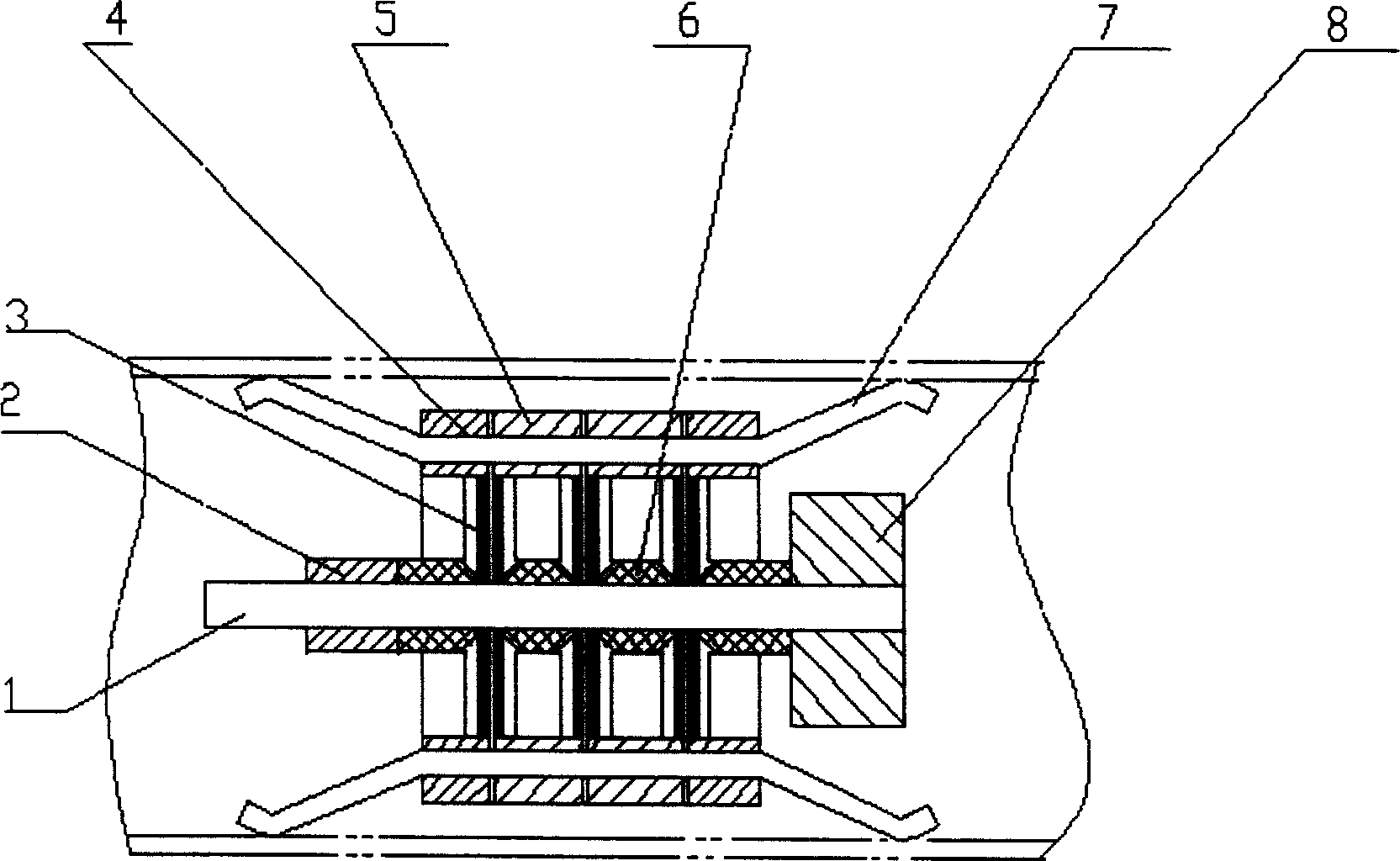

A metal oxide varistor integrally formed with a heat protection structure that will automatically go to open circuit in conditions of overheating due to sustained over-voltages. The metal oxide varistor integrally formed with a heat protection structure has a body, an insulation bracket, a number of terminals and a fuse. The insulation bracket is deposited on the body and has a number of slots. The fuse connects to the body and one of the terminals. The fuse is mounted one of the slots of the insulation bracket. The fuse reacts to the overheating timely and the melting fuse spreads quickly with the assistance of capillary action evolved by the slots of the insulation bracket to speed up the action to go to open circuit in against damage due to sustained over-voltages.

Owner:THINKING ELECTRONICS INDAL

Electronic device and method for displaying message in electronic device

InactiveUS20160313877A1Valid checkGo fastData switching networksInput/output processes for data processingHuman–computer interactionElectronic equipment

Owner:SAMSUNG ELECTRONICS CO LTD

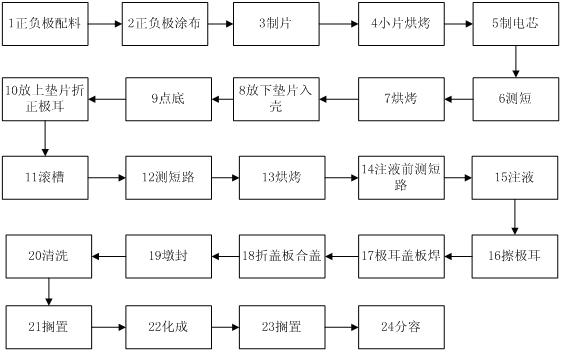

Production process of waterborne positive lithium ion battery

ActiveCN102185157ACoating speed is fastReduce the temperatureFinal product manufactureCell electrodesCarbon blackAdhesive

The invention belongs to the field of production of lithium ion batteries, in particular to a production process of a waterborne positive lithium ion battery. The production process comprises the following steps of: preparing an anode and a cathode, coating on the anode and the cathode, flaking, baking, preparing an electric core, testing short circuit, baking, putting a lower spacer into a shell, welding a bottom, putting an upper spacer and folding a positive lug, rolling a slot and testing short circuit; and injecting liquid, wiping the positive lug, welding the positive lug with a cover plate, folding the cover plate for covering, sealing, cleaning, standing, performing formation, standing and performing capacity grading. The anode comprises the following components in parts by weight: 100 parts of lithium iron phosphate, 3-4 parts of super conductive carbon black, 2-3 parts of conductive graphite, 3.5-4 parts of waterborne adhesive, 2.5-3 parts of NMP (N-methylpyrrolidone) and 80-85 parts of deionized water and is prepared by the following steps of: mixing the waterborne adhesive, the NMP and the deionized water; adding other raw materials; and stirring to obtain anode slurry. Compared with the conventional oily process of the lithium ion battery, the production process has the advantages of low energy consumption, high production efficiency, low product cost and the like.

Owner:安徽风驰新能源科技股份有限公司

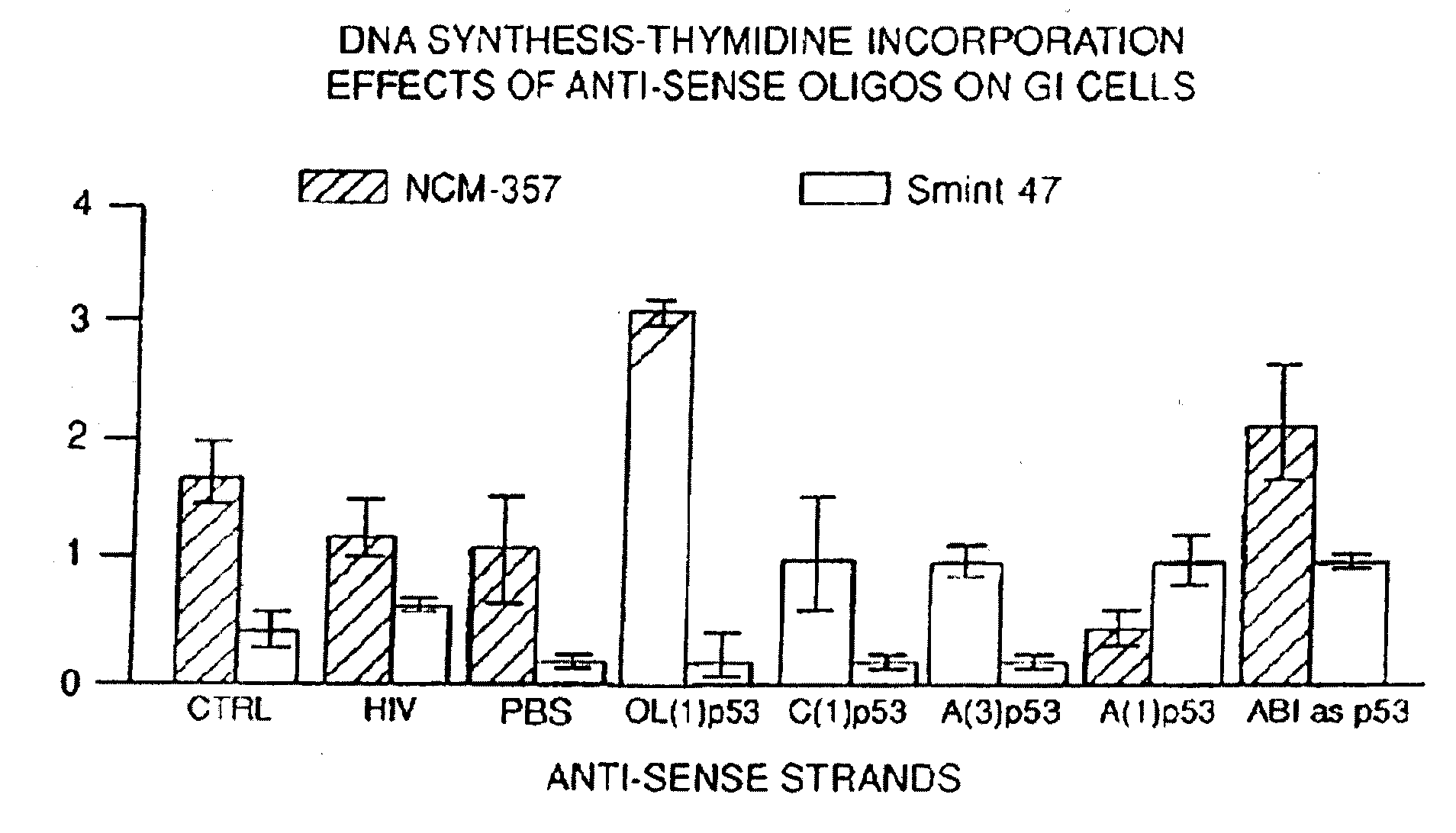

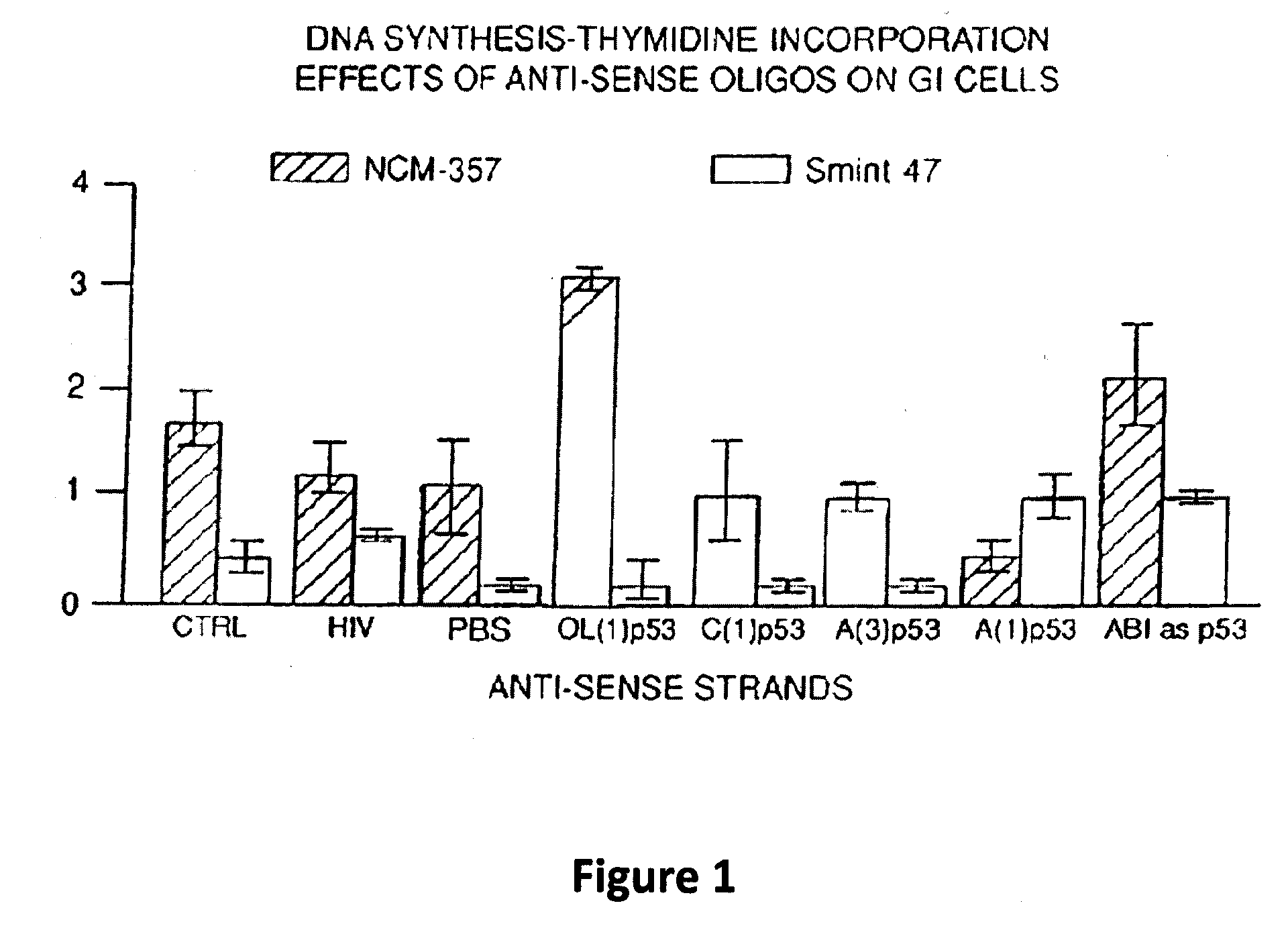

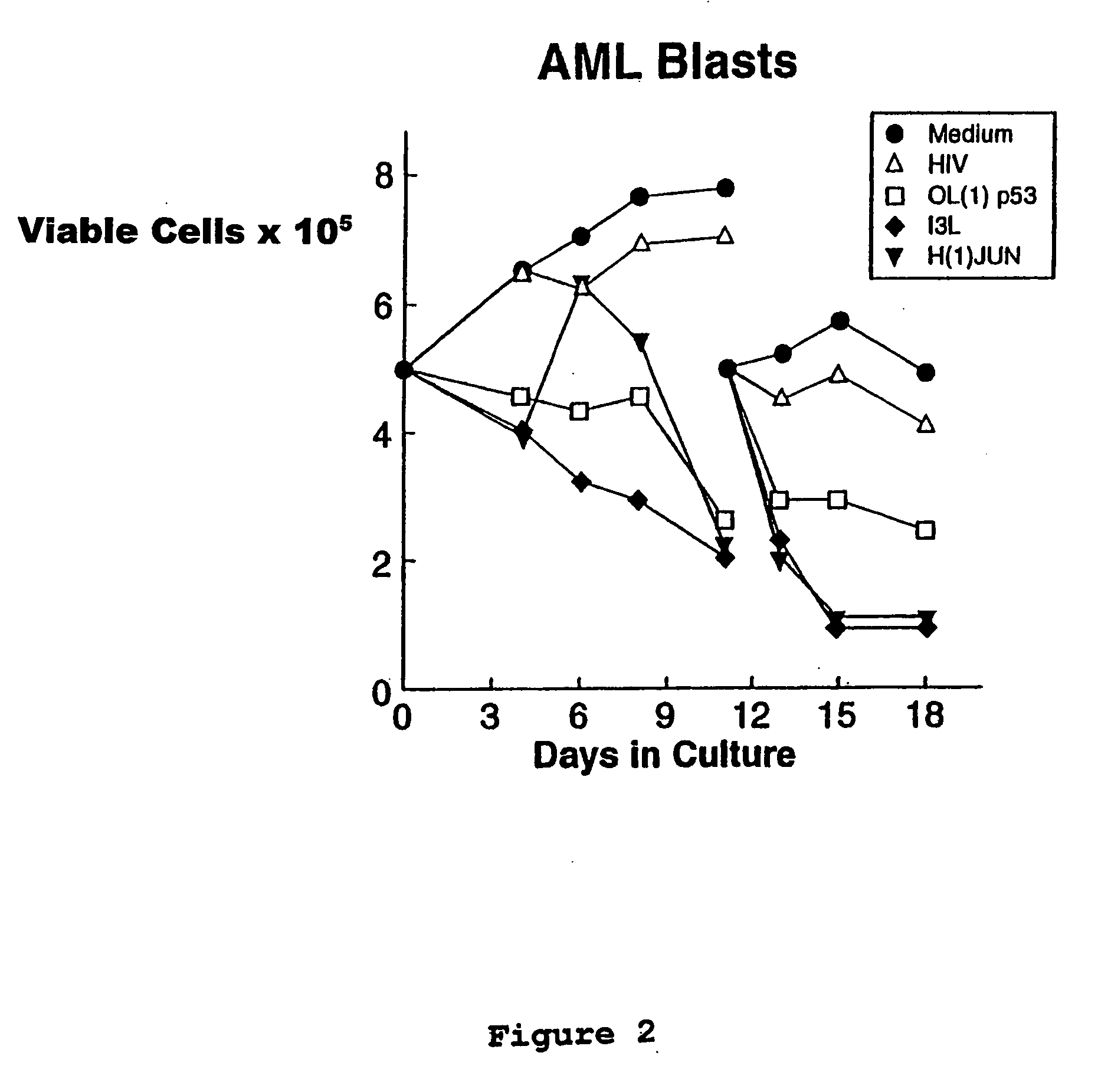

Methods and Compositions for Cellular Reprogramming

Compositions and methods useful for the treatment of aberrant programming diseases, particularly those associated with aberrant apoptosis are disclosed

Owner:BOARD OF RGT UNIV OF NEBRASKA

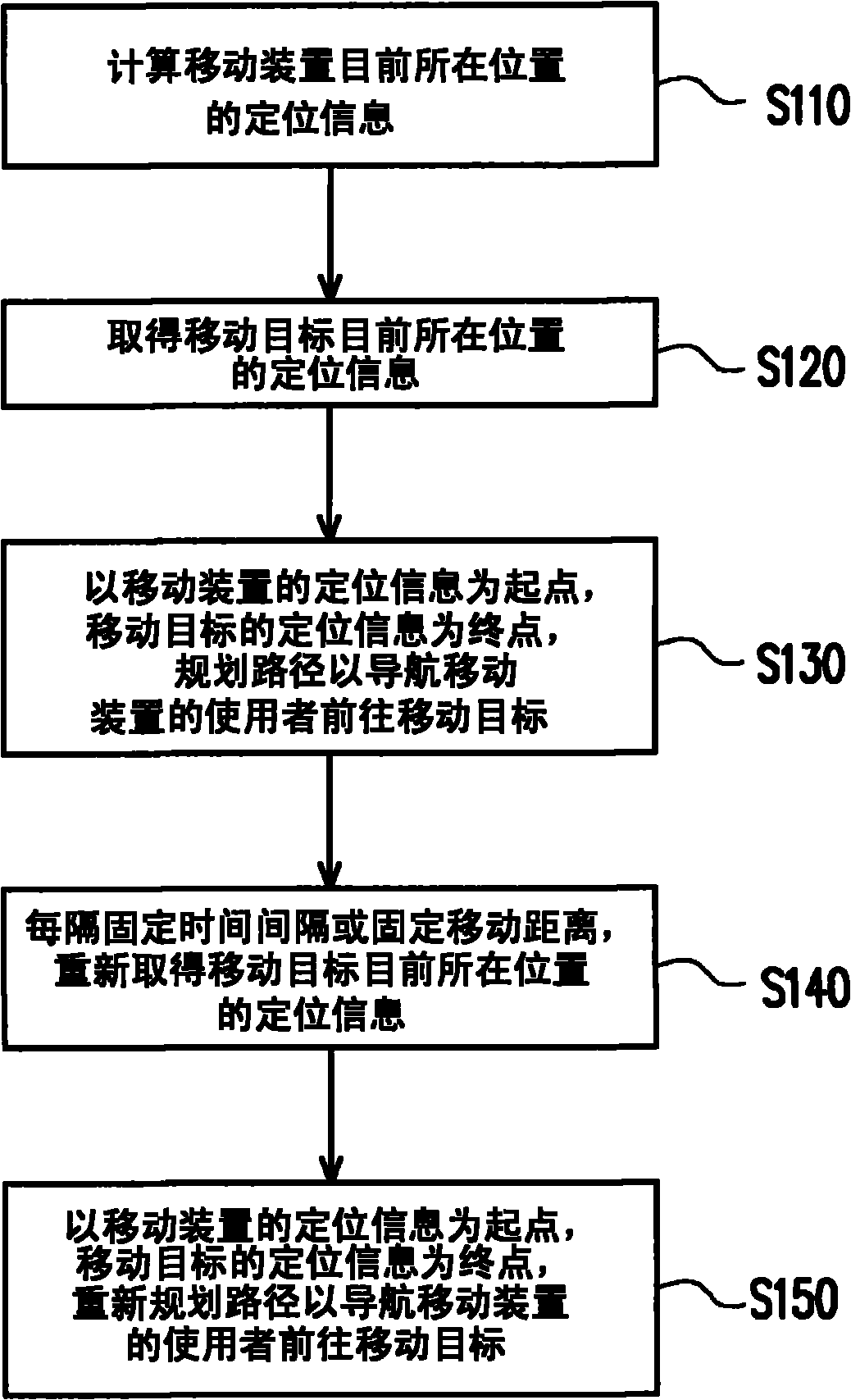

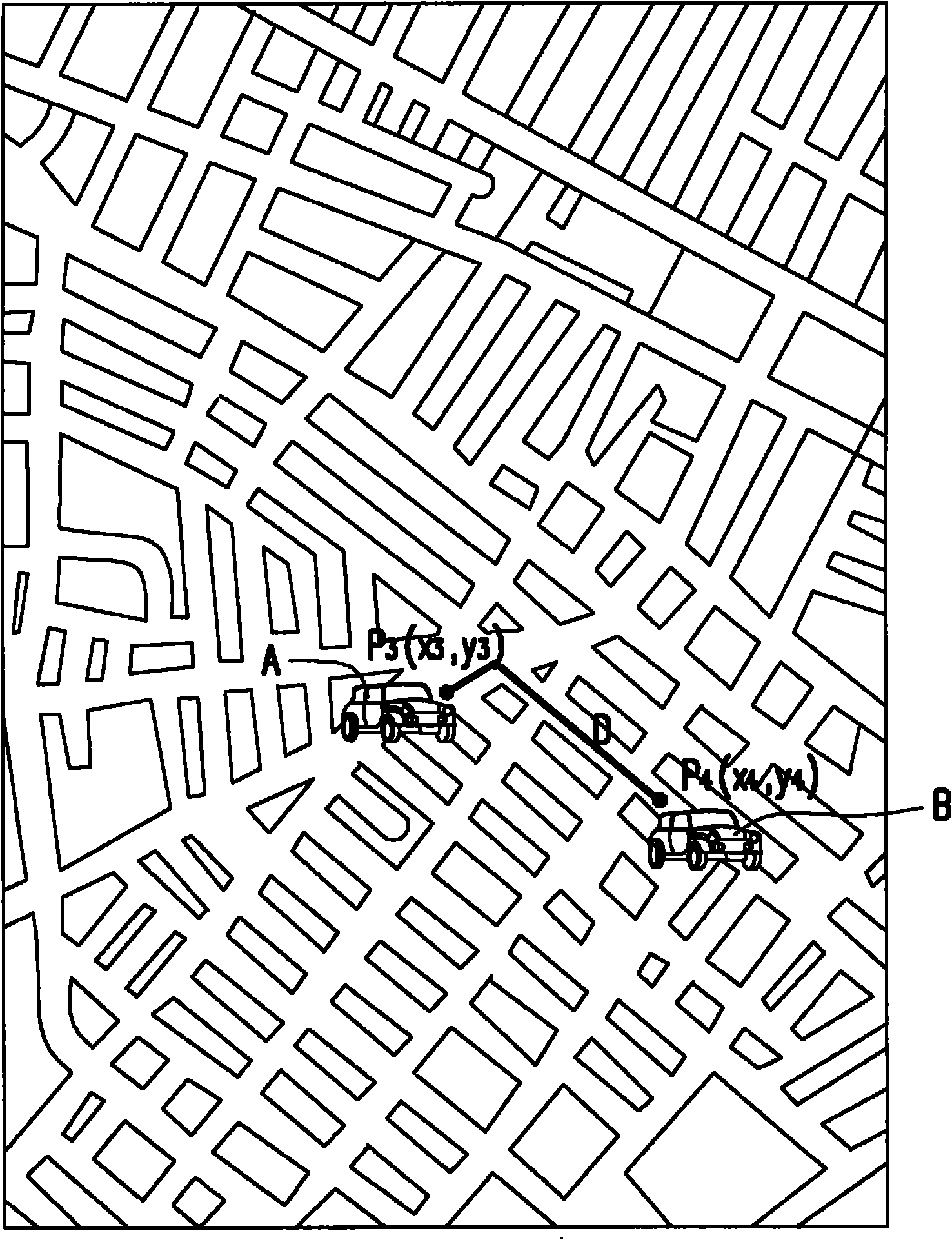

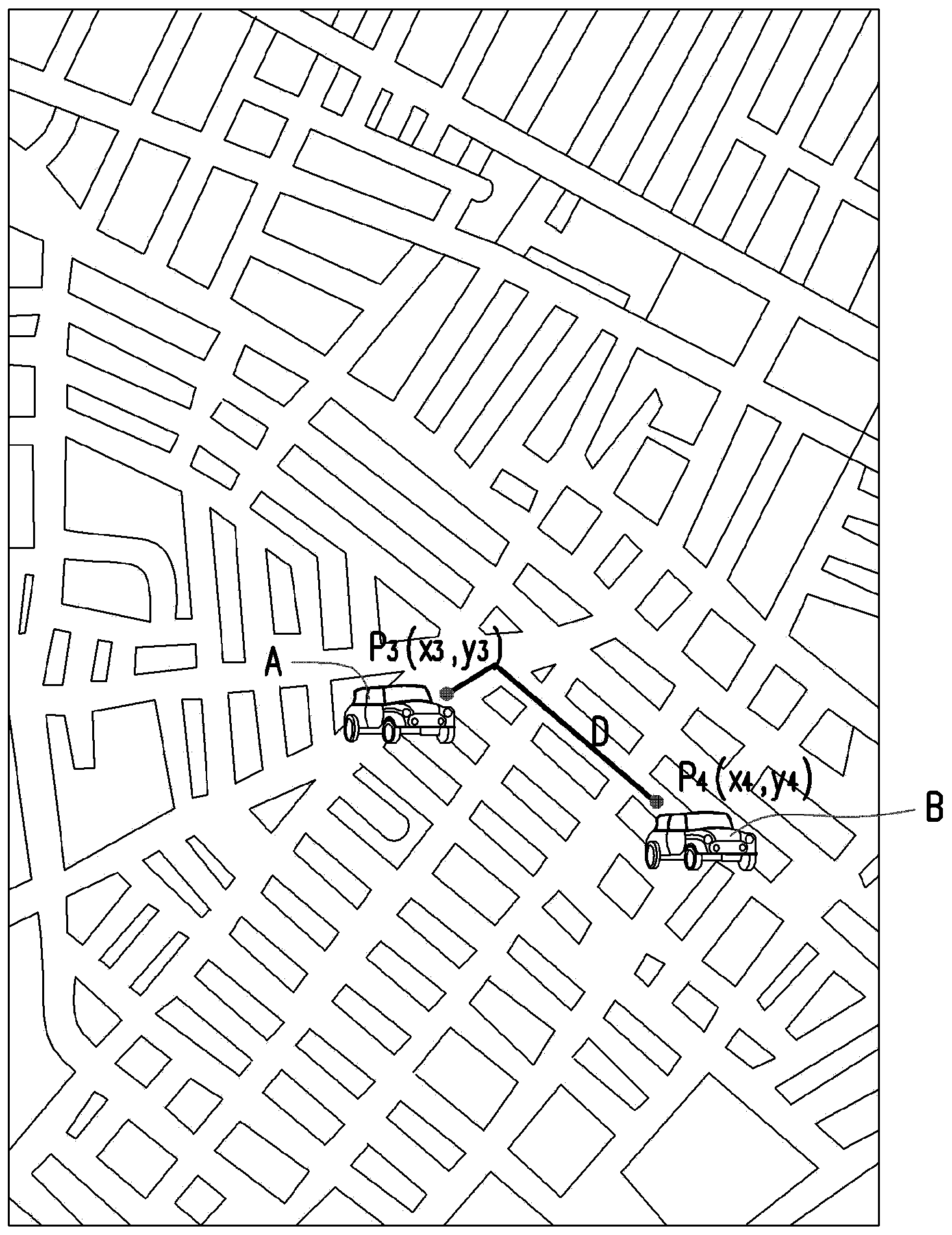

Mobile target tracking and navigation method, device thereof and computer program product used

The invention discloses a mobile target tracking and navigation method and a device thereof. The method comprises the following steps: calculating the positioning information of the position of a mobile device, obtaining the positioning information of the position of a mobile target, and planning a path for guiding the user of the mobile device to go to the mobile target with the positioning information of the mobile device as the starting point and the positioning information of the mobile target as the end point; then, re-obtaining the positioning information of the current position of the mobile target at intervals of fixed time span and / or fixed traveling distance, and re-planning a path for guiding the user of the mobile device to go to the mobile target with the positioning information of the mobile device as the starting point and the positioning information of the mobile target as the end point.

Owner:HTC CORP

Method and device for controlling to support foot of humanoid robot in single leg supporting period

InactiveCN103042526ARotate for increased stride lengthGo fastProgramme-controlled manipulatorFoot supportsEngineering

The invention discloses a method and a device for controlling to support a foot of a humanoid robot in a single leg supporting period and belongs to the field of robots. An expected virtual zero moment point is arranged outside the foot supporting region, and a step increasing quantity generated through the rotation of the robot can be acquired. The method comprises steps of calculating the virtual zero moment point and detecting the rotation angle of the supporting foot; determining the rotation angle of the supporting foot; determining the position of the virtual zero moment point; and limiting the position of the virtual zero moment point. The device comprises a calculating and detecting module, a rotary angle control module, a virtual zero moment point position control module and a virtual zero moment point position limiting module. By the aid of the method and the device, the humanoid robot can support the foot to rotate in the single leg supporting period, the walking step is increased, and the control is simple and reliable.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

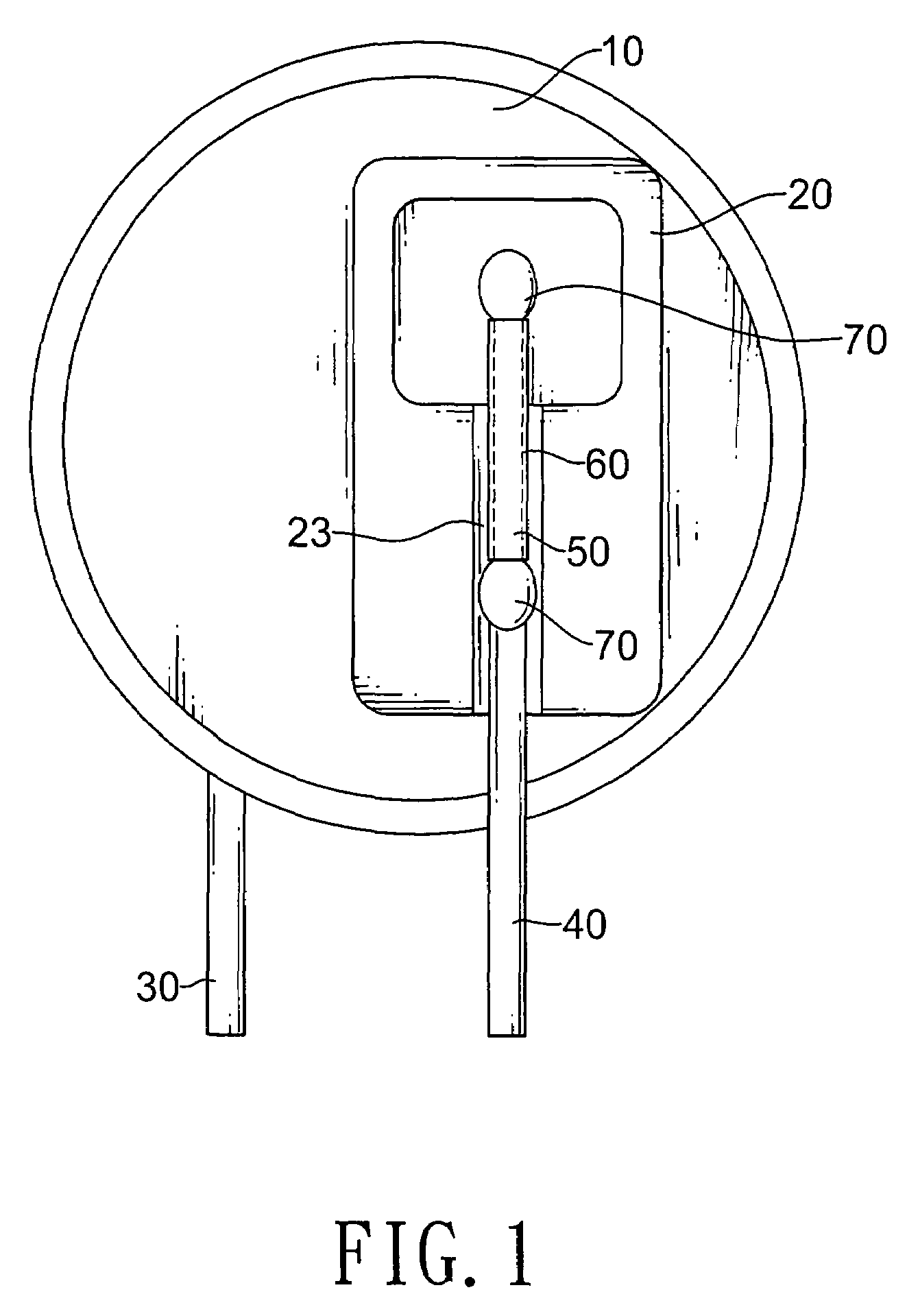

Metal oxide varistor with a heat protection

InactiveUS7453681B2Go fastFacilitate speed of actionCurrent responsive resistorsResistor cooling/heating/ventillationElectrical resistance and conductanceEngineering

A metal oxide varistor integrally formed with a heat protection structure that will automatically go to open circuit in conditions of overheating due to sustained over-voltages. The metal oxide varistor integrally formed with a heat protection structure has a body, an insulation bracket, a number of terminals and a fuse. The insulation bracket is deposited on the body and has a number of slots. The fuse connects to the body and one of the terminals. The fuse is mounted one of the slots of the insulation bracket. The fuse reacts to the overheating timely and the melting fuse spreads quickly with the assistance of capillary action evolved by the slots of the insulation bracket to speed up the action to go to open circuit in against damage due to sustained over-voltages.

Owner:THINKING ELECTRONICS INDAL

Flying motorcycle or automobile and flight attitude adjustment method thereof

The invention discloses a flying motorcycle or automobile and a flight attitude adjustment method thereof. A flying motorcycle or automobile body is provided with a thruster and a thruster driving device. A propeller is mounted in the thruster. The thruster driving device controls rotation direction of the thruster. The thruster comprises a left front thruster body, a right front thruster body and a rear thruster body, wherein the left front thruster body and the right front thruster body are mounted on the left side and the right side of the front portion of the motorcycle or automobile body symmetrically, and the rear thruster body is mounted on the rear side of the motorcycle or automobile body. According to the flight attitude adjustment method, angle inclination of the thruster bodies mounted on the two sides and the rear portion of the flying motorcycle or automobile is driven by the thruster driving device to achieve turning, forward movement, backward movement, left translation and right translation of the flying motorcycle or automobile. The flying motorcycle or automobile can be always kept in a horizontal state during flight, can be applied to the field of manned flight and is quite wide in application range.

Owner:JIANGSU DIGITAL EAGLE TECH DEV

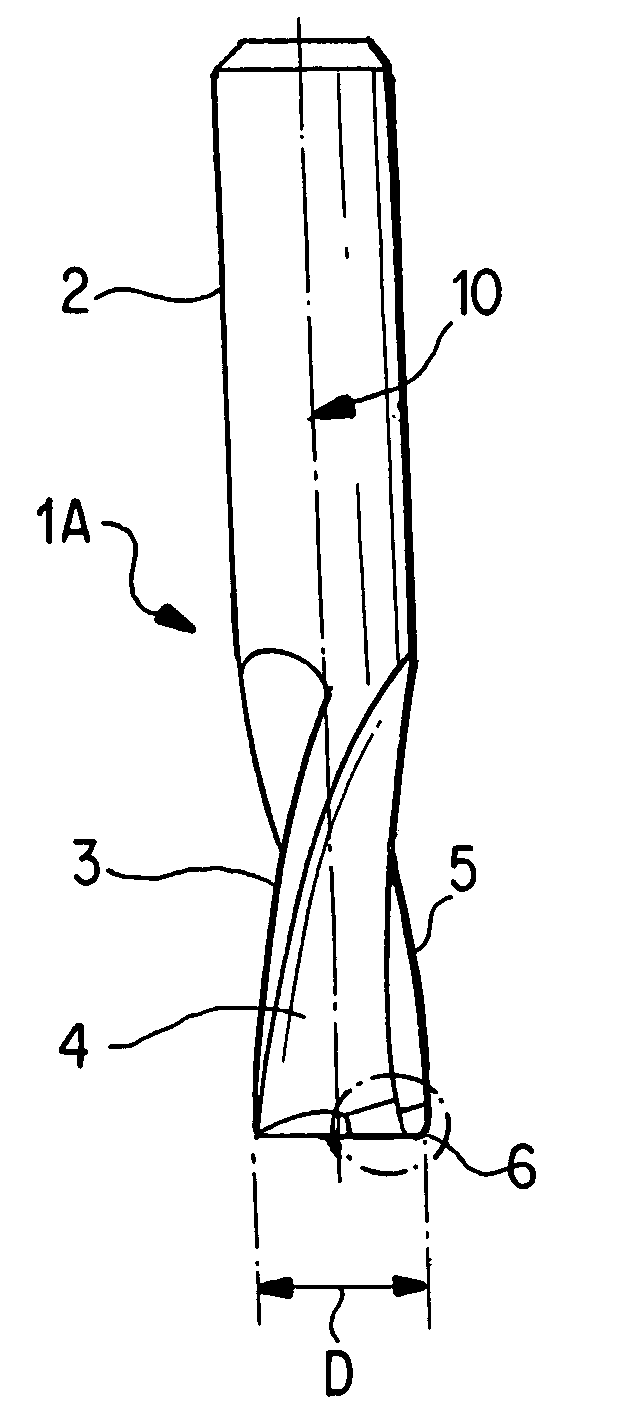

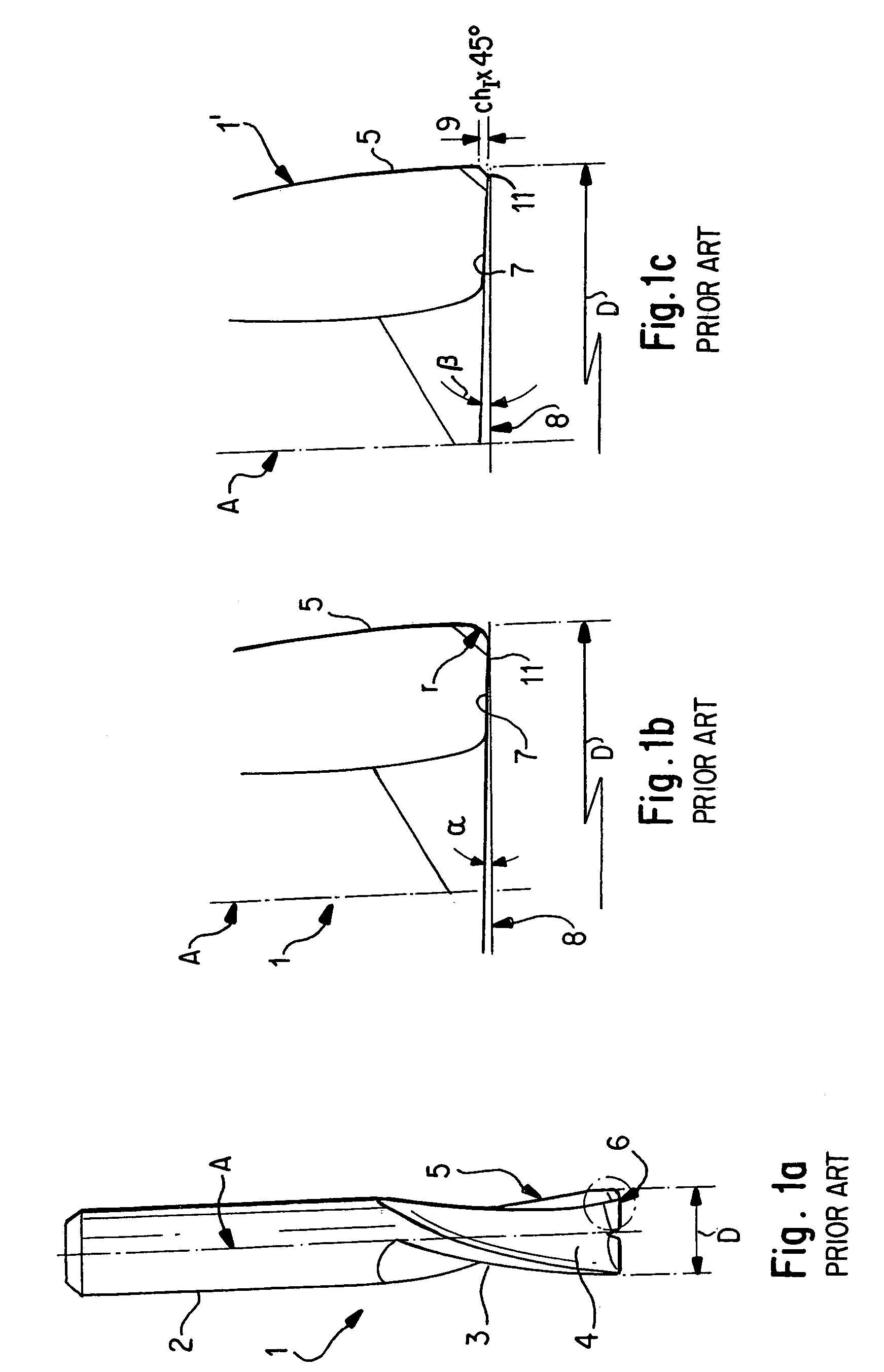

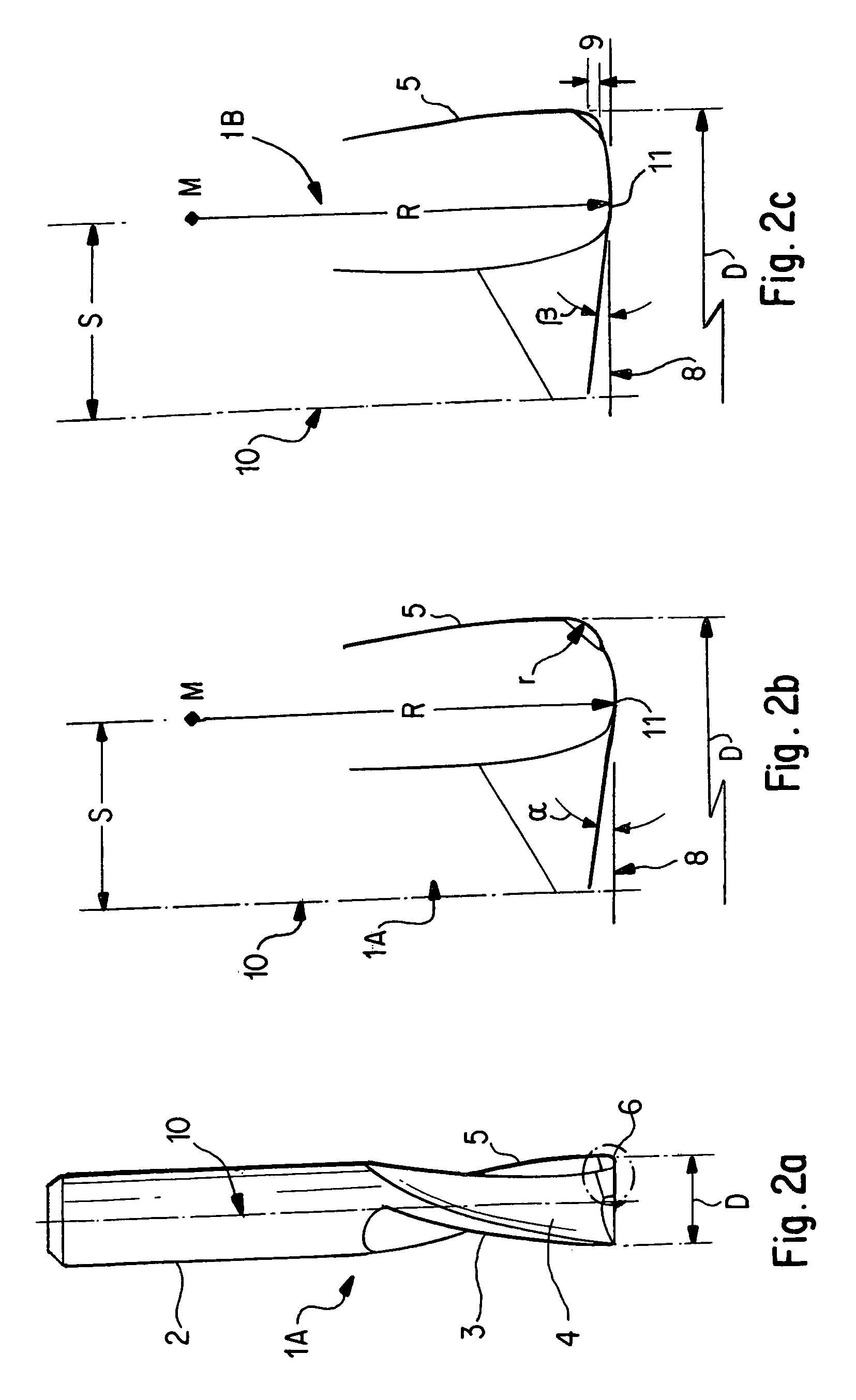

Shank milling cutter having a wiper radius

InactiveUS20050186037A1Easy surface processingExtend your lifeMilling cuttersShaping cuttersMilling cutterEngineering

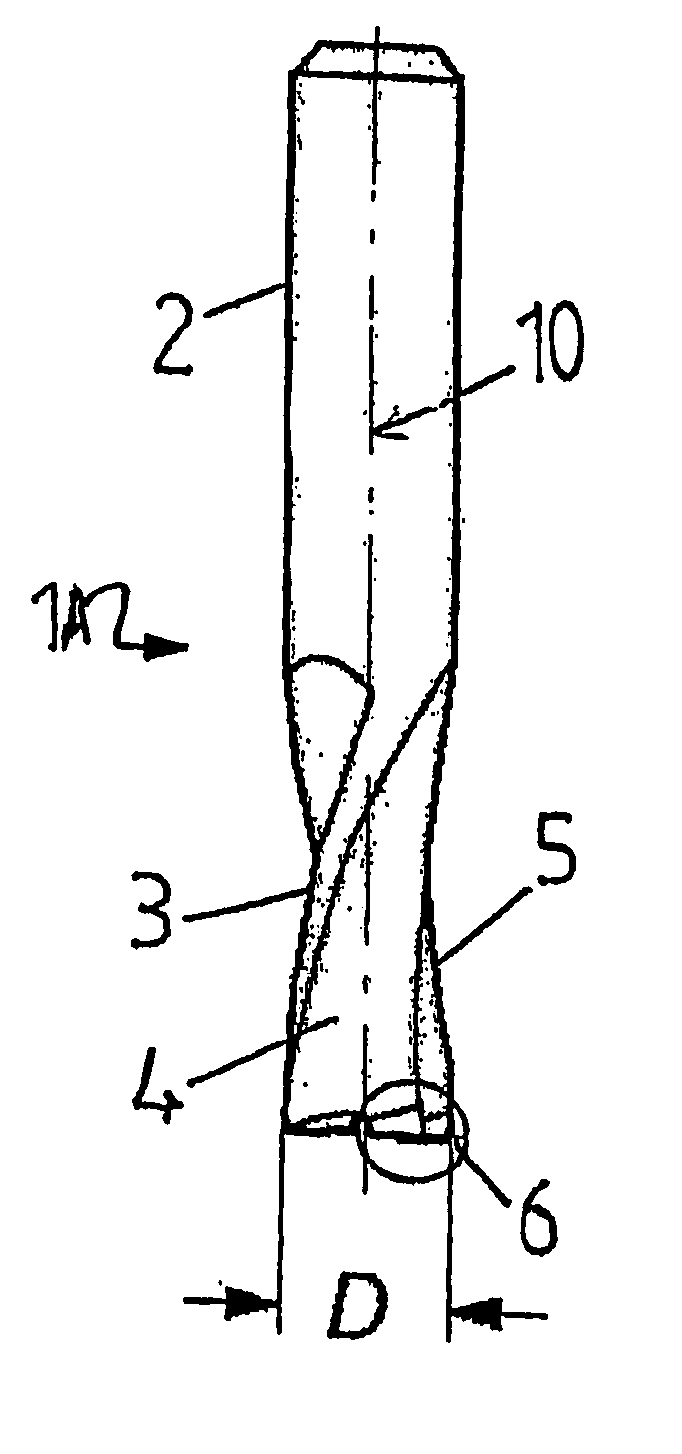

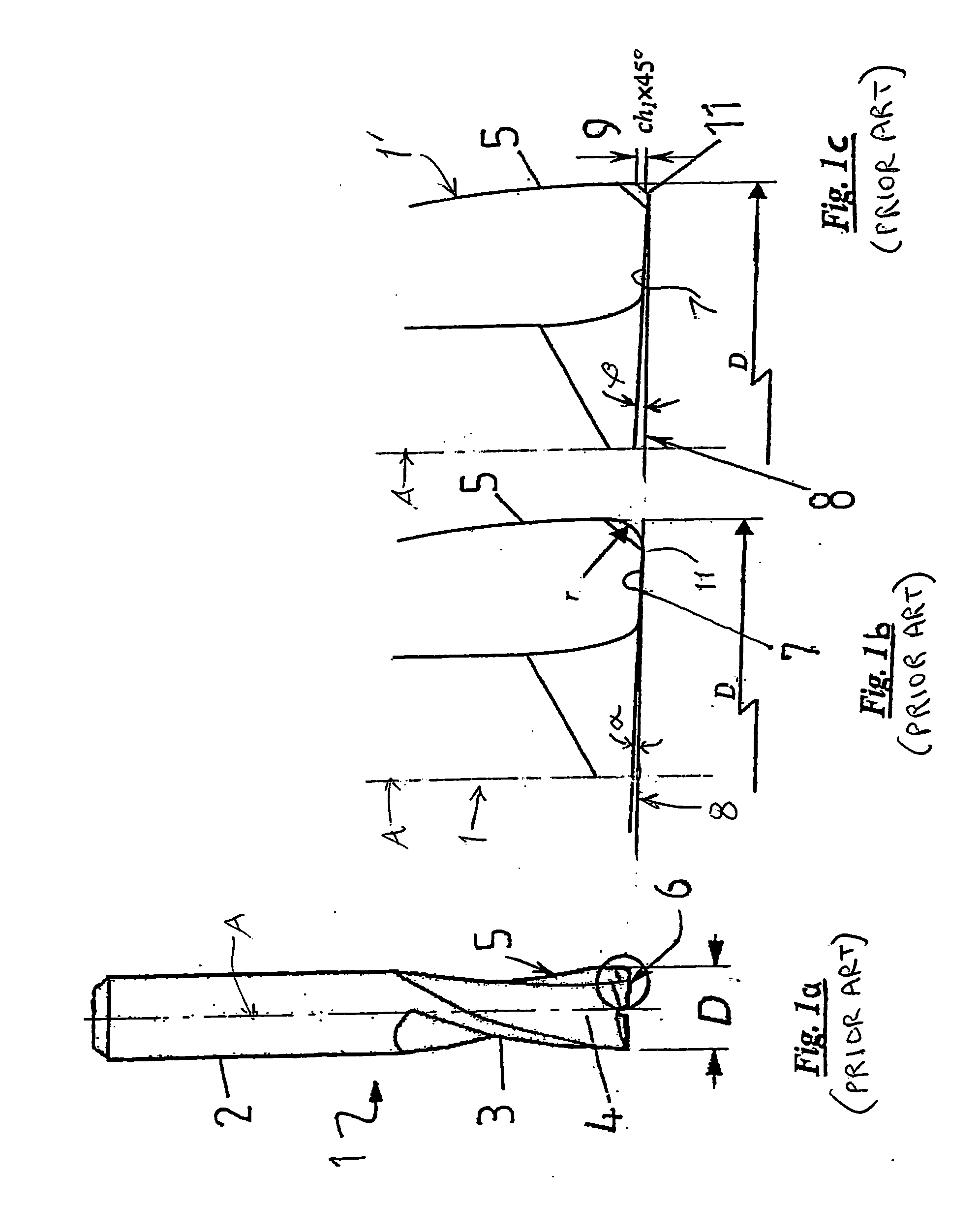

A shank milling cutter includes a cutting portion which is intended to come into engagement with the workpiece, wherein the envelope surface of the cutting portion is substantially cylindrical. At least one major cutting edge is arranged at the peripheral surface of the cutting portion and at least one minor cutting edge (face cutting edge) is arranged at the end face of the cutting portion and with an end diameter D. The minor cutting edge, in projection onto a plane containing the milling cutter axis, has a convexly curved portion with a radius of curvature R>D / 2 and a center of curvature M located such that a distance from the center of curvature M to the axis is in a range from zero to a value smaller than D / 2.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Composite oil cylinder

ActiveCN101929486ASimple structureShorten the lengthFluid-pressure actuatorsCylinder blockPiston rod

The invention discloses a composite oil cylinder, which comprises a main cylinder assembly and a secondary cylinder assembly, wherein the main cylinder assembly comprises a main cylinder body, a main piston rod and a main piston arranged in the main cylinder body, and a main cylinder rear cover assembly arranged at the tail part of the main cylinder body; the main piston divides the cavity of themain cylinder body into a main cylinder pressing cavity and a main cylinder return cavity; the main cylinder body is provided with an oil inlet part for communicating the main cylinder pressing cavity and an oil tank and an oil outlet part for communicating the main cylinder return cavity and the oil tank; a main rod cavity with one open end is formed in the main piston rod; the secondary cylinder assembly comprises a secondary piston rod passing through the main rod cavity, a secondary piston arranged at the inner end of the secondary piston rod and used for dividing the main rod cavity intoa secondary cylinder pressing cavity and a secondary cylinder turn cavity, an oil inlet structure for communicating the secondary cylinder pressing cavity and the oil tank, and an oil outlet structure for communicating the secondary cylinder return cavity and the oil tank; the outer end of the secondary piston rod is fixed on the main cylinder rear cover assembly; and an oil seal assembly linked with the main piston rod is arranged between the open end wall of the main rod cavity and the outer wall of the secondary piston rod and used for closing the secondary cylinder return cavity.

Owner:HUZHOU MACHINE TOOL WORKS

Intellectualized cooking method

InactiveUS8334004B2Disperse fastSufficient touchingMilk preservationKitchen equipmentProcess engineeringCooking methods

Owner:LIU XIAOYONG

Air conditioner and quick startup control method thereof

ActiveCN102353189AGo fastStart fastSpace heating and ventilation safety systemsSpace heating and ventilation control systemsFour-way valveSystem pressure

The invention discloses a quick startup control method of an air conditioner. The air conditioner includes an air conditioner main body and a remote controller. The control method includes the following steps: 1) during a refrigeration operation, the air conditioner receiving a stop instruction sent by the remote controller and then entering into a standby state, the opening of an adjustable throttling member being a maximum value, high pressure refrigerant in an outdoor heat exchanger fast flowing to an indoor heat exchanger through the adjustable throttling member; 2) during a heating operation, the air conditioner receiving the stop instruction sent by the remote controller and then entering into the standby state, the opening of the adjustable throttling member being the maximum value, the high pressure refrigerant in the indoor heat exchanger fast flowing to the outdoor heat exchanger through the adjustable throttling member; and 3) the air conditioner receiving a starting instruction sent by the remote controller and restarting. An electronic expansion valve of the invention can balance a system pressure in 15 seconds, and compared with the pressure balancing time of about 3 minutes of the prior art, the time is greatly shortened, so that the air conditioner can be quickly restarted, the comfort of the air conditioner can be effectively improved and the service life of the air conditioner can be effectively prolonged.

Owner:MIDEA GRP CO LTD

Invasive four-legged wheel type robot

The invention discloses an invasive four-legged wheel type robot. The robot comprises a supporting plate, a circuit board and four supporting legs, and is characterized in that each supporting leg consists of a rotary steering engine, a swinging steering engine, a direct-current motor and a wheel; an output shaft of each rotary steering engine is fixed on the supporting plate along the vertical direction; a shell of each swinging steering engine and the shell of each rotary steering engine are fixed together; the output shaft of each swinging steering engine is arranged along the longitudinal direction of the supporting plate; the output shaft of each direct-current motor is arranged along the horizontal direction of the supporting plate; each direct-current motor and the output shaft of each swinging steering engine are fixed by a U-shaped bracket; each wheel is fixed on the output shaft of each direct-current motor; the supporting plate is provided with an electromagnetic gun and a power supply capacitor. The robot disclosed by the invention is capable of quickly moving forwards, moving backwards, making a turn or rotating in situ by controlling the direct-current motor; the robot can walk by the four legs by controlling the swing steering engines and the rotary steering engines; therefore, the robot realizes the functions of crossing barriers and keeping away from the barriers, so the robot is applicable for walking in complicated environment; by the electromagnetic gun, the robot is capable of attacking a target.

Owner:麟州(巨野)孵化器有限公司

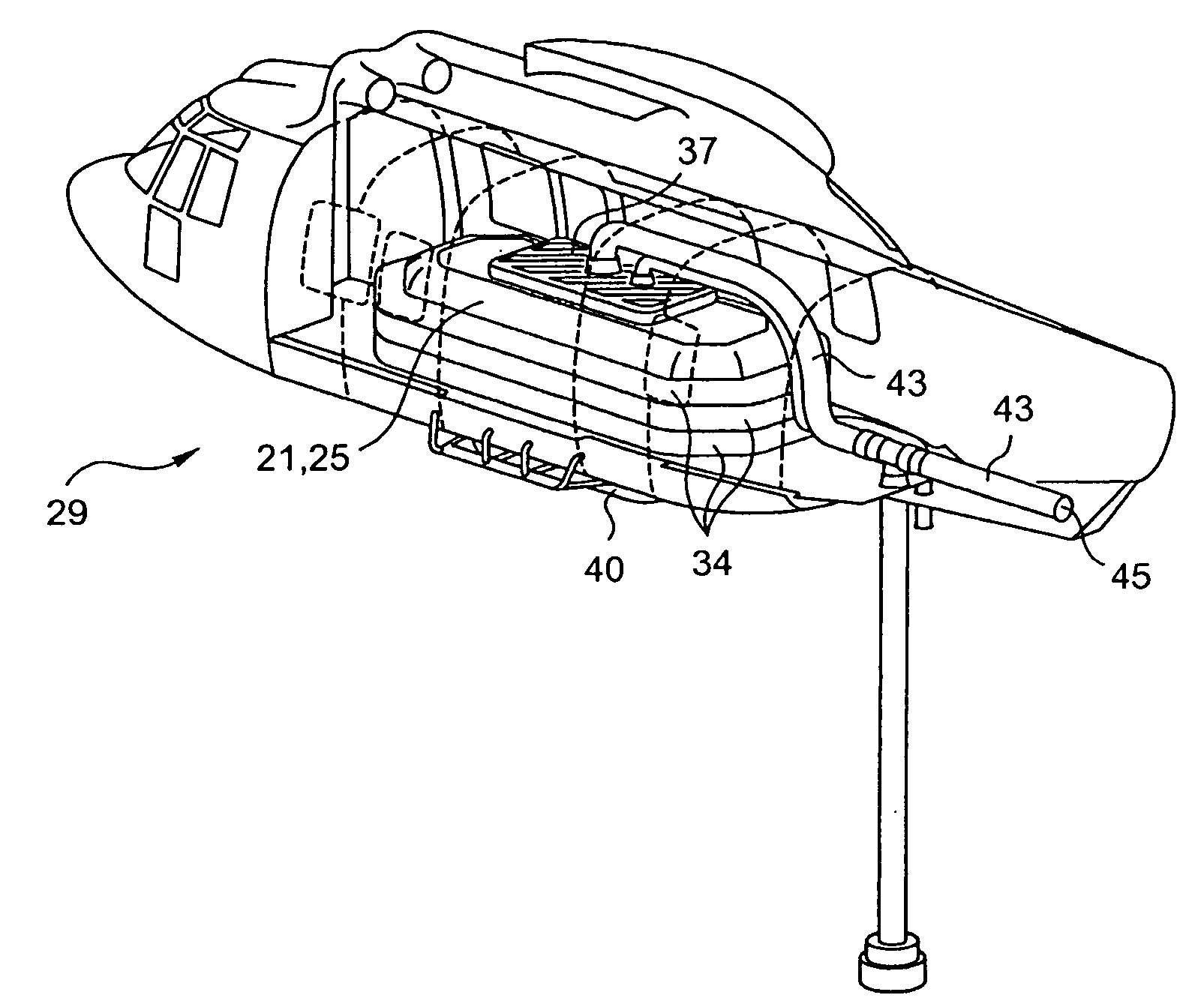

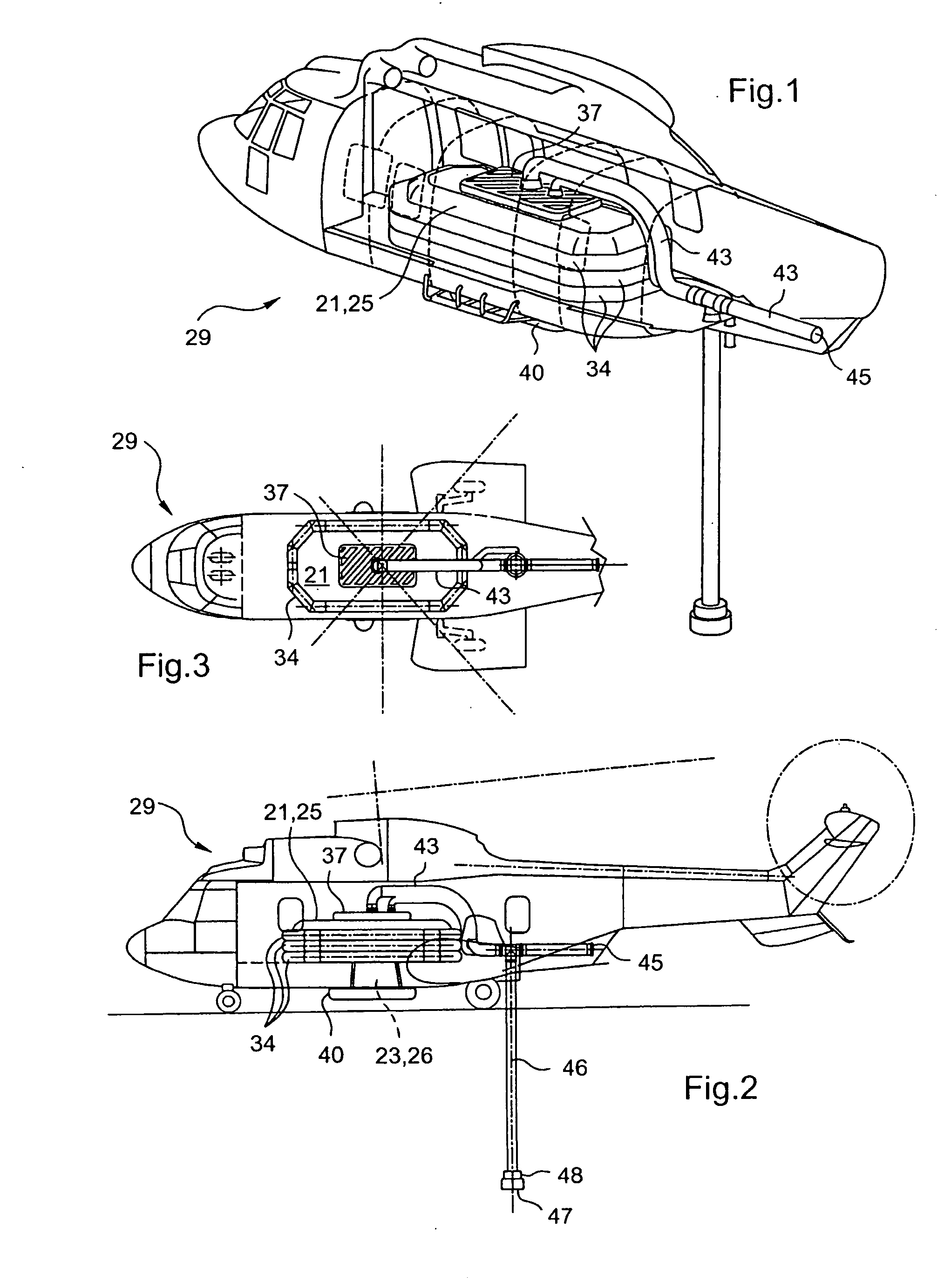

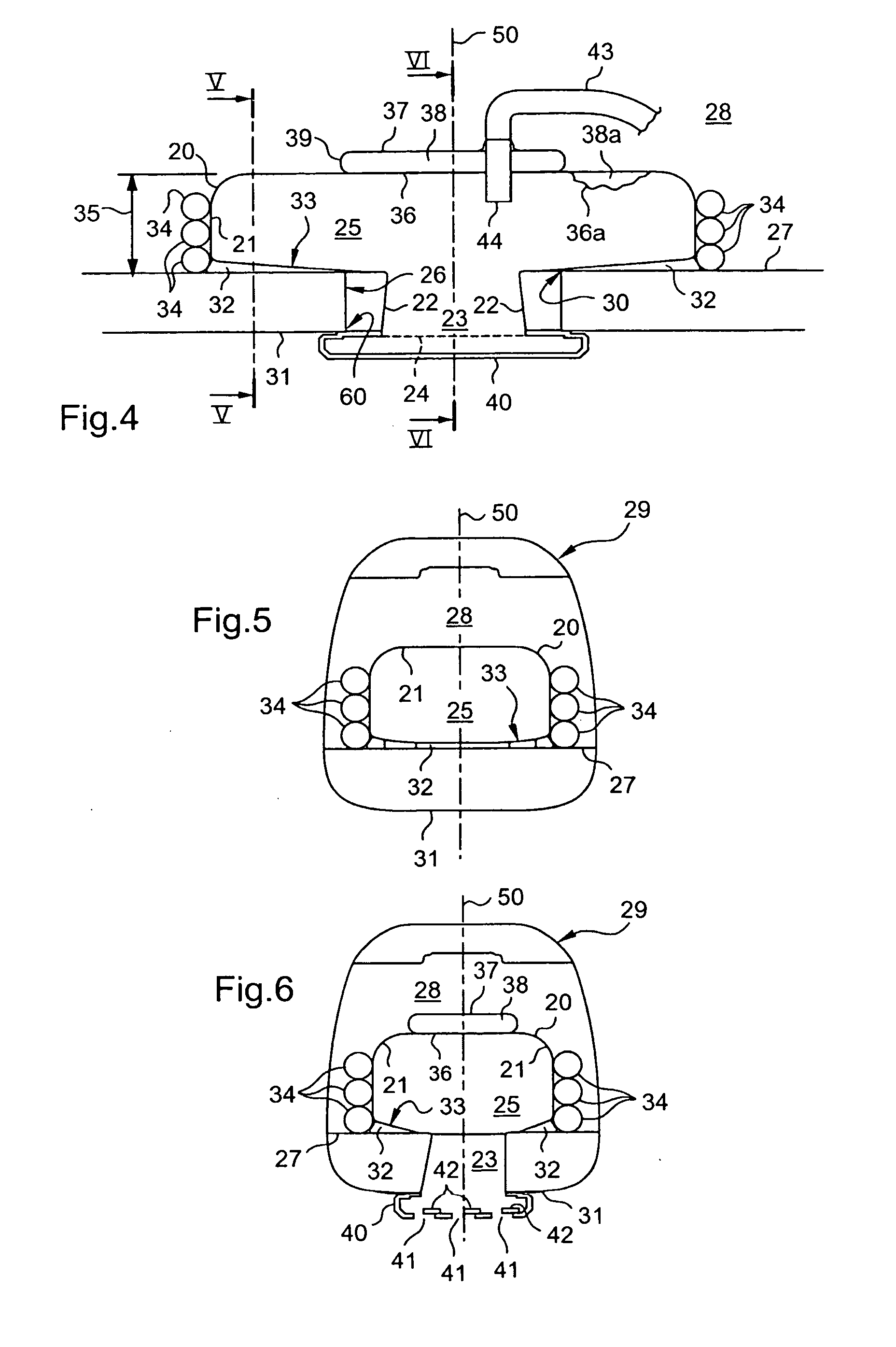

Aerially transportable tank for storing a composition for discharging in flight

InactiveUS20070164162A1Control stressFacilitates rapid fillingAircraft componentsFire rescueWaste management

The invention relates to an aerially transportable tank (20) for storing a composition for discharging in flight, the tank including a neck (23) terminated by a composition discharge opening (24), and having a wall (21) extending the neck that is sufficiently deformable to be received in part or in full within the neck.

Owner:EUROCOPTER

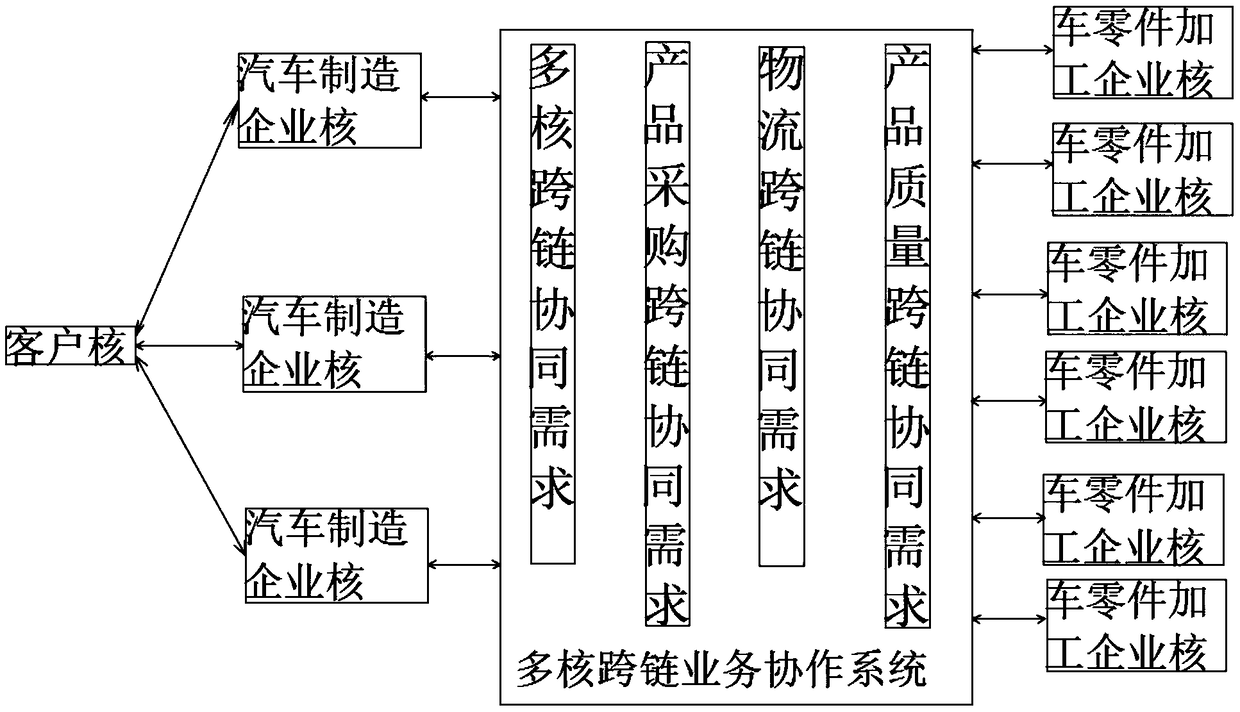

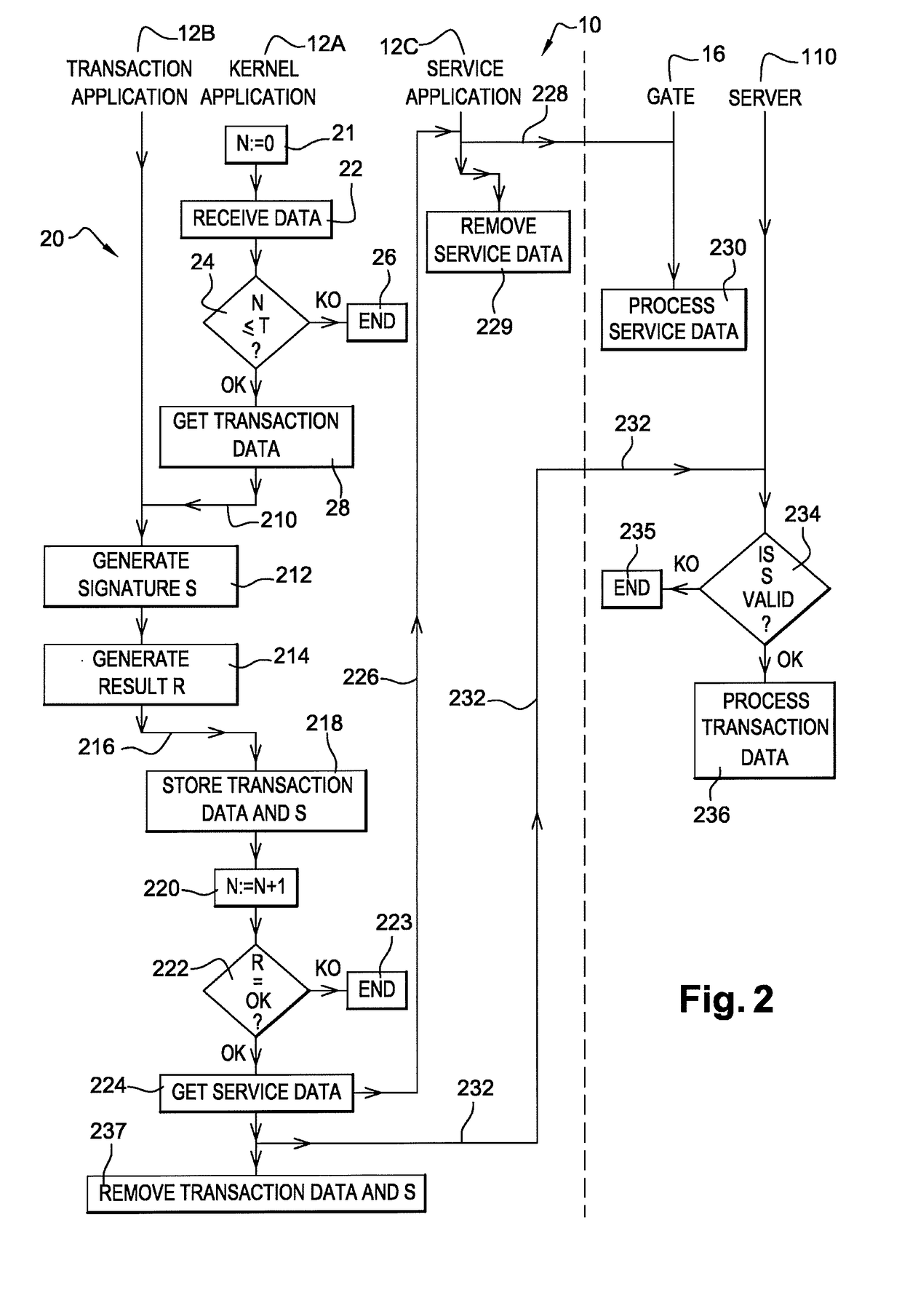

A multi-core cross-chain service cooperation system and an interactive method based on a cloud platform

InactiveCN109389370AGuaranteed to be manufactured at all timesGuaranteed assemblyOffice automationManufacturing computing systemsLogistics managementLogistic management

The invention discloses a multi-core cross-chain service cooperation system and an interactive method based on a cloud platform, including cloud platforms. cross-chain business collaboration includesthe collaboration between the customer core and the automotive manufacturing enterprise core, the multi-core and cross-chain business cooperation system between the automobile manufacturing enterprises and the automobile parts processing enterprises. The interaction method includes: setting up the interaction between between an automobile and after-sale comment module, a customer order operation feedback module, a logistics management module, and a vehicle part quality communication module on the cloud platform; service cooperation among automobile manufacturing enterprise nuclear, machiningenterprise of automobile parts, and customer cores reflects the diversity of choices and collaboration, the customer order operation feedback module safeguards the interests and rights of customers and automobile enterprises. Customer or expert evaluation can provide the improvement direction for automobile manufacturing enterprises and parts processing enterprises, and promote the automobile industry to advance, innovate and develop continuously.

Owner:CHENGDU UNIV OF INFORMATION TECH

Shank milling cutter having a wiper radius

InactiveUS7094005B2Quality improvementGo fastMilling cuttersShaping cuttersMilling cutterEngineering

A shank milling cutter includes a cutting portion which is intended to come into engagement with the workpiece, wherein the envelope surface of the cutting portion is substantially cylindrical. At least one major cutting edge is arranged at the peripheral surface of the cutting portion and at least one minor cutting edge (face cutting edge) is arranged at the end face of the cutting portion and with an end diameter D. The minor cutting edge, in projection onto a plane containing the milling cutter axis, has a convexly curved portion with a radius of curvature R>D / 2 and a center of curvature M located such that a distance from the center of curvature M to the axis is in a range from zero to a value smaller than D / 2.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Minisize linear driver based on dimorphic crystal piezoelectric film

InactiveCN1699032AIncrease peripheral sizeReduce volumeMicromanipulatorMechanical vibrations separationMetal foilEngineering

This invention relates to a mini linear driver based on the bimorph conductive film, which comprises a driving mechanism and a moving supporting mechanism, wherein the driving mechanism covers on the central bearing and is oriented by the inertia mass block and hub in two ends, the moving supporting mechanism comprises the rigid frame of bimorph conductive film and the resilient supporting pin connecting the frame; said bimorph conductive film comprises ceramics chip of metal foil, characterized in that the rigid frame is round, quadrangle or regular polygon, on the edge there is 3~4 circular small punch holes distributed evenly; said resilient supporting pin is elastic wire through the rigid frame and small punch holes to connect them. Said invention is fit for mini robot driver in the ultra-fine pipe whose bore diameter is below 10mm.

Owner:SHANGHAI UNIV

Method and machine for machining parts using spark-erosion milling

InactiveUS8519296B2Go fastEasy to operateArc welding apparatusElectrical-based machining electrodesMachine partsEngineering

Owner:AGIE CHARMILLES +1

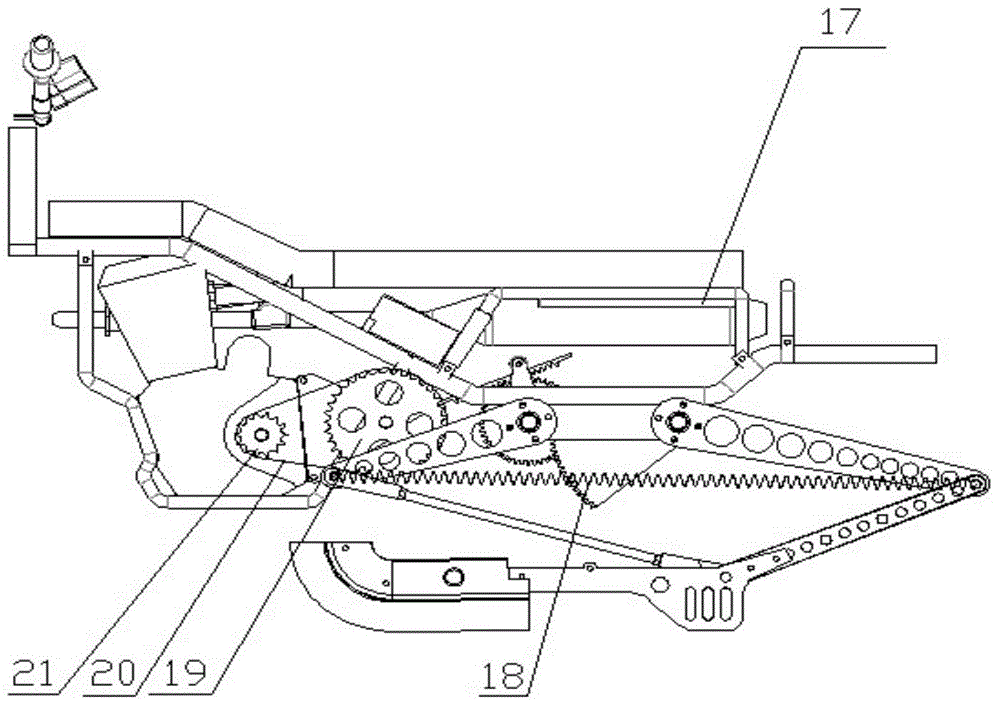

Load bearing jumping device of motorized gear shifting gear five-rod mechanism

The invention discloses a load bearing jumping device of a motorized gear shifting gear five-rod mechanism. The load bearing jumping device comprises a driving mechanism, an operation control mechanism, a transmission mechanism and a jumping mechanism; the operation control mechanism operates and controls the jumping mechanism to move; the driving mechanism takes an engine as a power source to provide power; the transmission mechanism adopts a gear-five rod mechanism and provides periodic and fulminic speed and energy for the jumping mechanism. A spring is fixed in the gear five-rod mechanism so as to realize the energy storage at the early stage of the starting and the energy releasing during ground touching. For ensuring the balance in air during jumping and stable ground touching, the jumping mechanism adopts the synchronous motion of a dual-foot skeleton and an arc rubber pad arranged at the front part; the rubber pad is used as a sole for buffering and absorbing vibration; the jumping device has good mobility and stronger capacity for adapting complex terrains; the load bearing jumping device is large in motion flexibility and capable of realizing continuous jumping and providing transportation capacity for a complex environment, and can also be used as a novel extreme sport equipment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Swing scooter

InactiveCN101905726AGo fastReduce volumeWheel based transmissionChain/belt transmissionFree energiesReduced size

The invention relates to a swing scooter which mainly comprises a vertical rod. The bottom end of the vertical rod is provided with a front wheel and a clamping seat which is used for assembling a left bracket and a right bracket, pedal plates and rear wheels are respectively mounted at the tail ends of the left bracket and the right bracket, a first folding mechanism is arranged at the bottom end of the vertical rod, close to the clamping seat, and the left bracket and the right bracket are respectively provided with a second folding mechanism and a third folding mechanism so that the vertical rod, the left bracket, the right bracket, the pedal plates and the rear wheels can be respectively folded. In addition, a rotary driving mechanism is arranged between the pedal plate and the rear wheel and can drive the rear wheel and the scooter to advance. Accordingly, the invention not only provides a transport means with great amount of exercise, but also has the advantages of reduced size and portability because of foldability and has the environment-friendly benefit by freeing energy use and multiple functions such as high entertainment, and the like.

Owner:LAING BAN INT

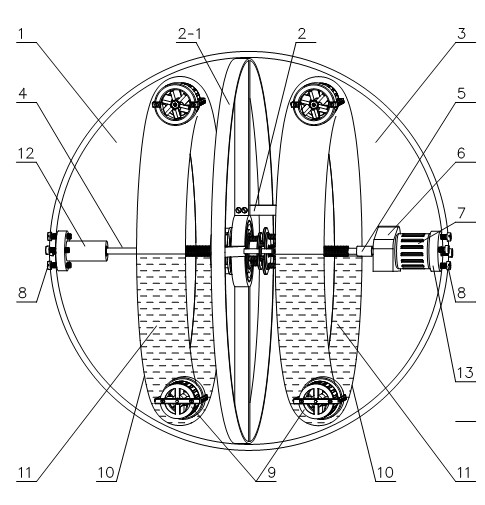

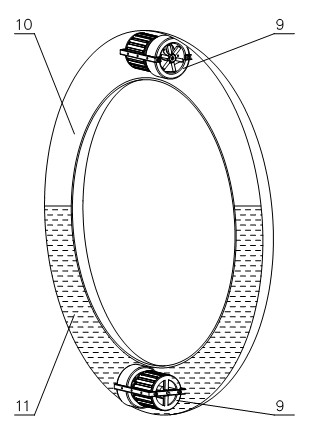

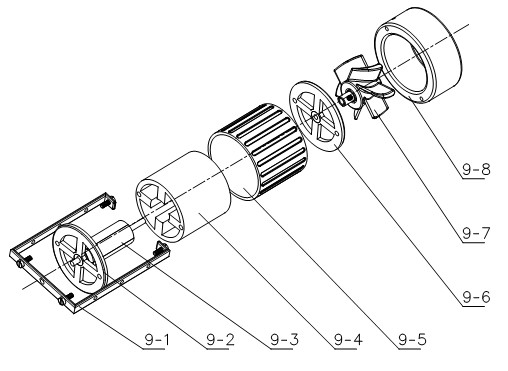

Double-fluid-ring drive omnibearing spherical robot

The invention relates to a double-fluid-ring drive omnibearing spherical robot, which comprises a spherical shell, at least one annular sealing container, at least one axial flow device, a hemispherical clutching mechanism and a lead screw shaft. The double-fluid drive omnibearing spherical robot is characterized in that the spherical shell consists of a left hemispherical shell and a right hemispherical shell, the annular sealing containers are arranged in each hemispherical shell, the outer annular surfaces and spherical shell surfaces of the annular sealing containers are coaxial with the lead screw, fluid is filled into the annular sealing containers, fluid volume is one second of the volume of each annular sealing container, the axial flow devices are mounted inside the annular sealing containers and drive fluid to flow in the annular sealing containers, and accordingly center of mass of each hemisphere of the spherical robot is changed. The hemispherical clutching mechanism in the hemispherical shell mainly comprises a left clutching part, a center clutching part, a right clutching part, a steering engine part and the like. By controlling the centers of mass and the direction of the left hemisphere and the right hemisphere, omnibearing rolling of the spherical robot can be realized.

Owner:TAISHAN UNIV

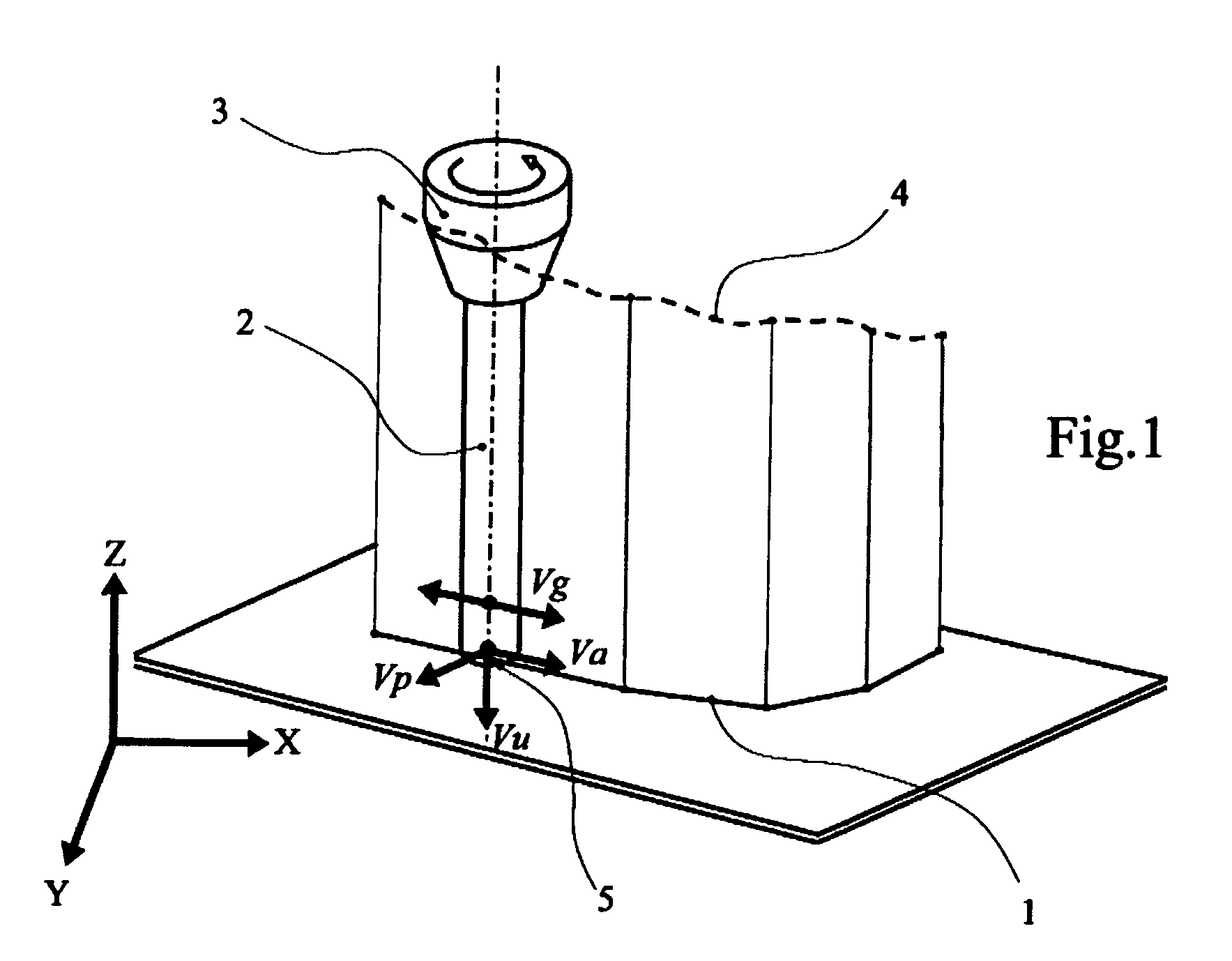

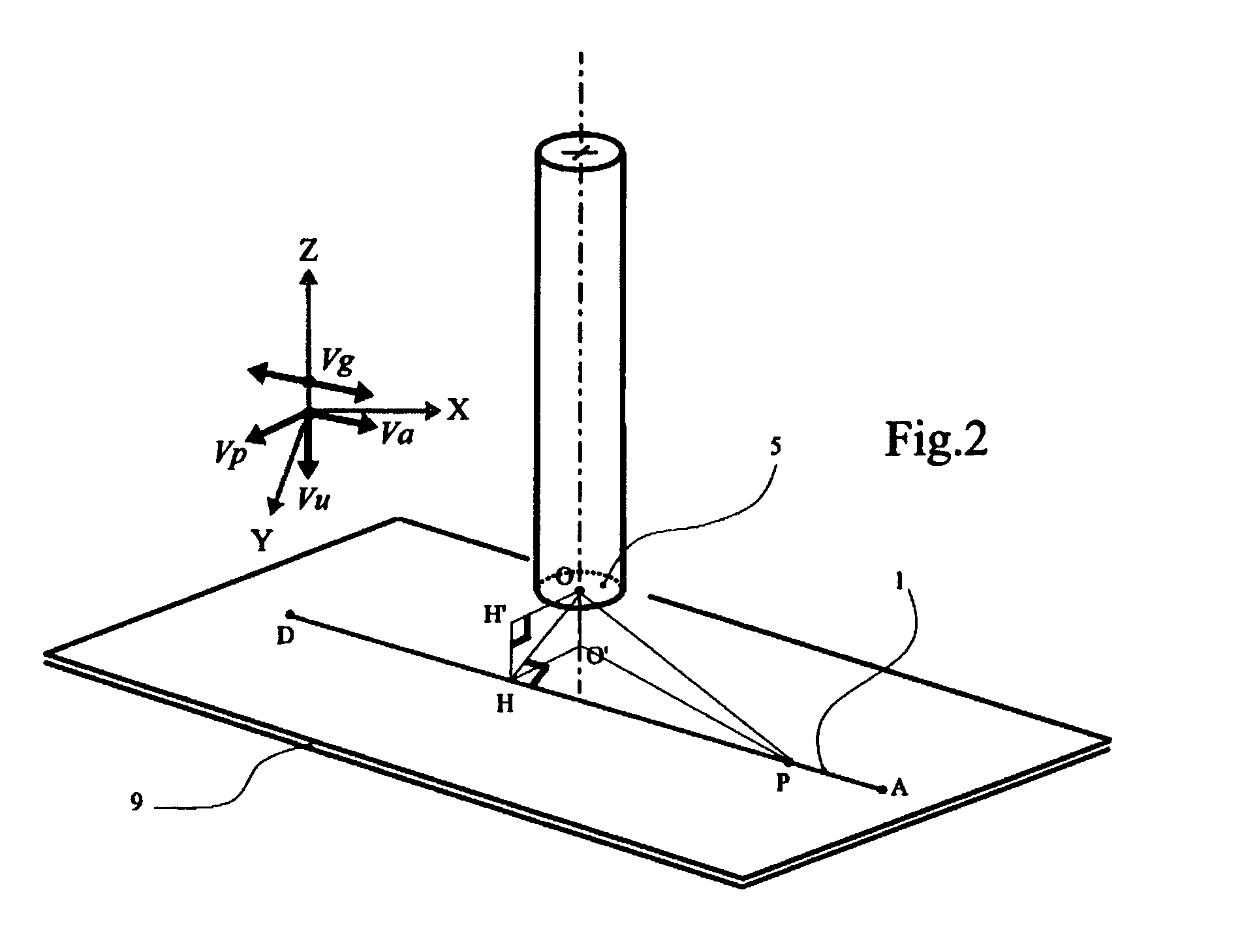

Method and machine for machining parts using spark-erosion milling

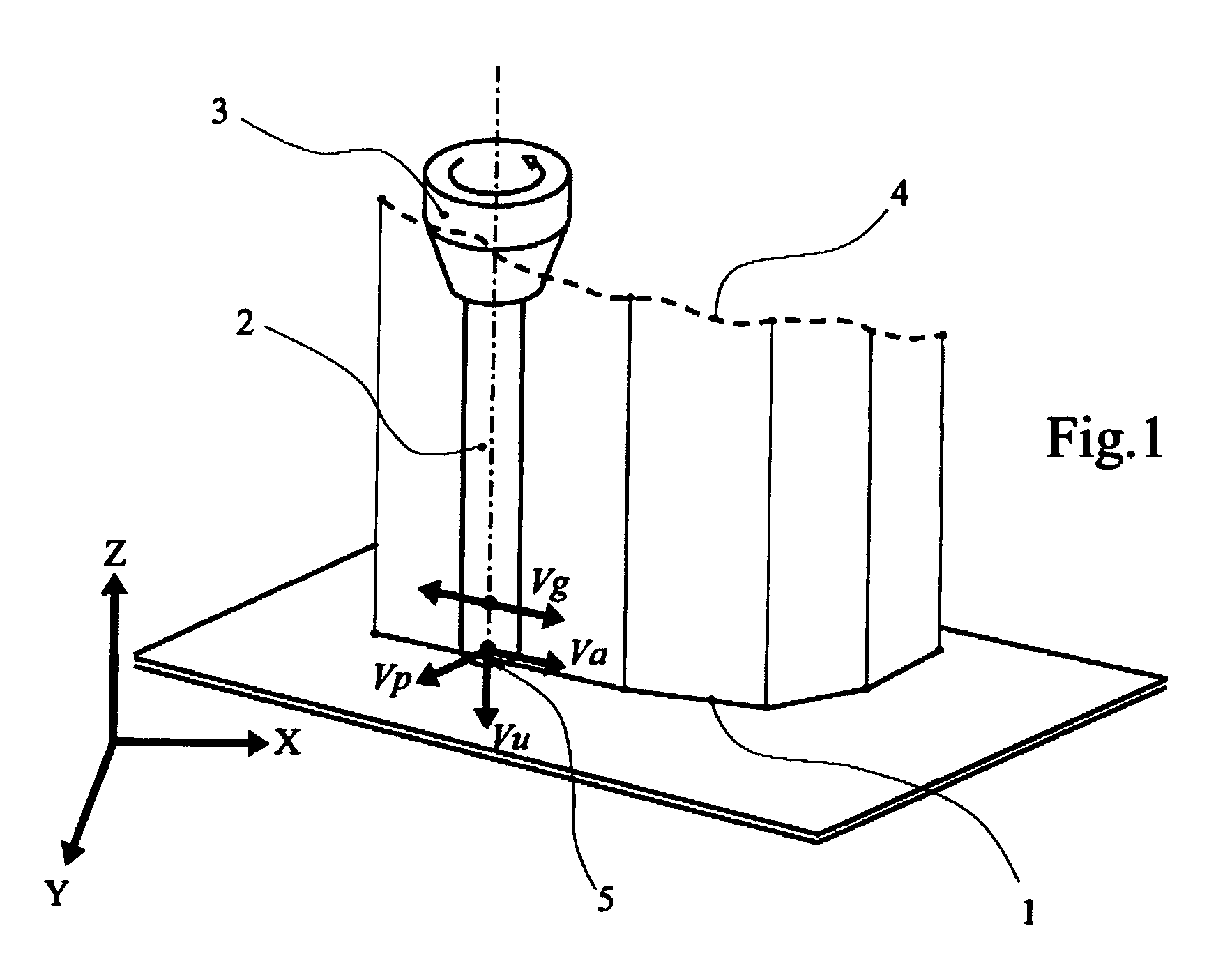

InactiveUS20110062118A1Easy to judgeEliminate displacement instabilityArc welding apparatusElectrical-based machining electrodesMachine partsControl vector

Spark-erosion machining method and machine implementing a machining gap, a process regulator, a numerical control system, a Nominal Trajectory. The latter describes the movement of the tool electrode relative to the part as it ought to proceed if no disturbance were to occur during the machining. Information contained in the Nominal Trajectory is used to define at least two control vectors Vg, Vp which orient, within the coordinate system XYZ, two independent regulation movements. The first, or Gap Vector Vg, defines the direction in which a first regulation movement of the axes of the machine must be performed to maintain the removal of material. The second, or Position Vector Vp, defines the direction in which a second regulation movement of the axes of the machining machine must be performed to correct a tool electrode position error. The respective amplitudes of the regulation movements are calculated in real time by the process regulator.

Owner:AGIE CHARMILLES +1

Double-ring clutch type electromagnetic-drive spherical robot

ActiveCN102602465AThe overall structure is simple and reliableFlexible and stable movementVehiclesElectric machineryEngineering

The invention relates to a double-ring clutch type electromagnetic-drive spherical robot, which comprises a left hemispherical shell, a hemispherical clutching mechanism, a right hemispherical shell, a lead screw shaft, a coupler, a speed reducer, a motor, bearing seat fixing screws, electromagnetic drive parts, magnetic steel rings, permanent magnetic steel pieces, a left bearing seat, a right bearing seat and rubber pads and the like. The left hemispherical shell and the right hemispherical shell form a spherical shell, one or more magnetic rings are arranged in each hemispherical shell, the magnetic steel rings and the spherical surface of the spherical shell are coaxial on the lead screw shaft, the permanent magnetic steel pieces are uniformly disposed on the magnetic steel rings, N-electrodes of two adjacent permanent magnetic steel pieces are opposite in direction, the electromagnetic drive parts mainly includes electromagnetic cores, electromagnetic coils, a control module, a power supply, a supporting plate, a plurality of infrared tubes and supporting wheels, the supporting plate is processed to be arc-shaped and concentric with the magnetic steel rings, and the infrared tubes are mounted on two sides of the supporting plate respectively. The spherical robot can progress and retreat according to the principle of electromagnetic stepping, is simple and reliable in structure, stable and flexible in motion and high in controllability when compared with conventional robots.

Owner:山东奥唯克智能科技有限公司

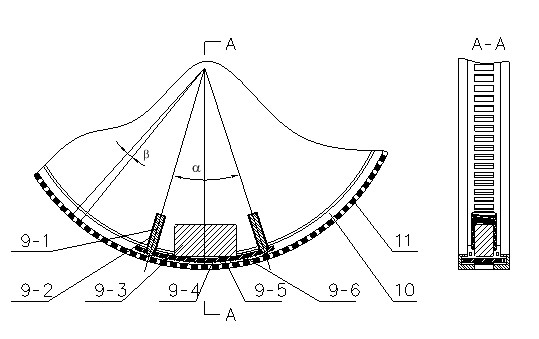

Method and device for accessing a service

InactiveUS20180018665A1Save timeGo fastMultiple keys/algorithms usageCryptography processingAuthorizationTransaction processing

In a method for accessing a service, a device receives data. The device gets, based upon the received data, transaction data. The device signs the transaction data by using a private key relating to a transaction processing, a signature operation result being a transaction signature. The device generates a transaction analysis result. The device stores the transaction data and the transaction signature. The device analyses whether the transaction analysis result is or is not a transaction authorization. Only if the transaction analysis result is a transaction authorization, the device gets, based upon the received data, service data. The device sends to a first external entity the service data. The device sends the transaction data and the transaction signature to either the first external entity or a second external entity.

Owner:GEMPLU

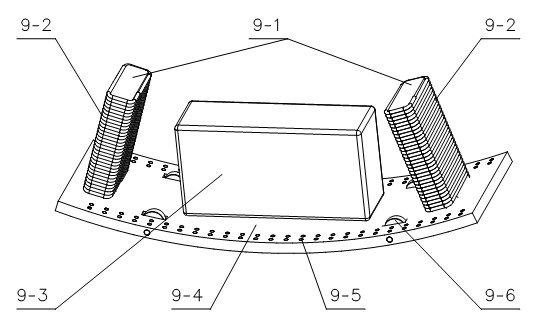

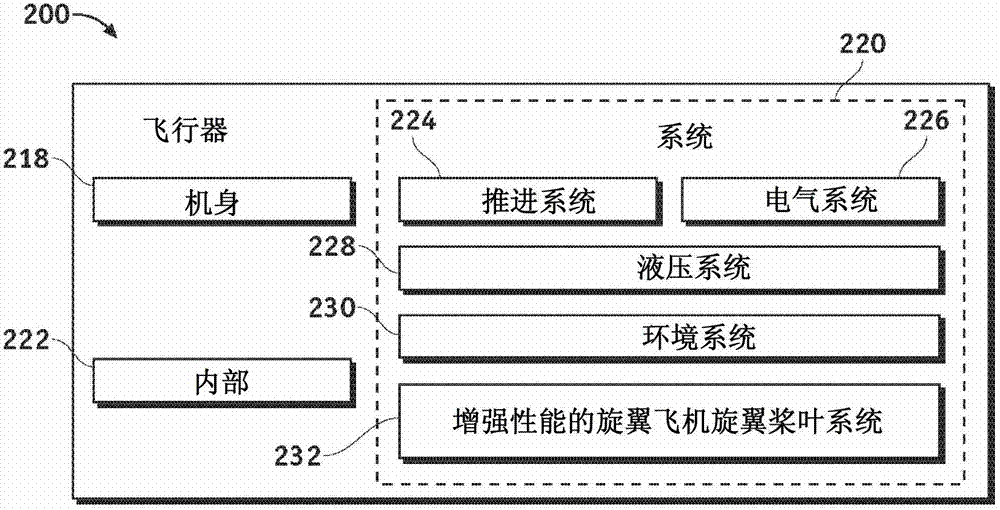

Enhanced performance rotorcraft rotor blade

ActiveCN103359285AEliminate or reduce the effects of stallGo fastAircraft controlWing lift eficiencyAngle of attackAirplane

An enhanced performance rotorcraft rotor blade system and methods are presented. A rotor blade comprises an inboard blade portion, and at least one controllable surface coupled to the inboard blade portion. The at least one controllable surface is operable to improve a lift of the inboard blade portion by altering an angle of attack of the inboard blade portion independent of the rotor blade.

Owner:THE BOEING CO

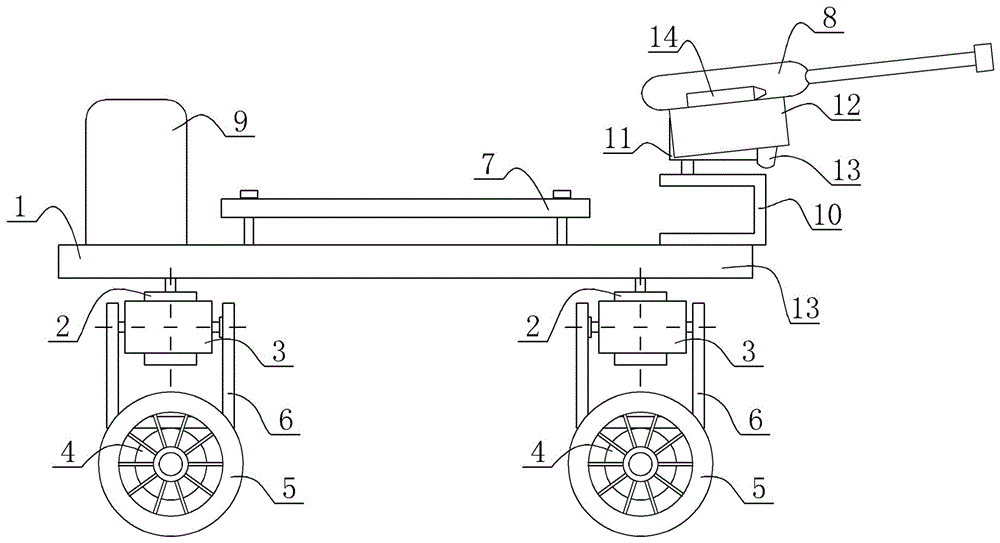

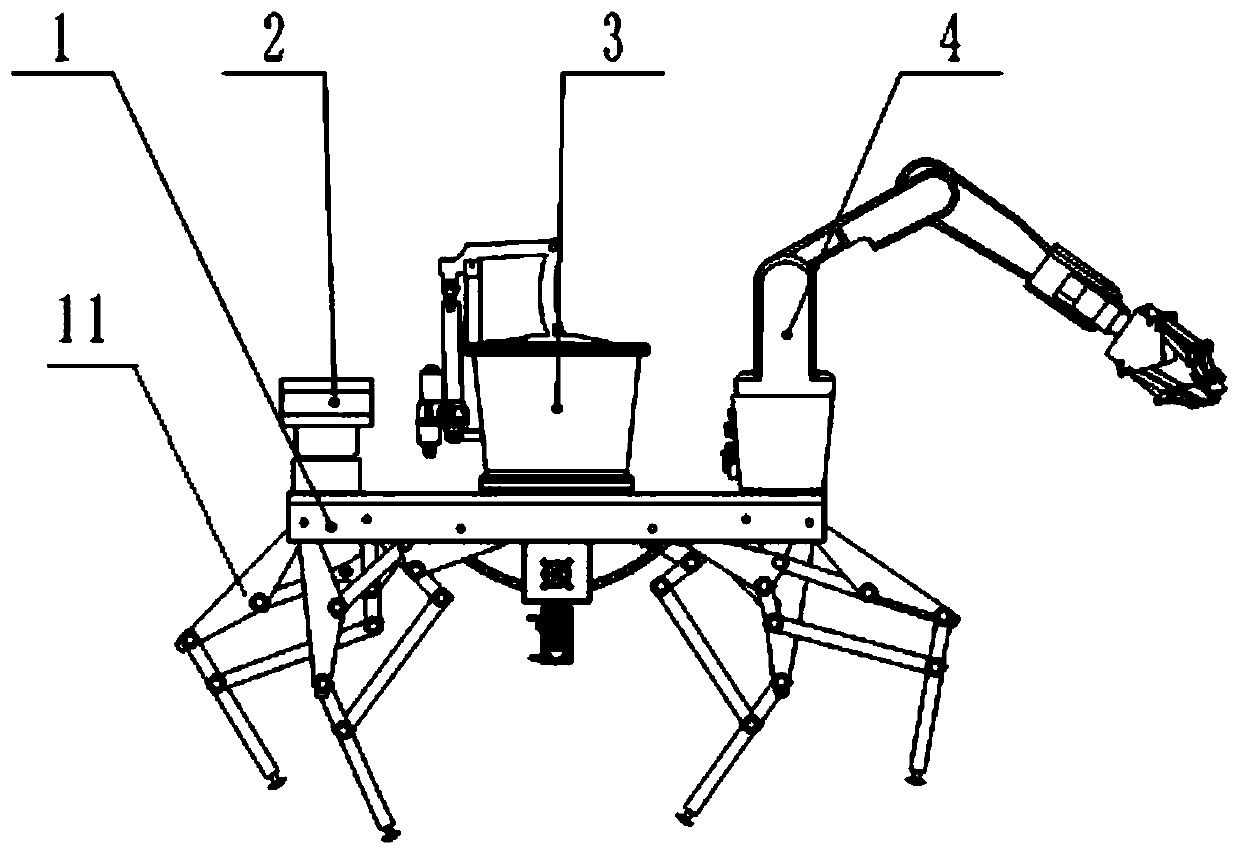

Anti-explosion robot with dual-motor eight-foot walking mechanism

PendingCN110666808AFlexible steeringNot easy to rolloverManipulatorVehiclesControl engineeringElectric machinery

The invention discloses an anti-explosion robot with a dual-motor eight-foot walking mechanism, and relates to the field of robots. According to the technical scheme, the robot comprises a rack, and steady-step advancing devices and transmission devices are arranged on the rack. The two steady-step advancing devices are located on the two sides of the rack and are arranged in parallel, and each steady-step advancing device comprises eight seven-connecting-rod mechanical legs, the seven-connecting-rod mechanical legs can do actions of raising, forward stretching, backward kicking and the like,and during stepping, the eight seven-connecting-rod mechanical legs in each steady-step advancing device operate. The transmission devices are used for driving the four sets of seven-connecting-rod mechanical legs on the single side of the rack to achieve stepping motion, the two transmission devices are located on the two sides of the rack symmetrically, and each transmission device comprises a stepping motor, two driving chain wheels, two transmission chains, two output chain wheels and an output shaft. The robot has the advantages that the robot can adapt to the terrain with the large fallor the fault, flexible steering and reversing are achieved, advancing vibration is small, and a driving device stably operates.

Owner:TAIYUAN UNIV OF TECH

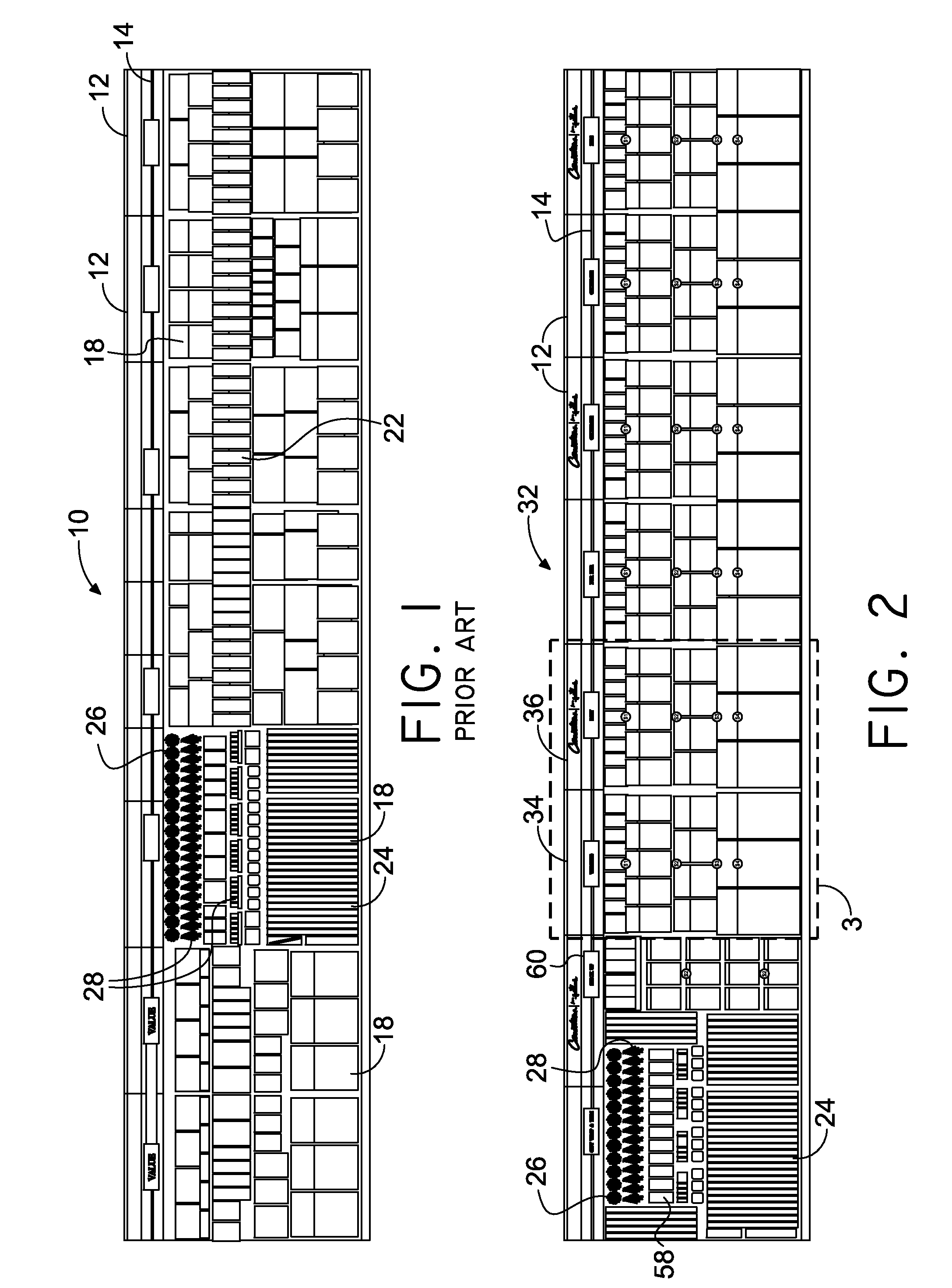

Method of displaying merchandise for retail sale

InactiveUS20090308821A1Easily conveying informationQuickly directShow cabinetsKitchen equipmentComputer graphics (images)Gift wrapping

A method of displaying merchandise which creates a more user friendly display that facilitates quicker and easier shopping for a consumer includes an arrangement of gift wrapping items in a section of a display fixture initially by size. The section includes a first display section for displaying items of a first average size, a second display section for displaying items of a second average size and a third display section for displaying items of a third average size. The display sections are adjacent one another and do not contain items that do not fall within the general size of the average display size. This arrangement by size quickly directs the consumer to a small subset of merchandise being displayed in a section that would meet the consumer's needs. A total number of price points may be reduced to at least partially correspond with the display sections. Sections may also be configured so that only items of a particular color and theme are displayed therein such that each section has an overall hue. Adjacent sections may then be configured to provide gradually darker hues. The consumer is then able to quickly narrow the search again by locating bags of an appropriate theme by the overall general color scheme of each section.

Owner:HALLMARK CARDS INC

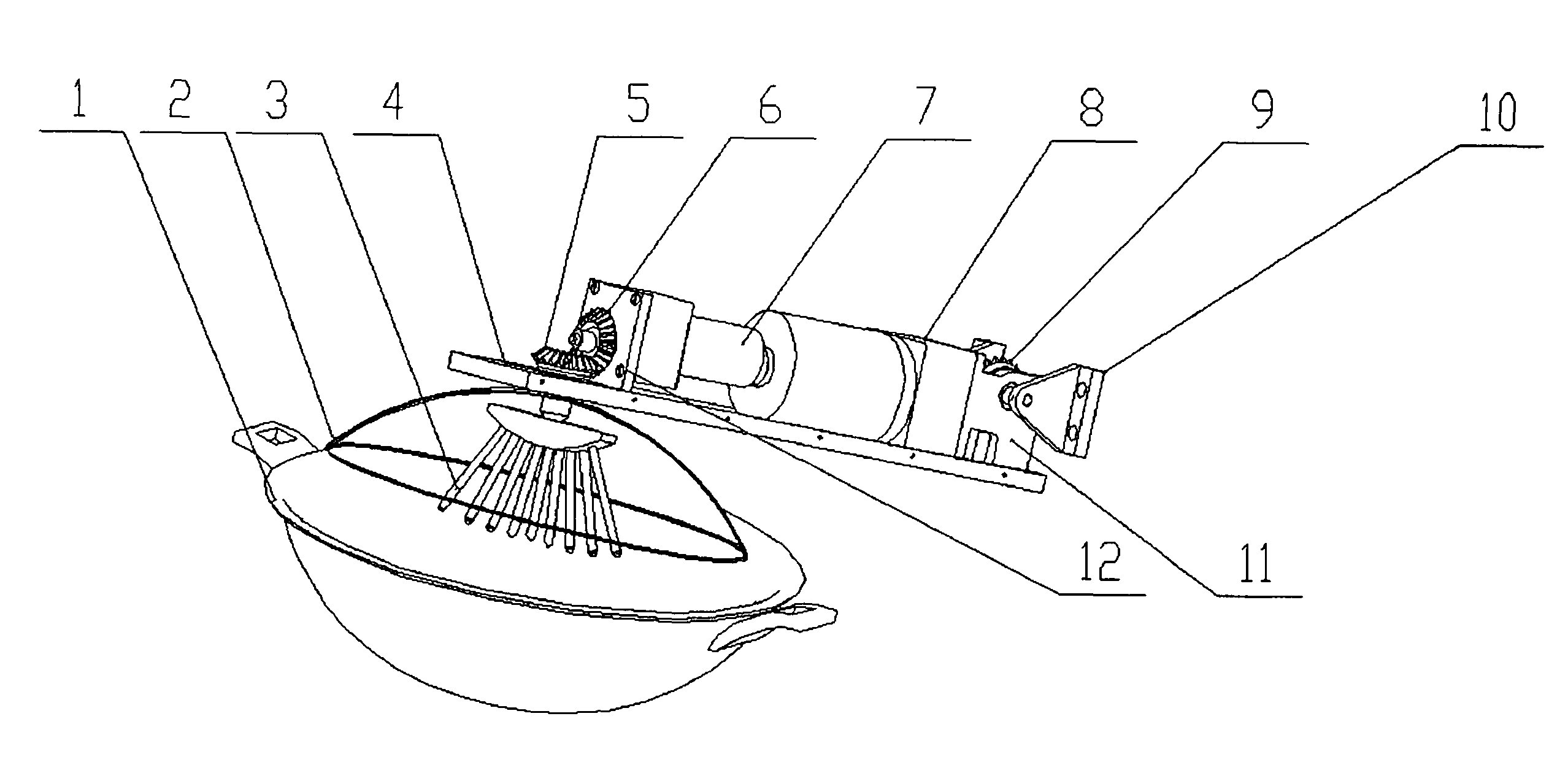

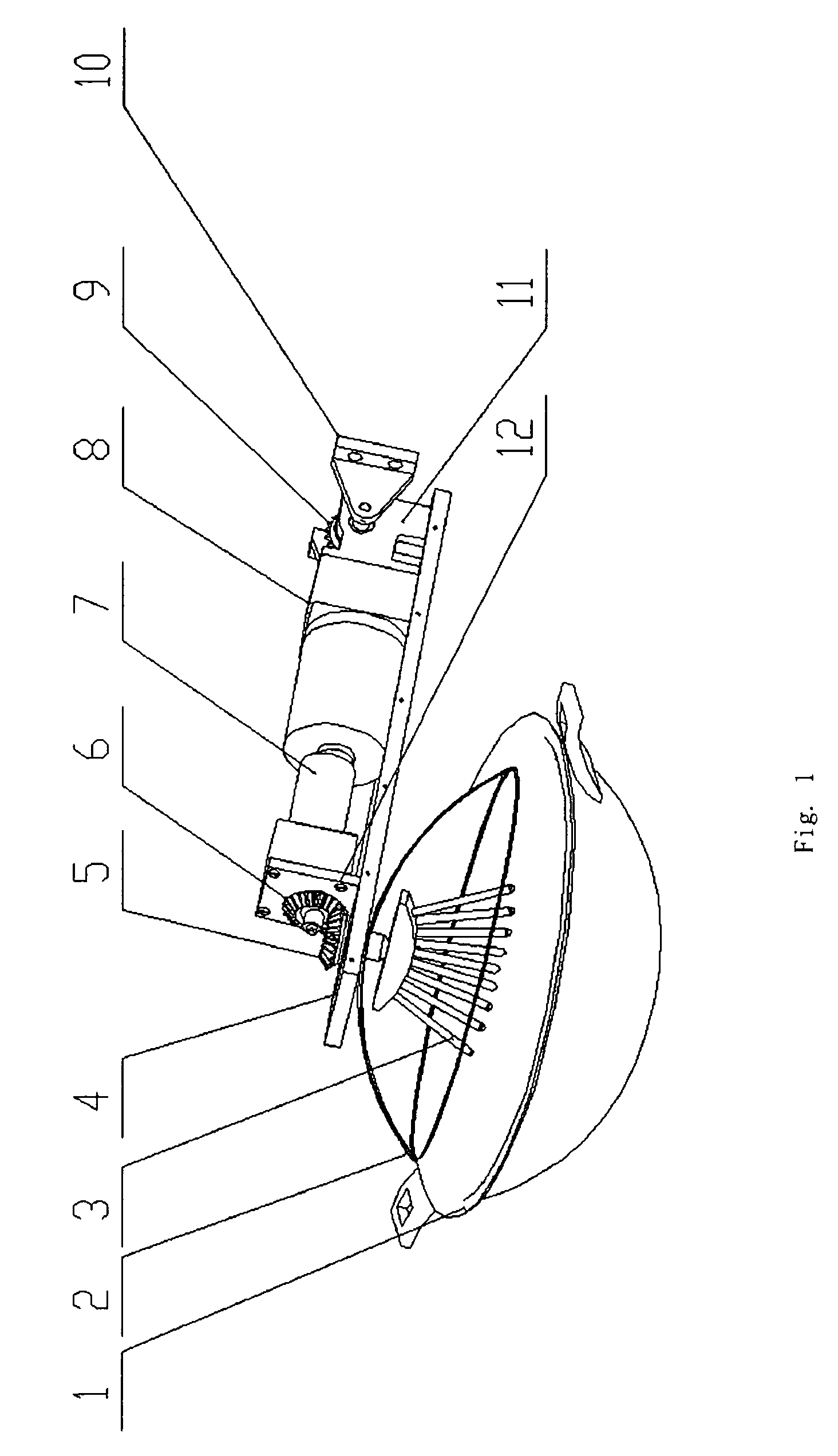

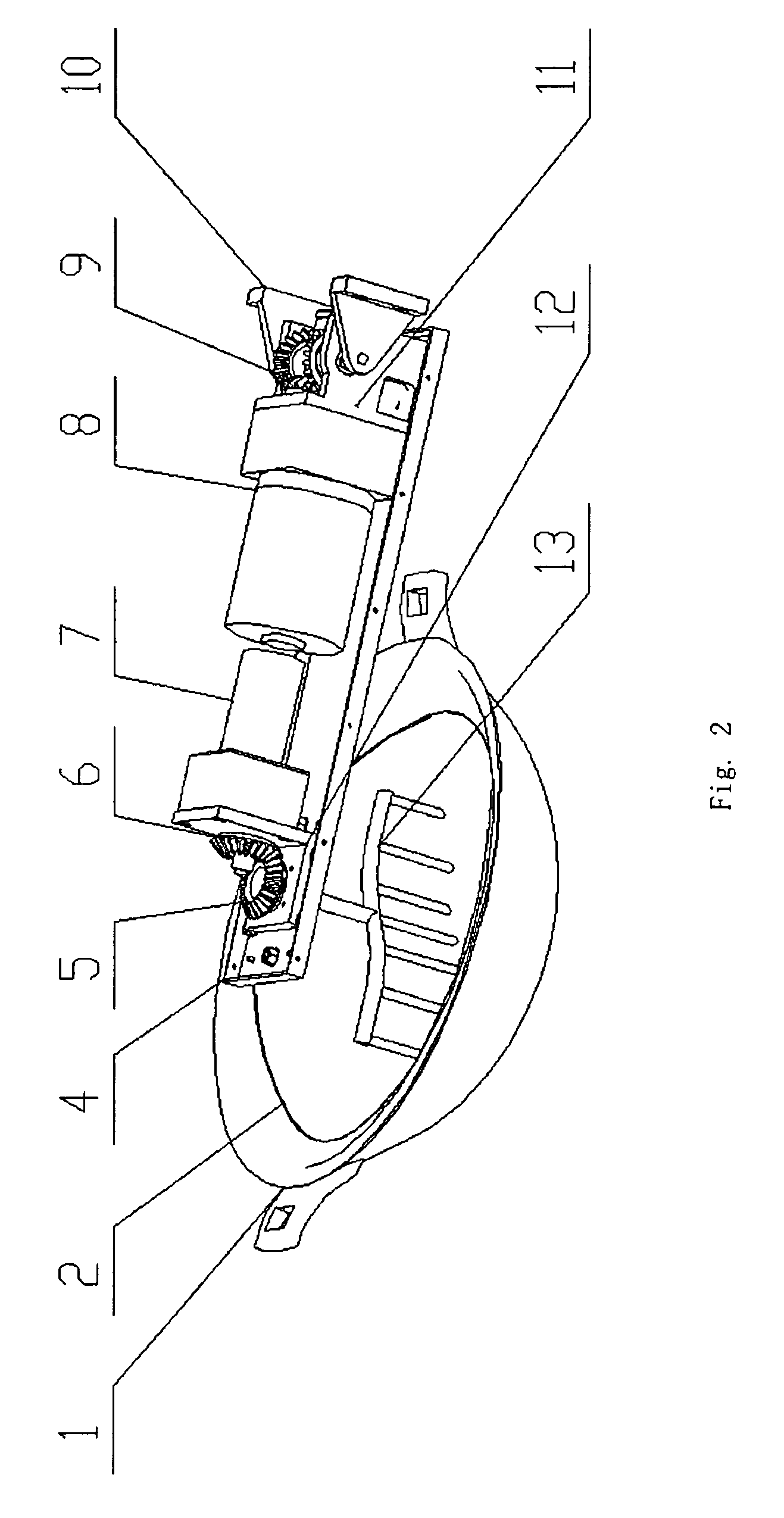

Dolphin type driving overwater bicycle

InactiveCN104843162ASimple structureImprove working abilityMuscle power acting propulsive elementsSpecial purpose vesselsJoystickEngineering

The invention discloses a dolphin type driving overwater bicycle which comprises a bicycle body, a direction control unit and a front driving mechanism. The direction control unit comprises a direction control lever and a direction blade, the direction control lever is rotatably borne on the bicycle body, and the direction blade is mounted on the direction control lever; the front driving mechanism comprises a front driving paddle lever, a front driving blade, a front reset spring, a front driving pedal and a front blade spring device, the front driving blade is hinged to one end of the front driving paddle lever while the other end is hinged to the bicycle body, the front driving pedal can be vertically, movably and slidably assembled on the bicycle body with the bottom end in abutted connection to the front driving paddle lever, the front blade spring device is connected between the front driving paddle lever and the front driving blade, and one end of the front reset spring is connected to the bicycle body while the other end is connected to the middle of the front driving paddle lever. The dolphin type driving overwater bicycle is simple in structure and high in acting effect, and forward speed is increased.

Owner:周玉平

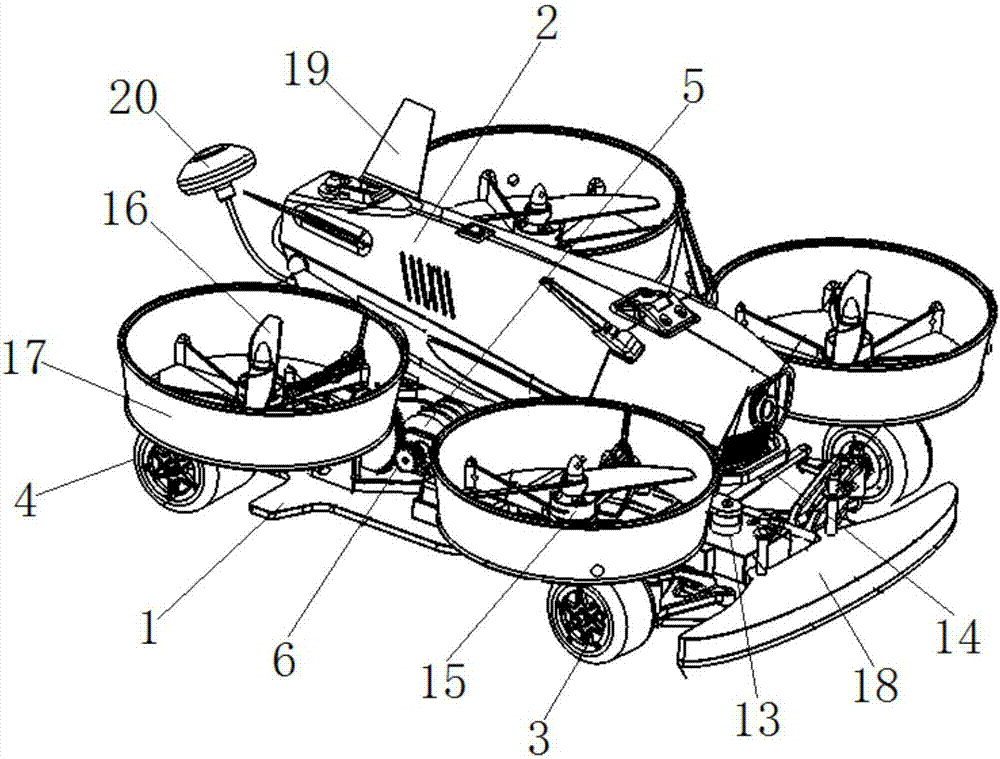

Four-rotor intelligent car

PendingCN106926655AReduce power consumptionSolve fast power consumptionResilient suspensionsAircraft convertible vehiclesElectricityAutomatic control

The invention relates to a four-rotor intelligent car. The four-rotor intelligent car comprises a chassis, a car body arranged on the chassis, an advancing mechanism, four-rotor flight mechanisms, and an automatic control system electrically connected with the advancing mechanism and the four-rotor flight mechanisms. The advancing mechanism comprises wheel assemblies, a wheel driving assembly and a wheel steering assembly, wherein the wheel assemblies are arranged on the two sides of the chassis, and the wheel driving assembly and the wheel steering assembly are in transmission connection with the wheel assemblies. The four-rotor flight mechanisms are located on the two sides of the car body. Under control of the automatic control system, the intelligent car automatically switches the movement states of the advancing mechanism and the four-rotor flight mechanisms so as to adapt to different road conditions. Compared with the prior art, the four-rotor intelligent car is combined with an unmanned aerial vehicle technology; the movement states can be automatically switched according to the real-time road conditions; ground four-wheel drive obstacle avoidance advancing and flight advancing are easily and conveniently achieved; the passing capability is high; the switching speed of the movement states is high; and application is wide.

Owner:SHANGHAI UNIV OF ENG SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com