Production process of waterborne positive lithium ion battery

A lithium-ion battery and production process technology, which is applied in the manufacture of non-aqueous electrolyte batteries, battery electrodes, electrolyte batteries, etc., can solve the problems of low pass rate, low specific energy, low oiliness, and restrictions on raw materials, etc., and achieve coating speed The effect of fast, low temperature and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

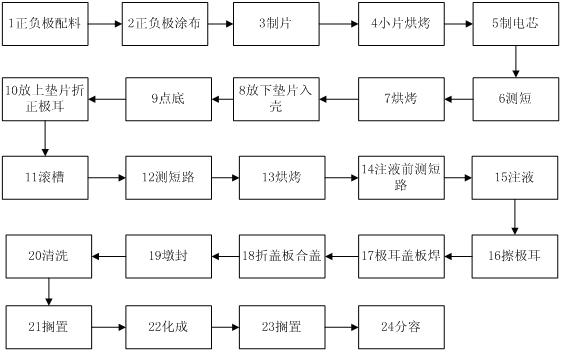

[0058] Here is an example of lithium iron phosphate steel shell cylindrical 18650 battery, and cooperate with figure 2 The process flow chart is described in detail.

[0059] (one).

[0060] 1. Cathode material and its weight ratio:

[0061] Lithium iron phosphate: 100 parts;

[0062] Super conductive carbon black (super-p): 3 parts;

[0063] Conductive graphite (ks-15): 2 parts;

[0064] Water-based adhesive: LA132, Chengdu Yindile Power Technology Co., Ltd., 3.5 parts;

[0065] NMP: 2.5 parts;

[0066] 80 parts of deionized water.

[0067] 2. Anode material and its weight ratio:

[0068] Artificial graphite: 100 parts;

[0069] CMC (Carboxymethylcellulose Sodium): 1 part;

[0070] 2 parts of SBR latex (SBR styrene-butadiene latex 50%):

[0071] Deionized water: 140 parts.

[0072] (2). The production process of the water-based cathode lithium-ion battery is as follows (see figure 2 ):

[0073] 1 Positive and negative ingredients: the equipment is Guangzhou Hon...

Embodiment 2

[0109] Here is an example of lithium iron phosphate steel shell cylindrical 18650 battery, and cooperate with figure 2 The process flow chart is described in detail.

[0110] (one).

[0111] 1. Cathode material and its weight ratio:

[0112] Lithium iron phosphate: 100 parts;

[0113] Super conductive carbon black (super-p): 4 parts;

[0114] Conductive graphite (ks-15): 3 parts;

[0115] Water-based adhesive: Chengdu Yindile adhesive LA132, 4 parts;

[0116] NMP: 3 parts;

[0117] 85 parts of deionized water.

[0118] 2. Anode material and its weight ratio:

[0119] Artificial graphite: 100 parts;

[0120] CMC (carboxymethyl cellulose sodium): 2 parts;

[0121] 3 parts of SBR latex (SBR styrene-butadiene latex 50%):

[0122] Deionized water: 143 parts.

[0123] (2). The production process of the water-based cathode lithium-ion battery is as follows (see figure 2 ):

[0124] 1 Positive and negative ingredients: the equipment is Guangzhou Hongyun 200L double plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com