Process for preparing iron based oxygen carrier

An oxygen carrier and iron-based technology, applied in the direction of iron oxide/hydroxide, iron oxide, alumina/aluminum hydroxide, etc., can solve problems that have not been reported in the literature, and achieve optimized pore size distribution, good repeatability, The effect of increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of metal nitrate and urea mixed solution

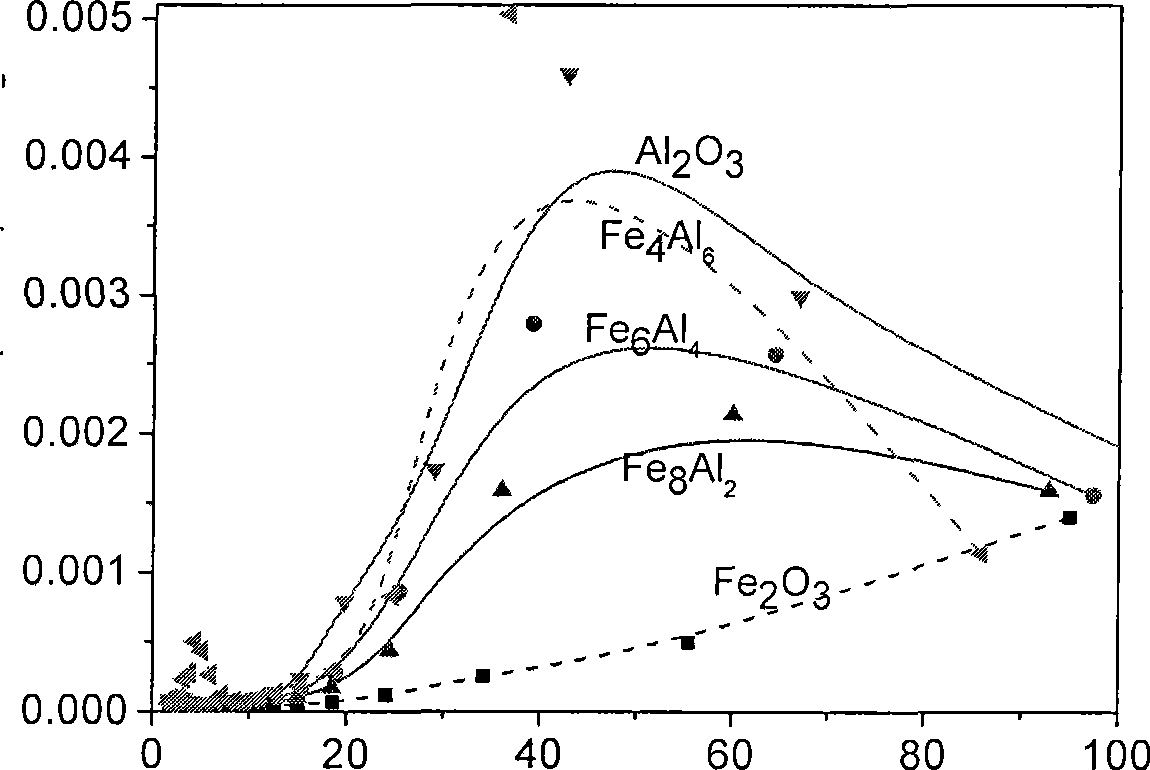

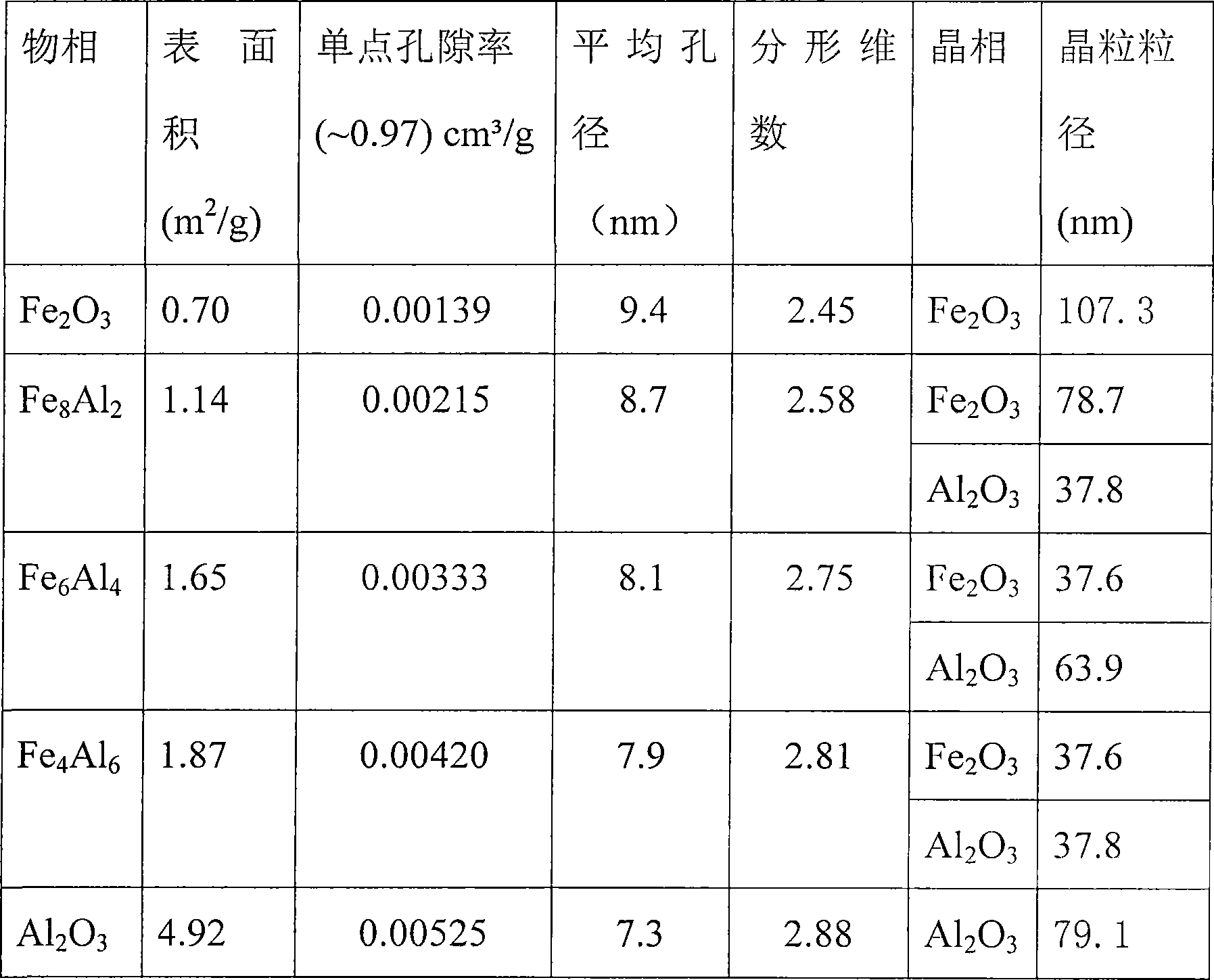

[0024] According to Fe 2 o 3 / Al 2 o3 The mass ratio is 6:4 and the stoichiometric coefficient of metal nitrate and urea is 1. Weigh quantitative ferric nitrate, aluminum nitrate and urea, add an appropriate amount of deionized water, and stir evenly to obtain a fully dissolved and uniformly mixed solution.

[0025] (2) Preparation of wet gel

[0026] Then, move the above solution to a magnetic stirrer with a constant temperature function set at 75°C, and stir at a constant speed, so that the water in the mixed solution is continuously evaporated, and the ferric nitrate, aluminum nitrate and urea are uniformly mixed and hydrolyzed. Complexation forms a viscous sol.

[0027] (3) Drying of wet gel

[0028] The wet gel formed above was moved into a muffle furnace to be dried in stages at 80°C and 120°C respectively.

[0029] (4) Ignition treatment of xerogel

[0030] The xerogel dried in stages in the muffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com