Self-bubricating lead-free bearing and manufacture method thereof

A lead-free bearing, self-lubricating technology, applied in the direction of bearing components, shafts and bearings, rolling resistance optimization, etc., can solve problems such as poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

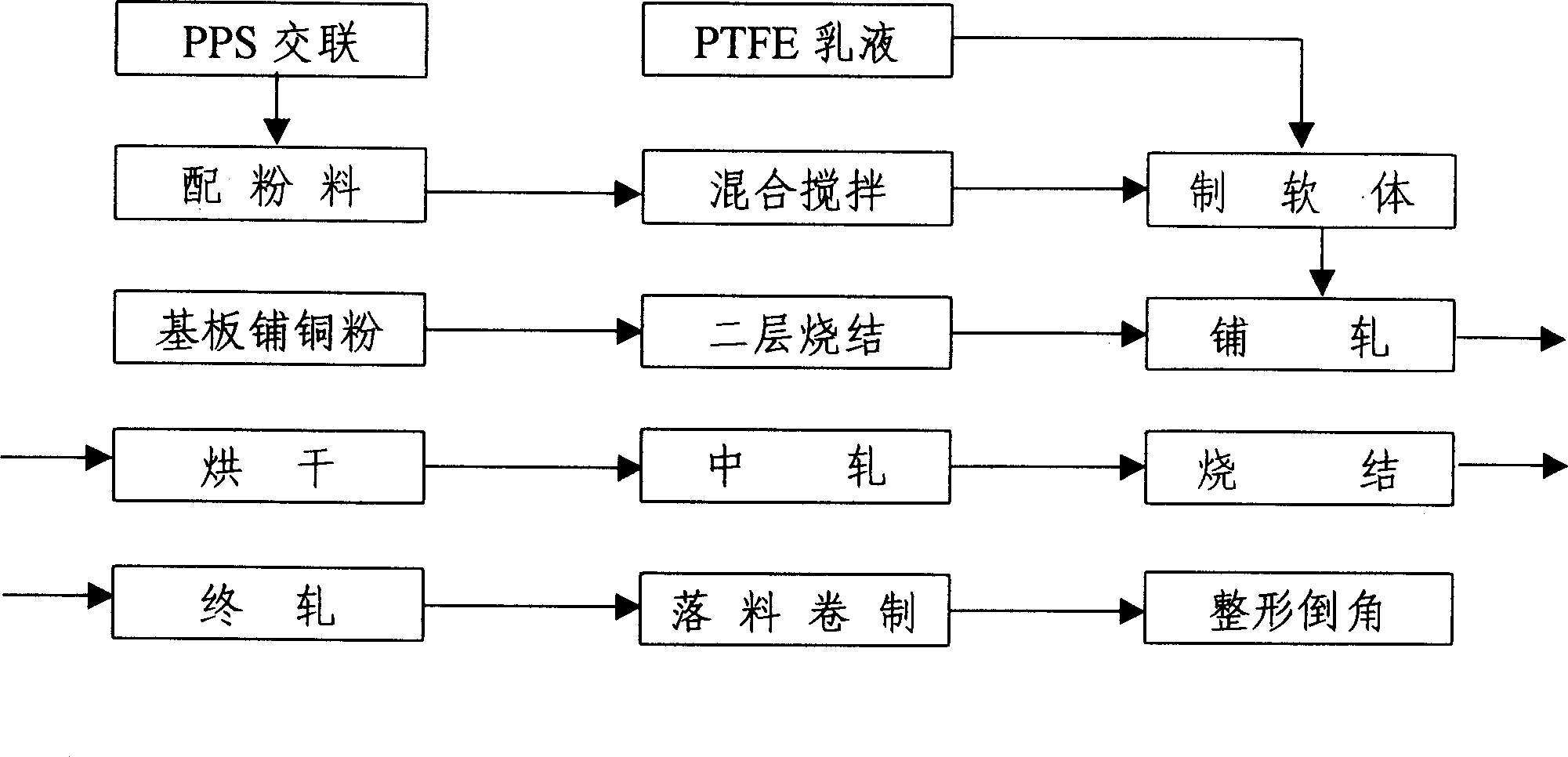

Method used

Image

Examples

Embodiment Construction

[0035] During implementation, as described in the invention scheme of the description, wherein the preferred data are as follows:

[0036] The material formula is by weight 32-34% of polytetrafluoroethylene; 32-34% of polyparaben; 7-8% of molybdenum disulfide; the rest is polyphenylene sulfide.

[0037] The drying temperature is 250-280°C, and the drying time is 20-30 minutes, depending on the water in the emulsion is fully developed as the best point.

[0038] The sintering is carried out in a nitrogen-protected sintering furnace, the sintering temperature is 375-385° C., the sintering time is 40 minutes, and the nitrogen purity is above 99.9%. For different sintering furnaces, the nitrogen flow rate and pressure are also different. It is best that the steel substrate is not oxidized.

[0039] During implementation, replace EKONOL with PI or polyimide or / and replace M with graphite 0 S 2 , which has a similar effect.

[0040] Of course, after blanking and rolling, shapin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com