Milk protein fiber blended color spinning yarn and its production method

A technology of milk protein fiber and spinning yarn, which is applied in the field of spinning engineering, can solve the problems of not fully reflecting the characteristics of milk protein fiber, hardening of milk protein fiber, and damage of milk protein fiber, so as to maintain the style of hand feeling, soft hand feeling, The effect of maintaining excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

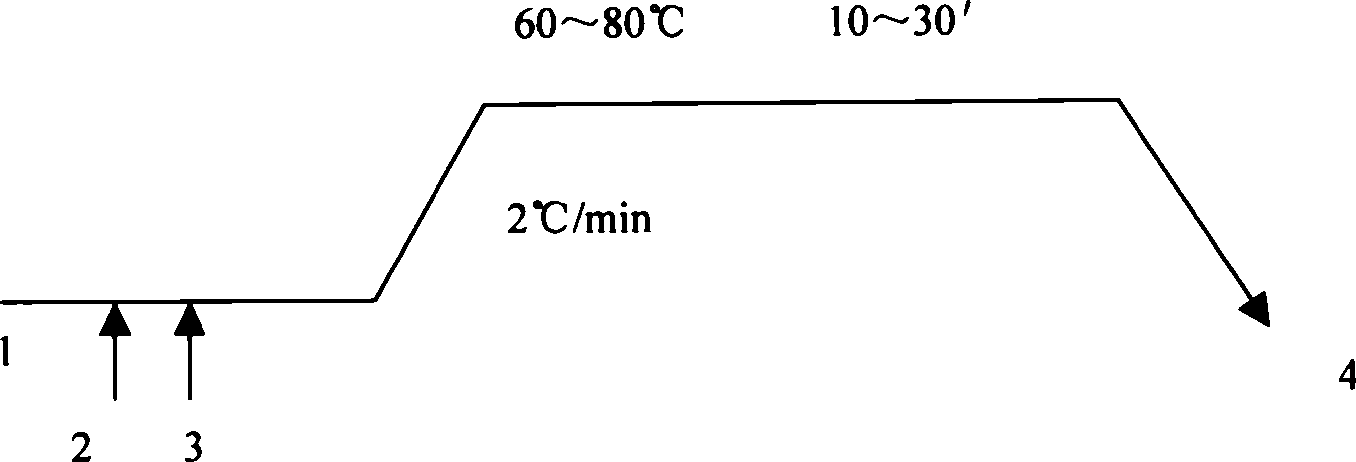

[0070] Select 100 kg of milk protein fiber loose fiber, put it into a solution with a bath ratio of 1:8 and contain 2 g / L of chelating dispersant at room temperature, 2 g / L of soaping agent, heat up to 70 ° C for 15 minutes, and let it stand. The feet are drained and overflowed with water; reactive dyes are used, and the dyes are dyed with Taiwan Yongguang economical three primary colors at medium temperature, 3BS red, 3RS yellow, and Yuanqing B. After the dyes are melted from the auxiliary vat, they are added to the dyeing vat, and the pH value is adjusted with HAC. About 5; Pour in 1 / 5 Yuan Mingfen and run at room temperature for 10 minutes, then add 2 / 5 Yuan Mingfen and run at room temperature for 30 minutes, then heat up to the temperature required for dyeing at 1°C / min, choose according to the characteristics of different dyes Appropriate alkali addition rate curve for adding soda ash, such as figure 2 As shown, the rate of adding alkali should be slow first and then fas...

Embodiment 2

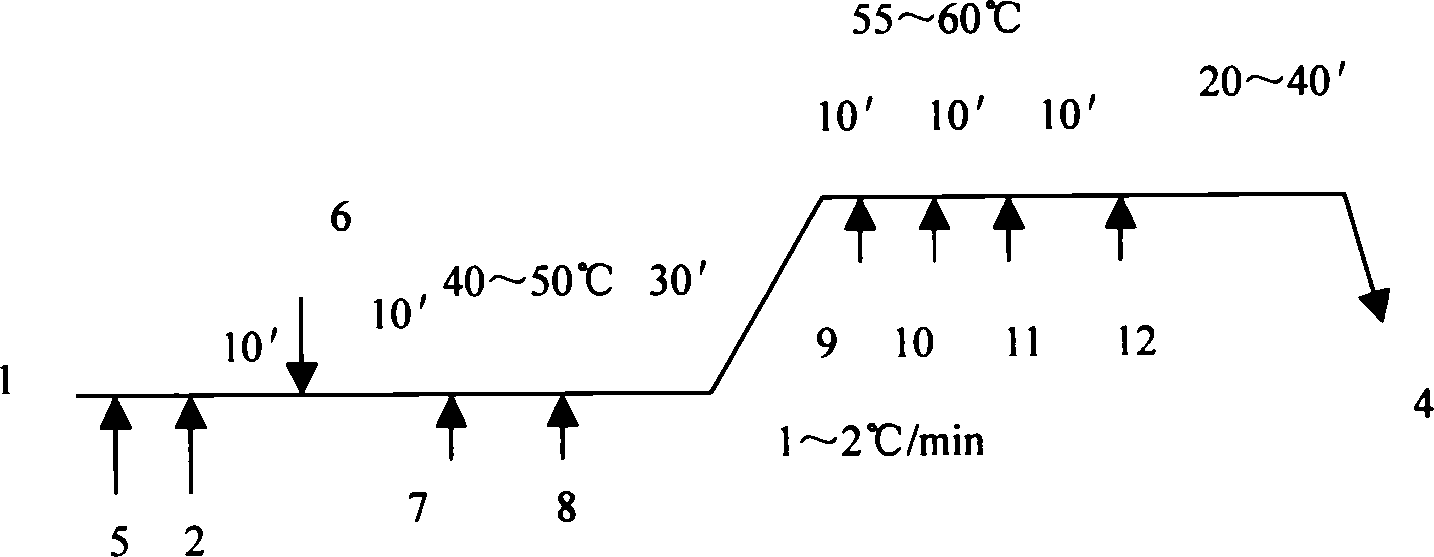

[0072] Select 150 kg of milk protein loose fiber, put it into a solution with a bath ratio of 1:15 and contain 3 g / L of chelating dispersant at room temperature, 3 g / L of soaping agent, heat up to 75 ° C for 20 minutes, and let it go. Foot water, clean with overflowing water; using reactive dyes, the dyes are dyed with the three primary colors of Korean Wurong SPD, SPD red, SPD yellow, SPD blue, the dyes are melted from the auxiliary tank and added to the dye tank, and the pH is adjusted to about 6 with HAC; Pour in 1 / 5 Yuan Mingfen and run at room temperature for 10 minutes, then add 2 / 5 Yuan Mingfen and run at room temperature for 30 minutes, then heat up to the temperature required for dyeing at 1°C / min, and choose the appropriate alkali according to the characteristics of different dyes Rate curves for adding soda ash, such as image 3 As shown, the rate of adding alkali should be slow first and then fast. The time of adding alkali is 30 minutes, and the temperature is mai...

Embodiment 1~4

[0077] The spinning process route and process are the same as the above-mentioned spinning production technology. Specific data such as variety, raw material ratio, spinning count, single yarn, strand twist of each embodiment are shown in Table 2, and the process design parameters of each embodiment spinning variety are shown in Table 3.

[0078] Example

[0079] flow

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com