Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Excellent mechanics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High heat-conducting thin graphene-based composite material, as well as preparation method and application thereof

InactiveCN103122075AGood thermal conductivityExcellent MechanicsHeat-exchange elementsCvd grapheneElectrospinning

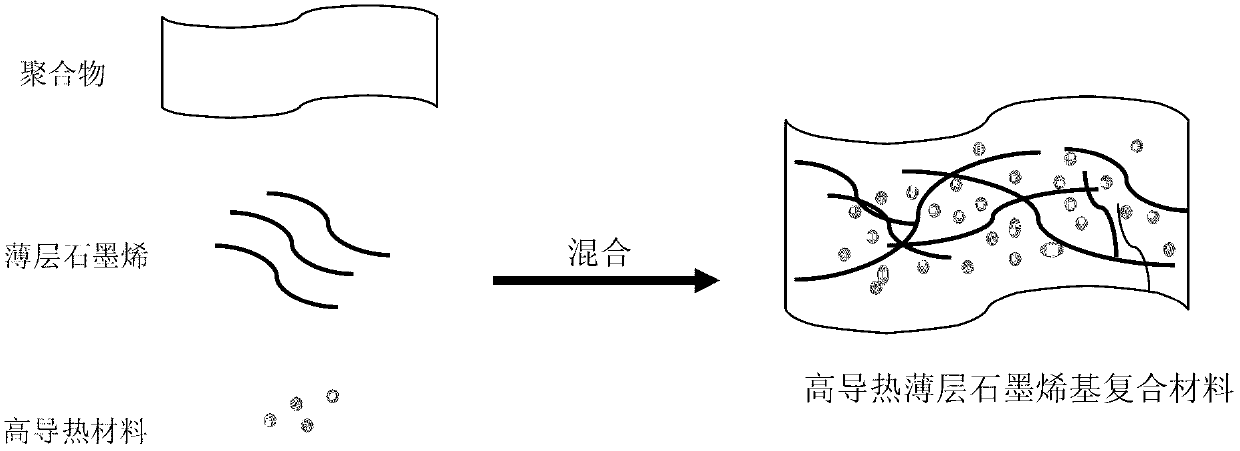

The invention discloses a high heat-conducting thin graphene-based composite material, as well as a preparation method and an application thereof. The composite material comprises a base body component and a packing component, wherein the base body component and the packing component respectively include thin graphene, polymer and / or polymer monomer and a high heat-conducting material; the preparation method comprises a step of compounding the base body component with the packing component; the compounding method comprises fusing, ball-milling, solution blending, electrostatic spinning, solution spinning, melt-spinning, extruding by double screws, mixing by an open mill or powder metallurgy. The polymer, the thin graphene, the traditional high heat-conducting material and the like are compounded by a simple process, so as to form the product with excellent heat conducting property, and good mechanical and electrical properties. Therefore, the process is easy to perform and control, and cost is low; and the obtained product has a wide application prospect in the aspects such as efficient heat conduction and radiation.

Owner:苏州格瑞丰纳米科技有限公司

Preparation method of soluble, colorless, transparent and low-thermal-expansion-coefficient polyamide imide film

InactiveCN105017534AReduce the potential energy of the condensation reactionExcellent mechanicsPolymer scienceThermal expansion

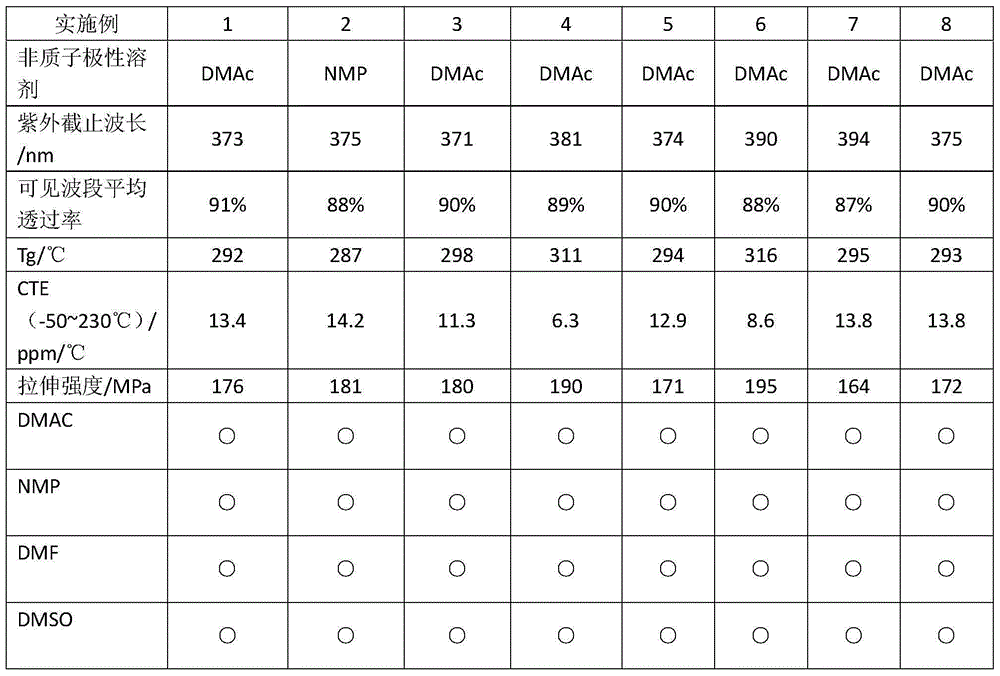

The invention discloses a preparation method of a soluble, colorless, transparent and low-thermal-expansion-coefficient polyamide imide film. According to the prepared film, fluorine-containing diamine monomers serve as diamine monomers, trimellitic anhydride acid chloride serves as anhydride monomers, and the polyamide imide film is further prepared through a trimethylchlorosilane activation mechanism under a simple and moderate synthesis condition. The prepared polyamide imide film has high dimensional stability (the CTE is 5-15 ppm / DEG C or so) and good temperature resistance (Tg is 300 DEG C or so), the transmittance of visible light wavebands is 90% or so, the prepared polyamide imide film can be dissolved in an aprotic polar solvent and is convenient to machine and process, and the comprehensive performance of the prepared polyamide imide film meets the material performance requirement of a part of devices in the microelectronics and optoelectronics field.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Composite material based on modified hollow glass microspheres and preparation method thereof

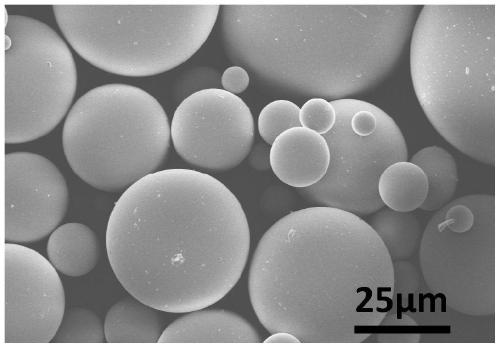

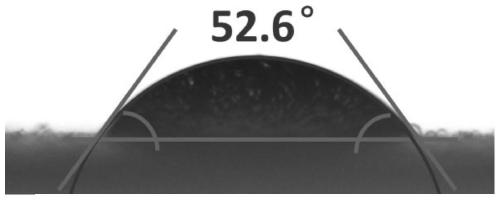

The invention discloses a composite material based on modified hollow glass microspheres. The composite material is prepared from the following raw materials: a resin matrix and the modified hollow glass microspheres. The preparation method of the modified hollow glass microsphere comprises the following steps: carrying out acid leaching treatment on the hollow glass microsphere; and carrying outsurface heat treatment or surface coupling treatment on the hollow glass microspheres subjected to acid leaching treatment to obtain the modified hollow glass microspheres. The composite material hasexcellent mechanical properties and stability. The invention also discloses a preparation method of the composite material.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

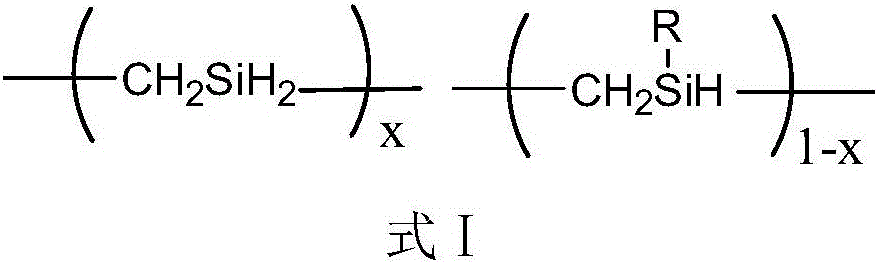

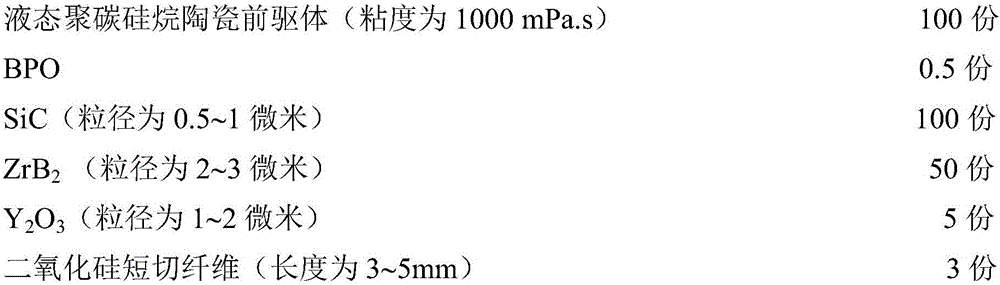

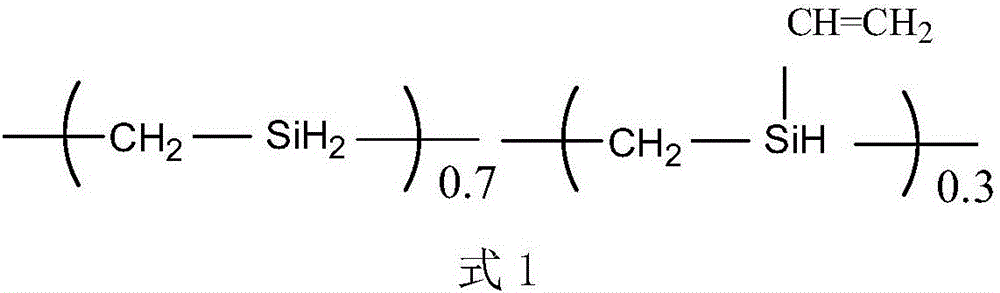

Superhigh temperature-resistant adhesive based on liquid polycarbosilane ceramic precursor and preparation method thereof

InactiveCN106497512AImprove temperature resistanceIncreased shear strengthNon-macromolecular adhesive additivesFiberAdhesive

100 parts of the liquid polycarbosilane ceramic precursor or modified polymer thereof, 0.5 to 5 parts of curing agent, 0 to 300 parts of solid filler, and 0 to 10 parts of chopped fiber. The superhigh temperature-resistant adhesive based on the liquid polycarbosilane ceramic precursor has the advantages that the temperature-resistant property is high, the shear intensity is still higher at the temperature of 1000 to 1700 DEG C, and the superhigh temperature-resistant adhesive can be applied to adhere ceramic and a composite material thereof and carbon-based composite materials, and also applied into oxidizing and inert atmospheres; better heat stability, mechanical property and adhering property are realized, and the temperature-resistant property is better than the temperature-resistant property of phenolic resin; compared with an inorganic adhesive, the toughness is better.

Owner:INST OF CHEM CHINESE ACAD OF SCI

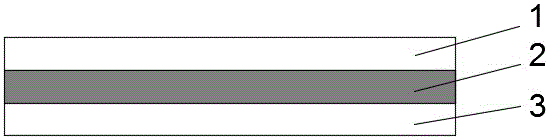

Ceramic metal composite substrate and production method thereof

The invention relates to a ceramic metal composite substrate and a production method thereof. The substrate mainly comprises an ultrathin ceramic sheet, a heat conduction glue and a metal substrate; the ceramic powder of the ultrathin ceramic sheet is a micropowder and a nanopowder mixture, and the volume proportion of nanopowder in the ceramic powder is 15-25%; and the heat conduction glue comprises, by volume, 20-30% of a one-dimensional high heat conduction material. The production method mainly comprises the following steps: making the ultrathin ceramic sheet; carrying out surface treatment on the metal substrate, coating the metal substrate with the heat conduction glue through a coating technology, and carrying out drying semi-solidification; and carrying out hot pressing on the ultrathin ceramic sheet and the glued metal substrate. The ceramic metal composite substrate has a good heat conduction performance, and has a good heat matching performance with chips, and the method has a high production efficiency, and is in favor of realizing development of the substrate to a small, light and thin direction. Tape casting makes the production efficiency of the ultrathin ceramic sheet be high; and the heat conduction glue comprises the one-dimensional high heat conduction material, so thermal resistance between the ultrathin ceramic sheet and the metal substrate is reduced.

Owner:SHANTOU UNIV

Geopolymer foam concrete and preparation method thereof

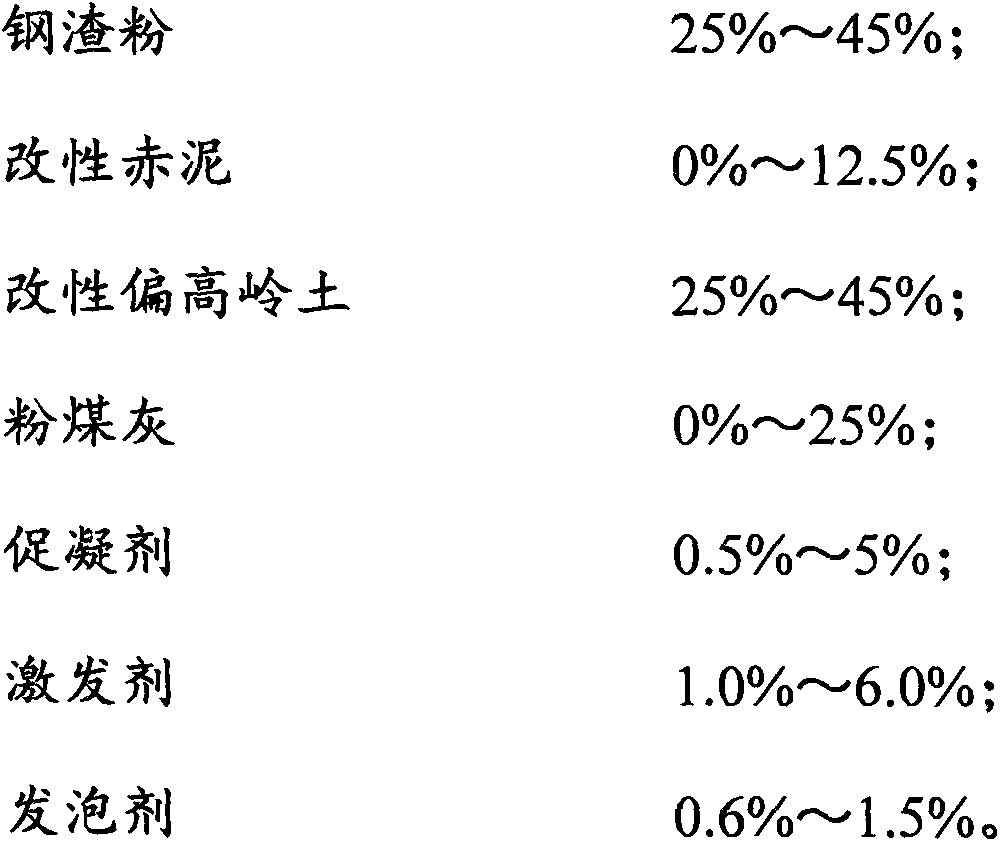

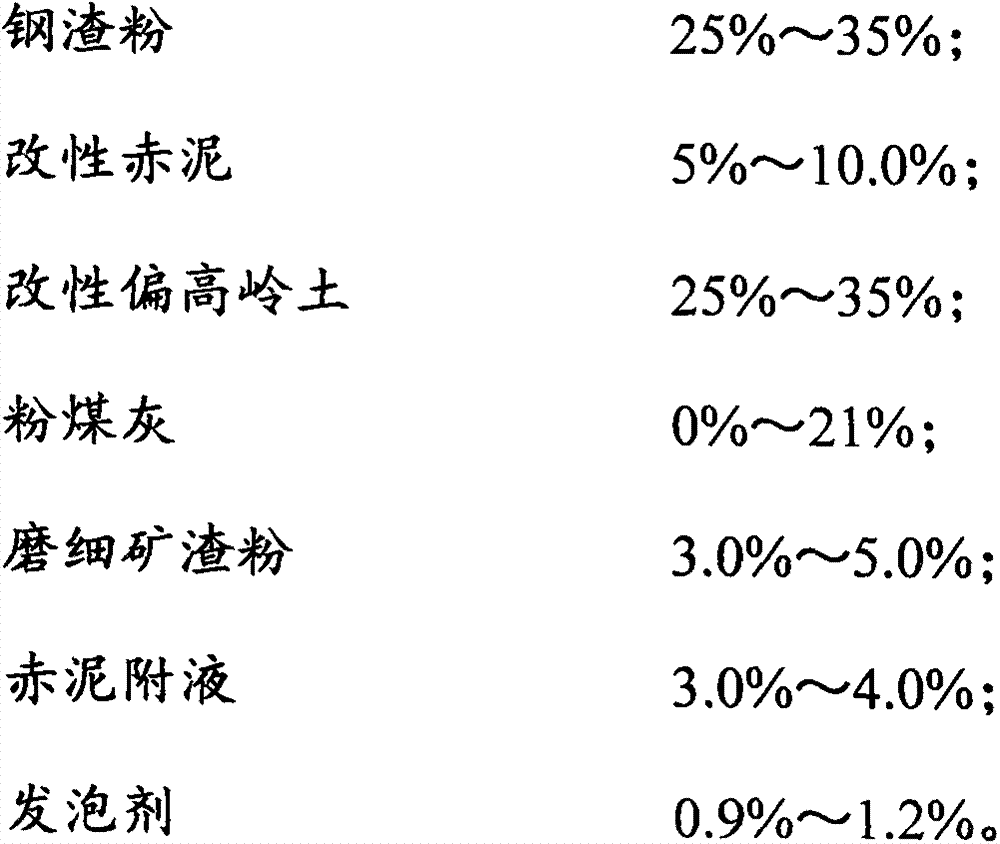

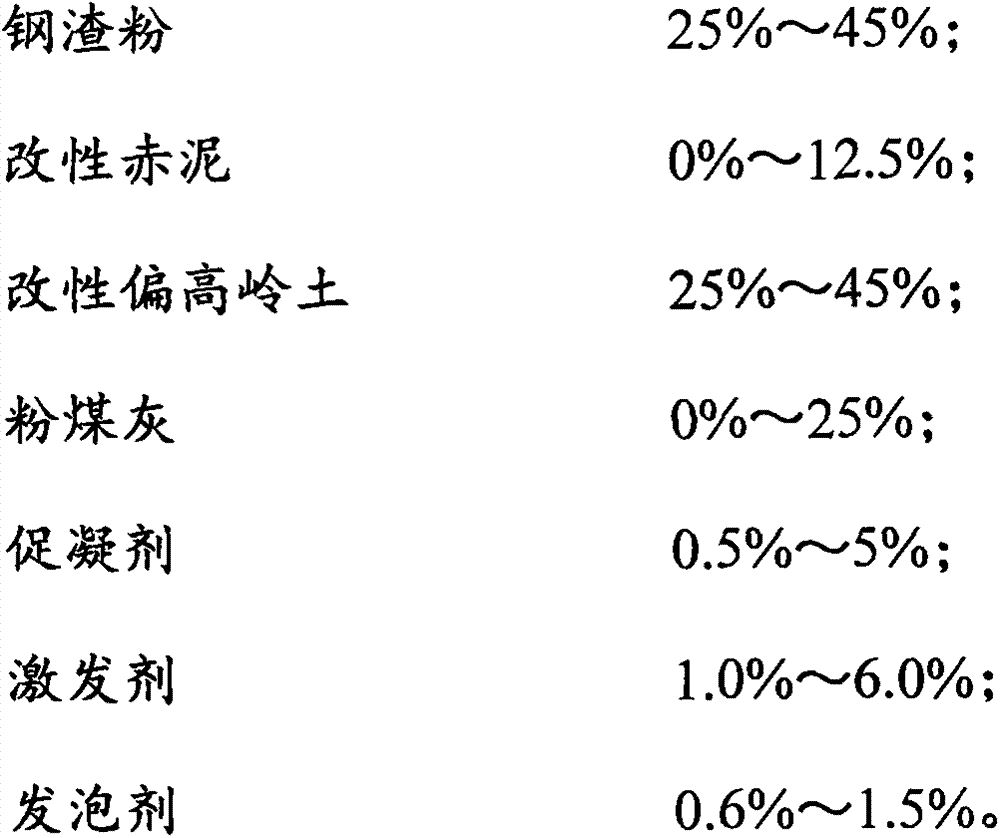

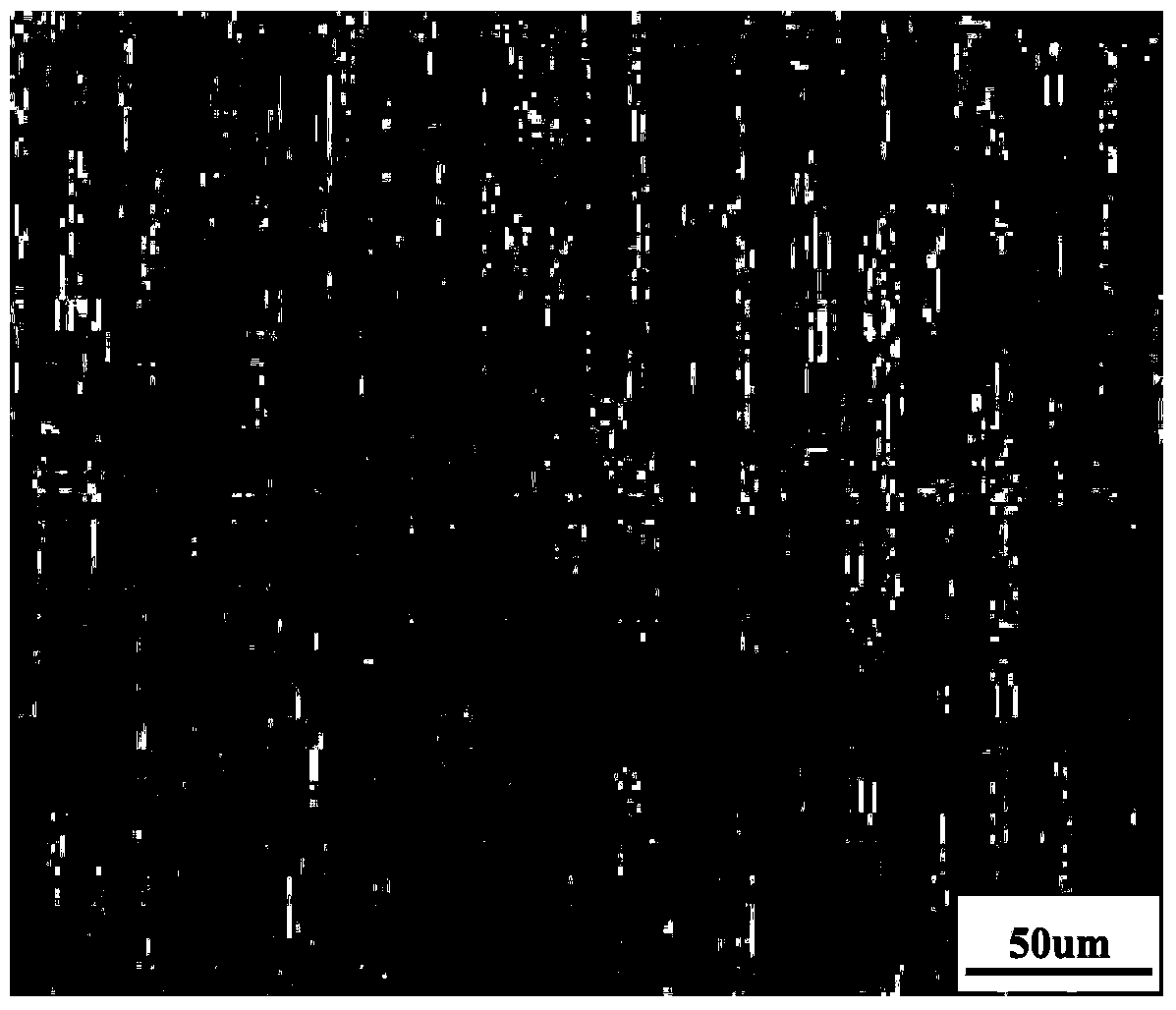

InactiveCN107188609AReduce accumulationReduce pollutionSolid waste managementCement productionFoam concreteFoaming agent

The invention discloses geopolymer foam concrete and a preparation method thereof. By means of the method, a large number of industrial waste and crop straw can be used, the strength of foam concrete is improved and cracking of the foam concrete is prevented. The method includes the steps that 25%-45% of steel slag powder, 0%-12.5% of modified red mud, 25%-45% of modified metakaolin, 0%-25% of fly ash, 0.5%-5% of coagulant and 1%-6% of exciting agent are mixed and stirred evenly to obtain material slurry; at the same time, a foaming agent is diluted with water according to the ratio of 1:15, and a vacuum foaming machine or a high-speed stirrer is used for preparing dense and stable foam; according to the density design requirement, obtained foam is mixed with the uniformly stirred material slurry according to the volume ratio, stirring and foam mixing are conducted, and geopolymer foam concrete is obtained, wherein the volume ratio of the foam to the material slurry is (1-4):1, and stirring is conducted for 2.5-3.5 min until the foam is evenly dispersed in the material slurry.

Owner:CHANGZHOU YINENG TECH

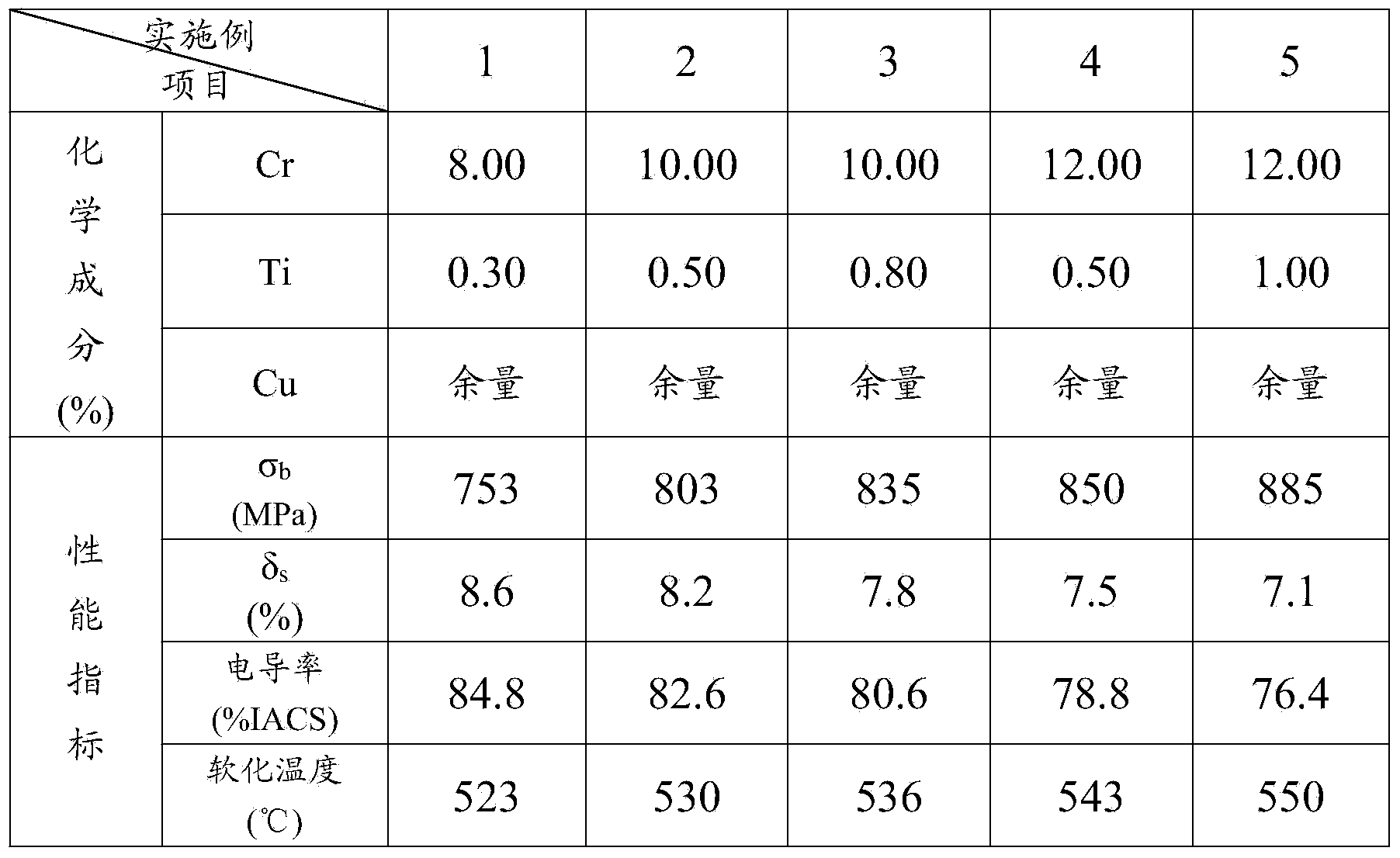

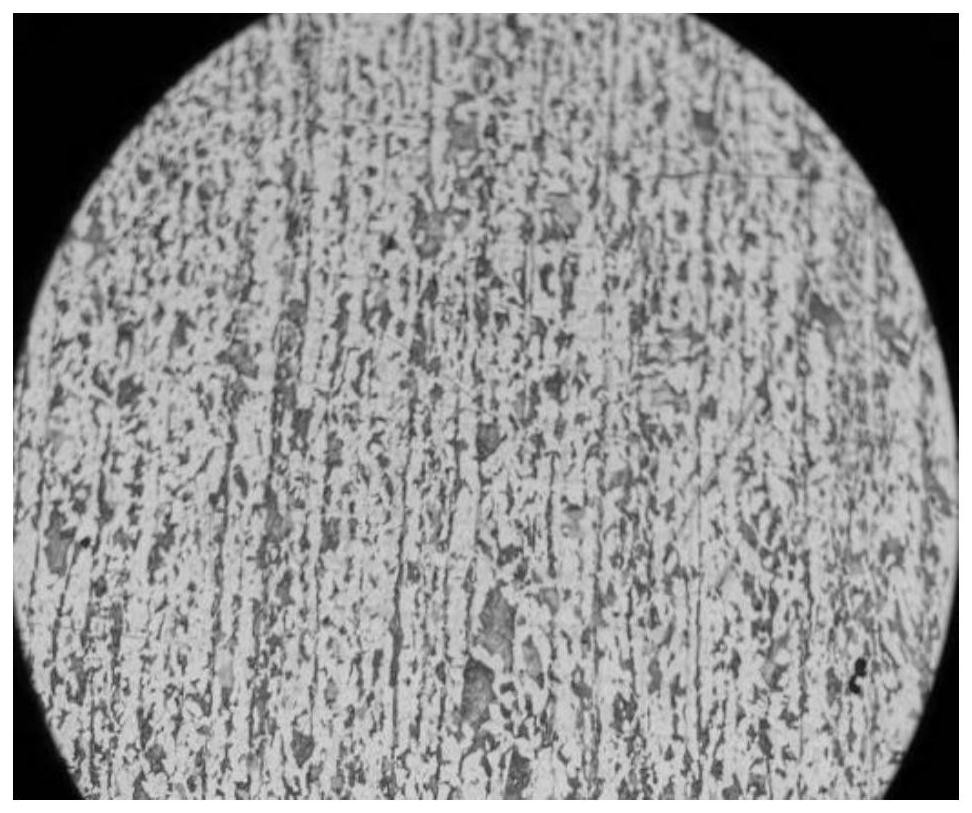

High-strength and high-conductivity Cu-Cr-Ti alloy conductor and manufacturing method thereof

InactiveCN103456385AImprove plastic deformation abilityExcellent mechanicsPolycrystalline material growthFrom frozen solutionsCrystal structureEconomic benefits

The invention relates to a high-strength and high-conductivity Cu-Cr-Ti alloy conductor and a manufacturing method of the high-strength and high-conductivity Cu-Cr-Ti alloy conductor. Alloy is made from the following chemical components: 8.0-15% of Cr, 0.0-3.0% of Ti, 0.1% or less than 0.1% of impurities and the balance of copper; an alloy pole stock with the diameter of 8-12mm is manufactured by using a continuous directional solidification system through casting; a Cu-Cr-Ti alloy wire rod with the diameter of 1-2mm is manufactured through the processes of cold drawing deformation-heat treatment-rolling deformation and the like. The high-strength and high-conductivity Cu-Cr-Ti alloy conductor manufactured in the method is of a continuous columnar crystal structure or monocrystal structure, overcomes the defect of mutual contradiction of high strength and high conductivity, and has broad application prospects and good economic benefits.

Owner:JIANGXI UNIV OF SCI & TECH

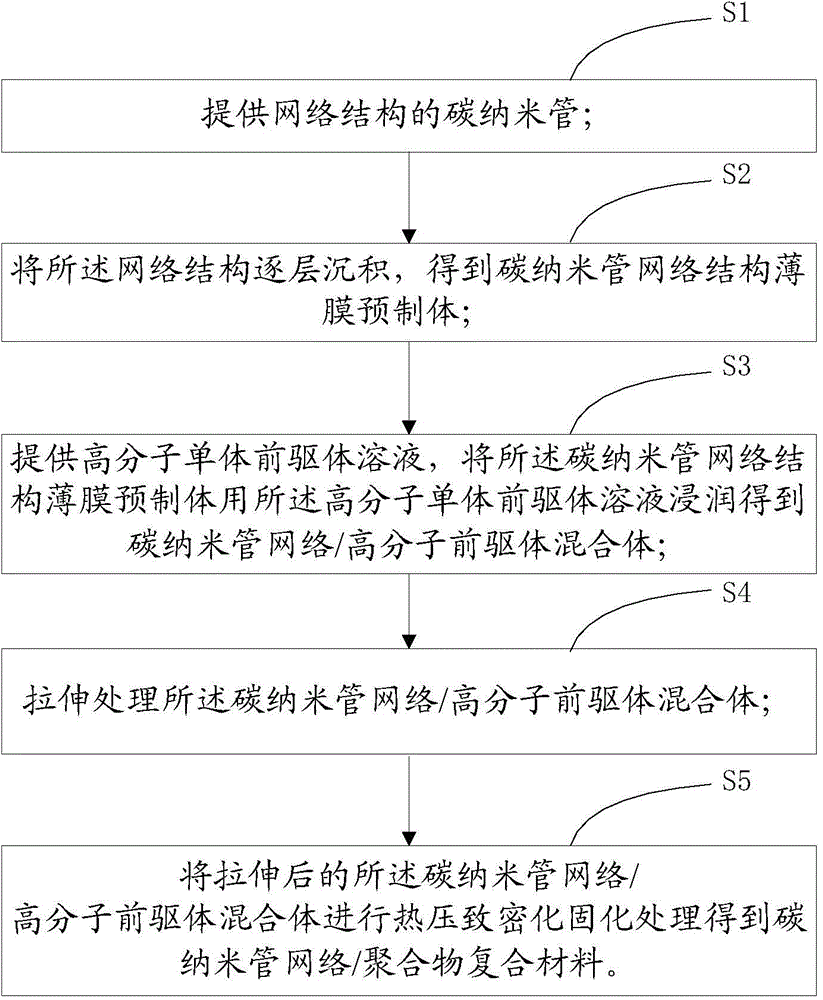

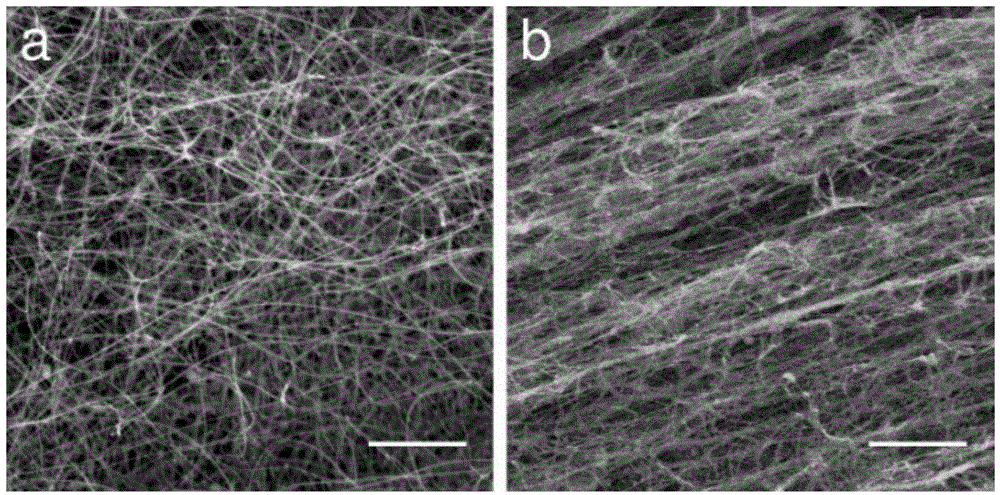

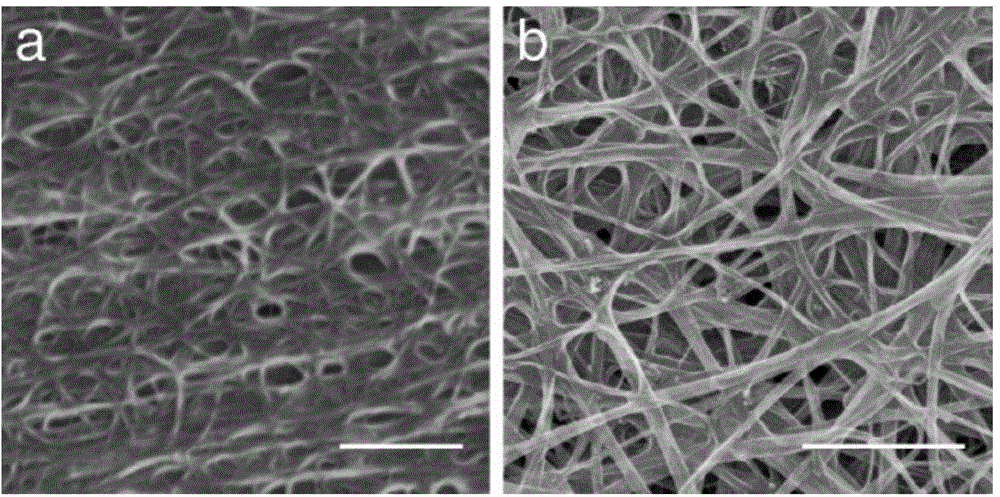

Carbon nano-tube network/polymer composite material and preparation method thereof

The invention discloses a carbon nano-tube network / polymer composite material. The carbon nano-tubes are mutually tangled to form a network structure, wherein the outer surface of the carbon nano-tube is uniformly wrapped with a polymer, and the carbon nano-tube and the polymer are all independently existed in a non-aggregated state. Compared with the prior art, the carbon nano-tube is existed in a non-aggregated state and the polymer is existed in a non-enriched state; by adopting the carbon nano-tube network / polymer composite material, the shortcomings of the traditional carbon nano-tube composite material such as the agglomeration of the carbon nano-tubes and the low content are solved, meanwhile, the excellent mechanical property, electrical property and thermal property of the carbon nano-tube are kept, and the carbon nano-tube is excellent in self-supporting property and is easy to process in the using process and has a wide application future in the fields such as the electromagnetic shielding materials, functional intelligent materials and electrode materials.

Owner:SUZHOU CREATIVE CARBON NANOTECH

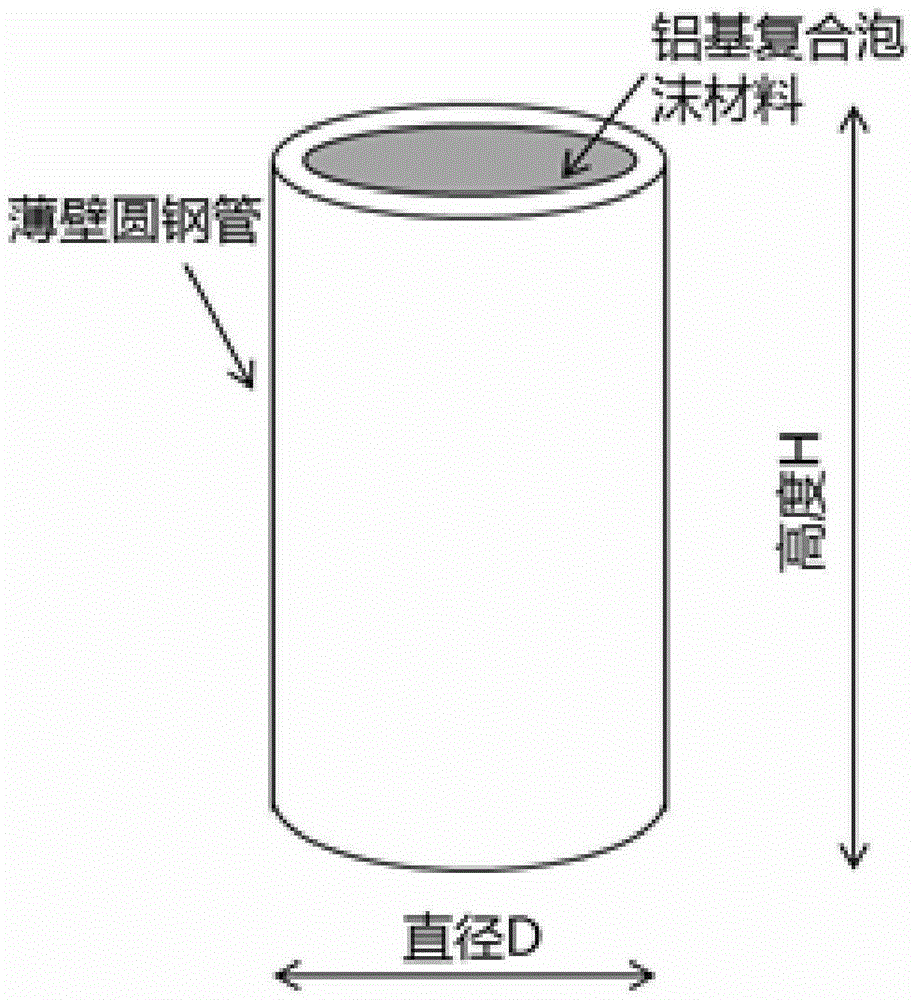

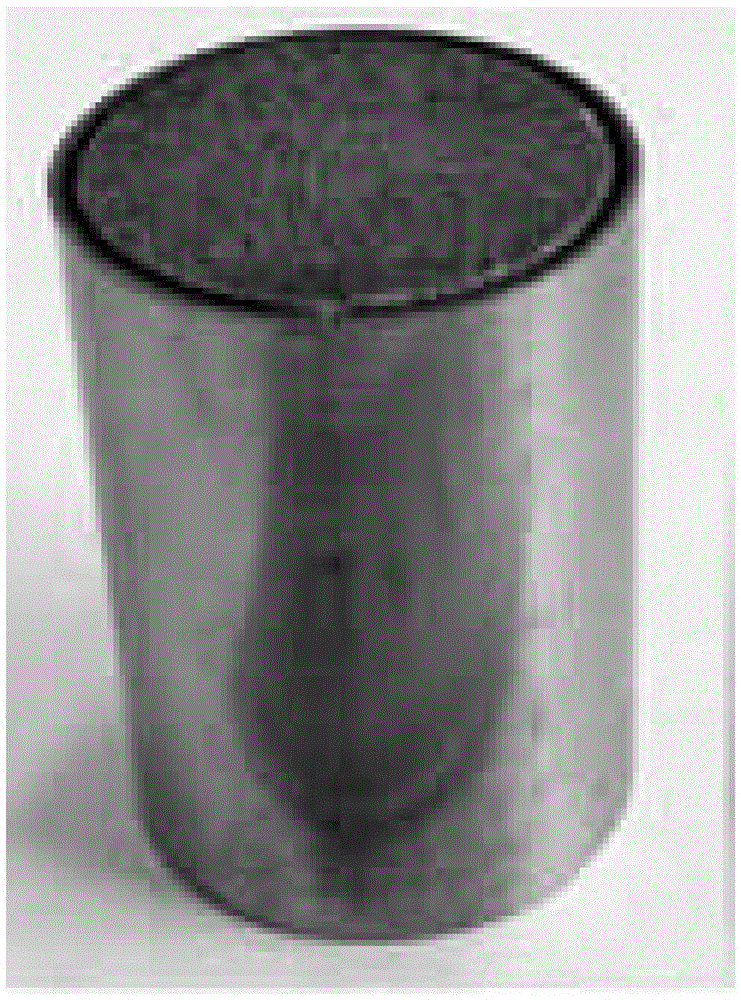

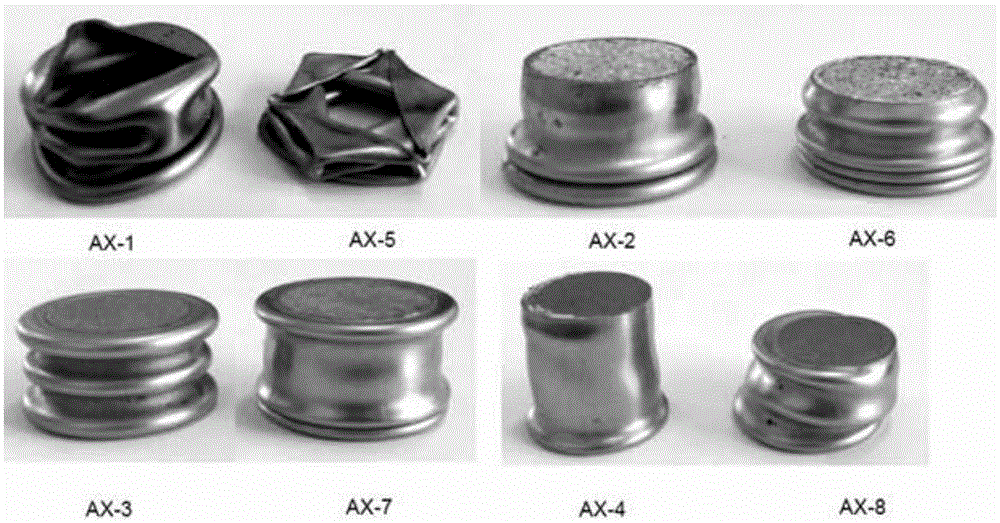

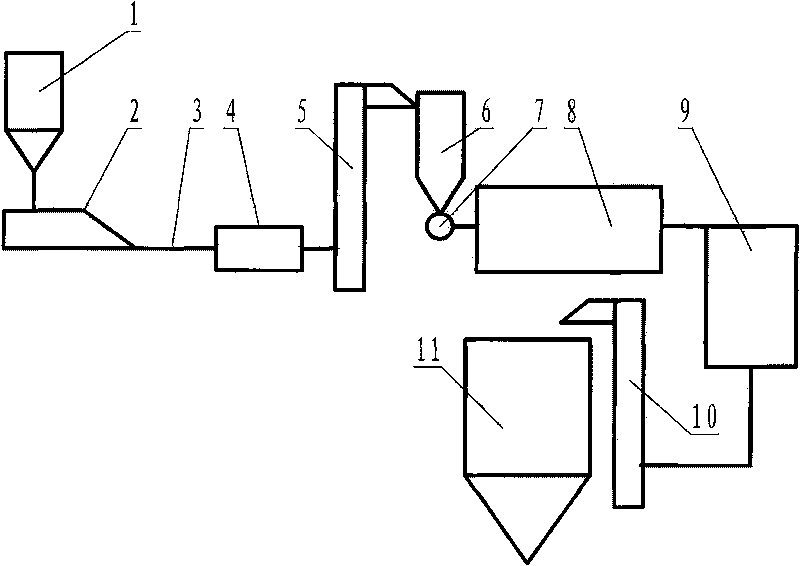

Buffering and energy absorption filling pipe

InactiveCN105299120AMake up strengthMake up structureElastic dampersRubber-like material springsStatic compressionEnergy absorption

The invention belongs to buffering and energy absorption components and discloses a buffering and energy absorption filling pipe. The problem that an existing foamed aluminum filling pipe is poor in energy absorption effect is solved. Aluminum-based composite foam materials are filler to be made into an aluminum-based composite foam filling pipe component, the energy absorption effect many times that of an ordinary foamed aluminum filling pipe component is achieved, the disadvantage that the aluminum-based composite foam materials cannot be independently used as an energy absorption or bearing structure due to poor intensity is overcome, and the high-intensity aluminum-based composite foam filling pipe component can fully play and integrate the advantages and mechanical property of various materials when bearing explosive blast, impact or other extreme loads, not only has the independent bearing capacity, but also has the outstanding advantages of being high in stability and energy absorption capacity and capable of working in the extreme environment and the like. Equivalent static compression tests are conducted on the buffering and energy absorption filling pipe and prove that the buffering and energy absorption filling pipe has the energy absorption capacity and mechanical property superior to those of the ordinary foamed aluminum filling pipe. Compared with a traditional hollow steel pipe and the ordinary foamed aluminum filling pipe, the crushing force and the energy absorption capacity are greatly improved.

Owner:HARBIN INST OF TECH

Building polymer powder based on composite silicate

InactiveCN101712537ALarge specific surface areaRich functionalitySolid waste managementPolymer scienceSlag

Owner:高庆越 +1

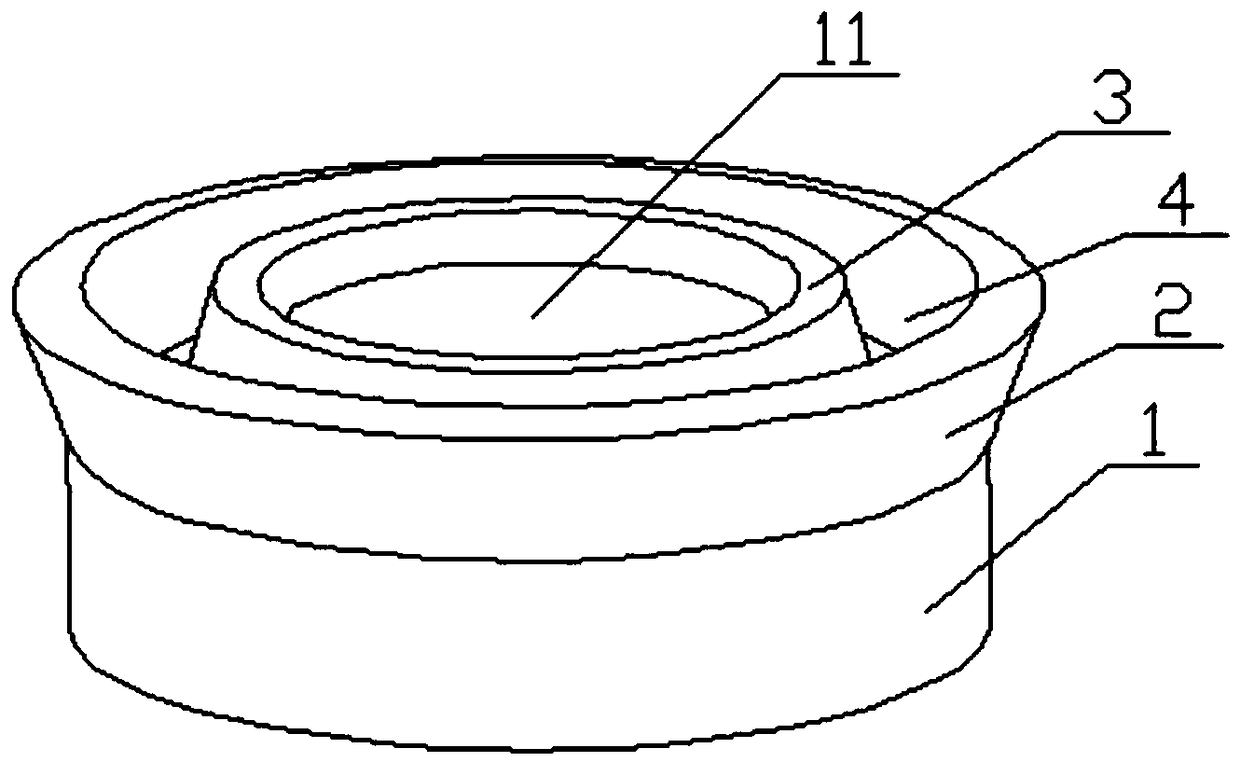

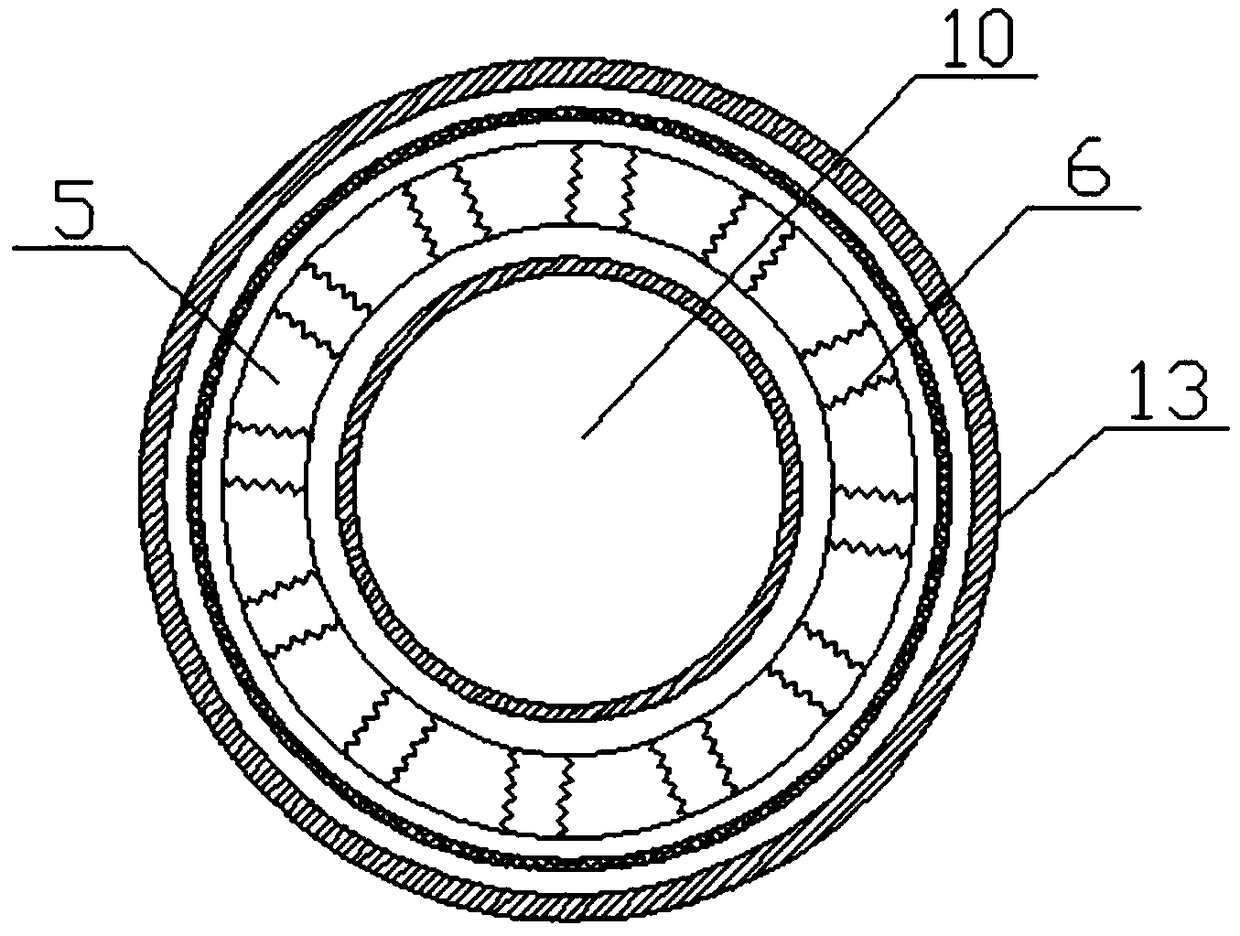

Automobile rubber sealing ring

The invention discloses an automobile rubber sealing ring and relates to the technical field of rubber sealing rings. The automobile rubber sealing ring comprises a sealing ring body, an outer sealinglip and an inner sealing lip. The upper surface of the sealing ring body is fixedly connected with the outer sealing lip, the middle position of the outer sealing lip is fixedly connected with the inner sealing lip, and a groove is formed between the inner sealing lip and the outer sealing lip. A first rubber layer is arranged in the sealing ring body, elastic reinforcing ribs are evenly buried in the first rubber layer, a second rubber layer is evenly wrapped on the outer wall of the first rubber layer, a metal ring frame is evenly wrapped on the outer wall of the second rubber layer, the inner wall of the metal ring frame is fixedly connected with the outer wall of the second rubber layer, and a third rubber layer is evenly wrapped on the outer wall of the metal ring frame. The automobile rubber sealing ring realizes the purposes of good sealing effect, good abrasion resistance, good aging resistance and tearing prevention and is prolonged in service life.

Owner:ANHUI AOFENG AUTOMOBILE FITTINGS

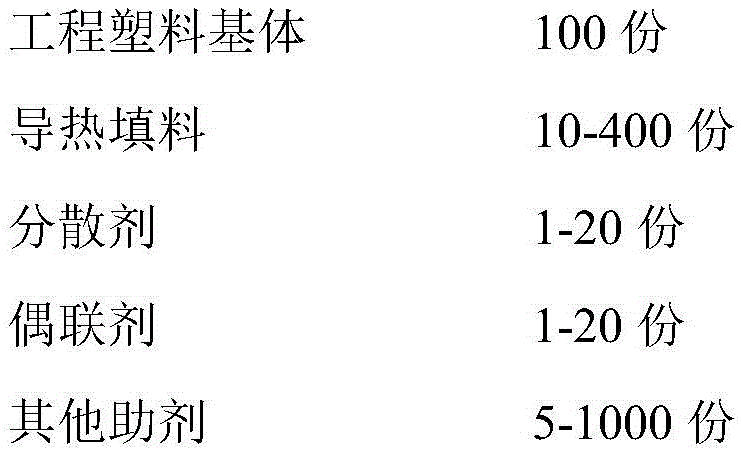

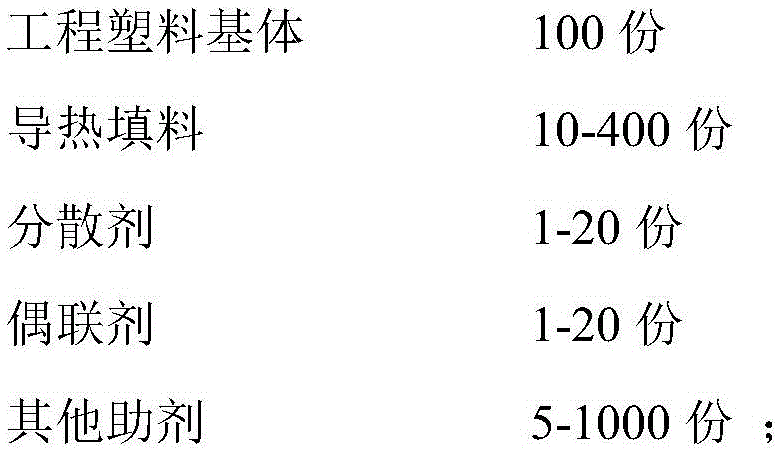

High-thermal-conductivity engineering plastic and preparation method thereof

The invention discloses high-thermal-conductivity engineering plastic and a preparation method thereof. The high-thermal-conductivity engineering plastic is prepared from raw materials as follows: in parts by mass, 100 parts of an engineering plastic matrix, 10-400 parts of thermal-conductive filler, 1-20 parts of a dispersant, 1-20 parts of a coupling agent and 5-1000 parts of other additives. The thermal-conductive filler of the engineering plastic evenly disperses in a plastic matrix solution, and is smashed after film formation and drying or spray drying to obtain granular materials. The engineering plastic prepared with the preparation method has relatively high thermal conductivity and good mechanical and machining performance.

Owner:ANHUI UNIVERSITY

Composite acid supported catalyst and catalytic synthesis method of bisphenol F

InactiveCN105536827AExcellent heat and humidity resistanceImprove insulation performanceOrganic chemistryPhysical/chemical process catalystsSynthesis methodsPhosphoric acid

The invention discloses a composite acid supported catalyst and a catalytic synthesis method of bisphenol F. A synthesis method of the composite acid supported catalyst comprises the following steps: adding phosphoric acid, diatomite, LiCl and titanium dioxide to ethanol according to a certain ratio, and refluxing and stirring above raw materials overnight (for 12-24h); and recovering ethanol after the above reaction ends, washing the obtained material with water 3 times, and carrying out vacuum drying for 12h to obtain the composite acid supported catalyst. The synthesis method of bisphenol F comprises the following steps: adding phenol and the composite acid catalyst to a reaction container, adding xylene, stirring above materials at room temperature, adding 37% of an aqueous formaldehyde solution in a dropwise manner, and heating the obtained solution to 100-150DEG C, wherein the temperatures are 100DEG C, 125DEG C and 150DEG C respectively, toluene is adopted as a solvent, and the reaction time is 2-8h; and recovering the catalyst, the solvent and phenol, and re-crystallizing the above obtained product with the recovered solvent to obtain pure bisphenol F. The catalyst has the advantages of increase of the bisphenol F yield, simple synthesis method, low cost, high catalysis activity and reusability.

Owner:JIANGNAN UNIV

High-entropy ceramic-based composite material and preparation method thereof

ActiveCN113321510AImprove mechanical propertiesImprove high temperature oxidation resistance and ablation resistancePorous carbonSlurry

The invention relates to a high-entropy ceramic-based composite material and a preparation method thereof. The method comprises the following steps: (1) preparing high-entropy ceramic slurry containing (Tix1Zrx2Hfx3Nbx4Tax5)C high-entropy ceramic powder and phenolic resin; (2) impregnating a porous carbon / carbon green body by using the high-entropy ceramic slurry, and then sequentially carrying out the steps of curing and high-temperature cracking to obtain a high-entropy ceramic-based composite material intermediate; and (3) carrying out liquid silicon infiltration reaction on the high-entropy ceramic-based composite material intermediate obtained in the step (2) to prepare the high-entropy ceramic-based composite material. The high-entropy ceramic-based composite material prepared by the method disclosed by the invention comprises a (Tix1Zrx2Hfx3Nbx4Tax5)C matrix and a SiC matrix which are high in modulus and resistant to high temperature, and has excellent mechanical and high-temperature ablation resistance.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

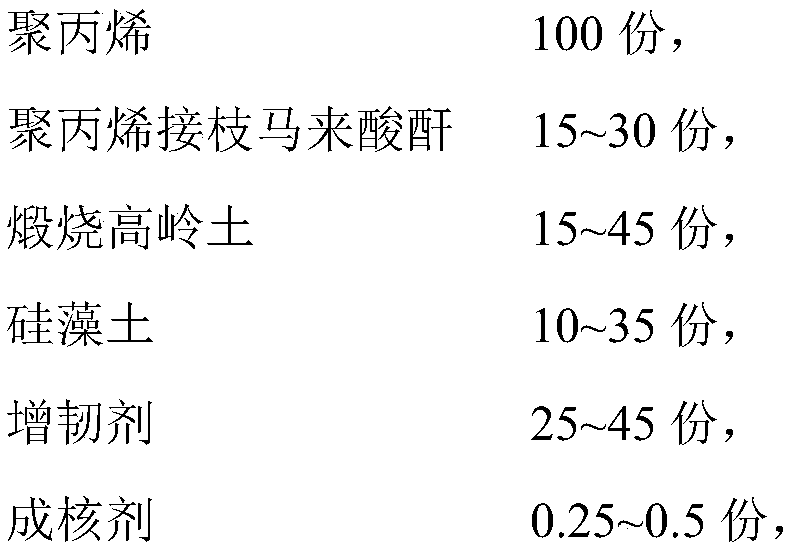

Low-after-shrinkage polypropylene composite material for automobile bumper and preparation method thereof

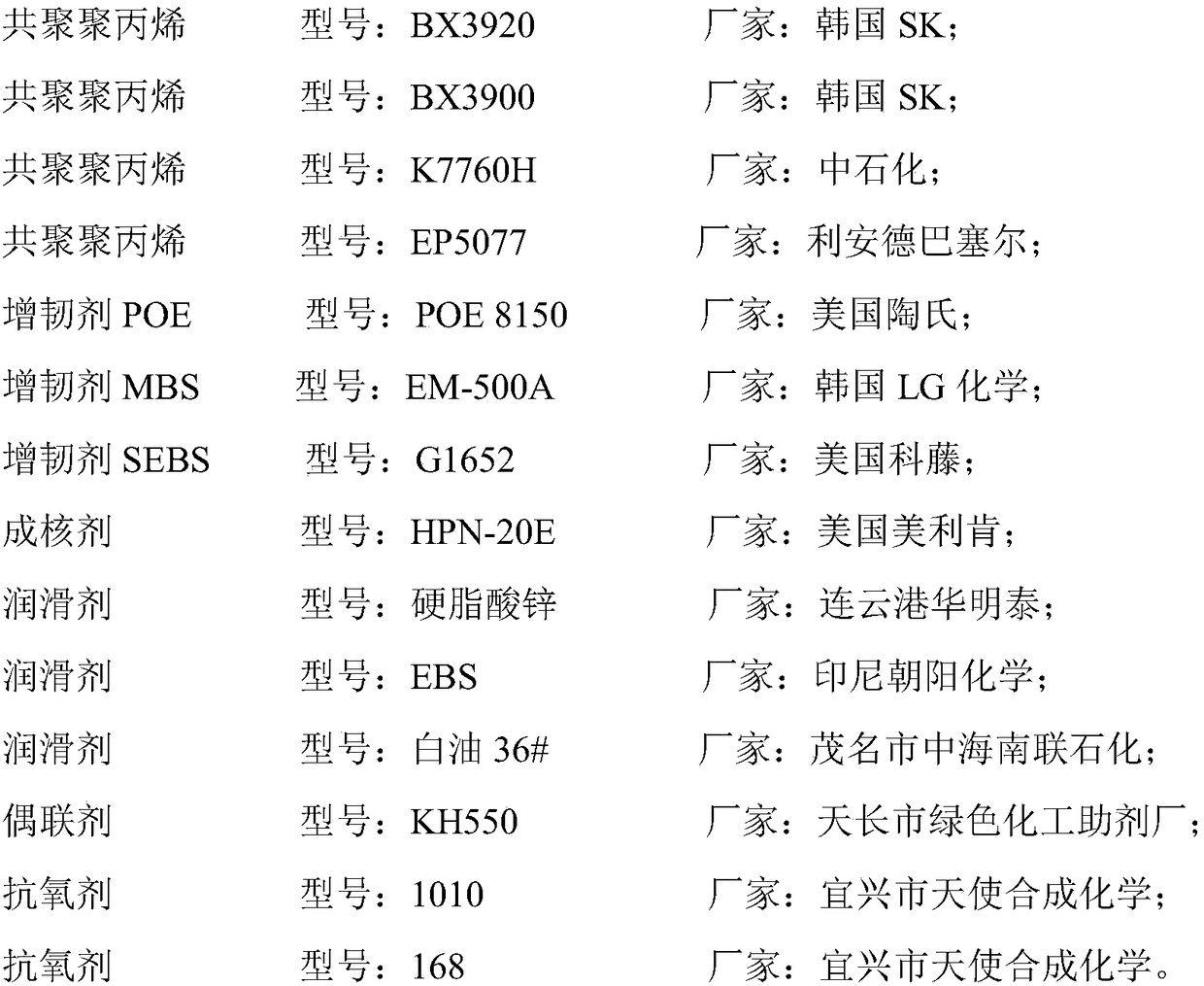

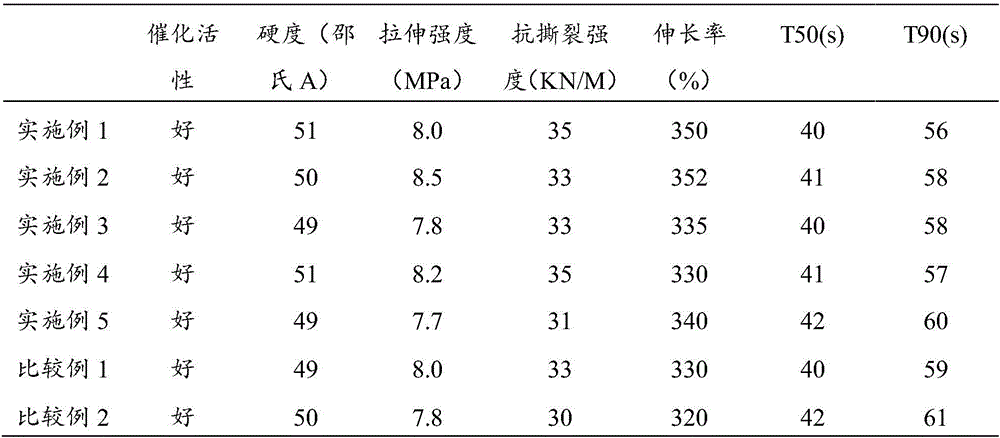

The invention provides a low-after-shrinkage polypropylene composite material for an automobile bumper and a preparation method thereof. The low-after-shrinkage polypropylene composite material is prepared from the following components: 100 parts of polypropylene, 15 to 30 parts of polypropylene grafted maleic anhydride, 15 to 45 parts of calcined kaolin, 10 to 35 parts of diatomite, 25 to 45 parts of a toughening agent, 0.25 to 0.5 part of a nucleating agent, 0.4 to 0.8 part of a lubricant, 0.2 to 0.3 part of a coupling agent and 0.15 to 0.4 part of an antioxidant; the low-after-shrinkage polypropylene composite material is prepared through mixing by steps, extruding and granulating. The polypropylene composite material provided by the invention has the advantages of low shrinkage rate and strong mechanical property; after the low-after-shrinkage polypropylene composite material is subjected to injection molding for 24h to 48h, the size stability is good and relatively small after-shrinkage is kept after the material is sprayed; the low-after-shrinkage polypropylene composite material can be used as the automobile bumper and the like.

Owner:HEFEI GENIUS NEW MATERIALS

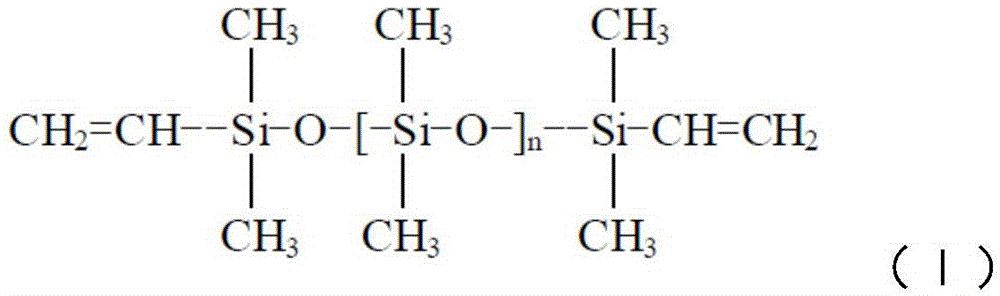

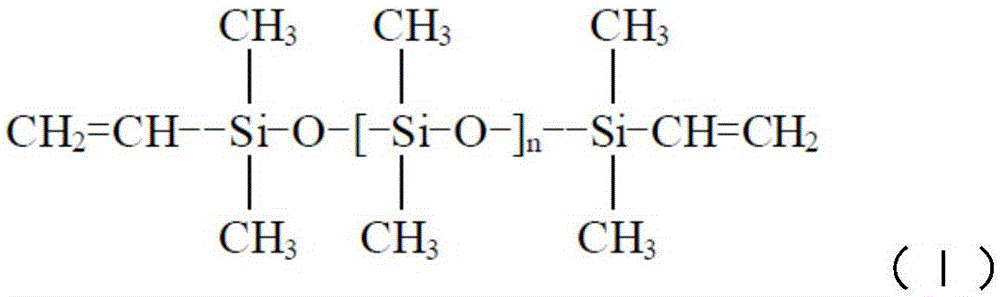

Platinum catalyst and preparing method thereof and preparing method of silicone rubber

ActiveCN106432734AExcellent activity and stabilityExcellent storage stabilitySimple Organic CompoundsPolymer science

The invention discloses a platinum catalyst. In the platinum catalyst, organic ligands are a compound containing vinyl and an organic compound containing nitrogen. A platinum complex formed through coordination of the two organic ligands and chloroplatinic acid not only breaks through traditional imprisonment that only a platinum catalyst containing a low content of platinum can be synthesized, and synthesizes the platinum catalyst with a high content of platinum, but also forms the platinum catalyst which has excellent catalytic activity and excellent storage stability. When the platinum catalyst is used for catalyzing and synthesizing silicone rubber, the obtained silicon rubber has excellent vulcanization activity and an excellent mechanical property. In addition, the prepared platinum catalyst can be diluted to various suitable concentrations according to the need so as to be used for silica gel products of various forms, and thus being easy to weigh and accurate in dosage.

Owner:东莞市贝特利新材料有限公司

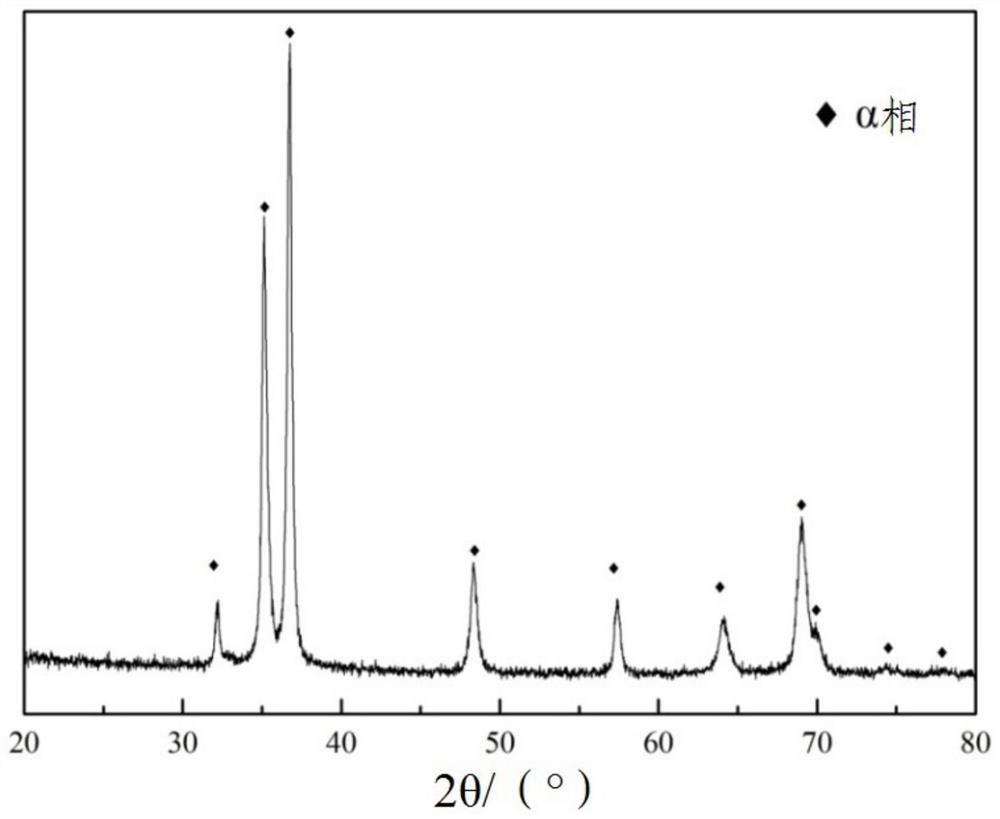

Corrosion-resistant high-strength neutron shielding alloy material and preparation method thereof

The invention discloses a corrosion-resistant high-strength neutron shielding alloy material which is composed of the following elements including, by mass, 49%-51% of Hf and the balance Zr and inevitable impurities. The invention also provides a preparation method of the corrosion-resistant high-strength neutron shielding alloy material. The method comprises the following steps of mixing sponge zirconium and sponge hafnium, conducting pressing and vacuum consumable electrode smelting to obtain an alloy cast ingot, sequentially machining and chamfering the alloy cast ingot, carrying out three-heating-number forging to obtain a forged alloy ingot, carrying out heat treatment on the forged alloy ingot, and cooling to obtain the alloy material. According to the corrosion-resistant high-strength neutron shielding alloy material and the preparation method, the Zr serves as a matrix, the Hf serves as a main alloy element, the alloy material is prepared through vacuum consumable electrode smelting and three-heating-number forging, and the prepared alloy material is single in phase and uniform in structure, has excellent neutron shielding performance and strength and meanwhile has extremely high corrosion resistance and machinable performance.

Owner:西安稀有金属材料研究院有限公司

Solid-liquid mixed foaming fireproof insulation board

The invention relates to an insulation board, in particular to a solid-liquid mixed foaming fireproof insulation board. A foaming fireproof filler is a hard sealed foam block body and expanded perlite or glazed hollow beads and a phenolic resin foaming material are solidified through phenolic resin foam to form the hard sealed foam block body. The solid-liquid mixed foaming fireproof insulation board has the advantages of being unique in structure, fireproof, good in thermal insulation performance, safe and reliable, and the material cost can be reduced.

Owner:廖万银

Modified graphene rubber and preparation method thereof

The invention discloses modified graphene rubber and a preparation method thereof. The modified graphene rubber comprises the following raw materials in parts by weight: 20-40 parts of butadiene rubber, 20-40 parts of natural rubber, 10-20 parts of modified graphene, 10-15 parts of solvent-free resin, 5-10 parts of a silane coupling agent, 1-5 parts of , nanometer aluminum oxide, 1-5 parts of nanometer silicon dixode, 5-15 parts of sepiolite fiber, 3-7 parts of decabromodiphenylethane, 1-3 parts of an accelerant and 0.5-1.5 parts of a tackifier. The modified graphene rubber prepared by the preparation method provided by the invention has high strength and good wear resistance; the preparation method has a simple production process and is suitable for wide application.

Owner:HUANGSHAN SHANGYI RUBBER & PLASTIC PRODS

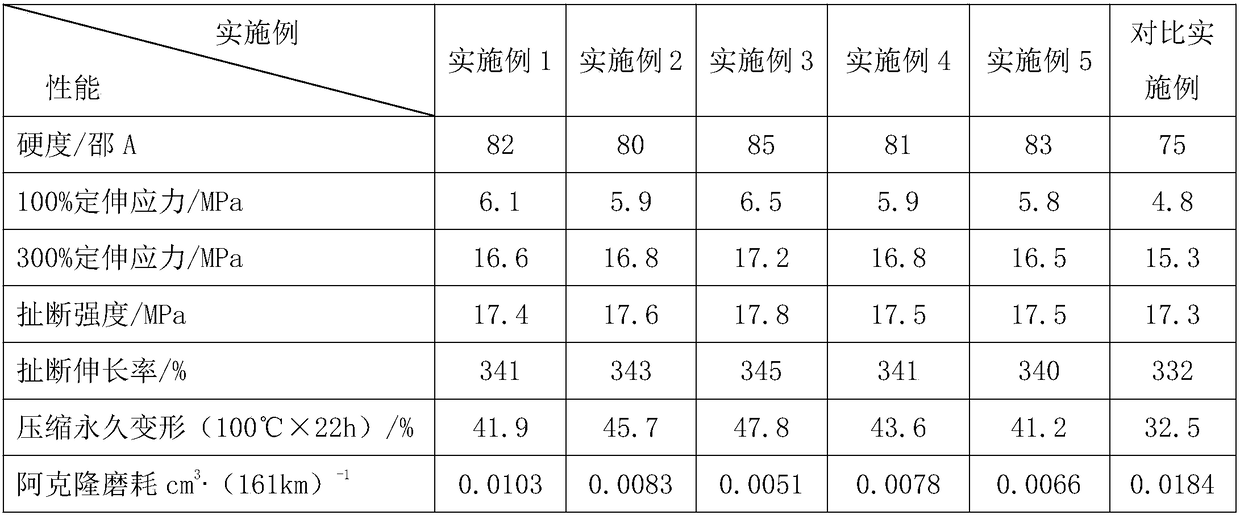

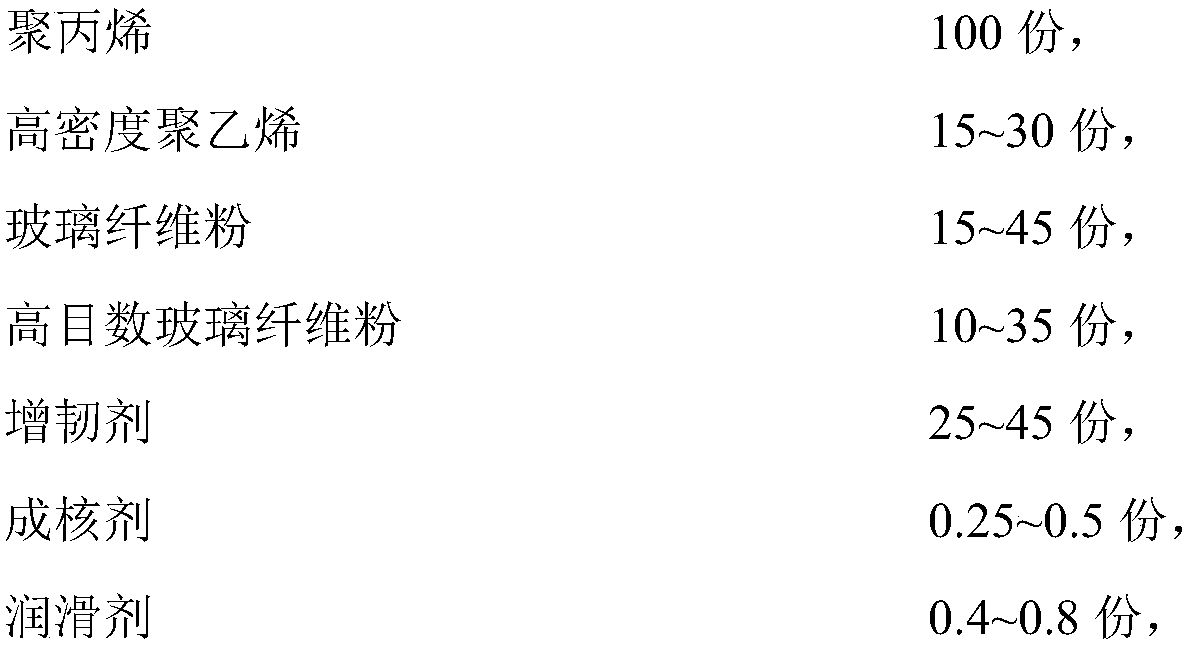

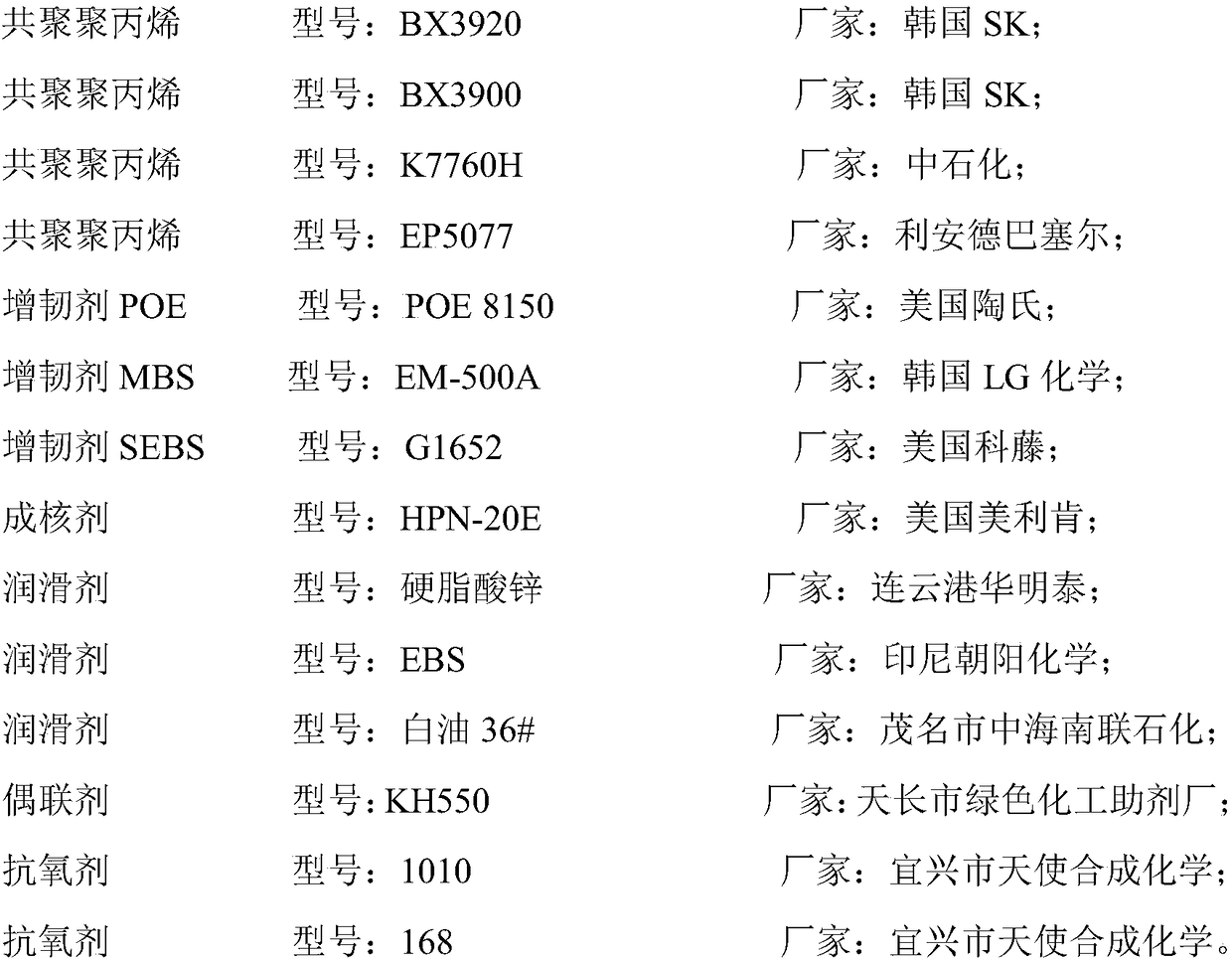

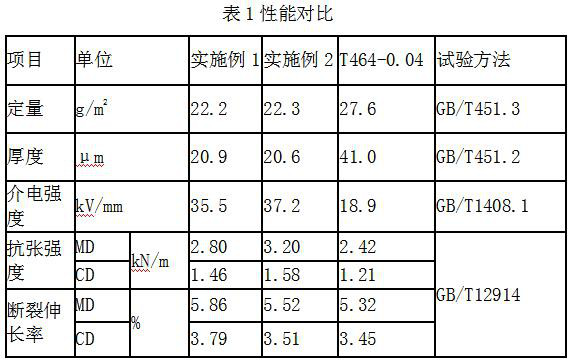

Low after-shrinkage polypropylene composite and preparation method thereof

The invention discloses a low after-shrinkage polypropylene composite and a preparation method of the composite. The composite is prepared from the following ingredients in parts by weight: polypropylene, high-density polyethylene, glass fiber powder, high-mesh glass fiber powder, a flexibilizer, a nucleator, a lubricant, a coupling agent and an antioxidant. The glass fiber powder is added, fed through a main feed port and a side feed port and compounded with the high-mesh glass fiber powder and high-density polyethylene for use to form the PP (polypropylene) composite with excellent comprehensive performance; at the same time, a shrinkage rate of the PP composite is greatly reduced; and the composite can be used as a bumper in high-end automobiles.

Owner:HEFEI GENIUS NEW MATERIALS

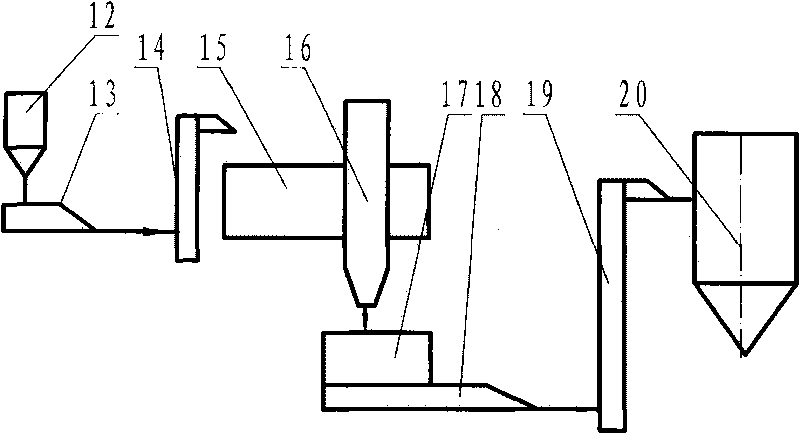

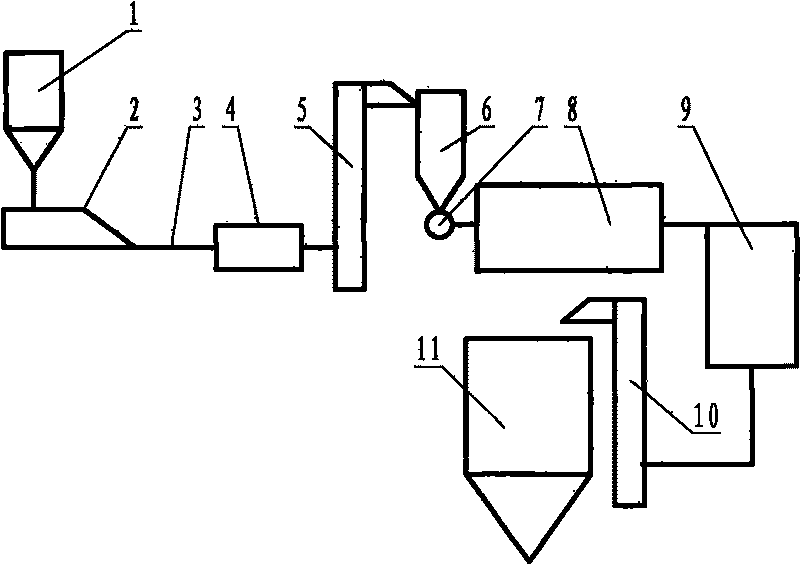

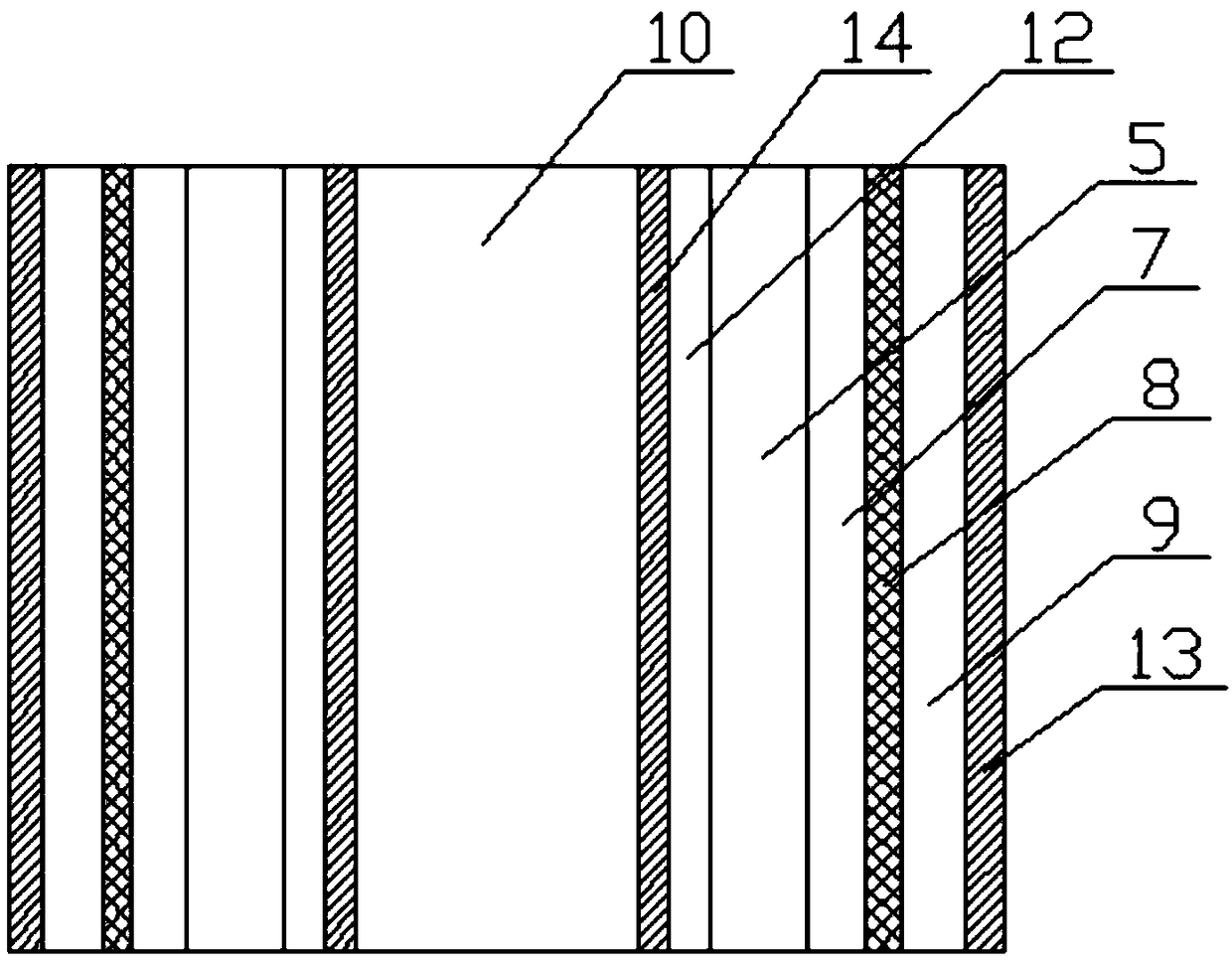

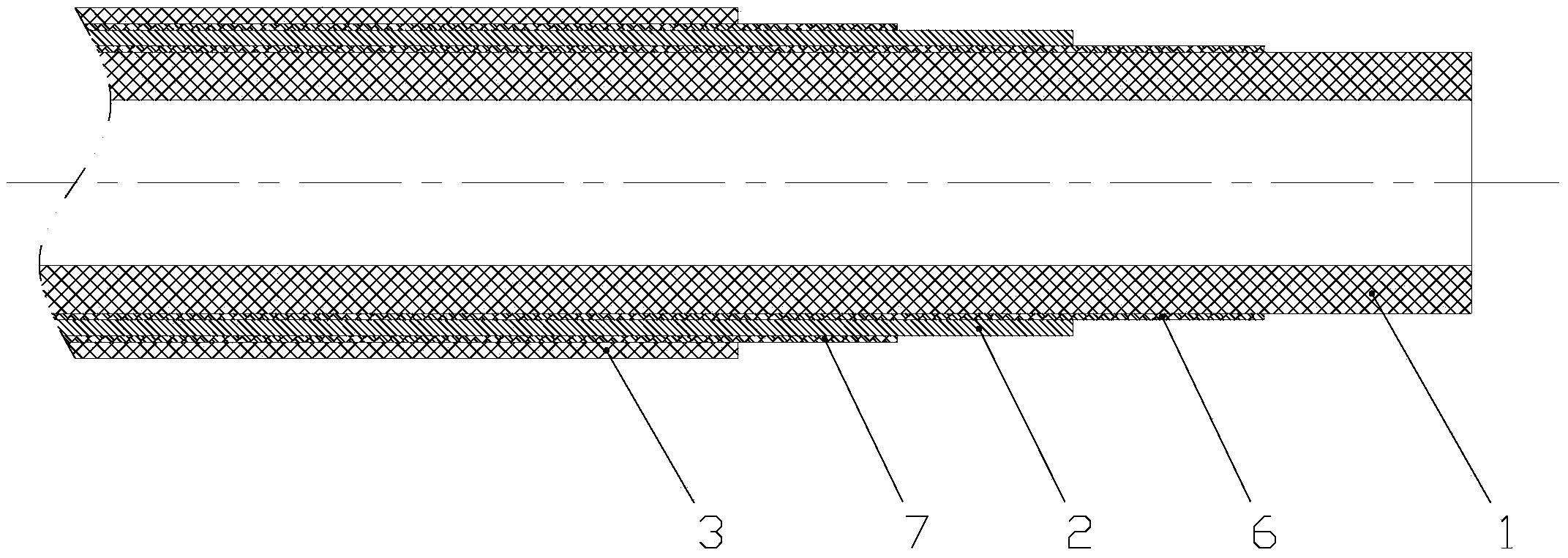

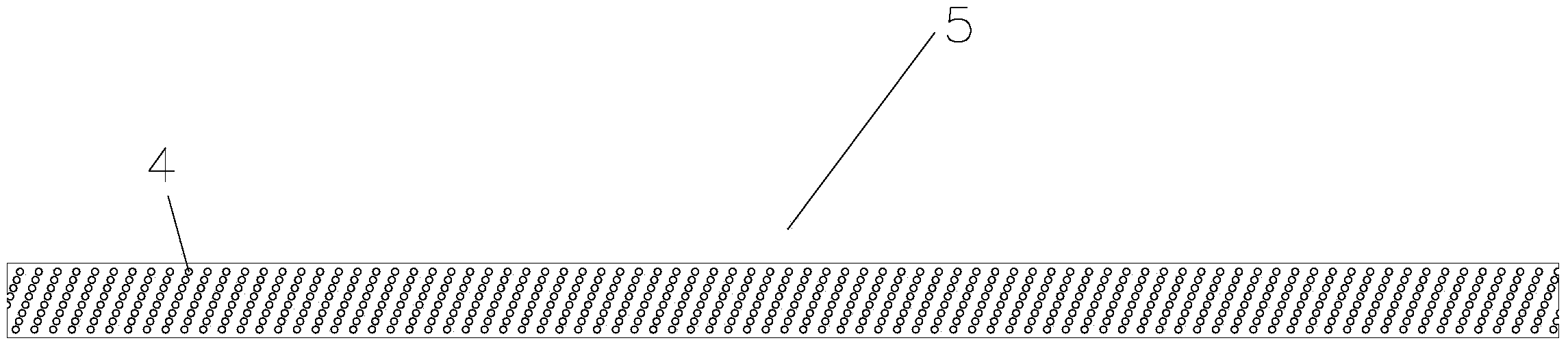

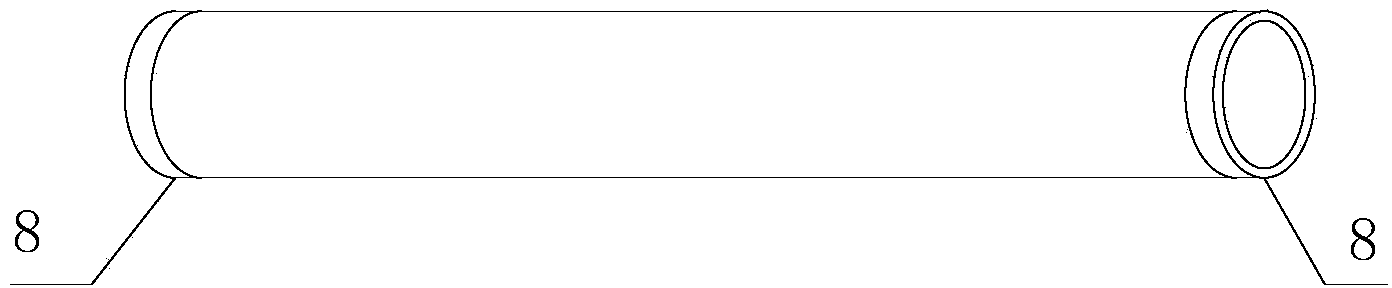

Composite pipe formed by winding plastic with netty steel belt and production method thereof

InactiveCN104165250AExcellent mechanicsExcellent chemical propertiesRigid pipesPolymer adhesiveButt welding

The invention relates to a composite pipe formed by winding plastic with a netty steel belt and a production method of the composite pipe. Two layers of HDPE solid-wall pipes and the netty steel belt are heated and combined stably through butt-welding and adhesive resin, and the two ends of the composite pipe are respectively provided with a plastic solid wall sealing ring through hot melting. The composite pipe has the advantages of being far superior to a steel mesh framework plastic composite pipe in physical and mechanical property and chemical property; the hydraulic pressure resistance of the composite pipe formed by winding the plastic with the netty steel belt is 2.0 Mpa-8.0 Mpa, rejects are easy to recycle, and production efficiency is high; due to the design of the sealing rings, the situation that netty steel belt sections of ports of the pipe meets with water and are corroded and rusted when the pipe is stored indoors and outdoors is prevented; the compatibility between the special polymer adhesive resin and HDPE resin is high, machining is easy, and compressive strength is high.

Owner:GOODY SCI & TECH CO LTD

Rolling production method for improving toughness of steel on line

ActiveCN113245365AReduce heating energy consumptionReduce manufacturing costWork heating devicesMetal rolling arrangementsTemperingContinuous rolling

The invention discloses a rolling production method for improving the toughness of steel on line. A continuous casting billet is taken as a raw material. The rolling production method sequentially comprises the following working procedures of billet heating, descaling, rough rolling, continuous rolling, through-water cooling, finish rolling through a bar reducing and sizing mill and cooling through a cooling bed, and finally a finished product bar is obtained; wherein a rolled material subjected to continuous rolling is subjected to through-water cooling to 650-850 DEG C, after through-water cooling, the rolled material is subjected to self-tempering to obtain the finish rolling temperature of the bar reducing and sizing mill, the finish rolling temperature is 500-700 DEG C, and the temperature of the bar on the cooling bed is 480-650 DEG C. According to the method, KOCKS rolling is adopted for finish rolling of the bar reducing and sizing mill, proeutectoid ferrite in a non-required form is eliminated by controlling the finish rolling temperature and the cooling temperature after rolling, the toughness of the steel is improved, and the grain size, hardness and mechanical performance of the non-quenched and tempered steel can be controlled by adopting the rapid cooling technology after rolling.

Owner:DAYE SPECIAL STEEL CO LTD

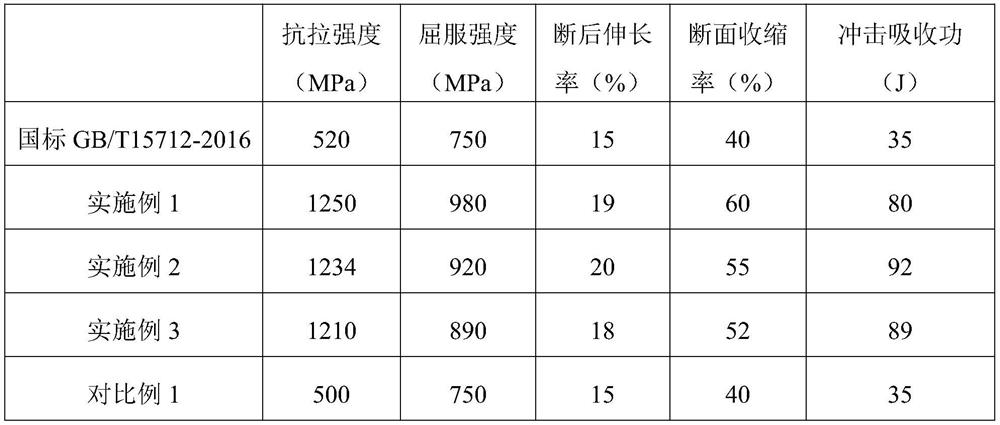

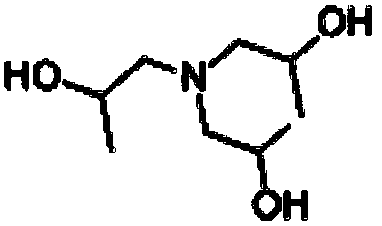

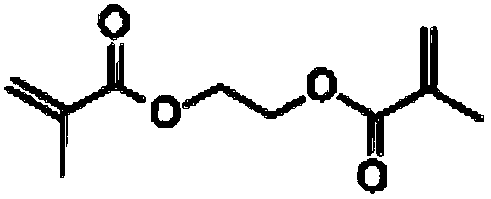

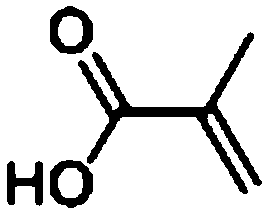

Preparation method of polymer foundation soil consolidation agent

ActiveCN109293293AImprove bearing capacityEnhanced compressive modulus of resilienceSlagWater reducer

The invention discloses a preparation method of a polymer foundation soil consolidation agent. The preparation method comprises following steps: a modified triisopropanolamine solution is prepared; methacrylic acid and N-isopropyl acrylamide are mixed at room temperature at a ratio of 1:2-3; cement, steel slag, a water reducer, and an anti-foaming agent are introduced into a homogenizer reaction vessel containing the modified triisopropanolamine solution in a manner that solid material first and liquid material second; the mixture of methacrylic acid and N-isopropyl acrylamide is added, and uniform stirring is carried out in the homogenizer reaction vessel so as to obtain the polymer foundation soil consolidation agent. The polymer foundation soil consolidation agent is capable of solidifying mud, mud powder soli, soft soil, muck, and the like with a water content ranging from 10 to 70%, and especially can be used for solidifying soil with an organic matter content lower than 30%, so that coagulable solid application range is widened, consolidated product compressive modulus of resilience and unconfined compressive strength are increased obviously, and it is ensured that without adding of broken stone, the consolidated is capable of providing higher foundation carrying capacity for upper engineering construction.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

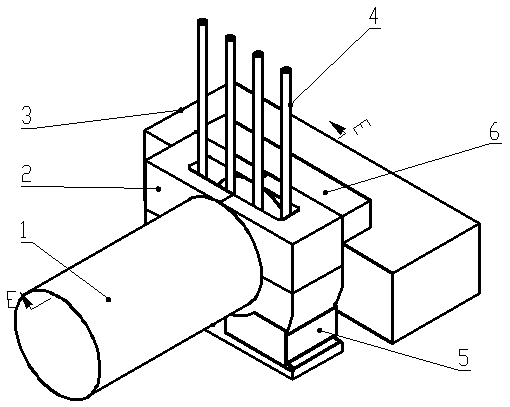

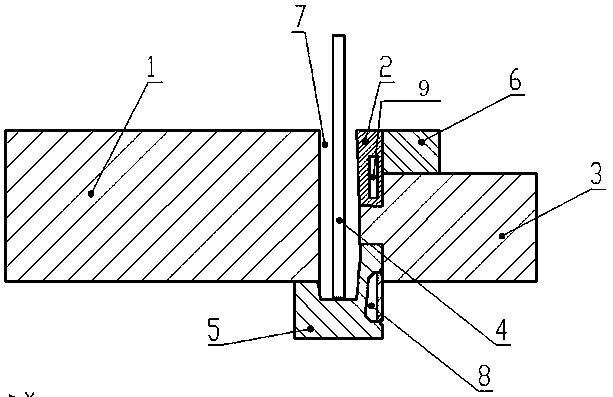

Anode steel claw welding tool and method

PendingCN109249126AAvoid high temperature oxidationHigh real-time monitoringShielded metal arc weldingElectroslag welding

The invention discloses an anode steel claw welding tool and method and aims to solve the technical problem that weld joint strength and conductivity are low in the prior art. The anode steel claw welding tool comprises a die formed by at least two combination modules and is characterized in that the die fixes a steel claw head welding end, is abutted against a to-be-welded crossbeam and allows asteel claw head to align with the rear of the crossbeam to form a weld joint weld pool with a top or lateral upper opening at a to-be-welded junction part; during welding, the steel claw head is placed in the combination modules of the welding die, the combination modules are combined to allow the crossbeam to align with the steel claw head welding end and be coordinated with the die to form a weld joint weld pool with a top or lateral upper opening at a to-be-welded junction part; a welding gun is used to perform electroslag welding through the opening of the weld joint weld pool until base metal on two sides is completely integrally fused. By the anode steel claw welding tool, anode steel claw welding cost can be lowered, service life can be prolonged, power consumption can be lowered, and the mechanical performance and conductivity of a steel claw welded by the tool are better than those of a steel claw welded by manual arc welding.

Owner:ZHENGZHOU JINGWEI TECH & IND

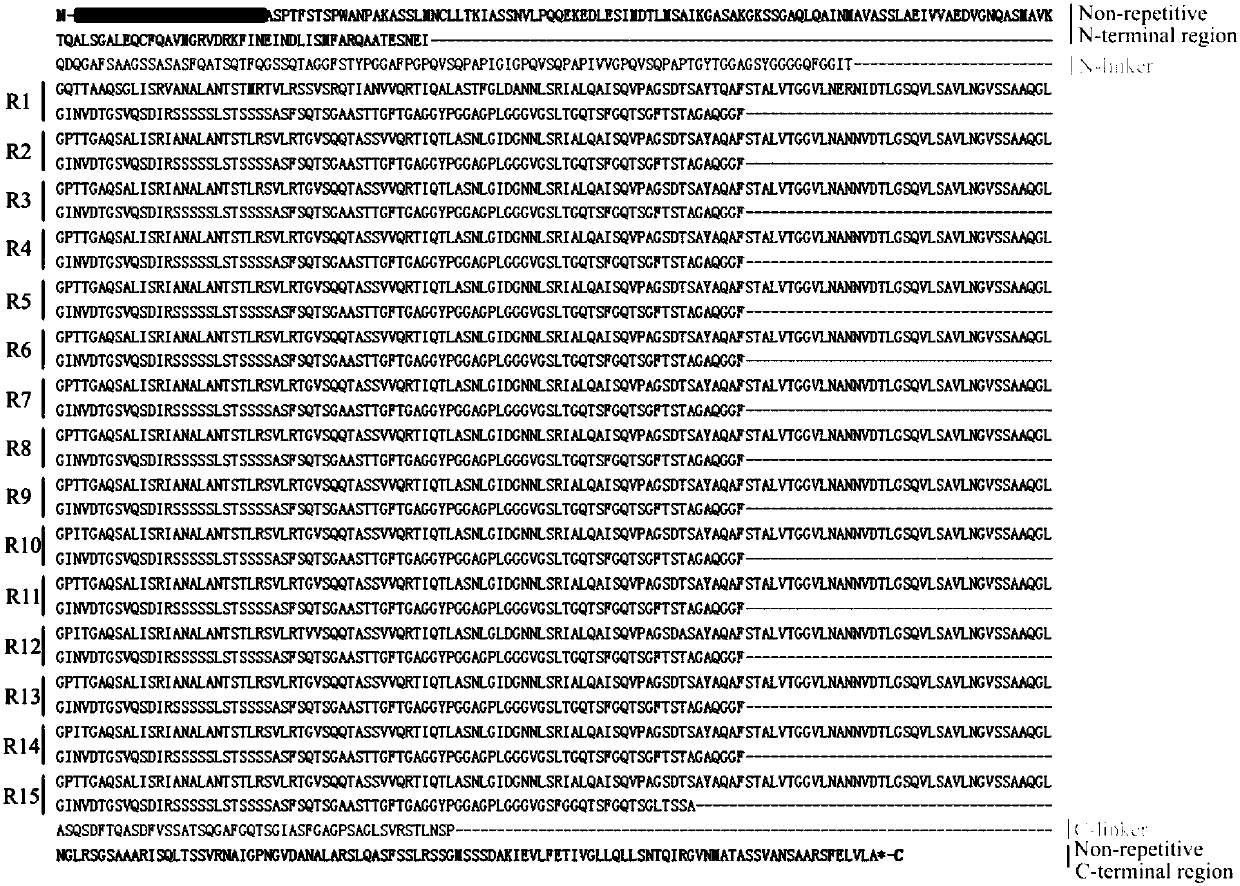

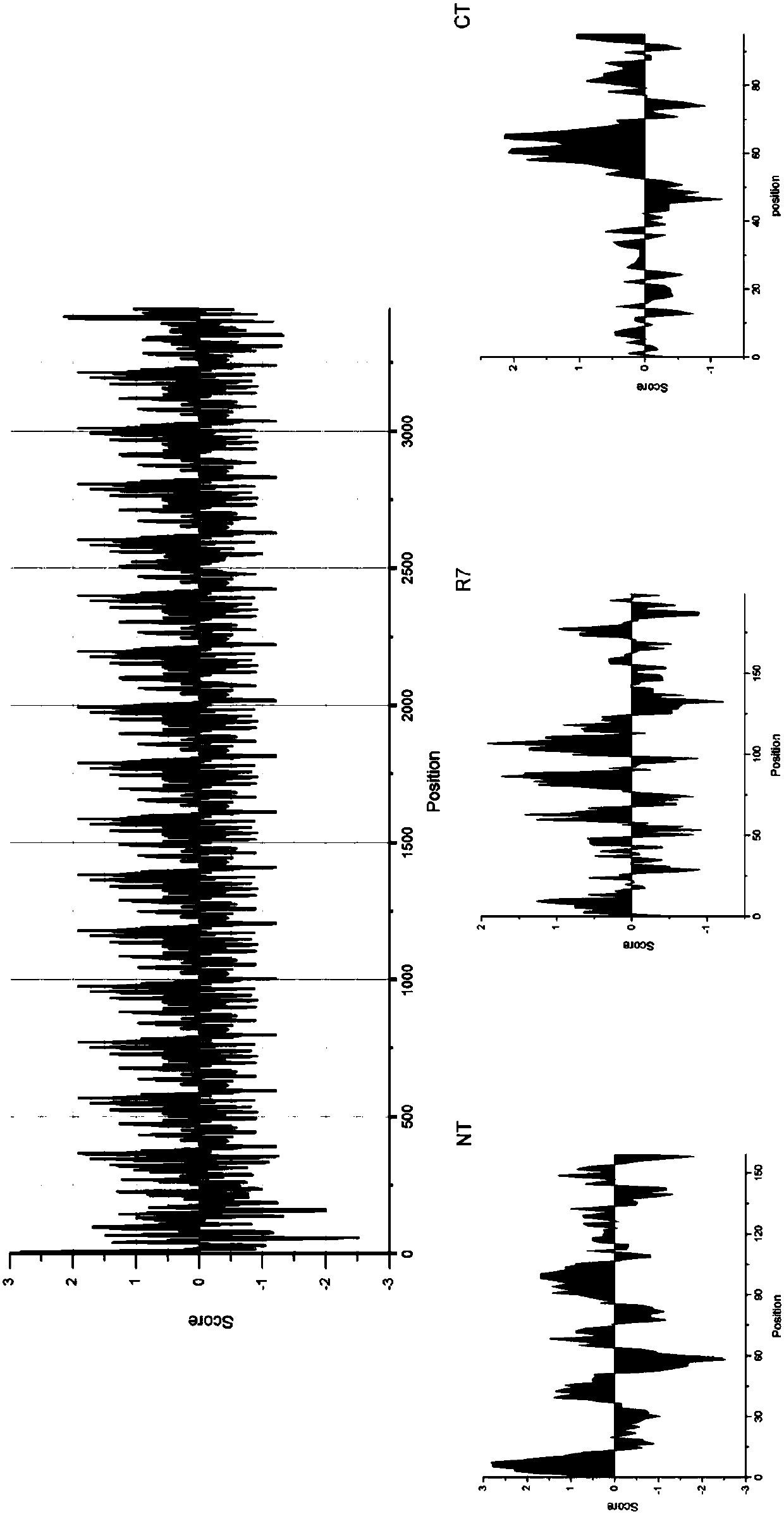

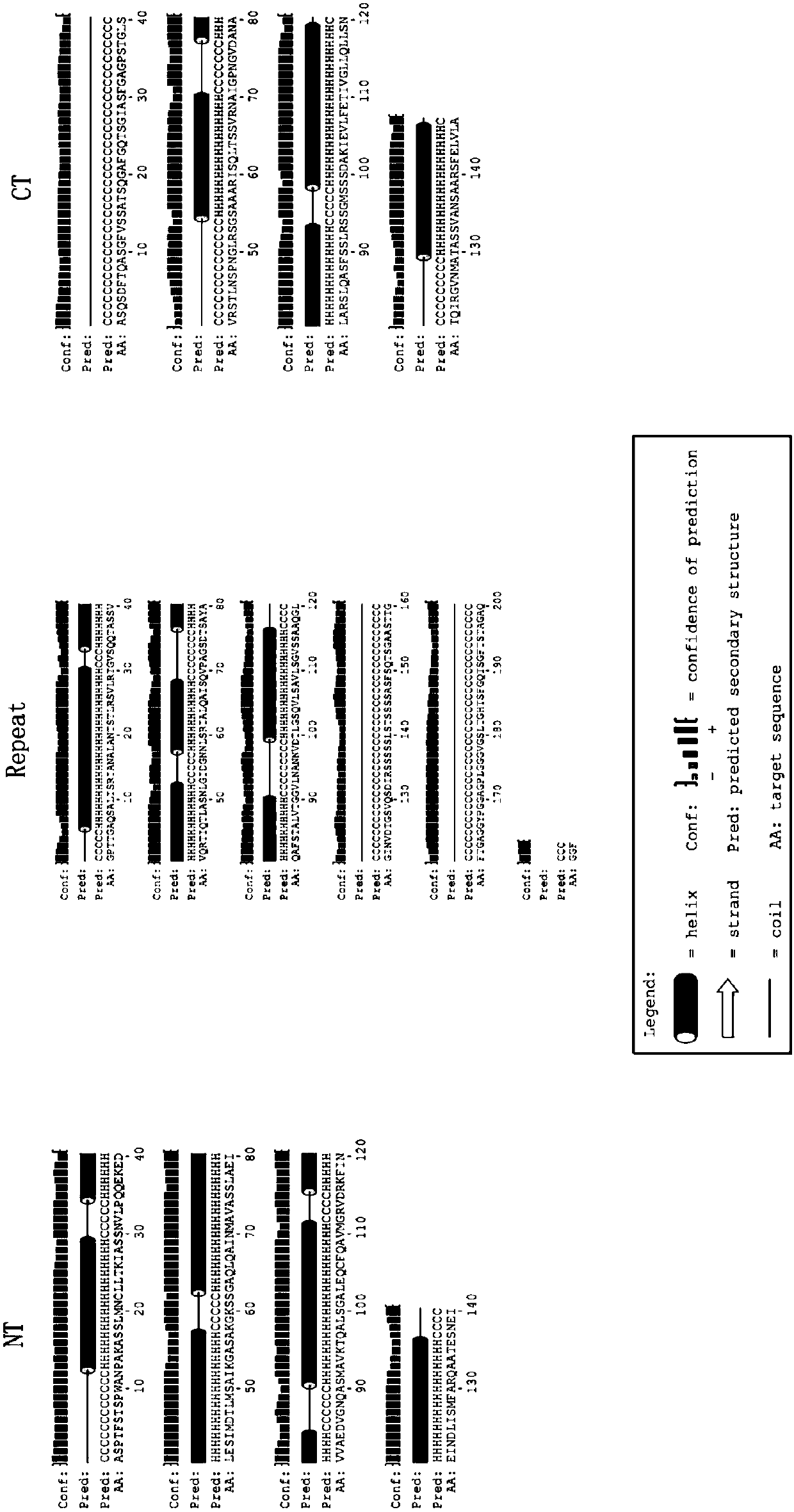

Araneus ventricosus wrapped fibroin full-length gene and preparation method thereof

InactiveCN107699567AStrong toughnessExcellent mechanicsFermentationAnimals/human peptidesFiberPlasmid

The invention relates to an araneus ventricosus wrapped fibroin full-length gene and a preparation method thereof. The sequence of the gene is as shown in SEQ ID NO.1. The preparation method comprisesthe following steps: amplifying an NT sequence partially wrapping a fibroin protin by using a degenerate PCR (Polymerase Chain Reaction) method, complementing the NT sequence through anchoring PCR, designing a pair of primers according to the NT sequence obtained through sequencing and a CT sequence obtained from the NCBI (National Center of Biotechnology Information), performing PCR amplification on a full-length AcSp gene, performing blunt end cloning on a segment obtained through amplification, extracting plasmid of a positive cloning bacterium with the full-length AcSp gene, and performing full-length sequencing, so as to obtain the gene. The gene is an araneus ventricosus wrapped fibroin full-length gene with a complete NT end, a repeating area and a complete CT end, and has potential application values in the field of artificial spider thread fiber preparation.

Owner:DONGHUA UNIV

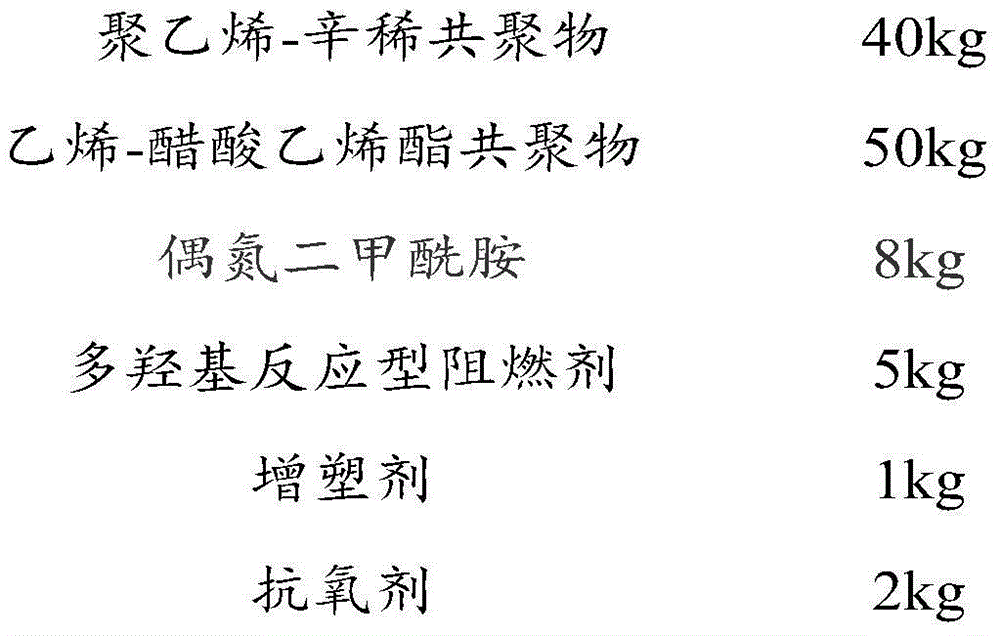

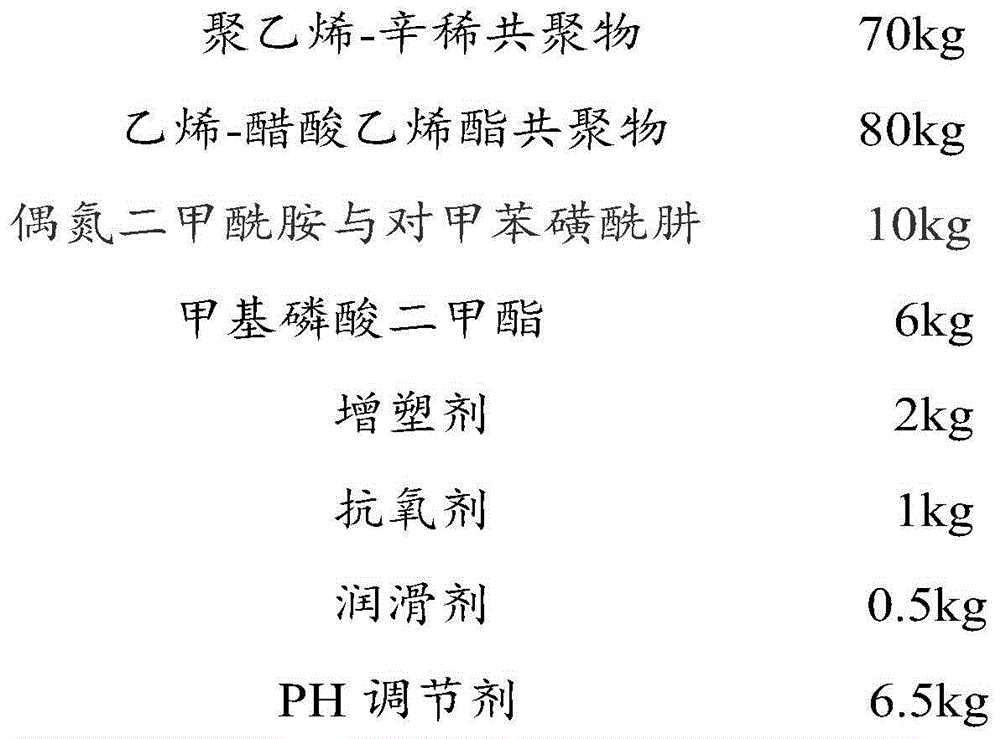

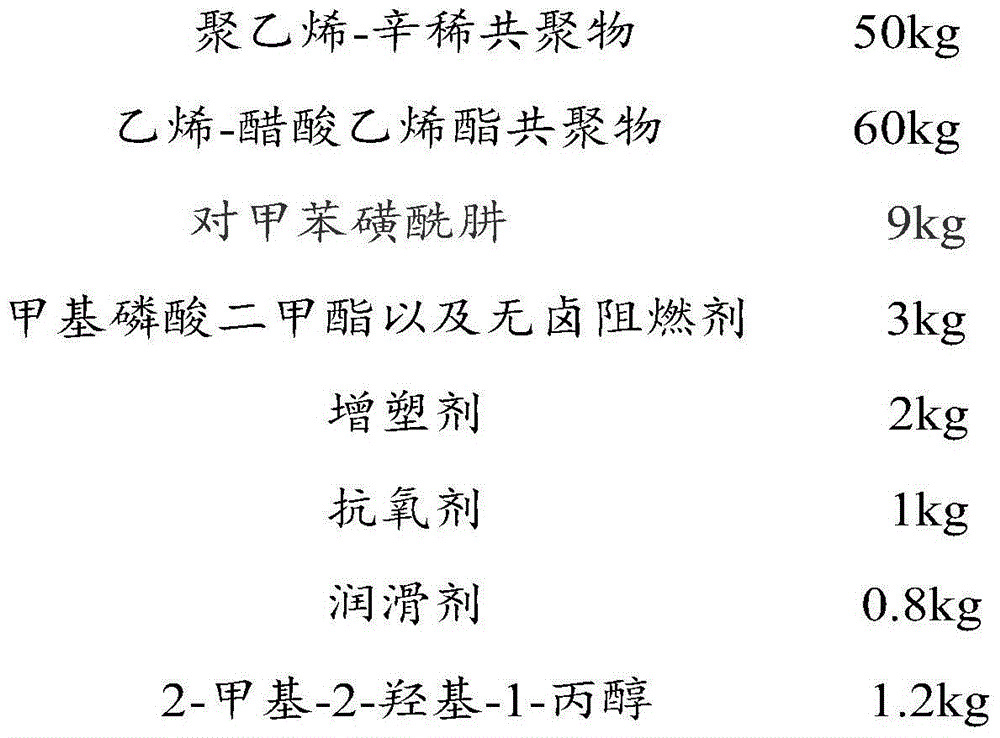

Composite filling material, preparing method thereof and application thereof

The invention provides a composite filling material, a preparing method thereof and an application thereof. The composite filling material mainly comprises, by mass, 40 parts to 70 parts of polyethylene-octylene copolymers, 50 parts to 80 parts of ethylene-vinyl acetate copolymers, 8 parts to 10 parts of foaming agents, 2 parts to 6 parts of fire retardants and 3 parts to 10 parts of processing agents. The preparing method includes the steps that A, the polyethylene-octylene copolymers, the ethylene-vinyl acetate copolymers and the foaming agents are evenly mixed and stirred and extruded through an extruder; B, in the extruding process, the fire retardants and the processing agents are added, then the mixture is extruded into a mold for vacuum shaping, and finally cooling is carried out to obtain the product. The composite filling material serves as fillers in a cushion, a mattress and a pillow to be applied. The composite filling material has the advantages that aging is not prone to occurrence, the air retaining performance is good, the affinity and the soft performance are good, and deformation is not prone to occurrence after long time use.

Owner:费珏璐

High-performance aramid fiber insulating film and preparation method thereof

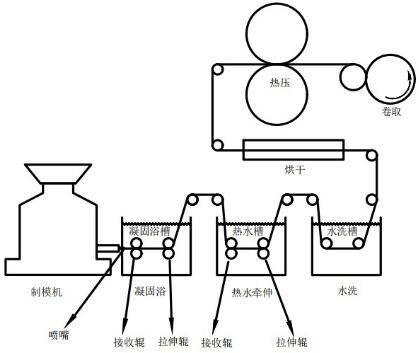

The invention provides a preparation method of a high-performance aramid fiber insulating film, and belongs to the technical field of electrical insulating film materials. The preparation method comprises the following steps of (1) at a low temperature of-10 to-20 DEG C and under the protection of inert gas, dissolving a cosolvent, aromatic diamine and aromatic dicarbonyl chloride in an amide polar solvent in sequence for stirring and mixing reaction to obtain an aramid fiber resin solution; (2) neutralizing hydrogen chloride in the aramid fiber resin solution obtained in the (1) by using a neutralizing agent to obtain an aramid fiber film-forming stock solution; (3) performing high-temperature vacuum defoaming and filtering on the film-forming stock solution obtained in the (2), spraying the film-forming stock solution into a coagulating bath mixed solvent through a nozzle of a film making machine to form a film, and then performing hot water drafting, water washing, drying, hot press molding, cooling and rolling to obtain the aramid fiber insulating film. The aramid fiber film is compact in structure and excellent in thickness uniformity, and has better mechanical properties and electrical insulation properties.

Owner:ZHUZHOU TIMES FIBER PIONEER MATERIAL TECH CO LTD

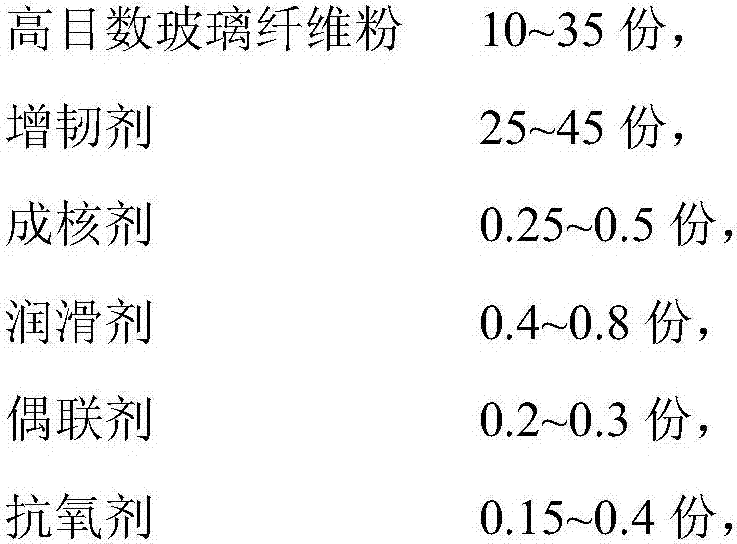

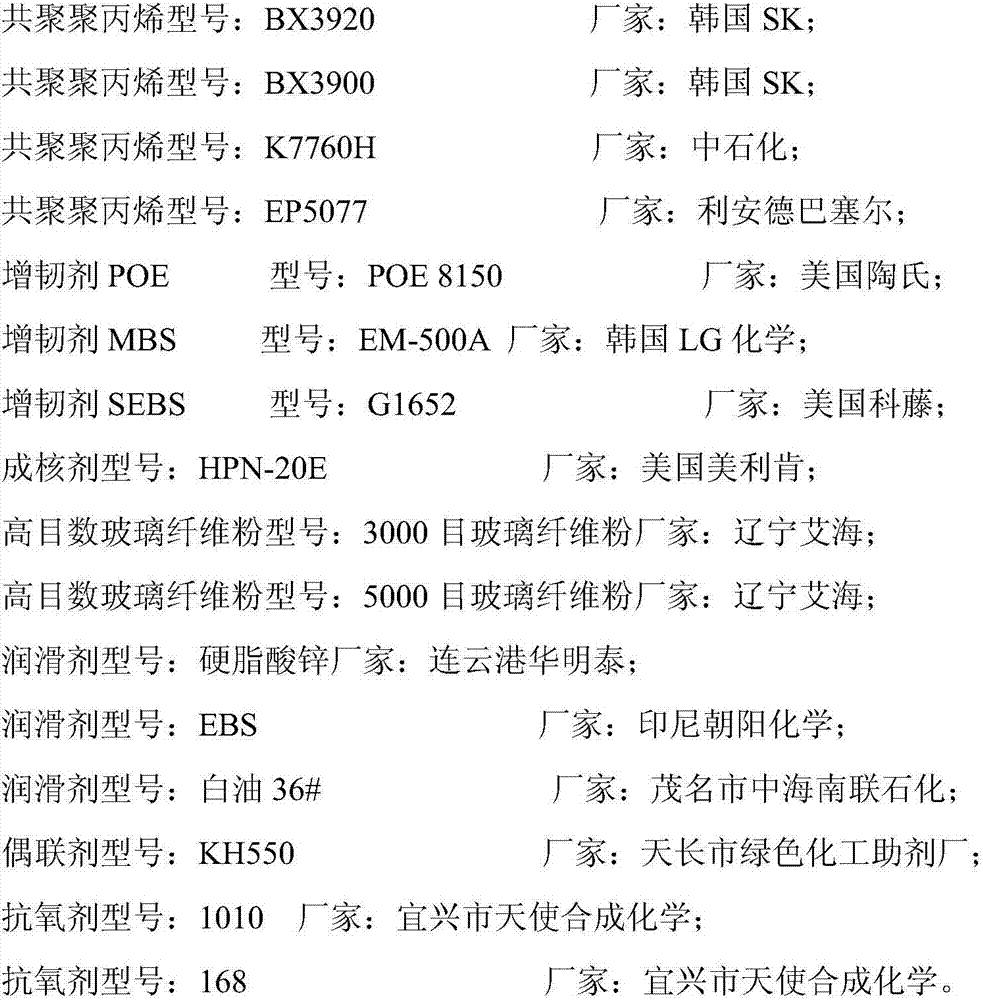

Special low post-shrinkage polypropylene composite material for vehicle bumpers, and preparation method thereof

The invention provides a special low post-shrinkage polypropylene composite material for vehicle bumpers, wherein 100 parts of polypropylene, 15-30 parts of polycarbonate, 15-45 parts of wollastonite, 10-35 parts of high mesh glass fiber powder, 25-45 parts of a toughening agent, 0.25-0.5 part of a nucleating agent, 0.4-0.8 part of a lubricant, 0.2-0.3 part of a coupling agent and 0.15-0.4 part of an antioxidant are subjected to by step by step mixing and extrusion granulation to prepare the special low post-shrinkage polypropylene composite material, and the particle size of the high mesh glass fiber powder is 3000-5000 mesh. According to the present invention, the special low post-shrinkage polypropylene composite material has advantages of low shrinkage, strong mechanical property, good dimensional stability 24-48 h after injection molding and low post-shrinkage after spray coating, and can be used as vehicle bumpers and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Novel Ni-Mn-Ga resin based composite material, and preparation method thereof

The invention provides a novel Ni-Mn-Ga resin based composite material and a preparation method of the Ni-Mn-Ga resin based composite material. The composite material is prepared by the following design scheme and process: firstly, preparing Ni-Mn-Ga powder particle as functive, stirring E51 epoxy resin matrix with a curing agent in order to mix uniformly, adding Ni-Mn-Ga powder particle, stirring completely, arranging a beaker in an ultrasonic cleaning machine during the whole process, in order to disperse particles and remove bubbles; slowly and evenly pouring turbid liquid in a mold, standing under normal temperature, curing the turbid liquid, and finally obtaining a composite material test piece, wherein the curing agent used in the epoxy resin is tetraethylenepentamine. The novel particle composite material provided by the invention has excellent mechanical property and damping performance.

Owner:BEIHANG UNIV

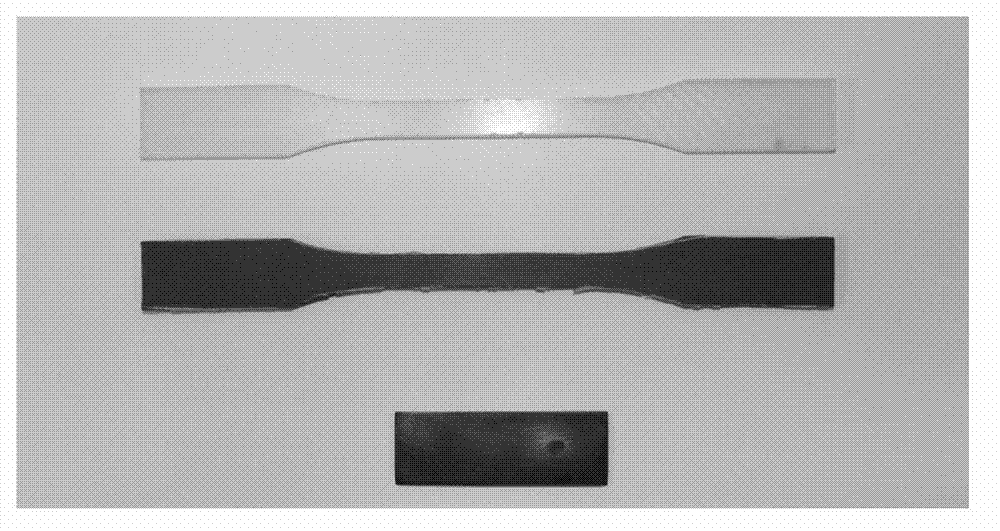

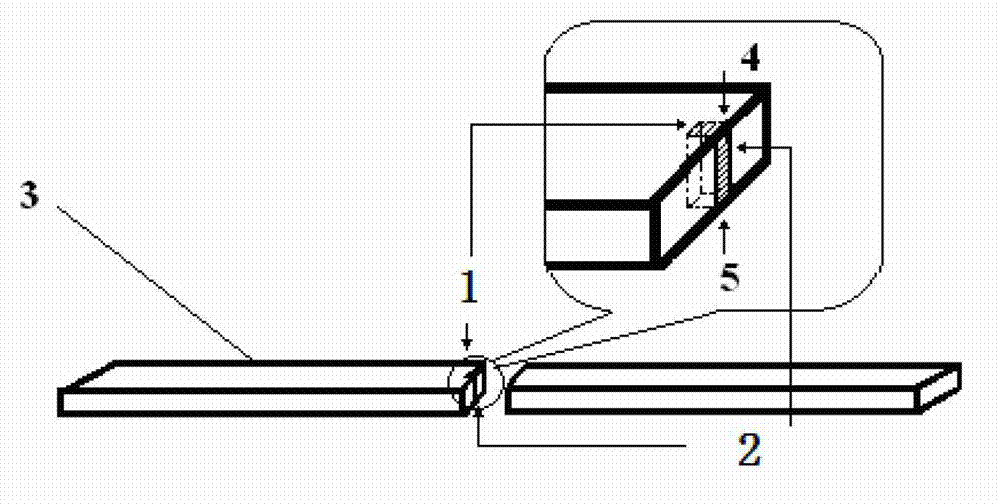

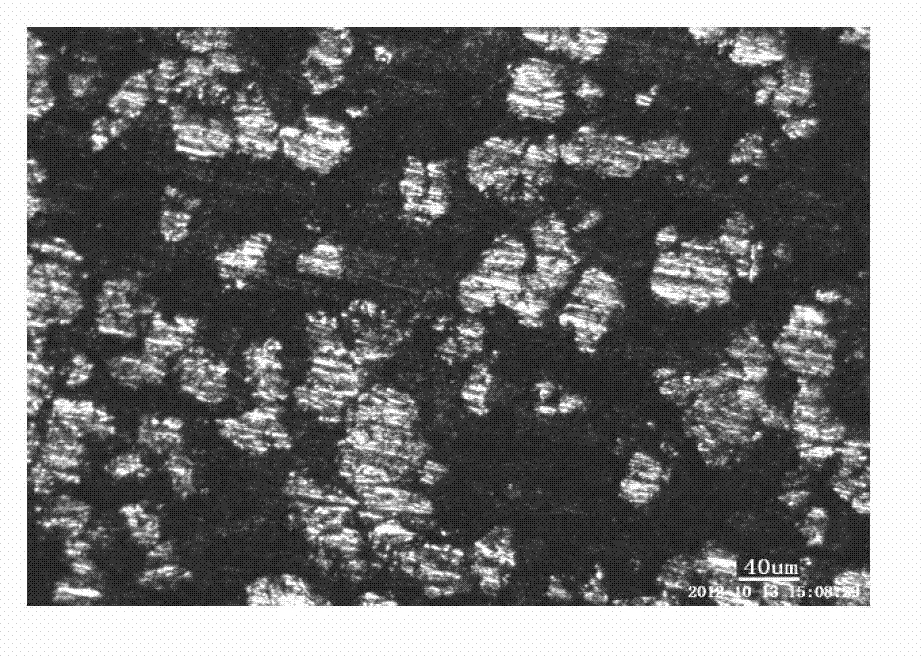

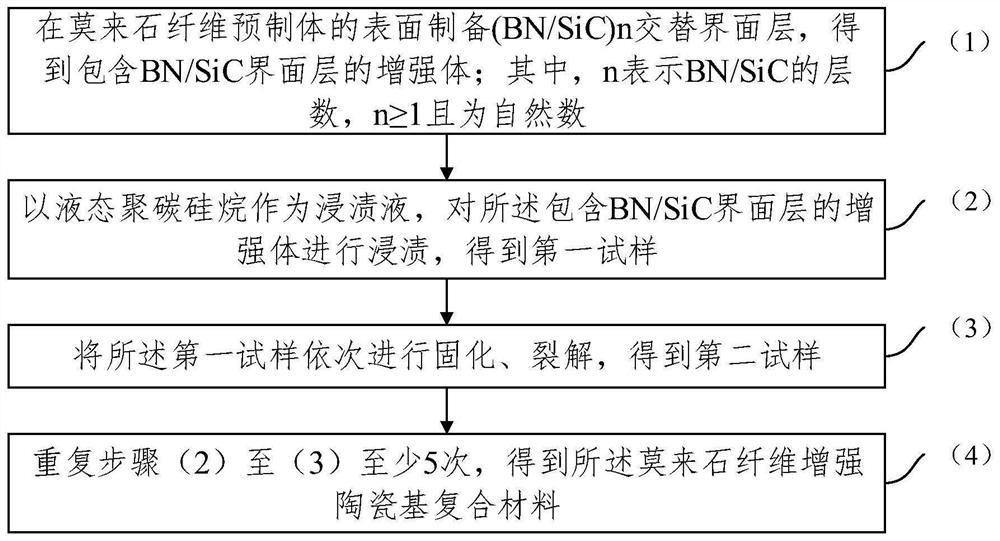

Mullite fiber reinforced ceramic matrix composite material and preparation method thereof

The invention particularly relates to a mullite fiber reinforced ceramic matrix composite material and a preparation method thereof. The method comprises the following steps: 1) preparing a (BN / SiC)n alternating interface layer on the surface of mullite fibers to obtain a reinforcement body containing the BN / SiC interface layer, wherein n represents the number of layers of BN / SiC, and n is greater than or equal to 1 and is a natural number; (2) dipping the reinforcement body containing the BN / SiC interface layer by using liquid-state polycarbosilane as a dipping solution to obtain a first sample; (3) curing and cracking the first sample in sequence to obtain a second sample; and (4) repeating the steps (2) to (3) at least five times to obtain the mullite fiber reinforced ceramic matrix composite material. The mullite fiber reinforced ceramic-based composite material prepared by the preparation method disclosed by the invention has excellent oxidation resistance.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com