Composite material based on modified hollow glass microspheres and preparation method thereof

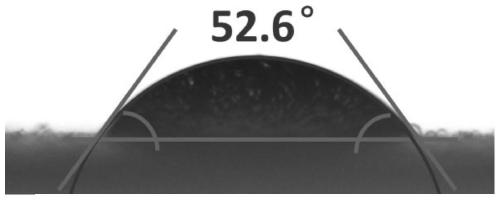

A technology of glass microspheres and composite materials, applied in the field of composite materials, can solve the problems of instant property weakening, weak interface state, and accelerated property evolution decay of composite materials, so as to improve structure and instant properties, improve poor wettability, and enhance stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

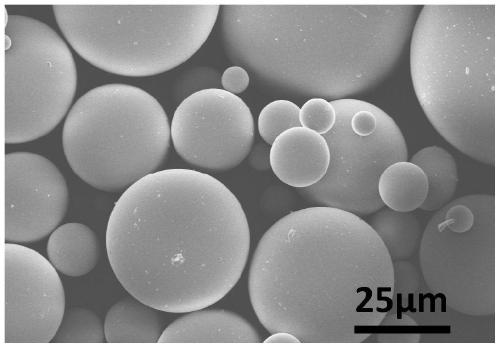

[0055] This example is to prepare a composite material by using hollow glass microspheres after high temperature treatment. Select self-made hollow glass microspheres (T38, that is, the density is 0.38g / cm 3 ) (the reference application number of self-made hollow glass microspheres in this embodiment is 201210056295.5, and the title of invention is "a hollow glass microsphere soft chemical preparation method and the prepared hollow glass microspheres and its application"), and its particle size is 20- 80 μm, the acid selected in the acidification treatment is 1mol / L hydrochloric acid, and the resin matrix selected is E51 epoxy resin.

[0056] The steps of the method for improving the mechanical strength of hollow glass microspheres in the present embodiment are as follows:

[0057] First, carry out hollow glass microsphere flotation: put hollow glass microspheres and ethanol or water at a volume ratio of 1:1 to stand and layer, then take the upper floating material, filter, d...

Embodiment 2

[0070] In this example, a composite material is prepared by using hollow glass microspheres treated with a coupling agent. Select self-made hollow glass microspheres (T30, that is, the density is 0.30g / cm 3 ) (the reference application number of self-made hollow glass microspheres in this embodiment is 201210056295.5, and the title of invention is "a hollow glass microsphere soft chemical preparation method and the prepared hollow glass microspheres and its application"), and its particle size is 20- 80 μm, the acid used in the acidification treatment is 0.1mol / L sulfuric acid, the selected coupling agent is KH560, and the selected resin matrix is polyurethane.

[0071] The steps of hollow microsphere surface treatment in the present embodiment are as follows:

[0072] First, carry out hollow glass microsphere flotation: put hollow glass microspheres and ethanol or water at a volume ratio of 1:1 to stand and layer, then take the upper floating material, filter, dry and set ...

Embodiment 3-13

[0076] Embodiment 3-13, concrete implementation steps are carried out by embodiment 1 and embodiment 2, and the density of concrete difference condition and the composite material that obtains is as shown in table 1:

[0077] Table 1

[0078]

[0079]

[0080] Explanation: In the above table 1, the type of hollow glass microspheres in the column ① are self-made microspheres (refer to our previous patent preparation: a soft chemical preparation method of hollow glass microspheres and the prepared hollow glass microspheres and their applications (201210056295.5 )); ② is the product of Zhongke Yali Technology Co., Ltd.; ③ is the product of Zhongke Huaxing New Material Co., Ltd.; ④ is the product of 3M Company in the United States;

[0081] Table 2

[0082]

[0083]

[0084] Table 2 is the performance of the composite material obtained in each embodiment. The uniaxial compressive strength is tested with reference to the national standard: test methods for the perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com