Mullite fiber reinforced ceramic matrix composite material and preparation method thereof

A technology of mullite fiber and composite materials, which is applied in the field of mullite fiber reinforced ceramic matrix composite materials and its preparation, can solve the problems of composite material performance degradation, easy oxidation, etc., to improve bonding strength, relieve thermal stress, excellent The effect of antioxidant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

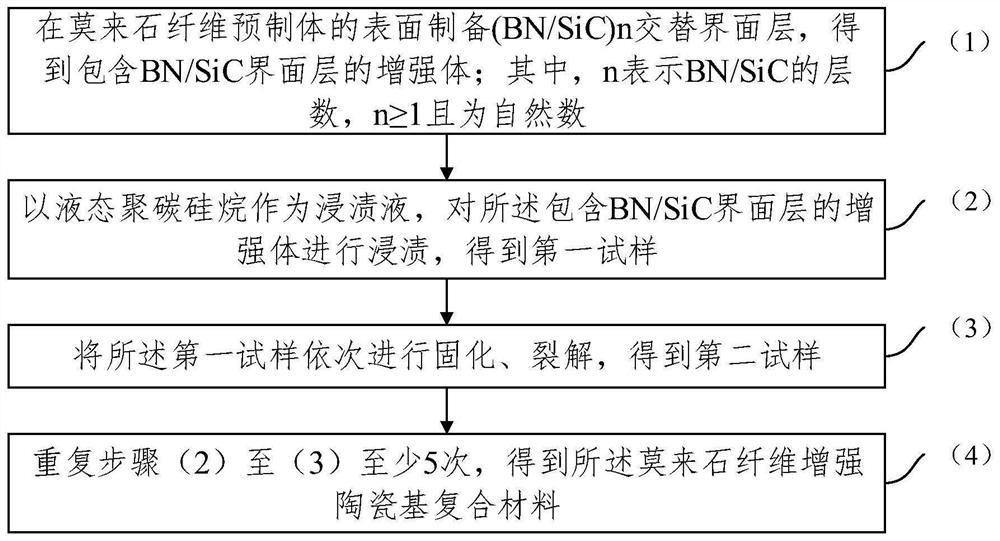

[0034] like figure 1 As shown, the present invention provides a kind of preparation method of mullite fiber reinforced ceramic matrix composite material, and this preparation method comprises the steps:

[0035] (1) Preparation on the surface of mullite fiber preform (BN / SiC) n Alternate interface layers to obtain reinforcements containing BN / SiC interface layers; where n represents the number of BN / SiC layers, n≥1 and is a natural number;

[0036] (2) using liquid polycarbosilane as an impregnating liquid, impregnating the reinforcing body comprising the BN / SiC interface layer to obtain a first sample;

[0037] (3) sequentially curing and cracking the first sample to obtain a second sample;

[0038] (4) Repeat steps (2) to (3) at least 5 times to obtain the mullite fiber reinforced ceramic matrix composite material.

[0039] It should be noted that n is 1, 2, 3, 4 or 5, etc., and n is specifically limited according to the actual requirements of the mullite fiber reinforced...

Embodiment 1

[0068] (1) Prepared by chemical vapor deposition method on the surface of mullite fiber preform (sewn preform, fiber volume fraction is 35%) (BN / SiC) 3 Alternating interfacial layers, resulting in reinforcements containing BN / SiC interfacial layers:

[0069] (1.1) The mullite fiber preform is placed in the first atmosphere (the molar ratio of boron trichloride and ammonia is 1:2) including boron trichloride, ammonia, hydrogen and nitrogen, and heated at 700°C , 6kPa under the condition of depositing 20h, obtain the third sample of surface deposition one deck BN layer (the thickness of monolayer BN layer is 200nm);

[0070] (1.2) Place the third sample in a second atmosphere including trichloromethylsilane, argon and hydrogen (the molar ratio of trichloromethylsilane and hydrogen is 1:2), and Under conditions, deposit 30h, obtain the 4th sample of surface depositing a layer of SiC layer (the thickness of single-layer SiC layer is 400nm);

[0071] (1.3) Repeat steps (1.1) to (...

Embodiment 2

[0076] Embodiment 2 is basically the same as Embodiment 1, except that the number of repetitions in step (4) is 8 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com