Modified graphene rubber and preparation method thereof

A graphene and modified technology, applied in the rubber field, can solve the problems of low friction resistance, short service life, poor tensile strength, etc., and achieve the effects of improving corrosion resistance, reducing Akron wear and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

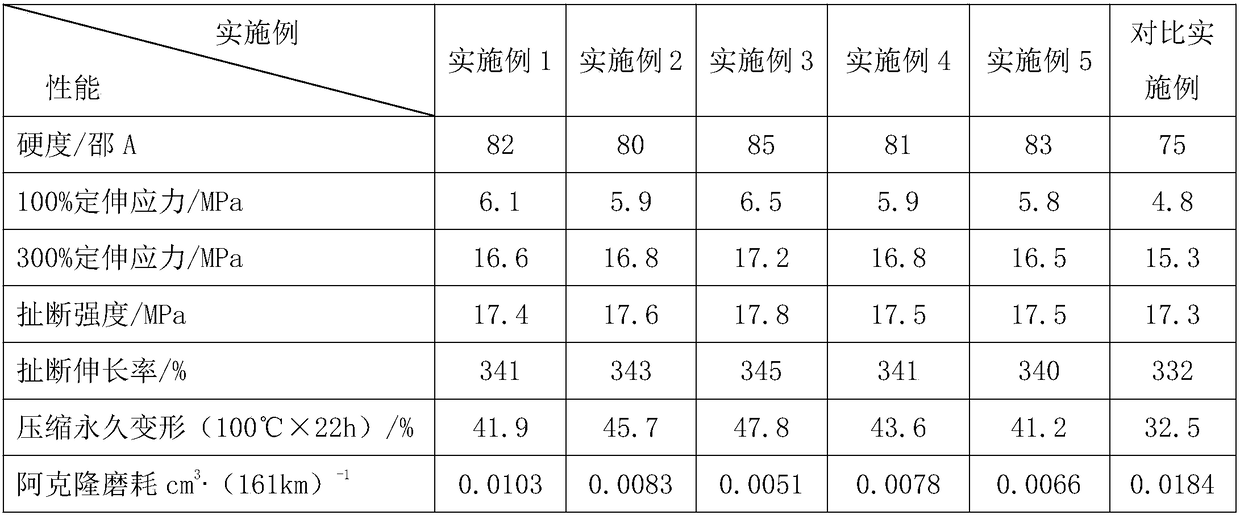

Examples

Embodiment 1

[0024] The modified graphene rubber proposed by the present invention comprises the following raw materials in parts by weight: 20 parts of butadiene rubber, 20 parts of natural rubber, 10 parts of modified graphene, 10 parts of solvent-free epoxy resin, and 5 parts of silane coupling agent , 1 part of nano-alumina, 1 part of nano-silica, 5 parts of sepiolite fiber, 3 parts of decabromodiphenylethane, 1 part of accelerator, and 0.5 part of tackifier; the accelerator is dithioaminomethyl Salt, the tackifier is a tackifying resin.

[0025] The preparation method step of described modified graphene is as follows:

[0026] S1: Preparation of graphene oxide suspension: mix and stir 15 parts by weight of graphite powder, 5 parts by weight of sodium nitrate and 70 parts by weight of concentrated sulfuric acid and add 15 parts by weight of potassium permanganate and high manganese while stirring The addition time of potassium acid potassium is controlled at 60s, and the temperature i...

Embodiment 2

[0033] The modified graphene rubber proposed by the present invention comprises the following raw materials in parts by weight: 40 parts of butadiene rubber, 40 parts of natural rubber, 20 parts of modified graphene, 15 parts of solvent-free polyurethane resin, 10 parts of silane coupling agent, 5 parts of nano-alumina, 5 parts of nano-silica, 15 parts of sepiolite fiber, 7 parts of decabromodiphenylethane, 3 parts of accelerator, and 1.5 parts of tackifier; the accelerator is tetramethyl autumn disulfide Lamb, the tackifier is a tackifying resin.

[0034] The preparation method step of described modified graphene is as follows:

[0035]S1: Preparation of graphene oxide suspension: mix and stir 15 parts by weight of graphite powder, 5 parts by weight of sodium nitrate and 70 parts by weight of concentrated sulfuric acid and add 15 parts by weight of potassium permanganate and high manganese while stirring The addition time of potassium acid potassium is controlled at 60s, and...

Embodiment 3

[0042] The modified graphene rubber proposed by the present invention comprises the following raw materials in parts by weight: 20-40 parts of butadiene rubber, 30 parts of natural rubber, 15 parts of modified graphene, 12 parts of solvent-free polyurea resin, silane coupling 8 parts of agent, 3 parts of nano-alumina, 3 parts of nano-silica, 10 parts of sepiolite fiber, 5 parts of decabromodiphenylethane, 2 parts of accelerator, and 1 part of tackifier; wherein the accelerator is 4, 4'-dimorpholine disulfide, the tackifier is a tackifying resin.

[0043] The preparation method step of described modified graphene is as follows:

[0044] S1: Preparation of graphene oxide suspension: mix and stir 15 parts by weight of graphite powder, 5 parts by weight of sodium nitrate and 70 parts by weight of concentrated sulfuric acid and add 15 parts by weight of potassium permanganate and high manganese while stirring The addition time of potassium acid potassium is controlled at 60s, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com