Rolling production method for improving toughness of steel on line

A production method and toughness technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of undiscovered, undiscovered toughness, and improve the toughness of steel, so as to reduce heating energy consumption, protect the environment, and save production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

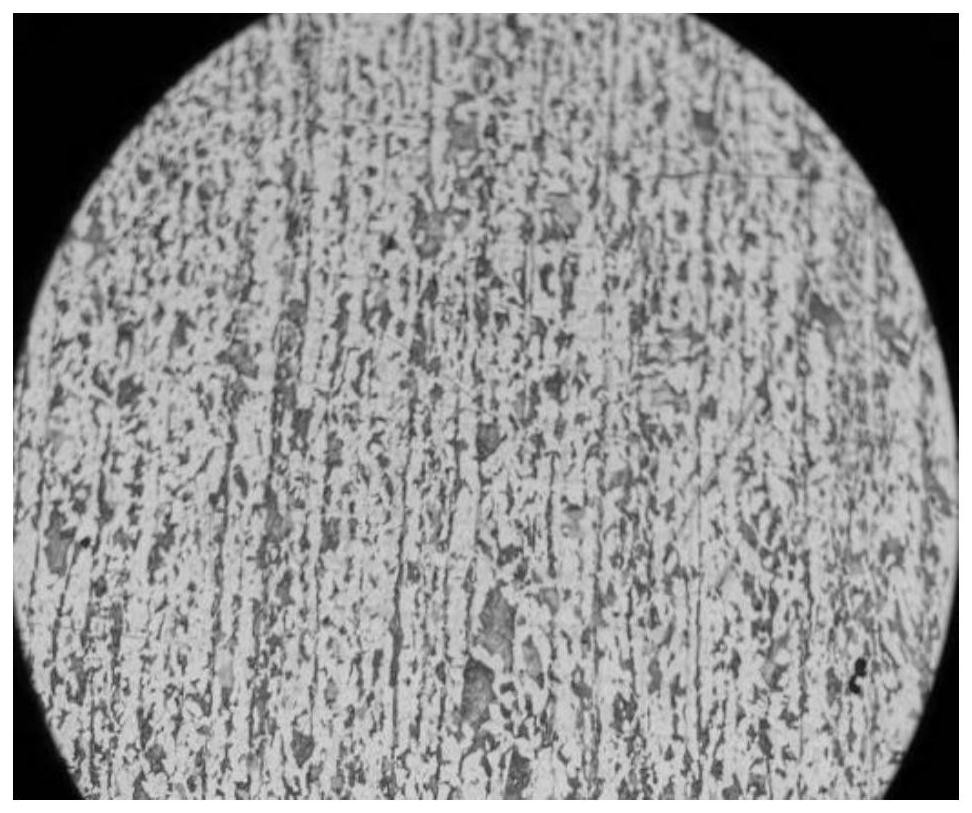

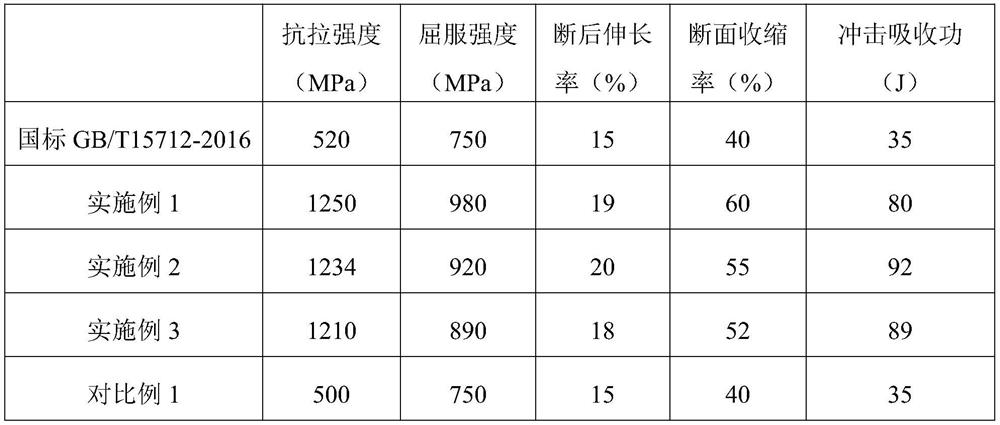

[0052] The rolling production method for improving the toughness of steel products on-line provided in this embodiment uses 40MnV non-adjusted steel continuous casting slab as raw material, and rolling production obtains a finished product 40MnV steel with a specification of 50mm. The rolling production method includes the following steps:

[0053] Step 1: Cut the 300×400×9000mm continuous casting slab and put it into the heating furnace by cold delivery or red delivery for reheating.

[0054] Step 2: Steel billet heating: adopt four-stage heating method to heat the steel billet, wherein the temperature of the second stage of heating meets the process requirements (ie 1100-1150°C); the temperature of the soaking section is 1160°C; the total heating in the heating process The time is 5h, and the soaking time in the soaking section is 70min.

[0055] Step 3: billet descaling: the heated billet is descaled with high-pressure water to remove scale; the pressure of the high-pressur...

Embodiment 2

[0065] The rolling production method for on-line improvement of steel toughness provided by this embodiment uses 40MnV non-adjusted steel continuous casting slab as raw material, and rolling production obtains a finished 40MnV steel bar with a specification of 85mm, including the following steps:

[0066] Step 1: Cut the 300×400×9000mm continuous casting slab and put it into the heating furnace by cold delivery or red delivery for reheating.

[0067] Step 2: Steel billet heating: adopt four-stage heating method to heat the steel billet, among which, the temperature of the preheating section is 590°C; the temperature of the heating stage is 1020°C; The temperature is 1150°C, which meets the process requirements; the total heating time in the heating process is 4.0h, and the soaking time in the soaking section is 78min.

[0068] Step 3: billet descaling: the heated billet is descaled by high-pressure water to remove scale, and the pressure of the high-pressure water is 50 MPa. ...

Embodiment 3

[0076] This embodiment provides a rolling production method for improving steel toughness on-line. Using 40MnV non-adjusted steel continuous casting slab as raw material, rolling production obtains a finished 40MnV steel bar with a specification of 75mm, including the following steps:

[0077] Step 1: Cut the 300×400×9000mm continuous casting slab and put it into the heating furnace by cold delivery or red delivery for reheating.

[0078] Step 2: Steel billet heating: adopt four-stage heating method to heat the steel billet, among which, the temperature of the preheating section is 580°C; the temperature of the heating section is 1020°C; The temperature is 1150°C, which meets the process requirements; the total heating time in the heating process is 5 hours, and the soaking time in the soaking section is 65 minutes.

[0079] Step 3: billet descaling: the heated billet is descaled by high-pressure water to remove scale, and the pressure of the high-pressure water is 50 MPa.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com