Geopolymer foam concrete and preparation method thereof

A foamed concrete and geopolymer technology, used in ceramic products, solid waste management, other household appliances, etc., can solve the problems of easy cracking, energy consumption, high thermal conductivity, low strength, etc., and achieve fast setting time, setting and hardening. , Good casting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

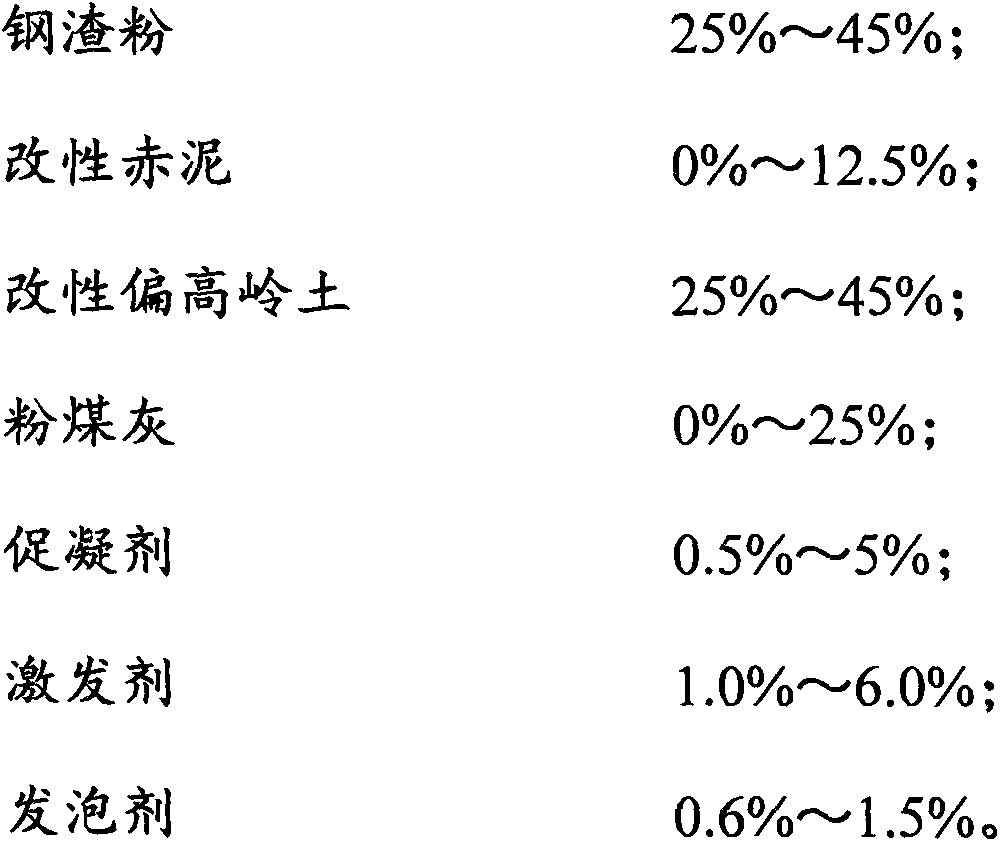

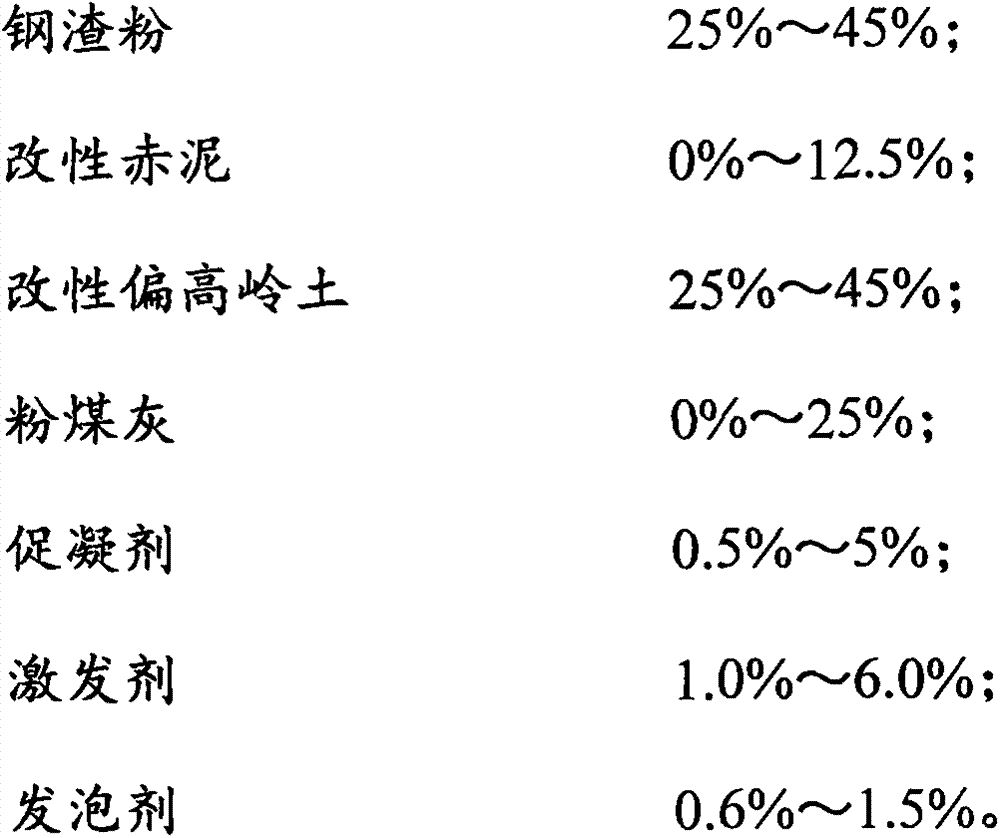

[0032] A kind of geopolymer foam concrete, its component and mass percent are as follows:

[0033] Steel slag powder 26.0%, modified red mud 5%, modified metakaolin 26.30%, ground slag powder 3.50%, red mud attached liquid 4.10%, foaming agent 1.20%.

[0034] Preparation method: Stir and mix dry materials such as steel slag powder, modified red mud, modified metakaolin, and finely ground slag powder evenly, add alkali activator and water and stir to make a uniform slurry; at the same time, mix foaming agent and water by 1 : Dilute to 15, use high-speed mixer to foam; then mix the prepared foam into the slurry according to the volume ratio, stir for 2.5-3min until the foam is evenly distributed in the slurry; finally injection molding, demoulding after 24h, standard maintenance 28d test Dry bulk density, compressive strength, flexural strength.

[0035] Test result: dry bulk density 1049kg / m 3 , the compressive strength is 19.3MPa, and the flexural strength is 3.8MPa.

Embodiment 2

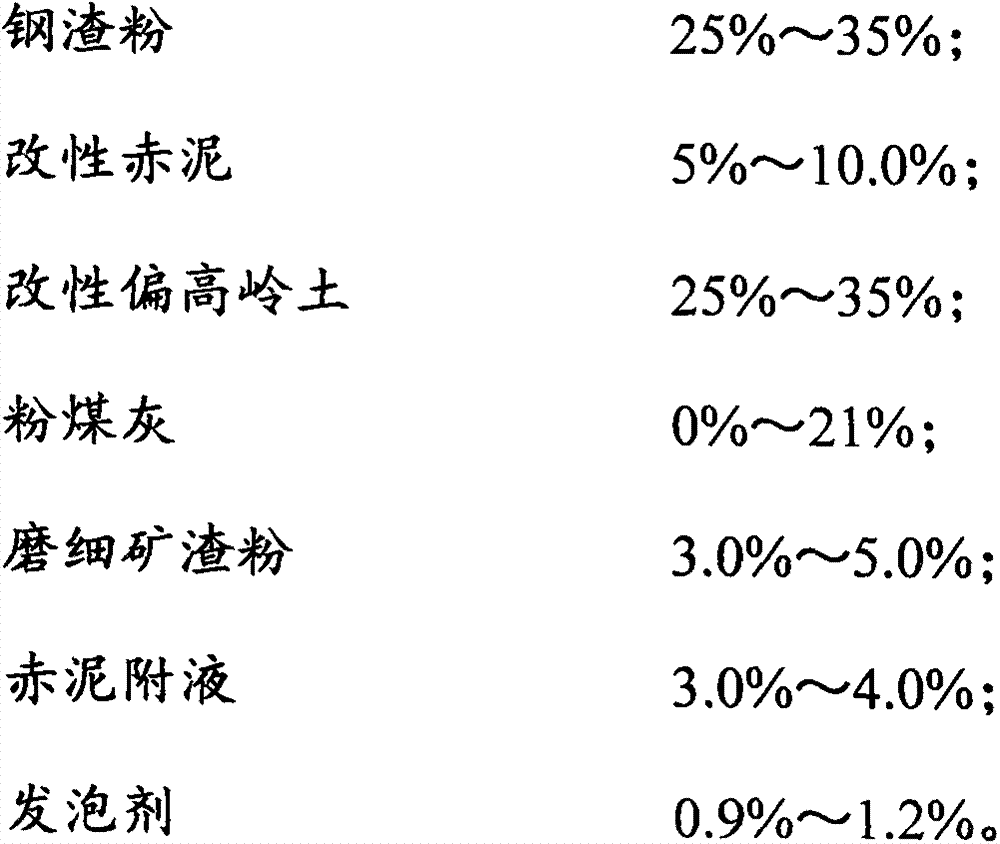

[0037] A kind of geopolymer foam concrete, its component and mass percent are as follows:

[0038] Steel slag powder 30.0%, modified red mud 7.50%, modified metakaolin 30.50%, ground slag powder 4.50%, red mud attached liquid 3.62%, foaming agent 1.16%.

[0039] Preparation method: Stir and mix steel slag powder, modified red mud, modified metakaolin, ground slag powder, etc., and add alkali activator and water to make a uniform slurry; Dilute and foam with a high-speed mixer; then mix the prepared foam into the slurry according to the volume ratio, and stir for 2.5-3 minutes until the foam is evenly distributed in the slurry; finally injection molding, demoulding after 24 hours, standard curing 28d to measure the dry volume Density, compressive strength, thermal conductivity.

[0040] Test result: dry volume density 730kg / m 3 , the compressive strength is 4.2MPa, and the thermal conductivity is 0.132W / (m·K).

Embodiment 3

[0042] A kind of metakaolin base polymer foam concrete, its component and mass percentage are as follows:

[0043] Steel slag powder 30.0%, modified red mud 7.50%, modified metakaolin 30.50%, ground slag powder 4.50%, red mud attached liquid 3.62%, foaming agent 1.16%.

[0044] Preparation method: Stir and mix dry materials such as steel slag powder, modified red mud, modified metakaolin, and finely ground slag powder evenly, add alkali activator and water and stir to make a uniform slurry; at the same time, mix foaming agent and water by 1 : Dilute to 15, use high-speed mixer to foam; then mix the prepared foam into the slurry according to the volume ratio, stir for 2.5-3min until the foam is evenly distributed in the slurry; finally injection molding, demoulding after 24h, standard curing 28d test Dry bulk density, compressive strength.

[0045] Test result: dry volume density 453kg / m 3 , the compressive strength is 1.5MPa, and the flexural strength is 0.6MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com