Composite pipe formed by winding plastic with netty steel belt and production method thereof

A composite pipe and steel strip technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of high recovery cost, low production efficiency, and difficulty in ensuring consistency, and achieve good compatibility and production efficiency. High, easy-to-recycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

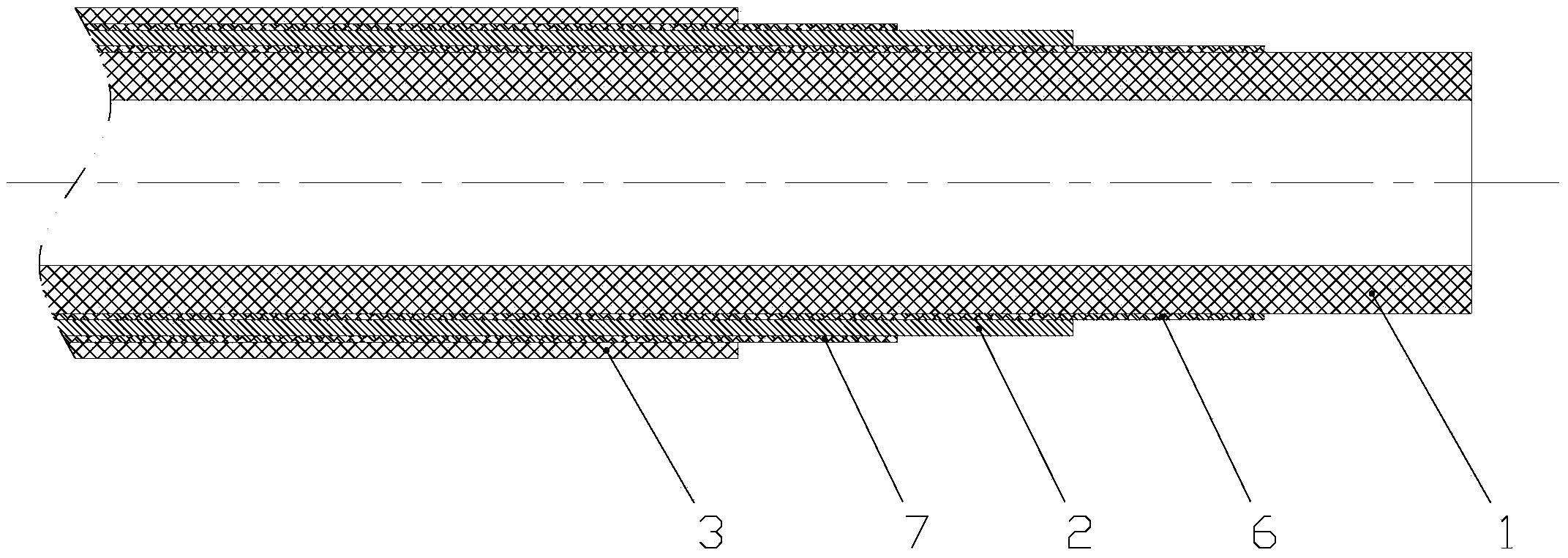

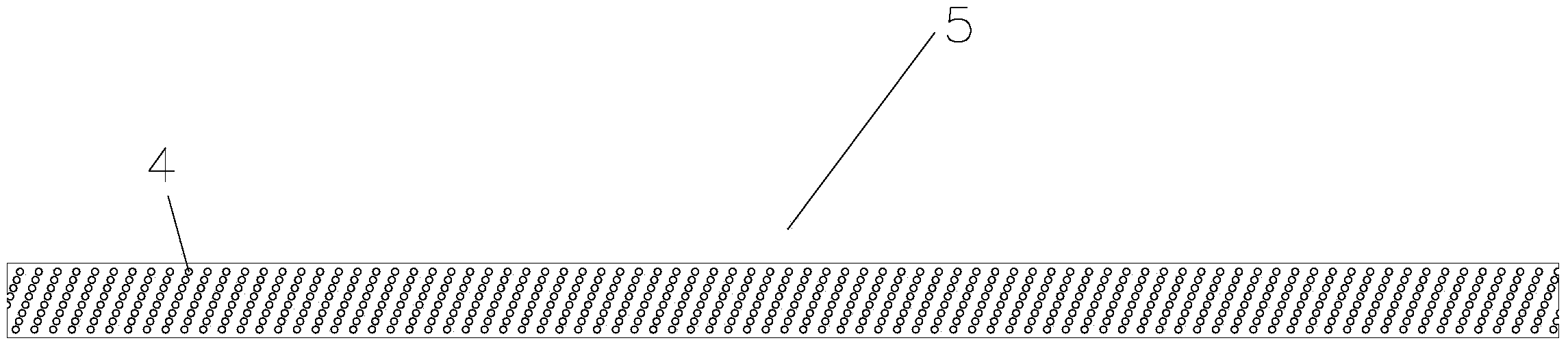

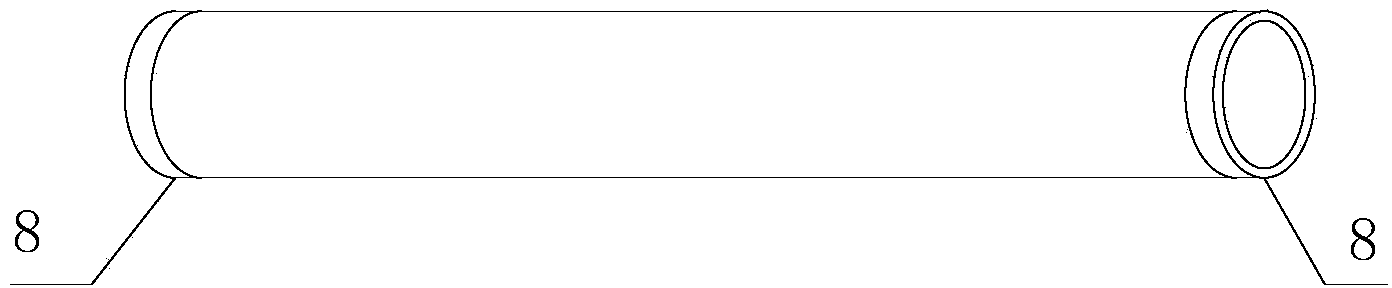

[0032] As shown in Figures 1-3, a plastic composite pipe wrapped with mesh steel tape according to the embodiment of the present invention includes a plastic inner layer solid wall pipe 1, a steel reinforcement layer 2, and a plastic outer layer solid wall pipe 3. The steel reinforcing layer 2 is a reticular steel strip 5 evenly provided with several through holes 4, and a polymer adhesive resin layer-6 is arranged between the plastic inner solid wall pipe 1 and the steel reinforcing layer 2, so that A polymer adhesive resin layer 2 7 is provided between the plastic outer solid-wall pipe 3 and the steel reinforcement layer 2, and the mesh-shaped steel strip-wound plastic composite pipe also includes plastic solid-wall sealing rings arranged at both ends of the pipe body. 8.

[0033] The plastic inner layer solid wall pipe 1 and the plastic outer layer solid wall pipe 3 are HDPE materials; the hole distance between the through holes 4 is 2 ~ 3MM; the mesh steel strip 5 is a col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com