Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about How to "Make up strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

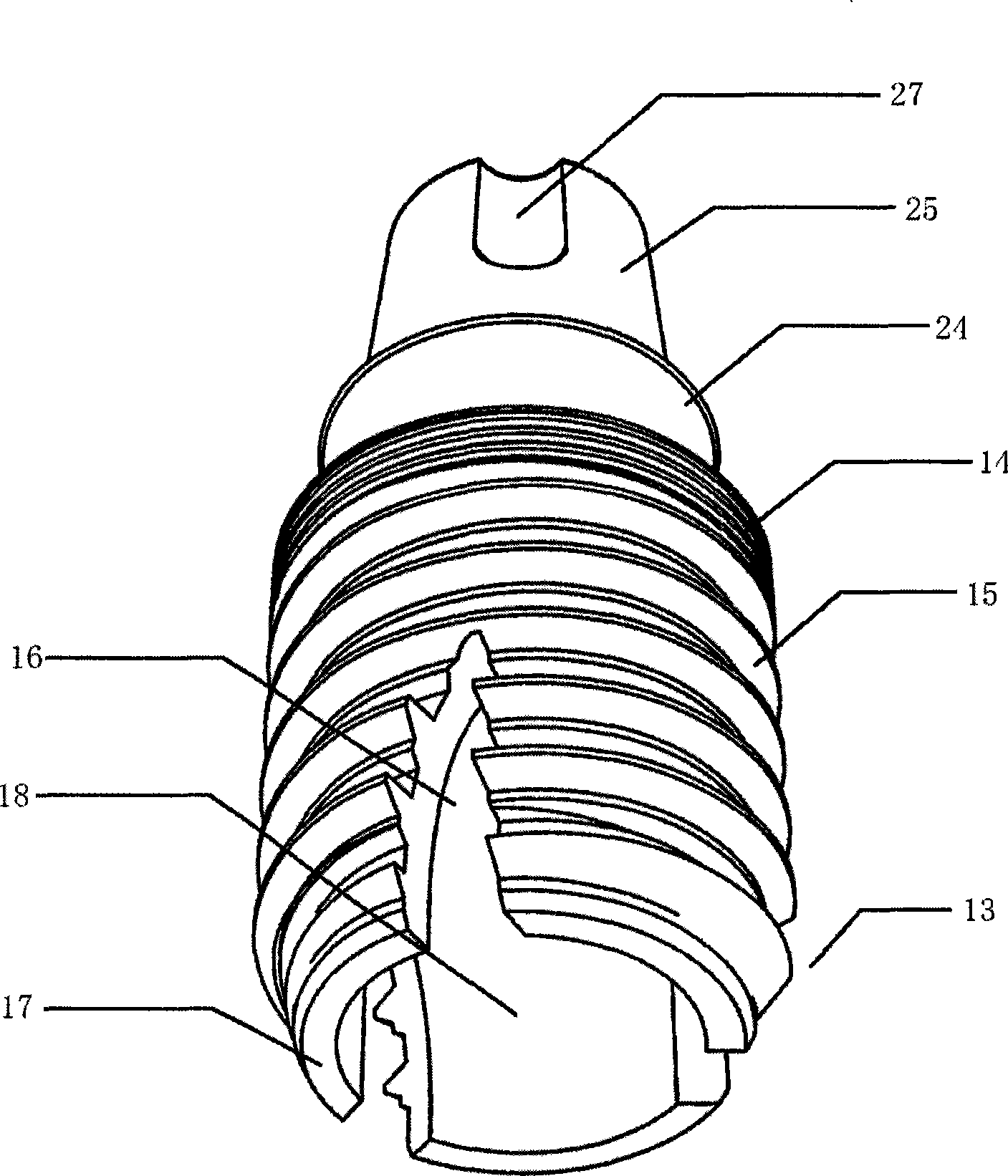

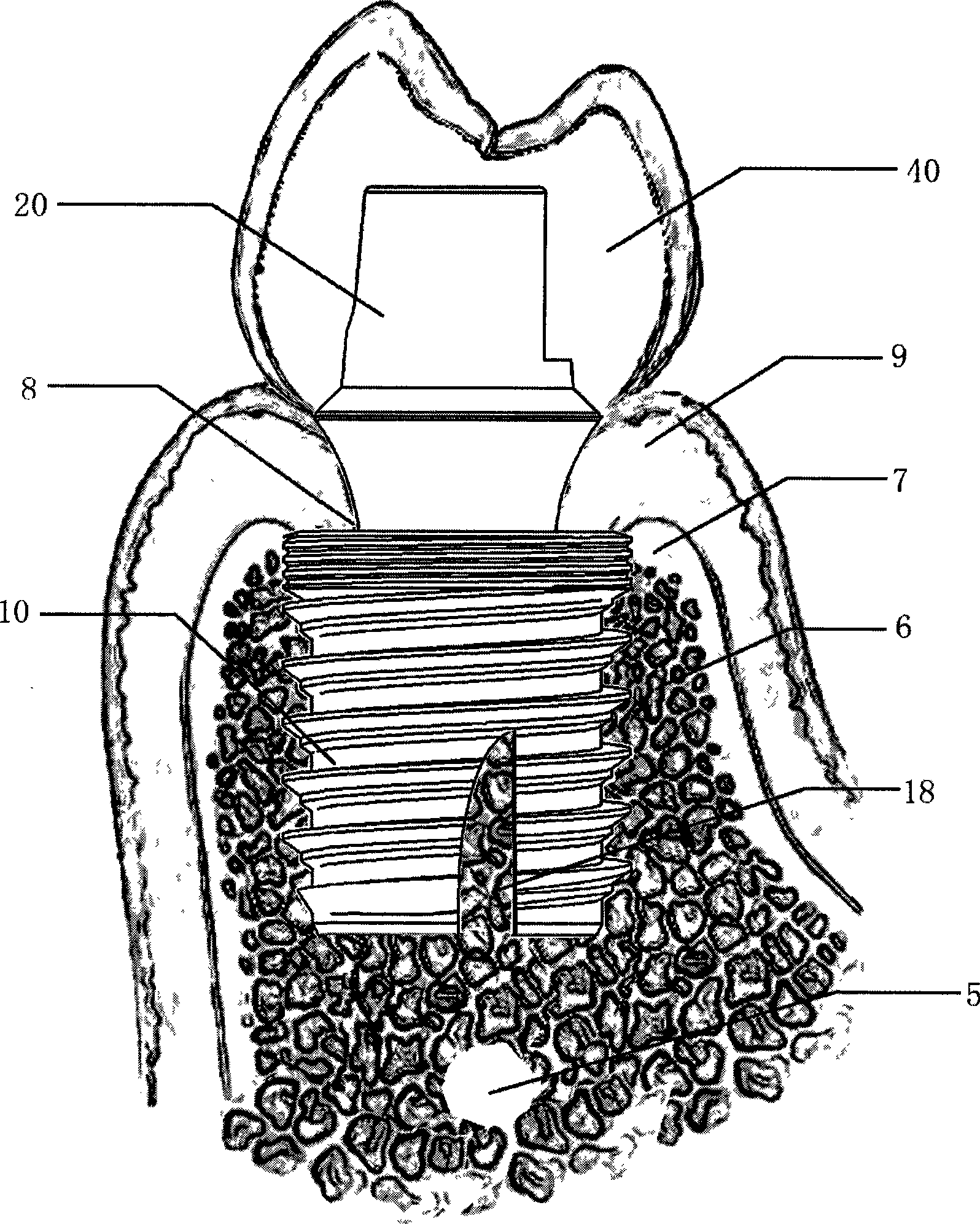

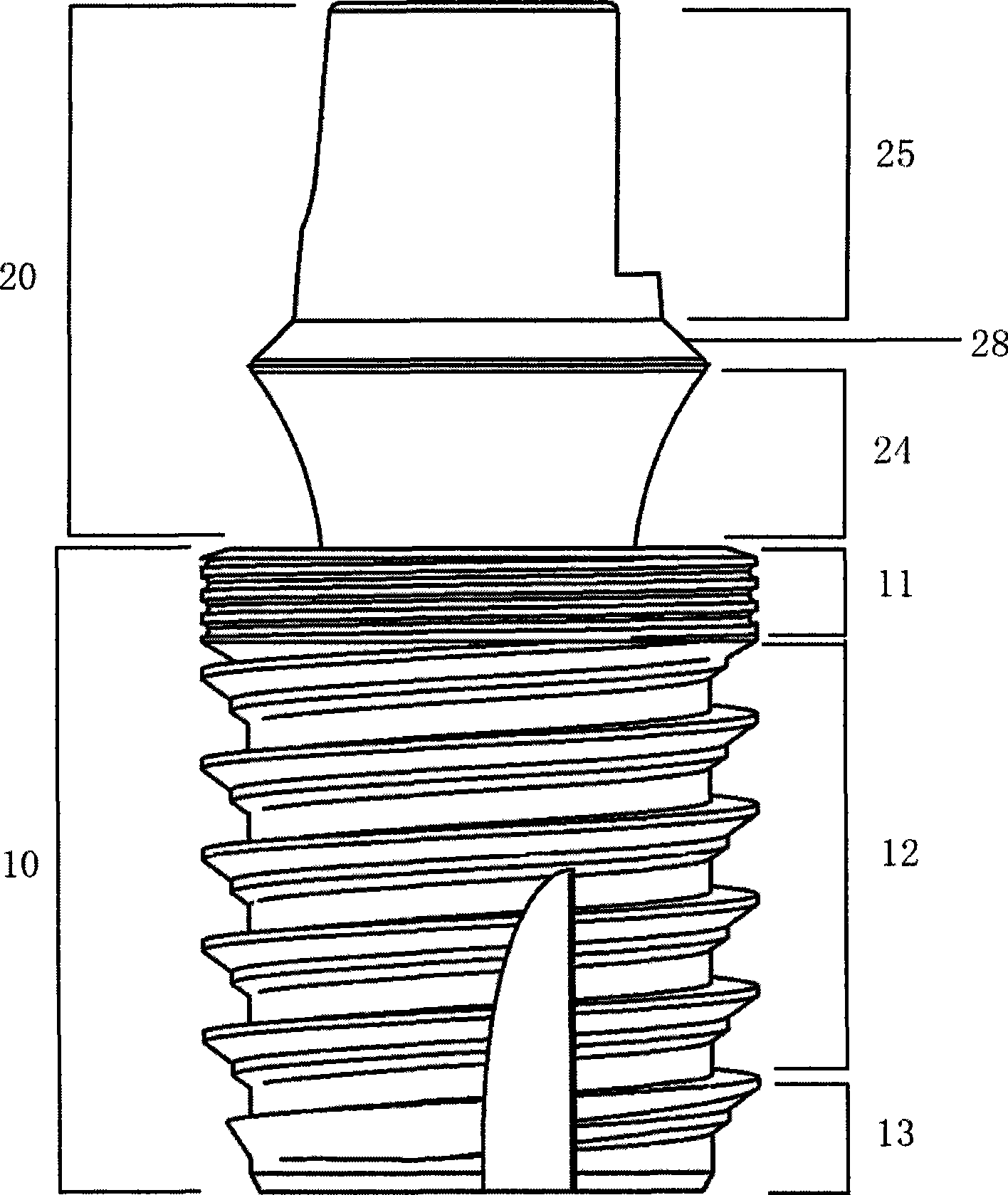

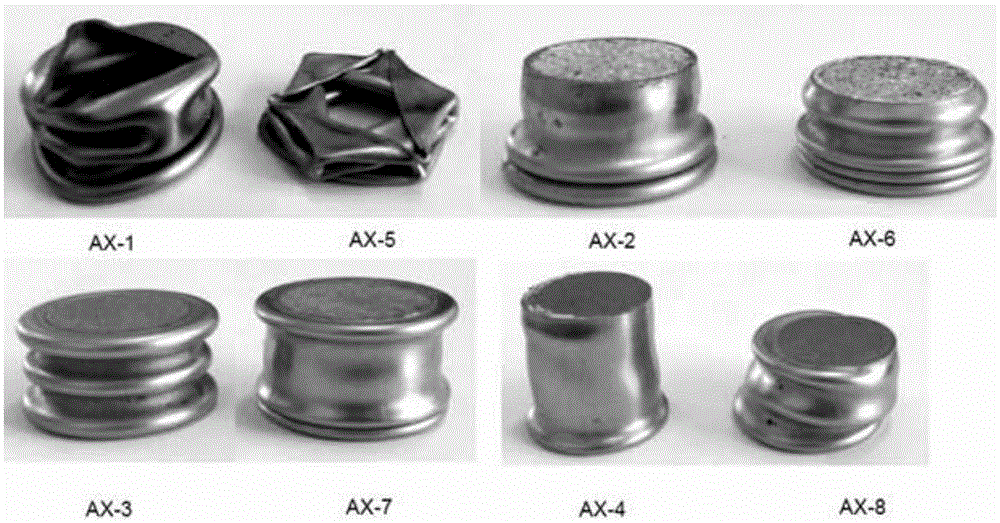

Hollow short grow body of oral cavity tooth grow

The invention relates to a hollow short implant of a dental implant, which comprises an one-stage structure and a two-stage structure, wherein the one-stage implant part is connected with an abutment part into a whole; the two-stage structure comprises an implant, a bridge adapter ring and a central bolt; peripheral cylinder spirochaeta of the implant part is divided into three stages, saw-tooth double thread in the main part of the implant can bear heavier load; the hollow structural design of the implant part keeps live bone column with a base and blood supply so as to enhance the supporting strength of the bone and the implant; a self-tapping socket can make bone tissue of the internal and external of the implant grow through and heal; a platform transfer design allows the epithelial cuff of the gum around the implant more reliable to avoid bone resorption caused by micro moving and micro leakage. The short hollow implant realizes combination of the internal and external bone, increases the combination area and supporting strength for a short or a long term, can be implanted rapidly with high strength, better retention in the early stage, high success rate in a long term, and solves the problem that the upper and lower jaws abrase the dental area in the conventional oral implant technology.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

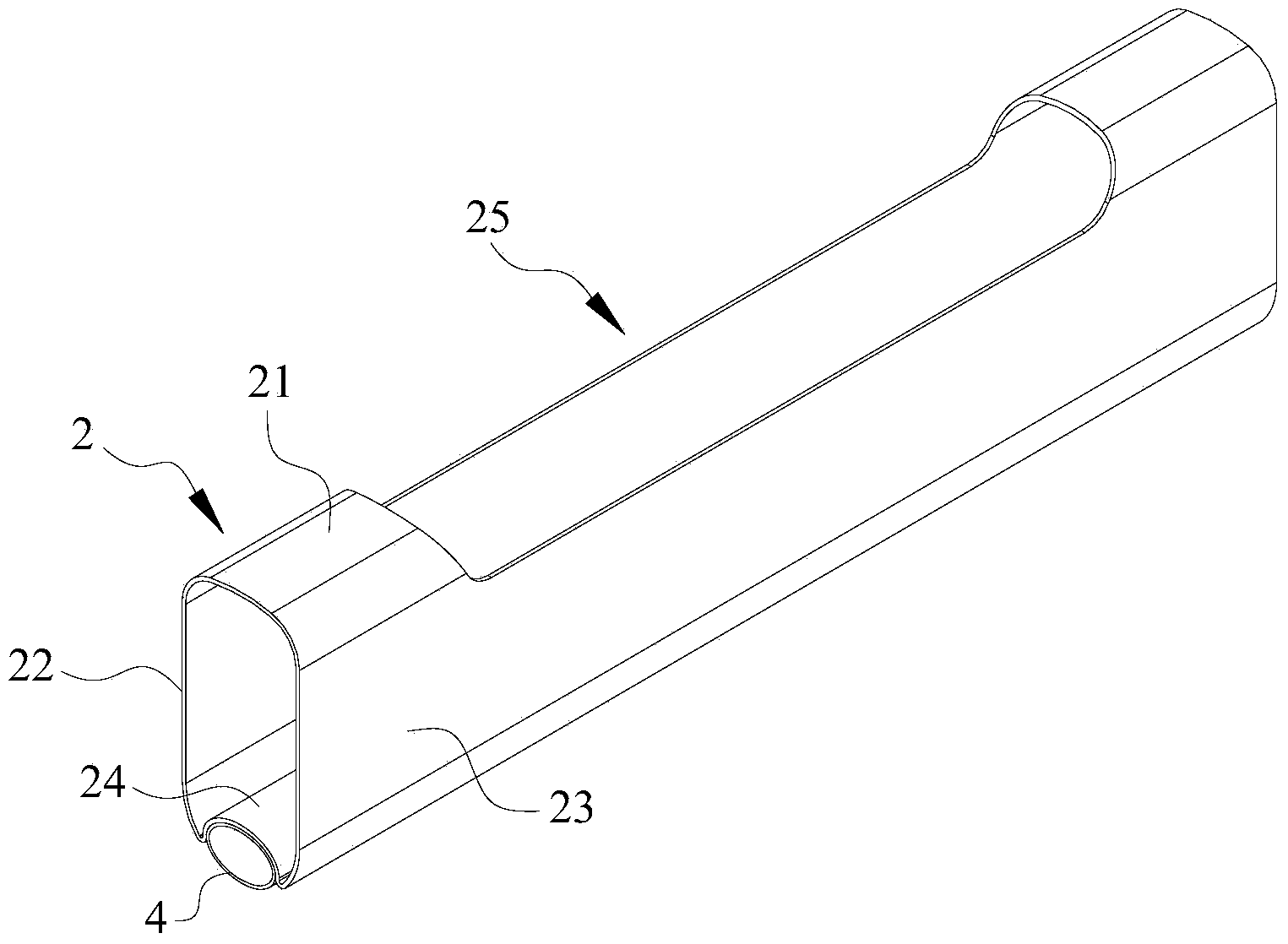

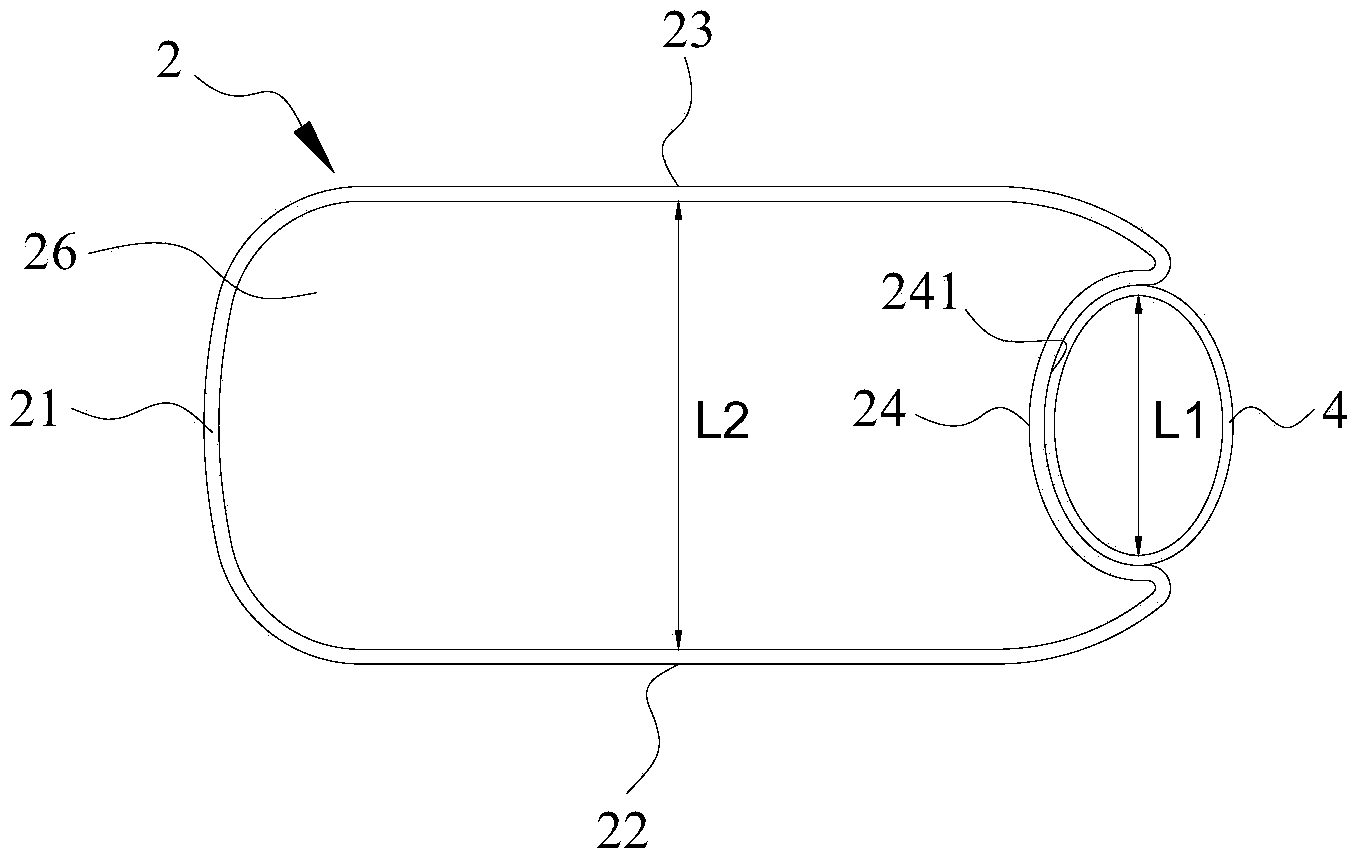

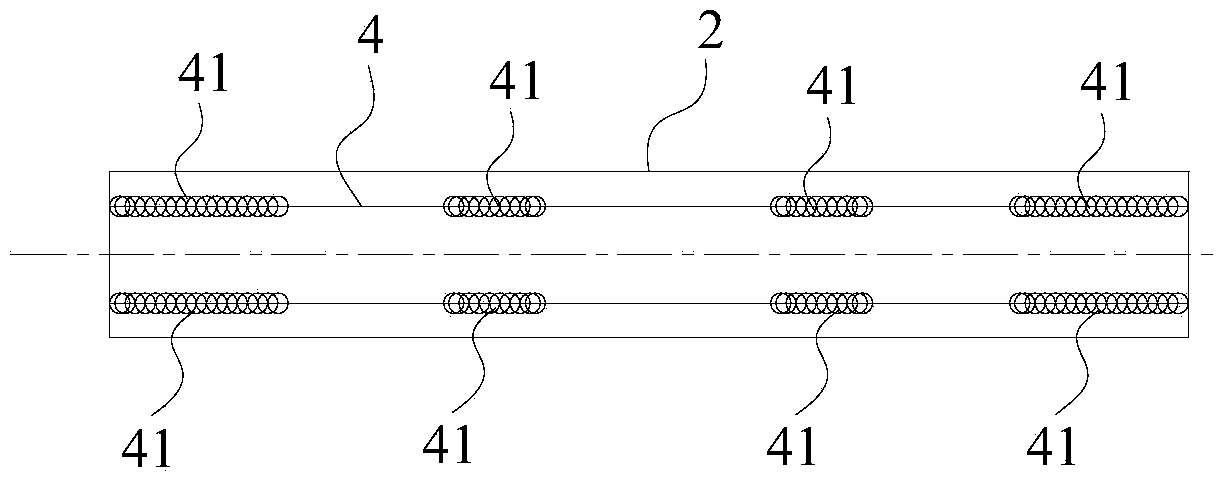

Electric bicycle and frame pipe thereof

The invention provides an electric bicycle and a frame pipe of the electric bicycle. The electric bicycle comprises a frame, wherein the frame pipe is arranged on the frame. The frame pipe comprises a main pipe body which is of a hollow pipe-shaped structure, a hollow inner cavity of the main pipe body is used for containing a battery, an opening which allows the battery to be placed into the inner cavity is formed in the pipe wall of the main pipe body, a reinforcing nozzle is further arranged in a non-opening position of the pipe wall, and the length direction of the reinforcing nozzle is the same as the length direction of the main pipe body. The reinforcing pipe is arranged on the frame pipe, and therefore the strength problem caused when the opening used for allowing the battery to be placed into the inner cavity is formed in the frame pipe is solved, and meanwhile the inner portion of the reinforcing pipe can also be used for wiring of the electric bicycle so that hidden wire arrangement can be formed and the whole bicycle can be more attractive and simpler.

Owner:SHENZHEN SONGI ELECTRIC BICYCLE

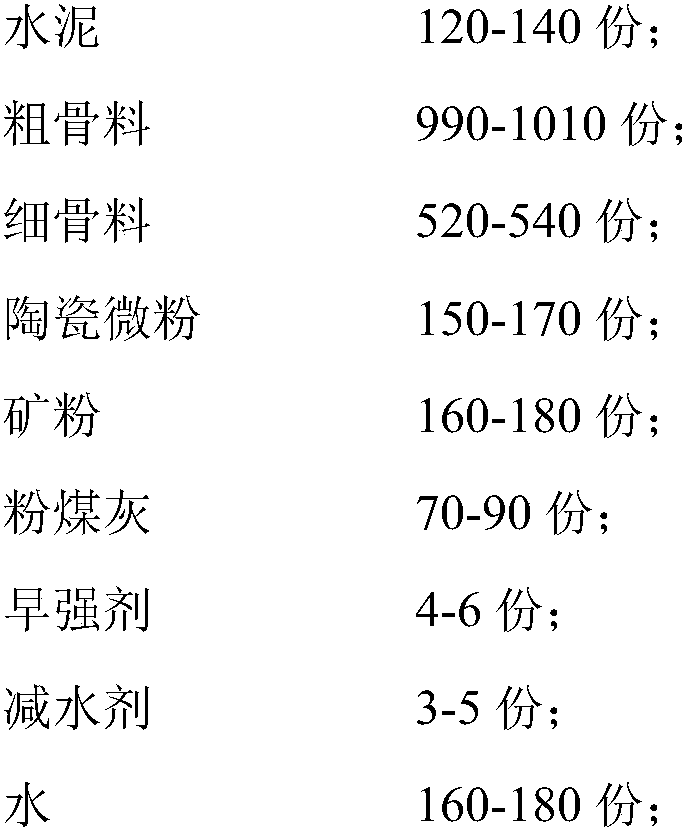

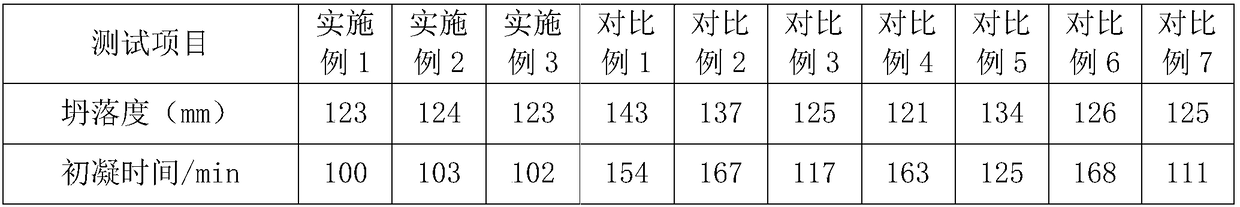

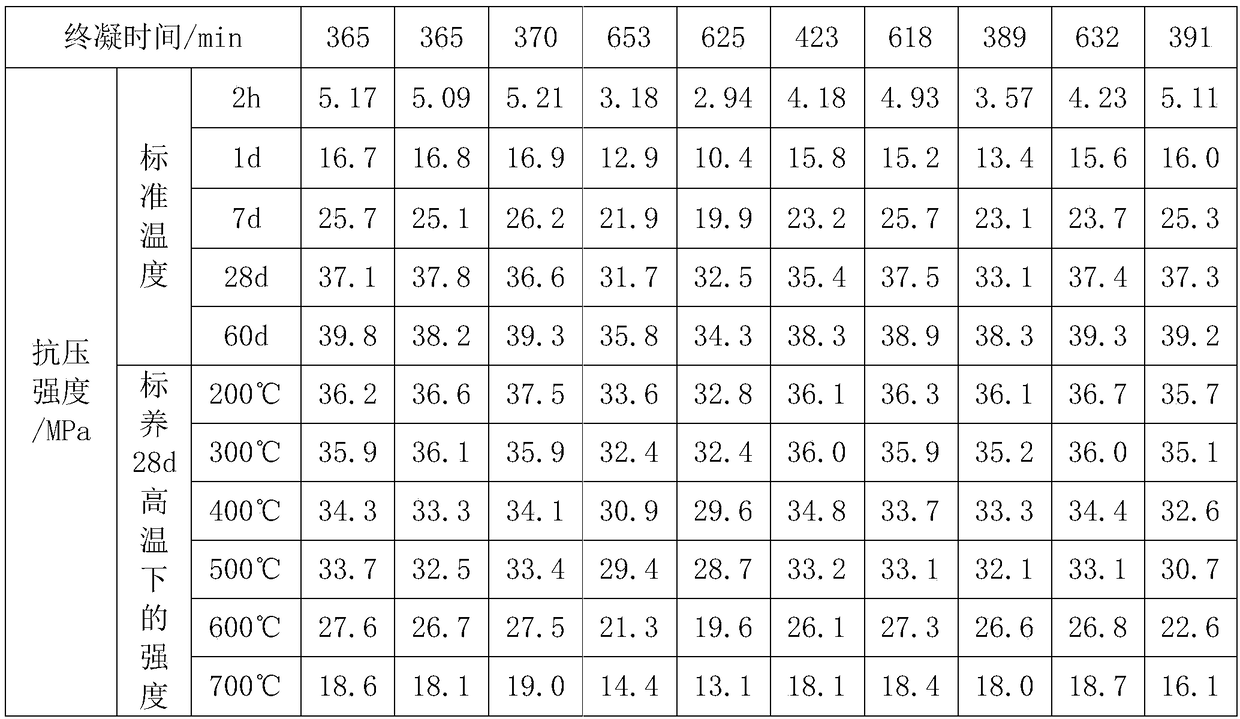

Heat-resistant concrete and preparation method thereof

The invention discloses heat-resistant concrete and a preparation method thereof and belongs to the technical field of concrete. According to key points of the technical scheme, the heat-resistant concrete comprises the following components in parts by weight: cement, coarse aggregate, fine aggregate, ceramic ultrafine powder, mineral powder, fly ash, an early strength agent, a water reducing agent and water. The coarse aggregate refers to basalt gravel and barite gravel; the fine aggregate refers to grain slag; the early strength agent comprises calcium formate and sodium silicate; the waterreducing agent comprises an early strength polycarboxylic water reducer. By replacing medium sand with grain slag, the grain slag can be effectively utilized, the long-term strength of the concrete can be improved, the heat resistance of the concrete is improved by the basalt gravel, the barite gravel and the ceramic ultrafine powder, the defects that low early strength of the concrete is broughtby the grain slag and the water demand is large can be overcome through the early strength agent and the water reducing agent, the compactness of the concrete is improved, and the compressive strengthof the concrete is improved.

Owner:北京建工新型建材有限责任公司

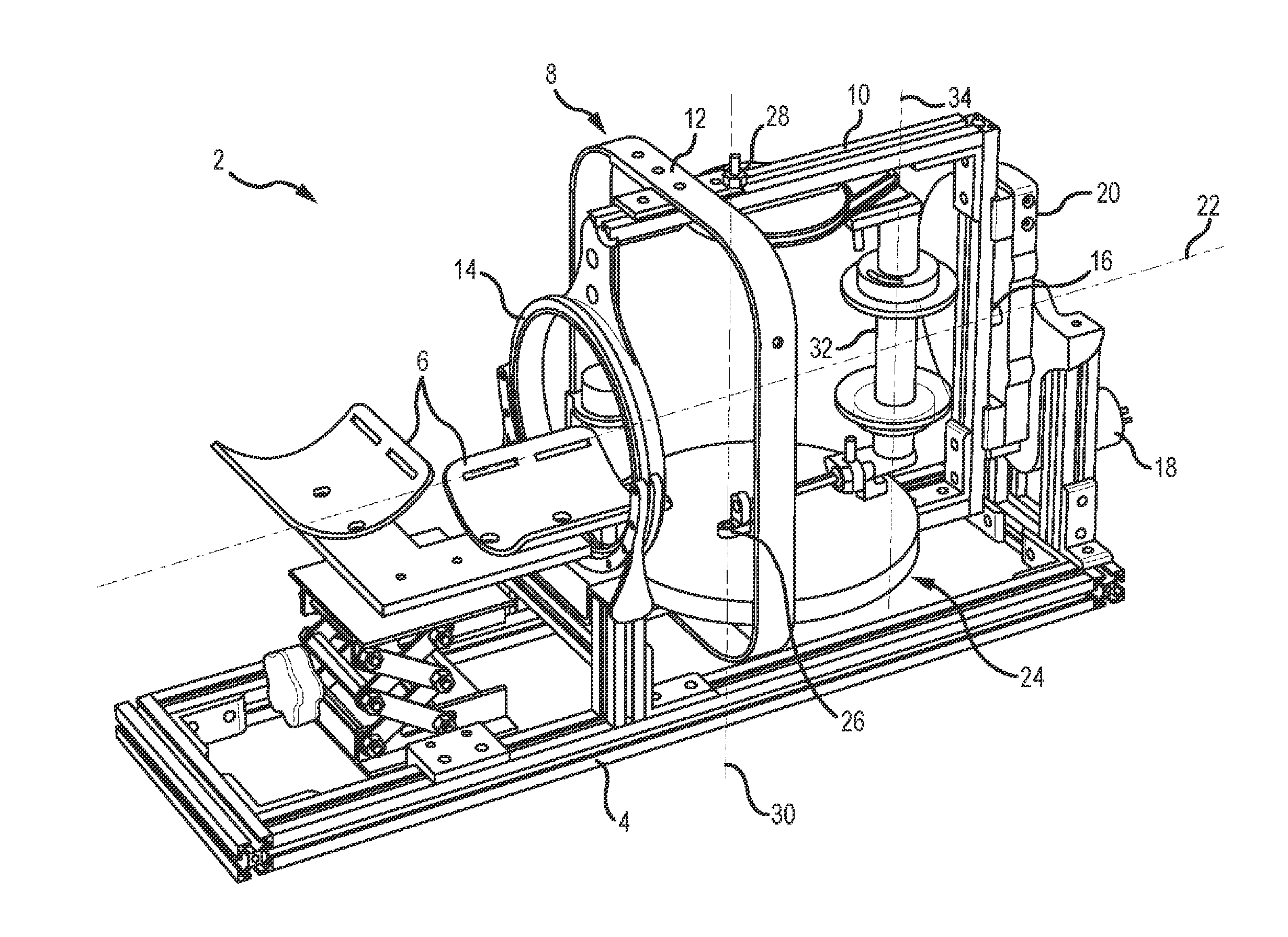

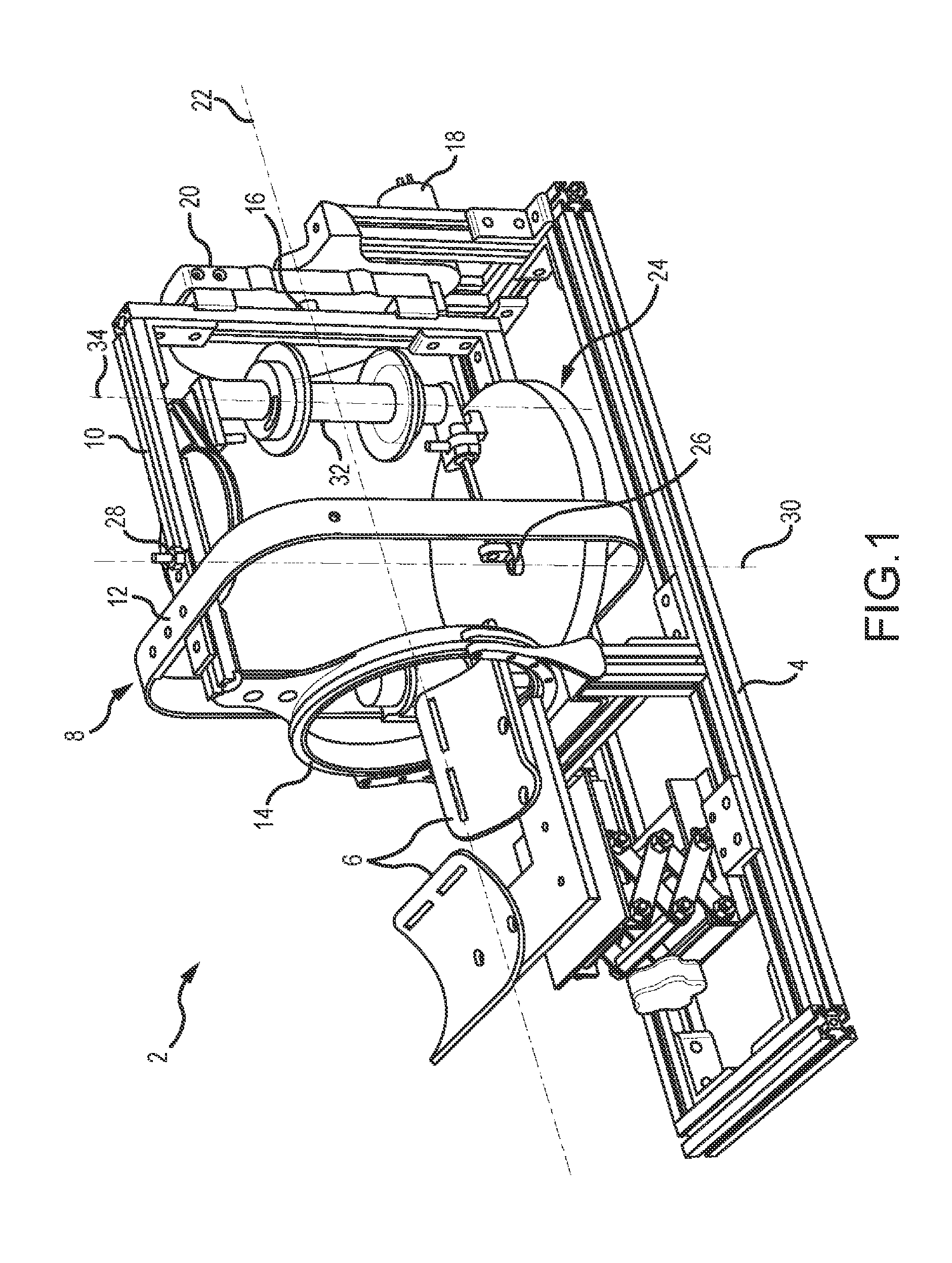

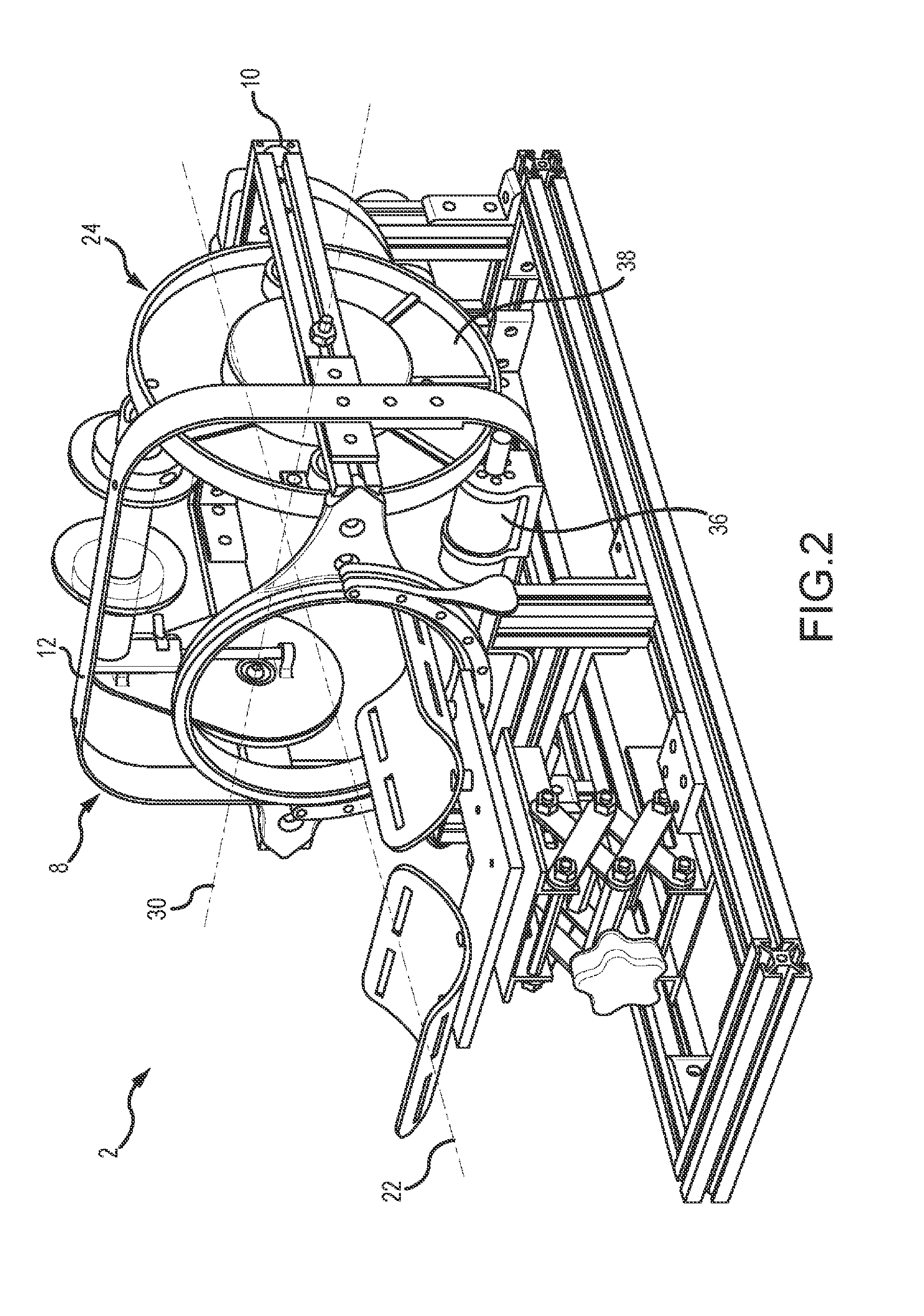

Wrist and forearm exoskeleton

InactiveUS20150359697A1Large range of motionMuscle strengthChiropractic devicesEye exercisersPronationsEngineering

An exoskeleton device and method of using the same is provided that helps rehabilitate limbs such has the lower arm. Embodiments of the exoskeleton device have multiple degrees of freedom so that a limb such as the lower arm may flex or rotate in multiple directions to establish or re-establish neural connections in the brain. With the lower arm example, a person may grasp a handle in the exoskeleton and then flex the lower arm about a pronation / supination axis, a flexion / extension axis, and / or an abductor / adductor axis. The exoskeleton device has several modes of operation where actuators can aid the person's motion, resist the person's motion, or passively allow free motion of the person's limb.

Owner:COLORADO SCHOOL OF MINES

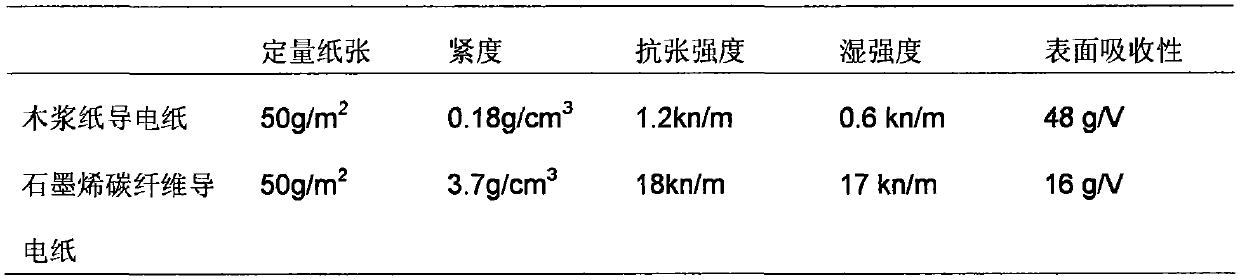

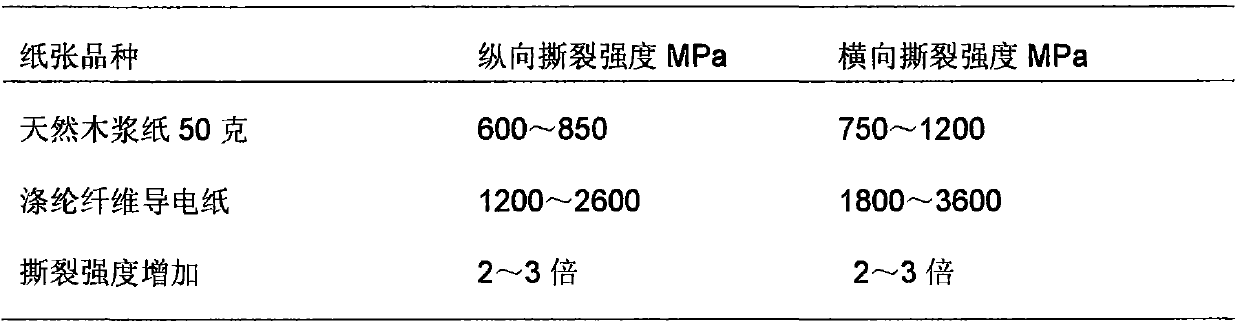

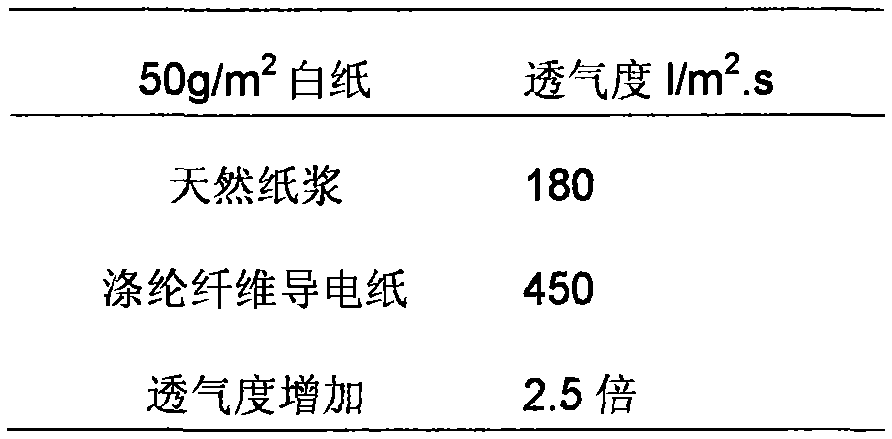

High-electrical-conductivity graphene carbon-fiber electrical-conductive paper and preparation method thereof

ActiveCN105369686AEvenly distributedUniform thicknessSpecial paperWater-repelling agents additionPolyesterFiber

The invention relates to a manufacturing technology of an electrical-conductive exothermic material, in particular to high-electrical-conductivity graphene carbon-fiber electrical-conductive paper and a preparation method thereof. The electrical-conductive paper comprises chopped carbon fibers, polyester super-short fibers, graphene powder and wood pulp fibers, and the high-electrical-conductivity graphene carbon-fiber electrical-conductive paper is obtained by conducting permeabilization treatment, defibering and dispersing, pulping treatment, mixing and papermaking on all the materials. According to the high-electrical-conductivity graphene carbon-fiber electrical-conductive paper and the preparation method thereof, the fibers are uniformly distributed, the thickness is uniform, the strength is high, water resistance is achieved, the air permeability is good, high electrical conductivity is achieved, the transition heat efficiency is high, the heat efficiency of the product is improved, the service life of the product is prolonged, and the electrical-conductive paper is a novel leap-upgrading and transformational breakthrough in the electrical exothermic material technology.

Owner:QINGDAO GRAPHENE CARBON NEW MATERIAL TECH CO LTD

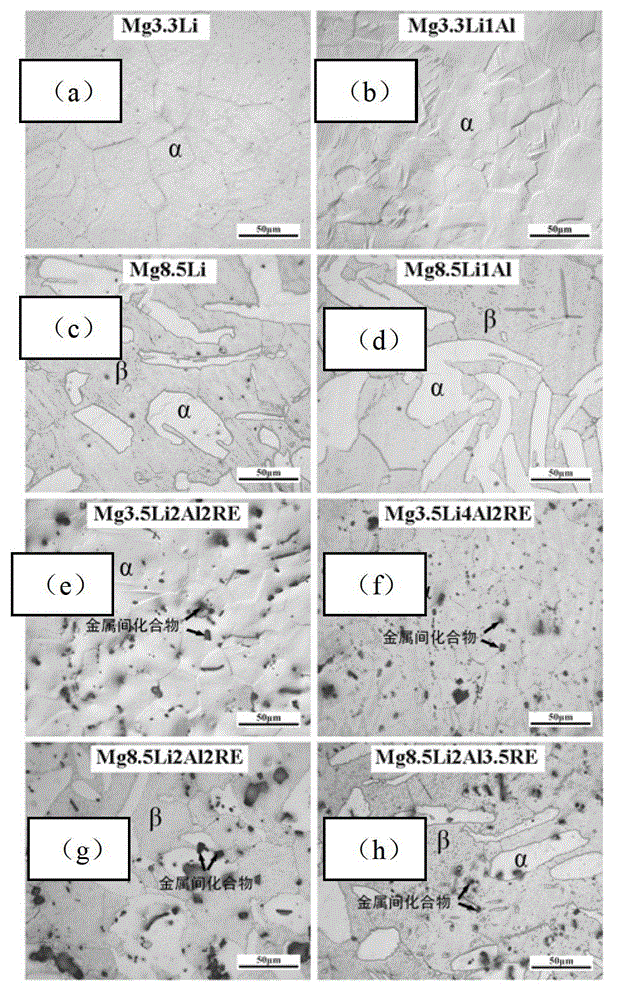

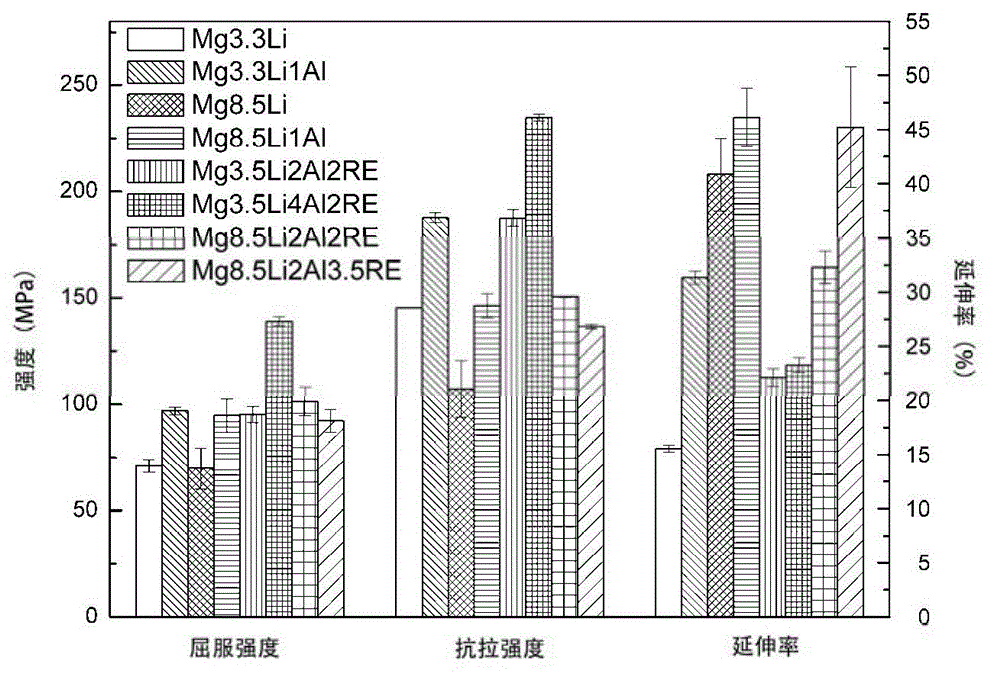

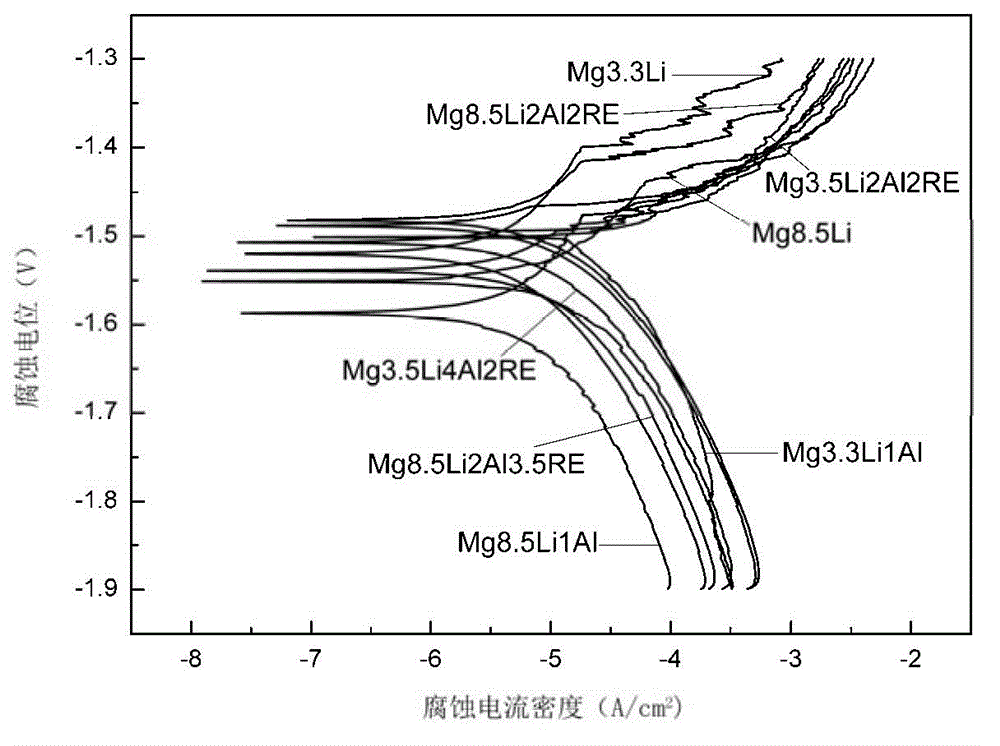

Mg-Li magnesium alloy and preparation method thereof

ActiveCN102978493AImproved low plasticityMake up for the lack of strength and corrosion resistanceCoatingsProsthesisAlloy elementBiocompatibility Testing

The invention discloses an Mg-Li magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following components in percentage by weight: 0-10% (excluding 0) of Li and the balance of Mg. The preparation method of the magnesium alloy comprises the following steps: adding one of the materials shown as (1) -(6) into molten Mg to obtain a melt: (1) Li; (2) Li and Al; (3) Li, Al and mixed rare earths; (4) Li and microelements; (5) Li, Al and microelements; and (6) Li, Al, mixed rare earths and microelements; smelting the melt to obtain a molten material; and extruding the molten material to obtain the magnesium alloy. The Mg-Li-(Al, RE) alloy for biodegradable intravascular stents disclosed by the invention adopts lithium with favorable biocompatibility as the alloying element, thereby overcoming the defect of low plasticity in the traditional magnesium alloy.

Owner:PEKING UNIV

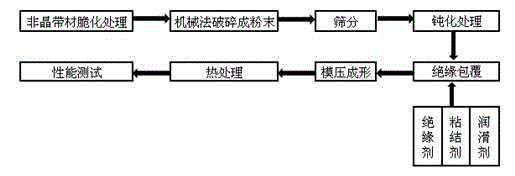

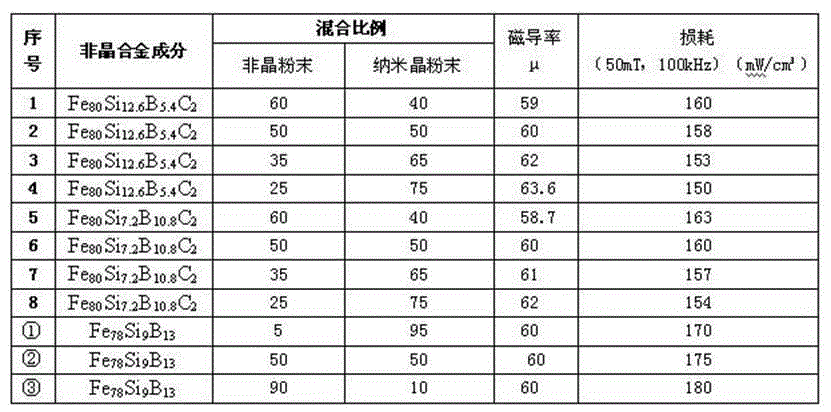

Amorphous-nanocrystalline composite magnetic power core and production method thereof

ActiveCN103559974AImprove magnetic propertiesImprove mechanical propertiesInorganic material magnetismInductances/transformers/magnets manufactureInorganic oxideNanocrystalline composites

The invention belongs to the field of function materials and particularly relates to an amorphous-nanocrystalline composite magnetic power core and a production method thereof. The amorphous-nanocrystalline composite magnetic power core is mainly made of iron-based amorphous powder, iron-based nanocrystalline powder, organic binder, and insulating agent. The insulating agent is a mixture of inorganic oxide, carbide and nitride. The organic binder and the insulating agent account for 0.5-2wt% and 0.5-4wt% of total weight of the two powders respectively. The production method includes: amorphous strip embrittlement, mechanical breaking for powdering, screening, passivation and insulation coating, die pressing, and heat treatment. The amorphous-nanocrystalline composite magnetic power core has excellent soft magnetic properties, thermal stability and mechanical strength under medium and high frequencies, and can be massively used for various inductive components, such as filters, current regulators and energy storage components, on various switch power modules.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

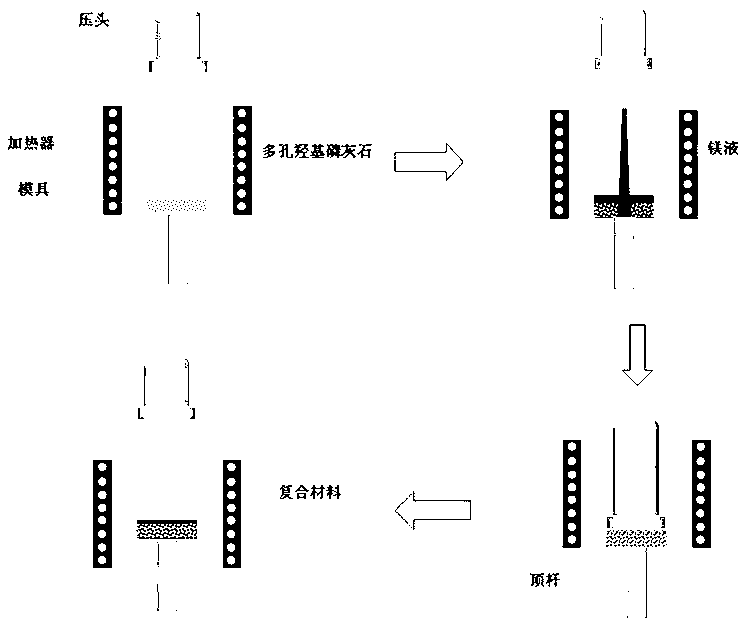

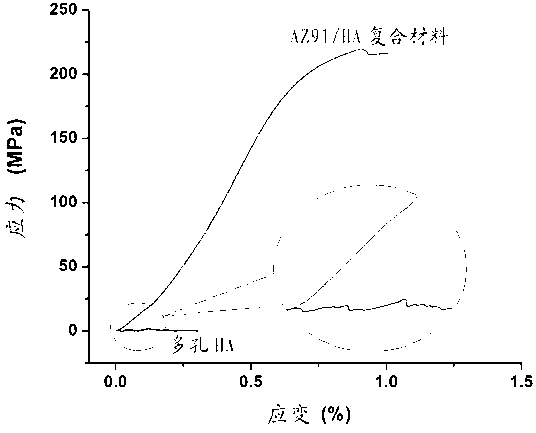

Magnesium or magnesium alloy-porous hydroxyapatite composite and preparation method thereof

InactiveCN103074512AGuaranteed biconnectivityHigh strengthGearingCylindersBone formingHydroxyapatite composite

The invention discloses a magnesium or magnesium alloy-porous hydroxyapatite composite and an extrusion casting preparation technology thereof. Aperture selection of the porous hydroxyapatite satisfies hundreds of micrometers required by clinical bone repair. In an extrusion casting process, smaller pressure is applied by a pressure head, so that a magnesium or magnesium alloy fusant is impregnated into pores of the porous hydroxyapatite, and then larger pressure is applied in a solidification process of the magnesium or magnesium alloy fusant, so that a structure of solidified magnesium or a solidified magnesium alloy is controlled. The magnesium or magnesium alloy-porous hydroxyapatite composite ensures double connectivity of the porous hydroxyapatite; magnesium or the magnesium alloy filled in the pores of the porous hydroxyapatite improves the strength; fracture of a structure of the porous hydroxyapatite is avoided; when the composite is used in the field of bone repair, the structure of the porous hydroxyapatite can still keep complete while magnesium or the magnesium alloy is degraded; bone cells can be induced to grow into multiple pores; and new bone forming is facilitated.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of drilling fluid diluent compound methyl silicate

ActiveCN103059821AEnhanced inhibitory effectLow viscosityDrilling compositionPtru catalystSilicic acid

The invention relates to a preparation method of a drilling fluid diluent compound methyl silicate. The method comprises the following steps: (1) preparing methyl silicate: adding water in a reactor, then adding alkali, heating to 70-90 DEG C after the alkali is dissolved, adding methyl silicic acid, continuing heating to 90-110 DEG C, and reacting to generate methyl silicate, wherein the weight ratio of water to methyl silicic acid to alkali is 1: 0.1-0.3: 0.2-0.6; and (2) preparing compound methyl silicate: adding sodium silicate and low molecular weight polyacrylate in generated methyl silicate, uniformly stirring sufficiently, adding an organic tin catalyst, and reacting for 3-5 hours at 90-120 DEG C to obtain a liquid diluent product compound methyl silicate with effective substance content of 25-40%. The drilling fluid diluent methyl silicate has the advantages of good diluting effect, low cost, wide application range, and long stabilization time, and can resist high temperature of more than 150 DEG C.

Owner:DAQING HEZHENG CHEM

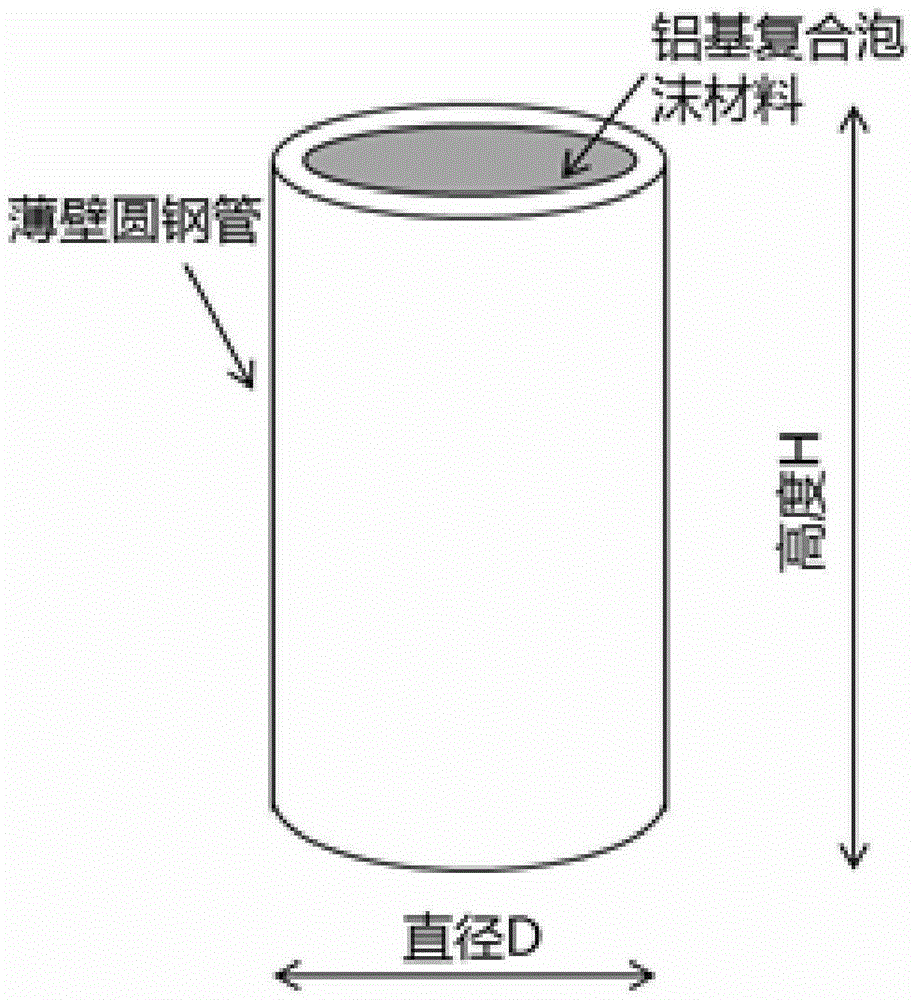

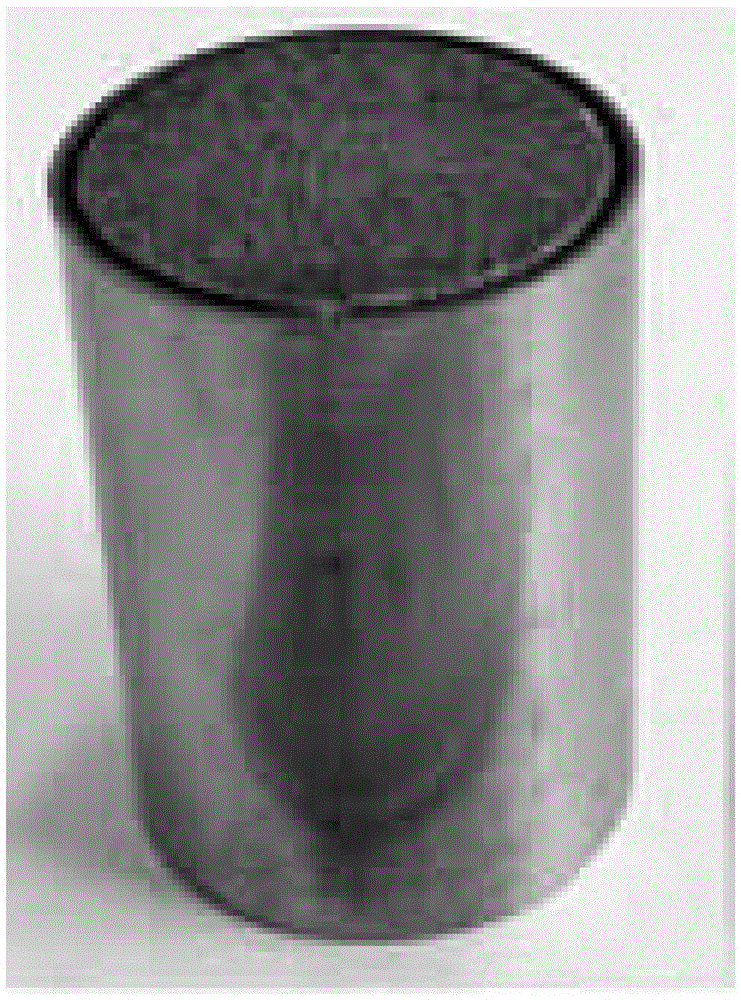

Buffering and energy absorption filling pipe

InactiveCN105299120AMake up strengthMake up structureElastic dampersRubber-like material springsStatic compressionEnergy absorption

The invention belongs to buffering and energy absorption components and discloses a buffering and energy absorption filling pipe. The problem that an existing foamed aluminum filling pipe is poor in energy absorption effect is solved. Aluminum-based composite foam materials are filler to be made into an aluminum-based composite foam filling pipe component, the energy absorption effect many times that of an ordinary foamed aluminum filling pipe component is achieved, the disadvantage that the aluminum-based composite foam materials cannot be independently used as an energy absorption or bearing structure due to poor intensity is overcome, and the high-intensity aluminum-based composite foam filling pipe component can fully play and integrate the advantages and mechanical property of various materials when bearing explosive blast, impact or other extreme loads, not only has the independent bearing capacity, but also has the outstanding advantages of being high in stability and energy absorption capacity and capable of working in the extreme environment and the like. Equivalent static compression tests are conducted on the buffering and energy absorption filling pipe and prove that the buffering and energy absorption filling pipe has the energy absorption capacity and mechanical property superior to those of the ordinary foamed aluminum filling pipe. Compared with a traditional hollow steel pipe and the ordinary foamed aluminum filling pipe, the crushing force and the energy absorption capacity are greatly improved.

Owner:HARBIN INST OF TECH

Super high temperature molybdenum disilicide zirconia composite heating element and its preparation method

InactiveCN1865191AOvercoming low temperature resistance is too smallOvercome the disadvantage of large high temperature resistanceHydrogenAdhesive

This invention relates to a hyperthermal molybdenum disilicon zirconium oxide compound heater, belonging to the heating material technology. This heater uses molybdenum disilicon zirconium oxide two-phage reticulated structure compound material as matrix, concretely it uses (Mo1-x,Wx)Si2 as one phage of the two-phage compound material, where X=0-0.5, and uses yttrium oxide / calcium oxide stabilized zirconium oxide powder as the other phage, where the content of the zirconium oxide powder is 30-70vol% of the compound material. The process comprises: charging the above two-phage compound material and sintering aid, adding in adhesive for pugging, extrusion molding, drying, burning and filming treatment, so as to obtain the product, wherein: the bar produced by organic adhesive molding and drying needs degreasing process under 0.1MPa hydrogen gas pressure, at 300-600Deg C for 3-30 hours, where the burning temperature is 1500-1750Deg C. The invention can produce high efficient and long-life heater at more than 1850Deg C.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

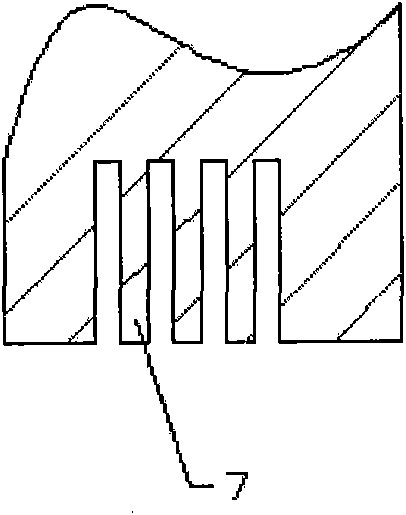

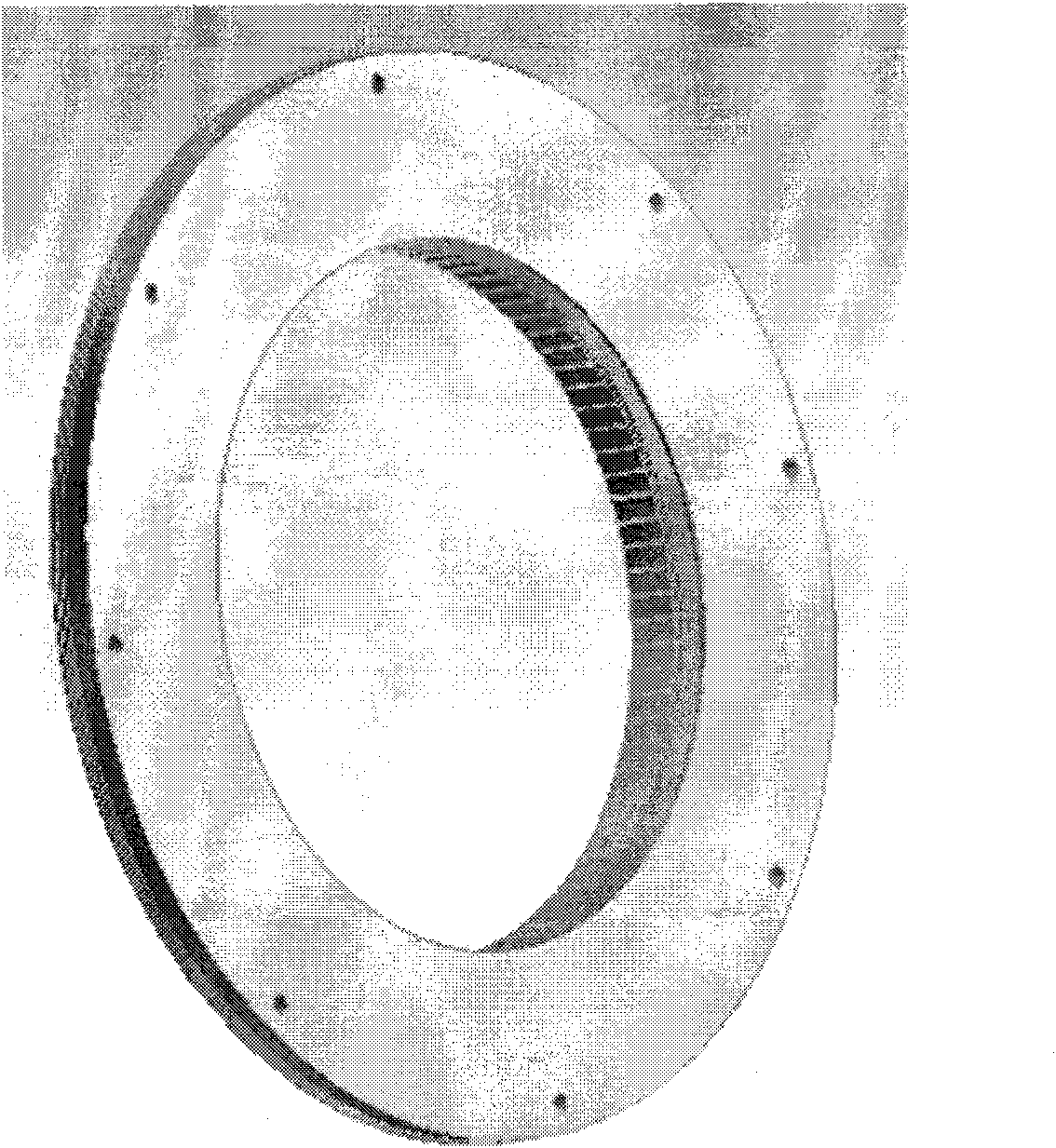

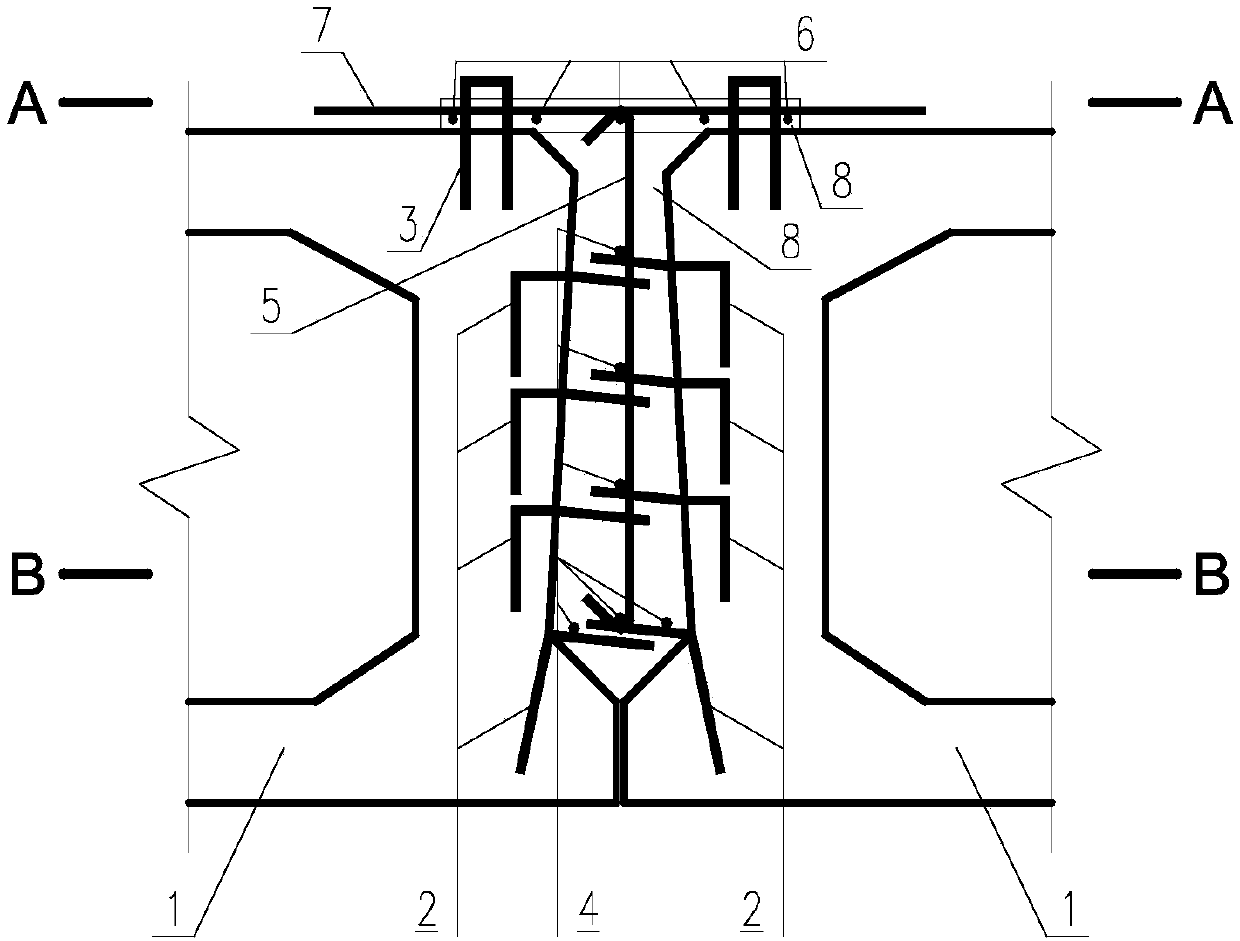

Labyrinth and fingertip combined type seal structure

The invention provides an improved labyrinth and fingertip combined type seal structure which adopts a fingertip seal and a fingertip seal front baffle plate as main bodies, wherein the fingertip sealfront baffle plate is improved into a labyrinth seal structure, the fingertip seal comprises two high-pressure seal grade fingertip pieces and a low-pressure seal grade fingertip piece with a fingertip shoe, arc-shaped gaps are arranged on the fingertip pieces, the three fingertip pieces are fixed together, the front baffle plate is arranged in front of the high-pressure seal grade fingertip pieces, a rear baffle plate is arranged at the rear of the low-pressure seal grade fingertip piece with a fingertip shoe, and the labyrinth seal is a seal tooth which is inlaid in the front baffle plate.The labyrinth and fingertip combined type seal structure is used for axially sealing a mechanical rotor of an impeller and can effectively prevent the axial gas leakage of an engine; and if the direction of the seal tooth is changed, the labyrinth and fingertip combined type seal structure can be used for sealing holes.

Owner:HARBIN ENG UNIV

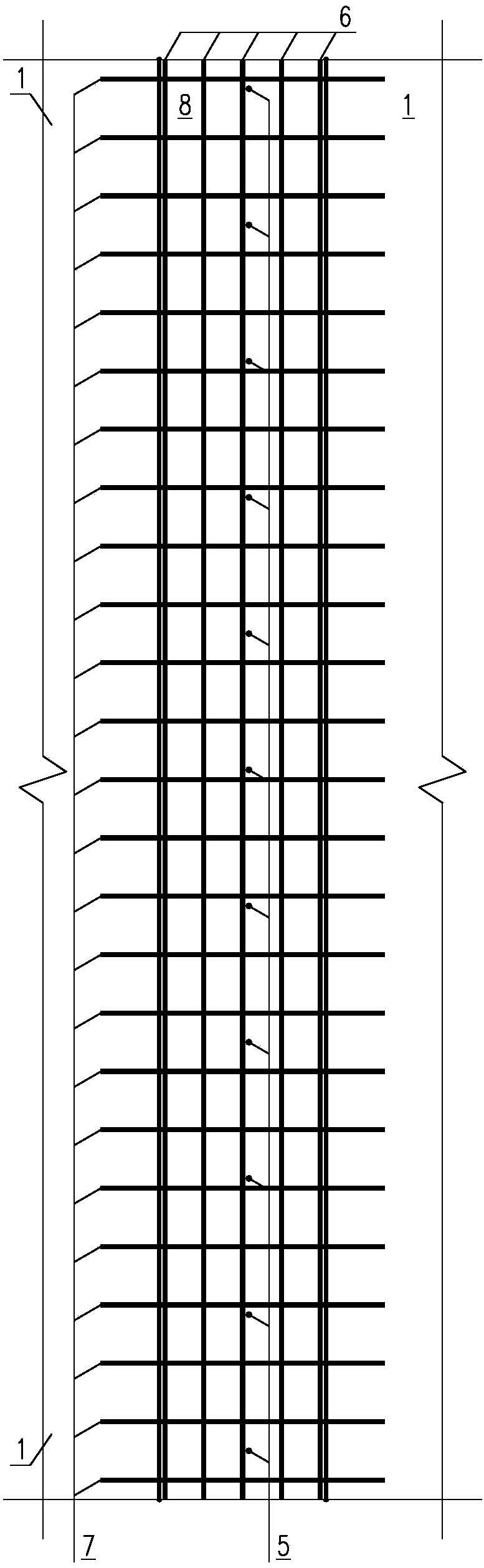

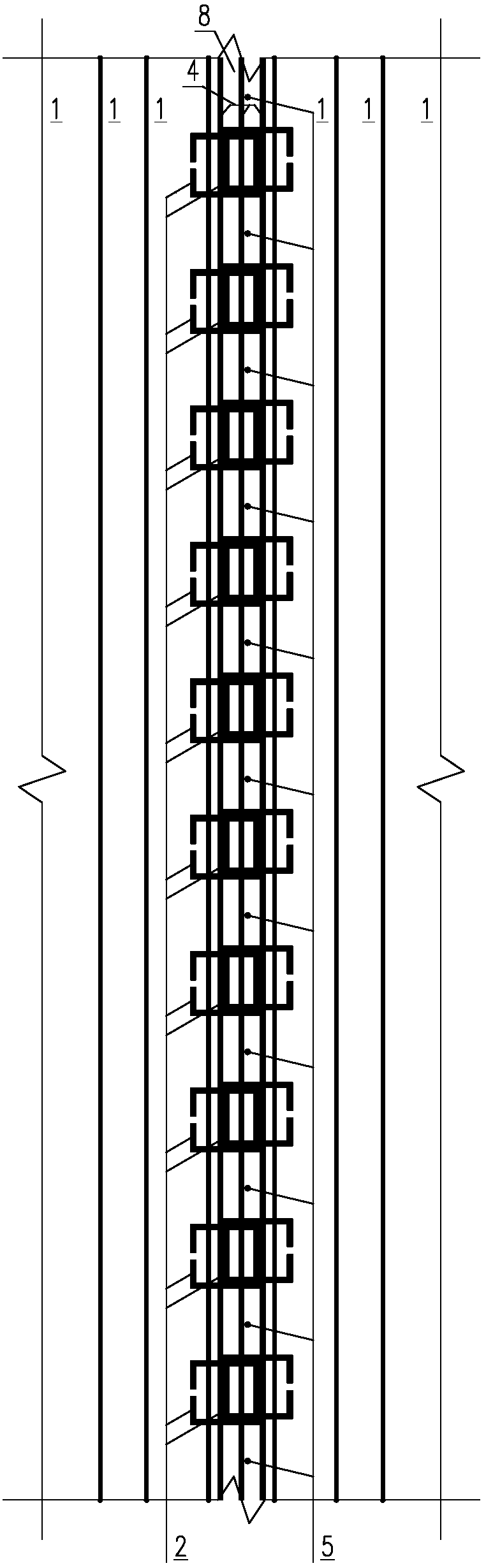

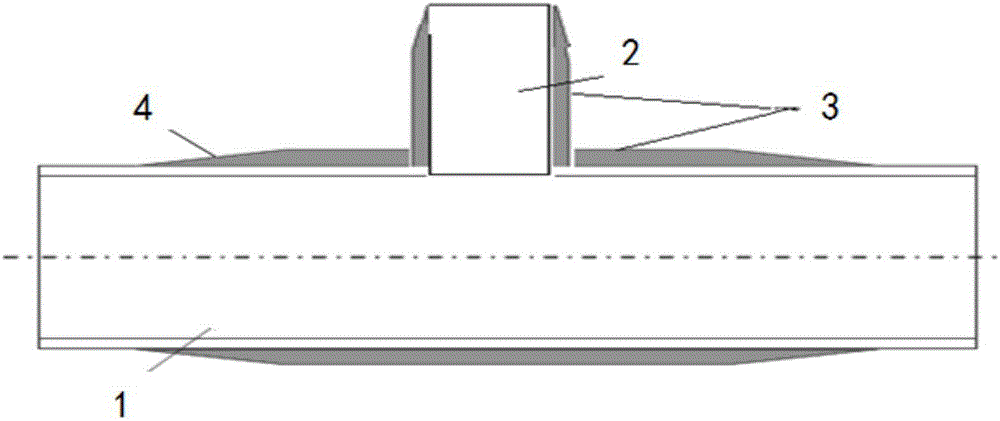

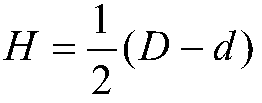

Integral hollow slab bridge structure based on ultra-high-performance concrete connection and construction method thereof

PendingCN107806008ASimple construction methodFast construction methodBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention discloses an integral hollow slab bridge structure based on ultra-high-performance concrete connection and a construction method thereof. The bridge structure is formed by connecting atleast three prefabricated hollow slab bridges in the transverse direction of the bridges through at least two ultra-high-performance concrete joints and a plurality of ultra-high-performance concretetransverse stripes. Each ultra-high-performance concrete joint comprises a hinge joint between every two hollow slab bridges and ultra-high-performance concrete longitudinal stripes. The hinge joint forms a basic frame through two prefabricated hollow slab bridge web plates, embedded transverse connecting steel bars extending out of the web plates, longitudinal steel bars and hoop bars and is filled with ultra-high-performance concrete. The ultra-high-performance concrete longitudinal stripes include steel bar frameworks formed by prefabricated bridge top slab extending steel bars, longitudinal steel bars and transverse steel bars, and the ultra-high-performance concrete longitudinal stripes and the hinge joints are filled with ultra-high-performance concrete simultaneously. The integral hollow slab bridge structure is good in stress performance, good in durability and remarkable in full-life economical benefit, and construction steps can be executed by adopting a traditional construction device and process and are simple, quick and convenient.

Owner:SHANXI PROVINCIAL RES INST OF COMM

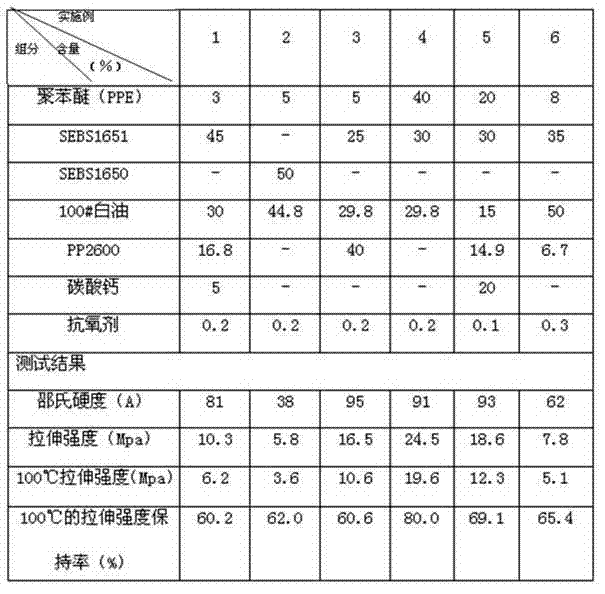

Polyphenyl ether elastomer composition and preparation method thereof

The invention relates to a polyphenyl ether elastomer composition and a preparation method thereof. The composition comprises the following components in percentage by mass: 3 to 40 percent of polyphenyl ether, 25 to 50 percent of styrene block polymer resin, 15 to 50 percent of rubber processing oil, 0 to 40 percent of polyolefin, 0 to 20 percent of inorganic mineral filler and 0.1 to 0.3 percent of antioxidant. The preparation method comprises the following steps of: weighing the materials in a mass ratio, mixing the materials at a high speed in a high-speed mixer, putting the mixture into a double-screw extruder, and performing melt extrusion and granulation to obtain the polyphenyl ether elastomer composition. Compared with the prior art, the polyphenyl ether elastomer composition hasthe advantages of softness, high heat resistance and the like.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

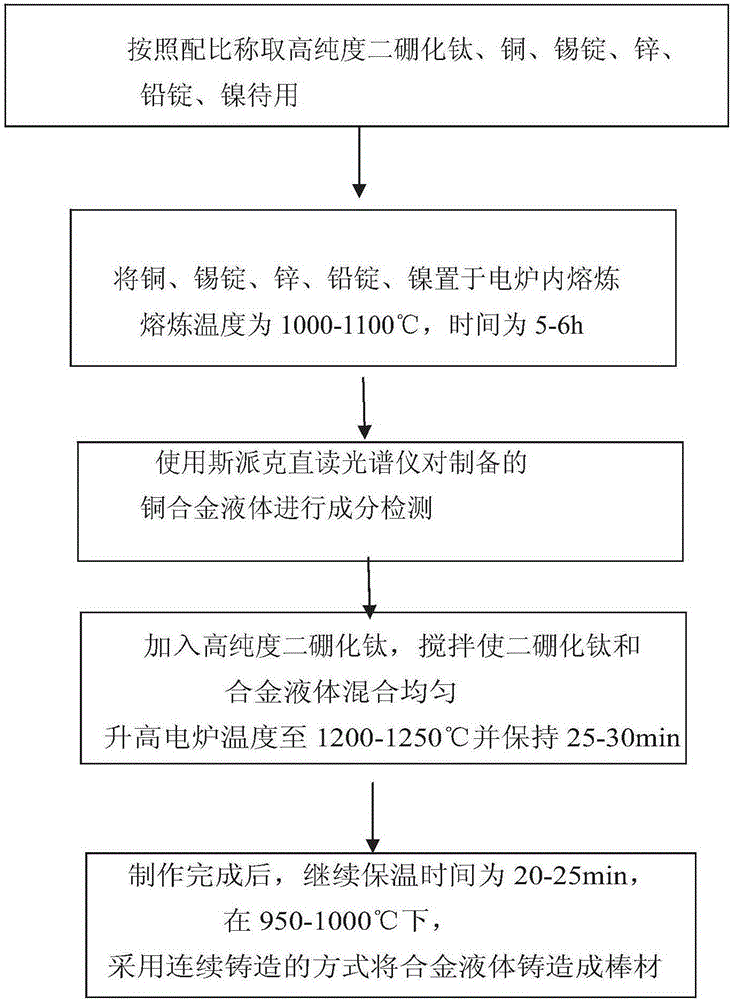

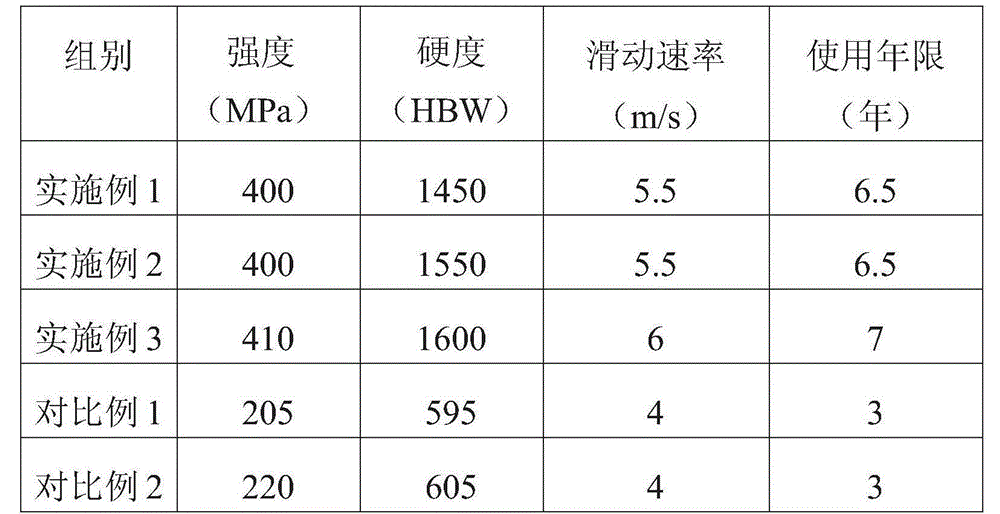

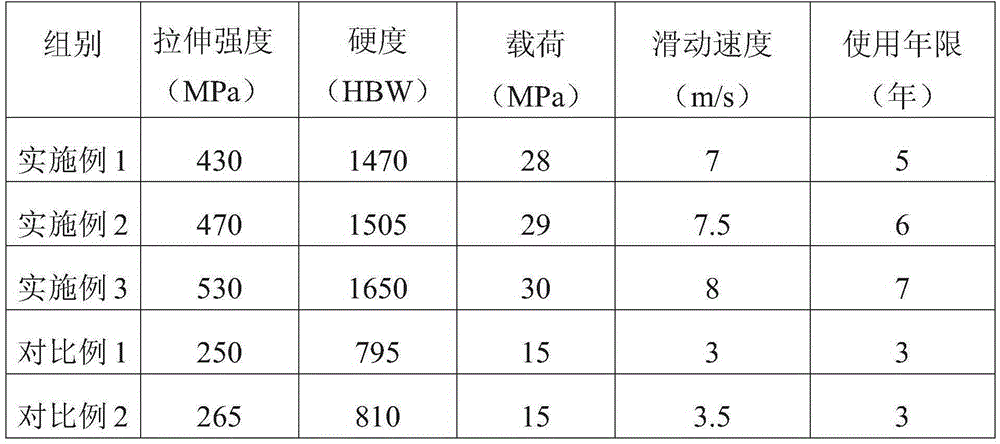

High-strength titanium diboride particle-reinforced copper-based composite material and preparation method thereof

The invention relates to a high-strength titanium diboride particle-reinforced copper-based composite material used for heavy equipment, and a preparation method thereof. The high-strength titanium diboride particle-reinforced copper-based composite material is composed of the following components, by volume percentage, of 6-9% of high-purity titanium diboride with the purity greater than 98%, and 91-94% of copper alloy ZCuSn5Zn5Pb5. The high-strength titanium diboride particle-reinforced copper-based composite material used for the heavy equipment is prepared through the steps of smelting, stirring, heat insulation, casting and the like. According to the high-strength titanium diboride particle-reinforced copper-based composite material used for the heavy equipment, which is provided by the invention, the strength, the hardness, the slide speed and the service life of the copper alloy ZCuSn5Zn5Pb5 are increased and prolonged while the original wear resistance and corrosion resistance thereof are ensured by virtue of the characteristics of a high melting point, corrosion resistance, high hardness, good heat stability, high-temperature oxidization resistance and the like of the high-purity titanium diboride, and therefore the requirements for applications of the high-strength titanium diboride particle-reinforced copper-based composite material to the heavy equipment are met.

Owner:SUZHOU RICHMOND ADVANCED MATERIAL TECH TRANSFER CO LTD

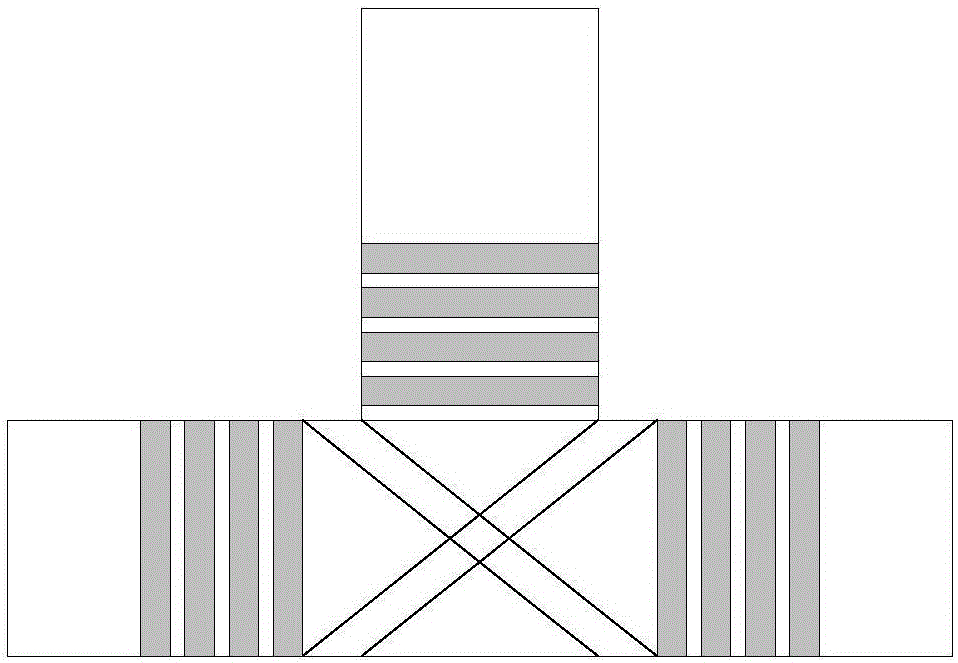

Composite material repairing and strengthening method for boss fillet weld

ActiveCN106238970AHigh strengthImprove structural strengthWelding/cutting auxillary devicesAuxillary welding devicesSteel tubeCrazing

The invention discloses a composite material repairing and strengthening method for a boss fillet weld. The composite material repairing and strengthening method comprises the following steps of: cleaning a to-be-repaired-and-strengthened steel tube surface within a width range, and sufficiently drying; coating the surface of a to-be-repaired-and-strengthened tube section with prepared epoxy resin sticky dipping glue; (3) according to strengthening width, the number of strengthening layers and groove requirements of a boundary, sequentially winding cut composite material fiber cloth and interlayer epoxy resin sticky dipping glue around steel tubes crosswise and spirally, wherein the composite material fiber cloth mutually overlaps by 50% during spiral winding; enabling the groove of the boundary to be a slope with an angle being 15+ / -5 degrees; and curing and naturally drying in air, thereby completing a composite material repairing and strengthening process for the boss fillet weld. The composite material repairing and strengthening method avoids safety accidents such as leakage in an operation process, especially avoids a phenomenon that cracks of a cross weld extend and fracture along a straight weld area of a performance main pipeline, and avoids occurrence of severe disasters and loss.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

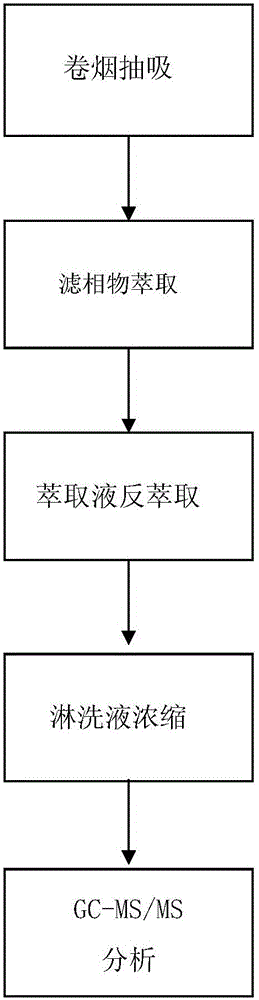

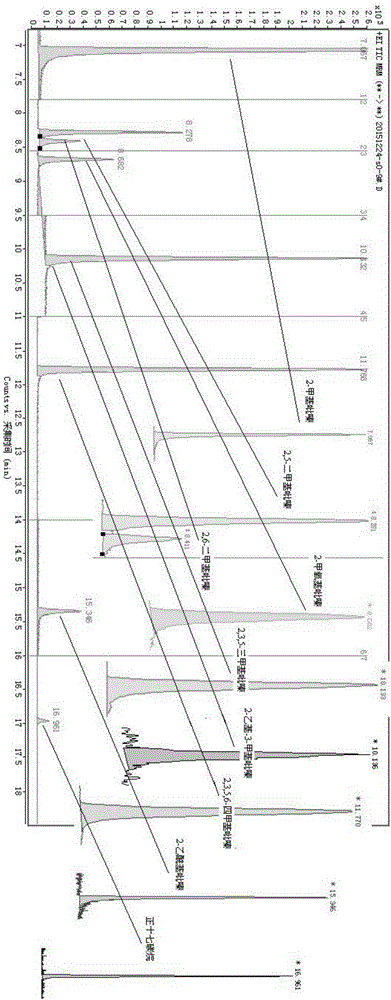

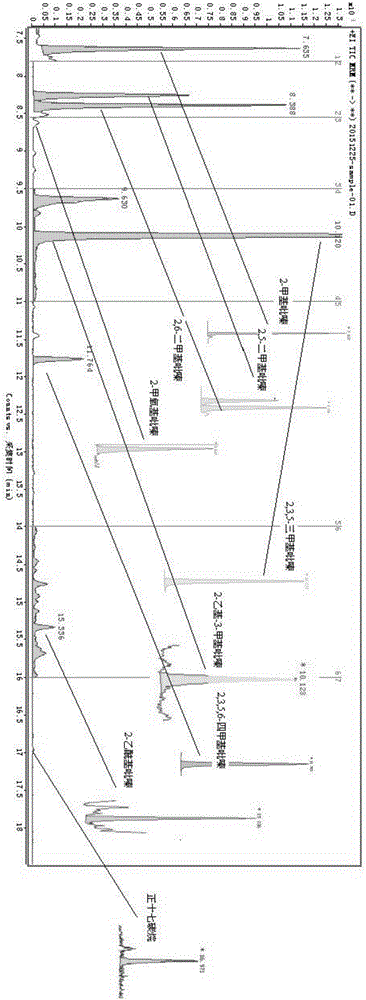

Method for quantitative analysis of main pyrazine flavor substances in cigarette mainstream smoke

ActiveCN105842374AGood effectSolve the impact of factors such as serious interference analysisComponent separationResponse sensitivityTetramethyl pyrazine

The invention discloses a method for quantitative analysis of main pyrazine flavor substances in cigarette mainstream smoke and relates to a method for gas chromatography-tandem mass spectrometer-based determination of eight main pyrazine flavor substances such as 2-methylpyrazine, 2, 5-dimethylpyrazine, 2, 6-dimethylpyrazine, 2-methoxypyrazine, 2, 3, 5-trimethylpyrazine, 2-ethyl-3-methylpyrazine, 2, 3, 5, 6-tetramethylpyrazine and 2-acetylpyrazine in cigarette mainstream smoke. The method comprises internal standard solution, standard work solution and sample solution preparation, gas chromatography-tandem mass spectrometry analysis and determination result calculation. The improved detection method can be operated simply, has response sensitivity and quantitative analysis accuracy, effectively reduces complex sample matrix-caused interference and is suitable for quantitative analysis of a trace quantity of a target object in a complex flue gas matrix.

Owner:CHINA TOBACCO JIANGSU INDAL

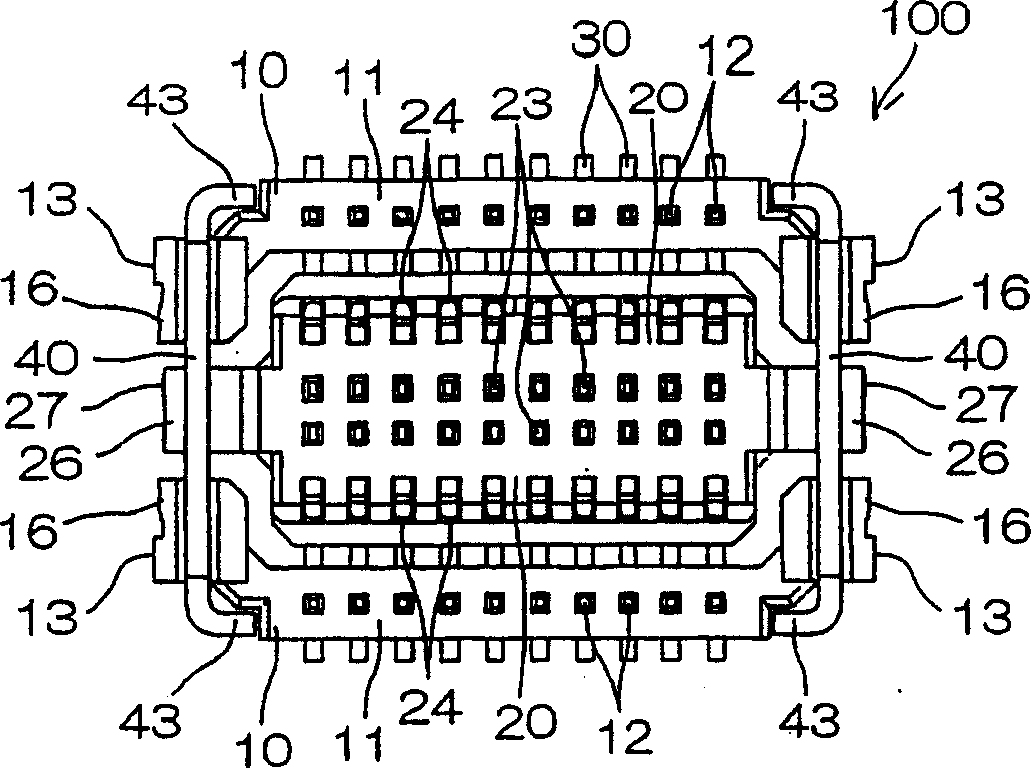

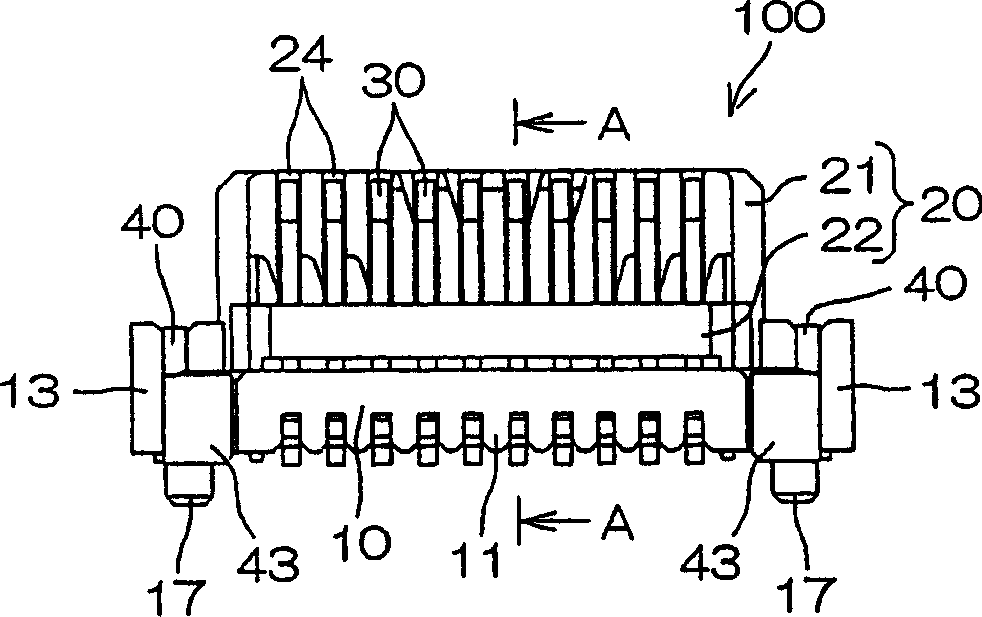

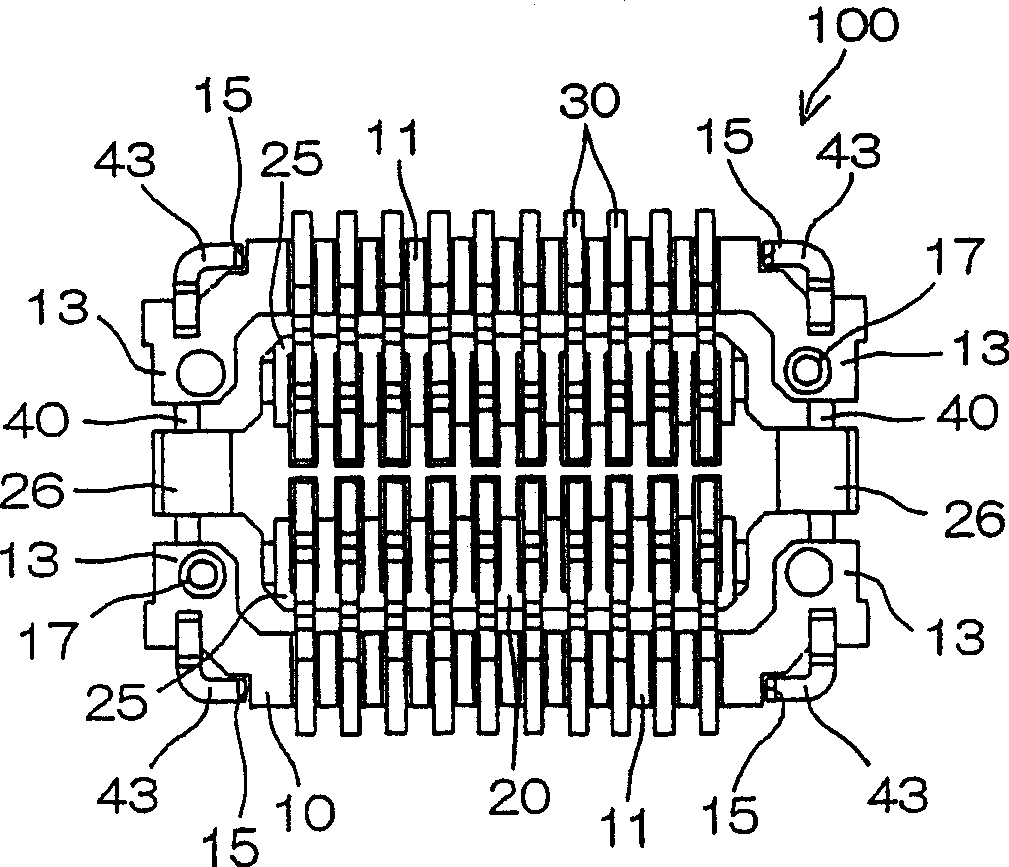

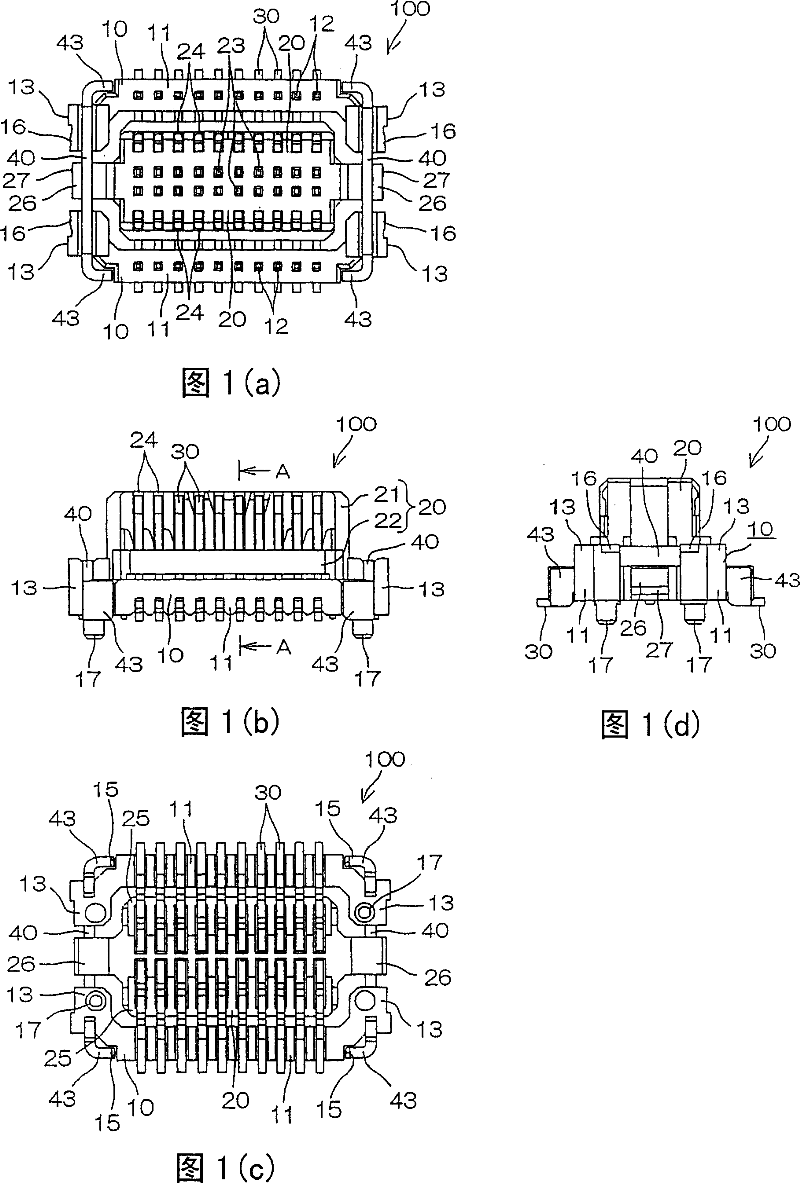

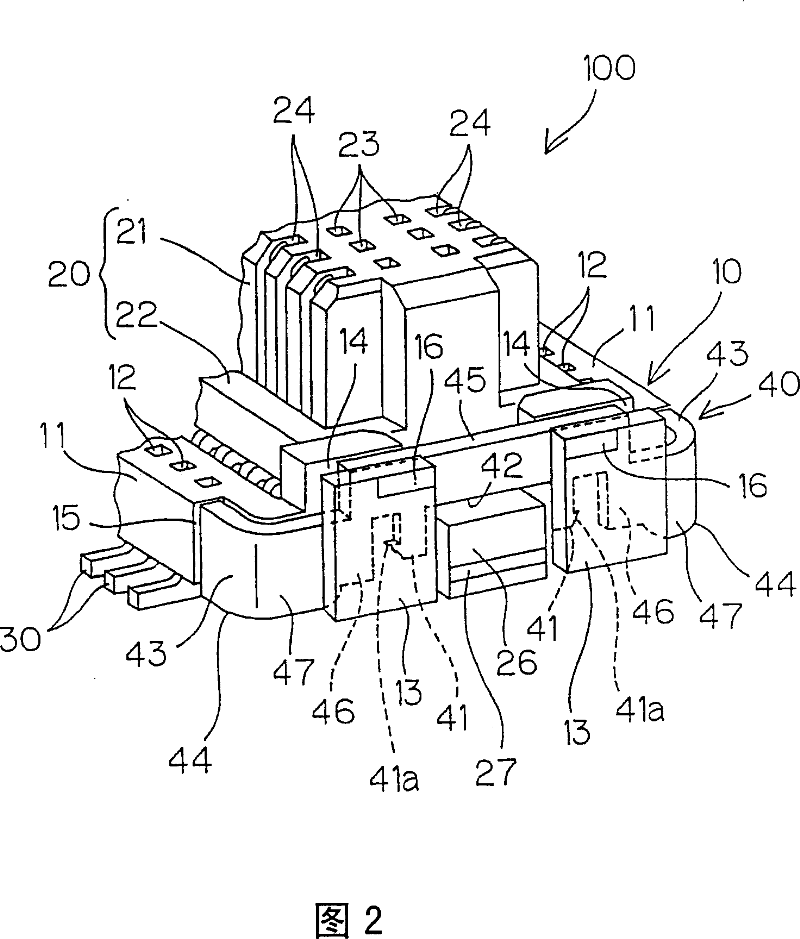

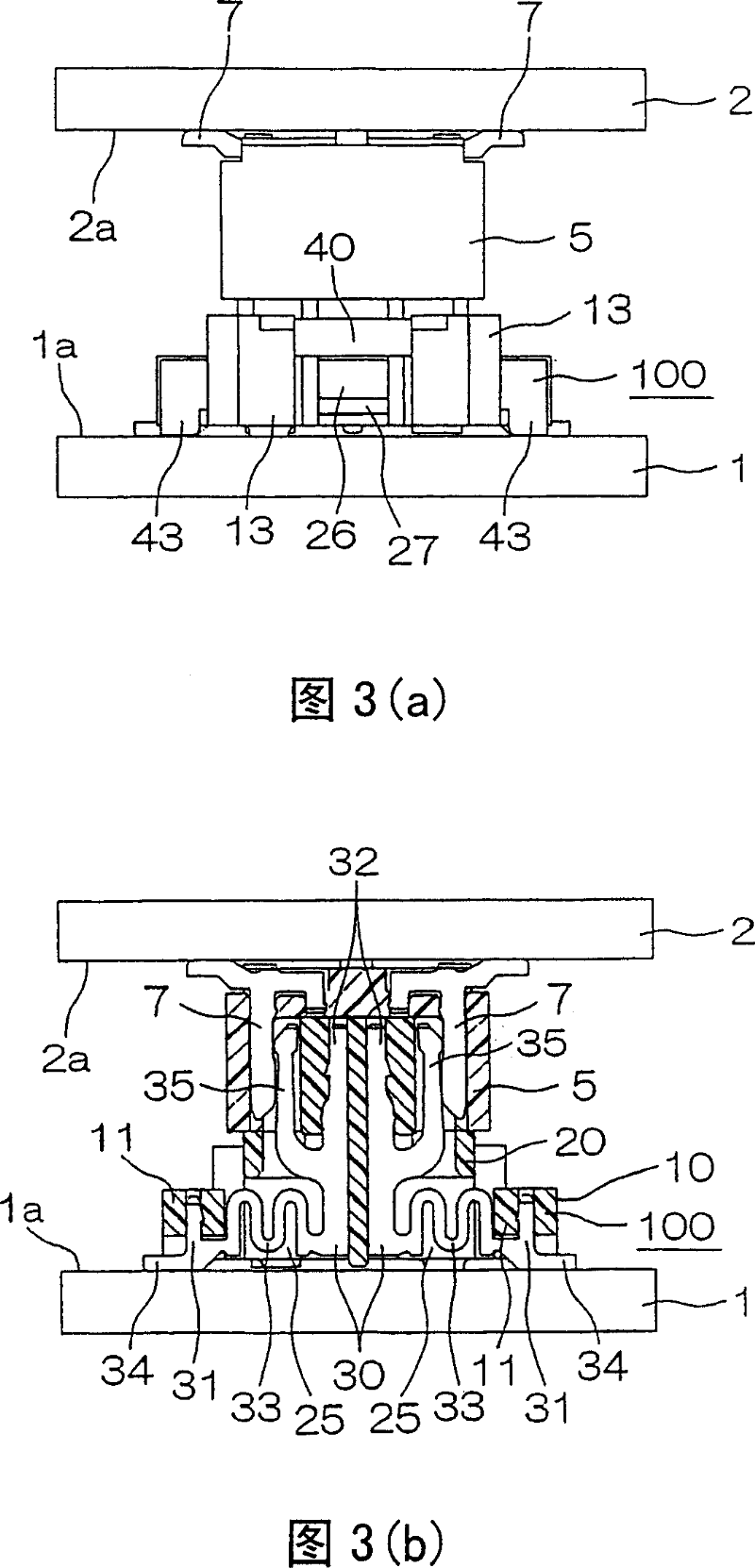

Reinforcing tab for movable connector and movable connector using the same

InactiveCN1732596APrecisely stipulatedUnreasonable phenomena such as poor brazing will not occurCoupling device detailsSolderingElectrical and Electronics engineering

A movable connector having a fixed housing fixed to a wiring board and a movable housing displaceably connected to the fixed housing, and a reinforcing tab for reinforcing the connector. The reinforcing tab comprises a connection part connected to the end part of the fixed housing, a pair of curved parts curved inward along the pair of side faces of the fixed housing, and a soldering part provided at the lower ends of the pair of curved parts and used for soldering to the wiring board.

Owner:JST MFG CO LTD

High-strength cast aluminum-silicon alloy material and application thereof to hydraulic shell

The invention relates to a high-strength cast aluminum-silicon alloy material and application thereof to a hydraulic shell. The alloy material comprises the following chemical components: 6.0 to 8.0 percent of Si, 0.2 percent of Fe, 0.3 to 0.6 percent of Cu, 0.2 percent of Mn, 0.55 to 0.75 percent of Mg, 0.2 percent of Zn, 0.1 to 0.2 percent of Ti, 0.01 to 0.02 percent of Sr and the balance of Al. according to the application of the alloy material to the files of automobiles, aviation and aerospace, the invention comprises: (1) according to the alloy material, the components are smelted and proportioned, and refined to remove gas to form a melt; (2) a casting process; and (3) a heat treatment process. Based on the alloy material and the heat treatment process, products can meet the using performance requirements.

Owner:上海嘉朗实业有限公司

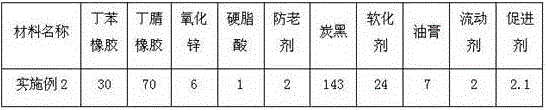

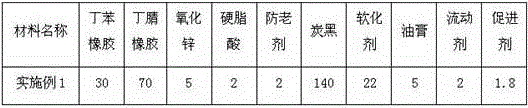

High-hardness rubber, and preparation method and application thereof

The invention provides a high-hardness rubber, and a preparation method and an application thereof. The high-hardness rubber is mainly prepared from, by mass, 30 parts of styrene butadiene rubber, 70 parts of nitrile rubber, 5-6 parts of zinc oxide, 1-2 parts of stearic acid, 2 parts of an antioxidant, 140-145 parts of carbon black, 20-25 parts of a softener, 5-7 parts of an ointment, 2 parts of a flow agent and 1.8-2.2 parts of a promoter. The preparation method is characterized in that the high-hardness rubber is prepared through rubber mixing, vulcanization, trimming and examination. The raw material proportioning and the preparation method of the high-hardness rubber effectively improve the integral performances of the above product, so the high-hardness rubber prepared in the invention has good oil, wear and ageing resistance, and can be applied to make V-shaped rubber seal rings in order to solve the technical problem of unable simultaneous use requirement reaching of the oil resistance, the wear resistance and the ageing resistance of present high-hardness V-shaped rubber seal rings and to make the V-shaped rubber seal rings have high reliability and long service life.

Owner:咸阳时代特种密封科技有限公司

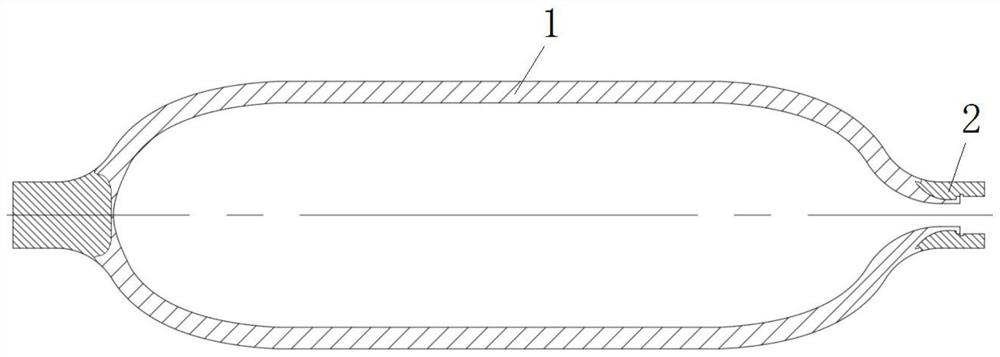

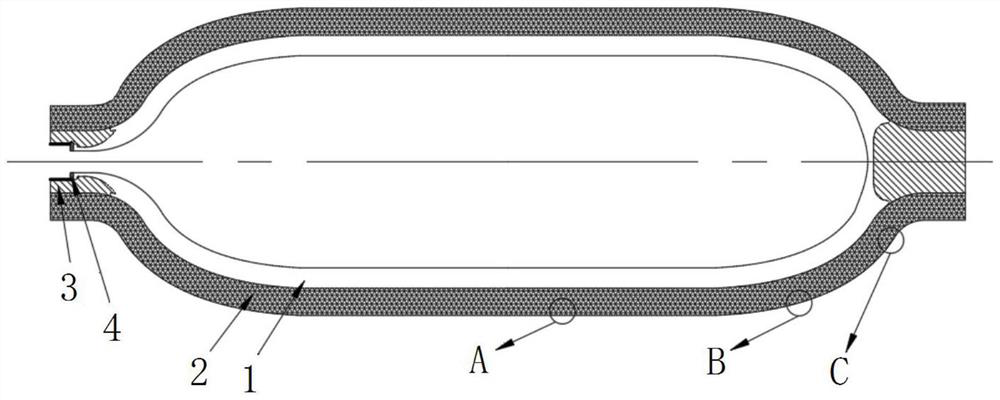

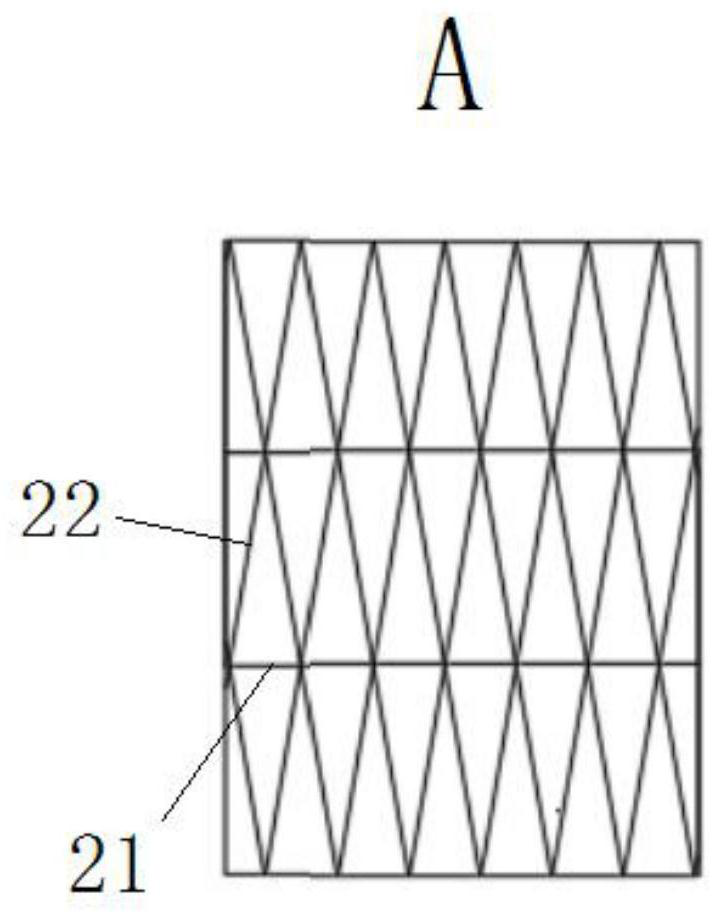

Preparation method of woven gas cylinder and woven gas cylinder

ActiveCN113478791AImprove axial strengthIncrease fiber densityVessel manufacturingVessel wallsFiberCeramic materials

The invention discloses a preparation method of a woven gas cylinder and the woven gas cylinder. The preparation method comprises the following steps that S1, an inner container with a gentle radian at an end socket is prepared; S2, a plurality of fiber layers are woven on the outer surface of the inner container, the fiber layers are evenly distributed on the outer surface of the inner container, the smooth sand phenomenon is avoided, the weaving angle of the fiber layers changes along with the radius change of the weaving portion, at the polar hole, the weaving angle is a small angle, and the distance between the axial fibers is reduced by weaving at the small angle, so that the condition that the radius at the polar hole is small is adapted, at the end socket section, the weaving angle is increased along with the increase of the radius of the weaving part, and in the cylinder body section, the weaving angle of the cylinder body section under the same fiber layer is maximum and is kept unchanged; S3, resin is poured, cured and formed; and S4, air tightness detection, grinding and polishing treatment are carried out. According to the preparation method, the weaving angle is changed along with the radius change of the weaving part, so that the fiber layers can be uniformly distributed on the outer surface of the inner container, the sand slipping phenomenon is avoided, and the gas cylinder is ensured to have enough strength and strength uniformity.

Owner:HEFEI UNIV OF TECH

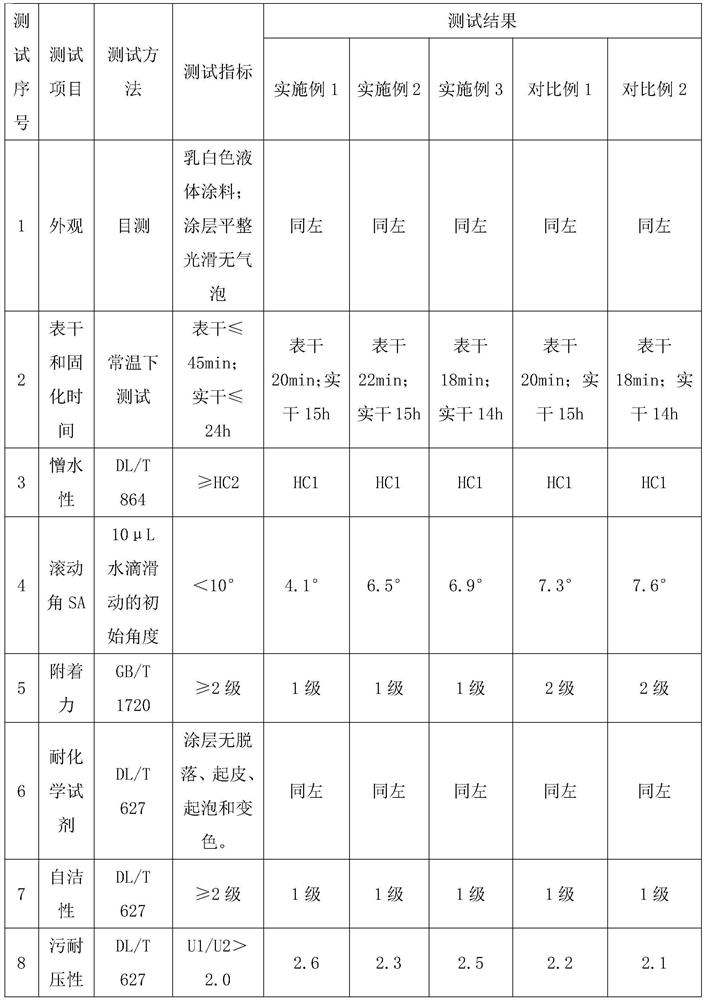

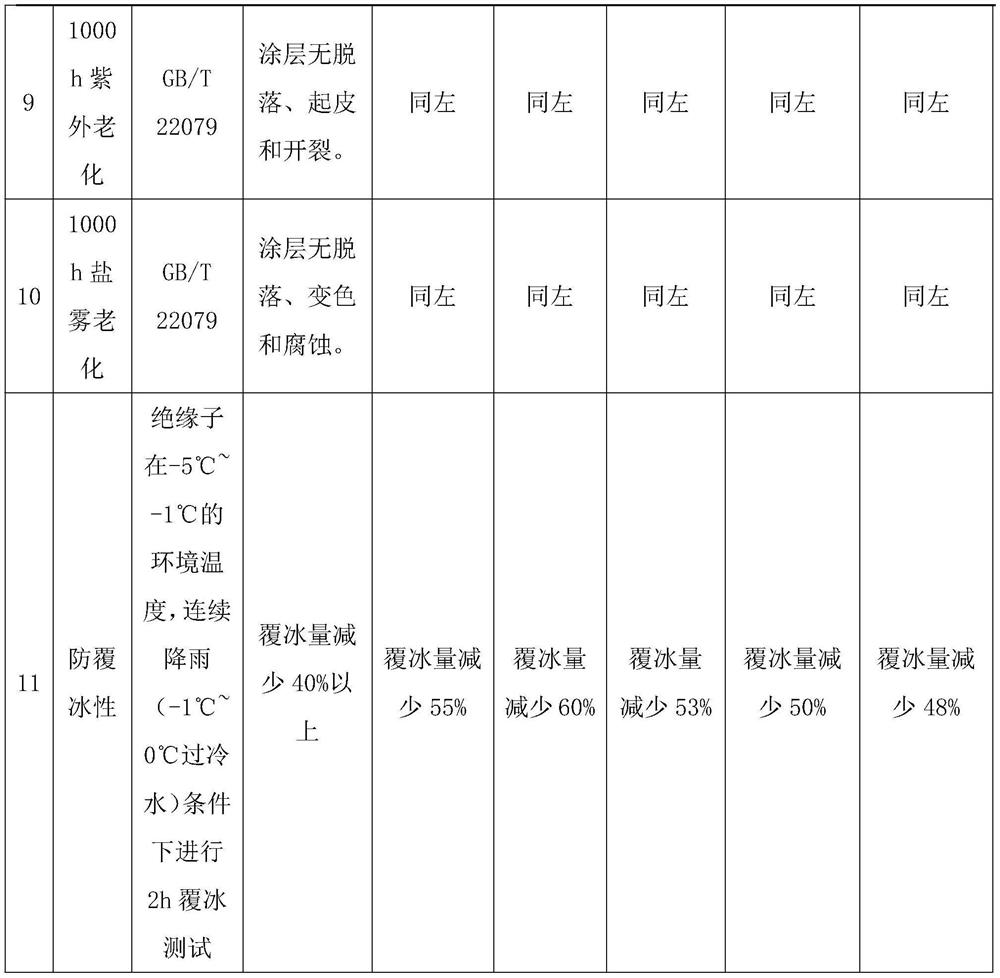

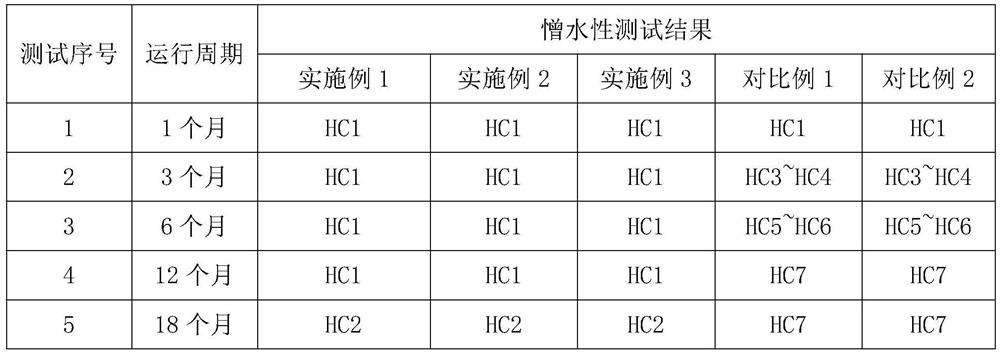

High-self-cleaning super-smooth anti-pollution flashover coating and preparation method thereof

InactiveCN113308150AImprove self-cleaningGood super slipperyAnti-corrosive paintsAerosol MistPolytetrafluoroethylene

The invention belongs to the technical field of coatings, and particularly relates to a high-self-cleaning super-smooth anti-pollution flashover coating and a preparation method thereof. The high- self-cleaning type super-smooth anti-pollution flashover coating is characterized by being prepared from the following raw materials in percentage by mass: 4 to 12 percent of lubricating oil, 10 to 15 percent of fluorocarbon resin, 68 to 80 percent of a solvent, 1 to 6 percent of hydrophobic SiO2, 1 to 5 percent of polytetrafluoroethylene (PTFE) and 0.2 to 1.5 percent of a silane coupling agent. A coating layer formed by spraying the paint through an aerosol can has good self-cleaning property, super-smoothness, pollution flashover resistance and icing resistance; and good corrosion resistance and aging resistance are achieved.

Owner:武汉露能科技有限公司

Light straw concrete wall material and preparation method thereof

The invention provides a light straw concrete wall material and a preparation method thereof. A standard mixture ratio of water to cement to ceramsite to sand is 50:100:106:123, wherein the standard mixture ratio is only a reference standard ratio and is not adopted as an actual operation ratio. Then, with the mass percentage of the cement as the standard, 1%-3% of the straw is added, and 5%-15% of the cement is replaced with fly ash. According to the volume percentage, the replacement rate of the aggregate is 0.25% or 50%, 0.25% or 50% of the ceramsite is replaced with stones, and meanwhile,the proportion of the sand is 38% or 40% or 42%. The problem that some straw piles are difficult to dispose can be solved, the weight of a wall body is reduced, and the requirements for the mechanicalproperties of the straw concrete wall material are met at the same time.

Owner:四川省三台县波特兰商品砼有限公司

Anti-microbial fabric

InactiveCN109514935AStrong adsorption capacityPowerful far infrared functionSynthetic resin layered productsClothingsPlain weaveHoneycomb

The invention provides an anti-microbial fabric. The anti-microbial fabric comprises an inner layer fabric and an outer layer fabric in turn from inner to outer; the inner layer fabric and the outer layer fabric are overlapped and connected with each other in the manner of yarn stitching; the inner layer fabric has a plain weave structure; the outer layer fabric has a concavo-convex honeycomb meshed structure formed by rib stitches and tuck stitches; the rib stitches are on lower side while the tuck stitches are on upper side; suspending arcs of two adjacent tuck loops of the tuck stitches areoverlapped; a convex part is formed by overlapped parts of suspending arcs of two alternated continuous horizontal tuck stitches; a concave part is formed by normally weaved loops. The anti-microbialfabric provided by the invention has the functions of adsorption purification, deodorizing, antibiosis, sterilization, mite dispelling, and the like.

Owner:SWOTO PROTECTION & TECH CO LTD +1

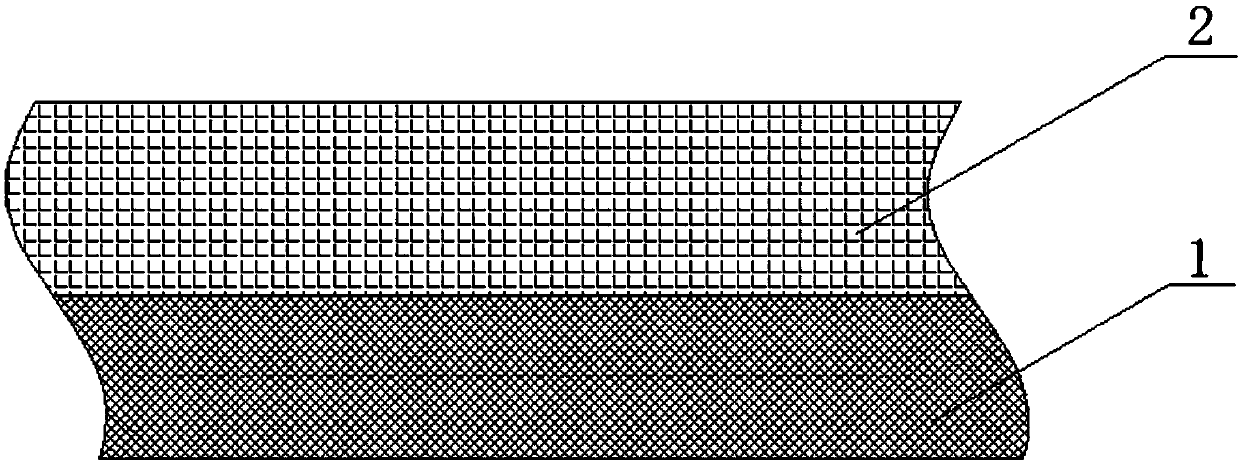

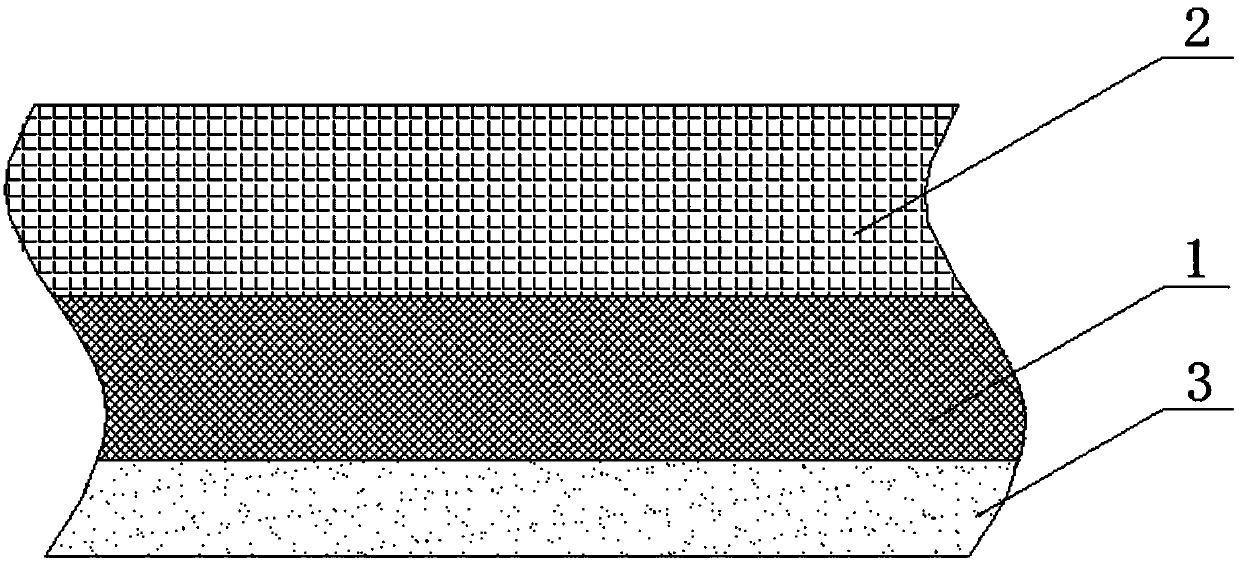

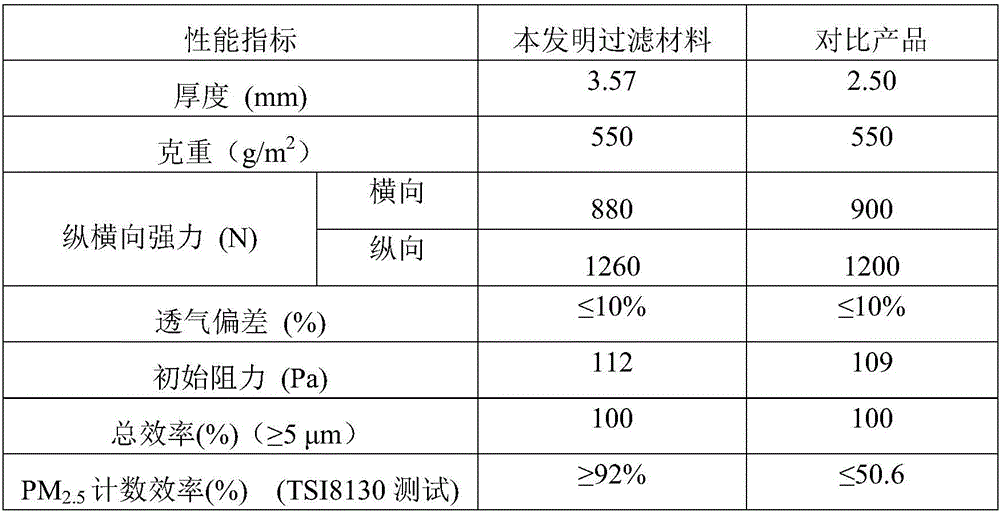

Filtering material for high-temperature smoke and dust and preparation method thereof

ActiveCN106422526ALow costMake up for efficiencyDispersed particle filtrationSynthetic resin layered productsFiberGlass fiber

The invention discloses a filtering material for high-temperature smoke and dust and a preparation method thereof. The filtering material is composed of five layers of symmetric composite structures and comprises high-temperature-resistant fiber nonwoven cloth on the outermost layers, high-temperature-resistant fiber woven cloth on the layers close to the outermost layers and superfine glass fiber nonwoven cloth on the middle layer. The preparation method includes: using the superfine glass fiber nonwoven cloth as a core filtering layer and composites of the high-temperature-resistant nonwoven cloth and the high-temperature-resistant woven cloth as upper and lower coating layers of the superfine glass fiber nonwoven cloth; reinforcing through ultrasonic binding or stitching with high-temperature-resistant stitching lines to prepare the filtering material. The filtering material can realize long-acting, low-resistance and high-accuracy filtering, so that energy consumption and raw material cost during use are lowered greatly.

Owner:榆林天盛缘玻璃纤维科技有限公司

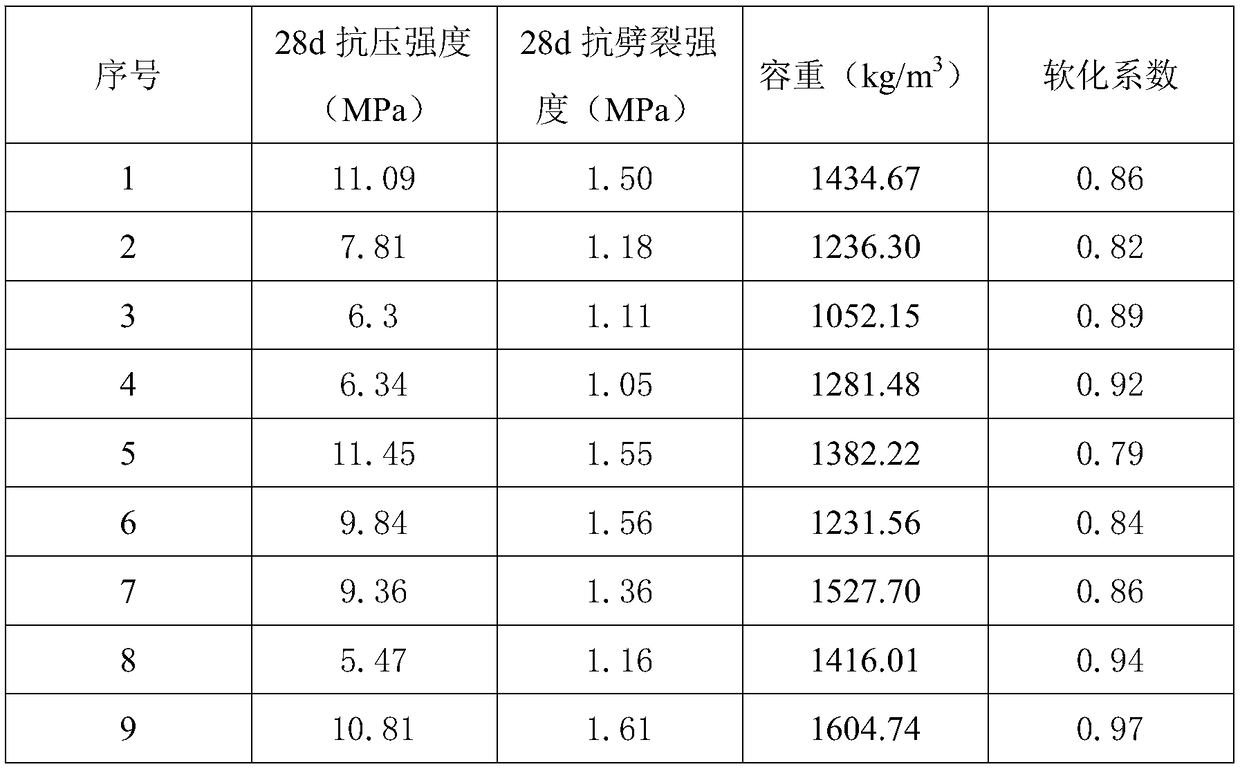

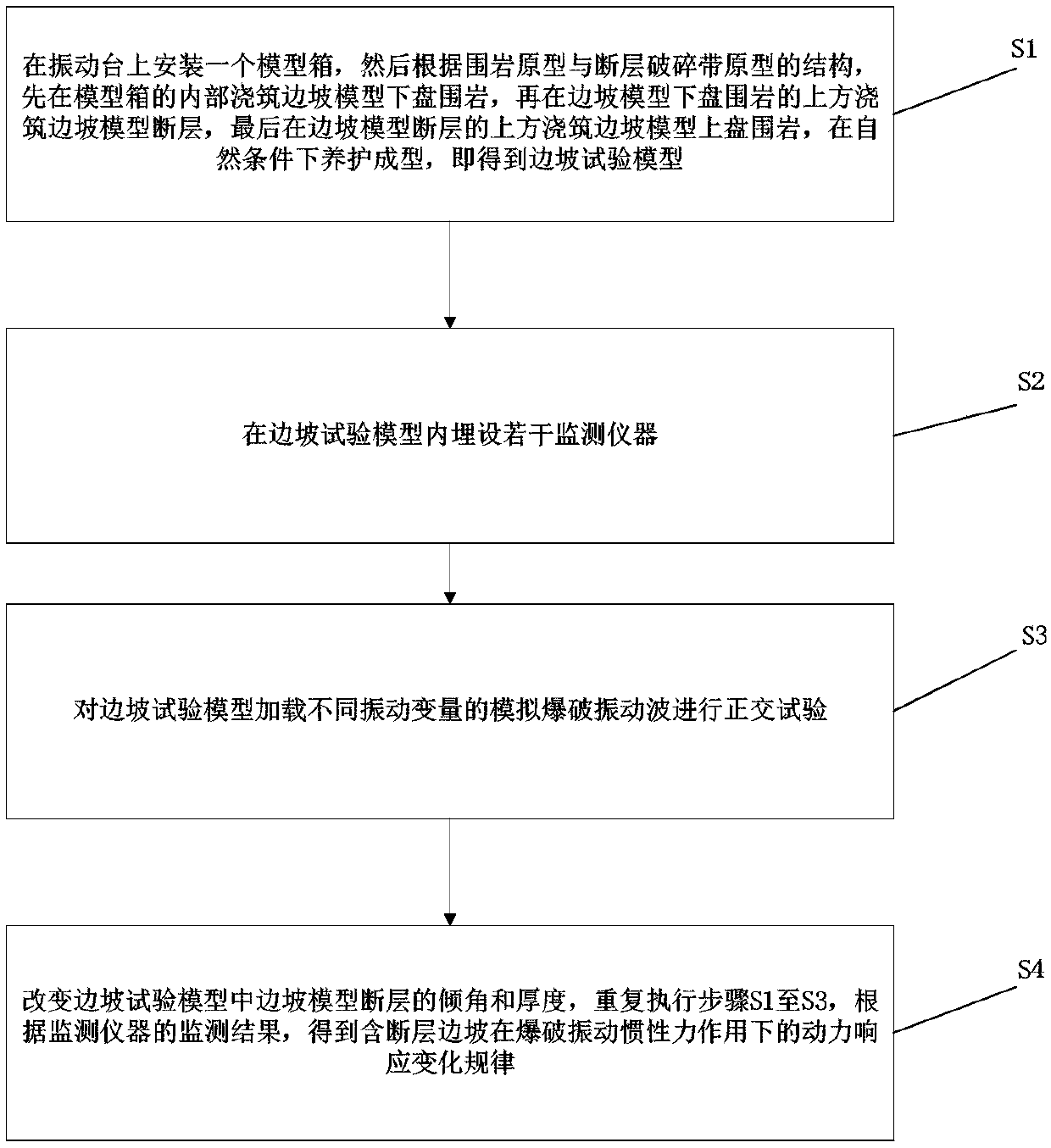

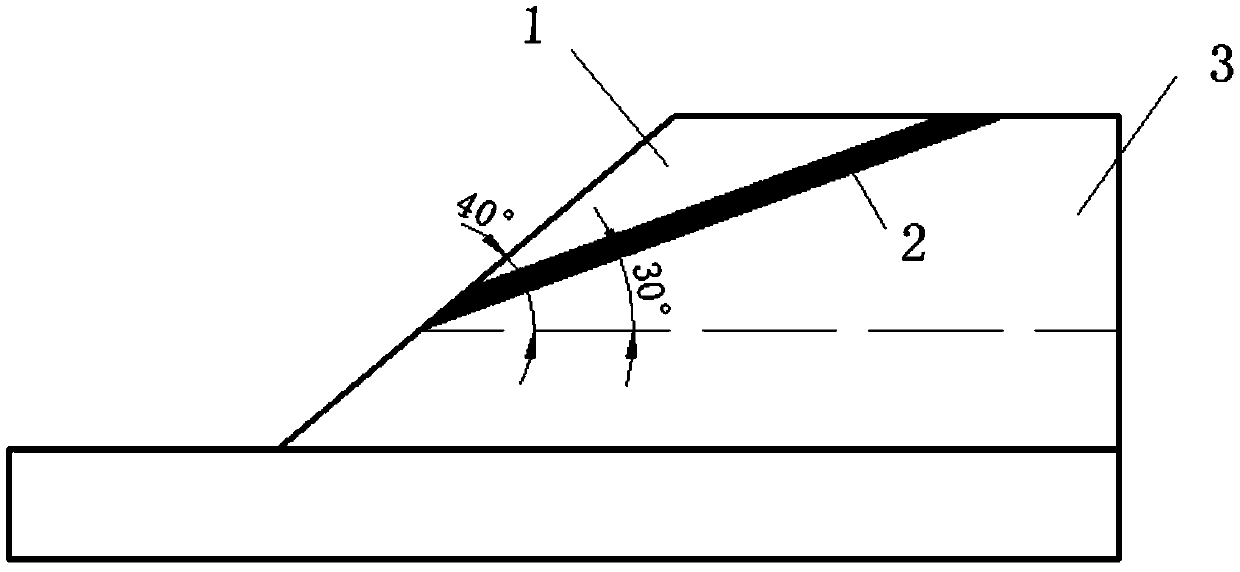

Method for researching dynamic response characteristics of fault slope under blasting inertia force effect

InactiveCN109580912AEasy to operateMake up strengthEarth material testingBlasting vibrationEngineering

The invention provides a method for researching dynamic response characteristics of a fault slope under the blasting inertia force effect. The method comprises the following steps that a model box ismounted on a vibration table, then, according to the structures of a surrounding rock prototype and a fault crushed zone prototype, slope model footwall surrounding rock is poured in the model box through a surrounding rock similar material firstly, then a slope model fault is poured on the upper part of the slope model footwall surrounding rock through a fault crushed zone similar material, finally, slope model hanging wall surrounding rock is poured on the upper part of the slope model fault through a surrounding rock similar material, curing forming is conducted under the natural condition,and thus a slope test model is obtained; a plurality of monitoring instruments are embedded in the slope test model; blasting simulation vibration waves with different vibration variables are loadedto the slope test model for an orthogonal test; and the inclination and thickness of the slope model fault in the slope test model are changed, the steps are executed repeatedly, and according to themonitoring result of the monitoring instruments, the dynamic response changing rule of the fault-containing slope under the blasting vibration inertia force effect is obtained.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

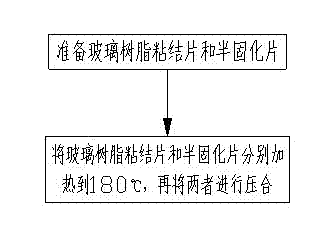

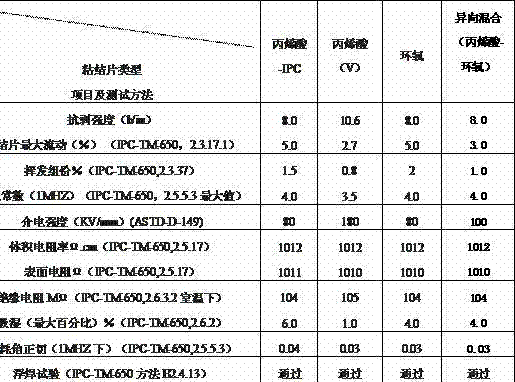

Double-sided bonding sheet for hard and soft combined plate and manufacturing method thereof

ActiveCN102950847AMake up strengthPerfect resistance to high temperature thermal shockSynthetic resin layered productsLaminationEngineeringResin bonding

The invention discloses a double-sided bonding sheet for a hard and soft combined plate and a manufacturing method thereof. The double-sided bonding sheet is formed by compounding two bonding sheets which are respectively a glass resin bonding sheet and a semi-solidified sheet. The manufacturing method comprises the following steps: a) preparing materials: the glass resin bonding sheet and the semi-solidified sheet, and b) compounding: respectively heating the glass resin bonding sheet and the semi-solidified sheet to be at 180 DEG C, and then pressing the glass resin bonding sheet and the semi-solidified sheet, thereby obtaining the double-sided bonding sheet. In such a mode, the defects of insufficient bonding strength and irregular gumming of the hard and soft combined plate are overcome by the double-sided bonding sheet for the hard and soft combined plate, and the hard and soft combined plate has perfect high-temperature thermal shock resistance and stable use effect under a severe environment.

Owner:江西强达电路科技有限公司

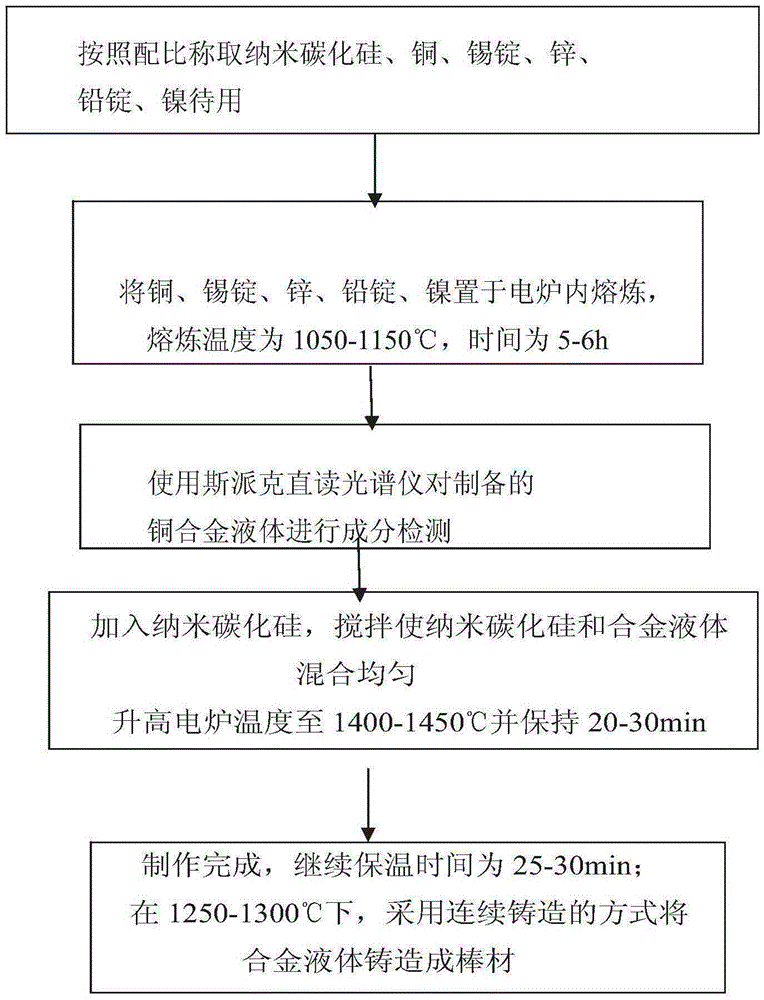

High-strength nanometer silicon carbide strengthening copper-based composite material and preparing method thereof

The invention relates to a high-strength nanometer silicon carbide strengthening copper-based composite material and a preparing method thereof. The high-strength nanometer silicon carbide strengthening copper-based composite material used for a high-load impeller is prepared from, by volume, 1.2-3.5% of nanometer silicon carbide and 96.5-98.8% of copper alloy ZCuSn10Zn2. Preparing of the high-strength nanometer silicon carbide strengthening copper-based composite material used for the high-load impeller includes the steps of stirring, smelting, casting and the like. According to the high-strength nanometer silicon carbide strengthening copper-based composite material used for the high-load impeller, the beneficial effects that the nanometer silicon carbide is high in hardness, good in wear resistance and self lubrication, high in heat conductivity, low in heat expansion coefficient, high in high-temperature strength and the like are utilized, the original corrosion resistance and machinable performance of the copper alloy ZCuSn10Zn2 can be ensured, meanwhile, the strength and hardness of the copper alloy ZCuSn10Zn2 are improved, and therefore the service life of the high-strength nanometer silicon carbide strengthening copper-based composite material in an important impeller accessory is prolonged.

Owner:SUZHOU RICHMOND ADVANCED MATERIAL TECH TRANSFER CO LTD

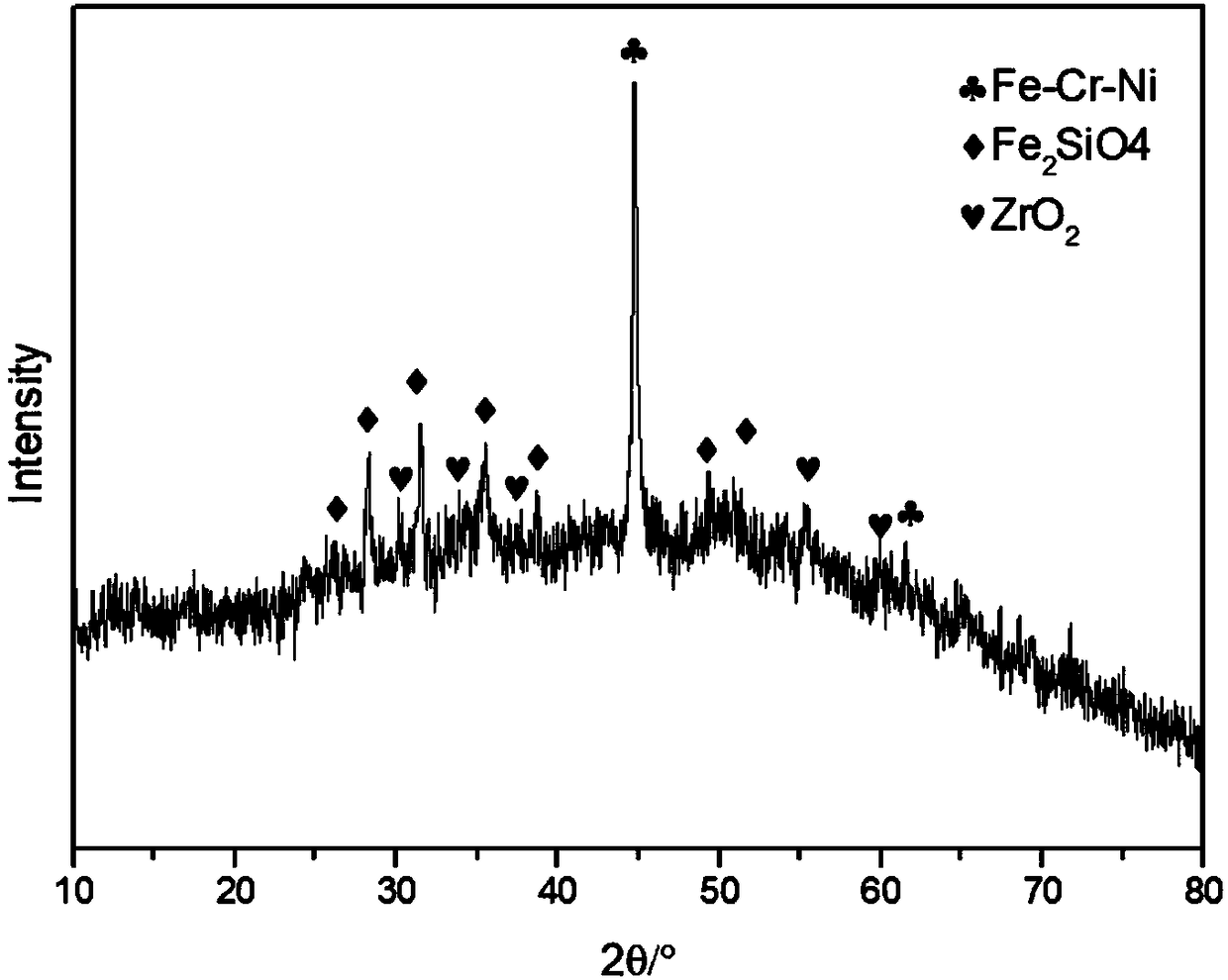

C/C-ZrC-SiC surface-layer iron-based alloy modified composite material and preparation method thereof

ActiveCN108277444AHas high temperature resistance to ablationAbility to resist ablation at high temperatureHot-dipping/immersion processesSurface layerUltimate tensile strength

The invention discloses a C / C-ZrC-SiC surface-layer iron-based alloy modified composite material and a preparation method thereof. The composite material comprises a C / C-ZrC-SiC matrix and a modifiedlayer; and the modified layer is an iron-based high-temperature alloy and uniformly fills and seals the surface layer of the matrix through a low-pressure suspension infiltration technology. A preparation technology for the composite material is characterized in that a blank is immersed into an iron-based high-temperature alloy melt to be subjected to low-pressure suspension infiltration, and themelt temperature is controlled to be 1545-1635 DEG C so as to obtain the C / C-ZrC-SiC surface-layer iron-based high-temperature alloy modified composite material. The composite material has the advantages that the iron-based high-temperature alloy is uniformly distributed on the surface layer of the matrix, the surface density is increased, the heat dissipation quantity is large in the evaporationprocess, so that the surface temperature of the matrix can be lowered, in addition, high-temperature and high-speed air flow washout can be resisted, the damage to the matrix caused by mechanical erosion can be avoided, and meanwhile, the high-temperature creep resistant performance of the iron-based high-temperature alloy is excellent, so that the defects of the matrix in strength and toughness can be overcome. The preparation method has the advantages of being simple in technological process, short in period, wide in application size range of workpieces and novel in ablation mechanism.

Owner:CENT SOUTH UNIV

Reinforcing tab for movable connector and movable connector using the same

InactiveCN100356631CMake up strengthInhibit sheddingCoupling device detailsTwo-part coupling devicesSolderingElectrical and Electronics engineering

A movable connector having a fixed housing fixed to a wiring board and a movable housing displaceably connected to the fixed housing, and a reinforcing tab for reinforcing the connector. The reinforcing tab comprises a connection part connected to the end part of the fixed housing, a pair of curved parts curved inward along the pair of side faces of the fixed housing, and a soldering part provided at the lower ends of the pair of curved parts and used for soldering to the wiring board.

Owner:JST MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com