Light straw concrete wall material and preparation method thereof

A concrete and straw technology, applied in the field of green building materials, can solve the problems of reducing the bulk density of the wall body and difficult to handle straw stacking, and achieve the effects of increasing the ductility, inhibiting the expansion of cracks, and reducing the basic treatment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1: Cut the dried rape stalks into 2-4 cm sections, then put them into an alkali solution with a mass concentration of 3.5% and soak them for 5-10 hours for modification treatment, and then dry them in the air; Mesh-sized flocculent straw powder.

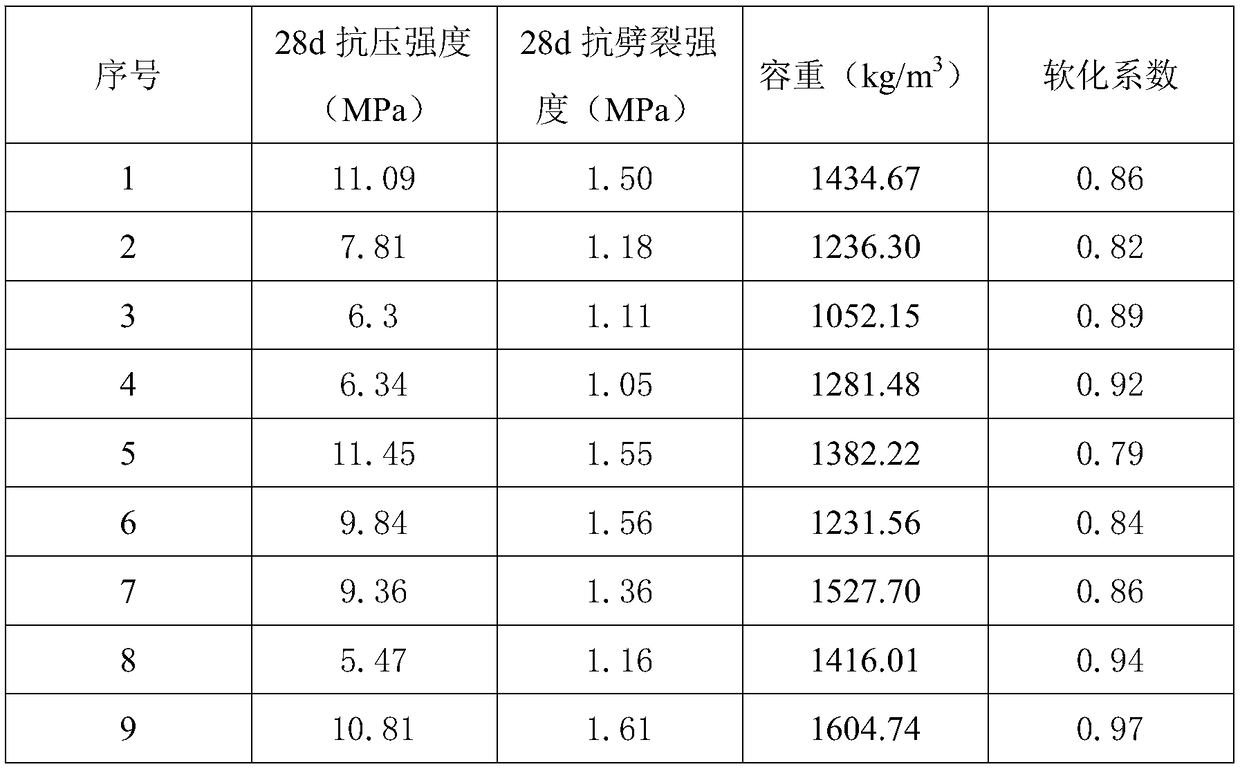

[0036] Step 2. The weight of the standard cement is 100kg according to the base mixing ratio. The cement is composed of 95% composite Portland cement and 5% fly ash. Based on the total mass of composite Portland cement and fly ash 100kg, take water as its weight 50% of straw, 1% of 4-16 mesh straw, 106% of shale ceramsite, 123% of sand, and 0% of stone. After demoulding, put the demoulded specimen into the standard curing room, and cure it for 28 days under the conditions of temperature 20±2°C and relative humidity above 95%, to obtain a new type of straw concrete wall material with a bulk density of 1434.67Kg / m 3 , 28d compressive strength reached 11.09MPa, 28d splitting strength reached 1.50MPa, 48h after water intru...

Embodiment 2

[0038] Step 1. Cut the dried rape stalks into 2-4cm pieces, soak them in 3.5% alkali solution for 5-10 hours, and then dry them in the air; turn on the pulverizer and crush the stalks into 4-mesh sized straw particles .

[0039] Step 2. The weight of the standard cement is 100kg according to the base mixing ratio. The cement is composed of 90% composite Portland cement and 10% fly ash. Based on the total mass of composite Portland cement and fly ash 100kg, take water as its weight 50% of straw, 2% of 4-16 mesh straw, 103% of shale ceramsite, 130% of sand, and 0% of stone. After demoulding, put the demoulded specimen into the standard curing room, and cure it for 28 days at a temperature of 20±2°C and a relative humidity above 95%, to obtain a new type of straw concrete wall material with a bulk density of 1236.30Kg / m3, 28d compressive strength reaches 7.81MPa, 28d splitting strength reaches 1.18MPa, 48h after water intrusion, compressive strength is 6.48MPa, softening coeffi...

Embodiment 3

[0041] Step 1: Cut the dried rape stalks into small pieces of 2 to 4 cm, soak them in 3.5% alkali solution for 5 to 10 hours, and then dry them; turn on the pulverizer and crush the straws into 4-mesh straw particles .

[0042] Step 2: The weight of standard cement is 100kg according to the base mixing ratio. The cement is composed of 85% composite portland cement and 15% fly ash. Based on the total mass of composite portland cement and fly ash 100kg, take water as its weight. 50%, 4-16 mesh straw 3%, shale ceramsite 99%, sand 136%, gravel 0%. After fully stirring and mixing, add waterproofing agent and pour in the mold; after pouring is completed, 3-5 days after condensation Remove the mold, and put the demoulded specimen into the standard curing room, and cure it for 28 days at a temperature of 20±2°C and a relative humidity above 95%, to obtain a new type of straw concrete wall material with a bulk density of 1052.15Kg / m 3 , 28d compressive strength reached 6.3MPa, 28d ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com