Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

611 results about "Titanium diboride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium diboride (TiB₂) is an extremely hard ceramic which has excellent heat conductivity, oxidation stability and resistance to mechanical erosion. TiB₂ is also a reasonable electrical conductor, so it can be used as a cathode material in aluminium smelting and can be shaped by electrical discharge machining.

Short fiber-particle synergetically-reinforced copper-based composite material and preparation method thereof

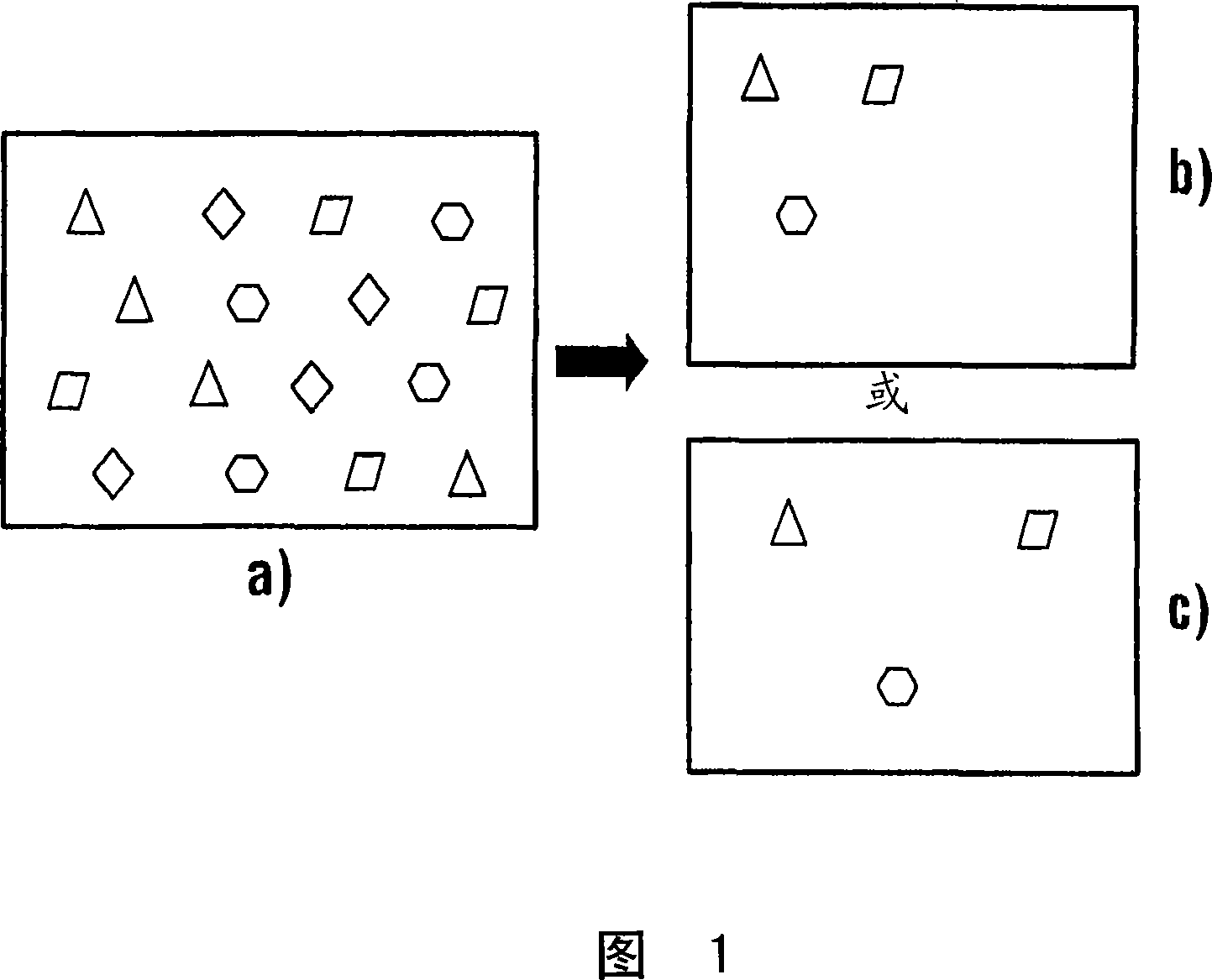

The invention relates to a copper-based composite material, and particularly relates to a short fiber-particle synergetically-reinforced copper-based composite material which is prepared through powder metallurgy. Short fibers and particles are used as reinforced phases, the content of the short fiber is 0.1-0.1 wt%, and the content of reinforcement particles is 0.1-10 wt%. The short fibers can be carbon nanotubes, carbon nanofibers, ceramic short fibers, and the like, and the particles used as reinforced phases can be aluminum oxide, zirconium oxide, magnesium oxide, titanium dioxide, silicon carbide, titanium carbide, tungsten carbide, silicon nitride, aluminum nitride, titanium nitride, titanium diboride, Ti3SiC2, and the like. The composite material is prepared through the steps of mixing, forming, sintering and processing, and the room temperature and the high temperature strength of the composite material can be increased by more than 3 times in comparison with those of pure copper; the electrical conductivity of the composite material can reach more than 80% of that of pure copper; the thermal conductivity of the composite material can reach more than 70% of that of pure copper; the coefficient of friction of the composite material can be reduced to be below 70% of that of pure copper; and the wear rate of the composite material can be reduced to be below 50% of that of pure copper.

Owner:UNIV OF SCI & TECH BEIJING

Lightweight dry refractory

A dry refractory composition having superior insulating value. The dry refractory composition also may have excellent resistance to molten metals and slags. The composition includes filler lightweight material, which may be selected from perlite, vermiculite, expanded shale, expanded fireclay, expanded alumina silica hollow spheres, bubble alumina, sintered porous alumina, alumina spinel insulating aggregate, calcium alumina insulating aggregate, expanded mulllite, cordierite, and anorthite, and matrix material, which may be selected from calcined alumina, fused alumina, sintered magnesia, fused magnesia, silica fume, fused silica, silicon carbide, boron carbide, titanium diboride, zirconium boride, boron nitride, aluminum nitride, silicon nitride, Sialon, titanium oxide, barium sulfate, zircon, a sillimanite group mineral, pyrophyllite, fireclay, carbon, and calcium fluoride. The composition also may include dense refractory aggregate, which may be selected from calcined fireclay, calcined Chamotte, a sillimanite group mineral, calcined bauxite, pyrophyllite, silica, zircon, baddeleyite, cordierite, silicon carbide, sintered alumina, fused alumina, fused silica, sintered mullite, fused mullite, fused zirconia, sintered zirconia mullite, fused zirconia mullite, sintered magnesia, fused magnesia, sintered spinel, and fused spinel refractory grog, a heat activated bonding agent, and a dust suppressant.

Owner:ALLIED MINERAL PROD

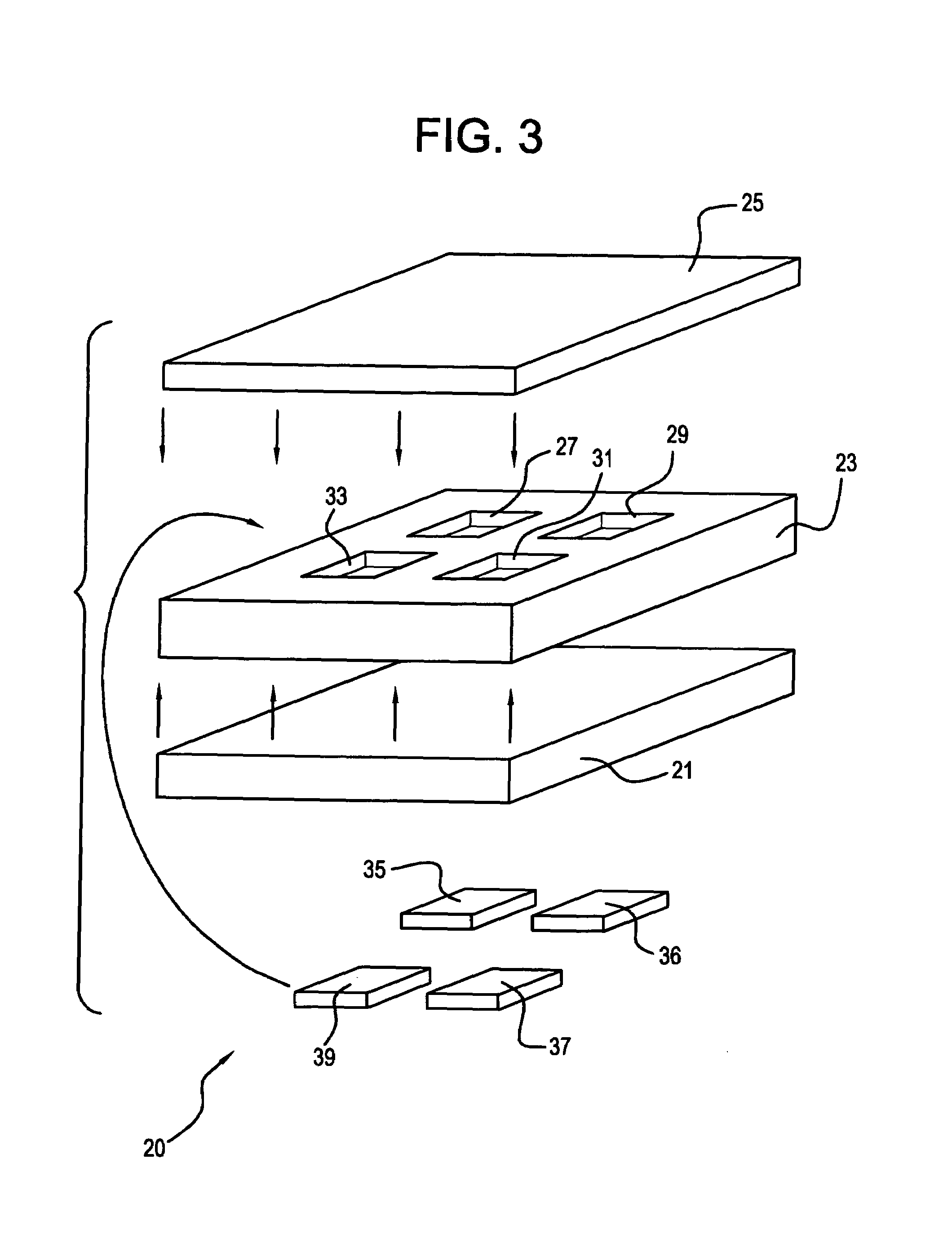

Coated pressing surfaces for abrasion resistant laminate and making laminates therefrom

A press plate for producing decorative laminate from resin impregnated paper, with alumina particles on its pressing surface, is coated with diborides selected from the group consisting of hafnium diboride, molybdenum diboride, tantalum diboride, titanium diboride, tungsten diboride, vanadium diboride, or zirconium diboride or mixtures thereof for making the press plate resistant to scratching. The preferred diborides are titanium and zirconium. The most preferred diboride is titanium. The color, gloss and surface appearance of laminate pressed with a titanium diboride coated press plate is substantially the same as laminate pressed with the press plate before coating.

Owner:WILSONART

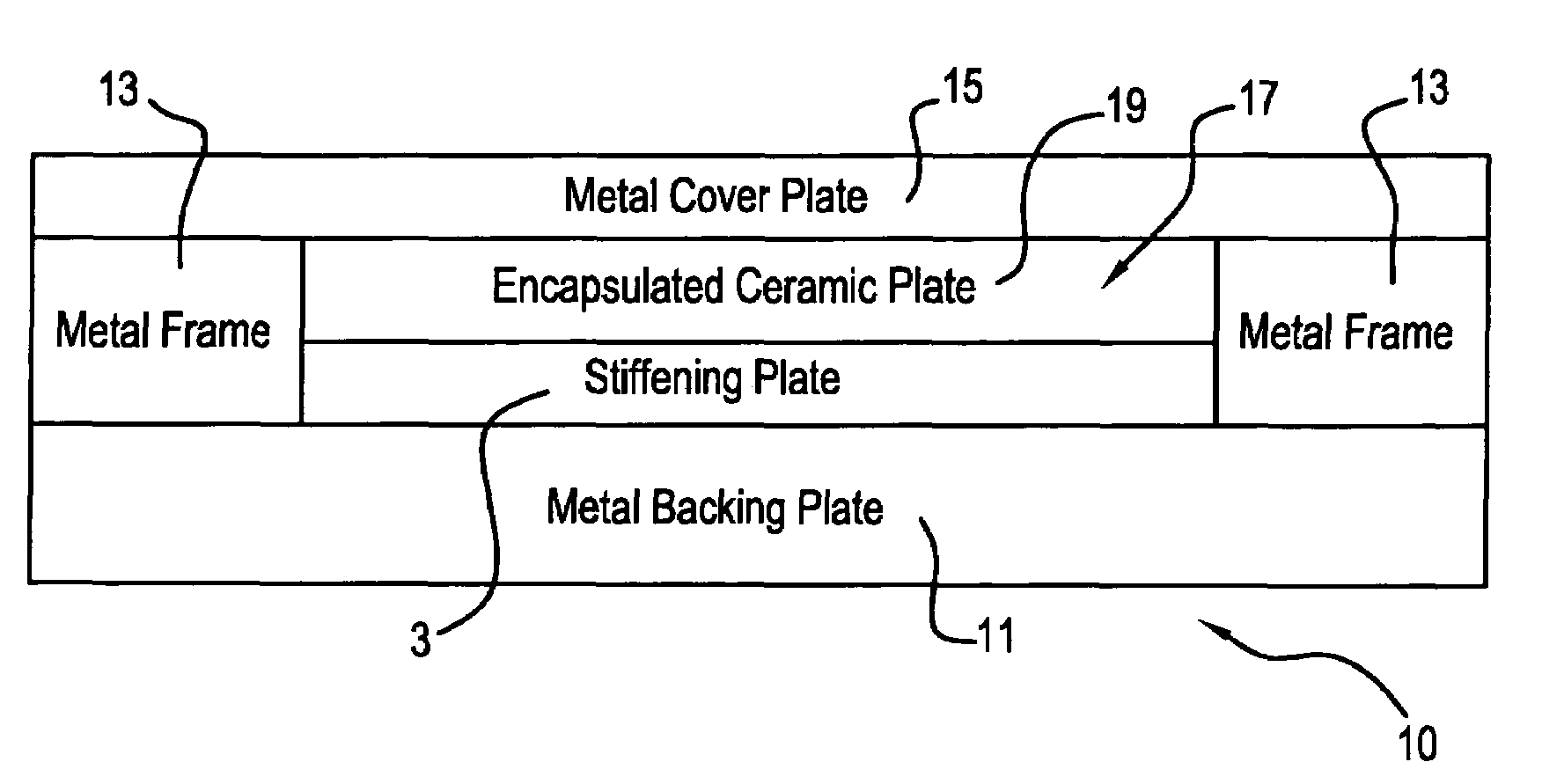

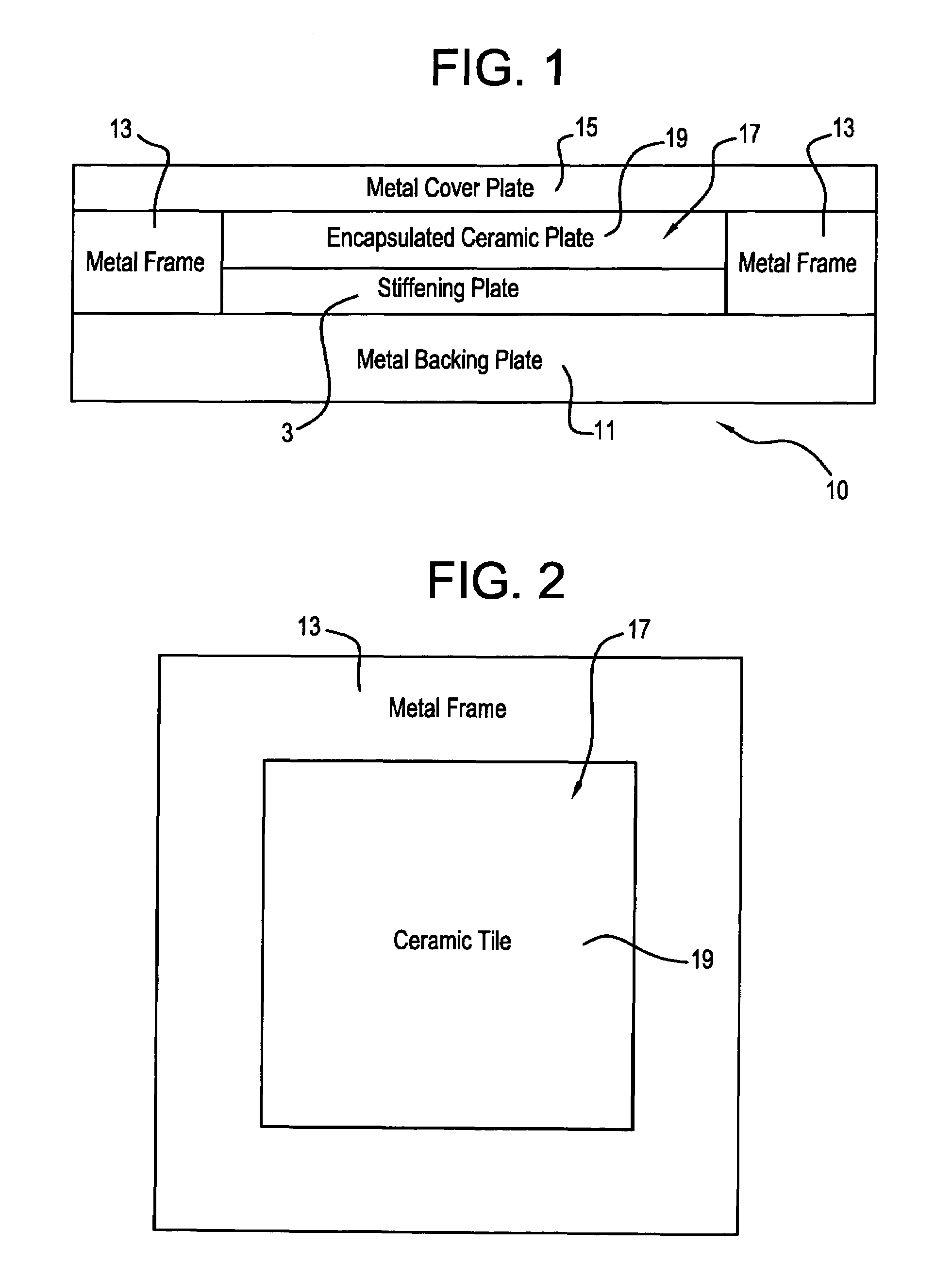

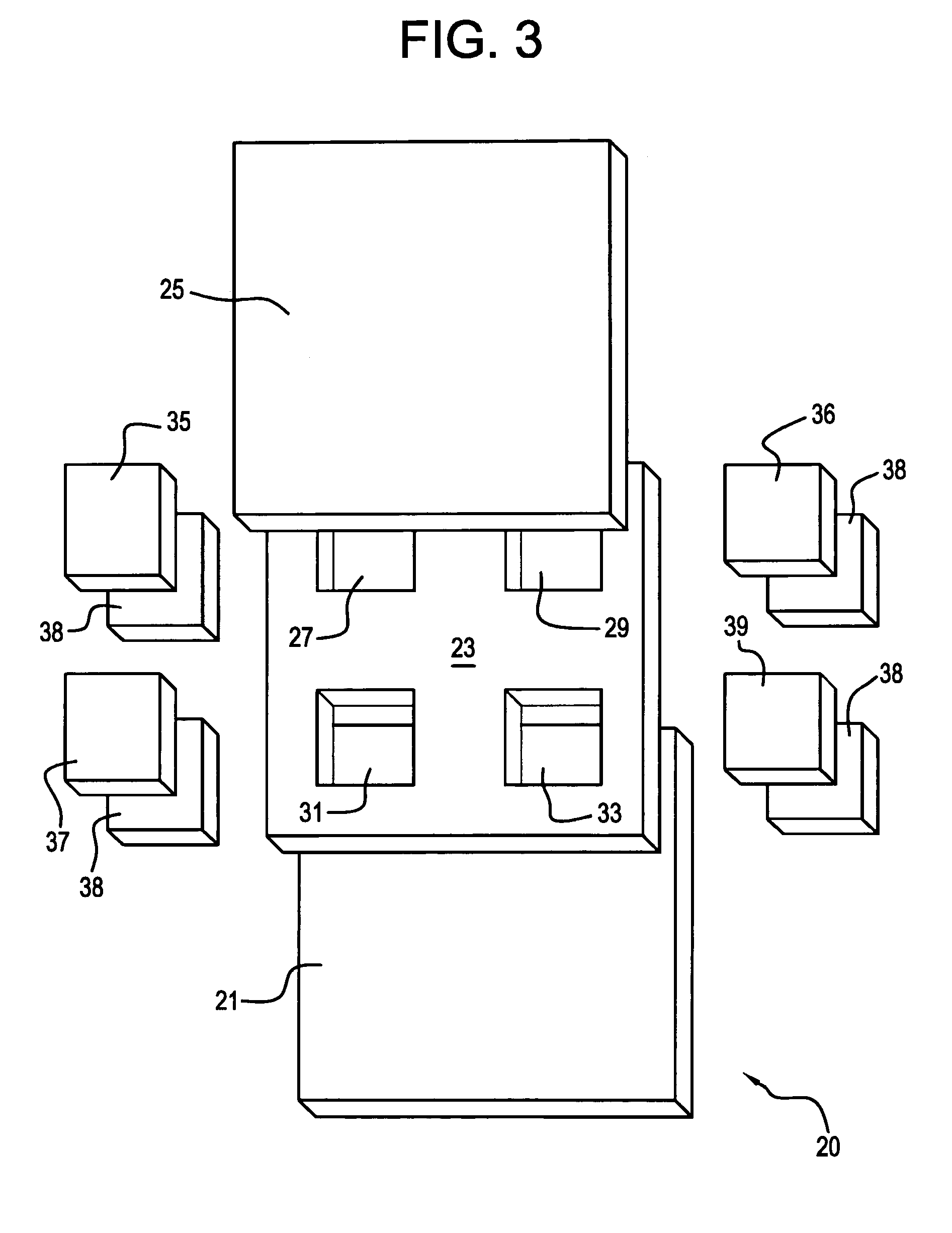

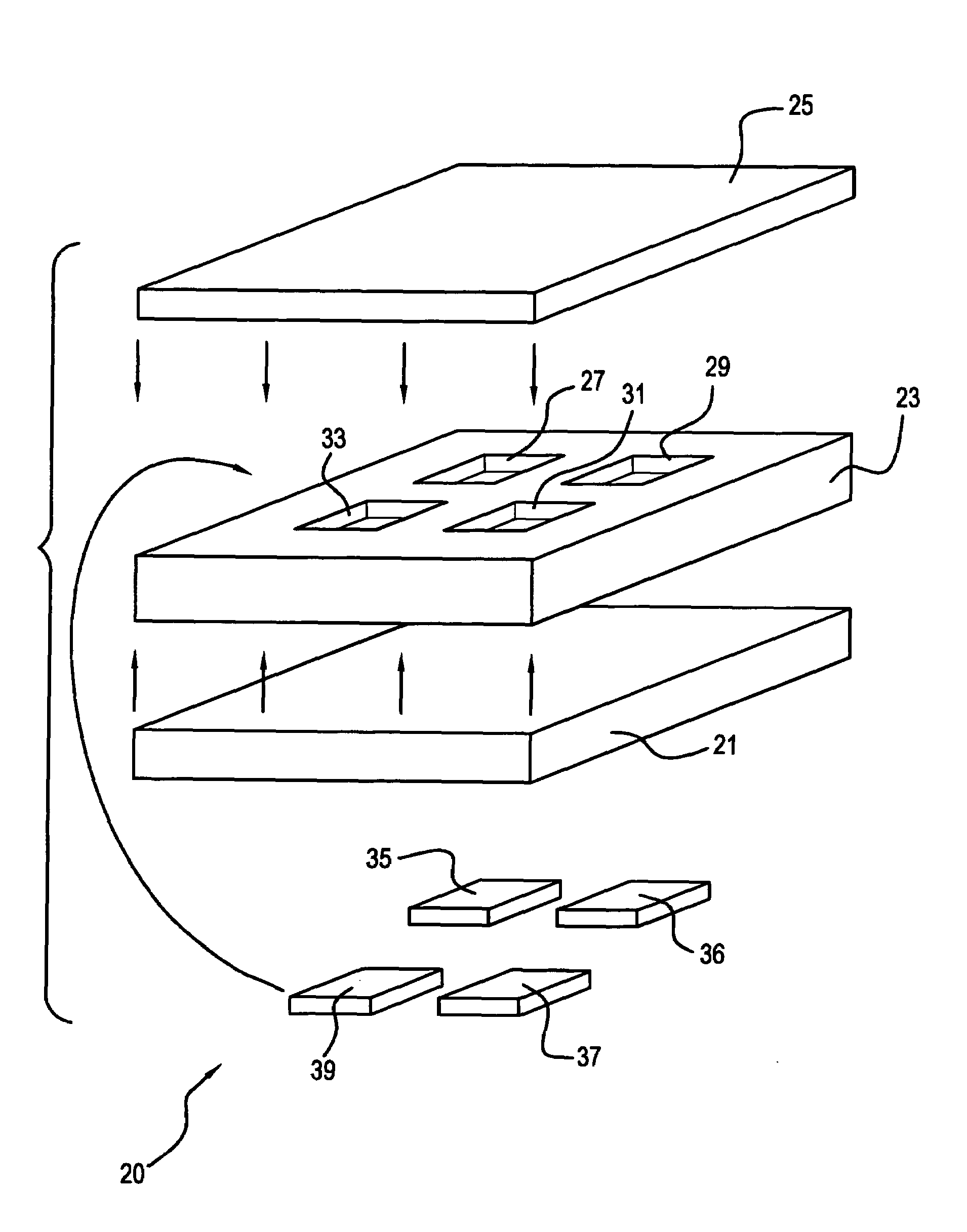

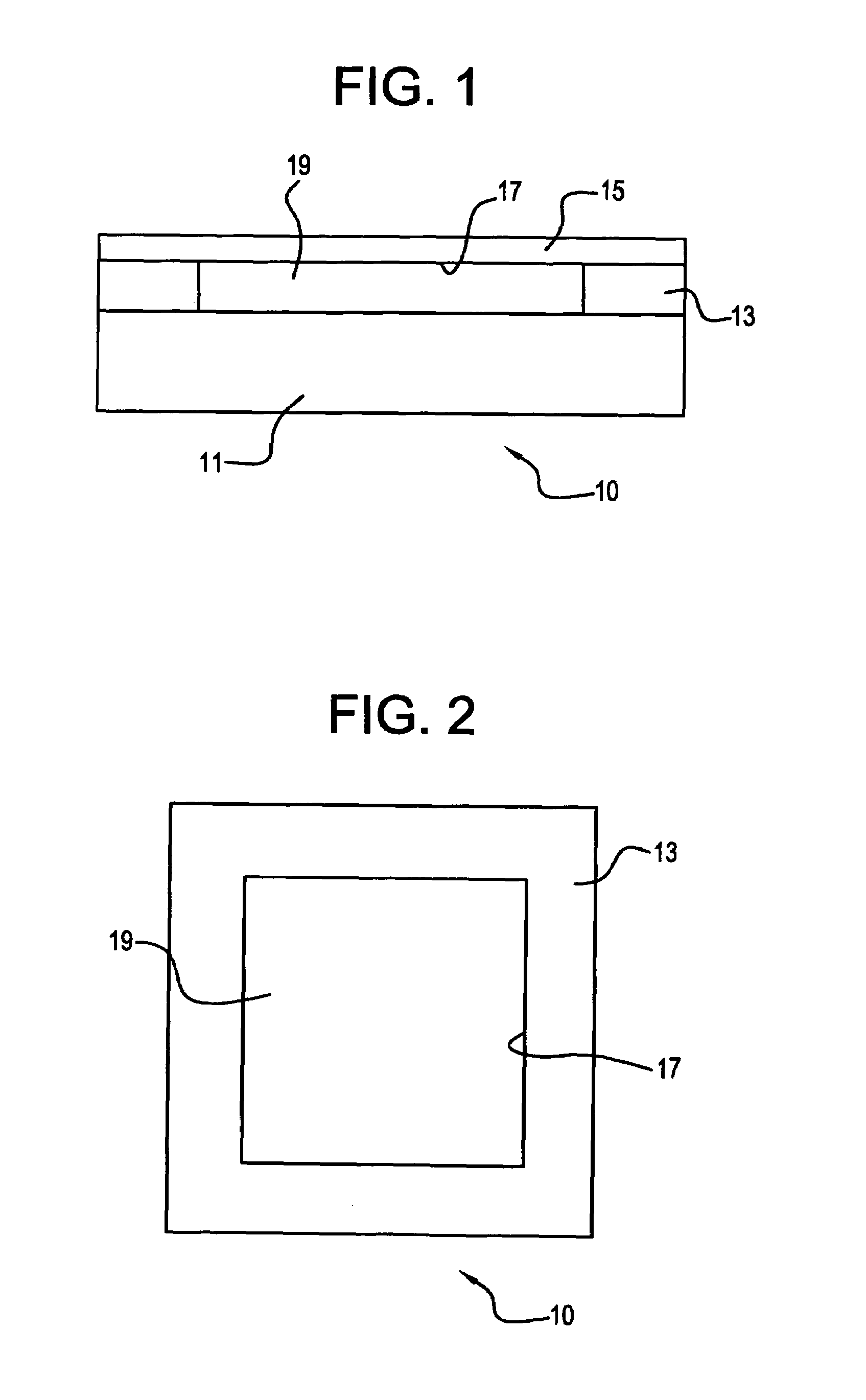

Ceramic armor and method of making by encapsulation including use of a stiffening plate

InactiveUS7069836B1Improve simplicityDoor/window protective devicesArmoured vehiclesCeramic compositeBoron carbide

A ceramic armor is disclosed in several embodiments. In a first embodiment, a metal base plate has a metal frame assembled on it having a central opening into which the ceramic material and stiffening plate are placed. A cover plate is placed over the frame to enclose the ceramic material on all sides. In a second embodiment, the frame has an open central area that has two crossing walls that define four sub-chambers. Four sets of ceramic material and stiffening plate are placed in the respective sub-chambers and a covering plate is placed over them. In a further embodiment, the frame has a plurality of cavities mechanically formed in it. A stiffening plate and a ceramic tile or plate are placed in each cavity and a cover plate is placed over the frame. The metal used to encapsulate the ceramic material may, if desired, comprise a Titanium alloy such as Ti-6Al-4V, and the ceramic material may comprise Silicon Carbide, Boron Carbide, Tungsten Carbide, Titanium Diboride, Aluminum Oxide or Aluminum Nitride. The stiffening plate is preferably made of a Ti—TiB cermet composite but may also be comprised of an armor ceramic such as WC, TiB2, Al2O3 or B4C. A hot pressing procedure is carried out on the armor to cause the metal to plastically deform about the encapsulated ceramic material.

Owner:BAE SYST ADVANCED CERAMICS

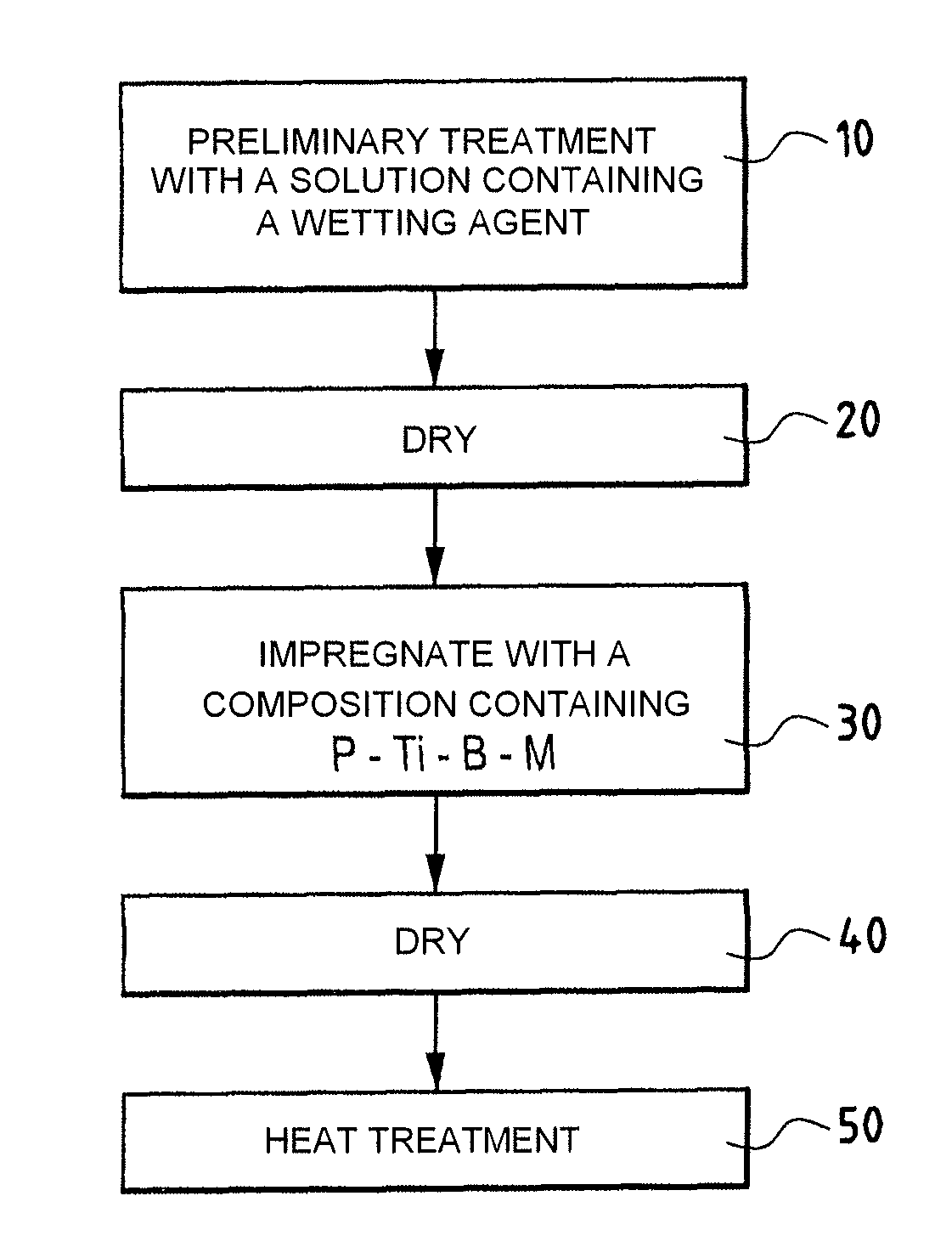

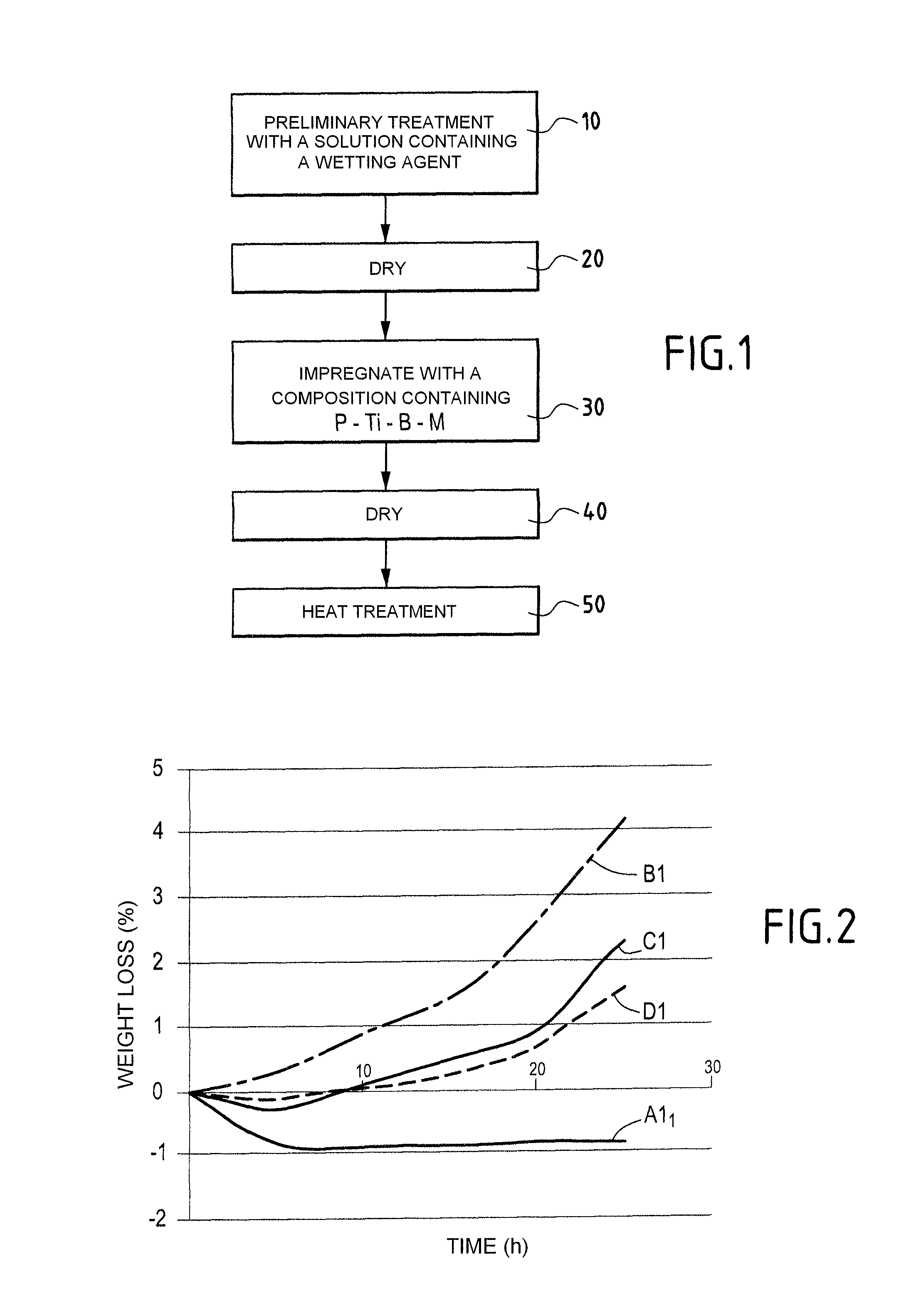

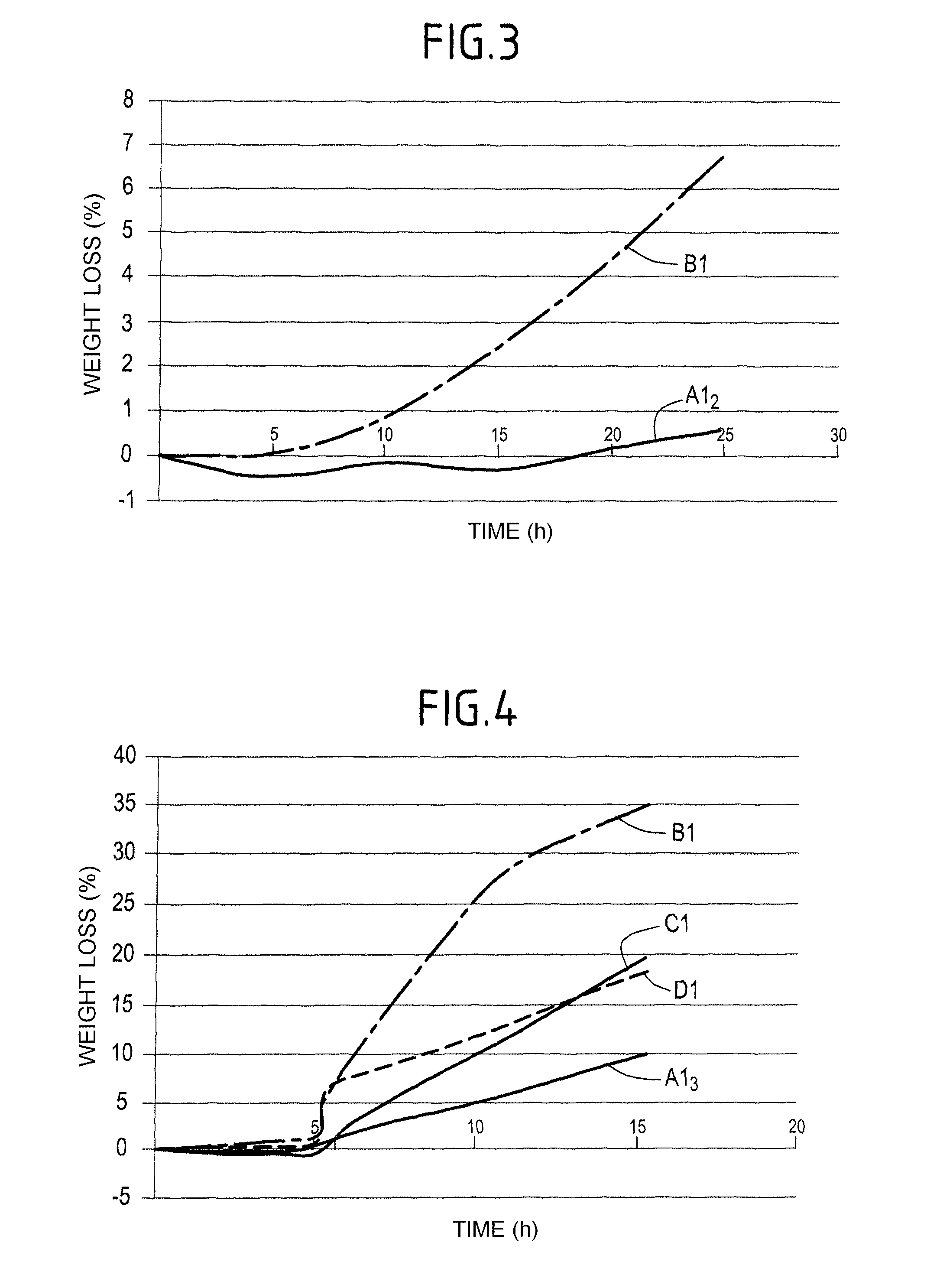

Protection Against the Oxidation of Composite Materials Containing Carbon

ActiveUS20080311301A1Efficient oxidationEasy to implementPretreated surfacesCoatingsCarbon compositesAlkaline earth metal

A part made of a porous material containing carbon, in particular a C / C composite material, is protected against oxidation by being impregnated with a composition in an aqueous medium containing at least a phosphorous compound, elemental titanium, and boron or a boron compound other than titanium diboride, to form in the presence of oxygen and at least one alkali or alkaline-earth element M that catalyses oxidation of carbon, at least one P—O—Ti-M type association bonded by boron oxide B2O3 and trapping the element M.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

WCoB ternary boride cermet material and preparation method thereof

The invention particularly relates to a WCoB ternary boride cermet material and a preparation method thereof. The adopted technical scheme is as follows: taking 5-30wt% of titanium diboride powder, 20-70wt% of tungsten carbide powder and 10-60wt% of cobalt powder as a mixing material; adding grinding ball and the mixing material into a ball mill, wherein, the mass ratio of the grinding ball to the mixing material is 4-10:1; then adding a grinding ball medium, and the liquid level of the grinding ball medium is 5-30mm higher than the layer of grinding ball and the mixing material; wetly milling for 10-100h by the ball mill; adding forming agent which accounts for 2-15wt% of the mixing material; mixing for 1-30h in the ball mill; granulating to obtain required powder; pressing the powder and sintering for 1-10h at the temperature of 1250-1500 DEG C to obtain the WCoB ternary boride cermet material. The WCoB ternary boride cermet material prepared by the method in the invention has low cost, simple process, higher abrasive resistance and high temperature resistant performance, and can satisfy higher service conditions.

Owner:WUHAN UNIV OF SCI & TECH

Preparation of high-purity titanium biboride ceramic micropowder by using self-spreading high-temp. reduction synthesis process

InactiveCN1341576AHigh purityLow energy consumptionSelf-propagating high-temperature synthesisTitanium

The preparation method of high-purity TiB2 ceramic micropowder uses active metal reducing agent and cleap oxide raw material, and adopts the following steps: uniformly mixing TiO2, B2O3 and metal Mg powder, die-pressing and forming, placing the above-mentioned obtained material in a self-spreading high-temp. synthesis equipment with argon protection at normal temp. and normal pressure, lighting to make combustion, breaking combustion product, pickling so as to obtain the invented high-purity TiB2 ceramic micropowder. As compared with traditional carbon thermal reduced TiB2 ceramic powder saidinvention possesses the advantages of high purity, fine crystal grain, simple process and low energy consumption and time consumption, and as compared with SHS simple substance synthetic TiB2 ceramicpowder it is low in production cost.

Owner:WUHAN UNIV OF TECH

Ceramic armor and method of making by encapsulation in a hot pressed three layer metal assembly

Owner:BAE SYST ADVANCED CERAMICS

High-strength plasticity aluminum-base composite material employing TiB2 particles and preparation method thereof

The invention provides a high-plasticity aluminum-based composite material containing TiB2 particles and a preparation method thereof, and relates to an aluminum-based composite material and a preparation method thereof. The invention solves the problems of the prior art, such as poor plasticity and toughness and difficulty in secondary processing. The composite material contains (by volume) titanium diboride reinforcement particles 10-25 percent, aluminum particles 25-35 percent, and aluminum alloy matrix in balance. The preparation method comprises: (1) weighing titanium diboride reinforcement particles, aluminum particles and aluminum alloy matrix; (2) mixing by mechanical dry method to obtain a reinforcement powder; (3) placing the reinforcement powder in a die and compression-molding; (4) heating the die; (5) melting aluminum alloy and casting in the die; (6) applying a pressure on the die with molten aluminum and maintaining the pressure for a period of time and cooling; (7) demoulding and taking the cast ingot, that is reinforced aluminum-based composite material. The inventive aluminum-based composite material has high plasticity and good wear resistance and is adapted to secondary processing and machining.

Owner:HARBIN INST OF TECH

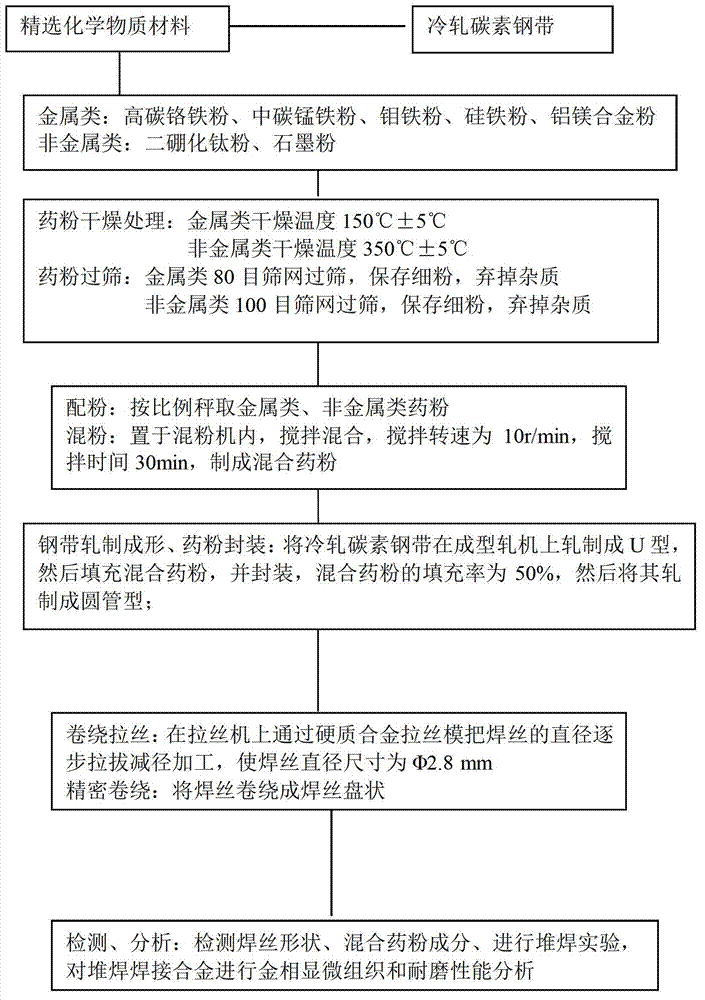

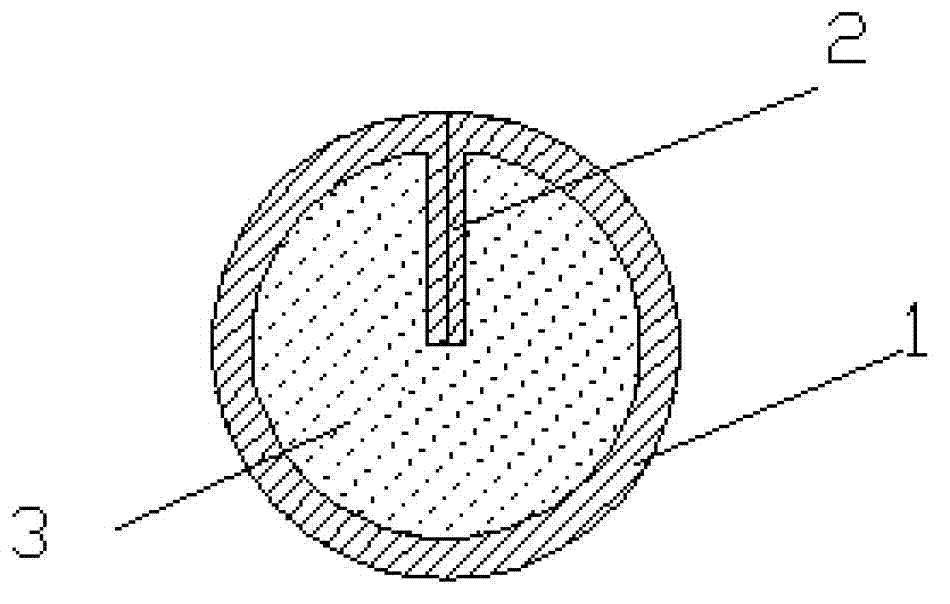

Method for manufacturing TiB<2> ceramic-reinforced wear-resistant surfacing flux-cored welding wire

InactiveCN103240547AImprove welding strengthImprove wear resistanceWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The invention relate to a method for manufacturing a TiB<2> ceramic-reinforced wear-resistant surfacing flux-cored welding wire. The method aims to overcome shortcomings of existing flux-cored welding wires for wear-resistant surfacing. The method includes mixing metal powder with nonmetal powder; manufacturing a steel strip of the welding wire; adding the powder into the steel strip; and winding the steel strip to form a reel and packaging the reel to obtain the titanium diboride ceramic-reinforced wear-resistant surfacing flux-cored welding wire. The metal powder includes high-carbon ferrochrome powder, medium-carbon ferromanganese powder, ferromolybdenum powder, ferrosilicon powder and aluminum magnesium alloy powder, the nonmetal powder includes titanium diboride powder and graphite powder. The method has the advantages that the proportion of chemical compositions of a powder core of the flux-cored welding wire is reasonable and advanced, data are accurate, the TiB<2> ceramic-reinforced wear-resistant surfacing flux-cored welding wire is good in welding effect and high in quality, a welded joint is high in strength and good in wear-resistant performance, the hardness of a welded layer reaches HRC68.4, the wear-resistant performance is improved by 20%, and the titanium diboride ceramic-reinforced wear-resistant surfacing flux-cored welding wire is perfect.

Owner:太原理工技术转移有限公司

Method for preparing TiC and TiB hybrid reinforced Ti-Al-Sn-Zr-Mo-Si-based composite board

The invention relates to a method for preparing a TiC and TiB hybrid reinforced Ti-Al-Sn-Zr-Mo-Si-based composite board, and relates to a method for preparing a titanium-based composite board. By the method, the problem that the tensile property of the conventional TiC granule reinforced Ti-Al-Sn-Zr-Mo-Si-based composite board is reduced drastically at the temperature of more than 650 DEG C. The method comprises the following steps of: calculating required titanium power, titanium diboride, graphite powder and other materials according to the volume percentage of TiC, TiB and Ti-Al-Sn-Zr-Mo-Si-based titanium alloys in the composite board; preparing a precast block by using the titanium power, the titanium diboride and the graphite powder, smelting the precast block together with other materials, and thus obtaining a cast ingot; and forging, rolling, performing heat treatment, and thus obtaining the composite board, wherein the tensile strength of the composite board is between 810 and 890MPa at the temperature of 650 DEG C, so the composite board can be used in the field of aerospace.

Owner:HARBIN INST OF TECH

Boron-containing titanium carbide nitride based metal ceramic cutter material and preparation technique thereof

ActiveCN101255512AHigh thermal conductivityImprove high temperature strengthSingle substanceBoron carbide

The invention discloses a boracic titanium carbonitride based cermet tool bit material and the preparing method thereof. The tool bit material is based on carbonitride as the parent metal, characterized in the tool bit is composed of 0.005% to 0.25% by mass of boron, 6% to 11% by mass of C, 2% to 7% by mass of N, 35% to 70% by mass of Ti, 5% to 20% by mass of W, 0 to 12% by mass of Mo, 0 to 9% by mass of Ta, 1% to 7% by mass of Nb and 6% to 25% by mass of Co and Ni, wherein boron is prepared by adding one or more selected from single substance boron, titanium diboride, molybdenum boride, boron carbide and boric oxide which are in raw material power form. The tool bit material is prepared mainly by mixing the raw material, ball-milling dispersing, press forming, pre-sintering and high-temperature sintering, its high-temperature hardness, high-temperature strength, red hardness and inoxidability are obviously improved, the cutting speed is greatly increased, and the service life is notably entended.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Set of processes for removing impurities from a silcon production facility

A set of three low cost processes for removing boron, phosphorus, carbon and other metal and nonmetal impurities during the process of converting metallurgical grade silicon to electronic grade silicon. One process removes boron by using one or more high temperature solids removal devices to remove solid titanium diboride from a halosilane reactor effluent stream where the high temperature is preferably greater than 200 C., more preferably greater than 300 C. and most preferably greater than 400 C. A second process removes carbon as methane and phosphorus as phosphine by means of a membrane separator which processes all or part of a hydrogen recycle stream to recover hydrogen while rejecting methane and phosphine. A third process separates a high boiling halosilane stream into a large low impurity stream and one or more small high impurity streams some of which can be sent for halogen recovery.

Owner:XSI INT A BRITISH VIRGIN ISLANDS +1

Boron nitride-titanium diboride ceramic composite material and preparation method thereof

The invention relates to a boron nitride-titanium diboride ceramic composite material and a preparation method thereof. The invention solves the problems that preparation of the traditional boron nitride-based ceramic composite material has high cost, long production period and difficulty in manufacturing products with large size. The boron nitride-titanium diboride ceramic composite material is prepared from carbonized boron powder, titanium powder and diluent powder. The boron nitride-titanium diboride ceramic composite material is prepared by the following steps of raw material drying, ball milling and mixing, blank production and self-propagating synthesis of the blank. The method has short production period and low cost ad can realize the production of products with large size.

Owner:HARBIN INST OF TECH

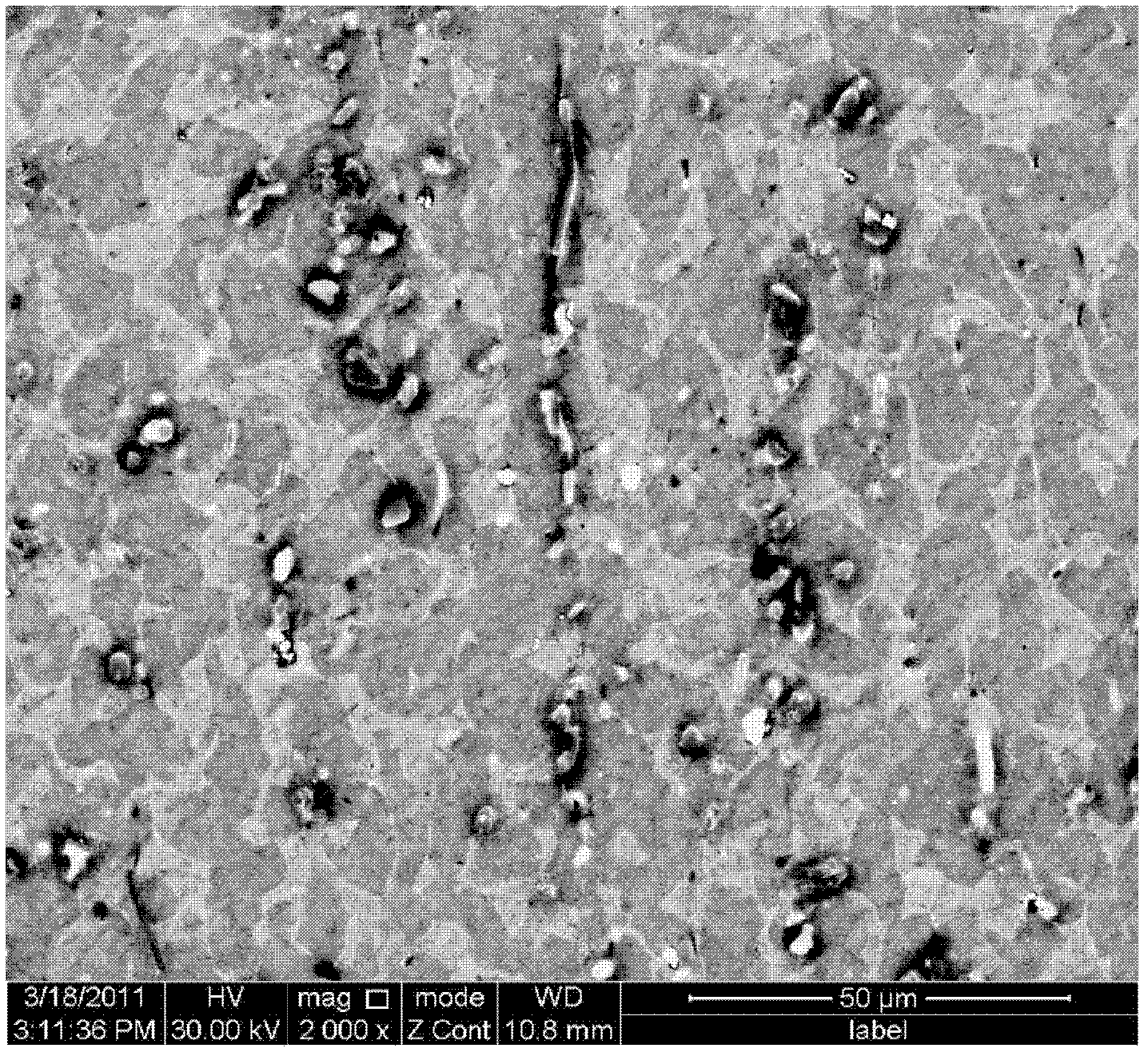

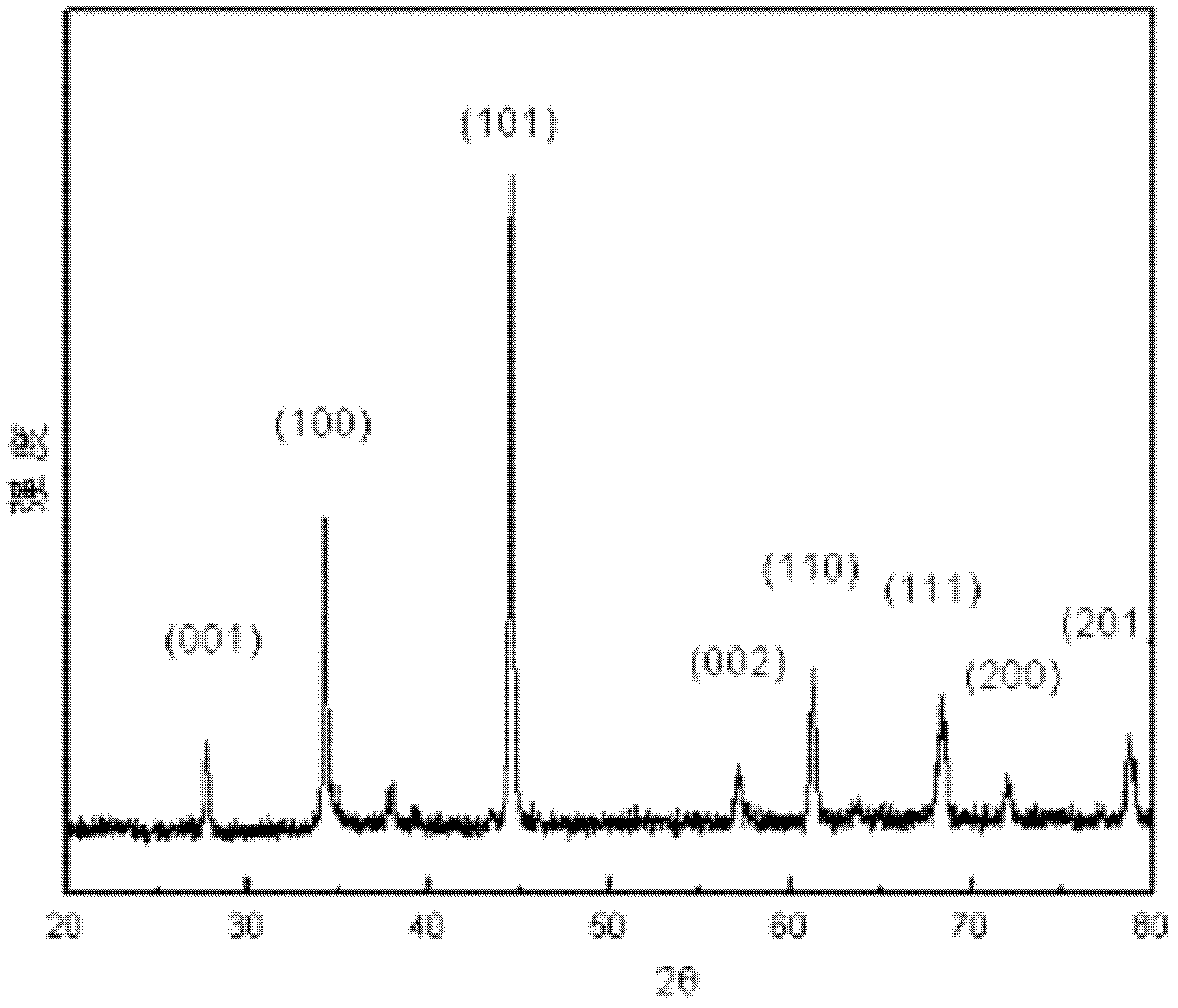

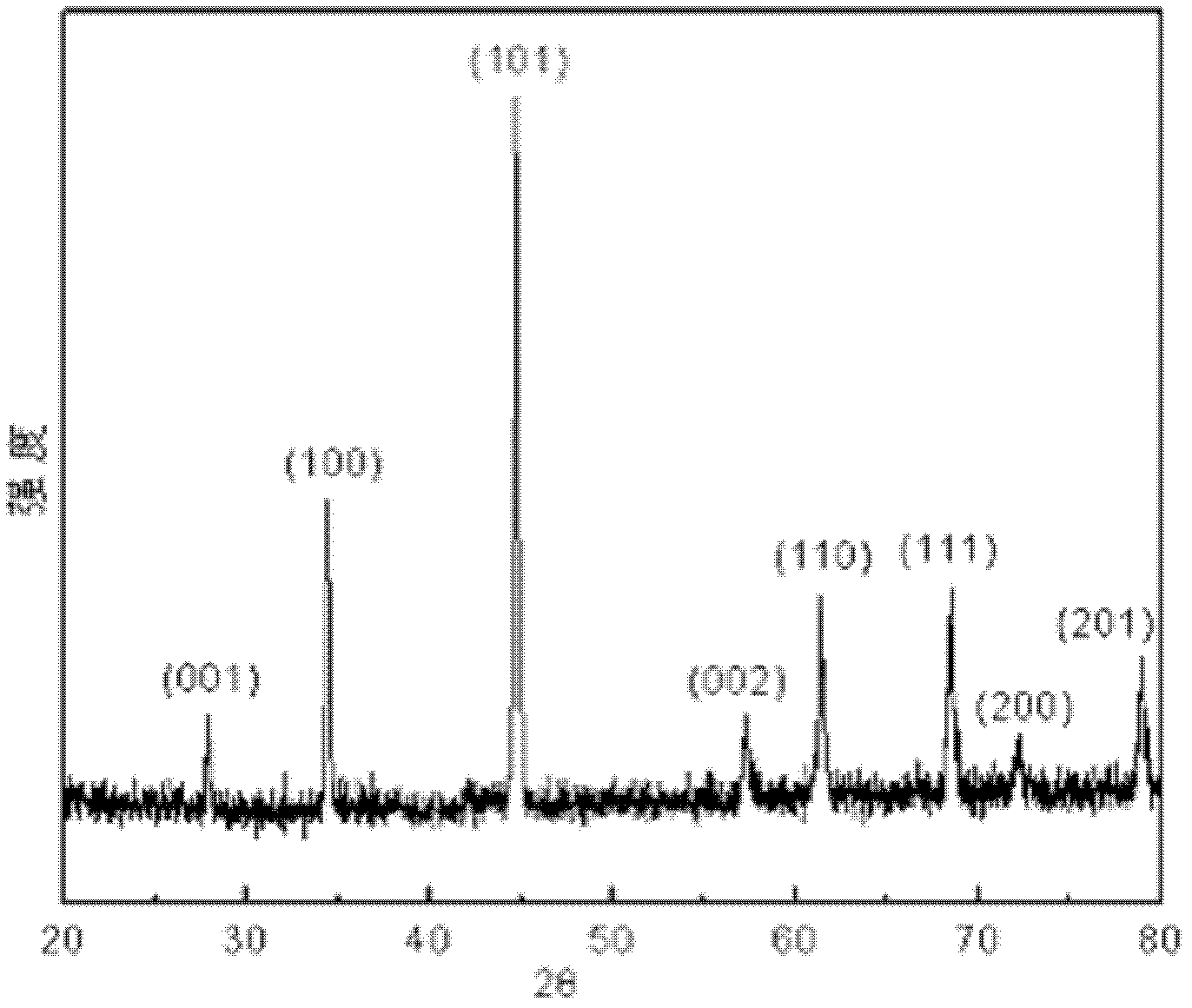

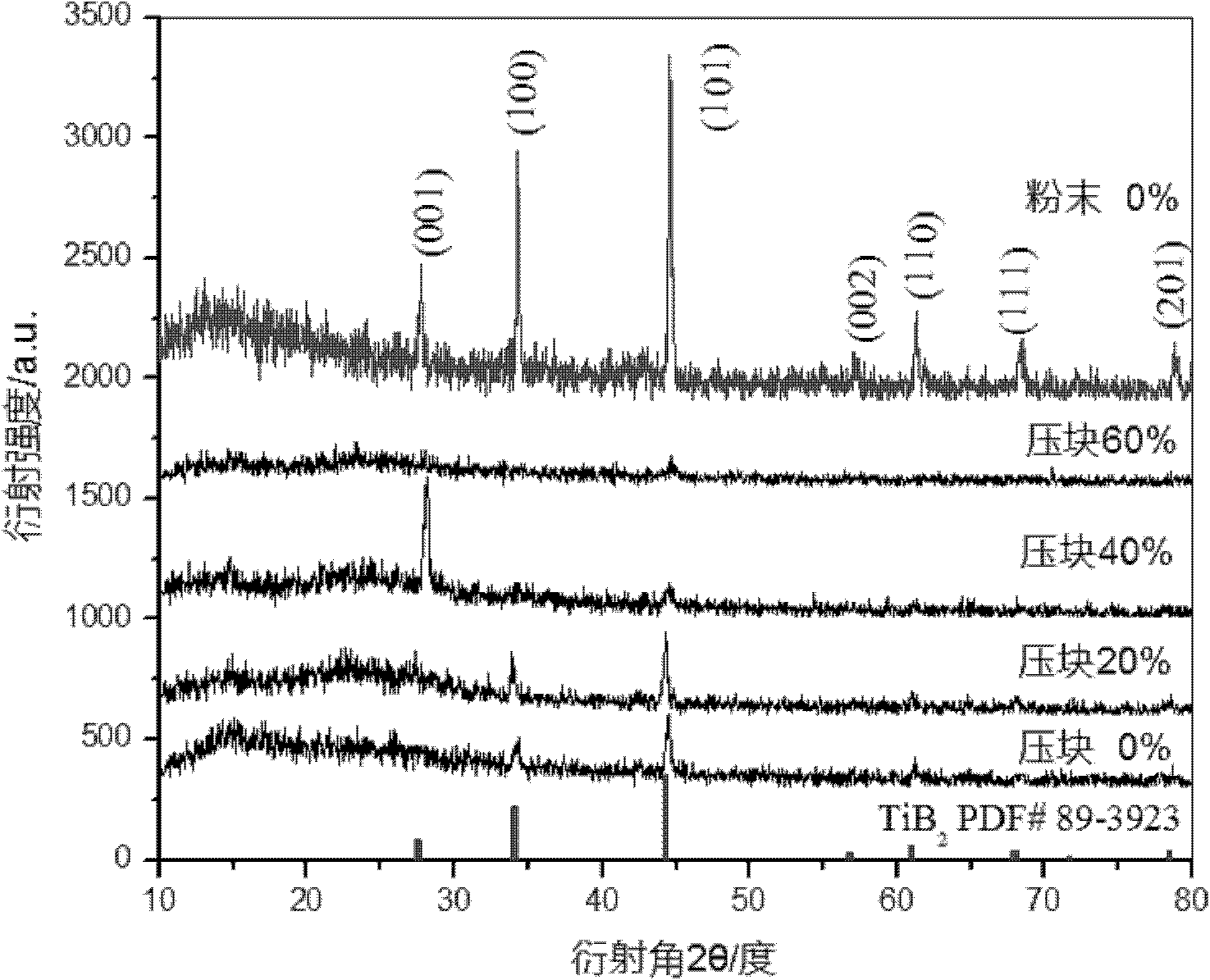

High-temperature high-pressure preparation method for titanium diboride

The invention relates to a high-temperature high-pressure preparation method for titanium diboride and belongs to the technical field of preparation for ultra-hard ceramic material. The method comprises the following steps of: taking titanium powder and boron powder as raw materials or titanium powder and carbon tetraborate powder as raw materials; preparing titanium diboride material by performing the processes of mixing materials, pressing into blocks, assembling, high-temperature high-pressure synthesis, cooling and releasing pressure; performing on a high-pressure device, after keeping temperature at 1300-2000K and pressure at 1.0-6.0GPa for 1-3 hours, cooling and releasing pressure, thereby obtaining TiB2 bulk sintered body. The method provided by the invention is simple and easily implemented; no fluxing agent is adopted; the pure-phase TiB2 material is prepared by changing the proportion of the raw materials and the compounding condition; a result of X-ray detection shows that the product is pure TiB2 phase and no other impure phase is introduced; and according to the TiB2 material prepared by taking B4C as the raw material, the residual C element is capable of enhancing the toughness of TiB2 or the C element is simply separated from TiB2.

Owner:JILIN UNIV

Improved neutron absorption effectiveness for boron content aluminum materials

A method is described for improving neutron absorption in aluminum-based cast composite material, which comprises preparing a molten composite from an aluminum alloy matrix and aluminum-boron intermetallics containing relatively large boron-containing particles, and either (a) heating the composite and holding for a time sufficient to partially dissolve the boron-containing particles and then adding titanium to form fine titanium diboride particles, and casting the composite, or (b) adding gadolinium or samarium to the molten composite or to the aluminum alloy matrix and casting the composite to precipitate fine particles of Gd-Al or Sm-Al within the cast composite, said fine particles filling gaps around the large boron-containing particles with neutron absorbing material. A neutron absorbing cast composite material is obtained comprising neutron absorbing compounds in the form of large particles comprising B4C or an aluminum-boron intermetallic and a distribution of fine particles or precipitates comprising TiB2 or (AlTi)B2, Sm-aluminum intermetallic compounds or Gd-aluminum intermetallic compounds.

Owner:ALCAN INT LTD

Method for preparing nano titanium diboride polycrystalline powder

InactiveCN101891215AReduce manufacturing costAvoid grain growthNanostructure manufactureMetal boridesReaction temperatureSide reaction

The invention relates to a method for preparing nano titanium diboride polycrystalline powder, which comprises the following steps of: mixing raw materials B2O3, TiO2, Mg and KBH4 uniformly, directly performing self-propagating reaction or performing self-propagating reaction after briquetting on the obtained mixed raw materials, and separating and purifying the self-propagating reaction product to obtain the nano titanium diboride polycrystalline powder. The method has the advantages that: (1) the method controls the heat effect of the reaction system, can save energy, reduce the self-propagating reaction temperature and inhibit side reaction and byproduct impurities, and greatly improves the purity of the product; (2) a large amount of gas formed in the reaction process inhibits product grain growth and sintering agglomeration and realizes grain size control of the nano TiB2; and (3) the method has simple reaction process and technique, is easy to control and suitable for industrial production, reduces the preparation cost for preparing the nano titanium diboride polycrystalline powder, and has great utility value.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

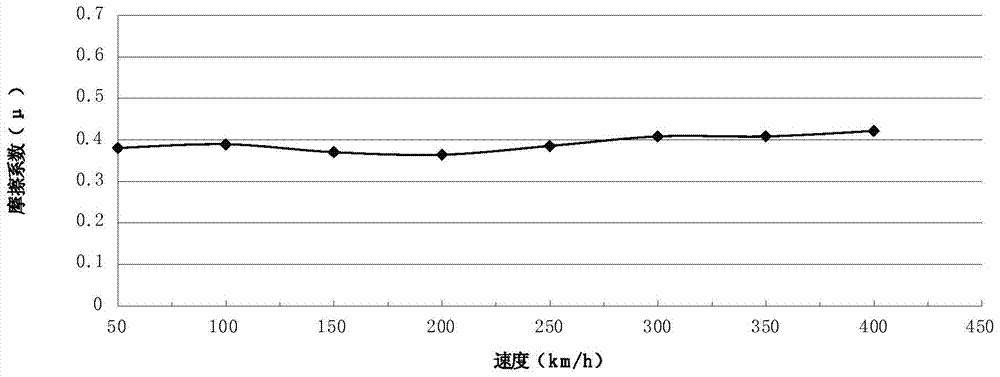

Copper-based powder dispersion ceramic as well as preparation method and application thereof

InactiveCN103667772AStrong impact pressureHigh mechanical strengthBraking membersCopperUltimate tensile strength

The invention relates to copper-based powder dispersion ceramic as well as a preparation method and application thereof, and relates to the field of ceramic materials. The copper-based powder dispersion ceramic is prepared from an anti-abrasion constituent element as one of the raw materials, wherein the anti-abrasion constituent element comprises the following components by mass percent of all the raw materials: 1-5 percent of diamond powder and 1-5 percent of titanium diboride powder. The copper-based powder dispersion ceramic is high in impact pressure resistance, high in mechanical intensity, high in friction and abrasion resistance, long in service life, high in heat dissipation property and heat recovery property, high in high-temperature and low-temperature resistance, high in acid, alkaline, oil, water and the like corrosion resistance and the like.

Owner:刘伟

Large granular spherical metal ceramic nano composite spraying powder

The invention relates to macro aggregate ball shape metal ceramic nm compounding spray coating powder that contains titanium diboride 50-70wt%, cobalt 10-24wt%, chromium powder 6-13wt%, tungsten boride 5-11%, and the other is rare earth powder. Mixing the powder according to the ratio, wet method ball milling, centrifuging, pressure spraying graining, vacuum heat treatment technology and grain classifying process, the 20-45um and 45-75um granularity of powder would be gained. It has good abrasion resistant, high temperature resistant and corrosion resistance capability.

Owner:SHANGHAI JIAO TONG UNIV

Modified graphene/thermosetting resin composite material and preparation method thereof

The invention relates to a modified graphene / thermosetting resin composite material and a preparation method thereof. The method comprises the steps of dispersing graphite oxide into N, N-dimethylformamide, adding titanium diboride oxide subjected to amination, filtering, washing and drying reactants to obtain modified graphene; curing modified graphene and molten heat-curable resin to obtain the modified graphene / thermosetting resin composite material. The composite material has the advantages of high dielectric constant, low dielectric loss and low percolation threshold value; moreover, the control of the dielectric properties of the composite material can be realized by regulating the changes of the content of graphene surface-coated titanium diboride. The preparation method of the composite material, provided by the invention, has the characteristics of simple process, low cost, wide applicability and the like.

Owner:SUZHOU UNIV

Method for preparing novel energy conservation inert anode material for zinc electrodeposition

ActiveCN101343758AShort production processDecrease cell voltagePhotography auxillary processesElectrodesMolten stateLead dioxide

The invention relates to a novel energy conserving inert anode material preparation method used for zinc galvanic deposition. The method adopts a multi-pulse galvanic deposition method to prepare and obtain lead-lead dioxide-titanium boride-cerium dioxide-polyanion composite plating layer (Pb-PbO2-TiB2-CeO2-PAN) energy conserving inert anode material on the aluminum base body, and when the composite electrode material is uaded in the metal galvanic deposition, a compact film layer is formed on the anode surface, to cause the anode to be in a non-molten state; the adoption of the composite electrode can obviously reduce the voltage of the galvanic deposition cell, and the electric consumption is reduced; simultaneously the electroplating solution cost of the invention is low, the equipment investment is less, the land occupation is less, and the effect is rapid; and the cell voltage can be reduced by 0.2 to 0.5V when zinc galvanic deposition is performed, and the current efficiency is improved by 1 to 3 percent.

Owner:晋宁理工恒达科技有限公司

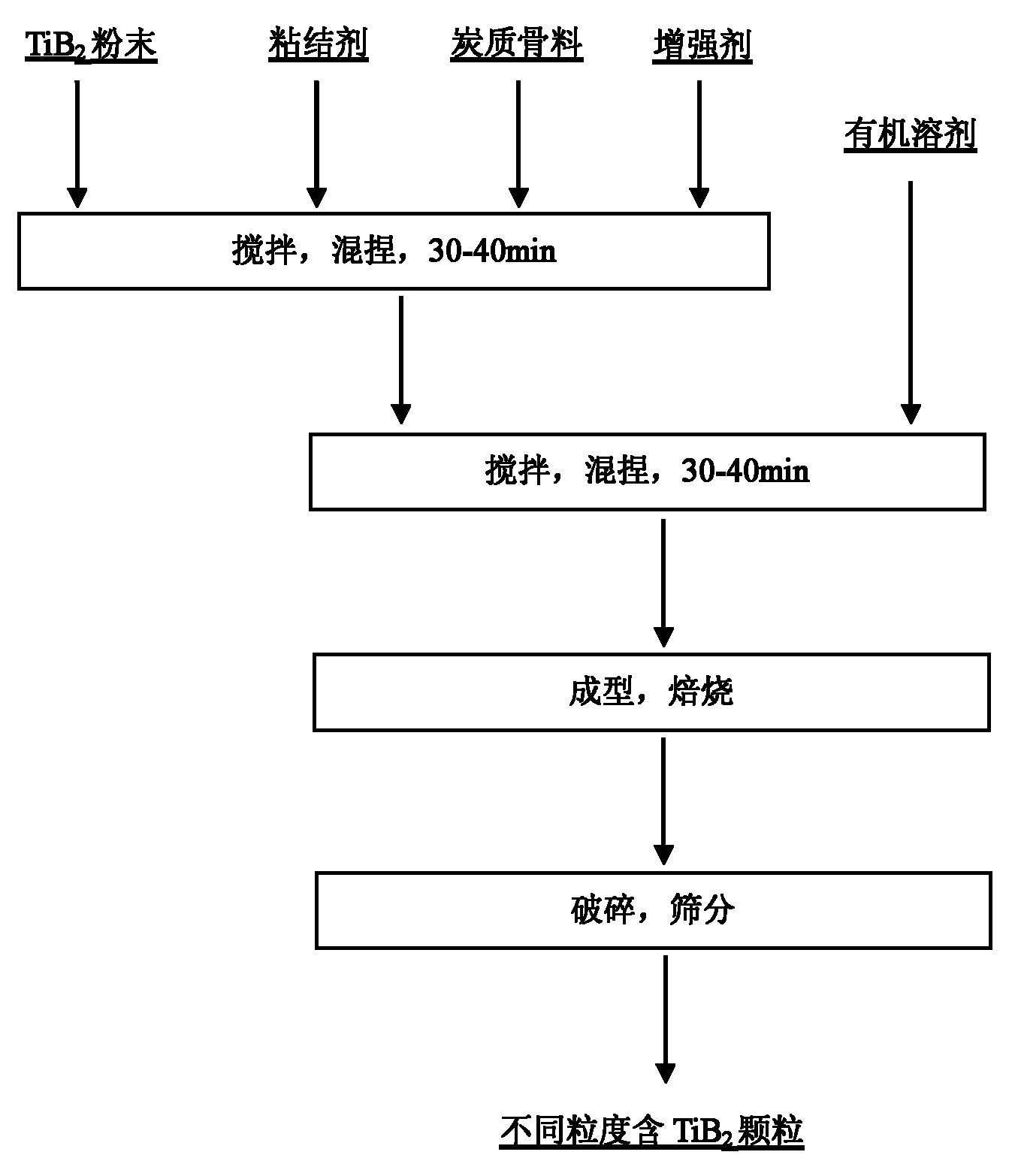

Pelleting method of titanium diboride powder

InactiveCN101844926AHigh resistance to sodium permeabilityGood resistance to sodium penetrationAluminium electrolysisGranularity

The invention provides a pelleting method of titanium diboride powder, which is suitable for preparing high-content high-strength large TiB2 particles for the wettable cathode of an aluminium electrolysis cell and is especially suitable for preparing the high-content high-strength large TiB2 particles for the wettable cathode of a deflector-type aluminium electrolysis cell. The method is characterized in that the high-content high-strength TiB2 particles are prepared by carrying out processes of kneading, shaping, roasting, crushing, sieving and the like on the titanium diboride powder as the main aggregate by adopting an organic binder or inorganic binder or a compound binder of the organic binder or the inorganic binder. The method has simple preparation process, controllable granularity and convenient application. The TiB2 particles prepared by the invention has the TiB2 content of 70-95 percent, the strength of 30-60MPa, and the resistivity of 0.5-40 muomega.m, and moreover, the TiB2 particles have small deformation and strong high temperature melt penetration resistance, can be completely wetted with aluminium liquid, realizes aluminium electrolysis production energy saving, prolongs the service life of the cathode of the aluminium electrolysis cell and reduces the aluminium electrolysis production cost.

Owner:CENT SOUTH UNIV

Nano-ceramic composite spraying powder and preparation method for same

ActiveCN103184400AStop growing upAvoid high temperature oxidationMolten spray coatingCharge manipulationOxide ceramicCeramic composite

The invention discloses a nano-ceramic composite spraying powder and a preparation method for the same. The nano-ceramic composite spraying powder comprises MCrAlTaY with definite components, nano-aluminium oxide and / or nano-yttrium oxide, and nano-titanium diboride, wherein in MCrAlTaY, M is Ni, Co or Ni-Co alloy; the MCrAlTaY and the nano-aluminium oxide and / or nano-yttrium oxide form an alloy oxide ceramic composite powder; and nano-titanium diboride is nano-metal ceramic powder. The preparation method comprises the following steps of: conveying the composite powder in a ball mill; adding a ball-milling medium and an organic adhesive; starting the ball mill and uniformly mixing; adding the ceramic powder; and starting the ball mill again until all the ceramic powder is uniformly wrapped on the particle surface of the composite powder, taking out the wet material and drying, and then obtaining the nano-ceramic composite spraying powder. The spraying powder is good in resistance to high-temperature oxidation and resistance to thermal corrosion, thus enhancing the toughness and the resistance to thermal fatigue strength of a coating; and the prepared powder is uniform and complete in coating shape and good in flowability, thus reducing spraying difficulty.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Method of bonding aluminum-boron-carbon composites

InactiveUS8186565B1Highly accurate alignmentDiffering melting pointSoldering apparatusGas flame welding apparatusCarbon compositesParticulates

An aluminum-boron-carbon (ABC) ceramic-metal composite bonded to a metal or metal-ceramic composite other than ABC composite is made by forming a porous body comprised of particulates being comprised of a boron-carbon compound that has a particulate layer of titanium diboride powder on the surface of the porous body. The porous body is infiltrated with aluminum or alloy thereof resulting in the simultaneous infiltration of the TiB2 layer, where the layer has an aluminum metal content that is at least about 10 percentage points greater by volume than the (ABC) composite. The ABC composite is then fused to a metal or metal-ceramic body through the infiltrated layer of titanium diboride, wherein the metal-ceramic body is a composite other than an aluminum-boron-carbon composite.

Owner:DOW GLOBAL TECH LLC

Wear-resistant and antifriction composite coating for aluminum alloy component surfaces and preparation method thereof

InactiveCN105624670AImprove microstructureReduce coefficient of frictionMetallic material coating processesAdhesiveWear resistance

The invention relates to a wear-resistant and antifriction composite coating for aluminum alloy component surfaces. The coating is composed of, by weight, 13-15% of tungsten carbide powder, 18-20% of titanium diboride powder, 2.0-4.0% of cerium oxide powder, 3.0-5.0% of nickel-coated molybdenum disulfide powder and the balance nickel-base alloy powder, wherein the components are blended through adhesives and then are arranged on the aluminum alloy component surfaces in a laser cladding mode for forming the coating; in the nickel-coated molybdenum disulfide powder, the coating ratio of nickel is 71-73%; nickel-base alloy is composed of, by weight, 0.75-0.85% of C, 15-16% of Cr, 3.5-4.5% of Si, 3.0-4.0% of B, 14.5-15.5% of Fe and the balance Ni. The coating is high in wear resistance and low in friction coefficient and solves the friction and wear problems of aluminum alloy used for friction members of mechanical equipment at high loads or impact loads, the service life is prolonged, and the friction energy consumption is lowered.

Owner:中国人民解放军理工大学野战工程学院

Protection Against the Oxidation of Composite Material Parts Containing Carbon and Parts thus Protected

InactiveUS20070199626A1Easy to implementEfficient methodSolid state diffusion coatingFriction liningCarbon compositesPhosphate

A part made of a composite material containing carbon, having an open internal residual porosity is protected against oxidation by performing at least one stage in which an impregnating composition is applied, said impregnating composition containing at least one metal phosphate and titanium diboride. Efficient protection against oxidation is thus obtained at temperatures of more than 1000° C., also in the presence of a carbon oxidation catalyst and in a damp medium.

Owner:MESSIER BUGATTI INC

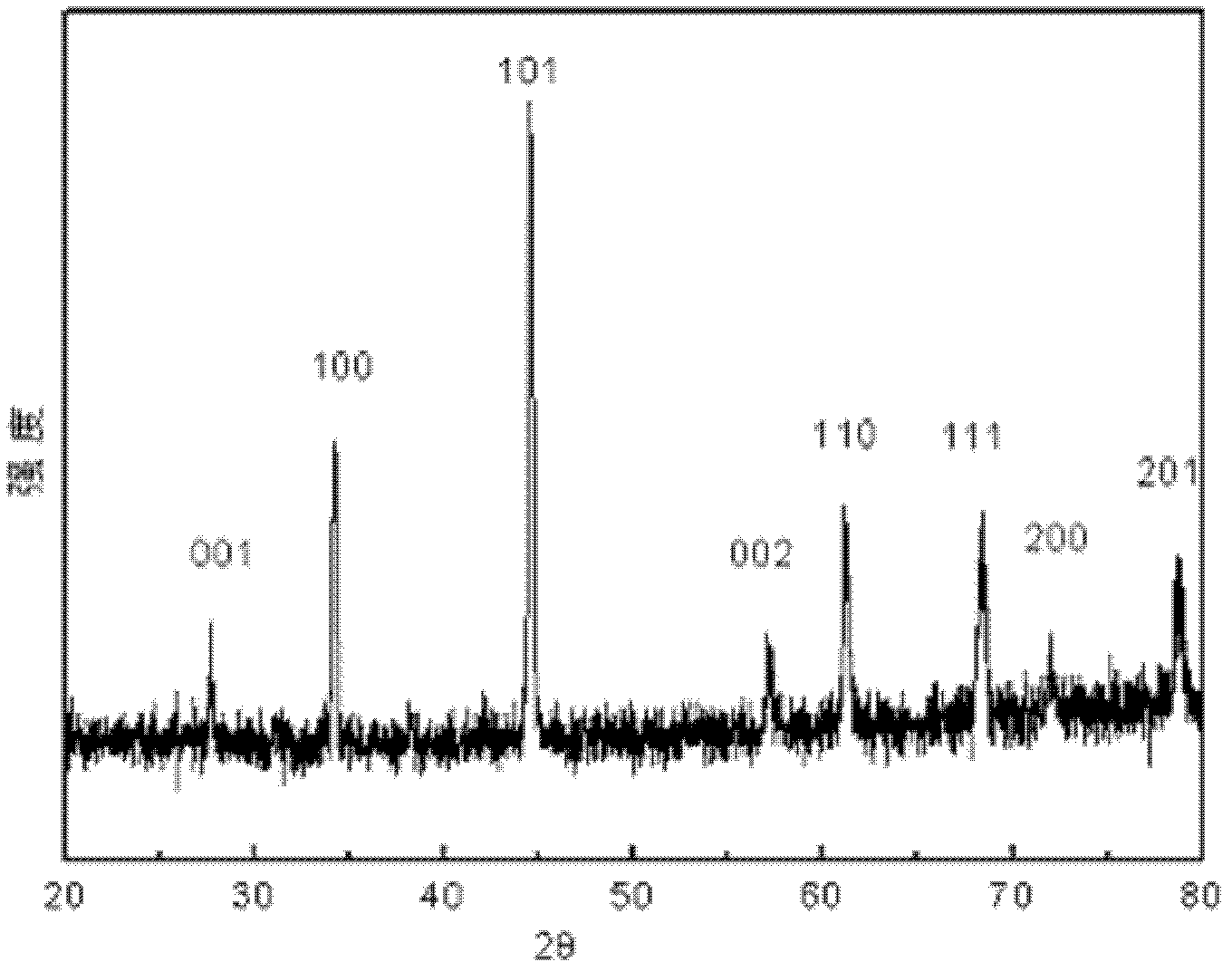

Cubic boron nitride compact

The present invention relates to CBN briquetting which contains CBN and matrix phase, the matrix phase combines with a second horniness phase and maximum titanium diboride, thereinto, the second horniness phase is selected from TiCN, TiC, TiN or its mixture and solid solution, the XRD peak height of thetitanium diboride peak (101)(after back ground emendation) is below 12 percent of the CBN peak (111) height.

Owner:ELEMENT SIX ABRASIVES

Metal treatment to eliminate hot tear defects in low silicon aluminum alloys

An aluminum alloy and a method of casting. At least one of zirconium, scandium, a nucleating agent selected from the group consisting of metal carbides, aluminides and borides, and rare earth elements are added to the alloy while in the molten state such that upon solidification, the cast alloy exhibits improved hot tear resistance. In a particular form, the nucleating agent may be titanium diboride for grain refining. Other agents that can be used for grain refining include scandium, zirconium, silicon, silver and one or more rare earth elements. In the case of rare earth elements, mischmetal may be used as a precursor. Combinations of titanium diboride and at least one other agent are especially effective in reducing the incidence of hot tearing in products cast from the modified aluminum alloy.

Owner:GM GLOBAL TECH OPERATIONS LLC

Wear-resistant ceramic material and preparation method thereof

The invention discloses a wear-resistant ceramic material and a preparation method thereof. The wear-resistant ceramic material comprises the following components in parts by weight: 65-70 parts of nano aluminum oxide, 10-15 parts of magnesium carbonate, 10-12 parts of kaolin, 5-12 parts of titanium diboride fibers, 5-8 parts of silicon carbide, 3-5 parts of sodium hydrogen carbonate, 5-7 parts of antimonous oxide and 3-5 parts of red mud. The invention further provides a preparation method of the wear-resistant ceramic material. The preparation method comprises the following steps: (1) weighing 10-15 parts of magnesium carbonate, 10-12 parts of kaolin, 5-12 parts of titanium diboride fibers, 5-8 parts of silicon carbide, 3-5 parts of sodium hydrogen carbonate, 5-7 parts of antimonous oxide and 3-5 parts of red mud and adding all the components into a high pressure homogenizer and uniformly mixing; (2) adding 65-70 parts of fully ball-milled nano aluminum oxide under an inertial atmosphere into the product obtained in the step (1), and raising the temperature to 700-710 DEG C to react for 1-2 hours; and (3) compressing and molding the product obtained in the step (2), heating to 1300-1350 DEG C at a temperature raising speed of 5 DEG C / minute, firing, insulating fro 2-4 hours, and cooling to obtain the wear-resistant ceramic material.

Owner:WUJIANG JIA BILLION ELECTRONICS TECH

High-dispersive-distribution nano-titanium diboride particle reinforced aluminum matrix composite material and preparation method thereof

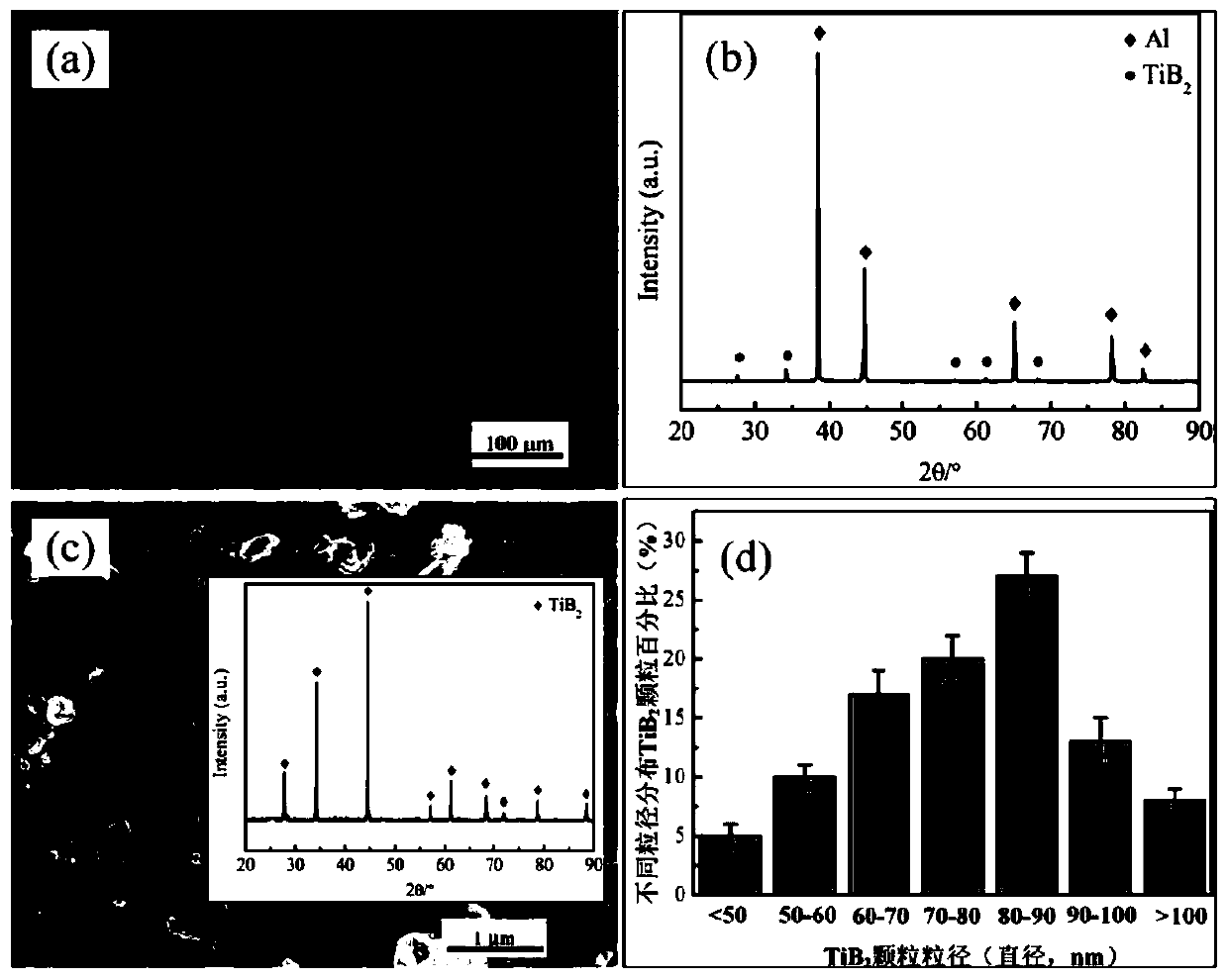

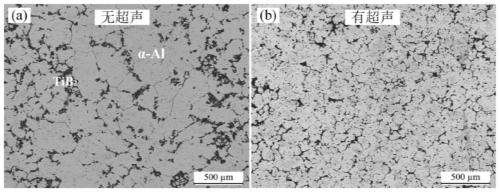

The invention discloses a high-dispersive-distribution nano-TiB2 particle reinforced aluminum matrix composite material and a preparation method thereof. Firstly, a uniform-structure Al-TiB2 intermediate alloy is prepared through an ultrasound assisted mixed salt reaction (K2TiF6 / KBF4-Al), wherein the average particle diameter of in-situ endogenous TiB2 particles is smaller than 100nm; the Al-TiB2 intermediate alloy and Al are used as raw materials, or Al-TiB2 intermediate alloy, Al and alloy elements are used as raw materials, the nano-TiB2 particles are introduced into an aluminum (alloy) matrix through an intermediate alloy dilution method, ultrasound agitation treatment is used as assistance, then pouring into a mold is performed, and ultrasound is applied during solidification (introduction through a bottom introduction method); and thus the high-dispersive-distribution nano-TiB2 particle reinforced aluminum matrix composite material is obtained.

Owner:咸阳瞪羚谷新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com