Method for preparing TiC and TiB hybrid reinforced Ti-Al-Sn-Zr-Mo-Si-based composite board

A composite material and sheet technology, which is applied in the field of preparation of reinforced Ti-Al-Sn-Zr-Mo-Si matrix composite material sheets, can solve problems such as the decrease of tensile properties, and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

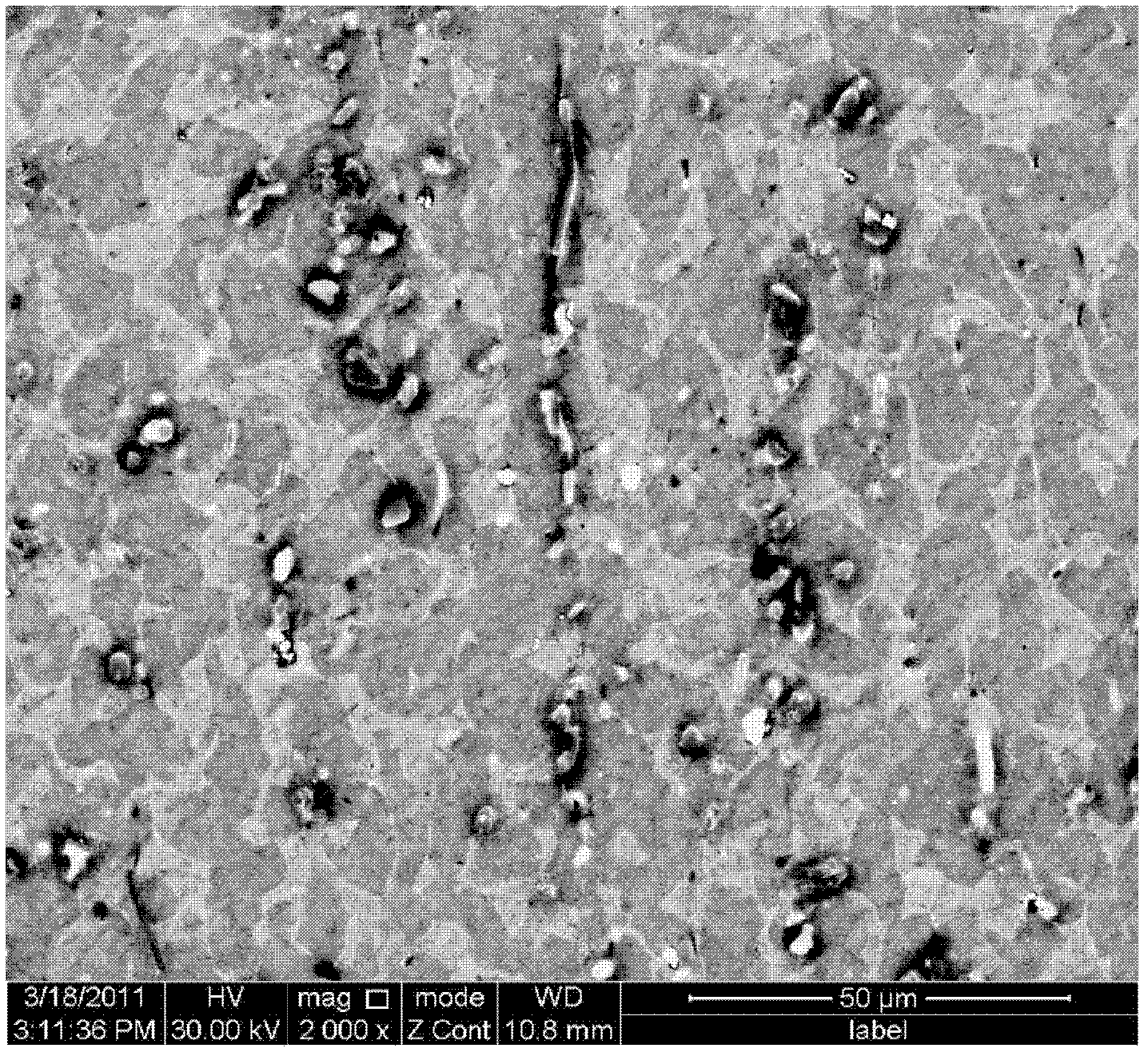

Image

Examples

specific Embodiment approach 1

[0010] Embodiment 1: The preparation method of the TiC and TiB hybrid reinforced Ti-Al-Sn-Zr-Mo-Si-based composite material plate of this embodiment is carried out according to the following steps: 1. Reinforce Ti-Al-Sn by TiC and TiB hybrid - The volume percentage of TiC particles in the Zr-Mo-Si based composite material plate is 0.5% to 12.5%, the volume percentage of TiB particles is 0.5% to 12.5%, and the volume percentage of Ti-Al-Sn-Zr-Mo-Si titanium alloy The percentage is 75% to 99%, and the titanium powder, graphite powder, titanium diboride powder and raw materials for preparing Ti-Al-Sn-Zr-Mo-Si titanium alloy are respectively weighed, and the molar ratio of titanium powder to graphite powder is 2~6:1, the molar ratio of titanium powder and titanium diboride powder is 2~6:1; 2. Add the titanium powder, graphite powder and titanium diboride powder weighed in step 1 into the mixer Mix evenly, and then use a cold isostatic press to keep the mixed powder at a pressure o...

specific Embodiment approach 2

[0011] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the fineness of the titanium powder described in step 1 is 300 mesh to 350 mesh, the fineness of graphite powder is 2 μm to 5 μm, and the titanium diboride powder The fineness is 2μm~5μm. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the fineness of the titanium powder described in step one is 325 mesh, the fineness of graphite powder is 3.5 μm, and the fineness of titanium diboride powder is 3 μm. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile properties | aaaaa | aaaaa |

| tensile properties | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com