High-strength plasticity aluminum-base composite material employing TiB2 particles and preparation method thereof

An aluminum-based composite material and high plasticity technology, applied in the field of reinforced aluminum-based composite materials and its preparation, can solve the problems of difficulty in ensuring the safety of structural parts, difficult to achieve secondary processing, reduced plasticity and toughness, etc., to achieve high plasticity, The effect of low cost and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

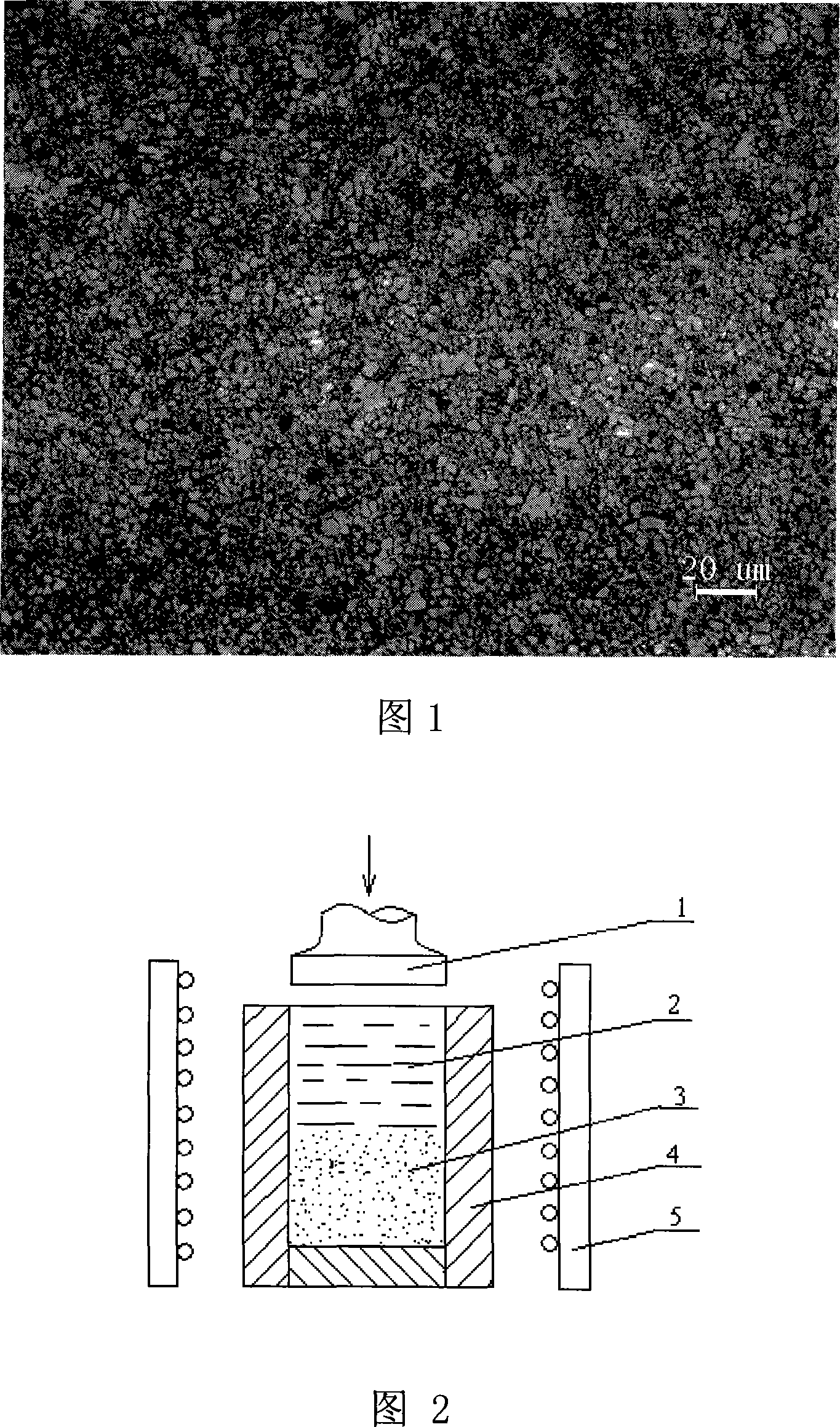

[0018] Specific embodiment one: This embodiment is composed of titanium diboride reinforcement particles, aluminum particles and matrix aluminum alloy, titanium diboride reinforcement particles account for 10-25% by volume, and the average particle size is 0.5-5 μm; aluminum Particles account for 25-35%, with an average particle size of 5-10 μm; the rest is the base aluminum alloy, and the base aluminum alloy is Al-Cu-Mg, Al-Mg-Si or Al-Zn-Mg.

specific Embodiment approach 2

[0019] Specific implementation mode 2: In this implementation mode, 10% of titanium diboride reinforcement particles, 35% of aluminum particles, and the rest are made of matrix aluminum alloy by volume percentage.

specific Embodiment approach 3

[0020] Specific implementation mode three: In this implementation mode, 25% of titanium diboride reinforcement particles, 25% of aluminum particles, and the rest are made of matrix aluminum alloy by volume percentage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com