Ceramic metal composite substrate and production method thereof

A composite substrate and ceramic metal technology, which is applied in the field of ceramic metal composite substrate and its preparation technology, achieves the effects of simple production process, reduced thermal resistance and low expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A ceramic aluminum metal composite substrate, the specific preparation process is:

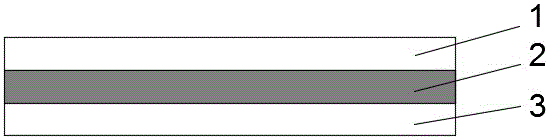

[0034] (1) First weigh the alumina ceramic powder according to the volume ratio of micron powder and nano powder as 85:15, and mix evenly; then add solvent, dispersant, plasticizer, and binder to the ceramic powder in sequence , film-forming agent, defoaming agent and other ball mills to prepare casting slurry, the mass of ceramic powder in the casting slurry accounts for 65%; then the casting raw tape is prepared by casting molding process, and finally dried, degummed, and sintered to prepare a thickness of 0.05mm ultra-thin ceramic sheet 1;

[0035] (2) Surface treatment is performed on the aluminum metal substrate 3 with a thickness of 1 mm to obtain a surface with a certain roughness or texture, and the surface is cleaned and dried;

[0036] (3) Then use the coating process to coat the thermally conductive adhesive 2 containing 20% carbon fiber (length-to-diameter ratio: 12~26) o...

Embodiment 2

[0040] A ceramic aluminum alloy composite substrate, the specific preparation process is:

[0041] (1) First weigh the cordierite ceramic powder according to the volume ratio of micron powder and nano powder as 80:20, and mix evenly; then add solvent, dispersant, plasticizer, and binder to the ceramic powder in sequence , film-forming agent, defoaming agent and other ball mills to prepare casting slurry, the quality of ceramic powder in the casting slurry accounts for 68%; then adopt the casting molding process to prepare the casting raw tape, and finally dry, degumming, and sintering to prepare a thickness of 0.5mm ultra-thin ceramic sheet 1;

[0042] (2) Surface treatment is performed on the aluminum alloy substrate 3 with a thickness of 2 mm to obtain a surface with a certain roughness or texture, and the surface is cleaned and dried;

[0043] (3) Apply the thermally conductive adhesive 2 containing 25% aluminum nitride whiskers (with an aspect ratio of 12~20) on the metal...

Embodiment 3

[0047]A ceramic copper metal composite substrate, the specific preparation process is:

[0048] (1) First weigh the ceramic powder according to 75% alumina micron powder and 25% aluminum nitride nano powder (volume ratio), mix evenly; then add solvent, dispersant, plasticizer to the ceramic powder in sequence Casting slurry is prepared by ball milling of additives, binders, film-forming agents, defoaming agents, etc., and the mass of ceramic powder in the casting slurry accounts for 70%; then tape-casting tapes are prepared by tape-casting molding technology, and finally dried, degummed, Sintering to prepare an ultra-thin ceramic sheet 1 with a thickness of 1 mm;

[0049] (2) Surface treatment is performed on the copper metal substrate 3 with a thickness of 1 mm to obtain a surface with a certain roughness or texture, and the surface is cleaned and dried;

[0050] (3) Then apply the thermally conductive adhesive 2 containing 30% Cu fibers (length-to-diameter ratio: 12-20) by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com