Anode steel claw welding tool and method

A technology for anode steel claws and welding tooling, applied in the field of anode steel claw welding tooling and welding, can solve the problems of low strength and electrical conductivity at the welding seam, and achieve the effects of improving welding efficiency, prolonging service life and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

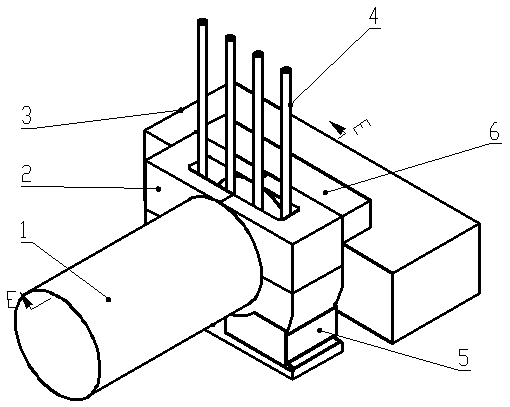

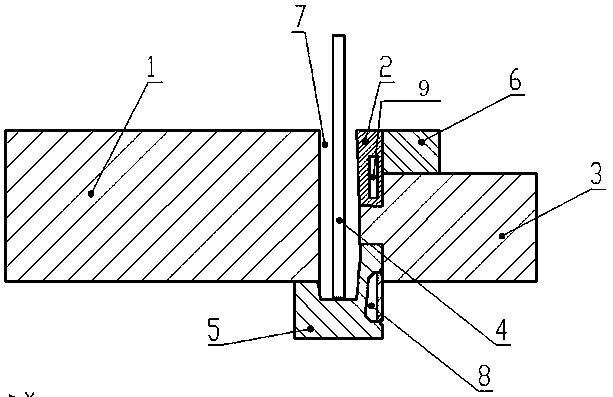

[0033] Embodiment 1: A kind of anode steel claw welding frock, see figure 1 with figure 2 , including a water-cooling mold composed of an upper water-cooling module 2 and a lower water-cooling module 5, and a positioning baffle (which has the functions of positioning and preventing melt outflow) 6 abutting on the side wall of the upper water-cooling module 2, the water-cooling The interior of the mold is provided with a cavity and a water channel for water circulation, including a lower circulation water chamber 8 and an upper circulation water chamber 9, and the material of the water-cooling mold is copper, graphite or high-alumina refractory material; the top of the upper water-cooling module 2 is provided with an opening, The upper water-cooling module 2 and the lower water-cooling module 5 are used for clamping and fixing the welding end of the steel claw head 1 and abutting against the beam 3 to be welded together with the positioning baffle 6, and the pair of steel cla...

Embodiment 2

[0034] Embodiment 2: Utilize the welding mold in embodiment 1 to carry out the method for anode steel claw welding, adopt wire electromechanical slag welding to cooperate with above-mentioned mold to carry out steel claw repair, concrete steps are as follows:

[0035] (1) Surface treatment is carried out on the surface to be welded of the steel claw head 1 and the beam 3 to remove the surface slag and oxide layer to expose the metallic luster; the surface to be welded of the steel claw head 1 and the beam 3 is a vertical surface, and no beveling is required. Standing seam welding can be done directly;

[0036] (2) Place the steel claw head 1 on the lower water-cooling module 5 of the welding mold, and make the upper water-cooling module 2 and the lower water-cooling module 5 mold together, and the beam 3 and the welding end of the steel claw head 1 are aligned and fit in For the water-cooled mold, the positioning baffle 6 is abutted against the side wall of the upper water-coo...

Embodiment 3

[0038] Embodiment 3: Repair the old anode steel claw by using the method of welding the anode steel claw in embodiment 2. The difference between the steps and embodiment 2 is that before step (1), the following steps are also included: the old steel claw Cut off the claw head, cut a suitable round steel as a new steel claw head, and satisfy the length of the round steel L = length of steel claw head removed l -Weld width D .

[0039] The invention is not only applicable to the manufacture and production of structural steel claws, but also applicable to the repair of old steel claws. The welding cost of the invention is low, and compared with the traditional technology, it can save the cost of beveling and repairing, has high efficiency, and reduces labor cost. The welded joints after welding have excellent mechanical properties (tensile strength ≥ 260Mpa), full-section welding can ensure good electrical conductivity, and can achieve the same performance as the base metal, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com