Ceramic-based composite turbine outer ring high-temperature sealing coating and preparation process thereof

A sealing coating, ceramic-based technology, applied in the field of high-temperature sealing coating of ceramic-based composite turbine outer ring and its preparation, can solve problems such as inability to meet high-temperature environment requirements, peeling, etc., to solve the problem of gas corrosion, reduce Fuel consumption, the effect of boosting thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

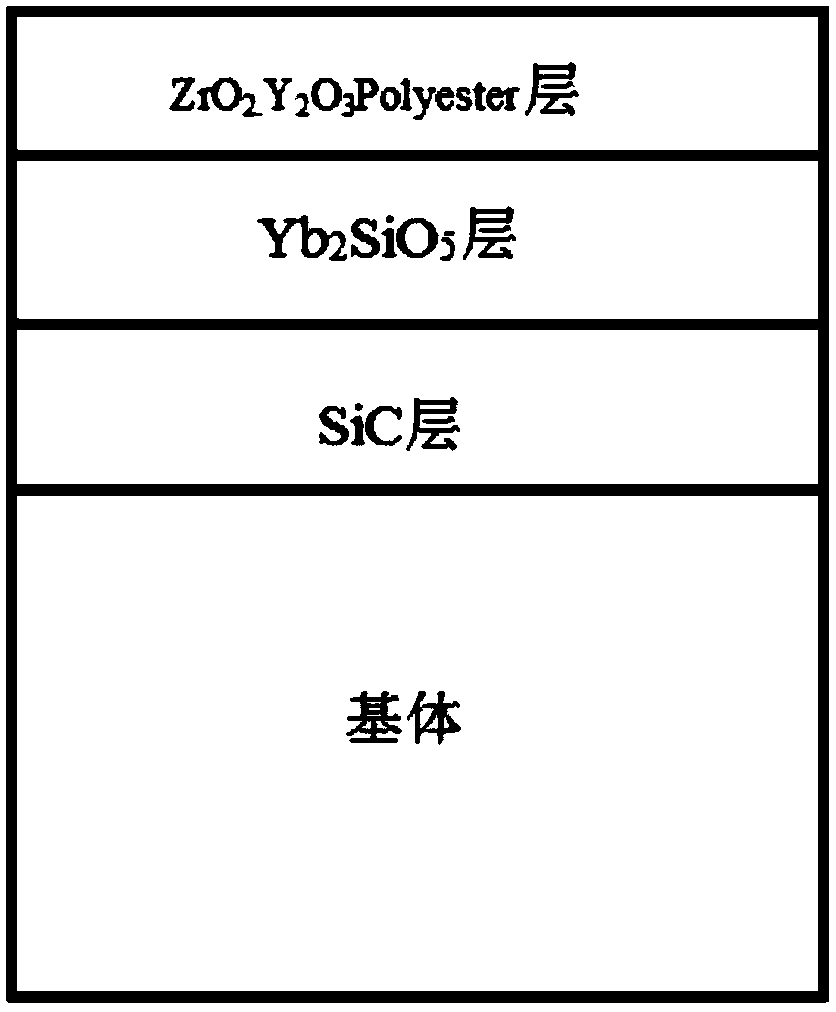

[0026] Step 1: Degrease and decontaminate the parts, use alcohol to wipe the sprayed area of the parts to remove oil and sundries;

[0027] Step 2: Protect the parts of the parts that do not need to be sprayed, and use metal tooling to shield them;

[0028] Step 3: Plasma spray silicon carbide coating on the parts to be sprayed. The specific parameters are current 750A, argon gas flow rate 50L / min, hydrogen gas flow rate 5L / Min, powder feeding rate 20g / min, and spraying distance 110mm. The spraying angle is 90°;

[0029] Step 4: Plasma spray ytterbium silicate coating on the parts to be sprayed. The specific parameters are current 650A, argon gas flow rate 50L / min, hydrogen gas flow rate 9L / Min, powder feeding rate 30g / min, and spraying distance 110mm , the spraying angle is 85°;

[0030] Step 5: Plasma spray yttria-stabilized zirconia + polyester coating on the parts that need to be sprayed. The specific parameters are current 550A, argon flow rate 40L / min, hydrogen flow ...

Embodiment 2

[0034] Step 1: Degrease and decontaminate the parts, use alcohol to wipe the sprayed area of the parts to remove oil and sundries;

[0035] Step 2: Protect the parts of the parts that do not need to be sprayed, and use metal tooling to shield them;

[0036] Step 3: Plasma spray silicon carbide coating on the parts to be sprayed. The specific parameters are current 850A, argon gas flow rate 60L / min, hydrogen gas flow rate 6L / Min, powder feeding rate 30g / min, spraying distance 100mm, The spraying angle is 75°;

[0037] Step 4: Plasma spray ytterbium silicate coating on the parts to be sprayed. The specific parameters are current 750A, argon gas flow rate 60L / min, hydrogen gas flow rate 10L / Min, powder feeding rate 40g / min, and spraying distance 100mm , the spraying angle is 90°;

[0038] Step 5: Plasma spray yttria-stabilized zirconia + polyester coating on the parts to be sprayed. The specific parameters are current 650A, argon flow rate 50L / min, hydrogen flow rate 9L / Min, ...

Embodiment 3

[0041] Step 1: Degrease and decontaminate the parts, use alcohol to wipe the sprayed area of the parts to remove oil and sundries;

[0042] Step 2: Protect the parts of the parts that do not need to be sprayed, and use metal tooling to shield them;

[0043] Step 3: Plasma spray silicon carbide coating on the parts to be sprayed. The specific parameters are current 800A, argon gas flow rate 55L / min, hydrogen gas flow rate 5.5L / Min, powder feeding rate 25g / min, and spraying distance 105mm , the spraying angle is 80°;

[0044]Step 4: Plasma spray ytterbium silicate coating on the parts to be sprayed. The specific parameters are current 700A, argon gas flow rate 55L / min, hydrogen gas flow rate 9.5L / Min, powder feeding rate 35g / min, and spraying distance of 105mm, the spraying angle is 75°;

[0045] Step 5: Plasma spray yttria-stabilized zirconia + polyester coating on the parts to be sprayed. The specific parameters are current 600A, argon flow rate 45L / min, hydrogen flow rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com