Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

963 results about "Crystallization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

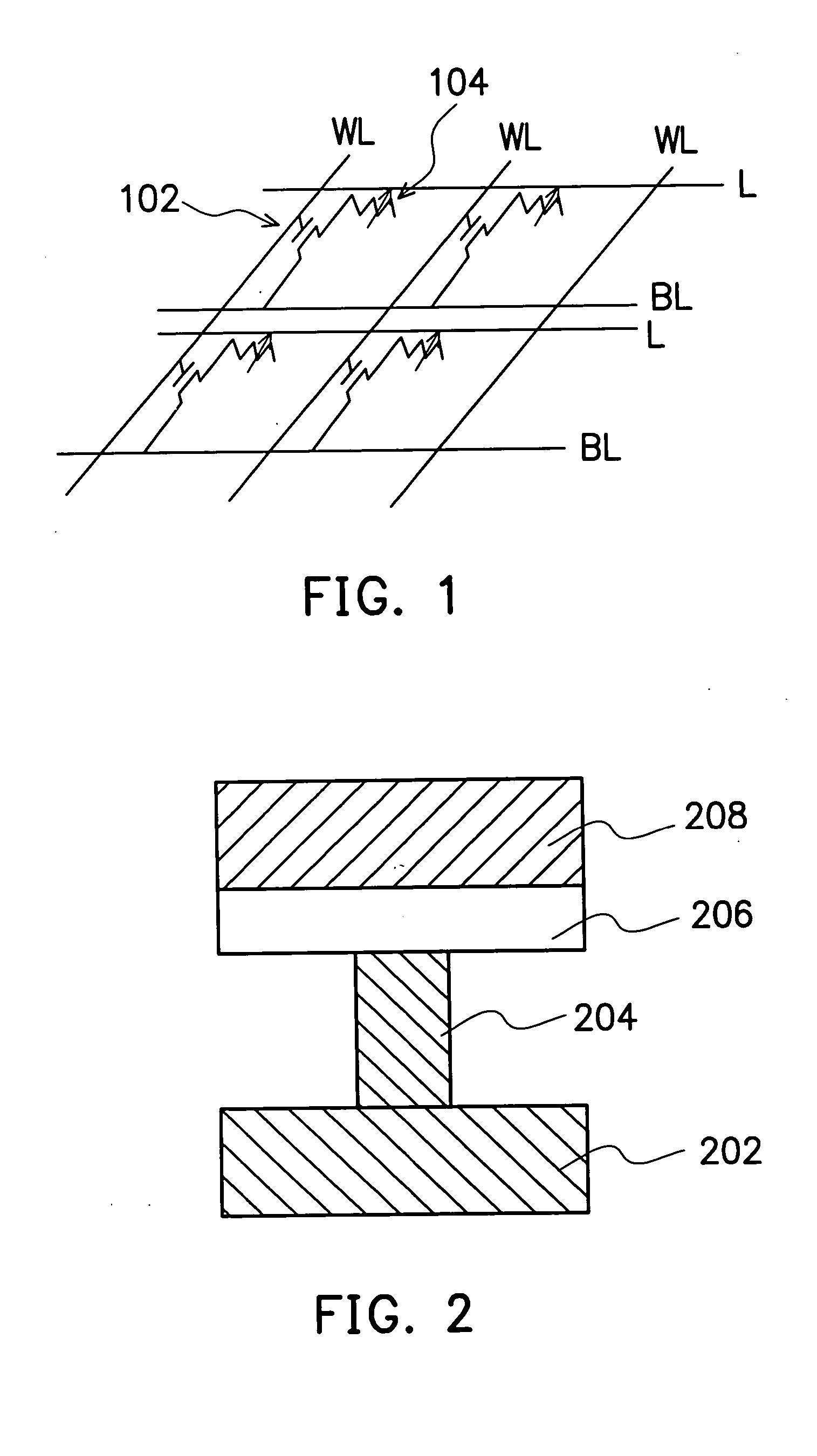

Chalcogenide phase-change non-volatile memory, memory device and method for fabricating the same

InactiveUS20050062087A1High speedIncrease the rate of crystallizationSolid-state devicesRead-only memoriesPhase-change memoryAlloy

A memory device adapted to a chalcogenide phase-change memory is disclosed. The memory device comprises a top electrode, a bottom electrode, and a phase-change thin film between the top electrode and the bottom electrode. The phase-change thin film is a chalcogenide (Ge-Sb-Te) alloy doped with Tin (Sn) therein. Tin (Sn) doped in the chalcogenide (Ge-Sb-Te) alloy can enhance the crystallization rate of the phase-change thin film for improving the operation speed of the memory.

Owner:MACRONIX INT CO LTD

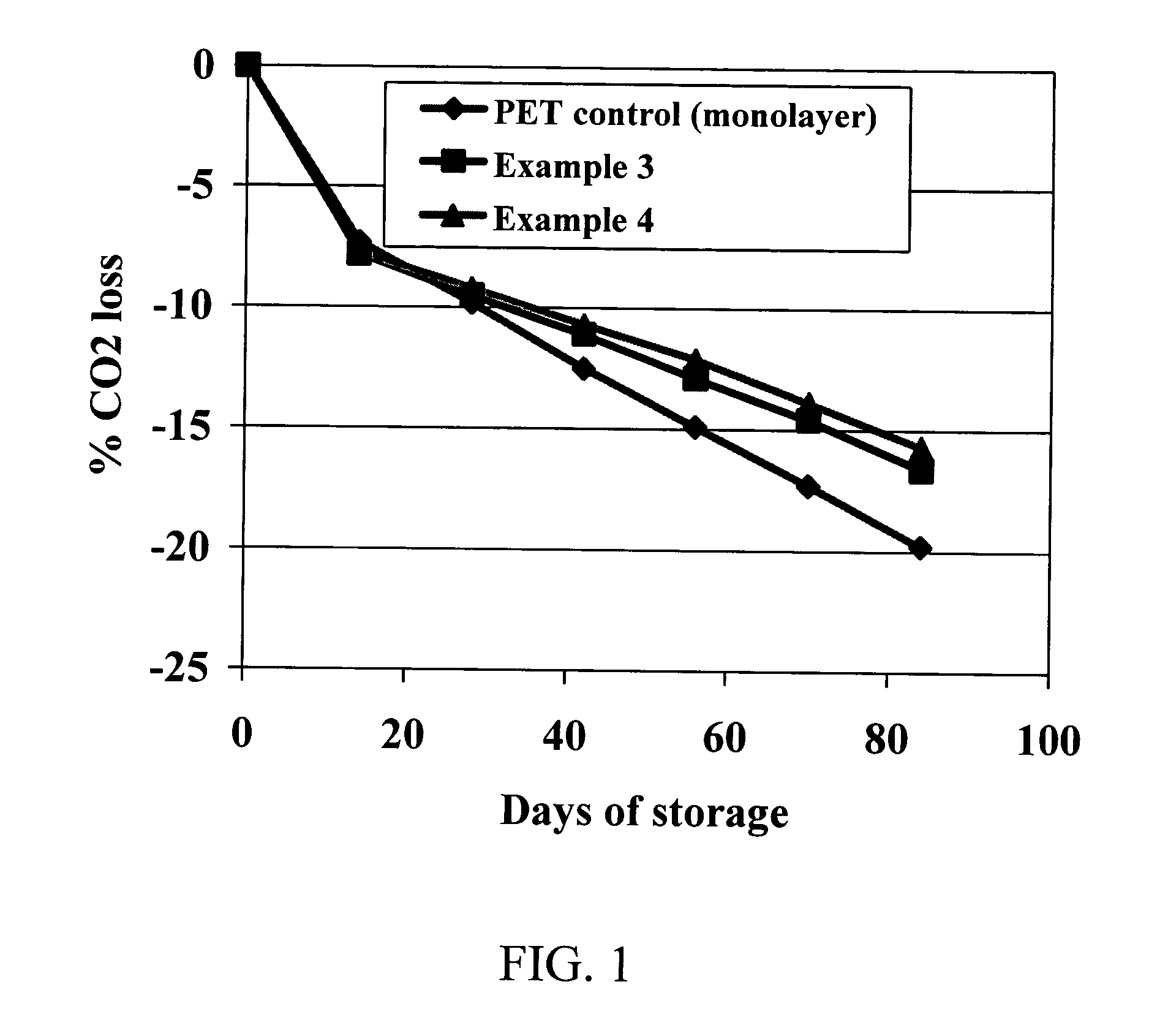

Delamination-resistant, barrier polyamide compositions for 3-layer pet beverage bottles

Gas barrier polyamide compositions exhibiting a low crystallization rate and good coinjection stretch blow moldability with polyethylene terephthalate (PET) to enable the fabrication of clear, high barrier multilayer PET bottles that have a long shelf life.

Owner:HONEYWELL INT INC

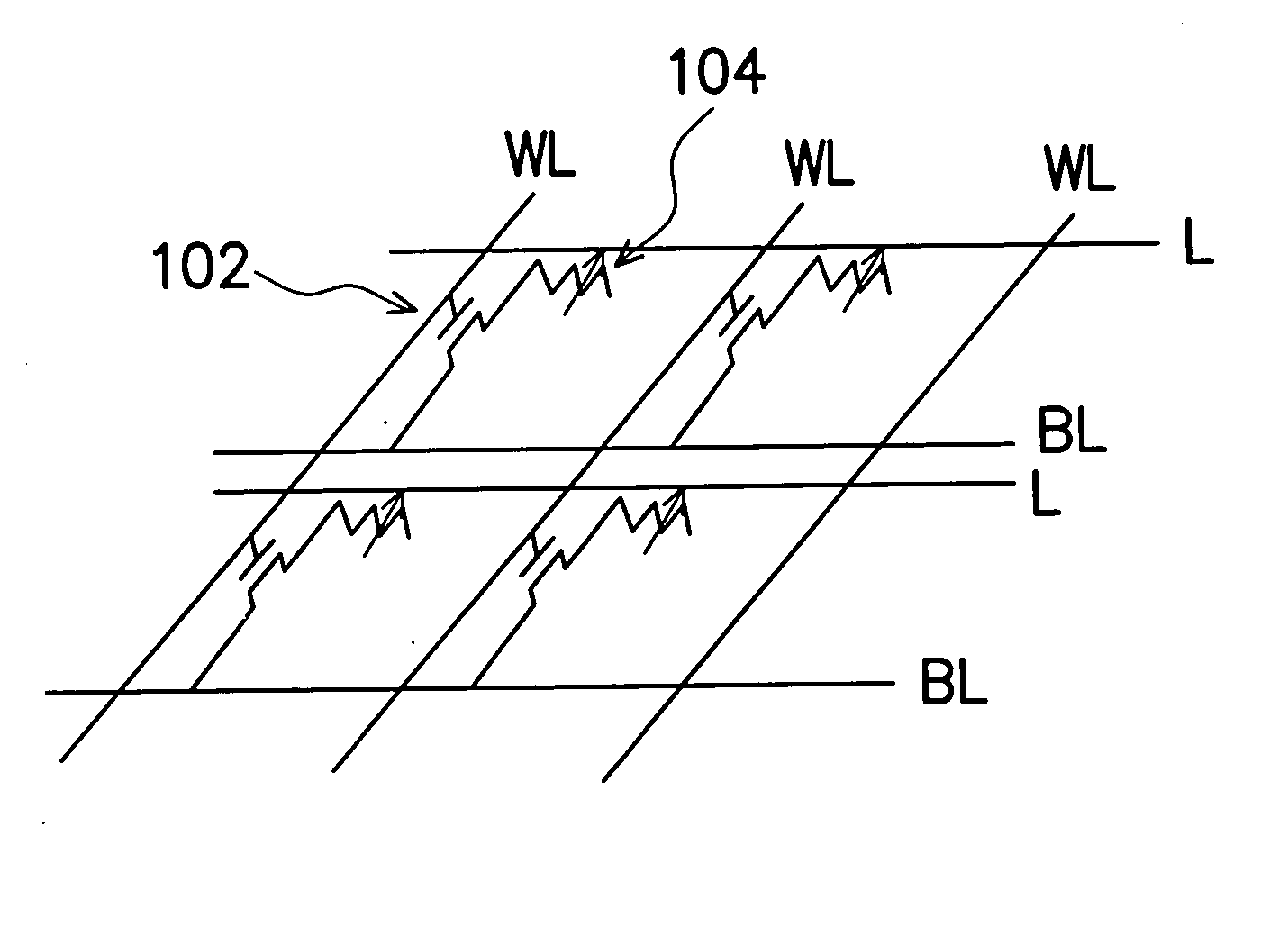

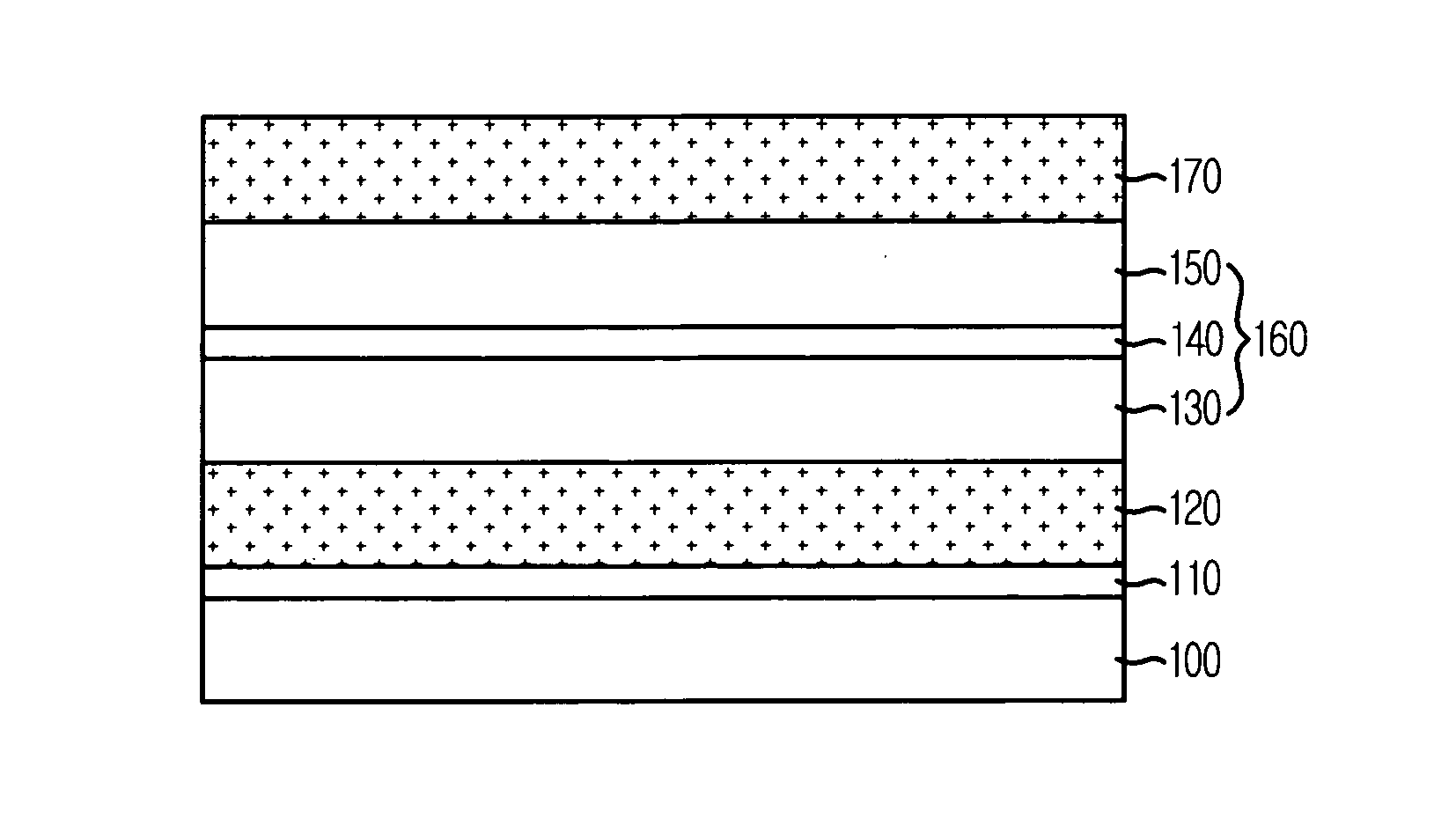

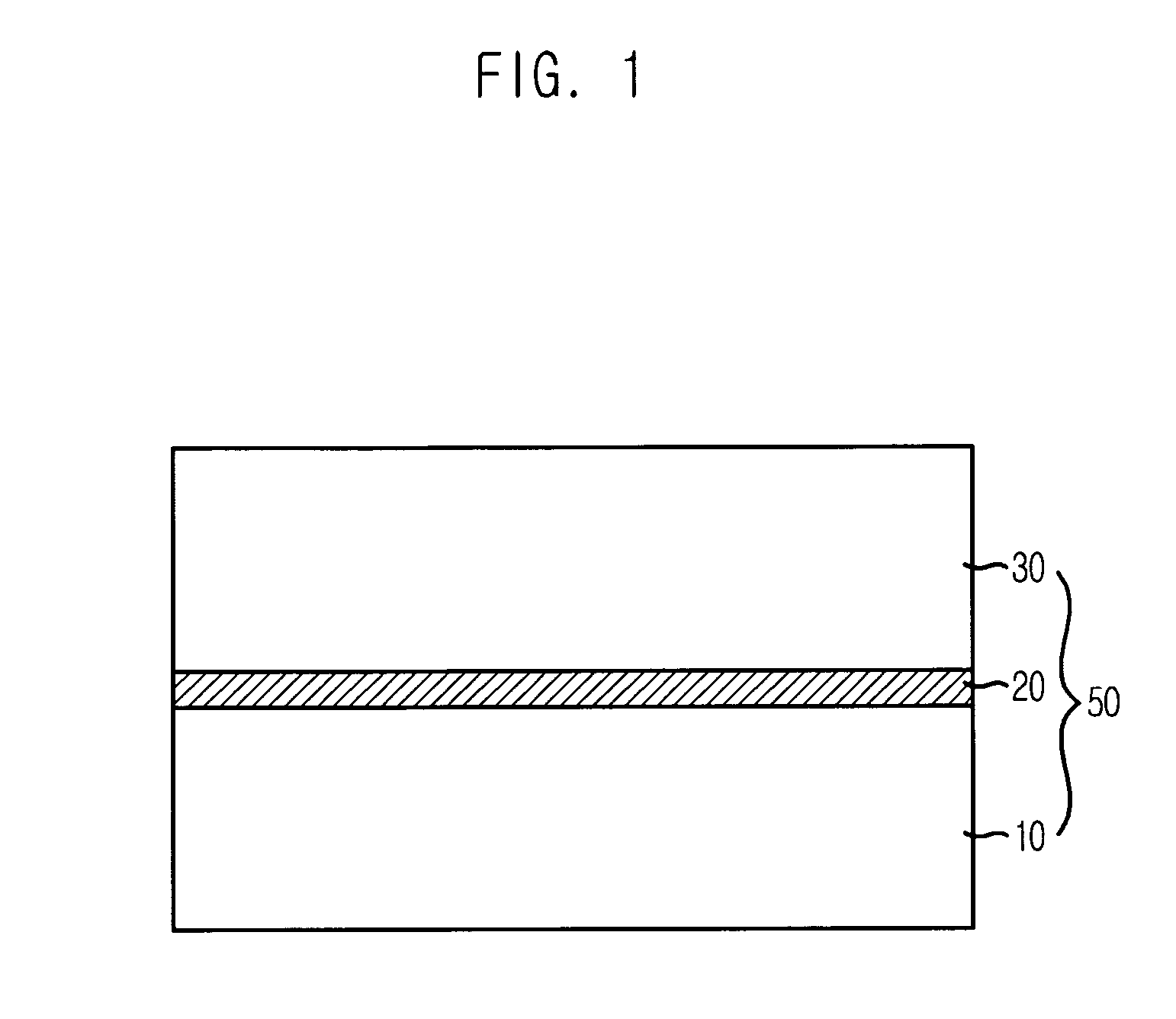

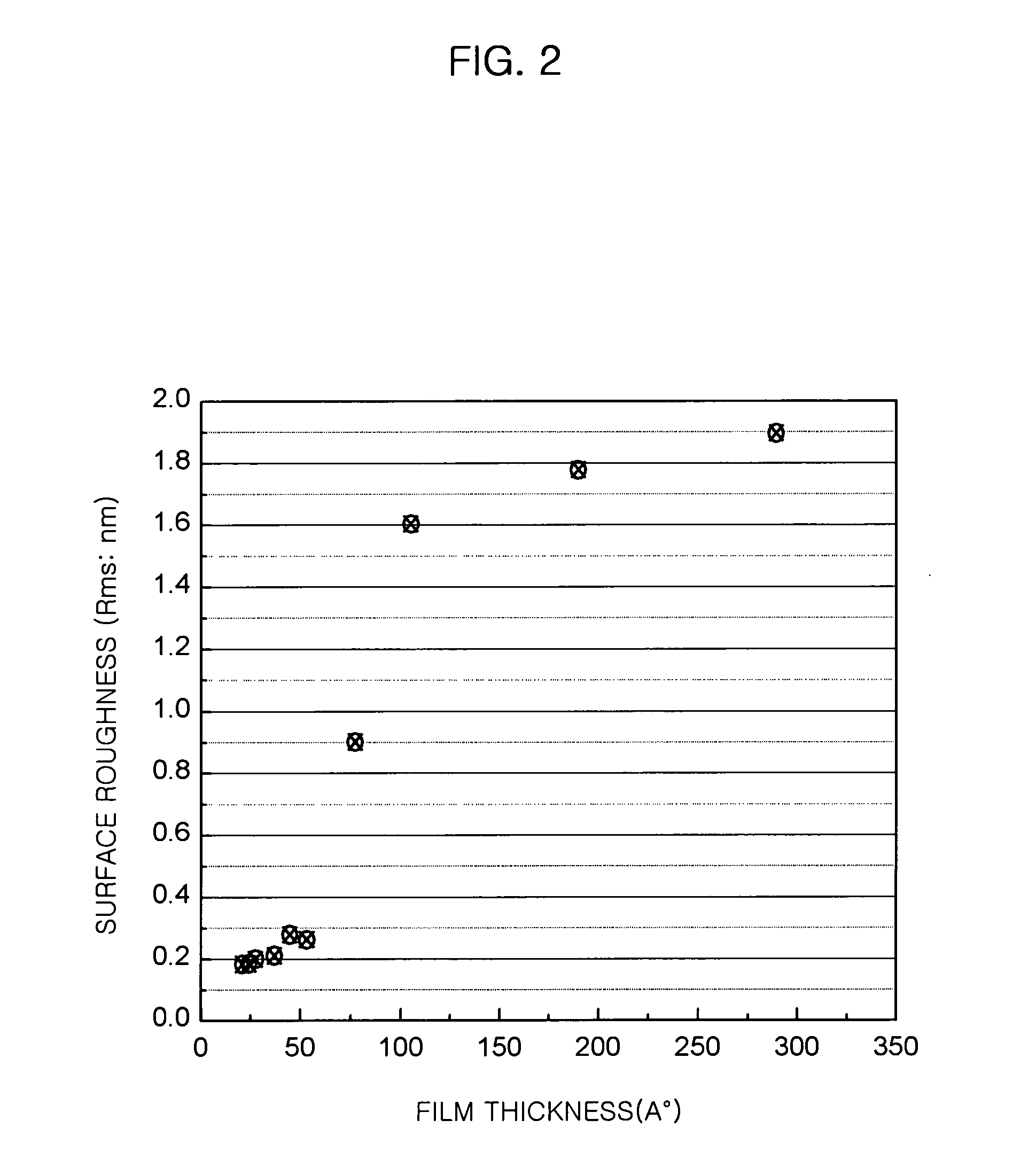

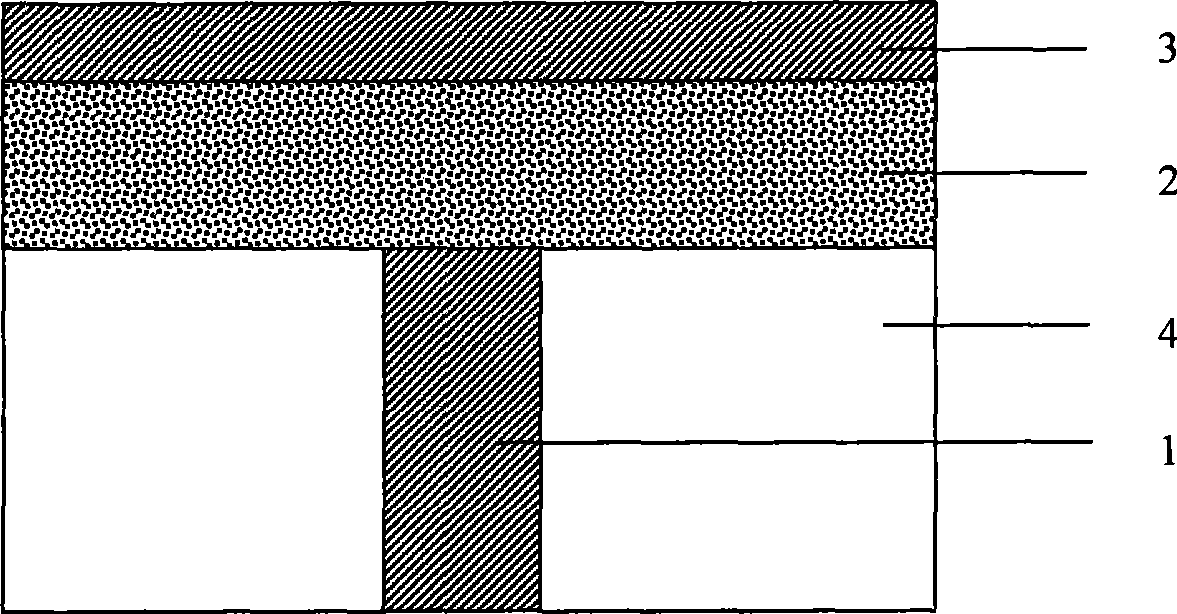

Semiconductor memory device with dielectric structure and method for fabricating the same

InactiveUS20070051998A1Increase currentTransistorSolid-state devicesDielectric structureDielectric layer

A semiconductor memory device with a dielectric structure and a method for fabricating the same are provided. The dielectric structure includes: a first dielectric layer having a dielectric constant of approximately 25 or higher; a second dielectric layer including a material having a crystallization rate lower than the first dielectric layer and formed over the first dielectric layer; and a third dielectric layer including a material substantially identical to that of the first dielectric layer and formed over the second dielectric layer.

Owner:SK HYNIX INC

Method to increase the crystallization rate of polyesters

InactiveUS6319576B1Increase chanceImprove clarityGroup 5/15 element organic compoundsSynthetic resin layered productsPolyesterPolymer chemistry

A method for increasing the crystallization rate of a crystallization polyester comprises incorporating into the polyester an effective amount of a hyperfunctional nucleation agent. The hyperfunctional nucleating agent comprises a plurality of functional groups and form stable nuclei around which the polyester crystallizes. The hyperfunctional nucleating agent facilitates faster crystallization and formation of many small crystallites. Methods of making articles such as containers with polyesters are also disclosed.

Owner:THE COCA-COLA CO

Polyester compositions and laminates and processes for producing biaxially stretched polyester bottles

InactiveUS6485804B1Increase crystallization rateMaintain good propertiesBottlesSynthetic resin layered productsCarboxylic acidDicarboxylic acid

The novel polyester (first polyester [A]) of the invention comprises dicarboxylic acid constituent units derived from at least one dicarboxylic acid selected from terephthalic acid, isophthalic acid and naphthalenedicarboxylic acid and diol constituent units derived from diols comprising ethylene glycol and a polyalkylene glycol having a C2-C10 alkylene chain, wherein the proportion of constituent units derived from the polyalkylene glycol is 0.001 to 10% by weight based on the diol constituent units. The polyester [A] has an excellent crystallization rate, is suitably used, singly or as compositions together with another polyester [B] and / or other polymers, for production of molded products such as films, sheets, laminates, preforms and bottles, which have excellent thermal, gas barrier and transparency properties.

Owner:MITSUI PETROCHEMICAL INDUSTRIES LTD

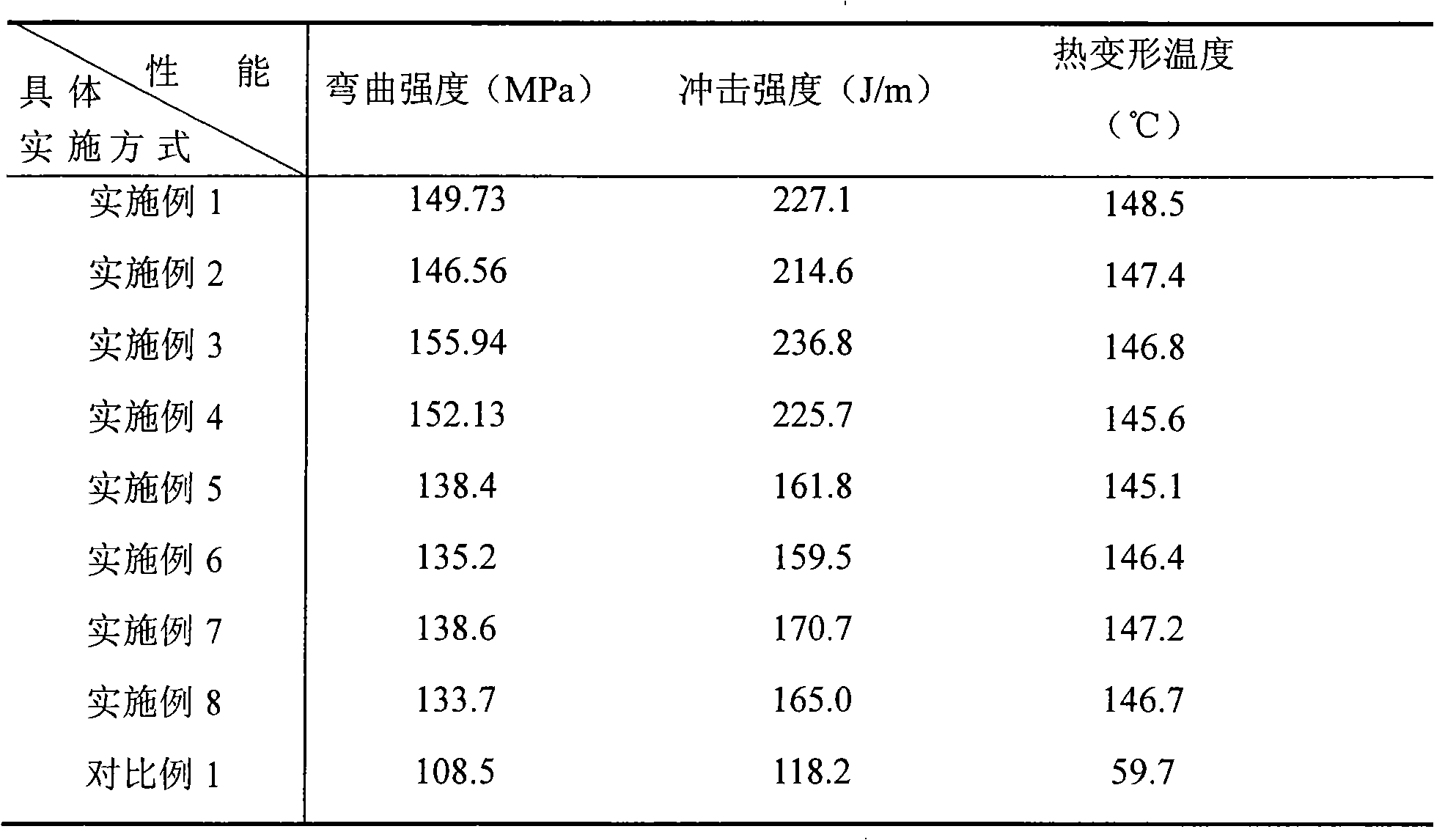

High strength and high heat resistance polylactic acid composite material and preparation method thereof

The invention relates to a high performance polylactic acid composite material and a preparation method. The high performance polylactic acid composite material comprises the following components in parts by mass: 40-85 parts of polylactic acid, 10-40 parts of modified inorganic or natural fibres; 1-10 parts of organic modified natural minerals, 0.8-5 parts of sensitizing agents, 0.1-2 parts of heat stabilizers, 0.1-1 part of antioxygen and 0.1-1 part of lubricating agent. The inorganic or natural fibre reinforced polylactic acid is selected to improve the mechanics performance, silane coupling agents are adopted to carry out surface processing to improve the compatibility with the polylactic acid matrix; and organic modified natural minerals are selected to improve the crystallization rate of the polylactic acid, also improve the material performance, reduce energy source consumption, and reduce the cost of products. After heat processing is carried out, the heat resistance and the mechanics performance of the composite material are further improved through the radiation crosslinking of crystallized polylactic acid. The prepared polylactic acid composite material has excellent mechanical property and heat resistance, and can avoid the problem of property reduction caused by a single modification method. The method is simple. The composite material can be prepared through the traditional plastic processing methods. The invention is suitable for industrial production.

Owner:SHANGHAI UNIV

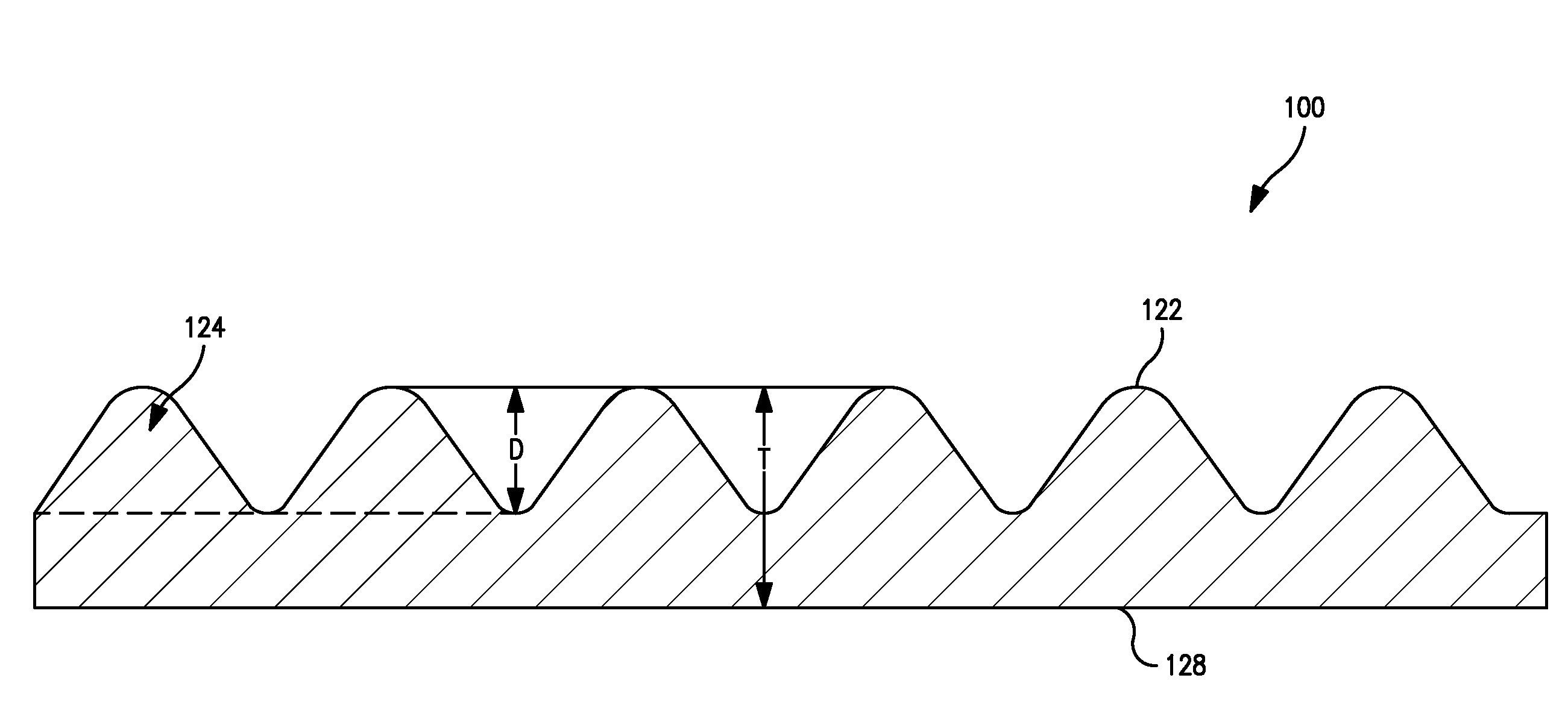

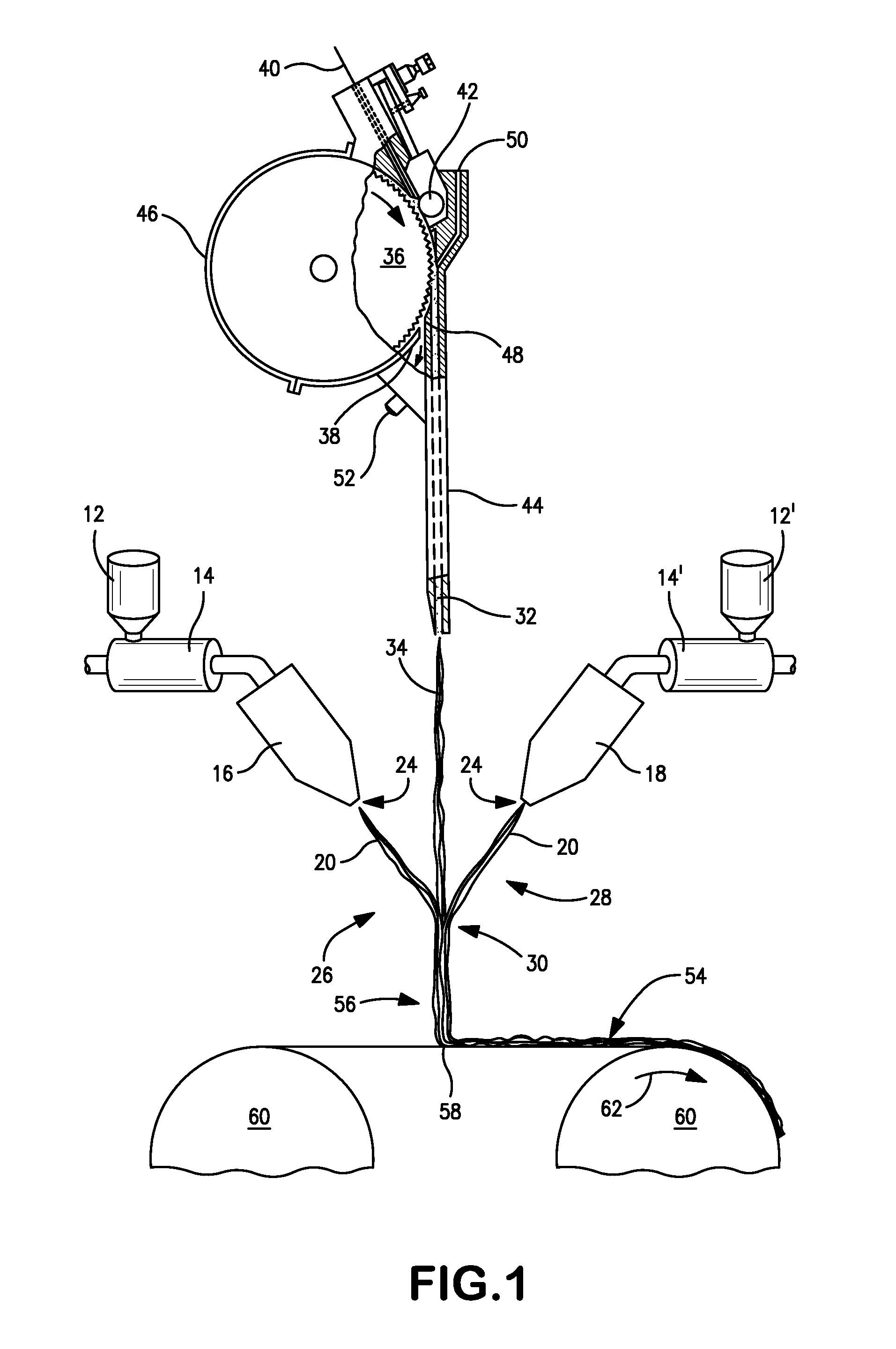

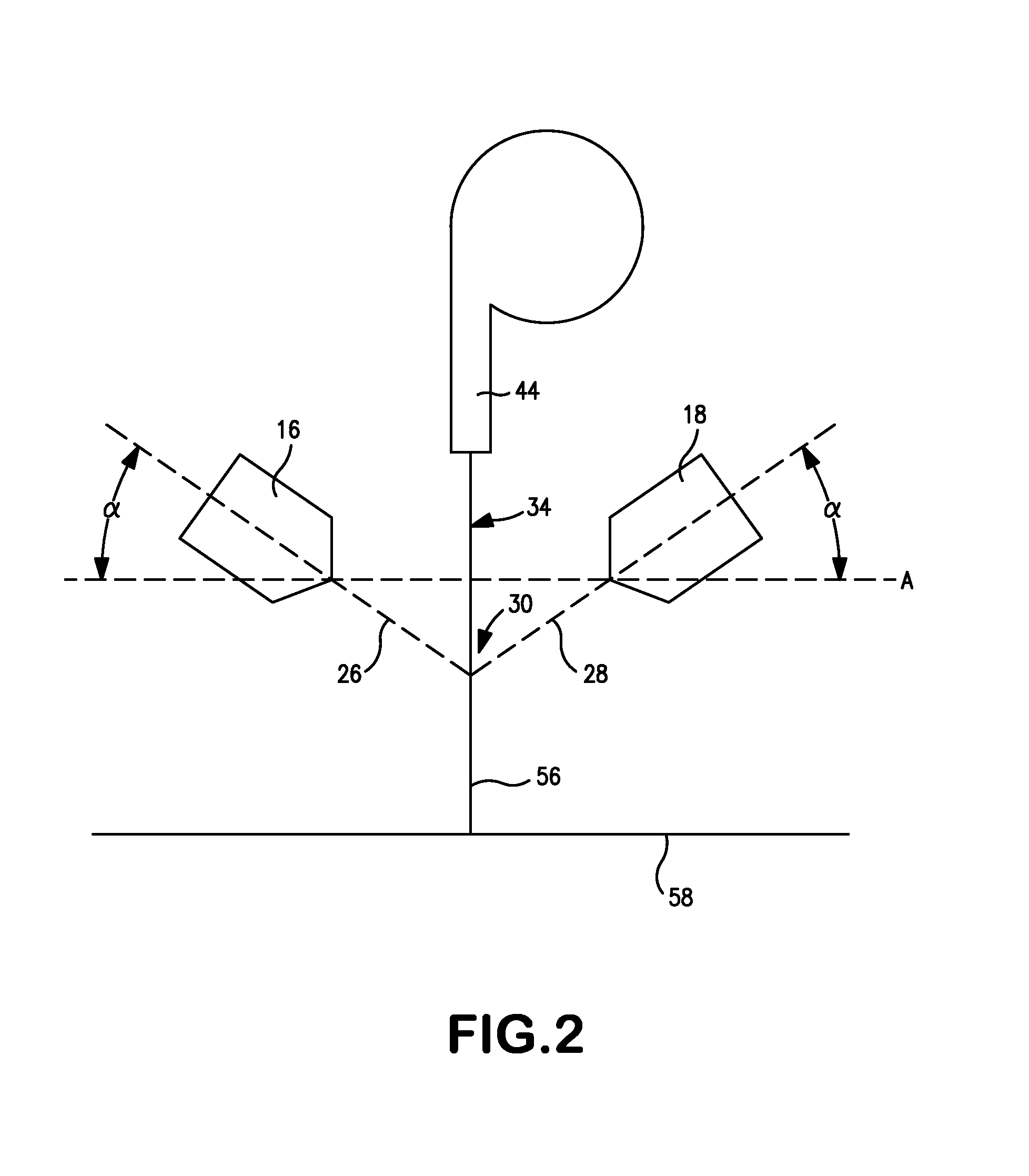

Coform Nonwoven Web Formed from Propylene/Alpha-Olefin Meltblown Fibers

A coform nonwoven web that contains a matrix of meltblown fibers and an absorbent material is provided. The meltblown fibers are formed from a thermoplastic composition that contains at least one propylene / α-olefin copolymer of a certain monomer content, density, melt flow rate, etc. The selection of a specific type of propylene / α-olefin copolymer provides the resulting composition with improved thermal properties for forming a coform web. For example, the thermoplastic composition crystallizes at a relatively slow rate, thereby allowing the fibers to remain slightly tacky during formation. This tackiness may provide a variety of benefits, such as enhancing the ability of the meltblown fibers to adhere to the absorbent material during formation of the coform web. In certain embodiments, the coform web may also be imparted with texture using a three-dimensional forming surface. In such embodiments, the slow crystallization rate of the meltblown fibers may increase their ability to conform to the contours of the three-dimensional forming surface. Once the fibers crystallize, however, the meltblown fibers may achieve a degree of stiffness similar to conventional polypropylene, thereby allowing them to retain their three-dimensional shape and form a highly textured surface on the coform web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

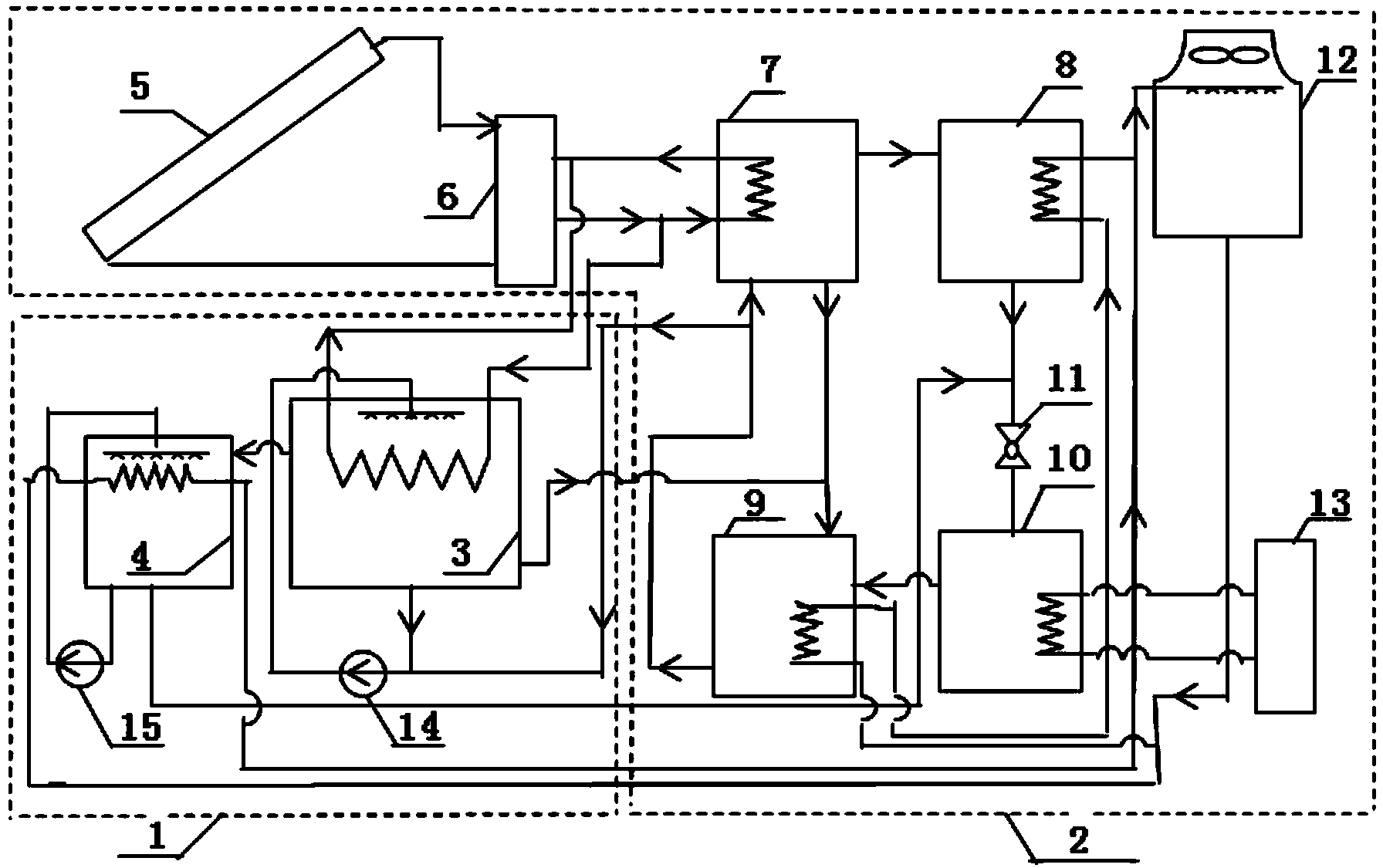

Three-phase energy storage method of solar air conditioner

ActiveCN104374025ATake advantage ofEasy to adjustClimate change adaptationEnergy efficient heating/coolingHigh energyVolumetric Mass Density

The invention provides a three-phase energy storage method of a solar air conditioner, and belongs to the field of solar air conditioners. An absorbing type refrigerating working pair serves as an energy storage medium, a three-phase energy storage device is connected with a generator in a solar absorbing type refrigerating system in parallel, a solar heat collecting medium provides heat for the three-phase energy storage device and the generator, surplus solar collected heat is stored in the three-phase storage device in an energy storage medium chemical potential energy mode by adjusting the flow of the heating collecting medium entering the three-phase energy storage device in real time, and good matching of a drive heat source and an air conditioner load is achieved. The three-phase energy storage method avoids the dangers brought by crystallization during serial connection of a two-phase energy storage device and a generator in the prior art, the load adjusting function of the solar air conditioner can be achieved through an energy storage system by means of gas-liquid-solid three-phase high energy storage density, and the crystallization rate of 50% enables the size of the energy storage device to be reduced by more than a half than the size of an energy storage device in a two-phase energy storage mode. The system is simple, adjustment is convenient and flexible, the amount of released cold is stable, and a common solar air conditioning system can be easily improved into an energy storage air conditioning system.

Owner:BEIJING UNIV OF TECH

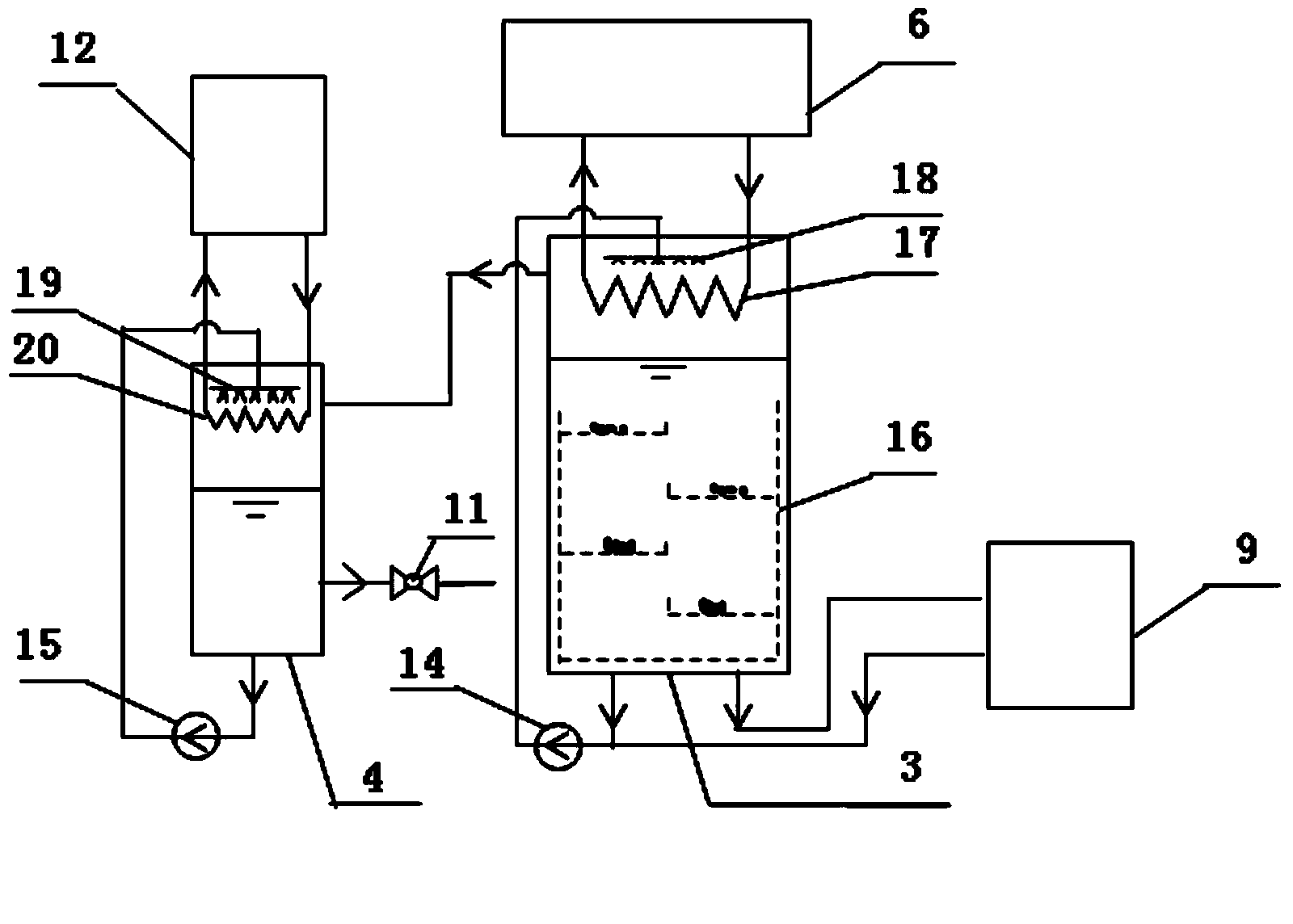

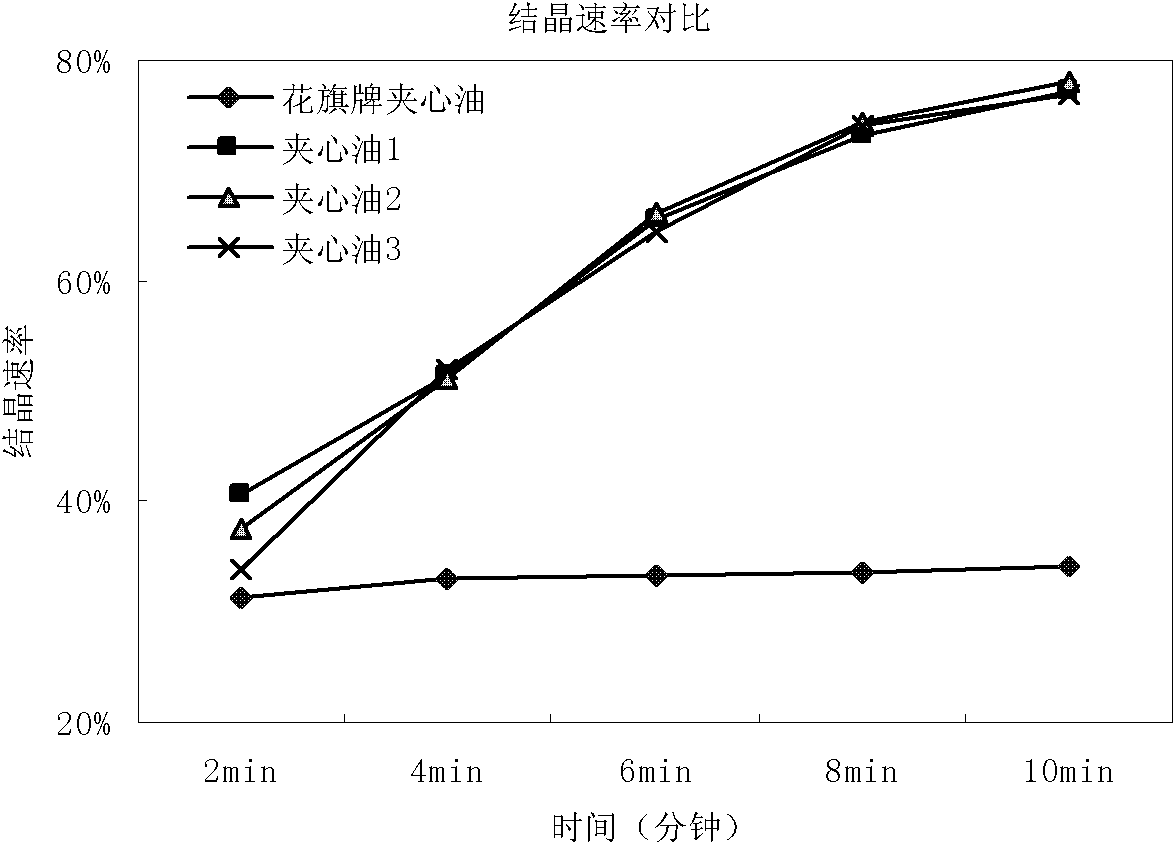

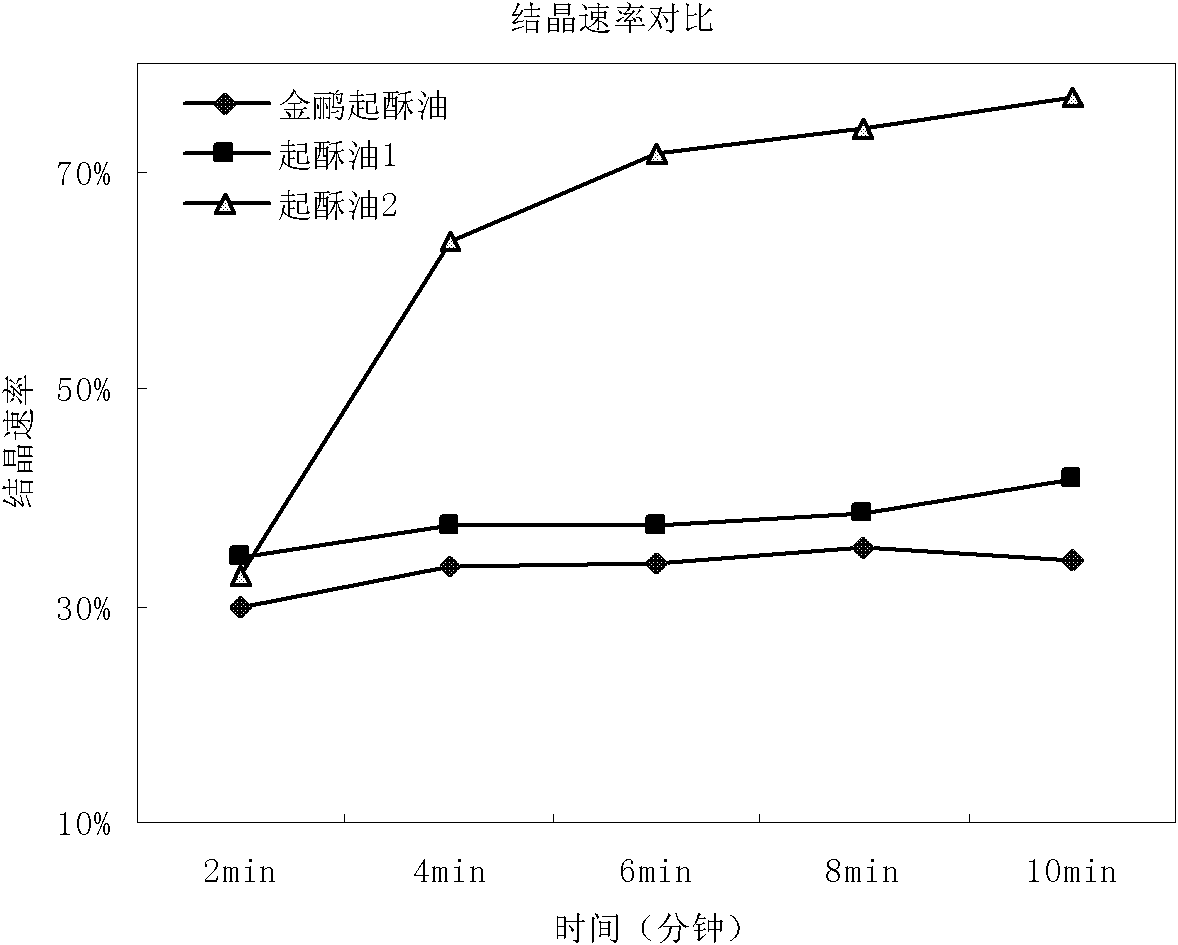

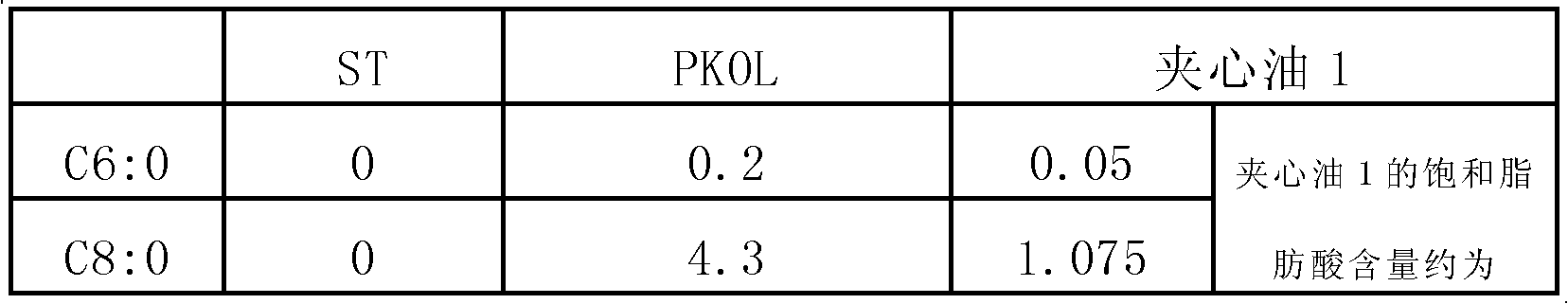

Oil composition, composite oil composition, product and production method

The invention relates to an oil composition, a composite oil composition compounded by the oil composition and natural plant oil, and a plastic oil product thereof. The oil composition comprises a triglyceride composition obtained by transesterification treatment. Oil raw materials adopted by the transesterification treatment comprise natural plant oil or its distillate oil. Weighed according to the weight of total fatty acids which form the oil composition, the content of saturated fatty acid is 50-80%, wherein the content of saturated fatty acid with its carbon atomic number being 12-14 is 5-35% and the content of saturated fatty acid with its carbon atomic number being 16-18. Weighed according to the gross weight of the oil composition, the content of three-phase saturated triglycerides containing three saturated fatty acids within molecules is 40-65%. The solid fat content of the oil composition at 25-30 DEG C is 10-52%, preferably 30-10% or 52-25%. The oil composition and the composite oil composition can be used to prepare the plastic oil, which has advantages of low trans-fatty acid content and fast crystallization rate. The invention also provides preparation methods of the above oil composition and the composite oil composition.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

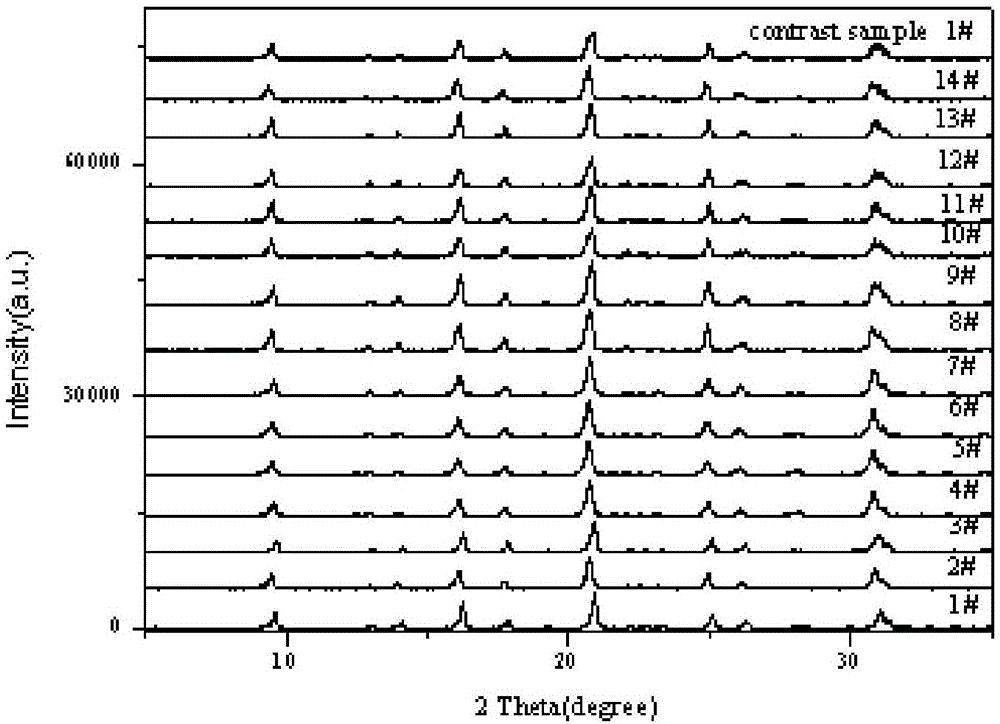

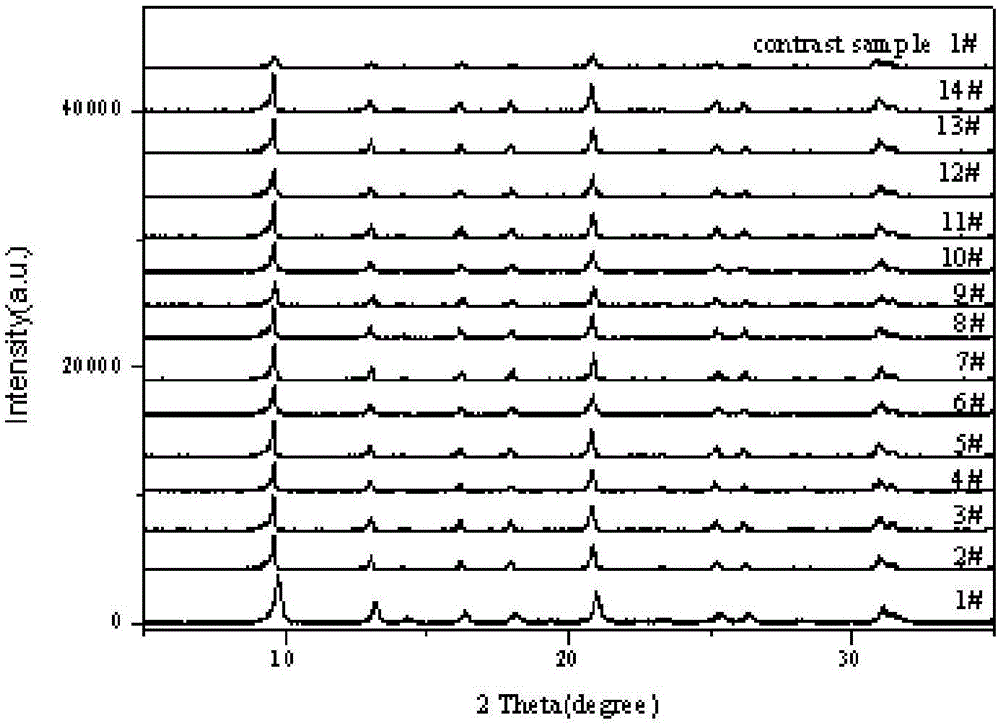

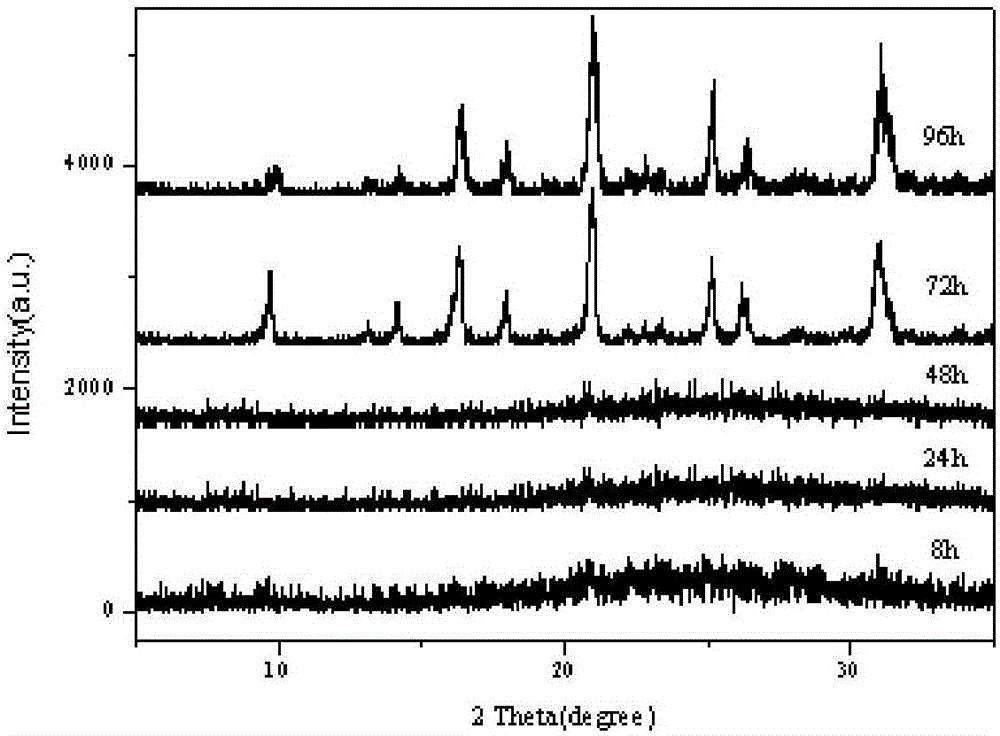

Nucleating agent of polyethylene glycol terephthalate and preparation method thereof

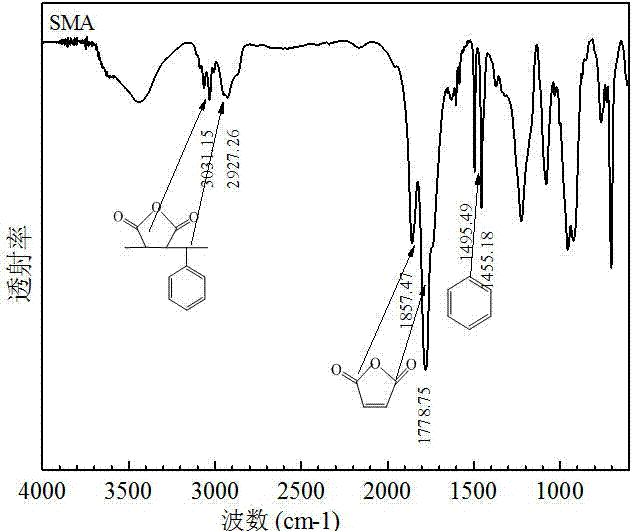

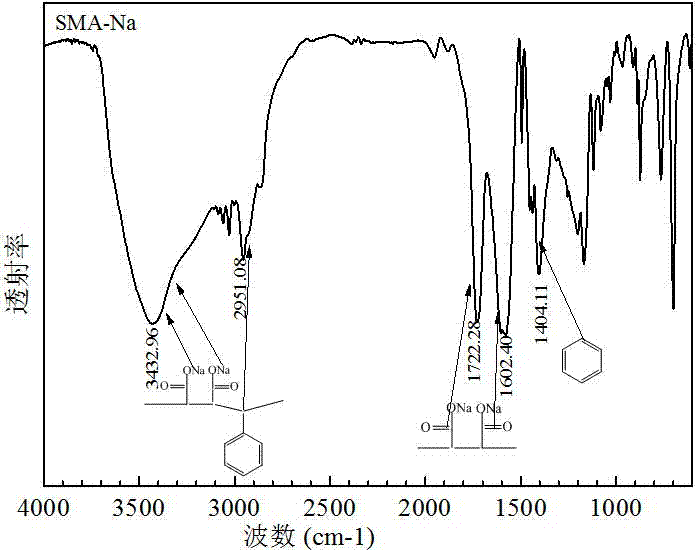

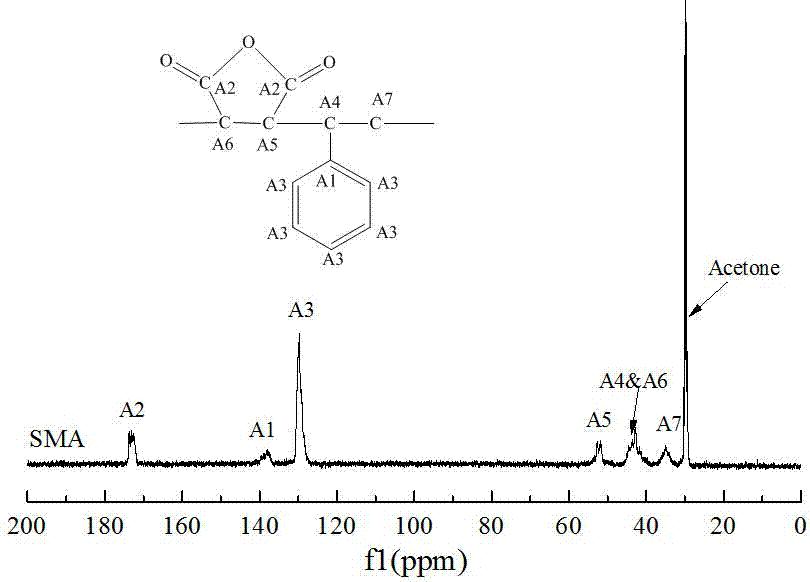

InactiveCN102924641ASimple preparation processImprove thermal stabilityPolyethylene glycolPolymer SMA

The invention belongs to the technical field of macromolecule materials, and particularly relates to a nucleating agent of the polyethylene glycol terephthalate and a preparation method thereof. The agent utilizes random copolymer or alternating copolymer of maleic anhydride and styrene as raw materials, and conducts hydrolysis, salinization and purification to obtain styrene-maleic anhydride ionomer. The styrene-maleic anhydride ionomer can serve as the nucleating agent of the polyethylene glycol (PET), increases crystallization temperature of the PET and increases crystallization rate. The nucleating agent is simple in preparation method, capable of adopting blending smelting reaction extrusion pelleting once process with the PET, convenient to operate, high in benefit, low in cost and suitable for industrial production.

Owner:FUDAN UNIV

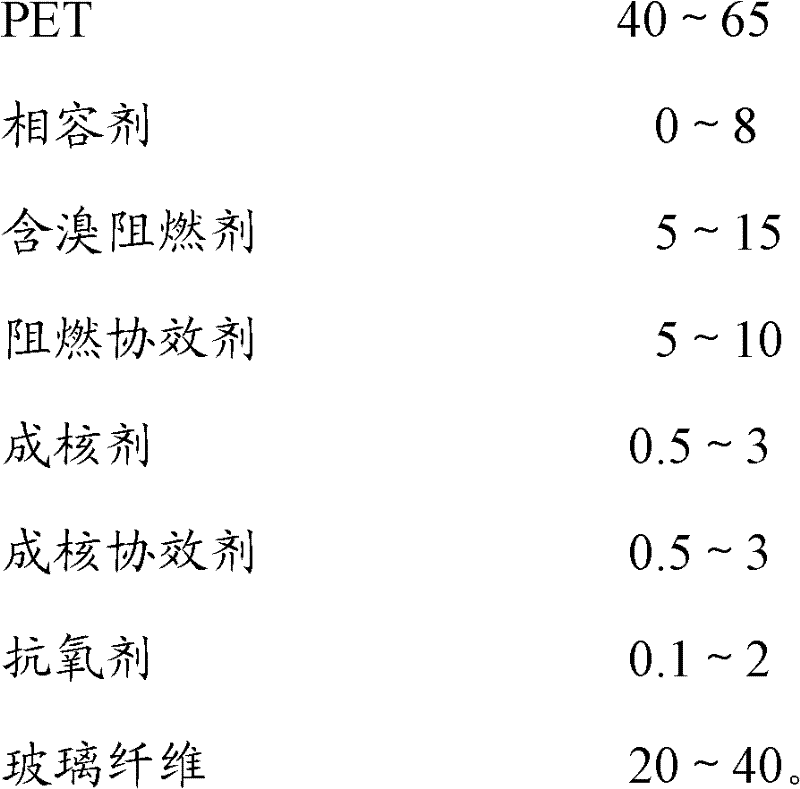

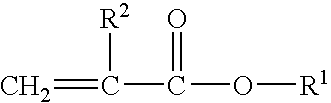

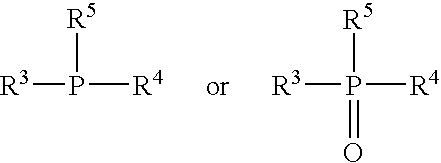

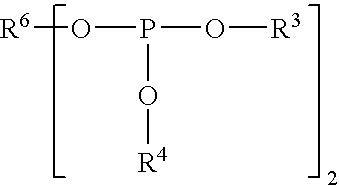

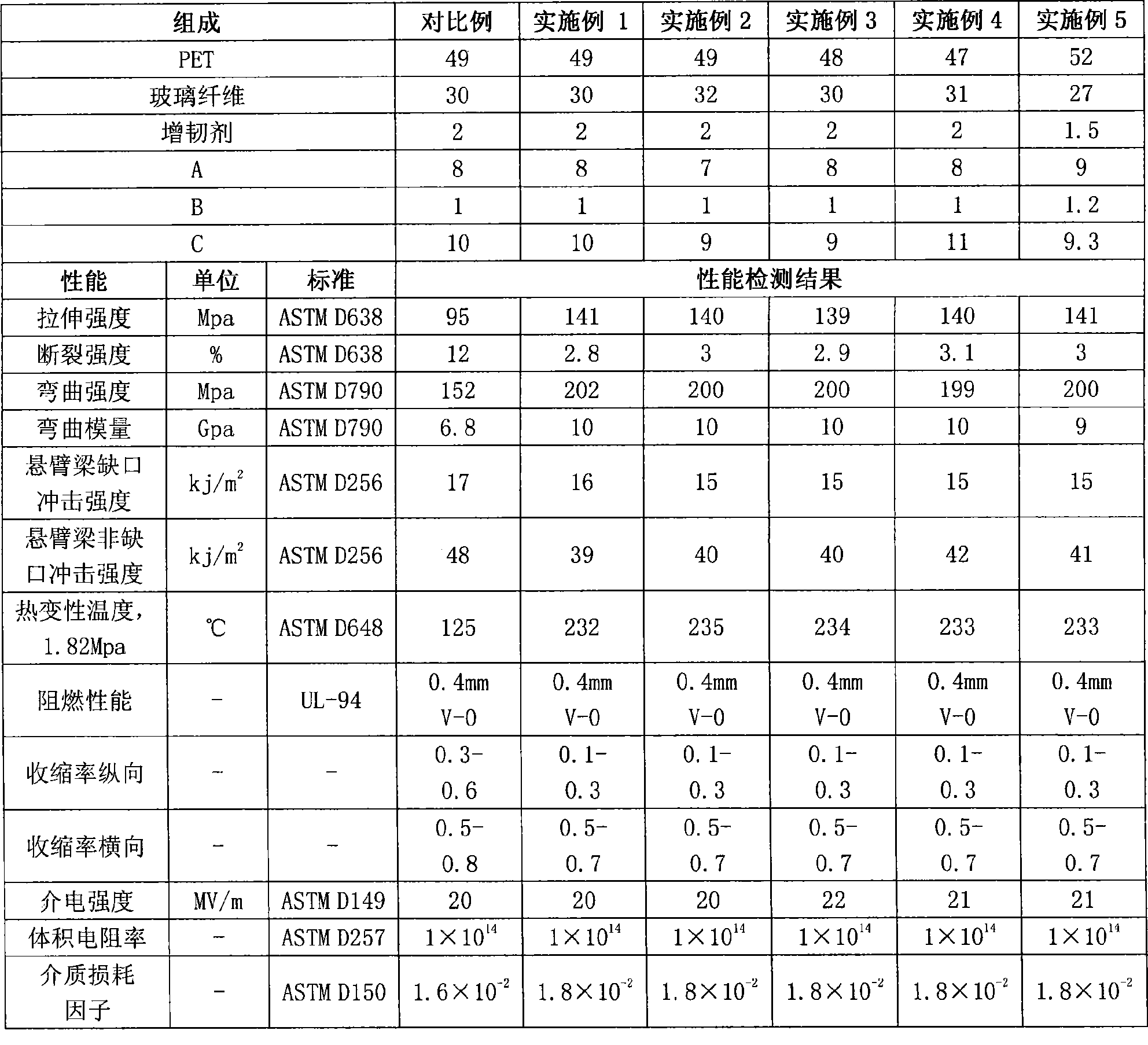

PET (polyethylene terephthalate) engineering plastic and preparation method and application thereof

InactiveCN102504500AEasy to stretchEasy to bendPolyethylene terephthalate glycolPolyethylene terephthalate

Owner:惠州市沃特新材料有限公司

Polyester compositions

InactiveUS6986864B2Improve impact performanceIncrease crystallization rateHollow wall articlesBeltsPolyesterPolyolefin

Disclosed are certain novel polyester compositions particularly useful for shaping or forming into containers and similar shaped articles by thermoforming procedures. The polyester compositions comprise a thermoplastic polyester, an impact modifier and a polyester crystallization rate enhancing component selected from poly(tetramethylene terephthalate) homo- and co-polymers. The polyester compositions exhibit improved crystallization rates as compared to similar compositions not including impact modifier or compositions using other types of crystallization rate enhancing components such as polyolefin-based polymers.

Owner:EASTMAN CHEM CO

Rapid crystallization polylactic acid composite material and preparation method thereof

InactiveCN101544813AIncrease the rate of crystallizationImprove mechanical propertiesNatural mineralMechanical property

The invention relates to a rapid crystallization polylactic acid composite material and a preparation technique thereof. The composite material comprises the following components in portion by weight: 59 to 98 portions of hypocrystalline poly-L-lactic acid, 1 to 40 portions of organic modified natural mineral, 1 to 20 portions of organic crystallization promoter, 0.1 to 1.0 portion of heat stabilizer, and 0.05 to 1.0 portion of lubricant. The sum of the mass percentage of the components is 100 percent. The preparation method for the material comprises the following steps: firstly preparing the modified natural mineral; then mixing the components according to the components of the composite material; agitating and mixing the raw materials evenly through a high-speed agitator; and adding the co-mixture into a twin screw extruder for extrusion and granulation. The method improves the crystallization rate of a polylactic acid matrix through the synergistic action of organized mineral and the crystallization promoter. Due to the addition of the organic crystallization promoter, the method strengthens the mechanical properties of the polylactic acid composite material, while simultaneously quickening the crystallization rate of polylactic acid, thereby avoiding the defect of greatly reducing the mechanical properties of the polylactic acid composite material caused by the addition of a single inorganic mineral nucleating agent. The price of adopted fillers is low; and the whole preparation method has a simple technological process and less consuming time of the technological process, and can realize the large-scale industrialized production.

Owner:SHANGHAI UNIV

Polyethylene having faster crystallization rate and improved environmental stress cracking resistance

InactiveUS20100105839A1Fast crystallizationAdditional stress crackCrystallization rateMedium molecular weight

Disclosed is a polyethylene composition having faster crystallization rate and improved environmental stress cracking resistance. The polyethylene composition comprises a multimodal polyethylene and a nucleating agent. The multimodal polyethylene comprises from 25 to 50 wt % of a low molecular weight ethylene homopolymer component, from 25 to 50 wt % of a medium molecular weight ethylene copolymer component and from 25 to 50 wt % of a high molecular weight ethylene copolymer component. The polyethylene composition has an environmental stress cracking resistance (ASTM D1693, Condition B in 100% Igepal) greater than or equal to 40 days and a crystallization half time less than or equal to 70% of the crystallization half time of the multimodal polyethylene without nucleating agent.

Owner:EQUSR CHEM LP

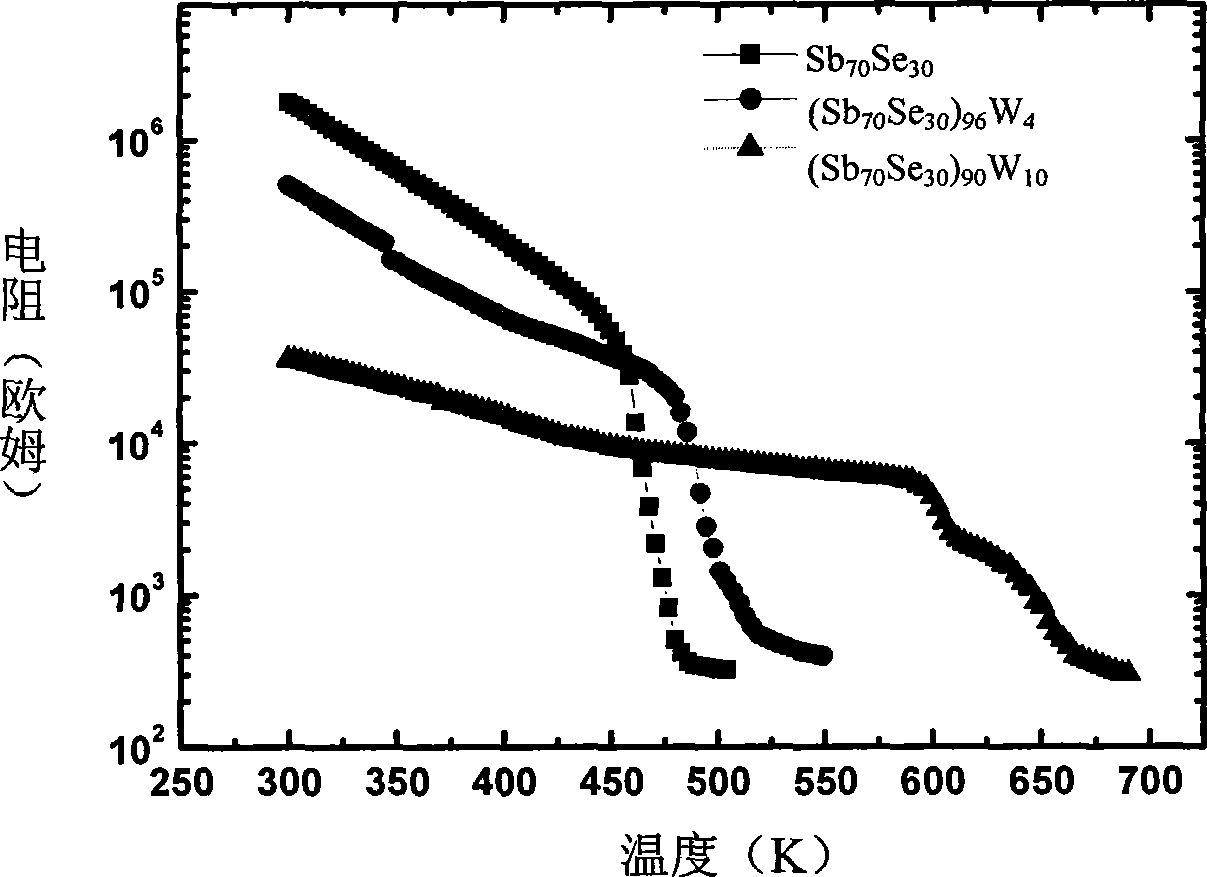

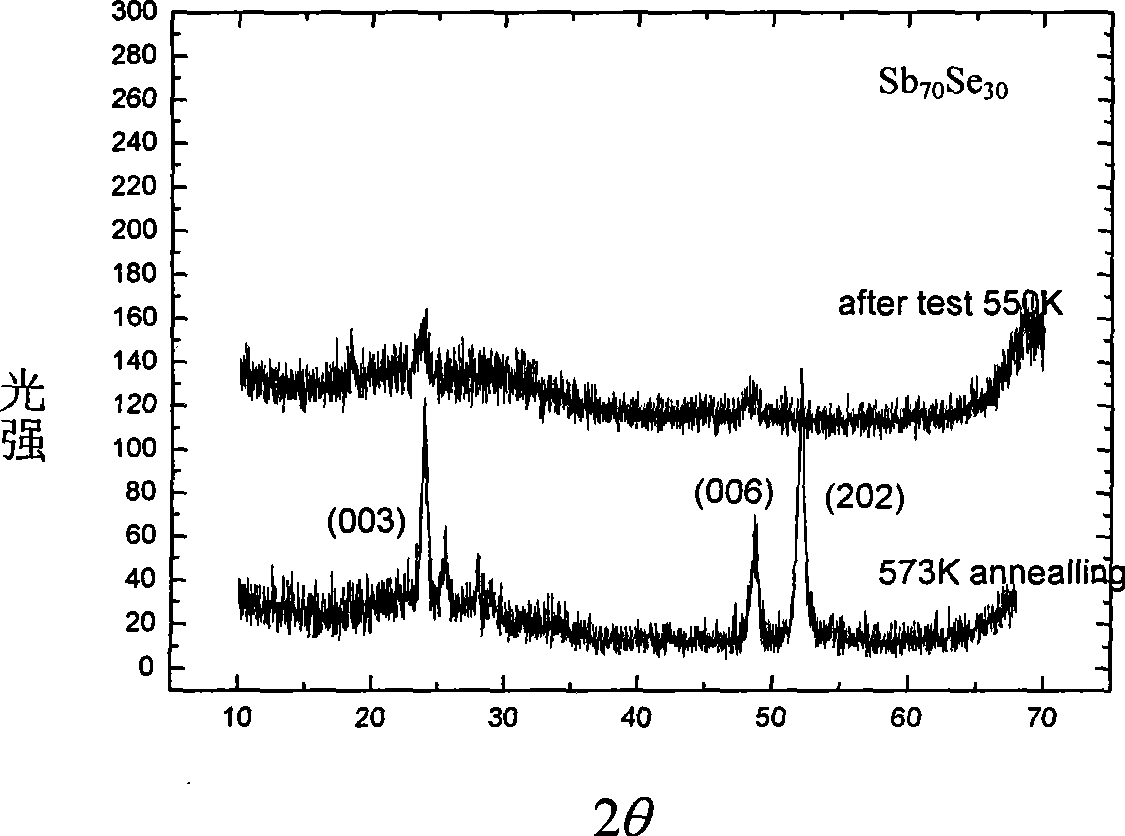

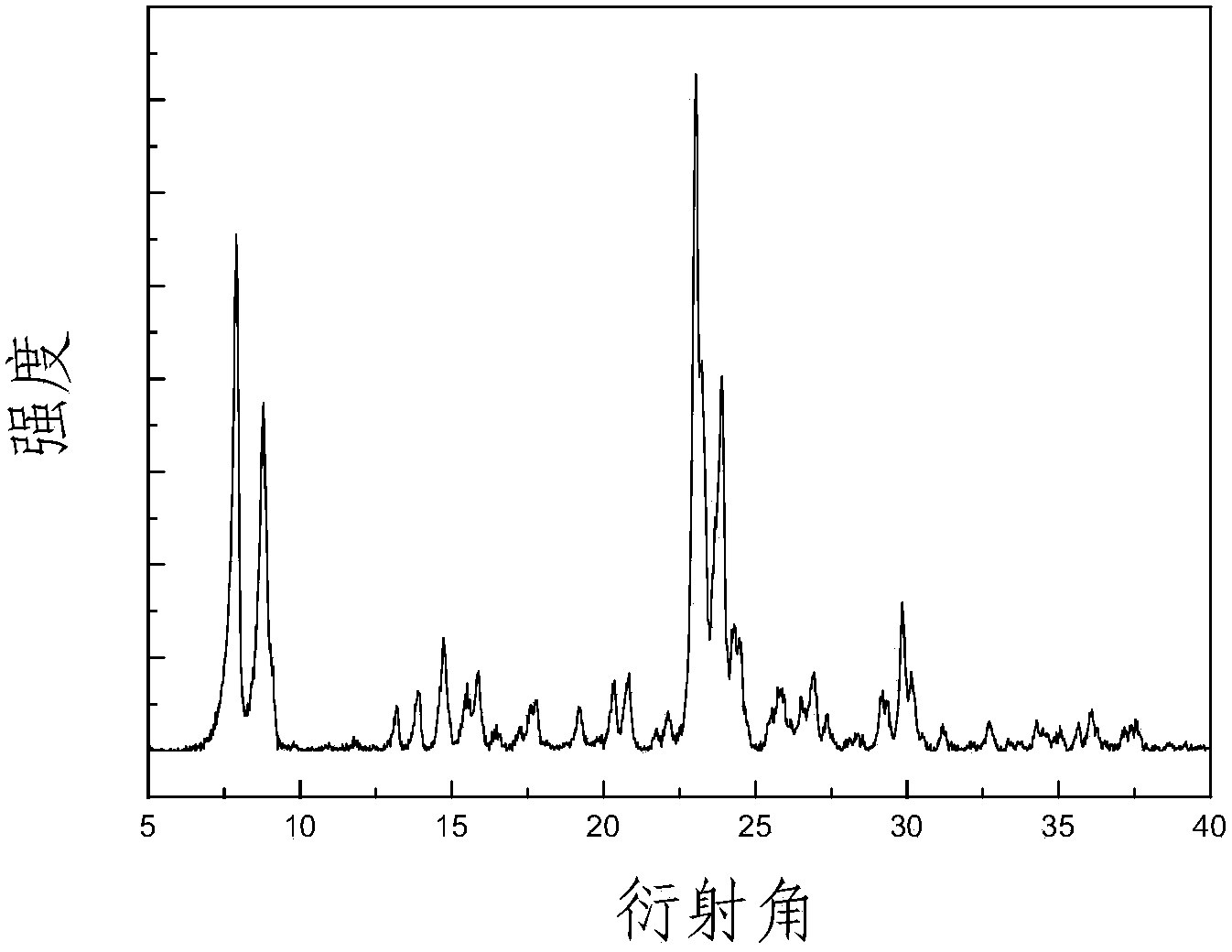

M-Sb-Se phase changing thin-film material used for phase changing memory

ActiveCN101488558AFast crystallizationFast reading and writingElectrical apparatusDigital storageIndiumPhase-change memory

The invention discloses an M-Sb-Se phase transition film material used for a phase transition storage and the ingredient thereof is (SbxSe(1-x))(1-y)My, wherein y is an atomic ratio of 0.2%-15%, x is the atomic ratio of 50%-95%, and doping elements of M comprise one or two elements out of tungsten, aluminum, indium, silver, copper, nickel, gallium, titanium , tin, oxygen and nitrogen. The M-Sb-Se phase transition film material of the invention has faster crystallization rate, faster read-write rate and better data holding property than the commonly used Ge2Sb2Te5 material and better thermal stability than SbSe binary material. Meanwhile, the material is free from element Te, thereby being environment friendly, and the material has good compatibility with CMOS technique.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

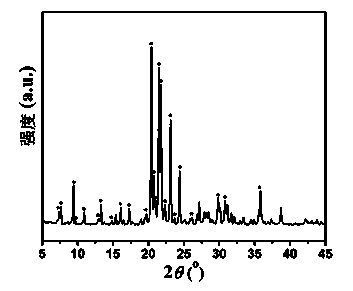

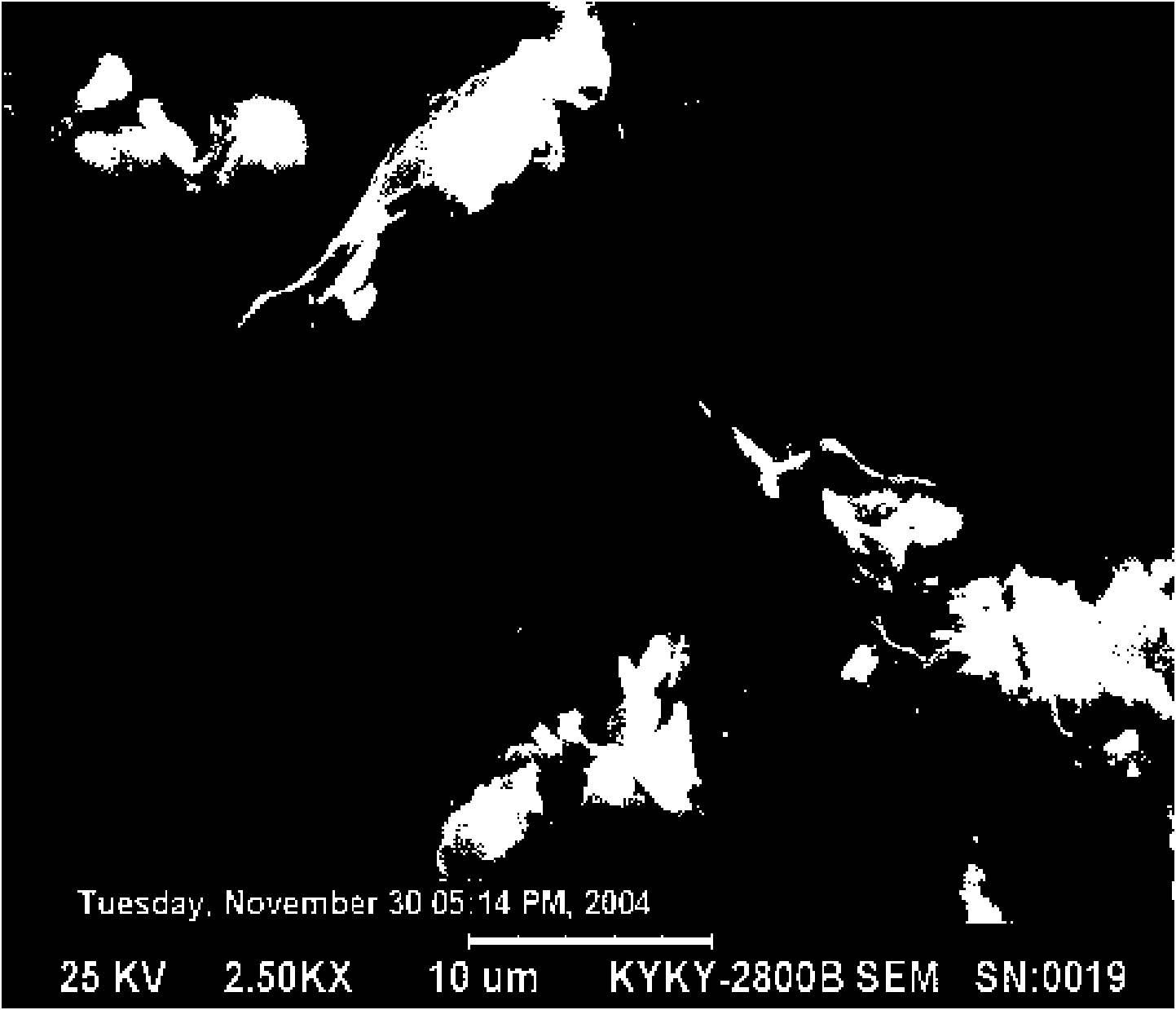

Nano MFI-type molecular sieve with hierarchical pore structure and preparation method and application thereof

ActiveCN103447078AHigh hydrothermal stabilityEasy to separateMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveHydrothermal synthesis

The invention belongs to the technical field of a catalyst and an application thereof, and particularly relates to a nano MFI-type molecular sieve which is easy to separate and has high hydrothermal stability and a hierarchical pore channel structure, and a preparation method and application thereof. The method comprises the following steps: (1) selecting a prepared nano MFI-type molecular sieve suspension as a mother liquid; (2) adding a cationic flocculant into the mother liquid to assemble the nano molecular sieve; (3) putting the assembled nano molecular sieve into a reaction kettle for hydrothermal synthesis to obtain a nano molecular sieve compound with a block size of 100 nanometers to 100 microns. The nano molecular sieve compound is subjected to conventional filtering, washing, drying and roasting to obtain the nano MFI-type molecular sieve with a hierarchical pore channel structure. The nano MFI-type molecular sieve prepared by the method can be separated through a filtering operation and has the advantages of open intercrystalline pore channel structure, large pore volume, high crystallization rate and high hydrothermal stability; in a methanol-to-propylene reaction, the nano MFI-type molecular sieve shows higher propylene yield and stability than the nano MFI-type molecular sieve prepared by a conventional method.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

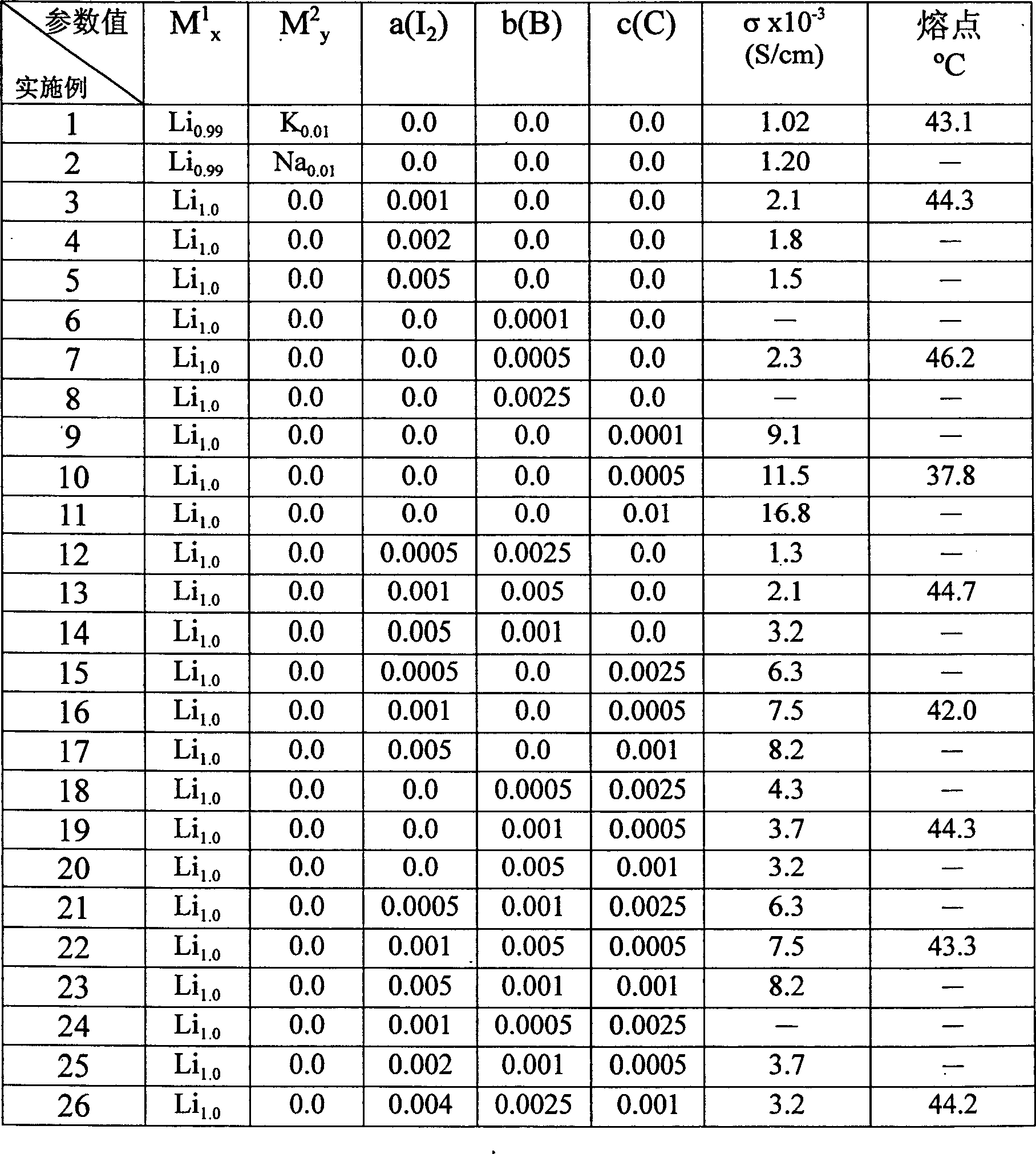

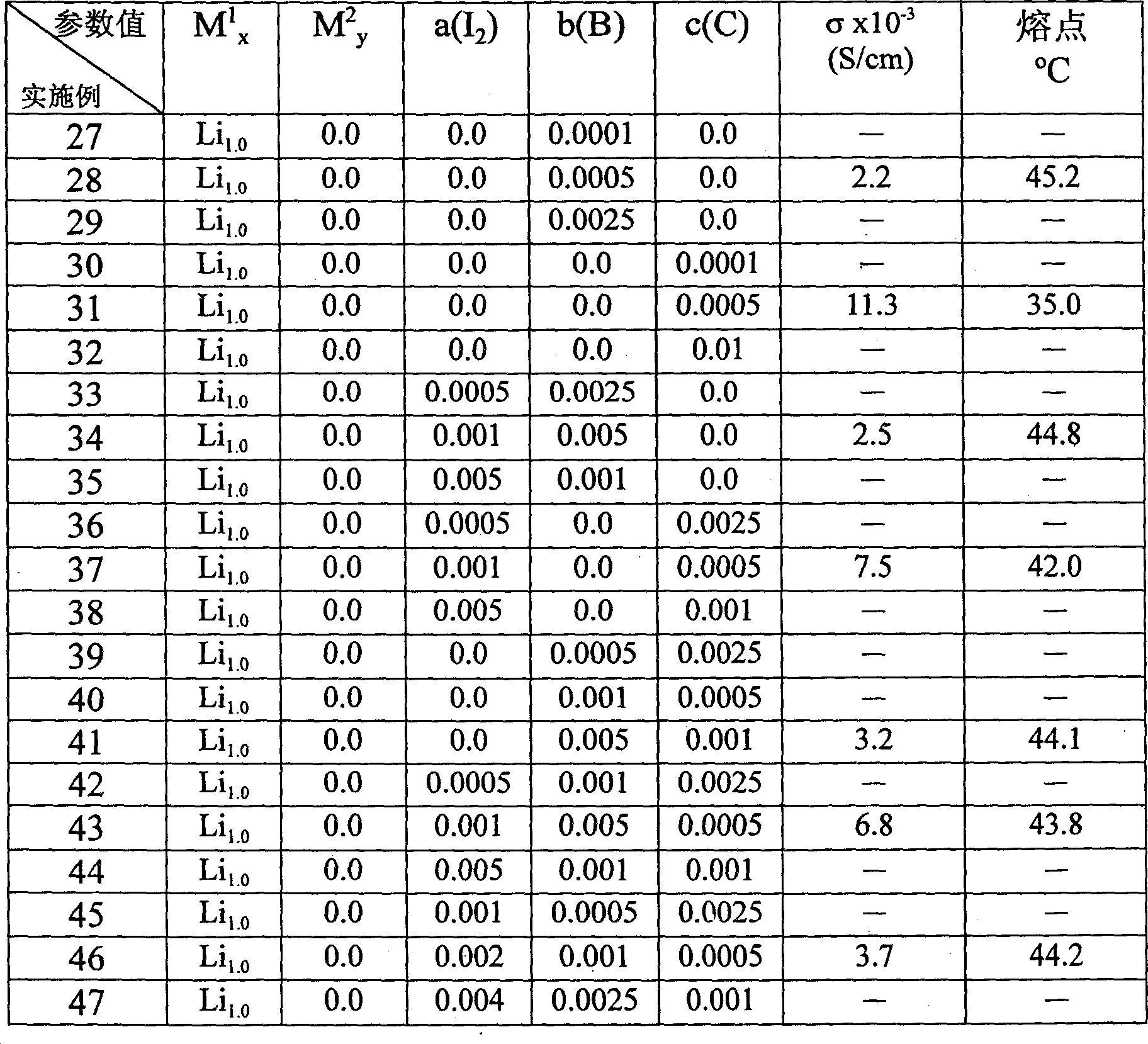

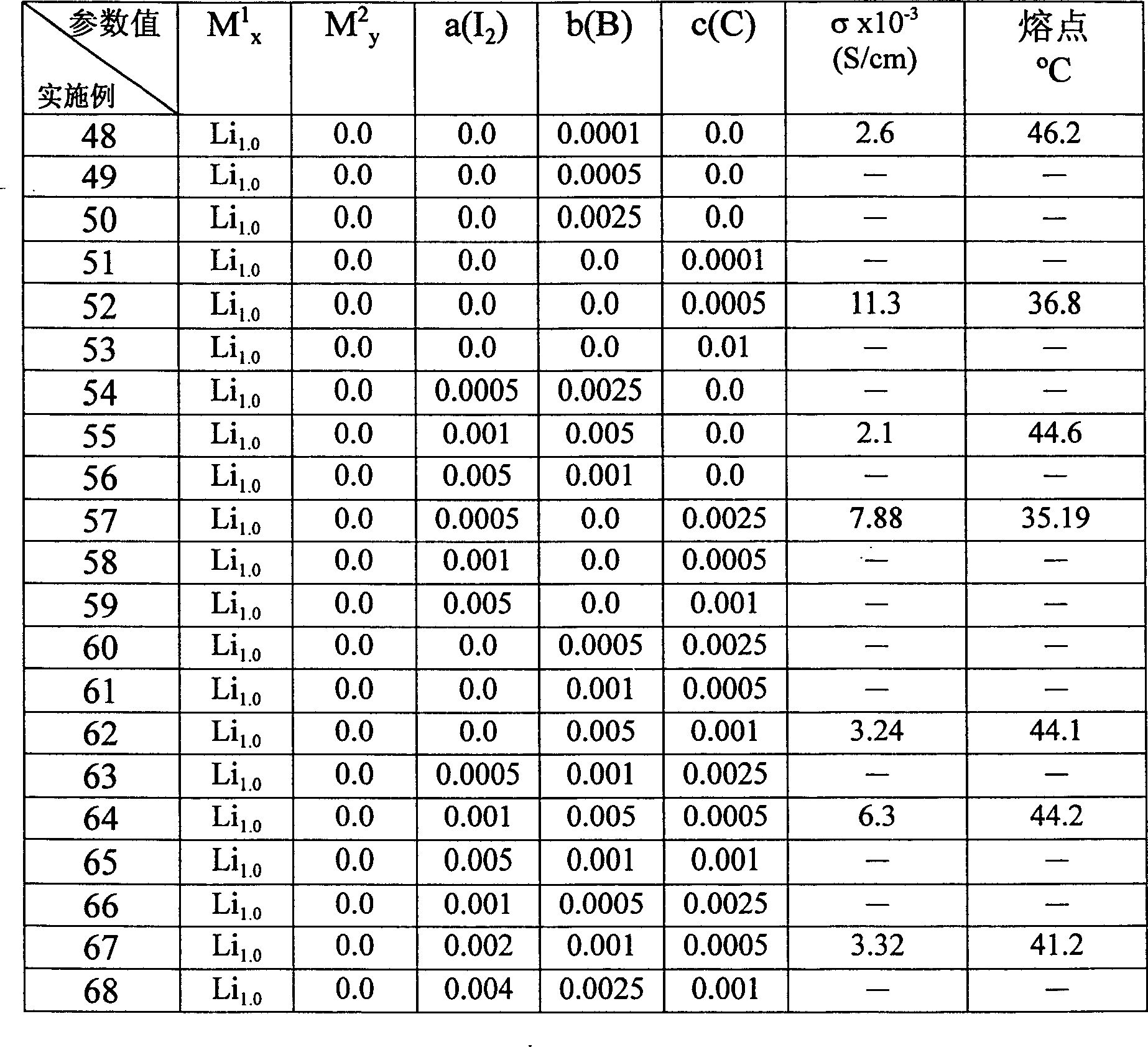

Composite electrolyte and its use

InactiveCN1512518AImprove performanceImprove conductivityNon-aqueous electrolyte cellsConductive materialIonHigh conductivity

This invention relates to a complex electrolyte and its usage which is an alcohol addition compound electrolyte generated by alcohol and polybase metallic salt halide or added by at least one of elementary iodine, control agent for rate of crystallization or monad nantokite compound having high conductivity, non-volatility and suitable fusion point used in solar energy battery, Li ion battery and fuel battery.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Crystallizer protecting cinder for continuous casting of crack sensitive steel and its prepn process

InactiveCN1974062AReduce crystallization rateLower crystallization temperatureProcess efficiency improvementManganese(II) carbonateWollastonite

The present invention provides one kind of crystallizer protecting cinder for continuous casting of crack sensitive steel and its preparation process. The protecting cinder is compounded with wollastonite, limestone, quartz sand, fluorite, industrial soda, manganese carbonate and carbon material. Chemically, it consists of CaO 28-42 wt%, SiO2 26-40 wt%, CaF2 10-20 wt%, Na2O 4-10 wt%, MnO2 2-8 wt%, Al2O3 0-6 wt%, and C 2-10 wt%, and has the weight ratio between CaO and SiO 2in 1.0-1.2. The crystallizer protecting cinder can reduce the heat transfer, maintain the crystallization rate and the crystallization temperature of protecting cinder, reduce longitudinal cracks in the surface of cast billet, and raise continuous casting efficiency and quality.

Owner:CHONGQING UNIV

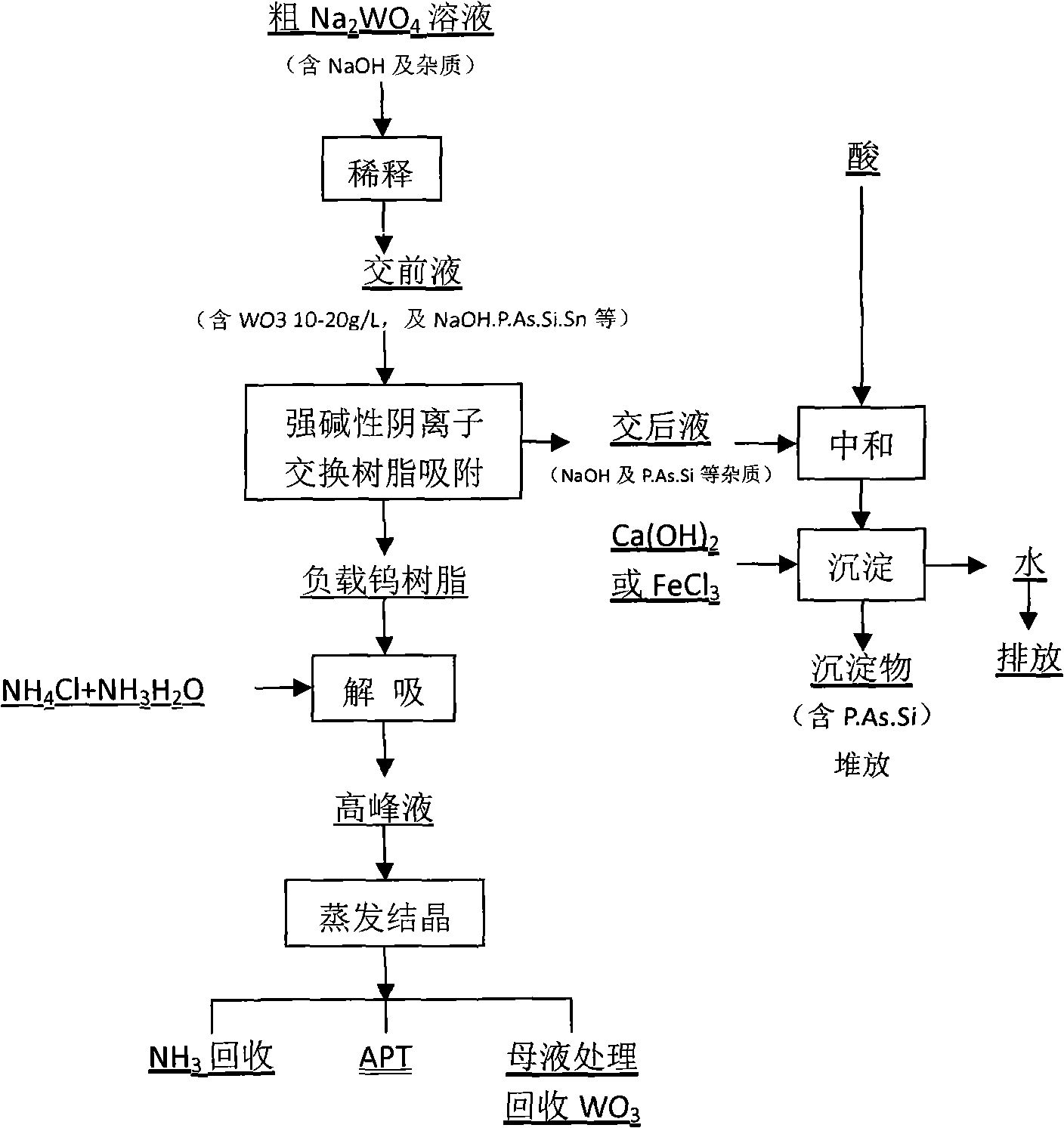

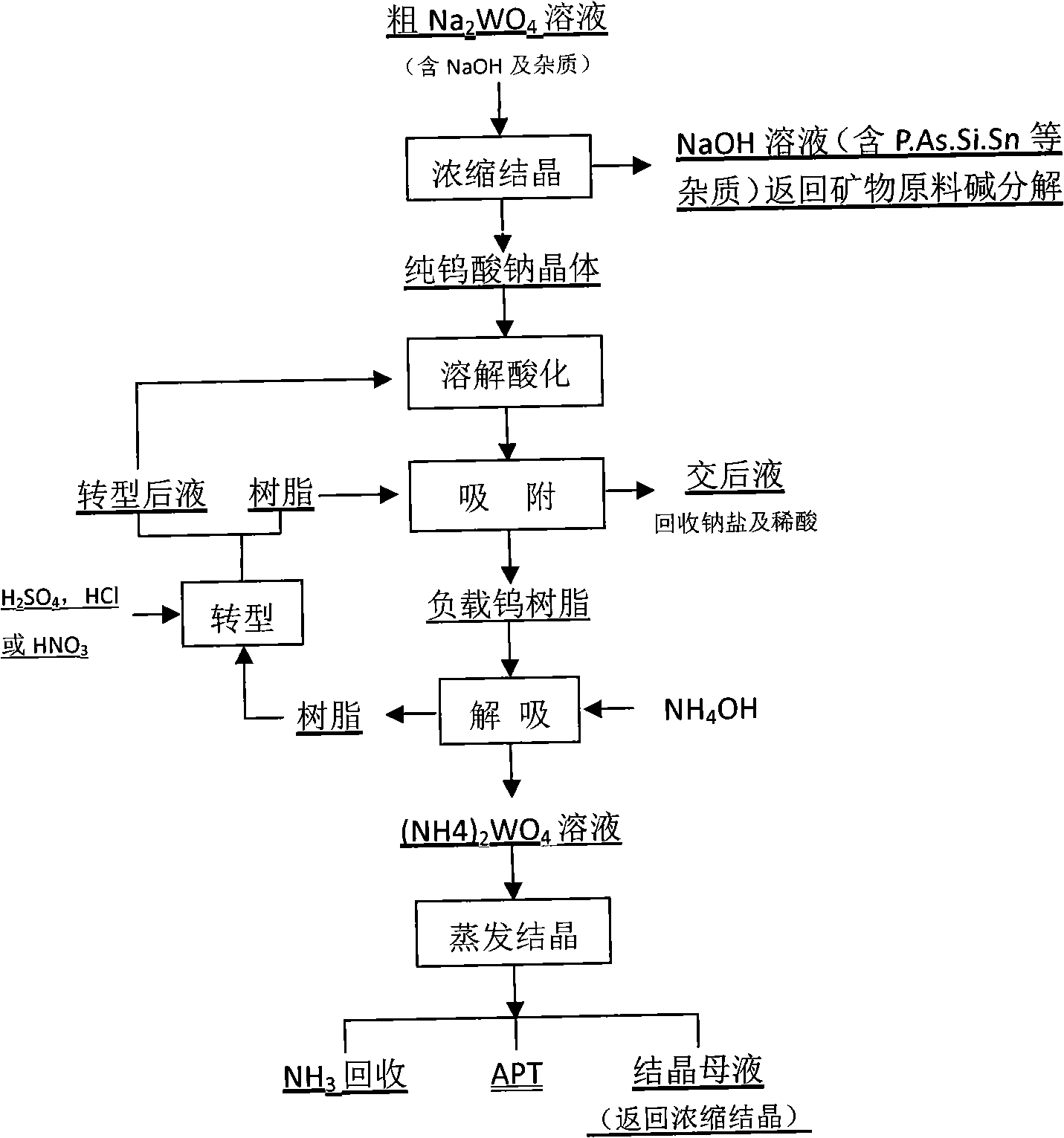

Method for preparing ammonium paratungstate from sodium tungstate solution

InactiveCN101570346AIncrease concentrationEmission reductionTungsten compoundsAmmonium paratungstateEvaporation

The invention provides a method for preparing pure ammonium paratungstate (APT) from crude Na2WO4 solution containing NaOH, P, As, Si, Sn and other impurities. The method comprises the following steps of crystallizing tungsten into Na2WO4 crystals through concentration, separating NaOH from impurities, redissolving and acidifying the Na2WO4 crystals till the pH of the crystals is between 2.0 and 6.0, adsorbing the crystals by use of macroporous weak alkaline anion exchange resin, desorbing the crystals by use of NH4OH, obtaining (NH4)2WO4 solution, performing evaporation crystallization and obtaining the APT. Under the condition that the crystallization rate is between 88 and 90 percent, the P, the As and the Si contained in the APT are all less than 10*10. The method has the outstanding advantage of small amount of discharged wastewater (mainly liquid after exchange), namely the volume of the discharged liquid after the exchange is one third to one twenty-fifth of that of liquid before the exchange; in addition, the discharged liquid after the exchange contains no detrimental impurities and is easy to control.

Owner:CENT SOUTH UNIV

Preparation method of SAPO-17 molecular sieves

InactiveCN103922361AMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesIsomerizationSynthesis methods

The invention provides a method for synthesizing SAPO-17 molecular sieve crystals. The method is characterized in that high-crystallinity and pure-phase SAPO-17 molecule sieves are quickly synthesized by adopting zeolite molecular sieves (crystalline silicon source) as a silicon source. Compared with a synthesis method adopting amorphous silicon sources such as silica sol and silicon powder, the method is capable of increasing the content of skeleton silicon and greatly increasing the crystallization rate of the molecular sieves; the synthesis time is shortened by 3-10 times. The SAPO-17 molecular sieves synthesized by the method have a weakly acidic activity center and can be used as a catalyst for conversion from methanol into olefins and isomerization of low-carbon hydrocarbon.

Owner:JIANGXI NORMAL UNIV

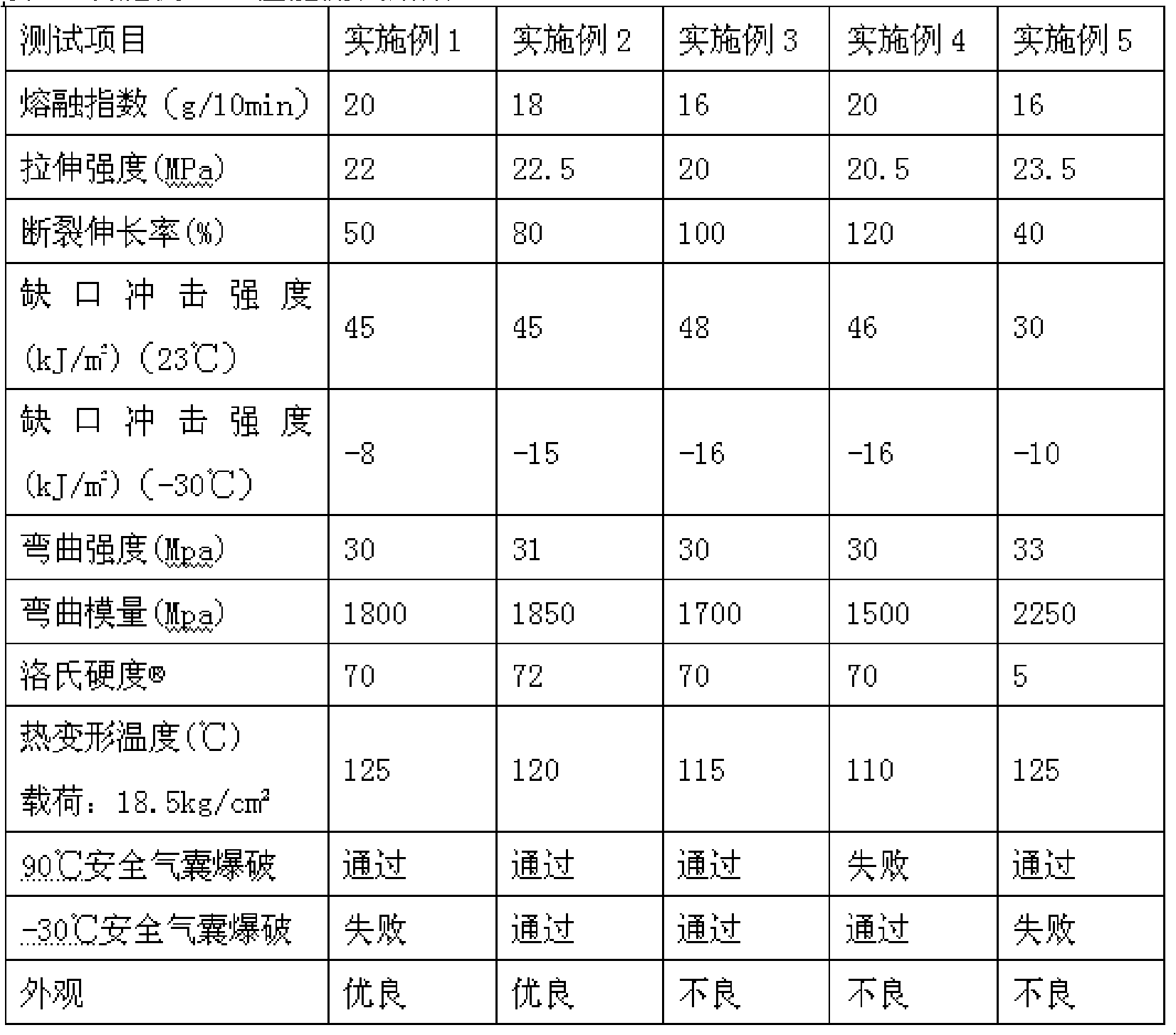

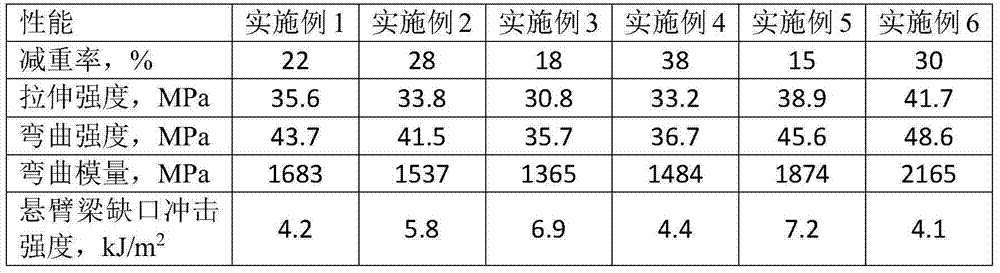

Polypropylene resin blend and preparing method thereof

InactiveCN101550252AImprove low temperature toughnessImprove liquidityPolypropylene compositesCelsius Degree

The invention discloses a polypropylene resin blend, which is prepared with polypropylene, polyethylene, vinyl co-polymer rubber, talcum powder, polypropylene and anti-oxidant. Compared to the existing technology, the polypropylene resin blend has excellent balance of rigidity and toughness, the low temperature notch impact strength is greatly higher than the general polypropylene composite materials, the crystallization rate is fast and crystal form is controllable, the period of injection molding is short, and there is no tiger skin veins on the surface of the injection molding articles, the heat resisting and oxidation susceptibility is excellent, can be processed in the higher molding temperature (higher than 240 Celsius system), therefore the adjusting range of this technology is large, and can be recovered many times. The blend is especially suitable for preparing instrument board of ensconcing safety airbag, the tensile strength of the blend is more than 20MPa, bend strength is more than 30MPa, the IZOD notch impact strength is more than 15KJ / m2 at the temperature of subzero 30 Celsius system.

Owner:贵州凯科特材料有限公司 +1

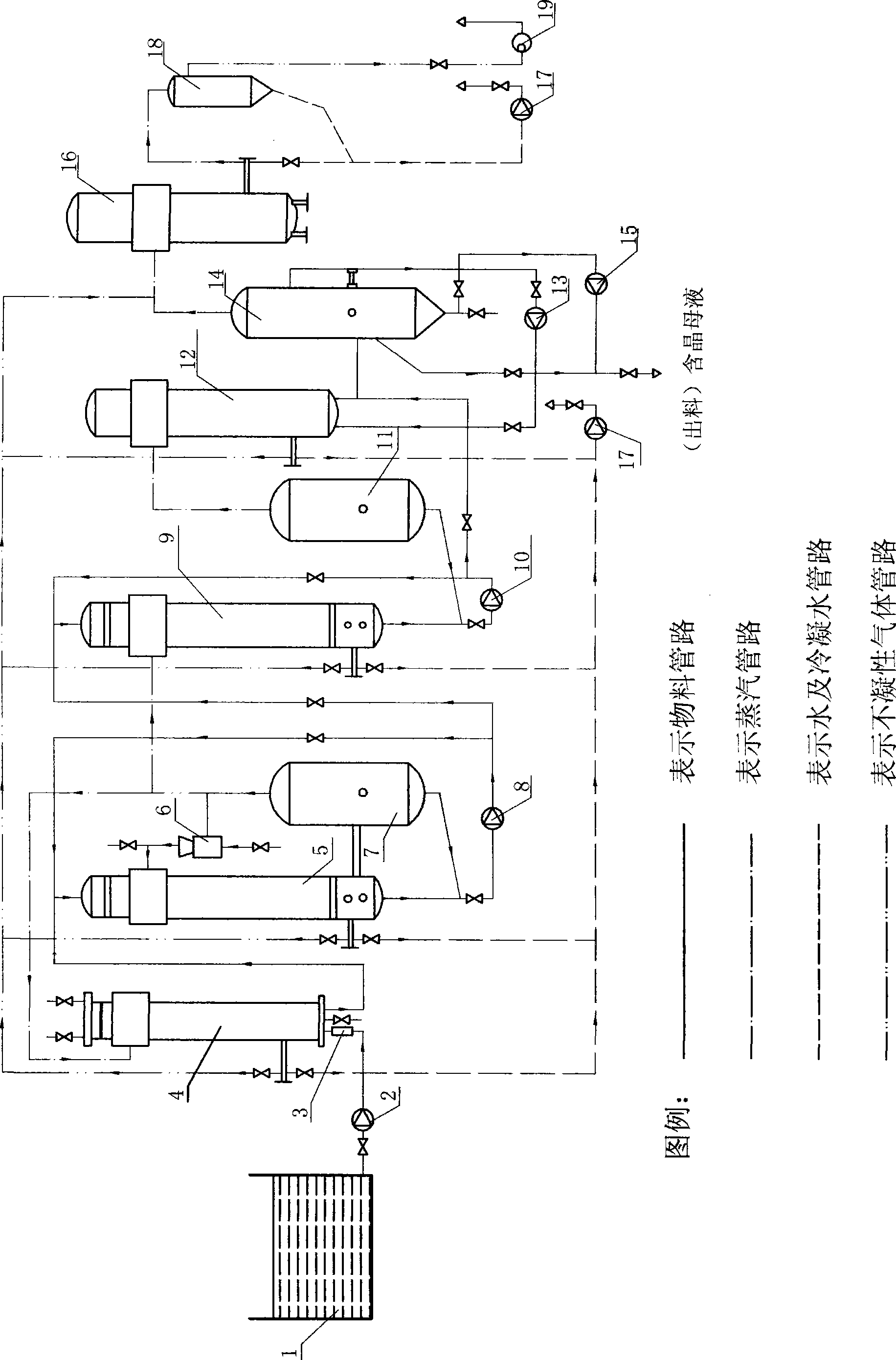

Production method and device for sodium gluconate energy-saving triple effect concentration and crystallization

InactiveCN101445449AIncrease production capacityImprove product qualityCarboxylic compound separation/purificationMoistureTriple effect

The invention discloses a production method and a device for sodium gluconate energy-saving triple effect concentration and crystallization. The continuity of sodium gluconate concentration and crystallization can be realized, that is, a raw material liquid enters a preheater continuously; the moisture can be evaporated after passing through 1st, 2nd and 3rd effect heating evaporators and 1st, 2nd and 3rd effect separators; the 2nd steam is separated continuously to heat and evaporate materials in the 1st, the 2nd and the 3rd effect heating evaporators; the crystal of sodium gluconate is separated out in the 3rd effect heating evaporator and pumped out continuously; therefore, the process of feeding, concentration and crystallization, and crystal separation at the same time is formed continuously, the 2nd steam is fully utilized, the steam consumption for evaporating moisture is 0.28 Tsteam / Twater, the crystallization rate achieves 65%, and materials can form a large amount of crystal in the 3rd effect heating evaporator. The invention can improve the productivity, reduce the steam consumption and improve the quality of products.

Owner:山东凯翔生物科技股份有限公司

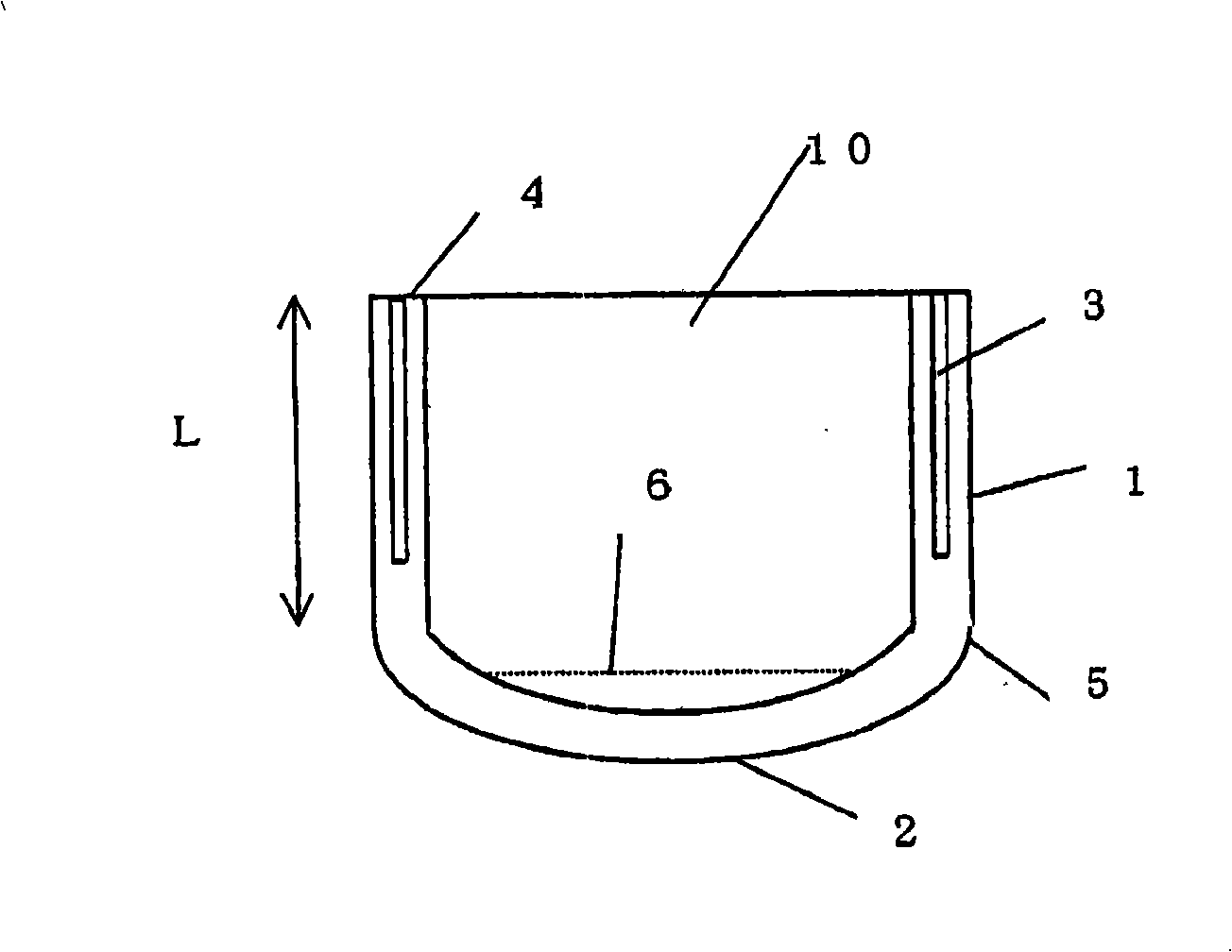

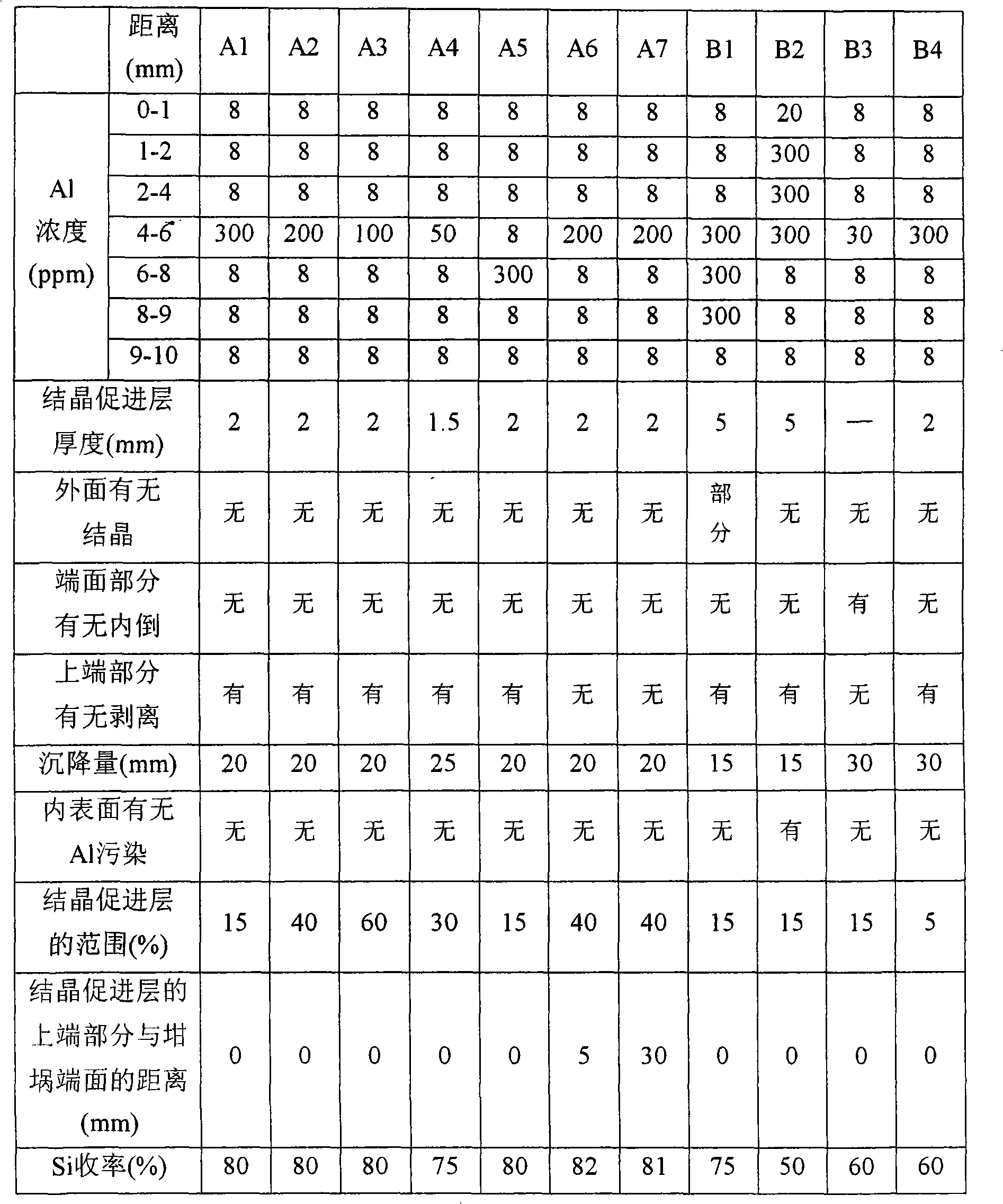

Quartz glass crucible, process for producing the same, and use

InactiveCN101316953APromote crystallizationHigh mechanical strengthPolycrystalline material growthBy pulling from meltSusceptorSingle crystal

A crucible has a structure where a layer containing a crystallization accelerating component such as aluminum or the like (a crystallization accelerating layer) is inserted inside a quartz glass layer of a crucible straight body part excepting a crucible bottom part. The crucible does not deform and fall inwardly at the straight body part since a part containing a crystallization accelerating component advances to crystallize so as to increase strength at a high temperature when the crucible is used in pulling up silicon single crystal. Therefore, a single crystallization rate can be increased. Further, since the crystallization accelerating layer is inserted inside the quartz glass layer, the crystallization accelerating component, such as aluminum or barium, does not contact with silicon melt or a carbon susceptor, contamination by eluting these metals does not occurs. Further, since the crystallization accelerating layer is not provided at the crucible bottom part, there is no danger to crack due to thermal distortion at a time of pulling up silicon single crystal and melt leakage does not occur.

Owner:JAPAN SUPER QUARTZ CORP

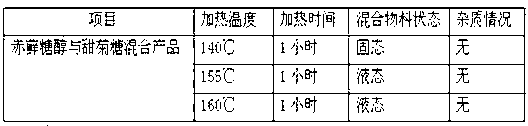

Erythritol crystal and preparation method of erythritol crystal

The invention relates to the technical field of compound sugar, in particular to an erythritol crystal, which comprises erythritol and sweet agents accounting for 1 to 2.5 percent of the weight of the erythritol. A preparation method of the erythritol crystal comprises the following steps that the erythritol and the sweet agents are mixed and dissolved to obtain liquid solution, the solution is simultaneously evaporated and crystallized, and the erythritol crystals are obtained; the erythritol and the sweet agents are mixed and are dissolved to obtain liquid solution, the liquid solution is subjected to non-evaporation crystallization, the filtering is carried out after the crystallization completion, and the erythritol crystals are obtained; the erythritol and the sweet agents are mixed in a solid from; and the mixed solids are subjected to melting, crystallization, crushing and drying to obtain the erythritol crystals. The sweetness of the erythritol is improved and reaches more than 80 percent of the sweetness of the cane sugar, the consistency of ingredients of compound products of the erythritol and the sweet agents is realized, the problem of cocrystallization of the erythritol and the sweet agents easily carbonized at high temperature is solved, the crystallization rate is improved to the maximum degree, the crystallization efficiency is 5 to 20 percent higher than that of the traditional crystallization technology, and the application field of the product is enlarged.

Owner:BAOLINGBAO BIOLOGY

Polypropylene structure foamed material with favorable appearance and preparation method thereof

The invention discloses a polypropylene structure foamed material with favorable appearance and a preparation method thereof. The material mainly comprises the following raw materials in parts by weight: 30-70 parts of homopolymer polypropylene resin, 10-50 parts of copolymer polypropylene resin, 0-10 parts of toughener, 0-30 parts of filler, 0-8 parts of glass fiber, 0.05-0.5 part of crystallization nucleating agent, 0.5-5 parts of foaming agent master batch and 0.1-3 parts of antioxidant. The invention also discloses a preparation method of the foamed polypropylene material in such structure. The material has higher flowability, higher crystallization rate, higher melt strength and lower exposed-perforation ratio; the crystallization nucleating agent is added to enhance the crystallinity and crystallization rate of the material, so that the plastic surface can be cured at higher temperature, thereby preventing the pores from shifting to the surface; and the glass fiber is added to enhance the high-temperature strength of the material and prevent the phenomenon of exposed perforation on the surface, so that the prepared structure foamed polypropylene material has the advantages of uniform pores, low density and high strength, and is widely applied in the aspects of weight reduction and sound insulation of automobile parts.

Owner:SHANGHAI KINGFA SCI & TECH +1

Halogen-free flame-retardant polyethylene terephthalate engineering plastic composite material and preparation method thereof

ActiveCN101445650AShortened nucleation induction periodPromote crystallizationPolyethylene terephthalate glycolPhosphate

The invention relates to a halogen-free flame-retardant polyethylene terephthalate engineering plastic composite material and a preparation method thereof. The halogen-free flame-retardant polyethylene terephthalate engineering plastic composite material is prepared by commonly introducing PET resin, glass fiber, flexibilizer and additional three components of A, B and C into a twin-screw extruder and carrying out extrusion, cooling and pelletizing; wherein, the A component is mother particles which are prepared after mixing organic rare earth phosphate salt nucleating agent, antioxidant, external lubricant and polyethylene; the B component is the mother particles which are prepared after mixing pigment and PE; the C component is a flame-retardant system which is obtained by complexing phosphorus-containing inorganic material melamine pyrophosphate and phosphorus-containing organic material ammonium polyphosphate to form phosphonate salt and then using rare earth coupling agent for treatment. The PET in the invention is characterized by rapid crystallization rate and good mobility, and the prepared product is characterized by excellent comprehensive performance, environmental friendliness and content of environment-associated substances which is in line with the EU RoHS standards, thereby being applicable to electronic and electrical appliance products.

Owner:BEIJING HUATENG NEW MATERIAL CO LTD

Synthesis method of SSZ-13 molecular sieve

ActiveCN106629761ASynthetic Method AdvantagesReduce usageCrystalline aluminosilicate zeolites1-adamantanamineSynthesis methods

The invention provides a synthesis method of an SSZ-13 molecular sieve. A USY molecular sieve or Beta molecular sieve with adsorbed N,N,N-trimethyl-1-adamantanamine cations is used as a structure guide agent to synthesize the SSZ-13 molecular sieve together with an aluminum source, a silicon source, an alkali source, water and mixed seeds, thereby greatly reducing the consumption of the expensive template N,N,N-trimethyl-1-adamantanamine cations in the traditional method, and obviously lowering the cost for synthesizing the SSZ-13 molecular sieve. The method can enhance the crystallization rate of the SSZ-13 molecular sieve and shorten the required crystallization time, and thus, is more beneficial to industrial production. The SSZ-13 molecular sieve synthesized by the method has high crystallinity and favorable hydrothermal stability; and the synthesized SSZ-13 molecular sieve can be used as an MTO (Methanol To Olefins) catalyst and can also be used as an automobile tail gas treatment catalyst support.

Owner:SHANGHAI NOVEL CHEM TECH

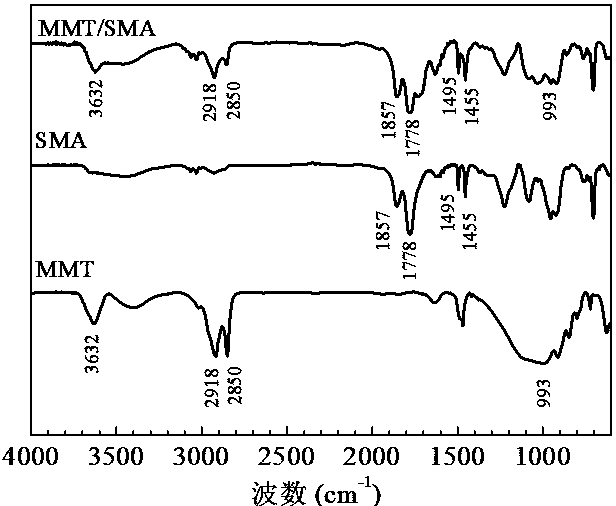

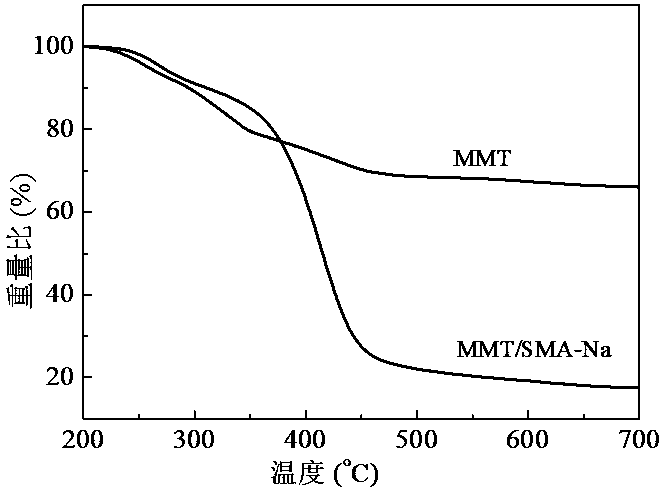

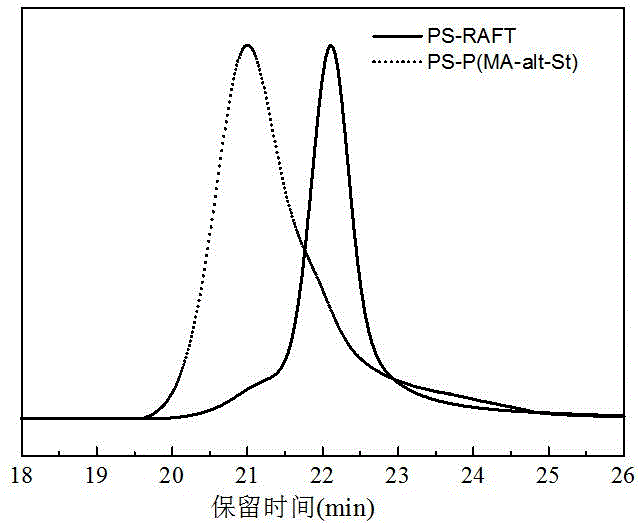

Exfoliated montmorillonite/maleic anhydride-styrene ionomer as well as preparation method and application thereof

The invention belongs to the technical field of high polymer materials, and particularly relates to an exfoliated montmorillonite / maleic anhydride-styrene ionomer composite material as well as a preparation method and an application thereof. The preparation method disclosed by the invention comprises the following steps: by virtue of in-situ intercalation free-radical polymerization, enabling monomers to enter organic montmorillonite (MMT) sheet layers via a diffusion action and then polymerizing among the MMT sheet layers, and opening and exfoliating the MMT sheet layers by virtue of polymerization heat, so as to form an exfoliated montmorillonite and maleic anhydride-styrene copolymer composite material; and performing hydrolysis and salinization on the copolymer composite material to prepare the exfoliated montmorillonite and maleic anhydride-styrene ionomer composite material. The ionomer composite material can be used as a nucleating agent for PET (polyethylene terephthalate), and is capable of remarkably increasing the crystallization temperature and crystallization speed of the PET. The ionomer composite material is simple in preparation method, capable of adopting a one-time process of mixing-reaction extruding granulation with the PET, convenient to operate, high in benefits, low in cost, and suitable for industrialized production.

Owner:FUDAN UNIV

Fat composition used for chocolate coating

The invention relates to a fat composition used for chocolate coatings, a preparation method thereof, and the chocolate coatings and food containing the fat composition. The fat composition is rich in SSU (1, 2-di-saturated fatty acid-3-unsaturated fatty acid triglyceride), low in trans fatty acid content, low in content of saturated fatty acids, free of lauric acid and high in crystallization rate, and can be solidified into a stable form CBR (cocoa butter replacer) without temperature adjustment.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

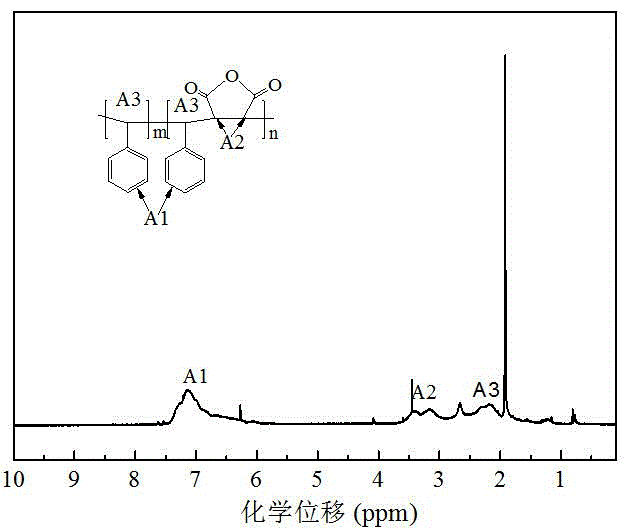

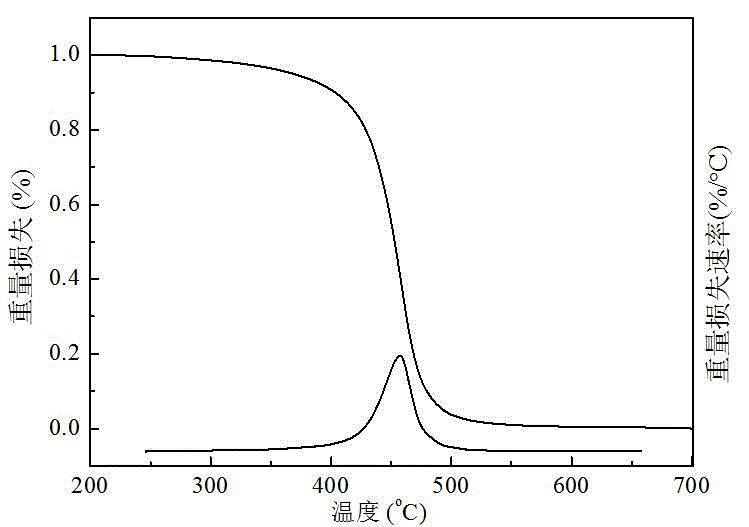

Polyethylene terephthalate nucleating agent and preparation method thereof

InactiveCN103145903ASimple preparation processImprove thermal stabilityPolymer sciencePolyethylene terephthalate glycol

The invention belongs to the technical field of high polymer materials, and in particular relates to a polyethylene terephthalate nucleating agent and a preparation method thereof. The method comprises the following steps of: based on polystyrene-b-poly(styrene-alt-maleic anhydride) diblock copolymer as a raw material, hydrolyzing, salinizing and purifying to prepare an ionomer of the polystyrene-b-poly(styrene-alt-maleic anhydride) diblock copolymer. A polystyrene block can form microphase separation in molten polyethylene terephthalate (PET), and thus, a crystal nucleus is provided for PET crystallization; and moreover, a poly(styrene-alt-maleic anhydride) block and PET are well compatible with each other, so that crystallization surface energy can be reduced, and the crystallization temperature and crystallization speed of the PET can be increased. In addition, a plasticizer such as di-2-ethylhexy1 azelate is added while the nucleating agent is added, the movement velocity of a PET chain segment can be further increased, so that the growing speed of crystals is increased. The preparation method is simple, convenient to operate, high in benefit, low in cost and suitable for industrial production.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com