Oil composition, composite oil composition, product and production method

A technology of oil composition and compound oil, which is applied in the direction of edible oil/fat, edible oil/fat phase, edible oil/fat production/processing, etc., can solve the problem of prolonging the ripening step of plastic oil, the inconvenience of plastic oil industrial production, and reducing the Production efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

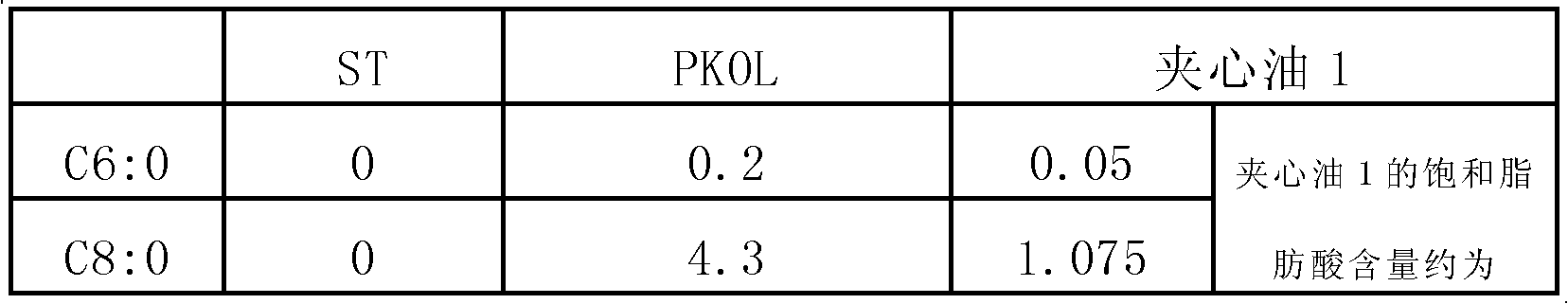

[0104] Preparation of Sandwich Oil 1

[0105] Palm Kernel Olein (PKOL) (IV: 22, purchased from Kerry Special Oils (Shanghai) Co., Ltd., IV is iodine value) and palm stearin (Palm Stearin, ST) (IV: 34; purchased From Kerry Special Oils (Shanghai) Co., Ltd.) in a weight ratio of 25:75. Example 1 See Table 1 for fatty acid composition of oil raw materials palm kernel liquid oil PKOL and palm stearin ST.

[0106] Vacuum dry the mixed oil and fat raw materials (stir in vacuum, heat up to 105°C, keep for 1h); then add 0.8% catalyst sodium methoxide, react at 100°C for 45min; then add 8% citric acid aqueous solution, stir for 30min, The reaction was terminated, and then the reactant was washed with water until the pH was 7, and then centrifuged to obtain transesterified oil.

[0107] Then carry out oil refining operation on the obtained transesterified oil: vacuumize and heat the transesterified oil to 105°C, keep it for 30min, dehydrate and dry; then add 2% activated clay, keep it...

Embodiment 2

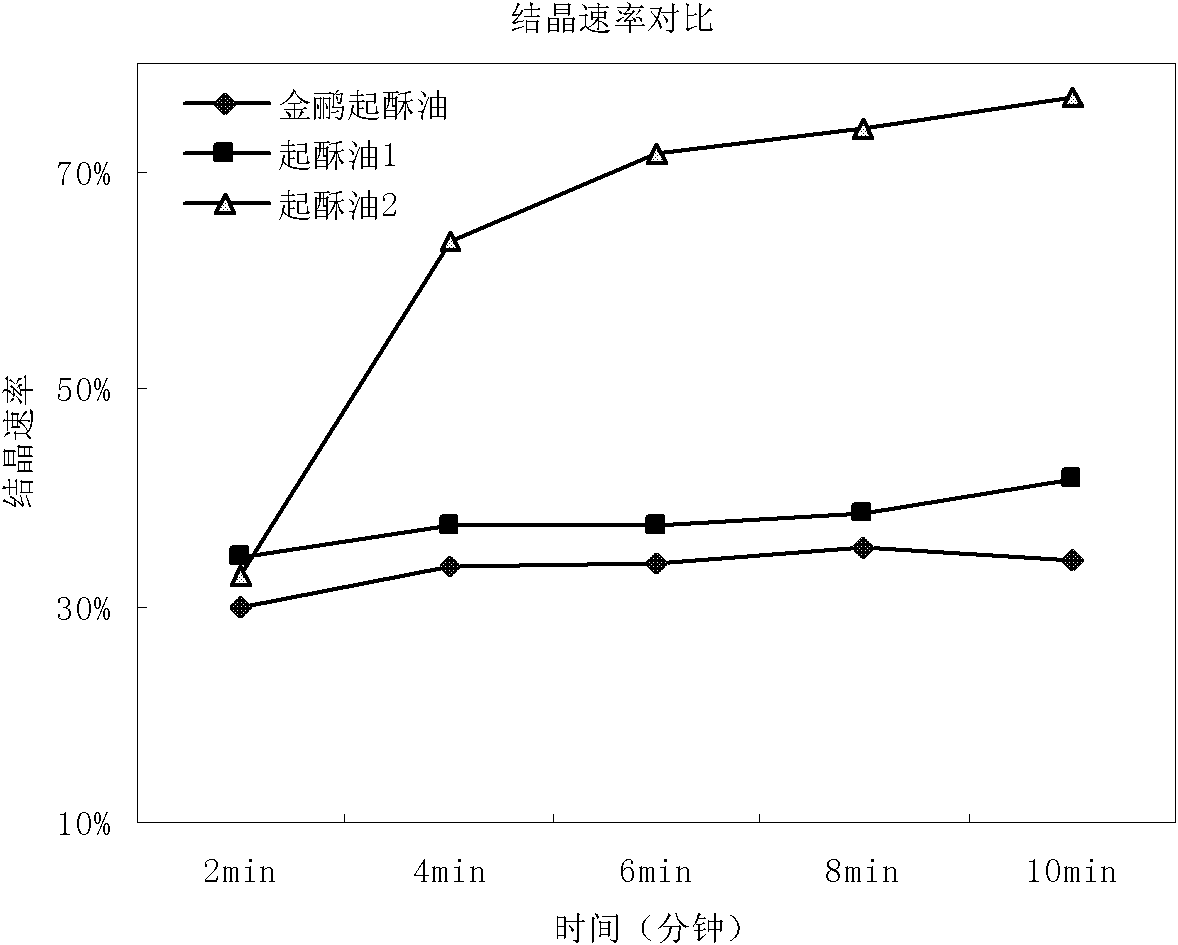

[0117] Preparing shortening 1

[0118] Raw materials PKOL (IV=24) and ST (IV=39) were mixed in a ratio of 10:90. Example 2 See Table 4 for the fatty acid compositions of the oil and fat raw materials PKOL and ST.

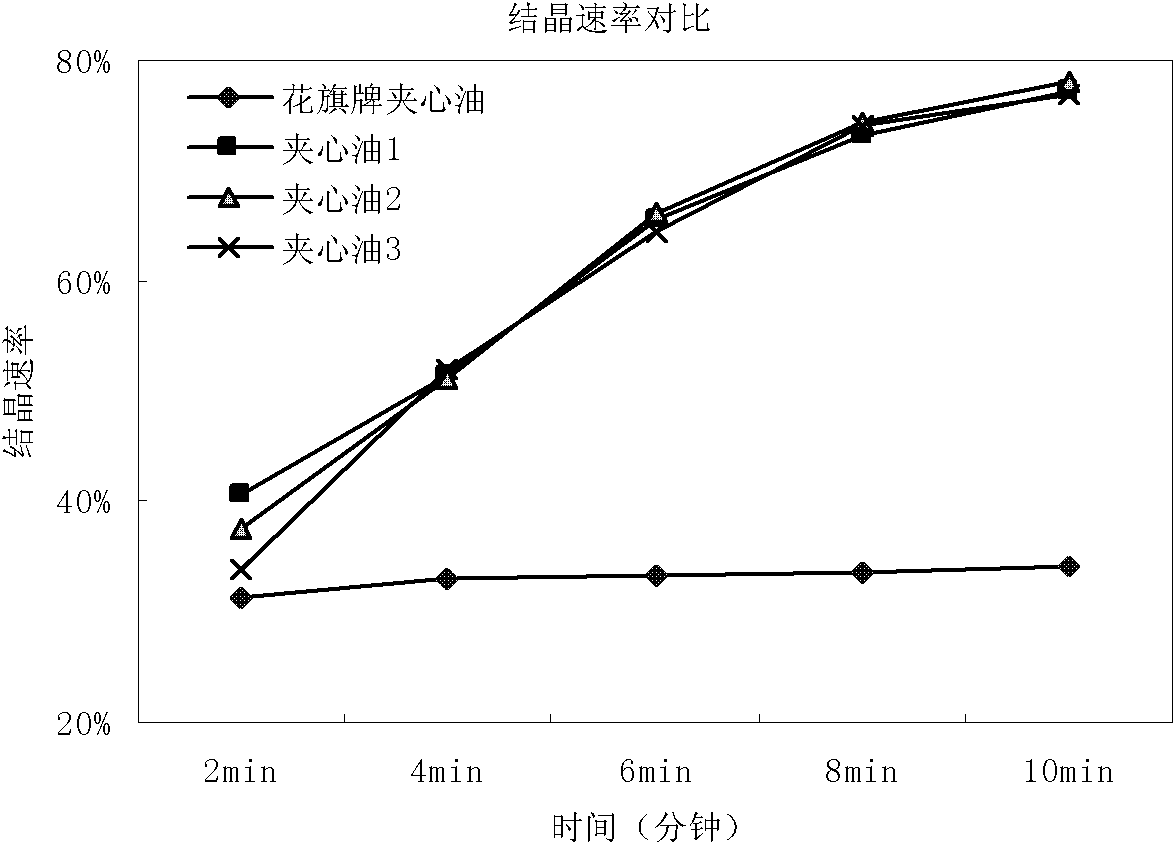

[0119] The preparation and refining process of transesterified fat are the same as in Example 1.

[0120] After oil melting, rapid cooling, kneading, and aging treatment (according to the conventional production method of margarine), the product shortening 1 is obtained, and its fatty acid composition (accounting for total fatty acid) is shown in Table 4, and its triglyceride composition (accounting for the total amount of sandwich oil) is shown in Table 4. Table 5, see Table 6 for the solid fat content at each temperature (accounting for the total sandwich oil), and see Table 16 for the crystallization rate (10° C.) of the aging step of shortening 1.

[0121] Table 4

[0122]

[0123] table 5

[0124]

S 2 u

u 2 S

UUU

C...

Embodiment 3

[0128] Prepare shortening 2

[0129]Palm Kernel Olein (PKOL) (IV: 22, purchased from Kerry Special Oils (Shanghai) Co., Ltd., IV is iodine value) and palm stearin (Palm Stearin, ST) (IV: 34; purchased From Kerry Special Oils (Shanghai) Co., Ltd.) in a weight ratio of 50:50. Example 3 The fatty acid compositions of palm kernel liquid oil PKOL and palm stearin ST as oil raw materials are shown in Table 7.

[0130] The preparation and refining process of transesterified fat are the same as in Example 1.

[0131] After oil melting, quenching, kneading, and aging treatment (according to the conventional production method of margarine), the product shortening 2 is obtained, and its fatty acid composition (accounting for total fatty acid) is shown in Table 7, and its triglyceride composition (accounting for the total amount of sandwich oil) is shown in Table 7. Table 8, see Table 9 for the solid fat content at each temperature (accounting for the total sandwich oil), and see Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com