PET (polyethylene terephthalate) engineering plastic and preparation method and application thereof

An engineering plastic, selected technology, applied in the field of plastics, can solve the problems of slow crystallization rate of PET materials, weak flame retardancy and tracking resistance, low crystallinity, etc., to achieve suppression of tracking, good stretching, Excellent heat deflection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

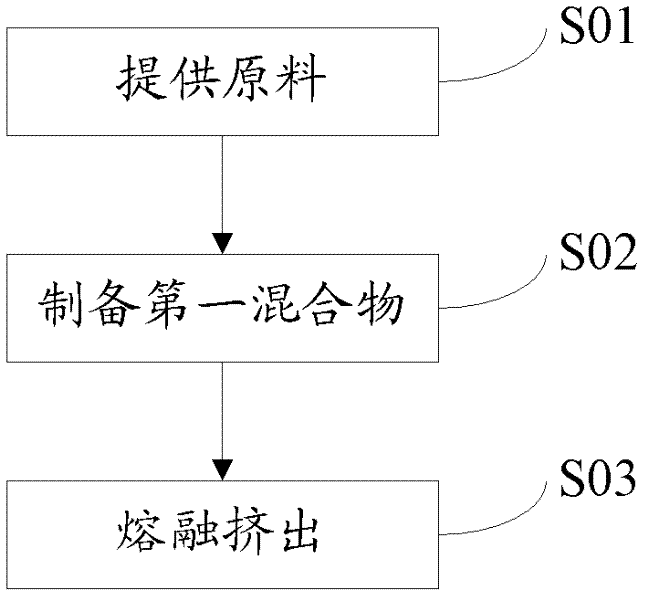

[0033] see figure 1 , figure 1 Show the above-mentioned PET engineering plastics preparation method flowchart of the embodiment of the present invention, comprise the following steps:

[0034] Step S01, providing raw materials:

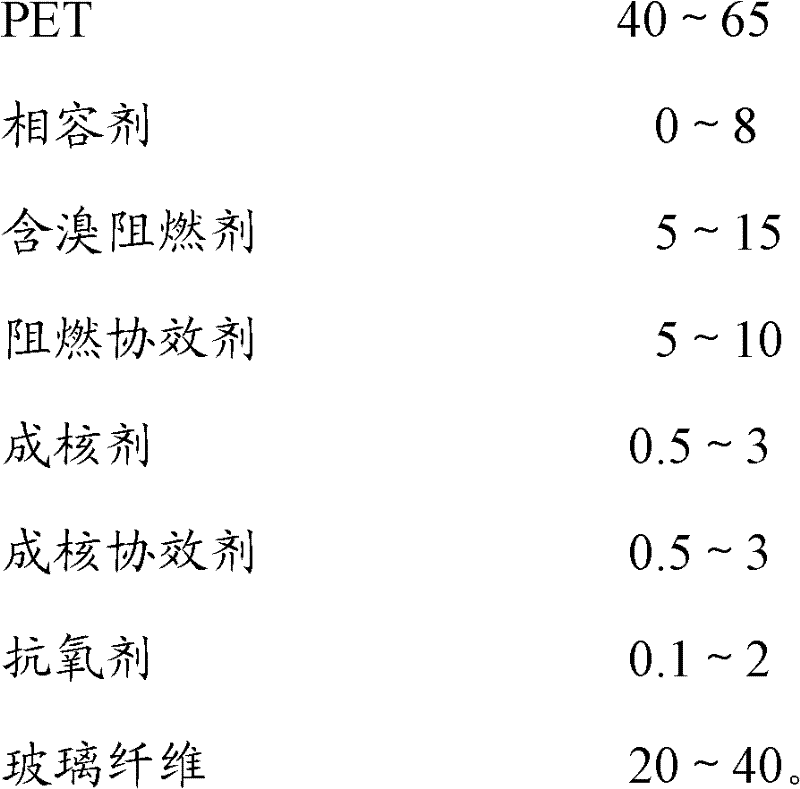

[0035] Get the components of following parts by weight:

[0036]

[0037] Step S02, preparing the first mixture:

[0038] Drying the PET, mixing the dried PET, a compatibilizer, a bromine-containing flame retardant, a flame retardant synergist, a nucleating agent, a nucleating synergist, and an antioxidant to obtain a first mixture;

[0039] Step S03, melt extrusion:

[0040] The first mixture is extruded, and the glass fiber is added in the extruding step to obtain PET engineering plastics.

[0041] Specifically, in the preparation method of PET engineering plastics in the embodiment of the present invention, the PET (resin), brominated flame retardant, flame retardant synergist, nucleating agent, nucleating synergist, antioxidant, other addi...

Embodiment 1

[0050] Embodiments of the present invention PET engineering plastics include the following components in parts by weight:

[0051]

[0052]

[0053] The preparation method of PET engineering plastics of the embodiment of the present invention comprises the following steps:

[0054] step 1,

[0055] Get the components of following parts by weight:

[0056]

[0057]

[0058] Step 2,

[0059] The above PET resin was air-dried at 100°C for 3 hours, and the dried PET resin and the above-mentioned brominated polystyrene, antimony trioxide, zinc borate, kaolin, melamine cyanurate, talcum powder, aromatic Sodium phosphate group, polyethylene glycol, 1010, and 168 are sequentially added to the mixer, and stirred and mixed for 5 minutes at a speed of 200 rpm to obtain a uniformly mixed first mixture;

[0060] Step 3,

[0061] Add the obtained first mixture into the twin-screw extruder, and then add the above-mentioned glass fiber from the side feed port of the twin-screw...

Embodiment 2

[0063] Embodiments of the present invention PET engineering plastics include the following components in parts by weight:

[0064]

[0065]

[0066] The preparation method of PET engineering plastics of the embodiment of the present invention comprises the following steps:

[0067] step 1,

[0068] Get the components of following parts by weight:

[0069]

[0070] Step 2,

[0071] The above-mentioned PET resin was air-dried at 130°C for 5 hours, and the dried PET resin and the above-mentioned pentabromobenzyl polyacrylate, antimony trioxide, zinc borate, kaolin, melamine cyanurate, talcum powder, Aromatic sodium phosphate, polyethylene glycol, 1010, and 168 were sequentially added to the mixer, and stirred and mixed for 4 minutes at a speed of 300 rpm to obtain a uniformly mixed first mixture;

[0072] Step 3,

[0073] Add the obtained first mixture into the twin-screw extruder, and then add the above-mentioned glass fiber from the side feed port of the twin-screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com