Nano MFI-type molecular sieve with hierarchical pore structure and preparation method and application thereof

A technology of nano-molecular sieve and molecular sieve, which is applied in the direction of molecular sieve catalysts, nanotechnology, chemical instruments and methods, etc. It can solve the problems of complex preparation of nano-MFI zeolite, low yield of nano-molecular sieve, and restrictions on wide-scale application, and achieve high propylene yield. The effect of catalyst stability, easy separation, and high hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

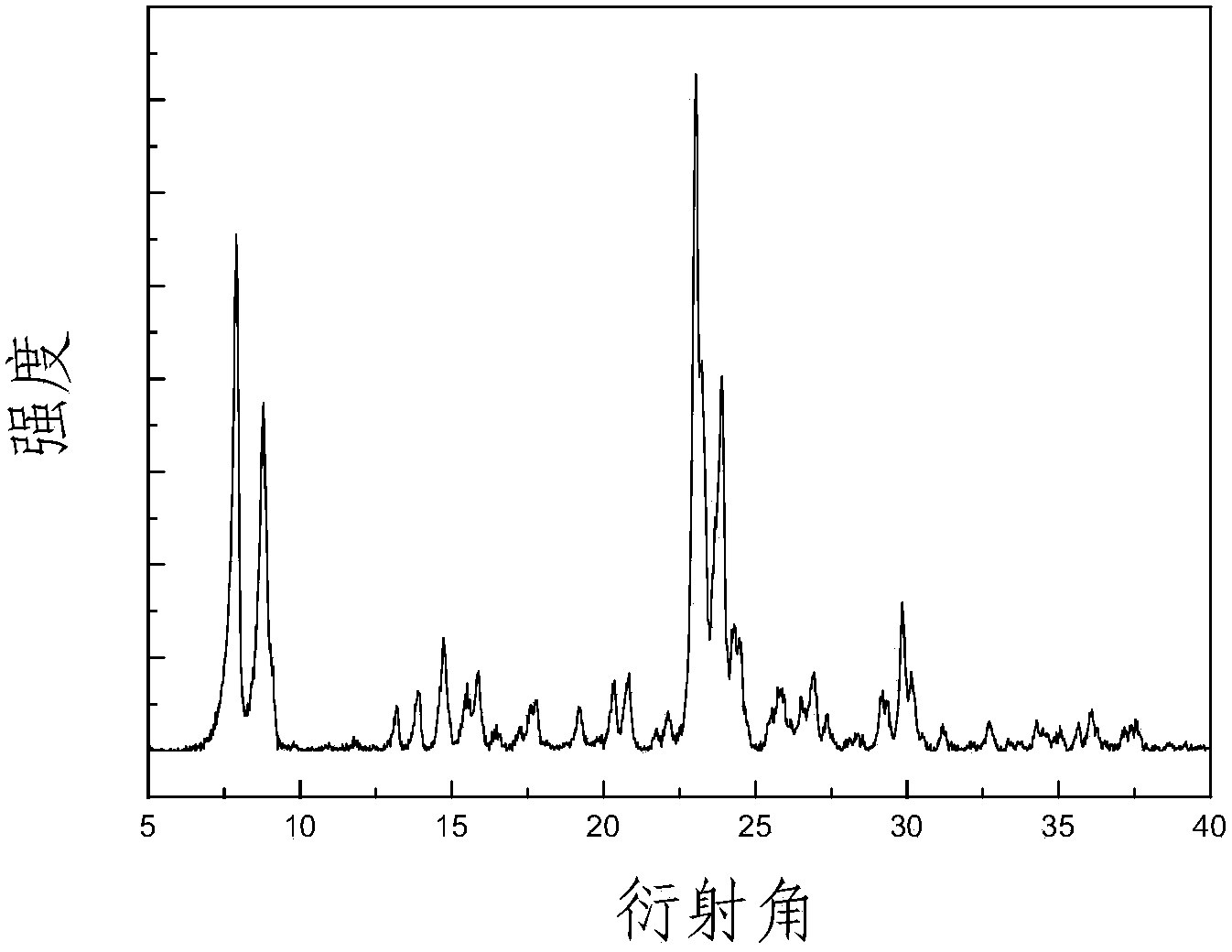

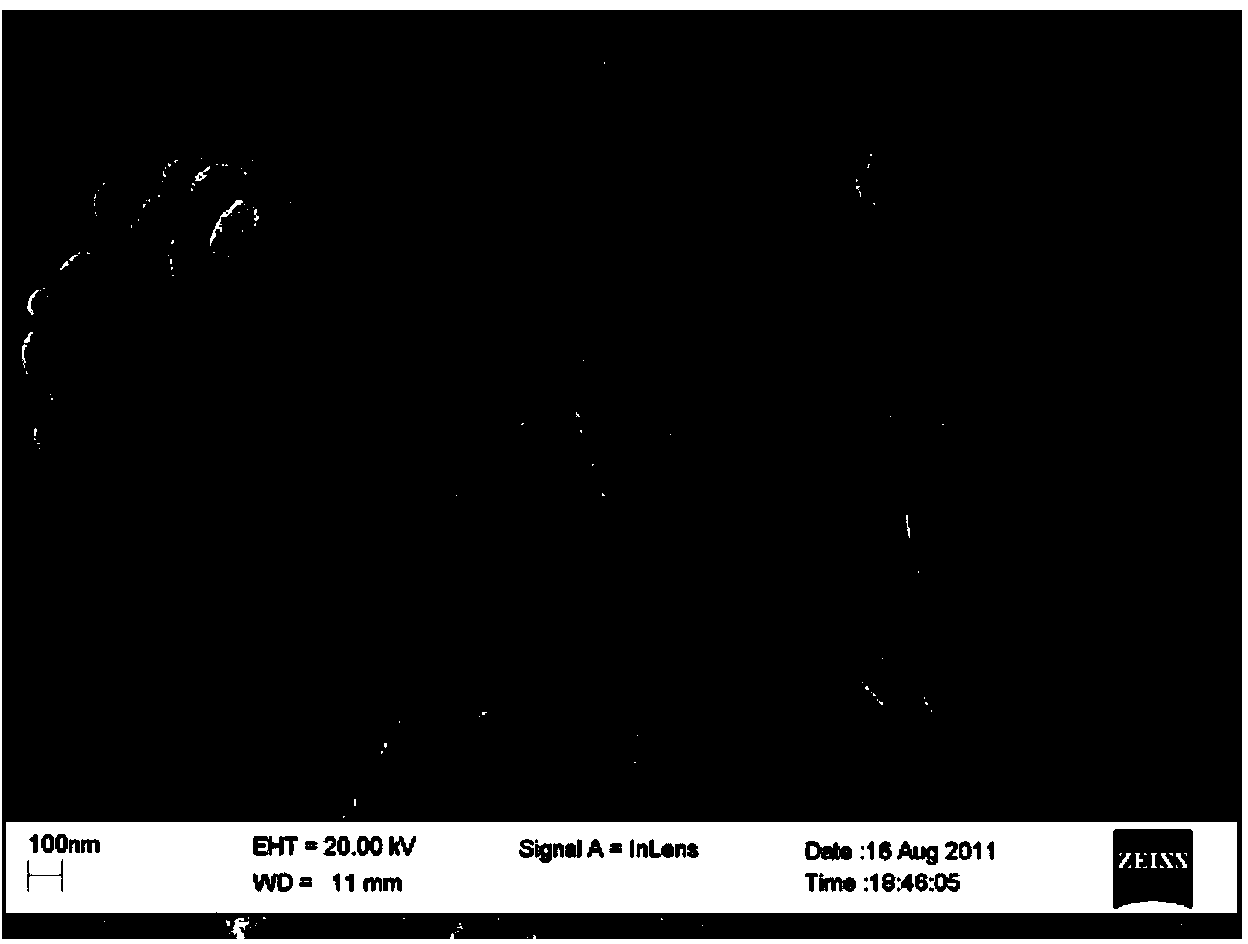

[0034] In this embodiment, the preparation method of high hydrothermal stability, easy separation, nano ZSM-5 type zeolite molecular sieve:

[0035] First, prepare a mother liquor containing nano-sized ZSM-5 molecular sieve: mix ethyl orthosilicate, tetrapropylammonium hydroxide, sodium metaaluminate, and deionized water in a molar ratio of 1:0.32:0.02:29, After complete hydrolysis of ethyl acetate, the above solution was placed in a reaction kettle for hydrothermal synthesis, and hydrothermal synthesis was performed at 130° C. for 6 hours to obtain a mother liquid of nano ZSM-5 molecular sieve. Add polybenzamide to the above-mentioned molecular sieve mother liquor (the amount of polybenzamide added is 5% of the mass of the molecular sieve mother liquor), stir at 12,000 rpm for 2 hours, then add to the reaction kettle, and conduct hydrothermal synthesis at 160°C for 6 hours, Made nano ZSM-5 molecular sieve compound. The obtained molecular sieve composite was filtered through ...

Embodiment 2

[0042] In this embodiment, the preparation method of high hydrothermal stability, easy separation, nano ZSM-5 type zeolite molecular sieve:

[0043] First, prepare a mother liquor containing nano-ZSM-5 molecular sieve: mix ethyl orthosilicate, tetrapropylammonium hydroxide, sodium metaaluminate, and deionized water in a molar ratio of 1:0.32:0.02:29, and wait for orthosilicate After complete hydrolysis of the ethyl ester, the above solution was placed in a reaction kettle for hydrothermal synthesis, and the hydrothermal synthesis was performed at 130° C. for 6 hours to obtain the nano ZSM-5 molecular sieve mother liquid. Add polydiallyldimethylammonium chloride (the amount of polydiallyldimethylammonium chloride is 7.5% of the mass of the molecular sieve mother liquor) to the above molecular sieve mother liquor, and stir at a high speed of 12000 rpm for 2 hours Afterwards, it was added to a reaction kettle, and was hydrothermally synthesized at 130° C. for 12 hours to make a n...

Embodiment 3

[0046] In this embodiment, the preparation method of high hydrothermal stability, easy separation, nano ZSM-5 type zeolite molecular sieve:

[0047] First, prepare a mother liquor containing nano-ZSM-5 molecular sieve: mix ethyl orthosilicate, tetrapropylammonium hydroxide, sodium metaaluminate, and deionized water in a molar ratio of 1:0.32:0.02:29, and wait for orthosilicate After complete hydrolysis of ethyl ester, the above molecular sieve mother liquor was placed in a reaction kettle for hydrothermal synthesis, and hydrothermal synthesis was carried out at 130° C. for 6 hours to obtain nano ZSM-5 molecular sieve mother liquor. Add cetyltrimethylammonium bromide to the above solution (the amount of cetyltrimethylammonium bromide is 3% of the mass of the molecular sieve mother liquor), stir at a high speed at 12000 rpm for 2 hours, then add Reactor, at 120°C, hydrothermally synthesized for 24 hours to make nano ZSM-5 molecular sieve composite. The obtained molecular sieve ...

PUM

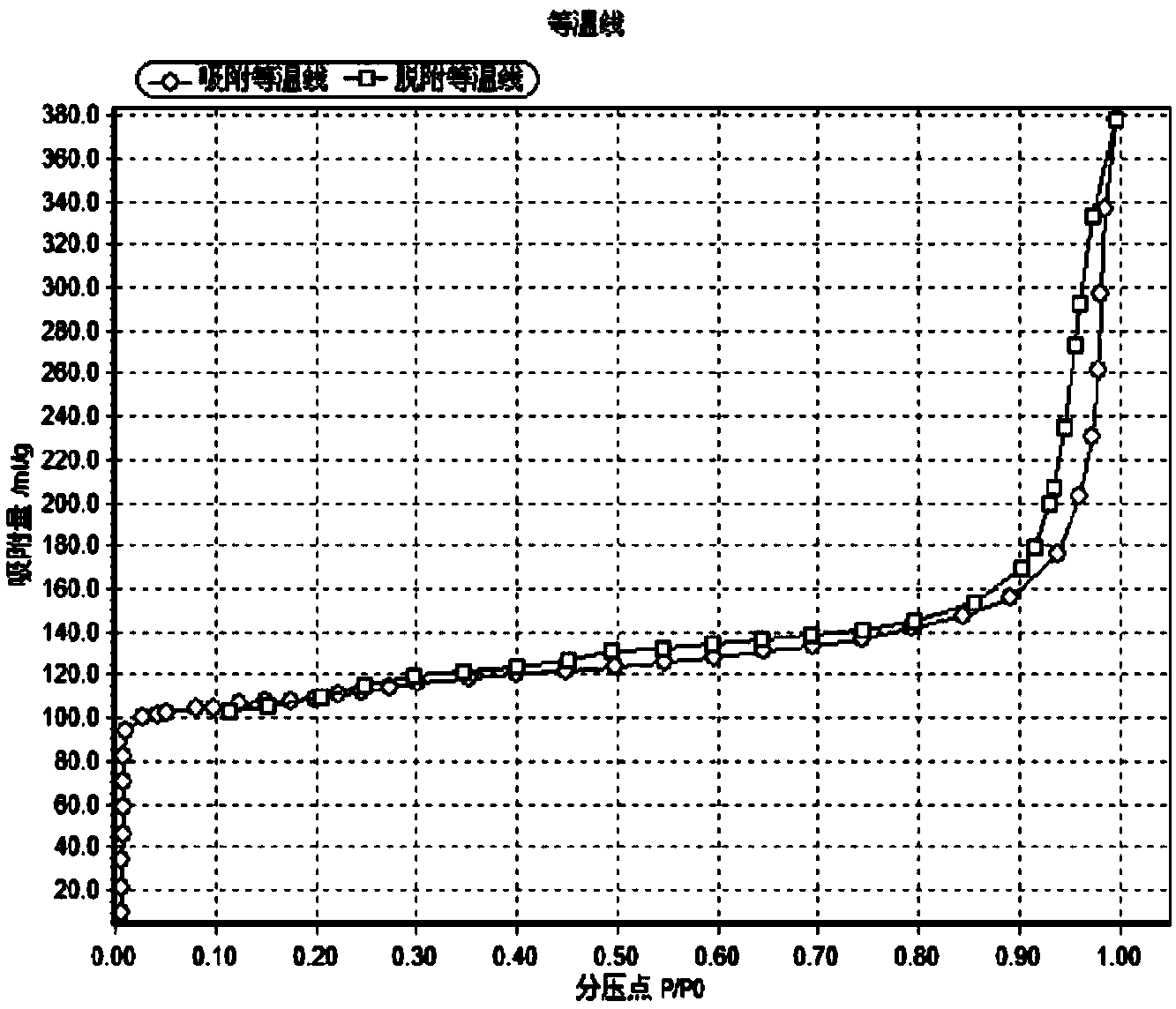

| Property | Measurement | Unit |

|---|---|---|

| Total pore volume | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com