Method for preparing ammonium paratungstate from sodium tungstate solution

A technology of ammonium paratungstate and sodium tungstate, applied in the field of producing ammonium paratungstate, can solve the problems of inappropriate comprehensive utilization or environmental protection, failure to recycle, etc., and achieve the effect of reduced workshop area, low emission and strong affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

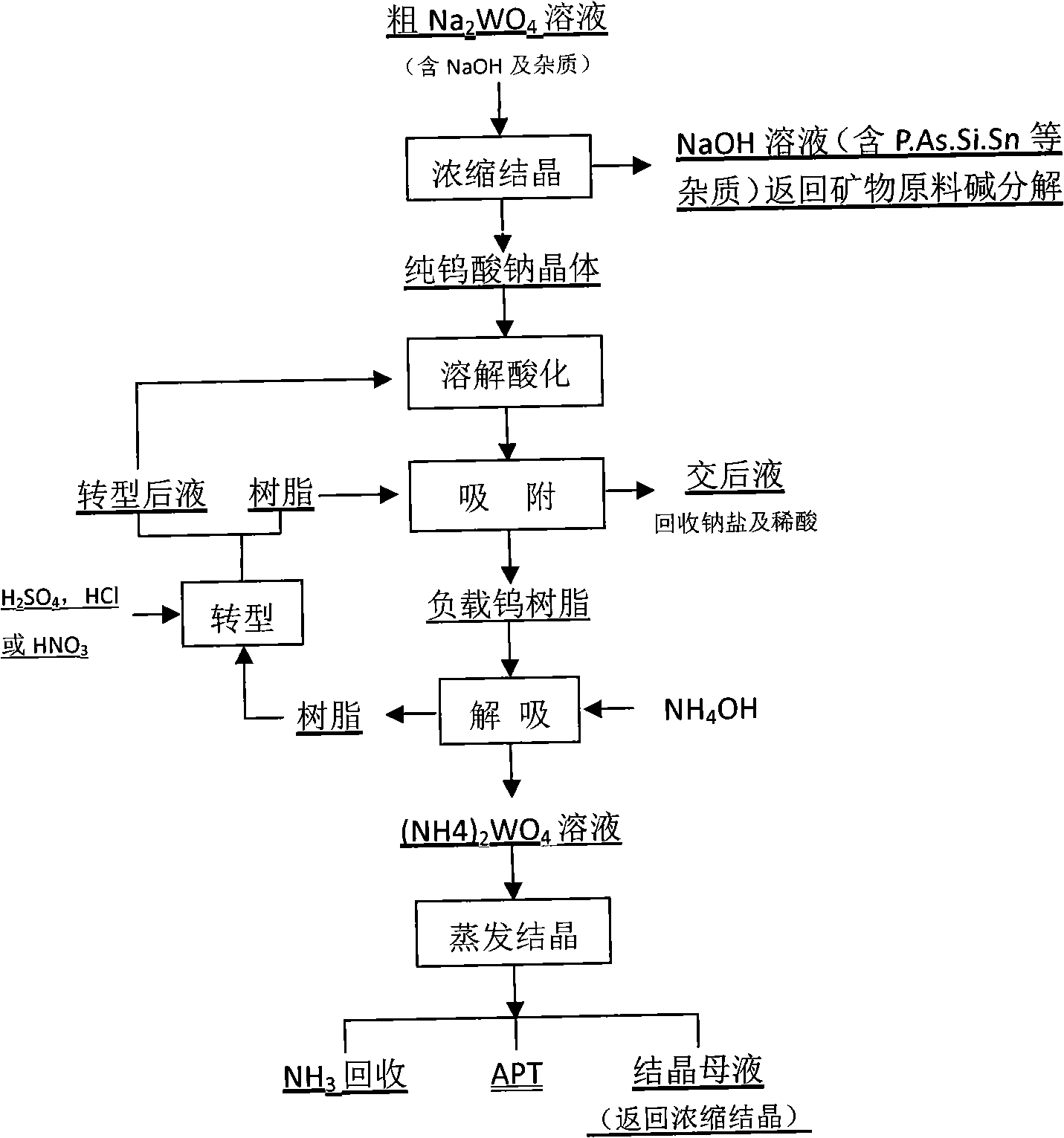

[0031] Crude Na obtained from the decomposition of tungsten mineral raw materials by NaOH 2 WO 4 Solution contains WO 3 147g / L, free NaOH50g / L, P 0.275g / L, As 0.3g / L, Si 0.7g / L, take 2L to concentrate and crystallize under boiling conditions to obtain Na 2 WO 4 Crystal 410g, which contains WO 3 65.5%, NaOH 2.1%. After the crystal water is dissolved, Na is obtained 2 WO 4 Solution contains WO 3 503g / L, free NaOH 16.1g / L, Si 0.09g / L, As 0.1g / L, P 0.1g / L. Crude Na 2 WO 4More than 95% of the P, As and 98% of the Si in the crystallization are in the alkali mother liquor after crystallization, and the alkali mother liquor contains 310g / L NaOH.

Embodiment 2

[0033] Crude Na as described in Example 1 2 WO 4 2L of solution is concentrated and crystallized under the condition of negative pressure of 50Kpa to obtain Na 2 WO 4 Crystal 425g, which contains WO 3 63.8%, NaOH 2.6%, the crystal dissolves into Na 2 WO 4 Solution contains WO 3 490g / L, NaOH 18.2g / L, Si 0.10g / L, As 0.11g / L, P 0.1g / L, crude Na 2 WO 4 About 95% of the P, As and more than 97% of the Si in the alkaline mother liquor, the alkaline mother liquor contains NaOH 300g / L.

Embodiment 3

[0035] Na as described in Example 1 2 WO 4 Na after dissolving crystal water 2 WO 4 Solution 0.5L contains WO 3 503g / L, add H 2 SO 4 Neutralize to a pH of about 6, make it and H 2 SO 4 The transformed macroporous weakly basic anion exchange resin D301 was used for ion exchange, and the post-delivery solution (post-adsorption solution) contained WO 3 0.02g / L. NH for loading tungsten resin 4 OH solution (containing NH 3 About 28%) desorption, may contain WO 3 208g / L(NH4) 2 WO 4 The solution is 1.20L, the latter is evaporated and crystallized to obtain APT. Under the condition that the crystallization rate is about 88%, APT contains impurities of less than 10×10 P, As, and Si by spectroscopic analysis. -6 , Sn is less than 1×10 -6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com