Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

837 results about "Sodium tungstate dihydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium tungstate is the inorganic compound with the formula Na2WO4. This white, water-soluble solid is the sodium salt of tungstic acid. It is useful as a source of tungsten for chemical synthesis. It is an intermediate in the conversion of tungsten ores to the metal.

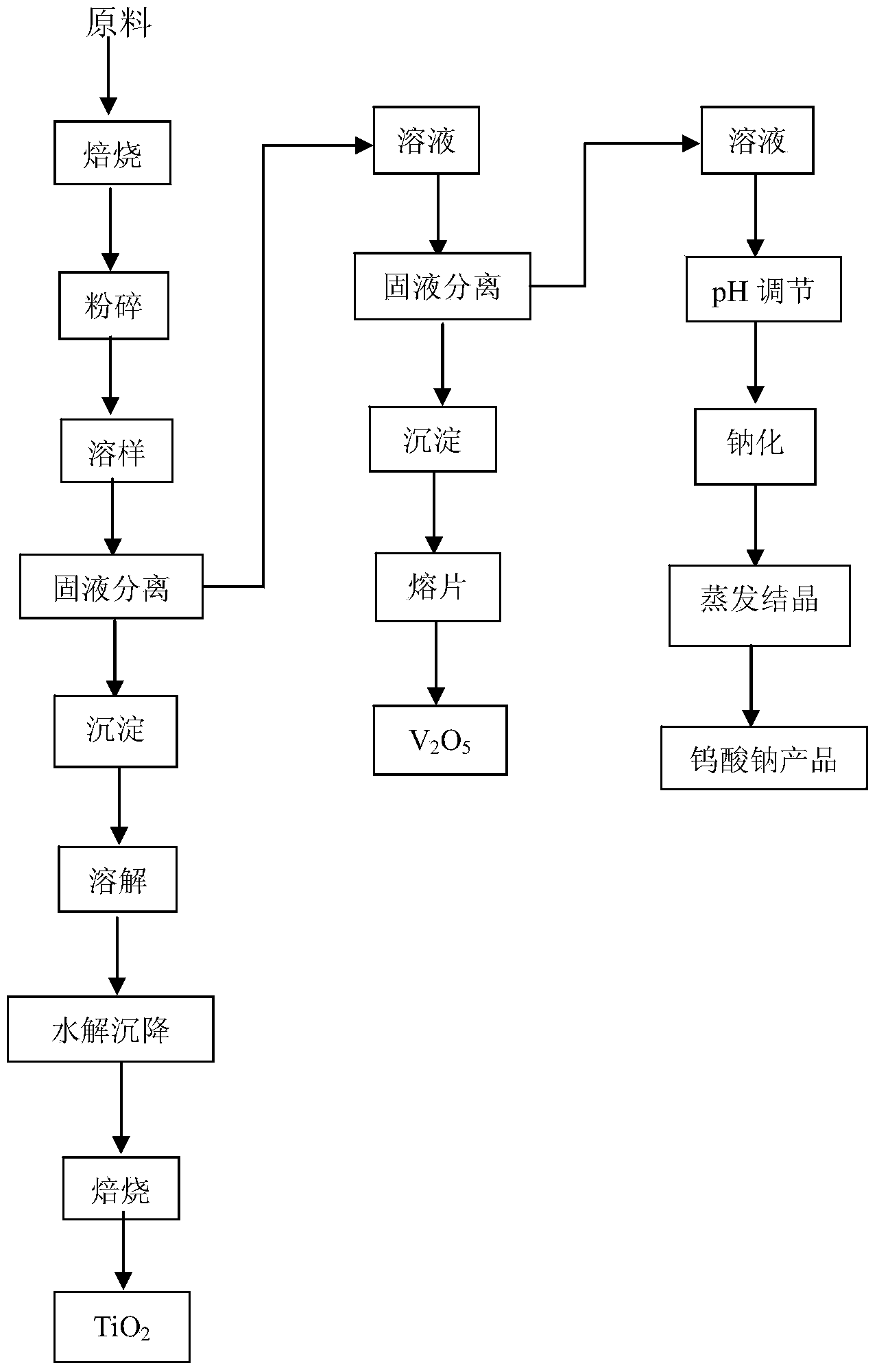

Method for extracting tungsten, titanium and vanadium from waste SCR (selective catalytic reduction) catalyst

InactiveCN102936049ASolve the pollution of the environmentLow equipment requirementsTungsten oxides/hydroxidesTitanium dioxideSlagStrong acids

The invention discloses a method for extracting tungsten, titanium and vanadium from a waste SCR (selective catalytic reduction) catalyst, which comprises the following steps: crushing the waste SCR catalyst, adding a strongly alkaline solution, and reacting; filtering, separating, then adding strong acid into the sodium tungstate and sodium vanadate mixed solution, and reacting to obtain tungstic acid and a sodium salt and vanadic acid mixed solution; regulating the pH value of the sodium salt and vanadic acid mixed solution until precipitate is separated out, thus obtaining ammonium vanadate; then adding sulfuric acid into the tungsten-and-vanadium-removed SCR catalyst, and reacting to obtain a titanyl sulfate solution and solids such as aluminum slag and the like; then adding water into the titanyl sulfate solution, and hydrolyzing to obtain titanic acid and a waste acid solution; and finally, respectively calcining the obtained ammonium vanadate, tungstic acid and titanic acid to obtain vanadium pentoxide, tungsten trioxide and titanium dioxide. According to the invention, tungsten, titanium and vanadium can be extracted from the SCR catalyst through the reaction with strong alkali and strong acid at a low temperature, the equipment requirement is low, the energy consumption is low, some products having added values can be coproduced, and no secondary pollution is generated, thereby facilitating popularization and application.

Owner:成都新智金森环保科技有限公司

Recovery method for SCR waste flue gas denitration catalyst

ActiveCN103526031AEasy to operateSimple requirementsProcess efficiency improvementPtru catalystRefining (metallurgy)

The invention relates to a recovery method for an SCR waste flue gas denitration catalyst, and adopts a hydrometallurgy process. After the SCR waste flue gas denitration catalyst is smashed and subjected to pre-calcination treatment, a NaOH solution is added according to a ratio for dissolution. After the catalyst is dissolved, solid-liquid separation is performed, sulfuric acid is added into the obtained precipitation, and the precipitation is steeped, precipitated, hydrolyzed, subjected to salt treatment, and calcinated to obtain TiO2. Sulfuric acid is added into the solution obtained from the first solid-liquid separation to adjust the pH value, excess ammonium nitrate is added to precipitate vanadium, and second solid-liquid separation is performed. Ammonium metavanadate obtained from filtration is subjected to pre-calcination to obtain a V2O5 finished product. Hydrochloric acid is added into the solution obtained from the second solid-liquid separation to adjust the pH value, and NaCl is added to obtain sodium tungstate. The sodium tungstate is subjected to purification, filtration, ion exchange, and other processes to separate impurities, and subjected to evaporative crystallization to obtain a sodium tungstate finished product. The method provided by the invention is simple in technology, general in equipment, easily available in raw material, low in cost and high in recovery rate.

Owner:UNIV OF SCI & TECH BEIJING

Multifunctional preparation for controlling biological corrosion and blockage of oilfield production system

ActiveCN101875839AEliminate pollutionEliminate cloggingDrilling compositionDisinfectantSulfate-reducing bacteria

The invention relates to a multifunctional preparation for controlling biological corrosion and blockage of an oilfield production system. The contents of functional preparations in the treating water are as follows: 20 to 200 ppm of disinfectant: glutaraldehyde, acrolein, dodecyldimethylbenzyl ammonium chloride or dodecyldimethylbenzyl ammonium bromide, 10 to 100 ppm of inhibitor: sodium nitrateor sodium nitrite; and / or 10 to 20 ppm of sodium molybdate, sodium tungstate or lithium molybdate; 10 to 20 ppm of corrosion inhibitor: imidazoline quaternary ammonium; or / and 20 to 50 ppm of desulphurizing reagent: trihydroxymethyl nitromethane; or / and 10 to 20 ppm of penetrating agent: alkylpheol ethoxylates. The components undergo synergistic action so that the concentration of the single component is reduced obviously and reaches 25 to 90%, and the efficiency of killing the SRB (Sulfate Reducing Bacteria) reaches more than 90%.

Owner:PETROCHINA CO LTD

Method for preparing high-purity phosphotungsticacid

ActiveCN1978327ALow in phosphateHigh purityPhysical/chemical process catalystsTungsten compoundsPhosphoric acidSodium tungstate dihydrate

This invention introduces a method for preparing pure PTA with sodium wolframate as the raw material including : 1, contacting sodium wolframate solution with inorganic acid solution till depositing active tungstenic acid, 2, contacting the deposition with phosphoric acid till dissolving the active tungstenic completely to get PTA solution, 3, adding an inorganic acid precipitator to the solution to deposit, filter and crystallize the deposition to get pure PTA, in which, the mol concentration of the precipitator in the system is 0.1-6mol / 1.

Owner:CHINA PETROLEUM & CHEM CORP +1

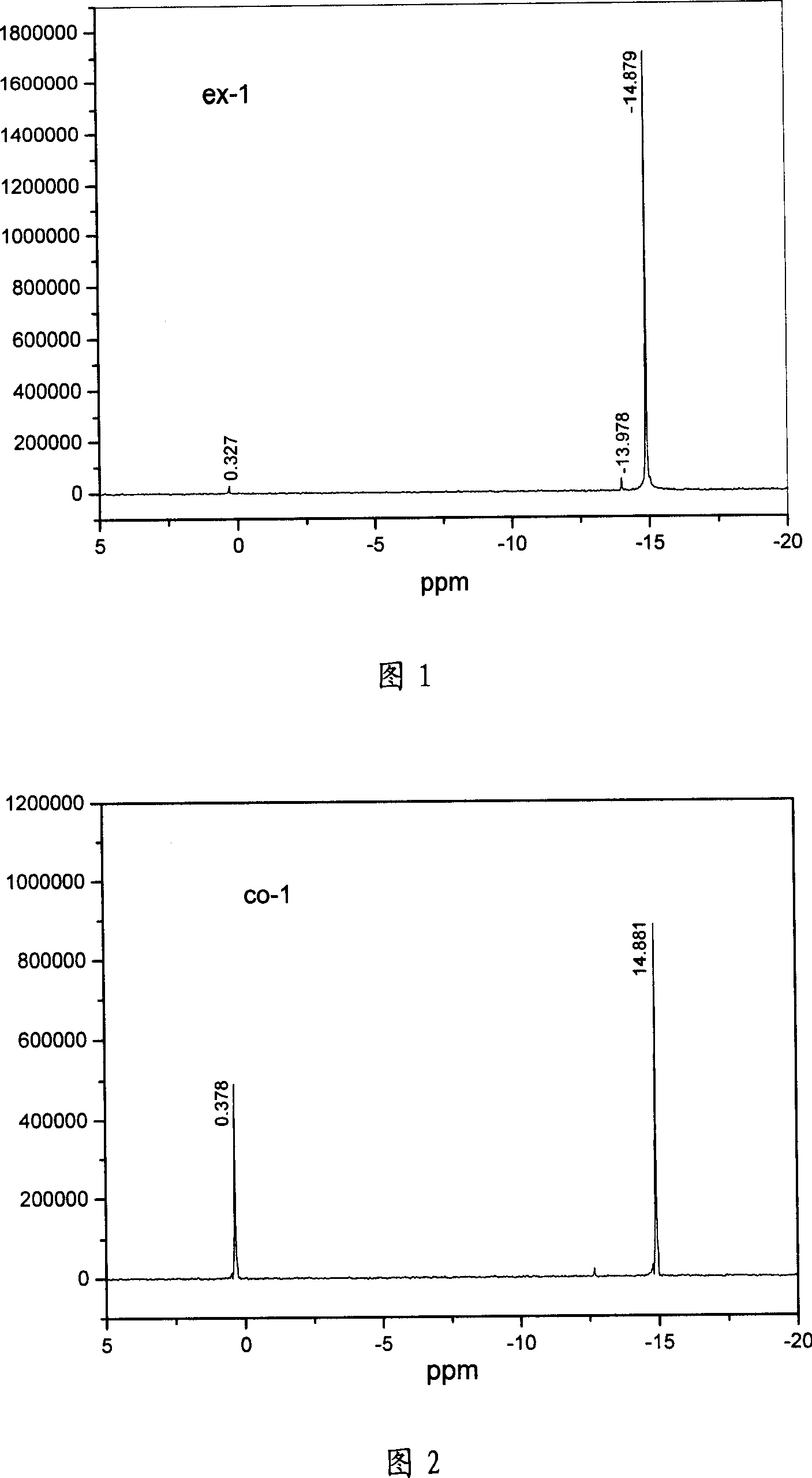

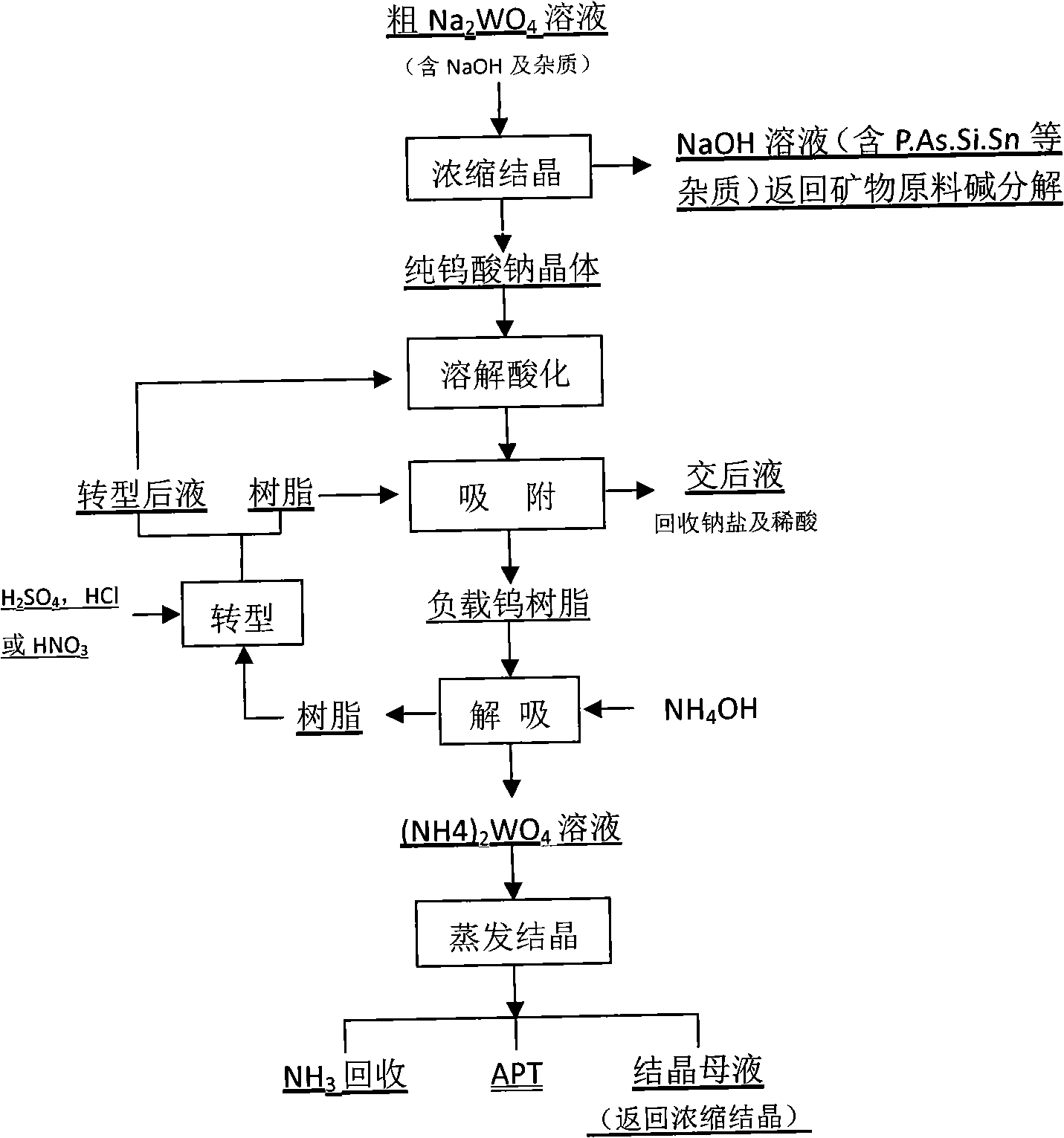

Method for preparing ammonium paratungstate from sodium tungstate solution

InactiveCN101570346AIncrease concentrationEmission reductionTungsten compoundsAmmonium paratungstateEvaporation

The invention provides a method for preparing pure ammonium paratungstate (APT) from crude Na2WO4 solution containing NaOH, P, As, Si, Sn and other impurities. The method comprises the following steps of crystallizing tungsten into Na2WO4 crystals through concentration, separating NaOH from impurities, redissolving and acidifying the Na2WO4 crystals till the pH of the crystals is between 2.0 and 6.0, adsorbing the crystals by use of macroporous weak alkaline anion exchange resin, desorbing the crystals by use of NH4OH, obtaining (NH4)2WO4 solution, performing evaporation crystallization and obtaining the APT. Under the condition that the crystallization rate is between 88 and 90 percent, the P, the As and the Si contained in the APT are all less than 10*10. The method has the outstanding advantage of small amount of discharged wastewater (mainly liquid after exchange), namely the volume of the discharged liquid after the exchange is one third to one twenty-fifth of that of liquid before the exchange; in addition, the discharged liquid after the exchange contains no detrimental impurities and is easy to control.

Owner:CENT SOUTH UNIV

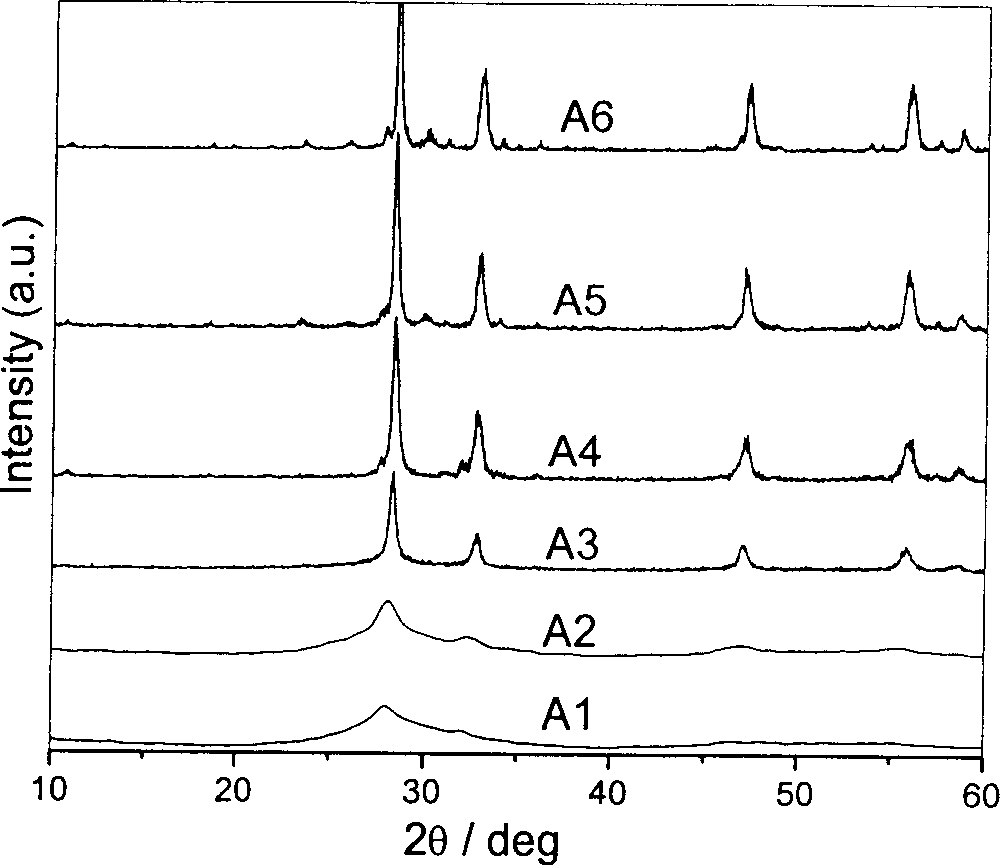

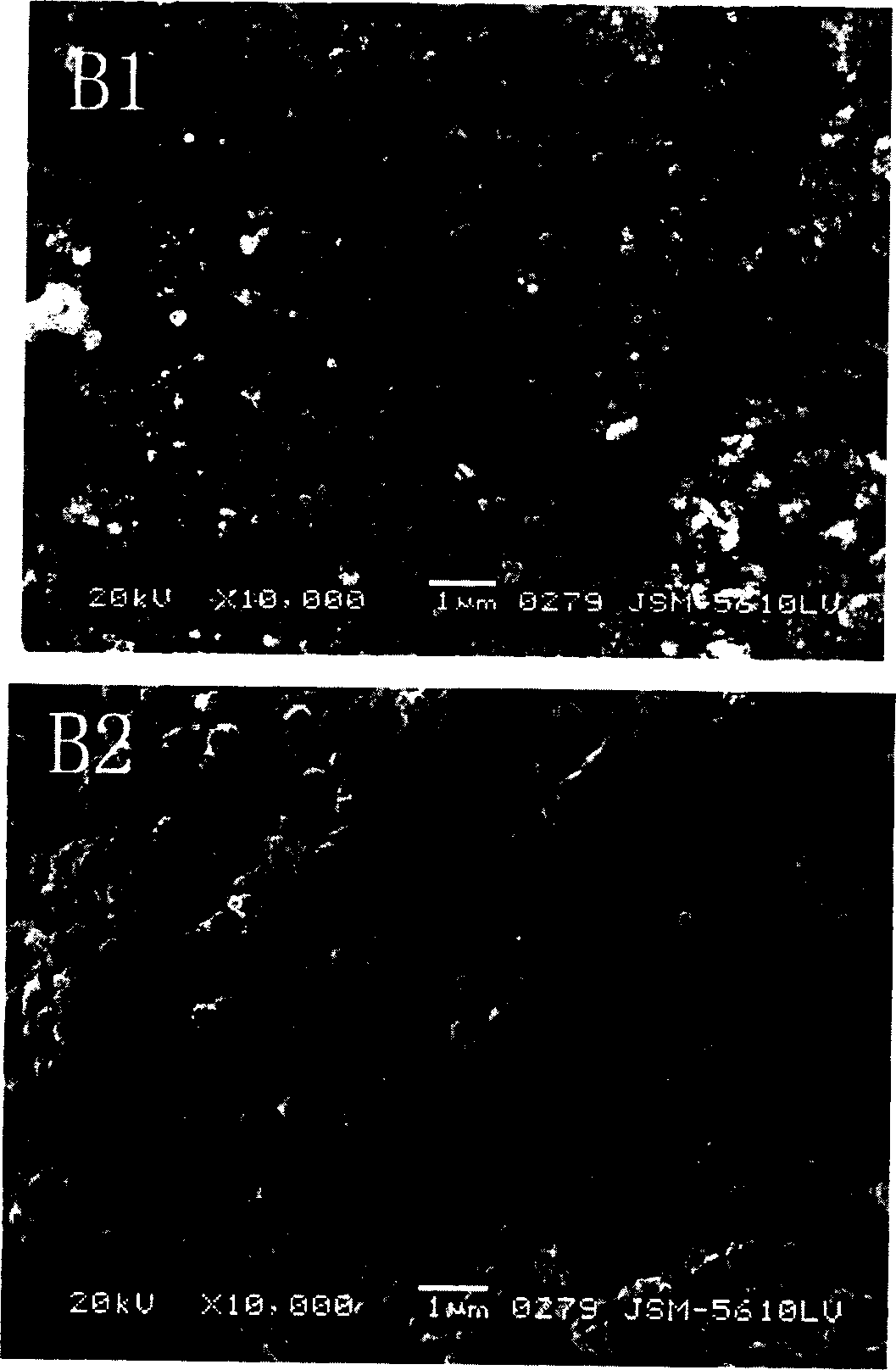

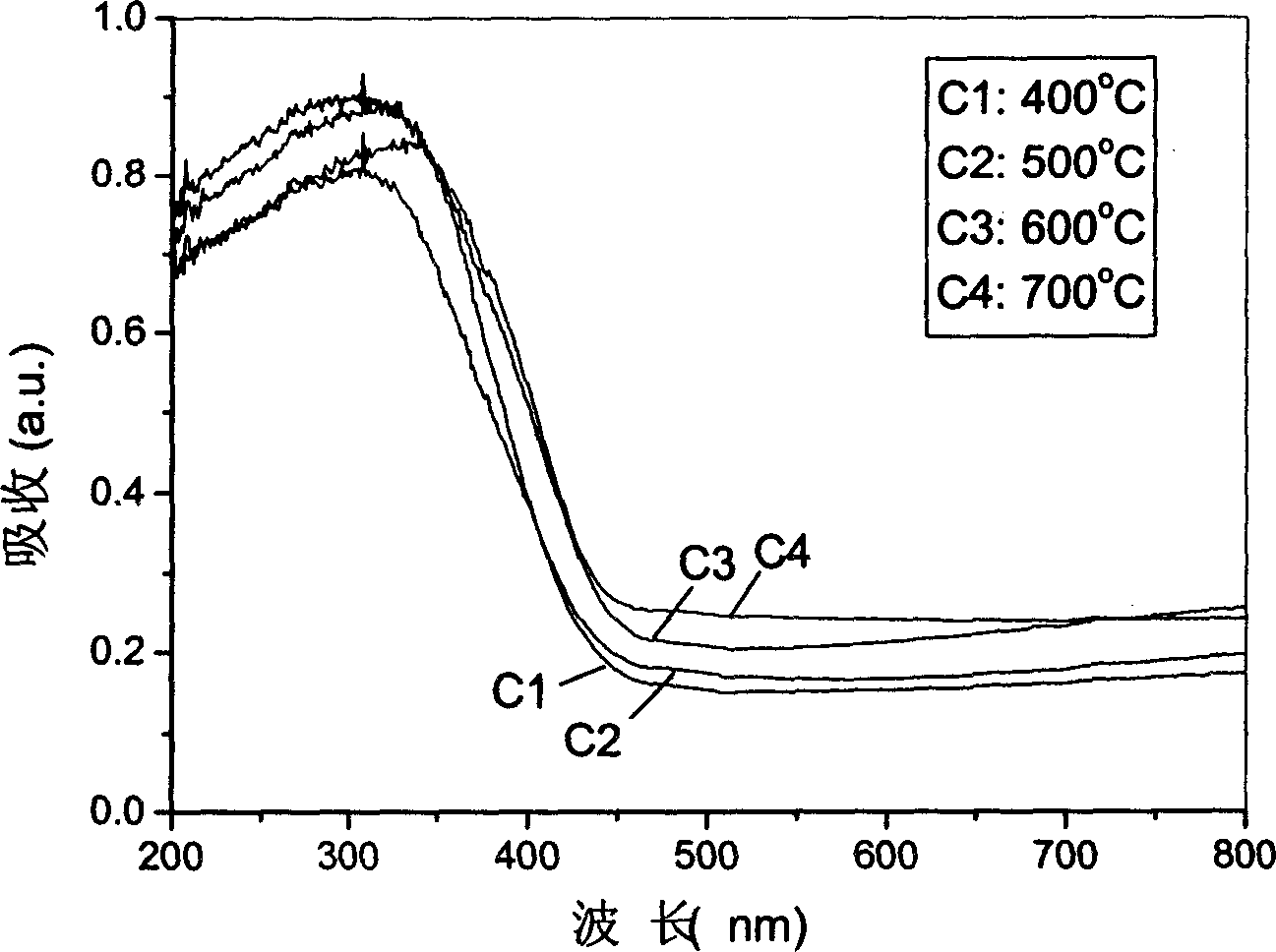

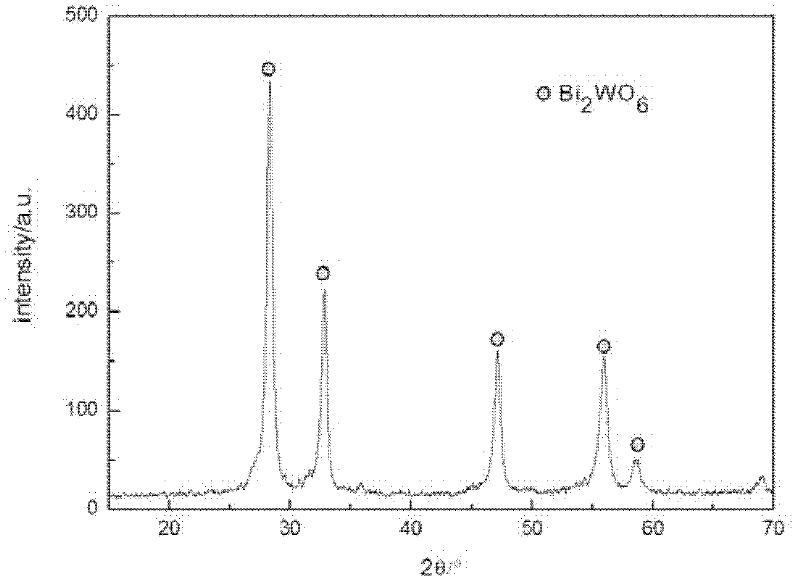

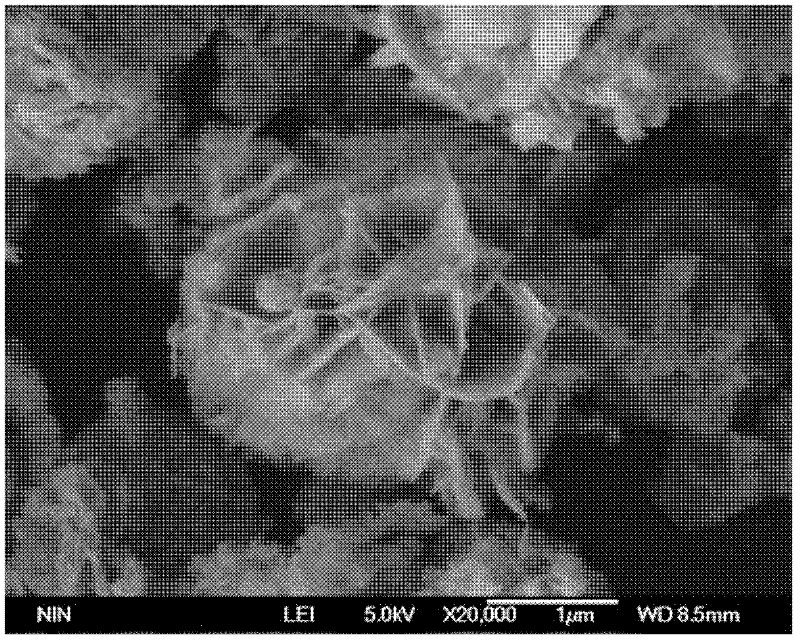

Hydrothermal method for preparing nano crystal Bi2WO6 powder photocatalytic material with visible light activity

InactiveCN1709567AImprove visible light photocatalytic activityLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsLight ActivityUltraviolet

The invention proposes a kind of hydrothermal method used for preparing light catalyzing material with visible light active nano crystal Bi2WO6 powder. The method makes bismuth nitrate and sodium tungstate as raw materials, prepare them into mixed solution, then add into reacting kettle and have hydrothermal treatment for 10 - 48 hours at 100 - 200 Deg. C, take out reacting kettle, after the system cooled to room temperature, repeatedly wash the got output to neutral with deionized water, then dry in vacuum condition, finally through 100 -1000 heat treatment for 0.5 -10 hours, we can obtain light catalyzing material with visible light active nanometer crystal Bi2WO6 powder. The method has such advantages as low synthesizing temperature, large specific surface area of obtained simples and small grains. The prepared material can not only show light catalyzing activeness in ultraviolet, but also show light catalyzing activeness in visible light bound as sunlight or indoor lamplight.

Owner:WUHAN UNIV OF TECH

Method for preparing bismuth tungstate powder with high photocatalytic activity by adopting high-temperature microwave hydrothermal method

InactiveCN102553568ASimple processShort reaction timeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMicrowaveTungstate

The invention provides a method for preparing bismuth tungstate powder with high photocatalytic activity by adopting a high-temperature microwave hydrothermal method. Bismuth nitrate pentahydrate is used as a Bi source, and sodium tungstate dihydrate is used as a W source. The method comprises the following steps of: dissolving the bismuth nitrate pentahydrate and the sodium tungstate dihydrate into deionized water in a molar ratio of Bi to W of 2:1, regulating the pH to be 1.5-3, magnetically stirring for 1 to 2 hours at room temperature to mix the raw materials uniformly to obtain a precursor solution for microwave hydrothermal reaction, transferring the precursor solution to a reaction kettle, reacting for 30 to 90 minutes at the temperature of 220 DEG C by adopting the microwave hydrothermal method, measuring the pressure at 3.0MPa, taking the reaction product out of the reaction kettle after the reaction is stopped, collecting sediment, cleaning and drying, and thus obtaining the bismuth tungstate powder. The bismuth tungstate powder is synthesized by the method at the relatively high temperature of 220 DEG C under the high pressure of 3.0MPa, and the obtained bismuth tungstate powder has high photocatalytic activity in visible light; and the method is short in reaction time which is probably 50 to 60 minutes, low in energy consumption and environment-friendly.

Owner:SHAANXI UNIV OF SCI & TECH

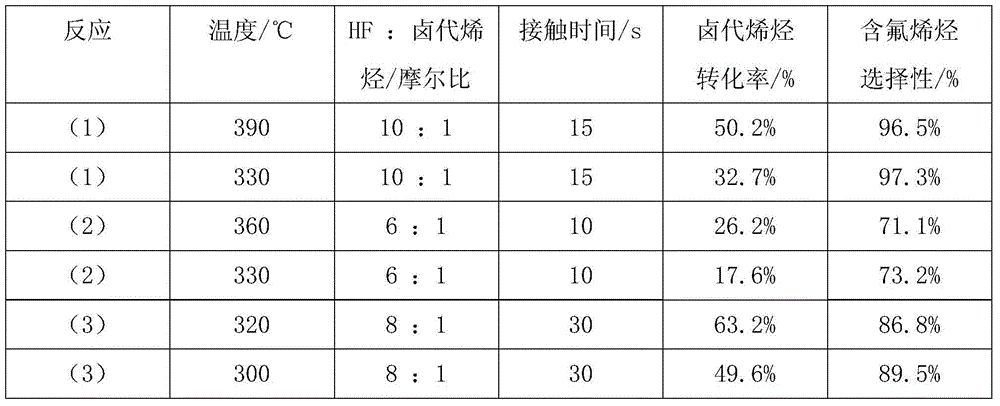

Fluorination catalyst, and preparation method and use thereof

ActiveCN104907065AIncrease the areaHigh pore volumePreparation by halogen replacementMetal/metal-oxides/metal-hydroxide catalystsChromium CompoundsChemical synthesis

The invention discloses a fluorination catalyst, and a preparation method and a use thereof, and belongs to the field of chemical synthesis. The precursor of the catalyst is formed by blending 40-95mass% of a trivalent chromium compound with 5-60mass% of tungstate, wherein the trivalent chromium compound can be chromic oxide or chromium hydroxide, and the tungstate can be zinc tungstate, nickel tungstate, magnesium tungstate, aluminum tungstate, silicotungstic acid, ammonium tungstate, ammonium paratungstate or ammonium metatungstate. The fluorination catalyst has the advantages of high use temperature, high catalysis activity and long service life, and can be mainly used in reactions for preparing fluorinated alkenes through gas phase catalysis of fluorination of alkenyl halides at a high temperature.

Owner:泉州宇极新材料科技有限公司

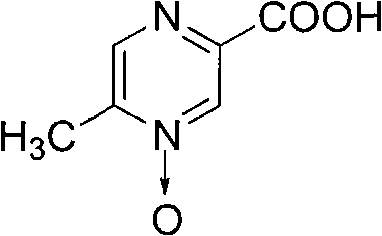

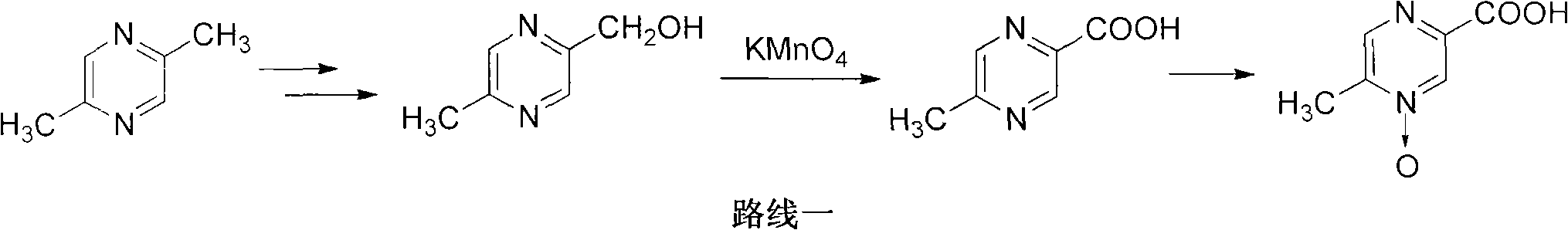

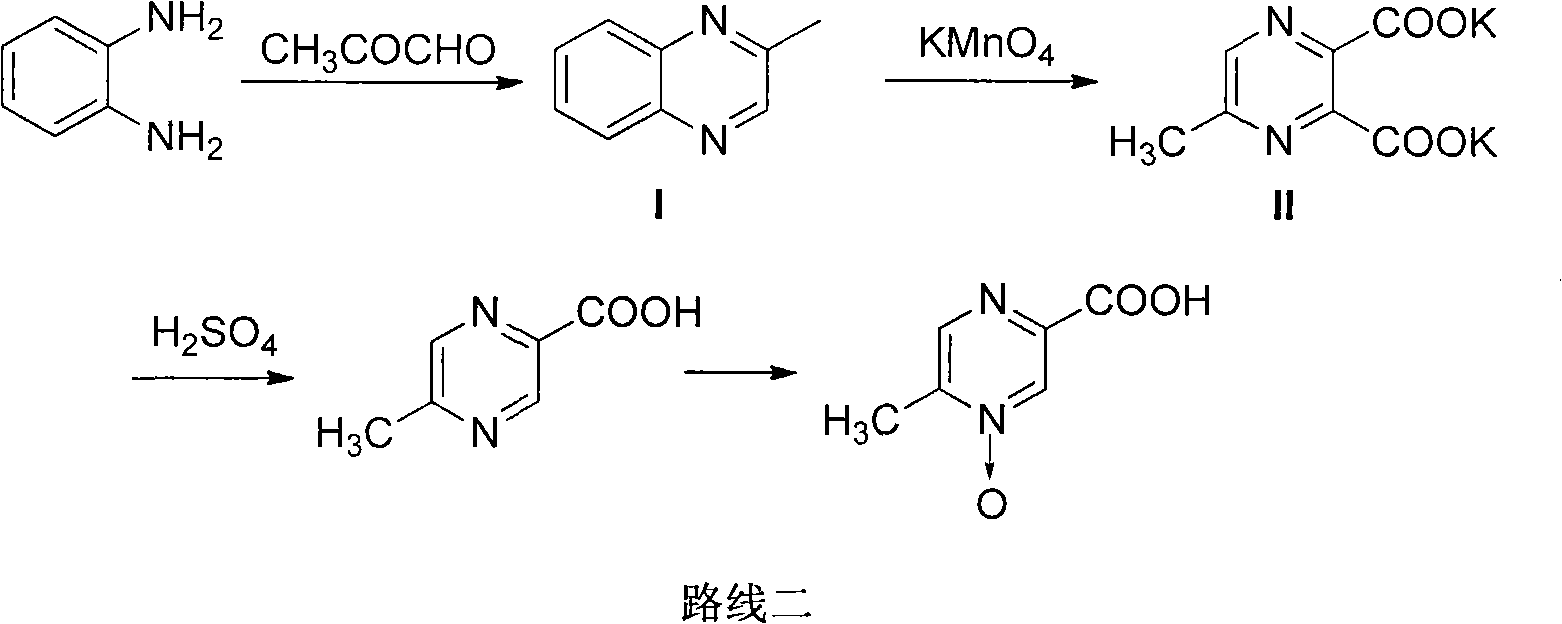

Preparation method of acipimox

InactiveCN103508963AReduce usageEasy to get materialOrganic chemistryAcetic anhydrideCarboxylic acid

The invention relates to a preparation method of acipimox for treating hyperlipidemia, belonging to the field of medicines. The invention provides an acipimox synthesis process which is simple and easy to operate. The preparation method comprises steps of with 2, 5-dimethylpyrazine as a raw material, carrying out nitrogen oxidation, reaction with acetic anhydride and alkaline hydrolysis to obtain 2-hydroxymethyl-5-methylpyrazine; directly oxidizing a post-treatment fluid by using 2,2,6,6-tetramethyl-1-piperidinyloxy / sodium hypochlorite / potassium bromide to obtain 5-methylpyrazine-2-carboxylic acid, wherein the post-treatment fluid is not needed to be dried and concentrated; oxidizing 5-methylpyrazine-2-carboxylic acid by using hydrogen peroxide / sodium tungstate to obtain acipimox.

Owner:WEIHAI WEITAI PHARMA TECH DEV

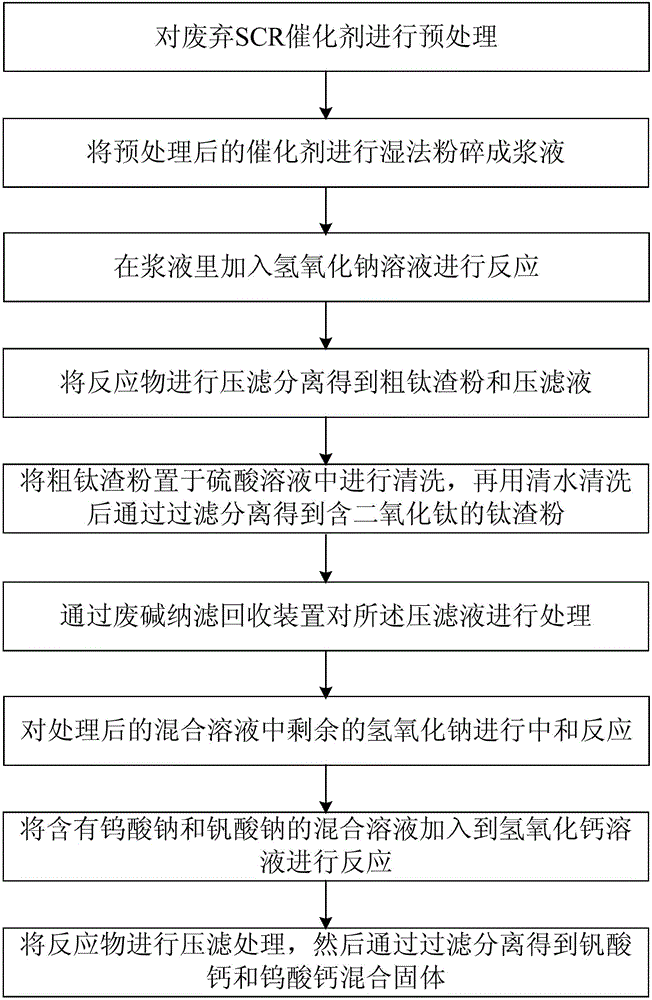

Method for extracting titanium slag, tungsten and vandic salt from waste SCR catalyst

ActiveCN106119544ASolve harmless disposalLow investment requirementProcess efficiency improvementSlurryCalcium tungstate

The invention provides a method for extracting titanium slag, tungsten and a vandic salt from a waste SCR catalyst. The method comprises the steps that the waste SCR catalyst is preprocessed and crushed into slurry by use of a wet method; a sodium hydroxide solution is added into the slurry for reaction; coarse titanium slag power and compression filtrate are obtained by filter-pressing and separating the slurry by use of a plate-and-frame filter press; the coarse titanium slag power is placed into a sulfuric acid solution for cleaning, cleaned with clear water, and then filtered and separated for obtaining titanium slag powder containing titanium dioxide; and the compression filtrate is treated through a waste alkali nanofiltration recovery device, the compression filtrate containing sodium tungstate and sodium vanadate is added into a saturated calcium hydroxide solution for reaction, products from the reaction are subjected to filter pressing, and then calcium vanadate and calcium tungstate mixed solid bodies are obtained through filtering and separating.

Owner:安徽思凯瑞环保科技有限公司

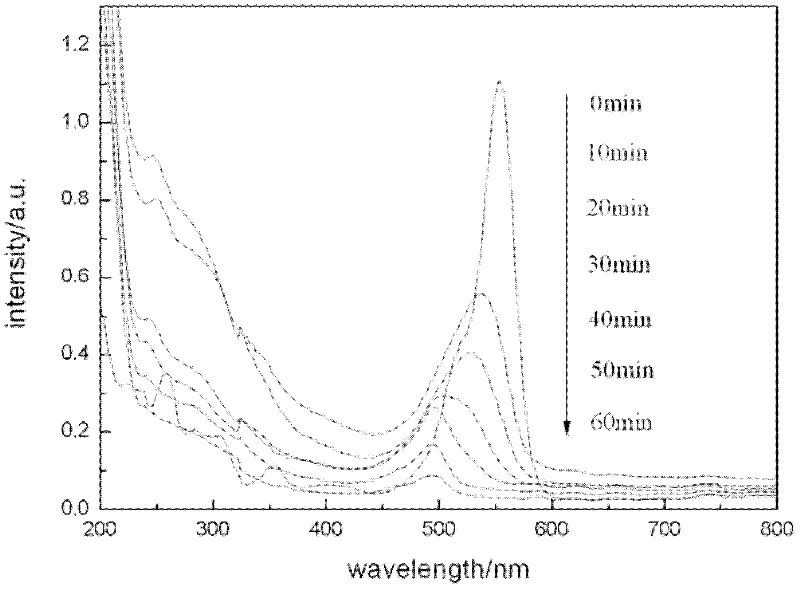

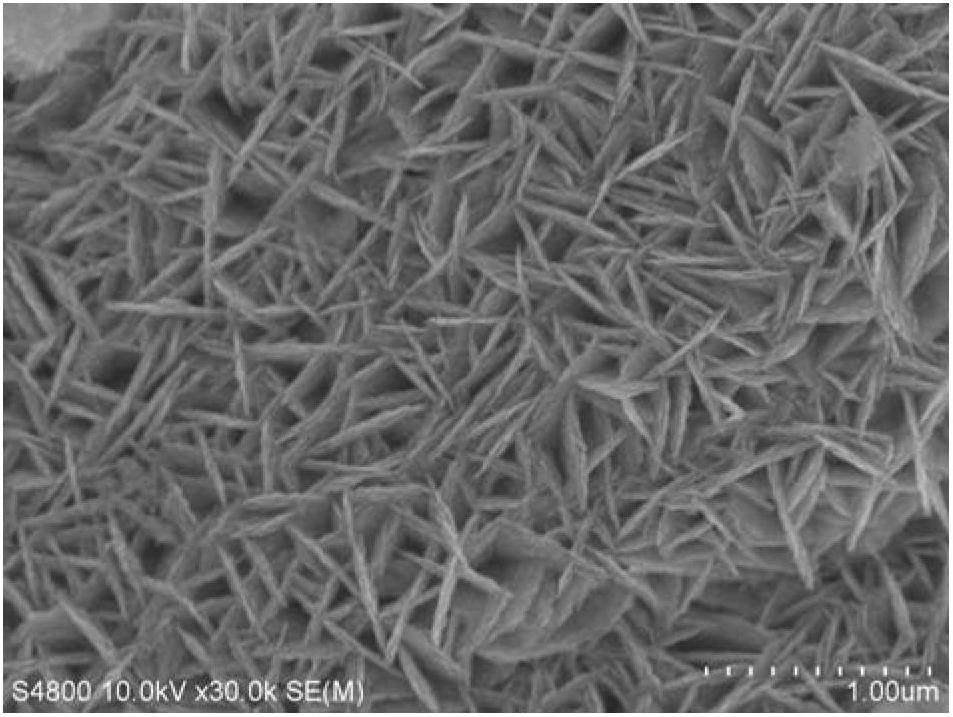

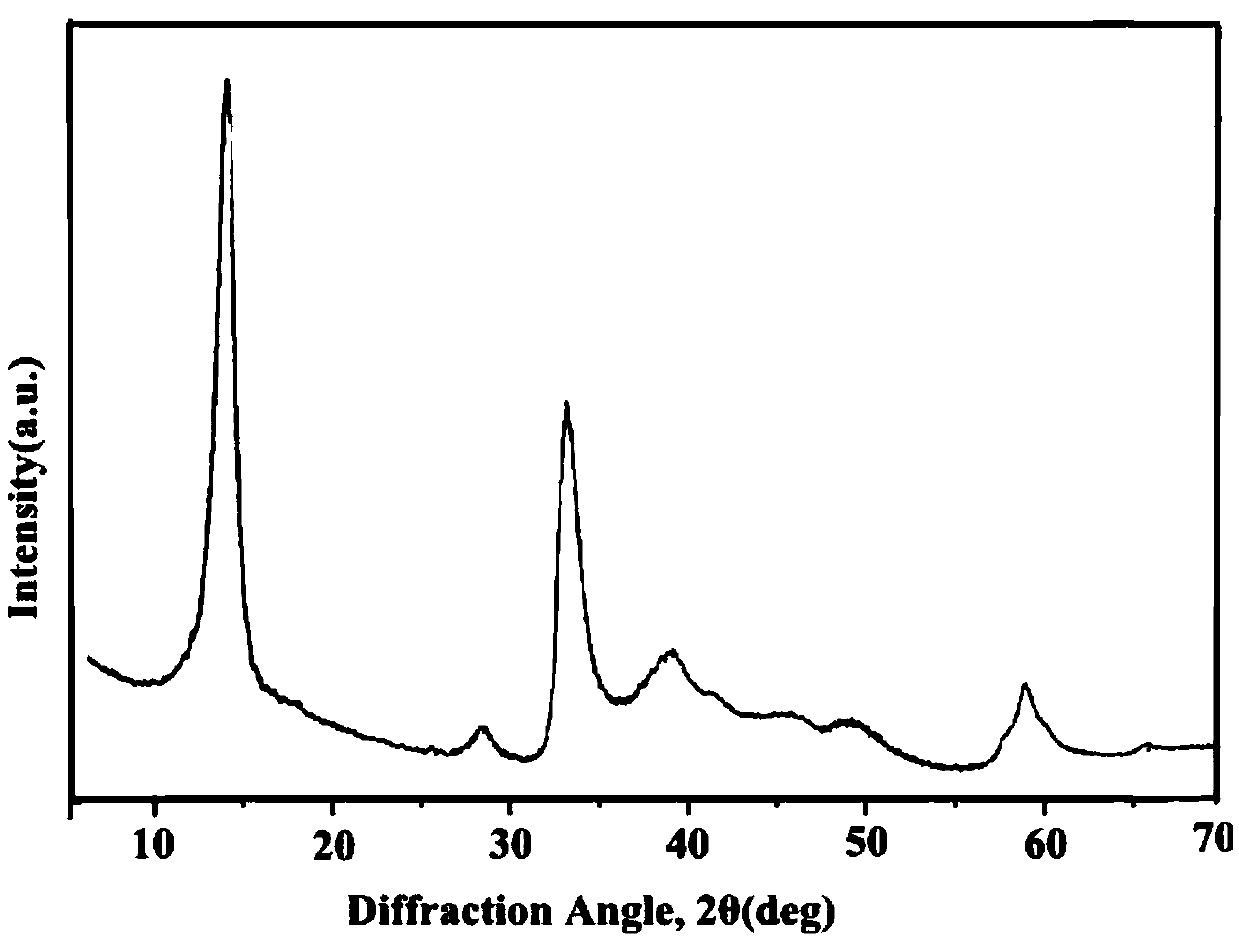

Synthesis method of tungsten trioxide

InactiveCN103011293ADifferent shapesDifferent optoelectronic propertiesTungsten oxides/hydroxidesHydration reactionOrganic dye

The invention provides a synthesis method of tungsten trioxide, belongs to the technical field of inorganic synthesis chemistry, and particularly relates to the synthesis method of the tungsten trioxide. The synthesis method comprises the following steps of: taking sodium tungstate dihydrate and sodium chloride as raw materials; utilizing hydrochloric acid to adjust a pH (Potential of Hydrogen) value of a reaction system to adjust the pH value to 1.5-3.0; carrying out hydrothermal reaction at 170-190 DEG C for 22-28 hours; and washing, centrifuging and drying to obtain tungsten trioxide powder. The obtained tungsten trioxide powder has different shapes and different photoelectric properties. According to the synthesis method disclosed by the invention, a one-step hydrothermal synthesis method is adopted, so that the operation is simple, the repetitiveness is good and the raw material cost is low; and the pH value is simply adjusted to obtain the tungsten trioxide powder with the different shapes and the different photoelectric properties, and the photocatalytic degradation efficiency on an organic dye is higher.

Owner:JILIN UNIV

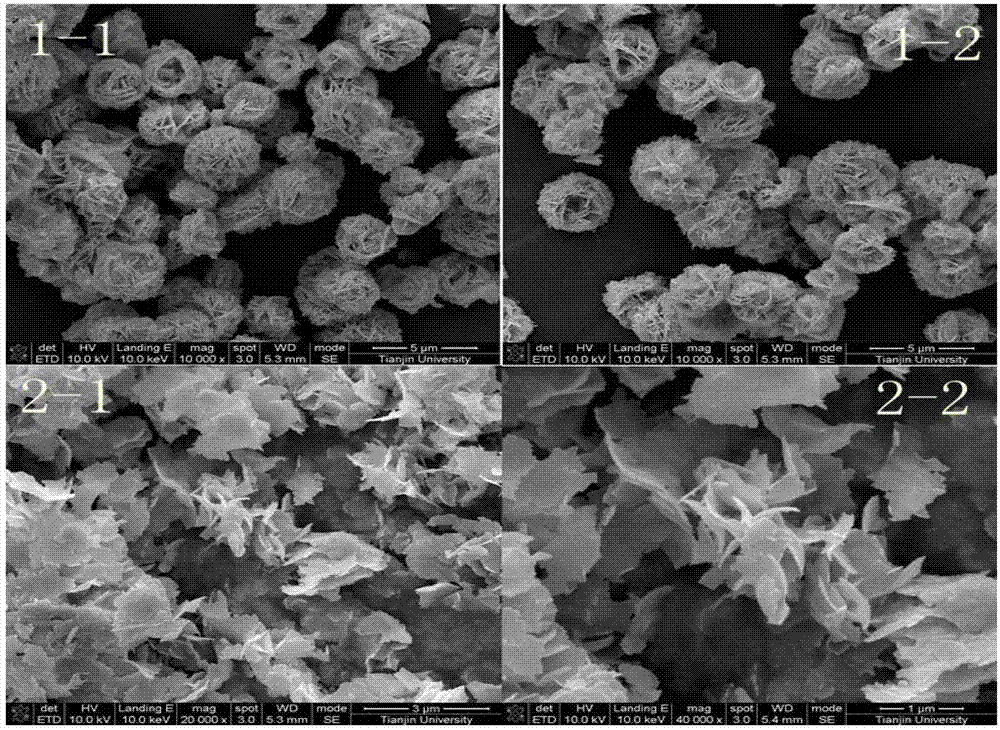

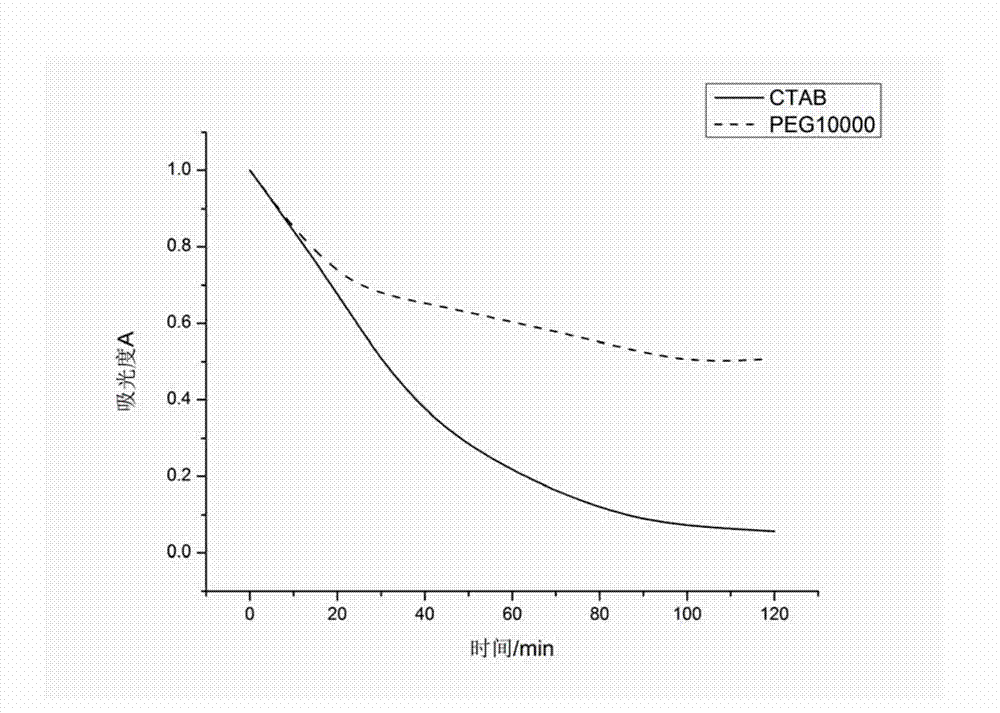

Hydro-thermal synthesis method of visible light photocatalyst mesoporous Bi2WO6

InactiveCN103191723ASimple processHigh catalytic activityMetal/metal-oxides/metal-hydroxide catalystsLevel structureSynthesis methods

The invention discloses a hydro-thermal synthesis method of a visible light photocatalyst mesoporous Bi2WO6. The hydro-thermal synthesis method comprises the following steps of: dissolving bismuth nitrate into a salpeter solution and stirring so as to obtain a solution A; dissolving sodium tungstate in deionized water and stirring so as to obtain a solution B; dropwisely adding the solution B in the solution A under intense agitation, adding a template agent and stirring so as to obtain a mixing solution, transferring the mixing solution to a reaction kettle an inner container of which is made of polytetrafluoroethylene, and carrying out a 180-degree thermostatic reaction for 24h, so as to obtain white precipitate; and washing for 2-3 times respectively by utilizing deionized water and absolute ethyl alcohol, and carrying out natural air-drying on a product so as to obtain a target object. The hydro-thermal synthesis method provided by the invention has the advantages that the process of the synthesis method is simple, the cost is low, the reaction is mild, the morphology of the product is good, the photocatalytic degradation efficiency is high, and the product is easy to recover, a prepared Bi2WO6 photocatalyst is of a three-dimensional flower shape assembled by nanosheets and has a mesoporous level structure, the Bi2WO6 photocatalyst has high catalytic activity on Rhodamine B, different template agents are adopted so as to have different influences on the degradation and morphology of the product, and the comparison phenomenon is obvious.

Owner:NANKAI UNIV

Preparation method of sunlight-responding mesoporous Bi2WO6 microspheres

InactiveCN102698739AThe hydrothermal method is simpleLow costMetal/metal-oxides/metal-hydroxide catalystsAlcoholMicrosphere

The invention discloses a preparation method of sunlight-responding mesoporous Bi2WO6 microspheres with a hydro-thermal method. The preparation method comprises the following steps of: dissolving bismuth nitrate and sodium tungstate into water respectively; dropwise adding a sodium tungstate aqueous solution into a bismuth nitrate suspension under a magnetic stirring condition to obtain a precursor liquid; putting the precursor liquid into a hydro-thermal kettle for performing a hydro-thermal reaction for 24 hours, wherein the filling volume of the precursor liquid is 80 percent, and the hydro-thermal temperature range is 120-180 DEG C; and centrifugally separating a product obtained after the hydro-thermal reaction, cleaning with water and absolute ethyl alcohol, and drying in the air of 80 DEG C to obtain powder serving as the sunlight-responding mesoporous Bi2WO6 microspheres. The preparation method has the advantages: (1) the hydro-thermal method for preparing a Bi2WO6 photocatalyst is simple, low in cost and environment-friendly, and has high yield; and (2) the Bi2WO6 microspheres with mesoporous structures can be used for realizing rapid degradation of organic pollutants by using sunlight, and have high photocatalytic activity.

Owner:NANKAI UNIV

Process for comprehensive recovery of metal-containing oxides in disabled SCR (selective catalytic reduction) denitration catalyst

InactiveCN104726713AHigh yieldImprove qualityProcess efficiency improvementSodium tungstate dihydrateTitanium

The invention relates to a method for disposal and recovery of wastes and particularly relates to a process for comprehensive recovery of metal-containing oxides in a disabled SCR (selective catalytic reduction) denitration catalyst. The process for comprehensive recovery of the metal-containing oxides in the disabled SCR denitration catalyst comprises the following steps: (1) performing pretreatment on raw materials: performing sweeping, ultrasonic treatment, bubbling and water washing on the disabled SCR denitration catalyst and performing high-temperature roasting at the temperature of 500-700 DEG C; (2) crushing: crushing the SCR denitration catalyst after high-temperature roasting, and crushing till the particle size is not more than 200 mu m to obtain uniform powder; (3) dissolving in a sodium solution; (4) separating and extracting titanium; (5) separating and extracting vanadium; and (6) reutilizing tungsten. By using the process provided by the invention, the yield of the metal oxides in the disabled SCR denitration catalyst is higher, wherein the recovery rate of TiO2 can be 95% or more, the recovery rate of V2O5 can be 95% or more, and the yield of a sodium tungstate product can be 98% or more.

Owner:ZHEJIANG UNIV

Synthesis of pyridine-N-oxide

Synthesis of pyridine-N-oxide is carried out by preparing sodium tungstate into carrier phosphate-tungstic acid by wetting method, vacuum drying to generate anhydrous product, putting anhydrous product and carrier into container, formulating solution by deionized water, agitating to remove water content, drying at high-temperature, activating to obtain catalyst, putting catalyst and pyridine into flask, oxidation reacting by hydrogen peroxide, filtering out catalyst and decompress distilling to obtain the final product. It's simple, fast and cheap and has less solvent.

Owner:天津维智精细化工有限公司

Single-layer bismuth tungstate nano-sheet composite photocatalyst modified by carbon quantum dots, preparation method of photocatalyst and application

InactiveCN106902810AVisible light response range is wideImprove degradation efficiencyWater/sewage treatment by irradiationWater treatment compoundsTungstateBismuth

The invention discloses a single-layer bismuth tungstate nano-sheet composite photocatalyst modified by carbon quantum dots, a preparation method of photocatalyst and an application. The composite photocatalyst comprises single-layer bismuth tungstate nano-sheets and the carbon quantum dots, the single-layer bismuth tungstate nano-sheets are modified by the carbon quantum dots, and the weight ratio of the carbon quantum dots to the single-layer bismuth tungstate nano-sheets is 0.03-0.05:1. The carbon quantum dots, hexadecyl trimethyl ammonium bromide, bismuth nitrate solution and sodium tungstate solution are mixed and react in a hydrothermal manner to obtain the composite photocatalyst. The composite photocatalyst has the advantages of wide visible light response range, high degradation efficiency, good photocatalyst stability and reusable performance and the like. The preparation method of the photocatalyst has the advantages that the preparation method is simple and convenient to operate, low in raw material cost and less in energy consumption, large-scale preparation can be achieved and the like. The composite photocatalyst belongs to green synthetic technique and can be used for treating antibiotic wastewater.

Owner:HUNAN UNIV

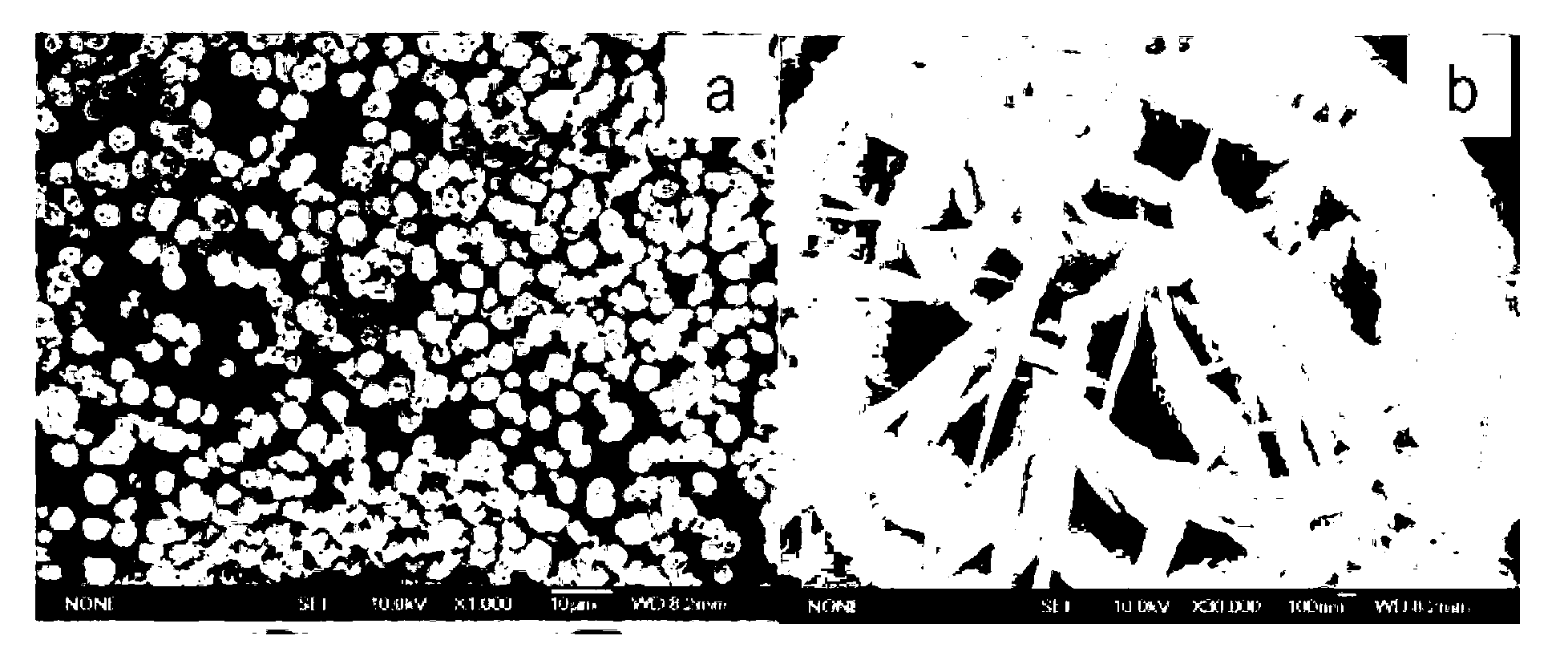

Nanometer photocatalyst bismuth tungstate and preparation method thereof

InactiveCN103157461APressure no requirementSimple ingredientsMetal/metal-oxides/metal-hydroxide catalystsTungstateSodium nitrate

The invention discloses a method for preparing nanometer bismuth tungstate by utilizing a fused salt method. According to the method, bismuth nitrate and sodium tungstate are adopted as raw materials, potassium nitrate / sodium nitrate and lithium nitrate are utilized as a fuse salt system, the raw materials are mixed and added into a molten salt system in a crucible, and the nanoscale bismuth tungstate powder is obtained through reaction. According to the method, the uniform mixing of raw material on a molecule scale can be realized, and the nanoscale bismuth tungstate powder with high purity is obtained. The method provided by the invention has the advantages that the equipment is simple, the technological process is short, the operation is simple, the product performance is excellent, and the method has an extensive application prospect.

Owner:NANJING UNIV OF SCI & TECH

Ni-W-P alloy plating solution for chemical plating and chemical plating method employing the same

InactiveCN101225516AFast platingLittle change in pHLiquid/solution decomposition chemical coatingChemical platingThiourea

The invention relates to a plating solution for chemical plating nickel-tungsten-phosphor alloy, comprising nickel vitriol of 24 to 28 g / l, sodium citrate of 40 to 70 g / l, gluconic acid sodium salt of 20 to 30 g / l, ammonium sulfate of 30 to 40 g / l, sodium pyroborate of 5 to 15 g / l, sodium tungstate of 30 to 50 g / l, sodium hypophosphite of 20 to 28 g / l, potash iodate of 10 to 20 mg / l, thiourea of 0.5 to 1.5 mg / l and sodium dodecyl sulfate of 5 to 15 mg / l. The plating solution is characterized in that: the chemical plating method using the plating solution comprises the following steps that: the pH value of the plating solution is adjusted to 8 to 9, and then the plating solution is heated to 80 to 90 degree centigrade, and then the processed plating articles are dipped into the plating solution; the time of dip plating is determined by the required plating layer thickness. The plating solution for chemical plating nickel-tungsten-phosphor alloy has the advantages of higher stability and higher plating speed.

Owner:罗森鹤

Preparation method of laminar-card-structure bisumth tungstate microcrystals

InactiveCN102674461AHigh crystallinityReduce energy consumptionTungsten compoundsCrystallinitySunlight

The invention relates to a preparation method of laminar-card-structure bisumth tungstate microcrystals, which comprises the following steps: adding sodium tungstate dihydrate into deionized water to obtain a solution A; adding bismuth nitrate pentahydrate into the solution A to obtain a solution B; regulating the pH value of the solution B to 3.8-5.2 with an NaOH solution to obtain a white suspension C; pouring the solution C into a hydrothermal reaction kettle to carry out hydrothermal reaction, opening the hydrothermal reaction kettle after the reaction finishes, collecting the product by centrifugal separation, respectively washing with deionized water and anhydrous alcohol, and drying to obtain the end product laminar-card-structure Bi2WO6 microcrystals. By using the hydrothermal preparation technique, the method provided by the invention has the advantage of low energy consumption and favorable product crystallinity, and can complete the reaction in the liquid phase at one time without any after-treatment. The Bi2WO6 microcrystals prepared by the method are in a laminar card structure, have excellent photocatalytic performance, and can quickly degrade rhodamine B under the irradiation of natural sunlight (the degradation rate after 2 hours reaches 95%).

Owner:SHAANXI UNIV OF SCI & TECH

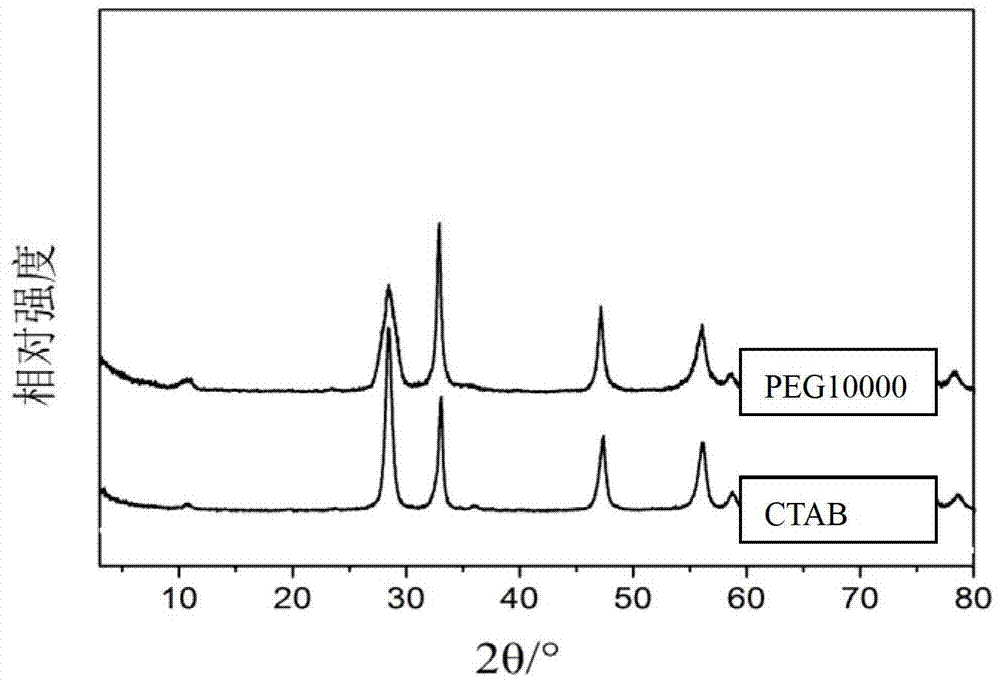

Preparation method of tungsten disulfide nanorod

ActiveCN105502502AGood size uniformityGood dispersionNanotechnologyTungsten compoundsHydroxylamineThiourea

The invention discloses a preparation method of a tungsten disulfide nanorod. The method comprises the following steps that sodium tungstate, hydroxylamine hydrochloride and thiourea are dissolved in water according to the molar ratio of 1 to (1.5-3) to (3-5) to form a solution, a mixed surfactant is added to the solution, the mixed surfactant is composed of CTAB, CTAC and F127 which are mixed according to the molar ratio of 1 to (1.5-3) to (0.6-1.8), the solution is moved into a stainless steel reaction kettle, and a reaction is conducted for 10-24 h at the temperature ranging from 170 DEG C to 200 DEG C. For the prepared tungsten disulfide nanorod, the diameter ranges from 20 nm to 100 nm, the length ranges from 200 nm to 350 nm, the maximum length difference is smaller than 150 nm, the length distribution is centralized, the size uniformity is good, and the dispersity is good; meanwhile, the prepared tungsten disulfide nanorod has the unexpected visible light absorption property and the wide application prospect in the photocatalytic aspect.

Owner:CHONGQING UNIV OF ARTS & SCI

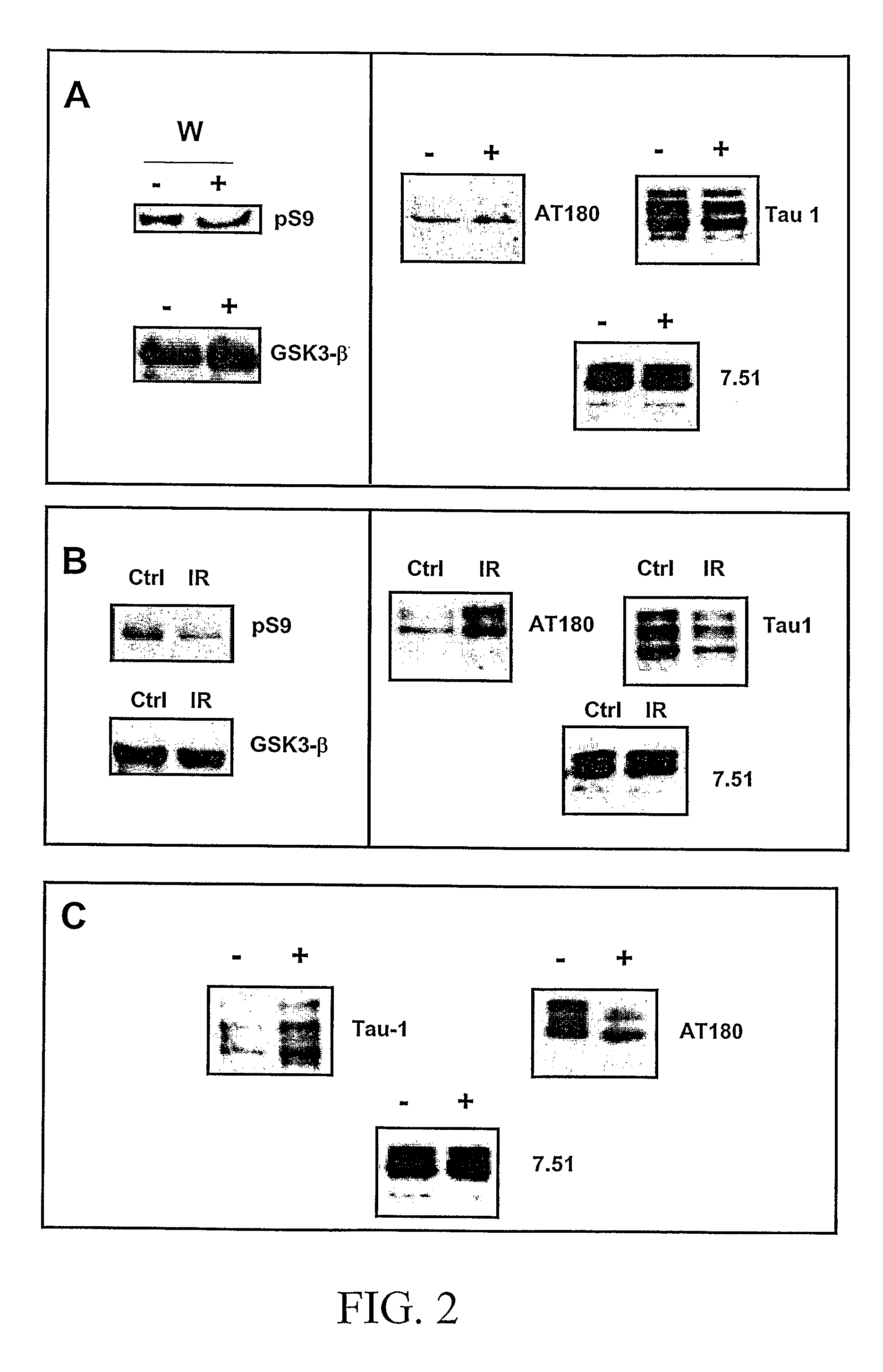

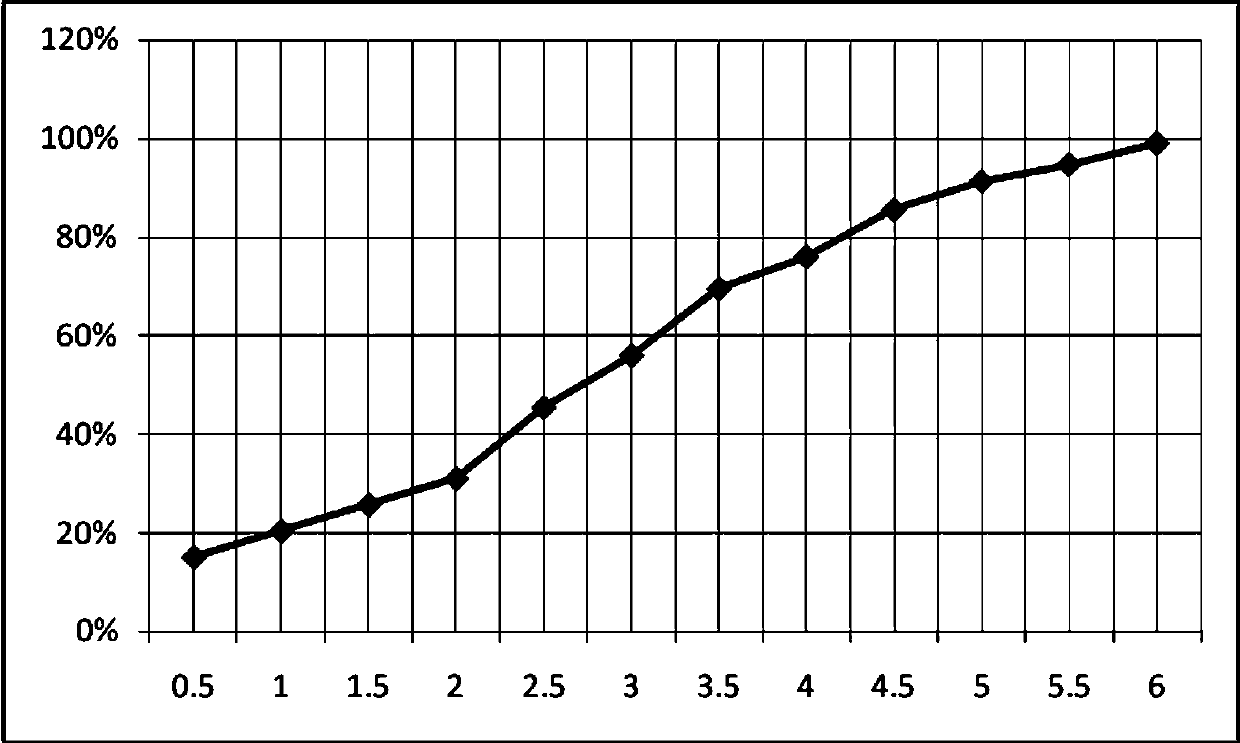

Pharmaceutical Compositions for the Treatment of Neurodegenerative Disorders

InactiveUS20080206356A1Low priceImprove solubilityBiocideHeavy metal active ingredientsTherapeutic treatmentInsulin resistance

Pharmaceutical compositions comprising an effective amount of a tungsten (VI) compound, preferably of a tungstate salt, and more preferably of sodium tungstate (Na2WO4), are useful for the prophylactic and / or therapeutical treatment of neurodegenerative disorders in a mammal, including a human, in particular, for the prophylactic and / or therapeutical treatment of Alzheimer's disease or schizophrenia. The effect of sodium tungstate dihydrate on the phosphorylation of tau in a model of rat insulin resistance and in a model of type-1 diabetes has been assessed. The therapeutic treatment of tauopathies that derives from this invention involves several advantages: it targets a GSK3; specificity since it reduces the abnormal hyperphosphorylation of a neural specific protein, tau, efficacy, lack of toxicity, and low price.

Owner:UNIV DE BARCELONA +1

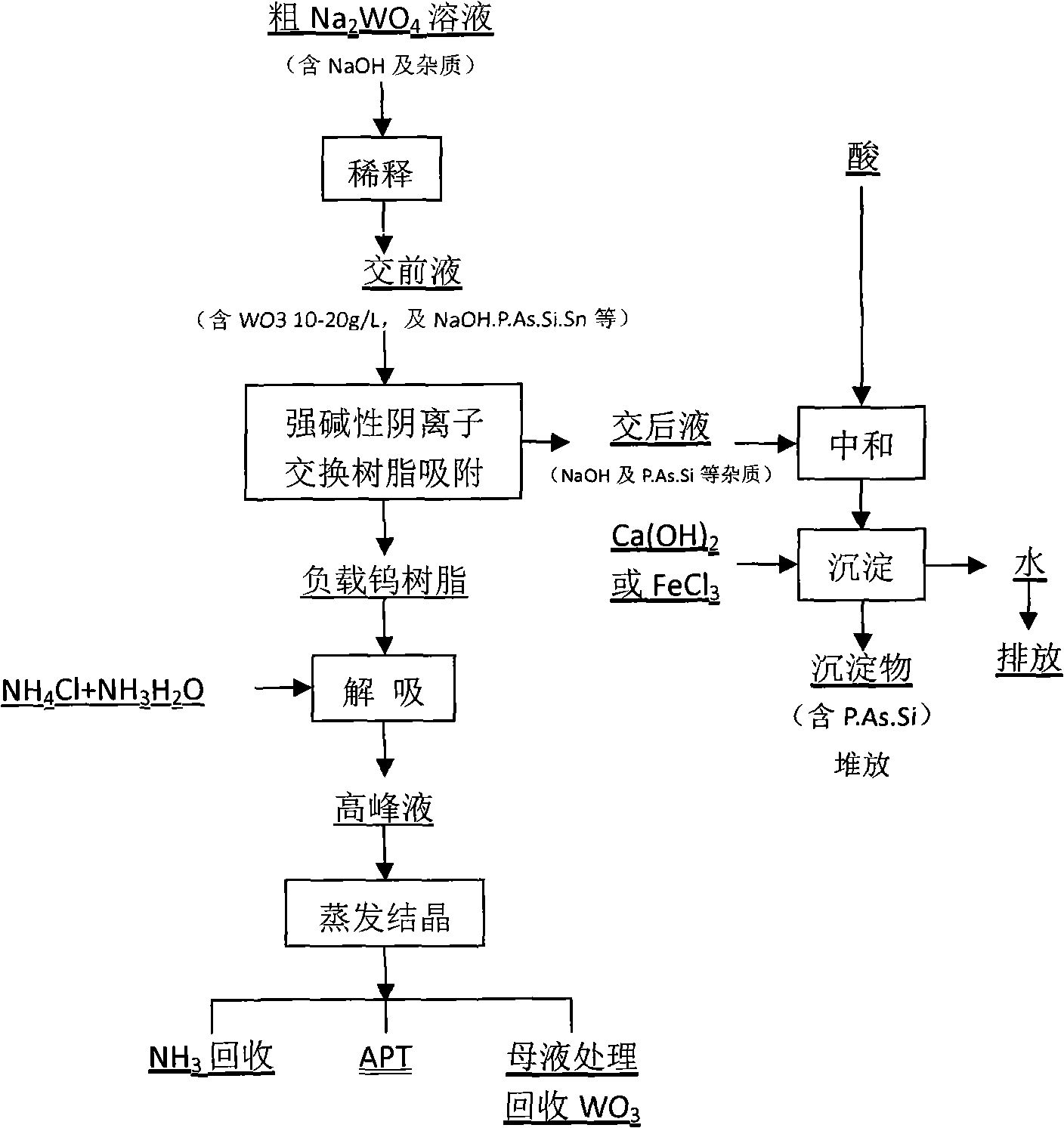

Method for preparing ammonium paratungstate by ion exchange method

The invention discloses a method for preparing ammonium paratungstate by an ion exchange method. The method includes the steps: (1) carrying out alkali treatment of a tungsten concentrate, so as to obtain an alkaline sodium tungstate material solution; (2) adding an acidic substance into the alkaline sodium tungstate material solution, heating, and carrying out neutralization treatment, so as to obtain a sodium tungstate material solution; (3) diluting the sodium tungstate material solution, so as to obtain a solution before ion exchange; (4) carrying out adsorption treatment of the solution before ion exchange by a weakly alkaline anion exchange resin, so as to allow tungsten in the solution before ion exchange to be adsorbed by the weakly alkaline anion exchange resin; (5) carrying out desorption treatment of the weakly alkaline anion exchange resin adsorbed with tungsten by using a desorption agent, so as to obtain a desorption solution; (6) carrying out impurity-removal treatment of the desorption solution, so as to obtained a solution after impurity removal; and (7) carrying out evaporation crystallization treatment of the solution after impurity removal, so as to obtain ammonium paratungstate. With use of the method, the concentration of tungsten trioxide in the solution before ion exchange can be significantly improved, generation of wastewater is reduced, and the qualified APT is prepared.

Owner:CHONGYI ZHANGYUAN TUNGSTEN

Preparation method of WO3/C3N4 mixed photocatalyst

InactiveCN104772158AImprove photocatalytic activityEasy to separatePhysical/chemical process catalystsPtru catalystPhysical chemistry

The invention discloses a preparation method of a WO3 / C3N4 mixed photocatalyst. The preparation method comprises the following steps: taking sodium tungstate and sodium chloride as the raw materials, preparing WO3 through a hydrothermal method, subjecting the WO3 to an ultrasonic dispersion treatment to obtain processed WO3; taking urea as the raw material, burning urea to obtain C3N4 in one step, subjecting C3N4 to an ultrasonic dispersion treatment to obtain processed C3N4; mixing the processed WO3 nano powder and processed C3N4 by a mechanical means and ultrasonic waves in sequence, washing the mixture, subjecting the mixture to a centrifugal treatment, and finally drying the mixture at a temperature of 70 to 80 DEG C to obtain the WO3 / C3N4 composite photocatalyst. Under the same conditions, the catalytic degradation rate of rhodamine B of the provided photocatalyst is increased by 8%, compared with that of a conventional WO3 / C3N4 composite photocatalyst, which is prepared through a grinding method; moreover, the catalytic time is shorter, and one hour after the starting of the catalytic reactions, the catalytic degradation rate of rhodamine B can reach 99%.

Owner:SHANGHAI INST OF TECH

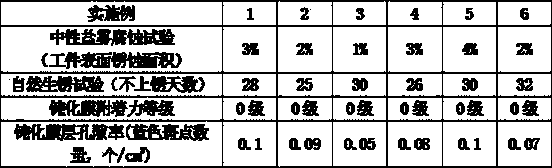

Anodization closing method for improving corrosion resistance of aluminum alloy

ActiveCN103173833AImprove corrosion resistanceOptimizing the anodizing processAnodisationSodium molybdateRare earth

The invention relates to an anodization closing method for improving the corrosion resistance of an aluminum alloy. The method comprises a step of aluminum surface pretreatment, a step of aluminum product anodization, a step of preparation of a supersaturated sodium molybdate solution or an aqueous sodium tungstate solution, a step of adjusting the pH value to 5.5-6.5, a step of primary closing at 70-100DEG C for 10-30min, a step of preparing a supersaturated aqueous La2(CO3)3 or Pr2(CO3)3 solution, a step of adjusting the pH value to 5.5-6.5, a step of secondary closing at 70-100DEG C for 10-30min, a step of cleaning, and a step of drying to complete the process. The method adopts a double closing technique to substitute single-time closing of a traditional technology, so the corrosion resistance of the aluminum alloy product is substantially improved; the sodium molybdate or sodium tungstate solution is adopted to carry out the primary closing; and rare earth carbonate is adopted to substitute nickel and cobalt salts to carry out the secondary closing, so the surface compactness of the aluminum alloy is greatly improved, and the corrosion resistance of the product is improved; and the method has the advantages of simple making technology, low equipment requirement and harmlessness to the environment.

Owner:LUOYANG WEIXIN ELECTRONICS TECH

Chromium-free passivation solution as well as preparation and using methods thereof

ActiveCN104404492AImprove corrosion resistanceStrong adhesionMetallic material coating processesSodium molybdateAcetic acid

The invention provides a chromium-free passivation solution as well as preparation and using methods thereof. The passivation solution is prepared by dissolving a solute composed of multiple substances into deionized water, wherein the solute in the solution comprises the following raw materials according to the ratio: 60-80g / L of sodium molybdate, 5-10g / L of sodium tungstate, 2-7g / L of ethanol, 15-50g / L of acetic acid, 20-40g / L of hydrogen peroxide, 5-10g / L of ethylenediaminetetraacetic acid disodium and the balance of water. The chromium-free passivation solution is firm in adhesive force, low in porosity and corrosion-resistant.

Owner:HUNAN JINYU CHEM

Technology for producing tungsten trioxide by prilling and roasting of tungsten slag

The invention discloses a technology for producing tungsten trioxide by prilling and roasting of tungsten slag. The technology is characterized by comprising the following steps of: (1) baking tungsten slag and then adding blind coal, mixing and crushing the tungsten slag and the blind coal, and then adding lime mud, sodium carbonate and water, priling in a priling disc to prepare the mixed tungsten slag balls; (2) putting the mixed tungsten slag balls into an open hearth kiln to carry out semi-enclosed insulated roasting so as to obtain a tungsten slag clinker; (3) soaking the tungsten slag clinker, and carrying out ion exchange to obtain high-concentration sodium tungstate mother liquor; (4) removing the impurity of the high-concentration sodium tungstate mother liquor, and then filtering, precipitating, leaching the sediment, dewatering and baking the sediment to obtain a calcium tungstate product. The tungsten slag, the blind coal, the lime mud and recycling wastewater are adopted as roasting agents to replace soda ash and burning acid with high price and large consumption for the traditional technology-wet firing method, so that the tungsten production cost of each metal ton is reduced by***, and the transformation rate of WO3 is improved by 25%; the chronic diseases of sodium-process rotary kiln roasting and caking shovel kiln stop production are successfully solved, and about 50% of energy consumption is saved on the traditional technology and wet firing production.

Owner:陈检辉

Environmentally friendly composite corrosion and scale inhibitor for circulating cooling water

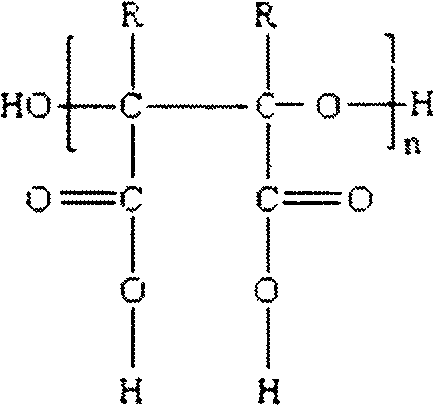

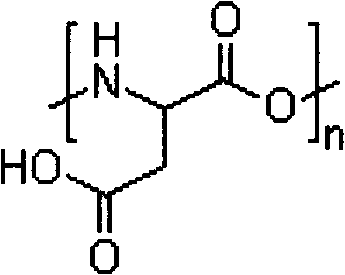

InactiveCN102417242AExcellent corrosion and scale inhibitionUse low concentrationScale removal and water softeningSalt contentSodium tungstate dihydrate

The invention relates to an environmentally friendly composite corrosion and scale inhibitor for circulating cooling water, which comprises polyepoxysuccinic acid, poly aspartic acid, benzotriazole, sodium gluconate and sodium tungstate according to a mass ratio of (1- 2.5): (3 -5): (1-2): (10-25): (3-5). The composite corrosion and scale inhibitor provided by the invention has the characteristics of no phosphorus, biodegradability, and less dosage of medicament, can be suitable for high-salt-content and high-hardness water and the like, is an environmentally friendly water stabilizer which has good corrosion inhibition, scale inhibition dispersion performances for a circulating cooling water system.

Owner:NANKAI UNIV

Visible light responded load type Bi2WO6/Bi2O3 heterojunction photocatalyst and preparation method thereof

InactiveCN104722293AImprove visible light absorptionEasy to recycleWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsHeterojunctionEngineering

The invention relates to a visible light responded load type Bi2WO6 / Bi2O3 heterojunction photocatalyst and a preparation method thereof. The visible light responded load type Bi2WO6 / Bi2O3 heterojunction photocatalyst is prepared from the following components in parts by weight: sodium oleate, an ethanediol solution, bismuth nitrate, sodium tungstate and a carrier. The preparation method is simple and the operation is simple and convenient; preparation conditions are moderate and are free from toxin and secondary pollution is not caused in a preparation process; the batch production can be realized; the prepared visible light responded load type Bi2WO6 / Bi2O3 heterojunction photocatalyst has a high visible light absorption capability, has strong light absorption property and strong organic matter light degradation capability in a visible light region, and has a good application prospect of degrading RhB under the visible light; and particularly, the degradation rate of rhodamine B can be up to 99.5% under the condition of illuminating for 90 minutes under visible light with the wavelength more than nm. The prepared composite photocatalyst is convenient to recycle and reuse, and the difficulty that the recycling is difficult when a photocatalysis technology is actually applied in environment purification can be solved.

Owner:JILIN UNIV

Tungsten oxide nanosheets, preparation method and catalysis application thereof

InactiveCN105498748AImprove oxidation activityImprove photocatalytic activityOrganic compound preparationTungsten oxides/hydroxidesOrganic dyeCatalytic oxidation

The invention provides tungsten oxide nanosheets. According to the tungsten oxide nanosheets, size is 140-160 nanometers, thickness is 10-20 nanometers, color is from light green to blackish green, and a sample is insoluble in water, acid, alkali and conventional organic solvents, and has catalytic activity. The invention also provides a preparation method of the tungsten oxide nanosheets, which is characterized in that under acidic condition, sodium tungstate monohydrate is taken as a raw material, a proper amount of an additive is added in a solvent, and the tungsten oxide nanosheets can be directly synthesized by a solvothermal method or a direct heating method through one step. The invention also provides an application of the tungsten oxide nanosheets in aspects of catalytic oxidation of thioether, catalytic oxidation of secondary amine, catalysis of olefin epoxidation, and catalysis of visible light for degrading organic dye pollutants. The preparation method has the advantages of simple process, low cost, easy operation, high yield, and purity, and the catalytic reaction has the advantages of zero discharge and zero pollution.

Owner:NANYANG NORMAL UNIV

SiO2-WO3 composite aerogel and preparation method thereof

ActiveCN102091589ALow densityLarge specific surface areaOther chemical processesAlkali metal oxides/hydroxidesAlkaneSilazane

The invention provides SiO2-WO3 composite aerogel and a preparation method thereof. The specific surface area of the SiO2-WO3 composite aerogel is 329 to 720m<2> / g, the pore volume is 0.6 to 1.8 cm<3> / g, the BJH most probable aperture is 4 to 10 nm and the average aperture is 4 to 9 nm. The preparation method mainly comprises: firstly, synthesizing SiO2-WO3 sol-gel by using sodium tungstate and industrial sodium silicate as raw materials; secondly, modifying a gel block by using modifying solution consisting organic silazane, organic siloxane and an alkane reagent; and finally, replacing pore water. The aerogel product has the characteristics of high specific surface area and high pore volume, the preparation method adopts cheap and readily available sodium tungstate and industrial sodium silicate raw materials and therefore can reduce production cost, and a normal pressure drying process is convenient and easy to implement and is suitable for industrial production and use.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com