Fluorination catalyst, and preparation method and use thereof

A fluorination catalyst, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the difficulty of increasing the complexity and repeatability of the impregnation method, Fluorination catalysts have problems such as low operating temperature and harsh operating temperature requirements to achieve the effects of inhibiting carbon deposition, improving catalytic activity, and large pore volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

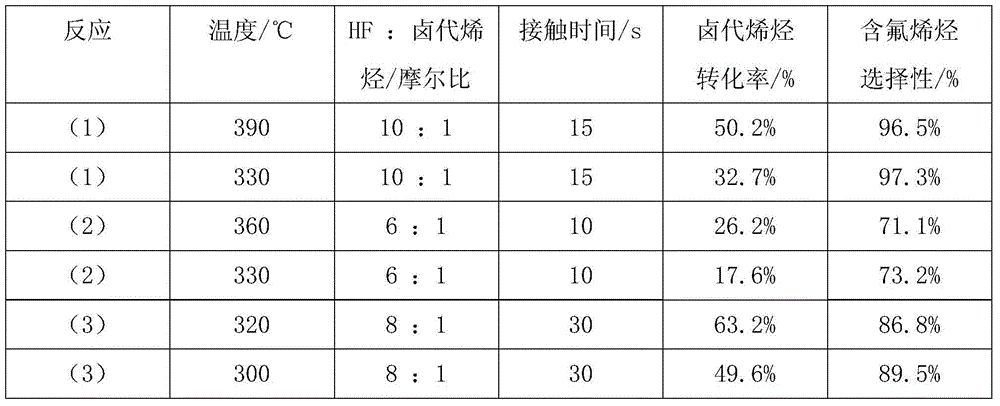

Examples

Embodiment 1

[0029] Dissolve chromium nitrate in water, add precipitant ammonia water at 60°C, control the pH range of the solution to 7.5-8.5, make it fully precipitate under stirring conditions, filter the formed slurry, wash with deionized water until neutral , and then dried at 150°C for 12 hours to obtain chromium hydroxide.

[0030] The obtained chromium hydroxide and zinc tungstate were divided into 60% and 40% by mass percentage, uniformly mixed, and pressed into tablets to obtain a catalyst precursor, and 60 mL of the catalyst precursor was loaded into a SUS316 glass with an inner diameter of 1 inch and a length of 23.6 inches. Tubular reactor, fed with nitrogen and roasted at 450°C for 8 hours, nitrogen space velocity is 200h -1 , and then lower the temperature to 300°C, and at the same time pass a mixed gas composed of hydrogen fluoride and hydrogen with a mass ratio of 10:1, and the total space velocity of the gas is 220h -1 , activate for 12 hours, stop the above mixed gas, a...

Embodiment 2

[0033] The preparation process of the catalyst is basically the same as in Example 1, except that the mass percentages of chromium hydroxide and zinc tungstate are 95% and 5%.

[0034] The specific surface area of the catalyst was determined by BET low temperature nitrogen adsorption method = 174.4m 2 / g, pore volume=0.46cc / g, average pore diameter 52.8

Embodiment 3

[0036] The catalyst preparation process is basically the same as in Example 1, except that the mass percentages of chromium hydroxide and zinc tungstate are 40% and 60%.

[0037] The specific surface area of the catalyst was determined by BET low temperature nitrogen adsorption method = 184.8m 2 / g, pore volume=0.58mL / g, average pore diameter 62.8

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com