Hydro-thermal synthesis method of visible light photocatalyst mesoporous Bi2WO6

A photocatalyst and hydrothermal synthesis technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., achieves good morphology, simple synthesis method and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A visible-light photocatalyst mesoporous Bi 2 WO 6 The hydrothermal synthesis method, the steps are as follows:

[0023] 1) Add 0.485g of Bi(NO 3 ) 3 1mol / L HNO dissolved in 10ml 3 In, solution A is obtained;

[0024] 2) Add 0.145g of Na 2 WO 4 Dissolve in 10ml of deionized water and stir to obtain solution B;

[0025] 3) Under vigorous stirring, drop solution B into solution A drop by drop, then add 0.1 g of CTAB, and stir vigorously for 30 minutes to obtain a mixed solution;

[0026] 4) Transfer the mixed solution to a reaction kettle with a PTFE liner of 30ml, and react at a constant temperature at 180°C for 24 hours under hydrothermal conditions;

[0027] 5) The white precipitate obtained after the reaction was centrifuged, washed 2-3 times with deionized water and absolute ethanol, and air-dried under natural conditions to obtain a light yellow powder, which is the target Bi 2 WO 6 catalyst of light.

Embodiment 2

[0029] A visible-light photocatalyst mesoporous Bi 2 WO 6 The hydrothermal synthesis method, the steps are as follows:

[0030] 1) Add 0.485g of Bi(NO 3 ) 3 1mol / L HNO dissolved in 10ml 3 In, solution A is obtained;

[0031] 2) Add 0.145g of Na 2 WO 4 Dissolve in 10ml of deionized water and stir to obtain solution B;

[0032] 3) Under vigorous stirring, drop solution B into solution A drop by drop, then add 0.1 g of PEG10000, stir vigorously for 30 minutes to obtain a mixed solution;

[0033] 4) Transfer the mixed solution to a reaction kettle with a PTFE liner of 30ml, and react at a constant temperature at 180°C for 24 hours under hydrothermal conditions;

[0034] 5) The white precipitate obtained after the reaction was centrifuged, washed 2-3 times with deionized water and absolute ethanol, and air-dried under natural conditions to obtain a light yellow powder, which is the target Bi 2 WO 6 catalyst of light.

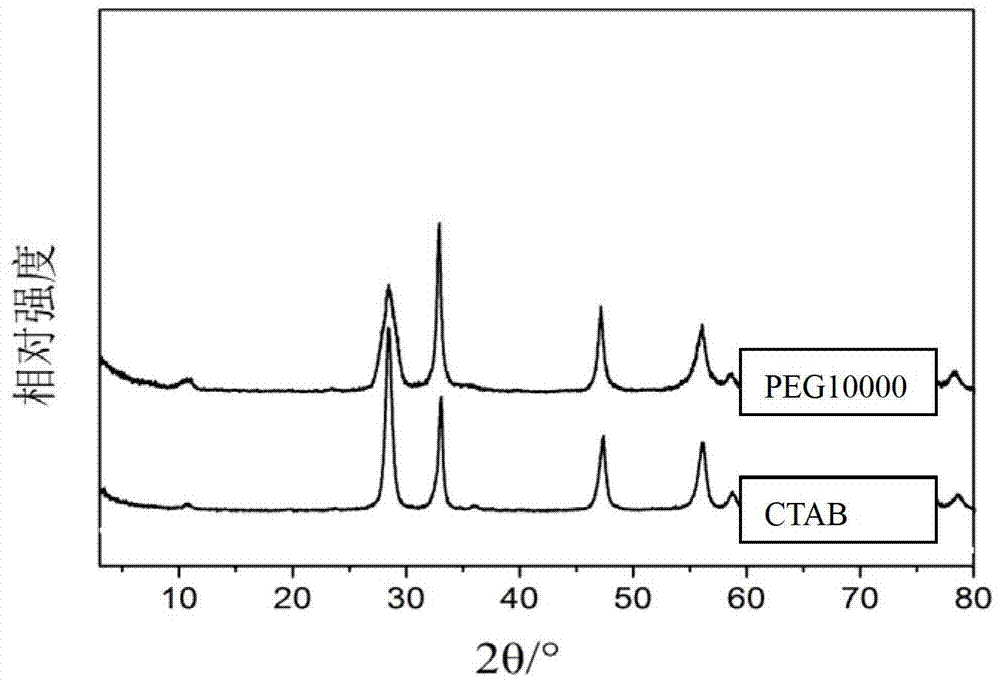

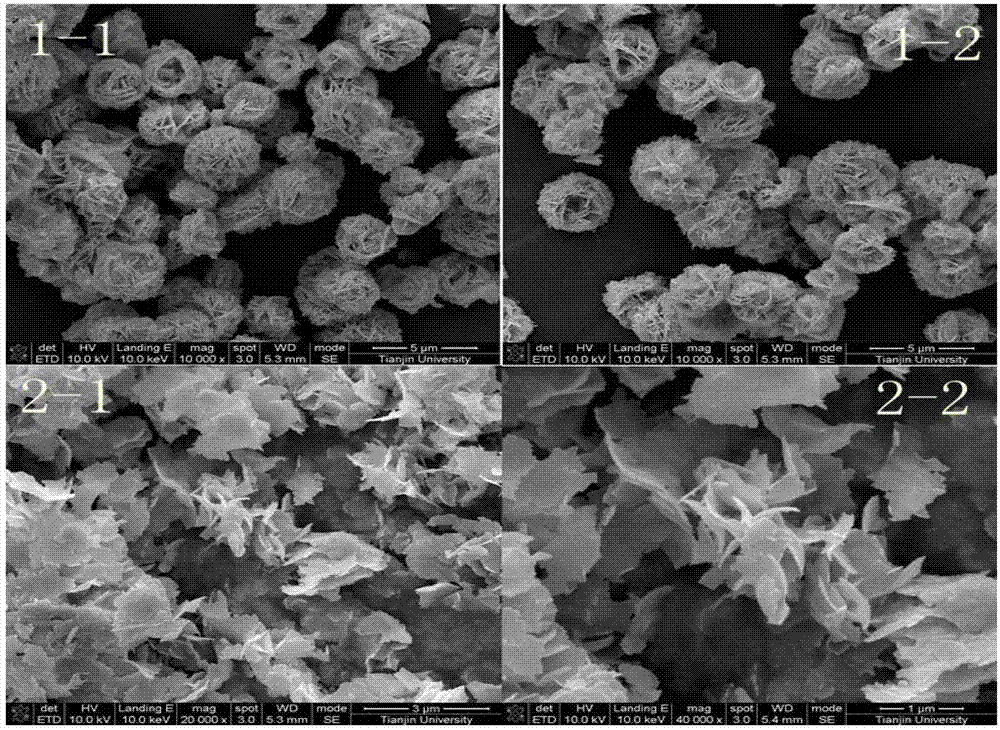

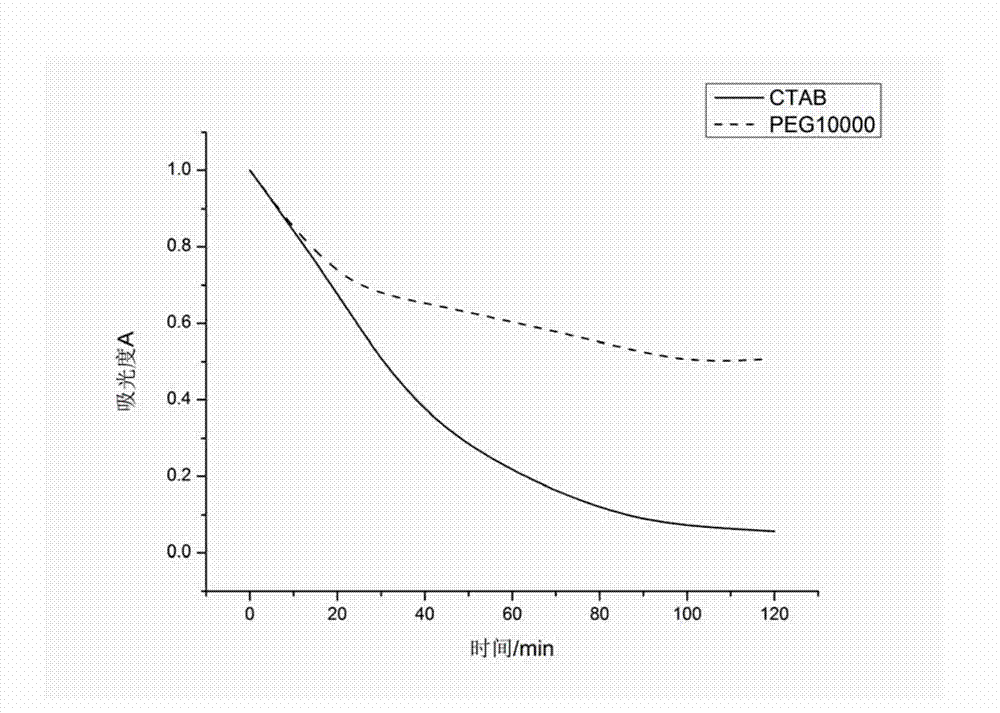

[0035] figure 1 For the Bi prepared in Example 1,2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com