Preparation method of tungsten disulfide nanorod

A technology of tungsten disulfide and nanorods, which is applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve problems affecting applications, large length difference, uneven size distribution, etc., and achieve concentrated length distribution and good dispersion , the effect of a wide range of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

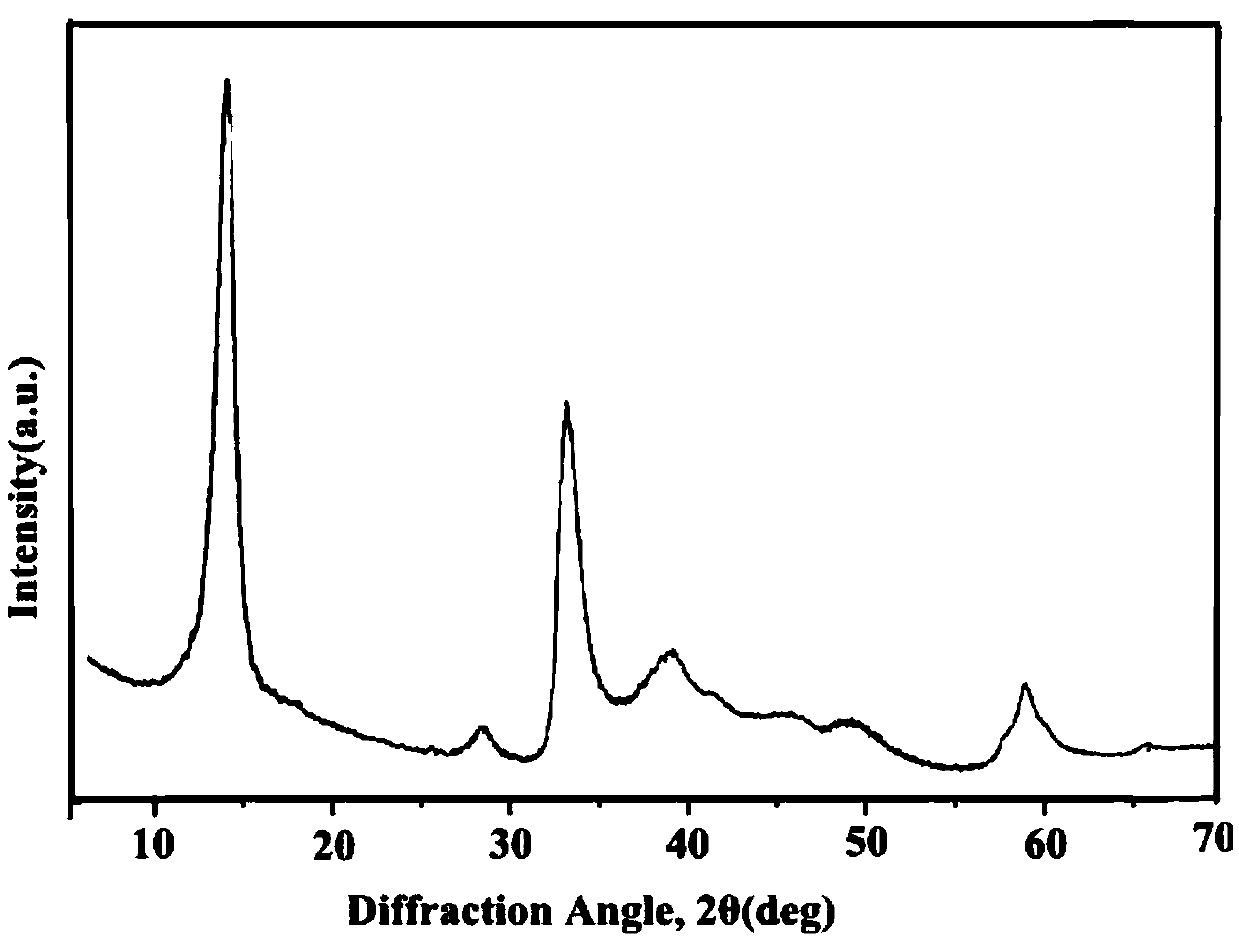

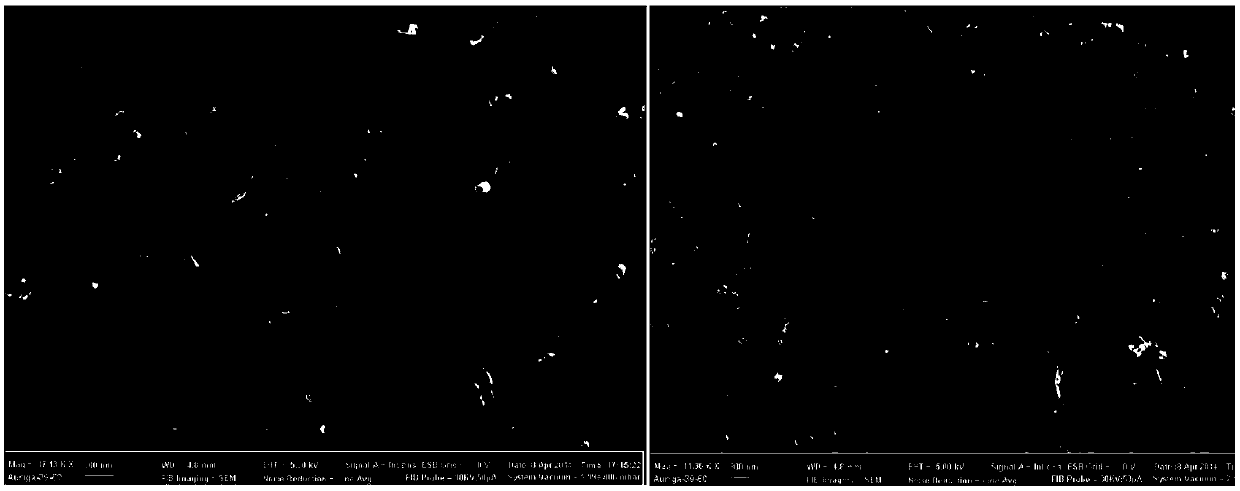

[0025] The preparation method of the tungsten disulfide nanorod of embodiment 1, comprises the following steps:

[0026] (1) Dissolve 1g (3mmol) sodium tungstate, 0.42g (6mmol) hydroxylamine hydrochloride and 0.91g (12mmol) thiourea in 60ml water, stir and dissolve to form a transparent solution, then adjust the solution with 2mol / L hydrochloric acid pH to 5.5;

[0027] (2) Add 0.43 mmol of mixed surfactant to the solution obtained in step (1), and stir to dissolve; the mixed surfactant is composed of CTAB, CTAC and F127 in a molar ratio of 1:1.8:1.2;

[0028] (3) Transfer the solution obtained in step (2) into a stainless steel reactor, seal it, and react at 180°C for 18 hours;

[0029] (4) Cool the reaction product obtained in step (3) to room temperature, centrifuge the reaction product, discard the supernatant, wash the black precipitate with deionized water and absolute ethanol, and store the product in a vacuum oven at 60°C Dry in medium to obtain tungsten disulfide na...

Embodiment 2

[0034] The preparation method of the tungsten disulfide nanorod of embodiment 2, comprises the following steps:

[0035] (1) Dissolve 1g (3mmol) sodium tungstate, 0.32g (4.5mmol) hydroxylamine hydrochloride and 0.68g (9mmol) thiourea in 60ml of water, stir and dissolve to form a transparent solution, then adjust the solution with 2mol / L hydrochloric acid pH to 5;

[0036] (2) Add 0.6 mmol of mixed surfactant to the solution obtained in step (1), and stir to dissolve; the mixed surfactant is composed of CTAB, CTAC and F127 in a molar ratio of 1:1.5:0.6;

[0037] (3) Transfer the solution obtained in step (2) into a stainless steel reactor, seal it, and react at 170°C for 24 hours;

[0038] (4) Cool the reaction product obtained in step (3) to room temperature, centrifuge the reaction product, discard the supernatant, wash the black precipitate with deionized water and absolute ethanol, and store the product in a vacuum oven at 60°C Dry in medium to obtain tungsten disulfide n...

Embodiment 3

[0040] The preparation method of the tungsten disulfide nanorod of embodiment 3, comprises the following steps:

[0041] (1) Dissolve 1g (3mmol) sodium tungstate, 0.63g (9mmol) hydroxylamine hydrochloride and 1.14g (15mmol) thiourea in 60ml water, stir and dissolve to form a transparent solution, and then adjust the solution with 2mol / L hydrochloric acid pH to 6;

[0042] (2) Add 0.3 mmol of mixed surfactant to the solution obtained in step (1), and stir to dissolve; the mixed surfactant is composed of CTAB, CTAC and F127 in a molar ratio of 1:3:1.8;

[0043] (3) Transfer the solution obtained in step (2) into a stainless steel reaction kettle, seal it, and react at 200°C for 10 hours;

[0044] (4) Cool the reaction product obtained in step (3) to room temperature, centrifuge the reaction product, discard the supernatant, wash the black precipitate with deionized water and absolute ethanol, and store the product in a vacuum oven at 60°C Dry in medium to obtain tungsten disul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com