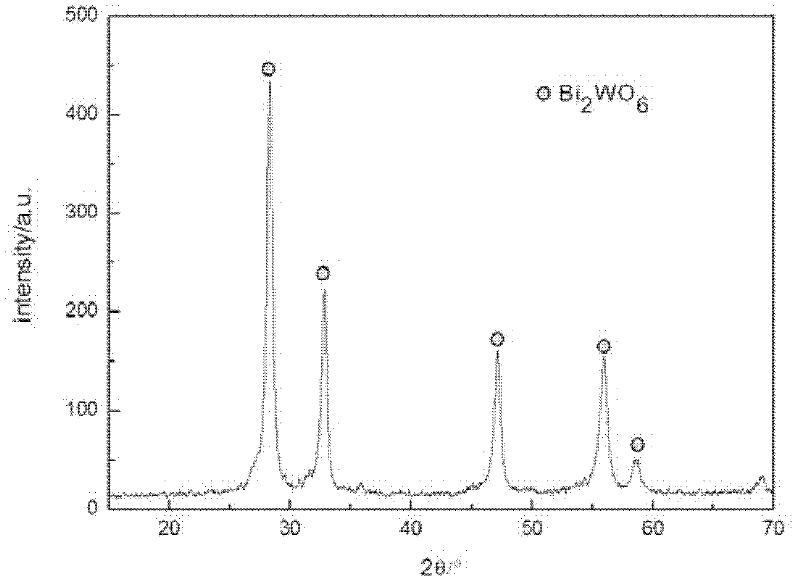

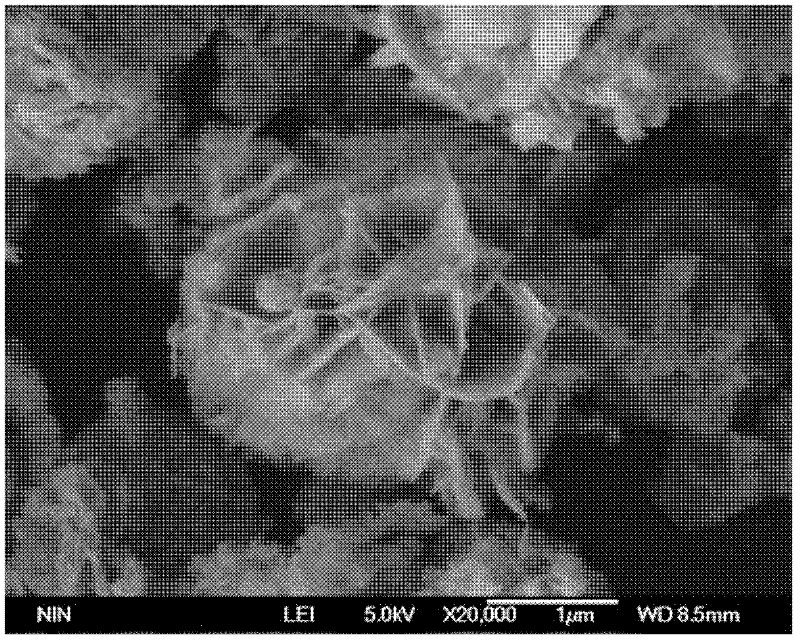

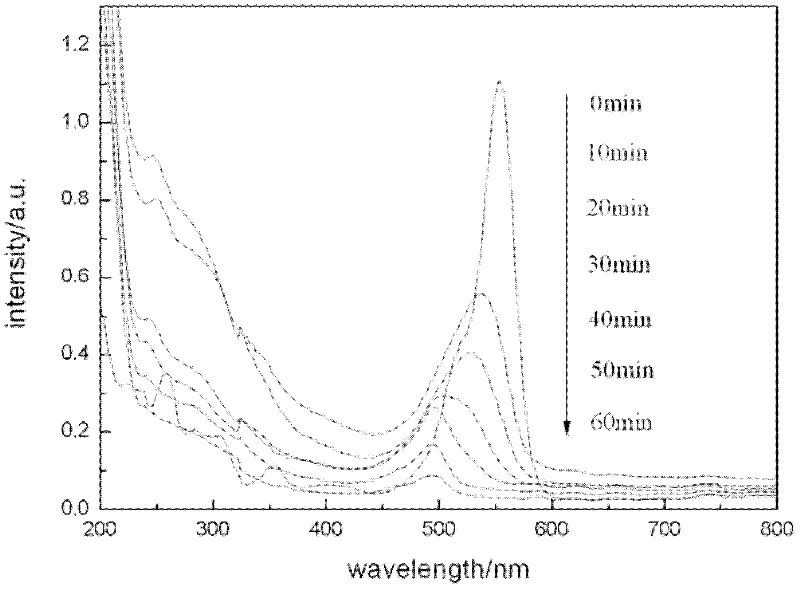

Method for preparing bismuth tungstate powder with high photocatalytic activity by adopting high-temperature microwave hydrothermal method

A microwave hydrothermal method, catalytic activity technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Weigh Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O was put into a beaker (the raw materials used were analytically pure), and an appropriate amount of deionized water was added to the beaker to make the Bi(NO 3 ) 3 ·5H 2 O concentration is 0.05mol / L, Na 2 WO 4 2H 2 O concentration is 0.025mol / L;

[0032] Step 2: adjust the pH to 1.6, stir magnetically at room temperature for 1 hour to mix the raw materials evenly, and obtain a precursor solution for microwave hydrothermal reaction;

[0033] Step 3: Put the precursor solution obtained in step 2 into a polytetrafluoroethylene-lined reactor, then put the reactor into a microwave hydrothermal reactor MDS-8, set the power to 300W, and set the temperature at 220°C The reaction time is 60mins, and the measured pressure is 3.0Mpa;

[0034] Step 4: After the reaction temperature drops to room temperature, take out the precipitate in the reaction kettle; wash the precipitate with water and absolute ethanol until n...

Embodiment 2

[0036] Step 1: Weigh Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O was put into a beaker (the raw materials used were analytically pure), and an appropriate amount of deionized water was added to the beaker to make the Bi(NO 3 ) 3 ·5H 2 O concentration is 0.04mol / L, Na 2 WO 4 2H 2O concentration is 0.02mol / L;

[0037] Step 2: adjust the pH to 2.6, stir magnetically at room temperature for 1.5 hours to mix the raw materials evenly, and obtain the precursor solution for microwave hydrothermal reaction;

[0038] Step 3: Put the precursor solution obtained in step 2 into a polytetrafluoroethylene-lined reactor, then put the reactor into a microwave hydrothermal reactor MDS-8, set the power to 350W, and set the temperature at 220°C Respond for 30mins, the measured pressure is 3.0Mpa;

[0039] Step 4: After the reaction temperature drops to room temperature, take out the precipitate in the reaction kettle; wash the precipitate with water and absolute ethanol until neutral; dr...

Embodiment 3

[0041] Step 1: Weigh Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O was put into a beaker (the raw materials used were analytically pure), and an appropriate amount of deionized water was added to the beaker to make the Bi(NO 3 ) 3 ·5H 2 O concentration is 0.15mol / L, Na 2 WO 4 2H 2 O concentration is 0.075mol / L;

[0042] Step 2: adjust the pH to 1.5, stir magnetically at room temperature for 2 hours to mix the raw materials evenly, and obtain a precursor solution for microwave hydrothermal reaction;

[0043] Step 3: Put the precursor solution obtained in step 2 into a polytetrafluoroethylene-lined reactor, then put the reactor into a microwave hydrothermal reactor MDS-8, set the power to 450W, and set the temperature at 220°C Respond for 80mins, the measured pressure is 3.0Mpa;

[0044] Step 4: After the reaction temperature drops to room temperature, take out the precipitate in the reaction kettle; wash the precipitate with water and absolute ethanol until neutral; dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com