Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105 results about "Calcium tungstate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scheelite is a calcium tungstate mineral with the chemical formula Ca W O 4. It is an important ore of tungsten . Well-formed crystals are sought by collectors and are occasionally fashioned into gemstones when suitably free of flaws.

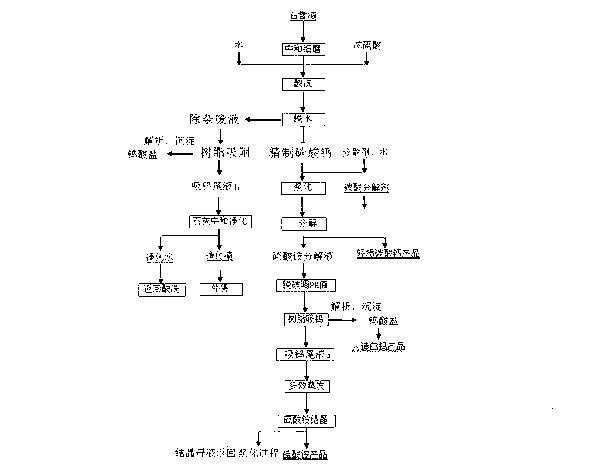

Recycling method for waste denitration catalyst

InactiveCN104099476AEmission reductionShort production processProcess efficiency improvementMagnesium saltAmmonium paratungstate

A recycling method for waste denitration catalyst is characterized by comprising the following steps: (1) the waste denitration catalyst is smashed into powder of 100 to 200 meshes; (2) the powder reacts with an alkali solution under a heating and stirring condition to obtain a titanium-rich material and a solution containing elements such as vanadium, tungsten, silicon and aluminum; (3) the titanium-rich material reacts with chlorine gas to generate titanium tetrachloride, then the titanium tetrachloride is condensed and reacts with oxygen to generate titanium dioxide, and the titanium dioxide is treated with surface finish and drying to obtain a titanium dioxide finished product; (4) the pH value of the solution obtained in the step (2) is adjusted; a magnesium salt is added into the solution to remove silicate ions and obtain a solution containing vanadium and tungsten; calcium chloride powder is added into the solution containing vanadium and tungsten to generate calcium tungstate; the calcium tungstate reacts with hydrochloric acid to generate tungstic acid; the tungstic acid is treated with ammonia dissolution and evaporative crystallization to obtain ammonium paratungstate crystals; (5) a precipitant ammonium chloride is added, and centrifugal drying is carried out to obtain solid ammonium vanadate. The method has the advantages that the operation is easy; three wastes are reduced; the economic efficiency is improved; the waste denitration catalyst is recycled.

Owner:CECEP L&T ENVIRONMENTAL TECH

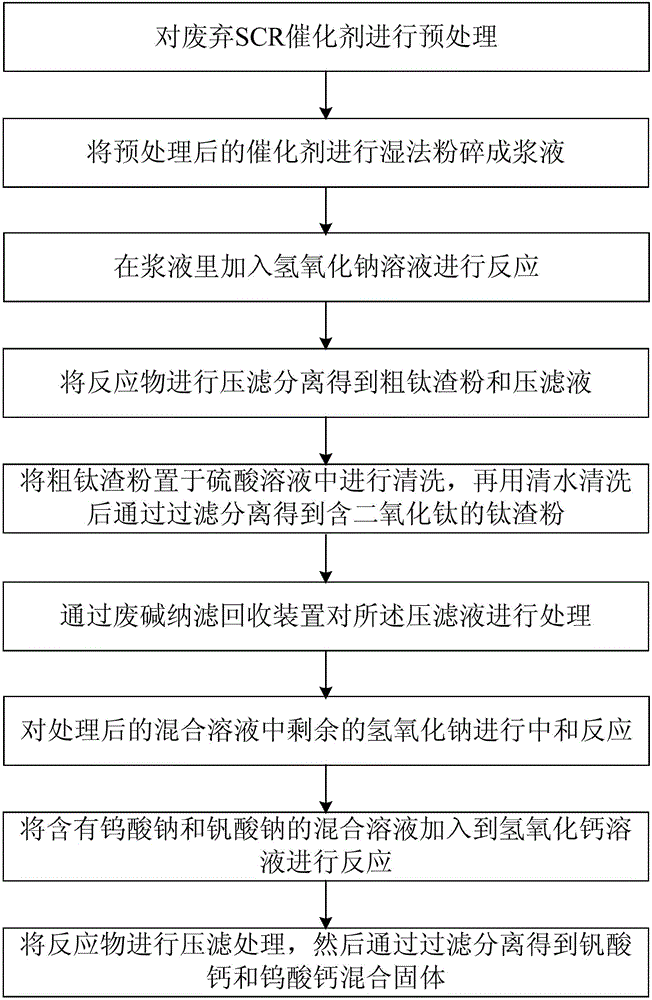

Method for extracting titanium slag, tungsten and vandic salt from waste SCR catalyst

ActiveCN106119544ASolve harmless disposalLow investment requirementProcess efficiency improvementSlurryCalcium tungstate

The invention provides a method for extracting titanium slag, tungsten and a vandic salt from a waste SCR catalyst. The method comprises the steps that the waste SCR catalyst is preprocessed and crushed into slurry by use of a wet method; a sodium hydroxide solution is added into the slurry for reaction; coarse titanium slag power and compression filtrate are obtained by filter-pressing and separating the slurry by use of a plate-and-frame filter press; the coarse titanium slag power is placed into a sulfuric acid solution for cleaning, cleaned with clear water, and then filtered and separated for obtaining titanium slag powder containing titanium dioxide; and the compression filtrate is treated through a waste alkali nanofiltration recovery device, the compression filtrate containing sodium tungstate and sodium vanadate is added into a saturated calcium hydroxide solution for reaction, products from the reaction are subjected to filter pressing, and then calcium vanadate and calcium tungstate mixed solid bodies are obtained through filtering and separating.

Owner:安徽思凯瑞环保科技有限公司

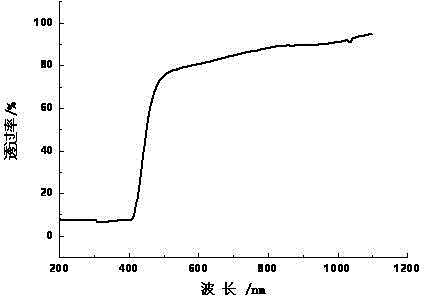

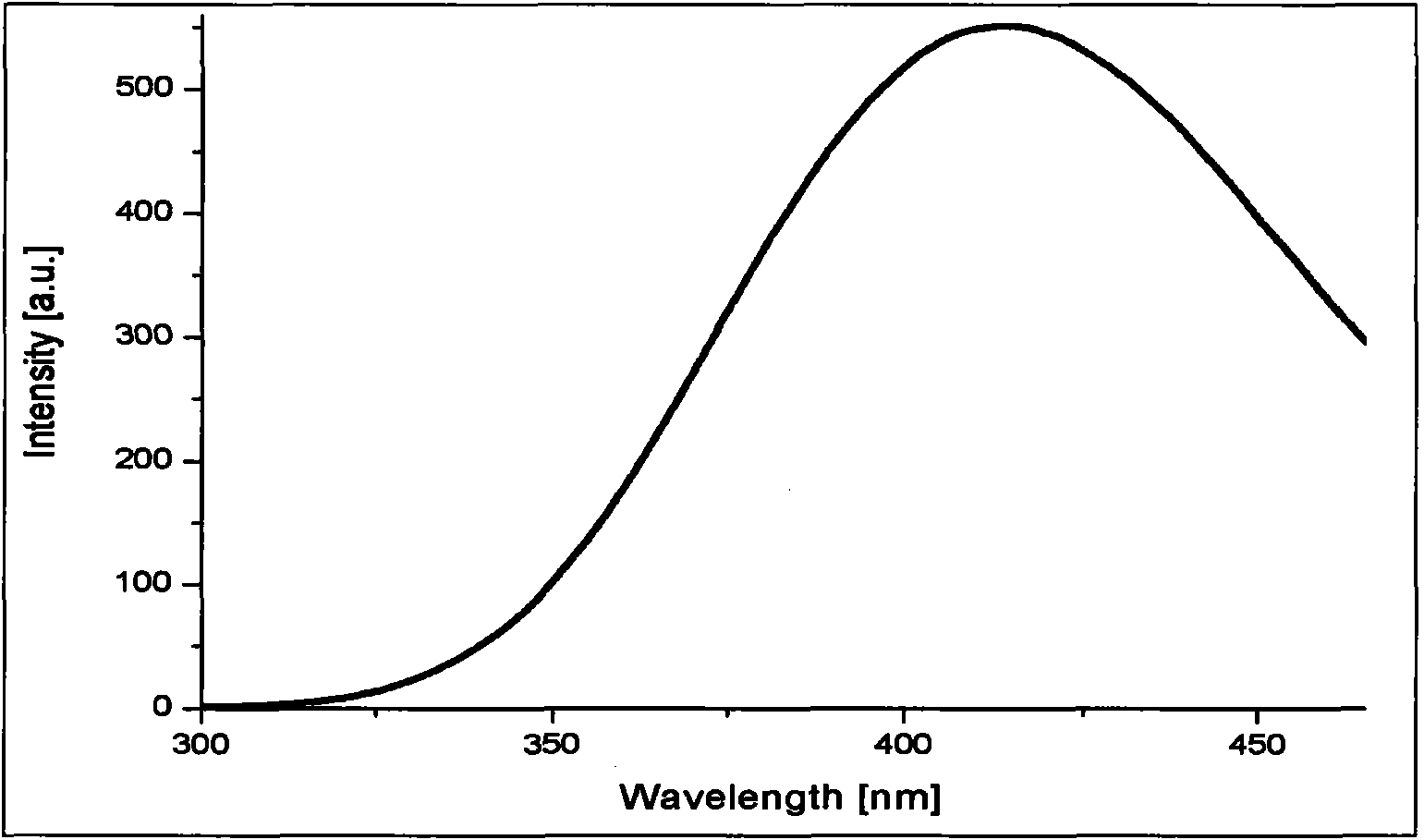

Europium-doped tungstate transparent glass ceramic and preparation method thereof

The present invention relates to a europium-doped tungstate transparent glass ceramic and a preparation method thereof, wherein the europium-doped tungstate transparent glass ceramic comprises, by mass, 25-35% of CaCO3, 5-15% of WO3, 35-45% of SiO2, 10-15% of H3BO3, 5-15% of NaF, 0.5-1.5% of Sb2O3, and1-5% of Eu2O3, and the preparation method uses a melt crystallization technology. According to the present invention, the main crystal phase of the europium-doped tungstate transparent glass ceramic is calcium tungstate, the transmittance of the europium-doped tungstate transparent glass ceramic having the thickness of 1 mm in the visible light region is 85-86%, two emission peaks exist at 592 nm and 614 nm under the excitation at the wavelength of 394 nm and are respectively corresponding to the <5>D0(arrow)<7>F1 transition and the <5>D0(arrow)<7>F2 transition of the Eu<3+>, and the europium ions enter the crystal phase, such that the fluorescence intensity of the product of the present invention is higher than the fluorescence intensity of the glass having the same chemical composition.

Owner:CHANGCHUN UNIV OF SCI & TECH

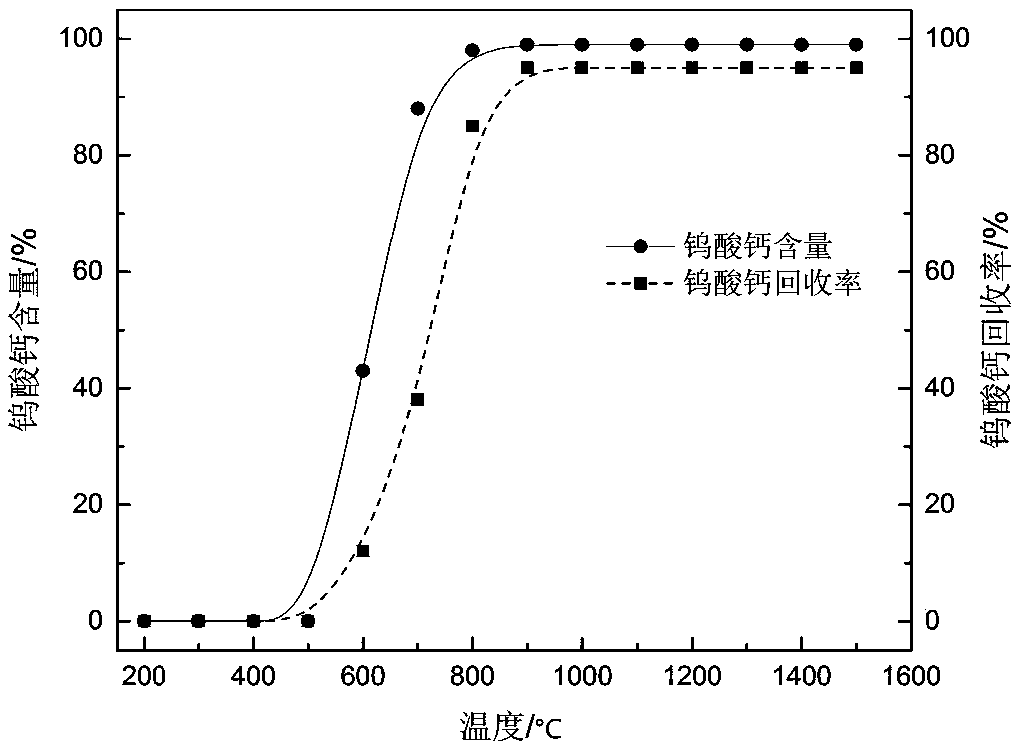

Method of treating scheelite

ActiveCN108754123AReduce the difficulty of leachingImprove leaching efficiencyTungstateMagnesium salt

The invention discloses a method of treating scheelite, comprising: mixing scheelite and a magnesium salt, and roasting at high temperature; washing the roasted product via water; performing acid leaching or alkali leaching to obtain tungstic acid or tungstate solution. The magnesium salt is utilized in the method to convert CaWO4, difficult to extract by acid or alkali leaching, in scheelite intoMgWO4 easy to extract by acid or alkali leaching; tungsten ore leaching rate is increased. The method helps solve the problem tungsten is difficult to extract directly from calcium tungstate.

Owner:CENT SOUTH UNIV

Technology for producing tungsten trioxide by prilling and roasting of tungsten slag

The invention discloses a technology for producing tungsten trioxide by prilling and roasting of tungsten slag. The technology is characterized by comprising the following steps of: (1) baking tungsten slag and then adding blind coal, mixing and crushing the tungsten slag and the blind coal, and then adding lime mud, sodium carbonate and water, priling in a priling disc to prepare the mixed tungsten slag balls; (2) putting the mixed tungsten slag balls into an open hearth kiln to carry out semi-enclosed insulated roasting so as to obtain a tungsten slag clinker; (3) soaking the tungsten slag clinker, and carrying out ion exchange to obtain high-concentration sodium tungstate mother liquor; (4) removing the impurity of the high-concentration sodium tungstate mother liquor, and then filtering, precipitating, leaching the sediment, dewatering and baking the sediment to obtain a calcium tungstate product. The tungsten slag, the blind coal, the lime mud and recycling wastewater are adopted as roasting agents to replace soda ash and burning acid with high price and large consumption for the traditional technology-wet firing method, so that the tungsten production cost of each metal ton is reduced by***, and the transformation rate of WO3 is improved by 25%; the chronic diseases of sodium-process rotary kiln roasting and caking shovel kiln stop production are successfully solved, and about 50% of energy consumption is saved on the traditional technology and wet firing production.

Owner:陈检辉

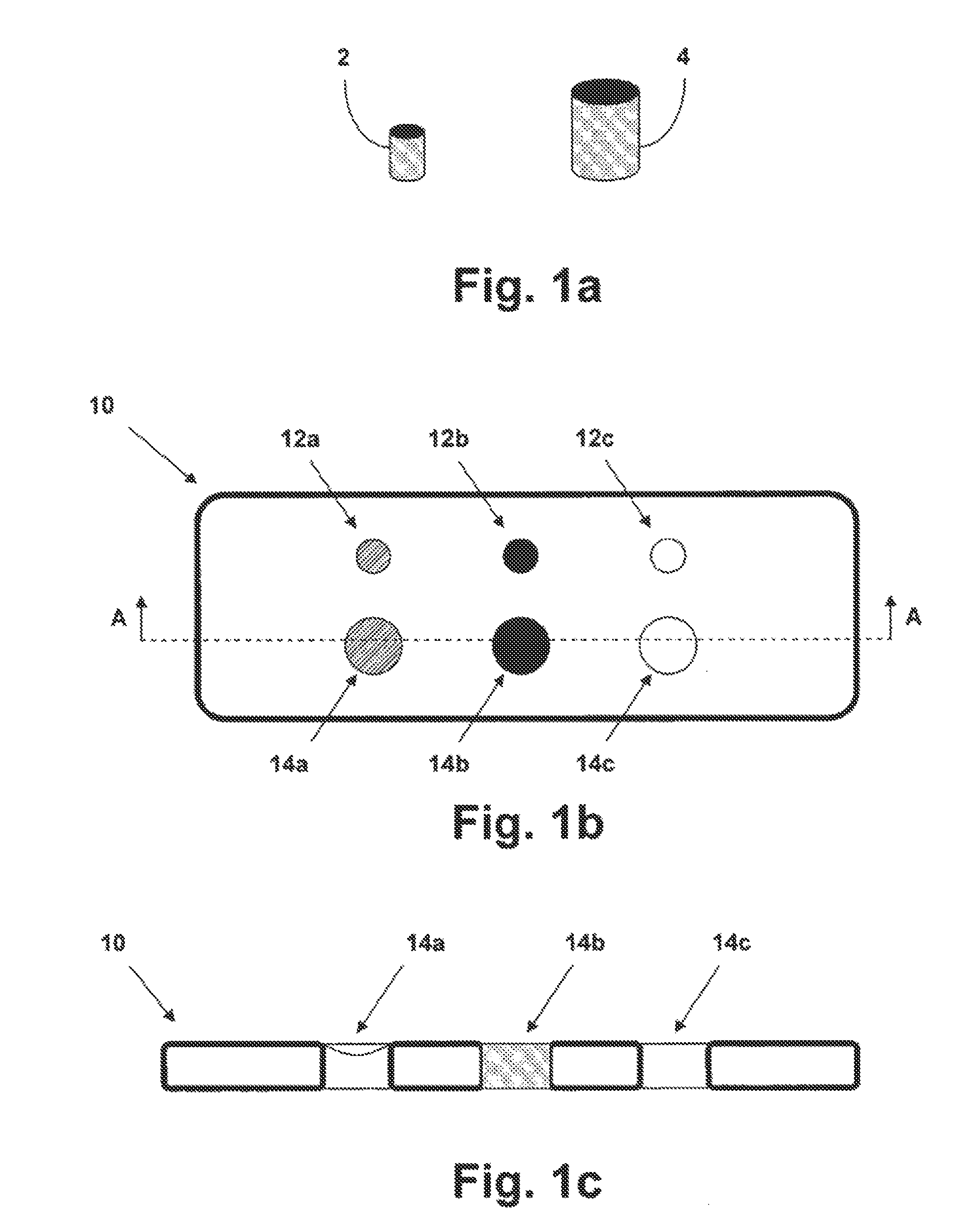

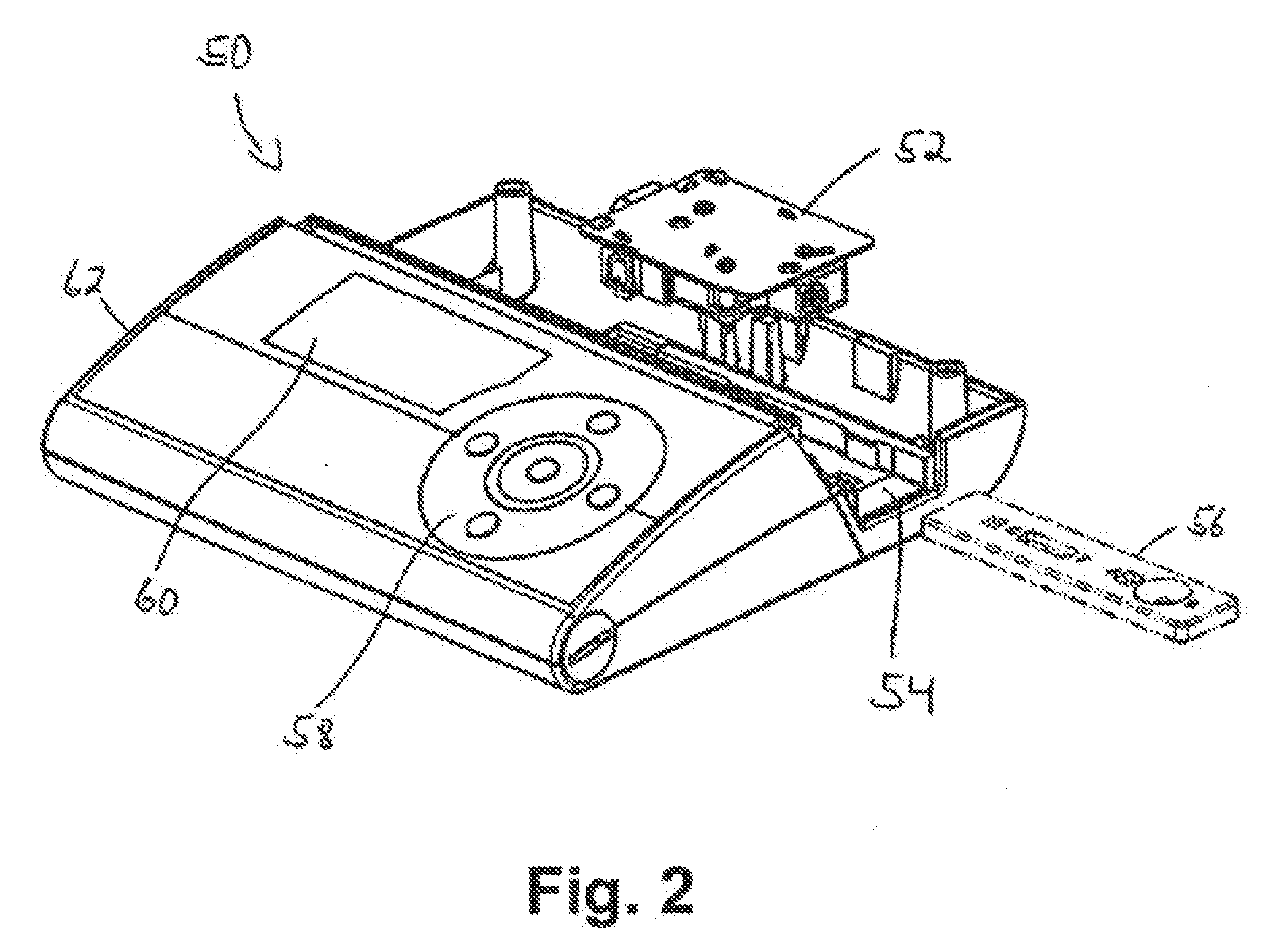

Fluorescence standard, and the use thereof

InactiveUS8704158B2Improve homogeneityOptical radiation measurementBioreactor/fermenter combinationsFluorescenceApatite

Owner:QIAGEN LAKE CONSTANCE GMBH

Fluorescence standard, and the use thereof

InactiveUS20110076687A1Improve homogeneityBioreactor/fermenter combinationsPhotometry using reference valueFluorescenceApatite

The invention concerns fluorescence standards, and in particular fluorescence standards for calibrating optical detectors. According to the invention, a fluorescent mineral or mixtures of minerals are employed for use as a fluorescence standard. The fluorescent mineral can be a naturally occurring mineral or a synthetically produced mineral. Preferred fluorescent minerals for use as fluorescence standards are corundum, fluorite, turquoise, amber, zircon, zoisite, iolite or cordierite, spinel, topaz, calcium fluorite, sphalerite or zincblende, calcite or calcspar, apatite, scheelite or calcium tungstate, willemite, feldspars, sodalite, a uranium mineral, a mineral containing Al3+, and in particular ruby and sapphire.

Owner:QIAGEN LAKE CONSTANCE GMBH

Method for separating and extracting calcium tungstate and tin slag by utilizing tungsten-containing tin furnace residue or tungsten-tin middlings

InactiveCN101148268ATo achieve the purpose of separationNo pollution in the processCalcium/strontium/barium compoundsTungsten compoundsSlagHigh pressure

The process of separating and extracting calcium tungstate and tin slag from tungsten-containing tin slag or mixed W-Sn middlings includes the steps of grinding tungsten-containing tin slag or mixed W-Sn middlings into powder, adding NaOH and oxidant through high pressure stirring and leaching to obtain Na2WO4 solution with impurity and tin slag, depurating the Na2WO4 solution to obtain purified Na2WO4 solution, adding CaCl2 to react obtaining wet CaWO4 and stoving to obtain calcium tungstate. The process is simple, and has great production capacity, best utilization of non-ferrous metal resource, environment friendship and other advantages.

Owner:黄玄俊

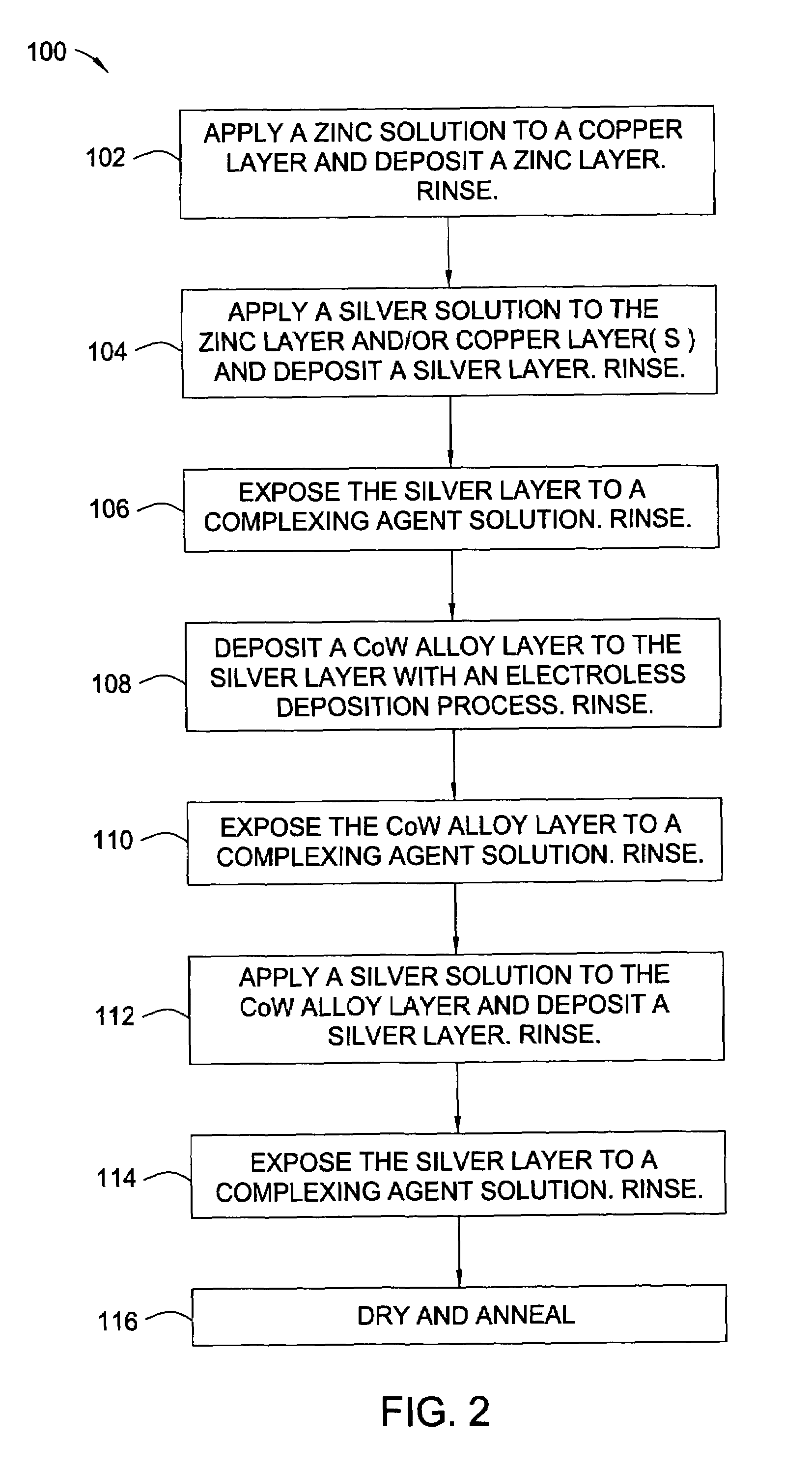

Silver under-layers for electroless cobalt alloys

ActiveUS7064065B2Semiconductor/solid-state device detailsSolid-state devicesElectroless depositionCopper

Owner:APPLIED MATERIALS INC

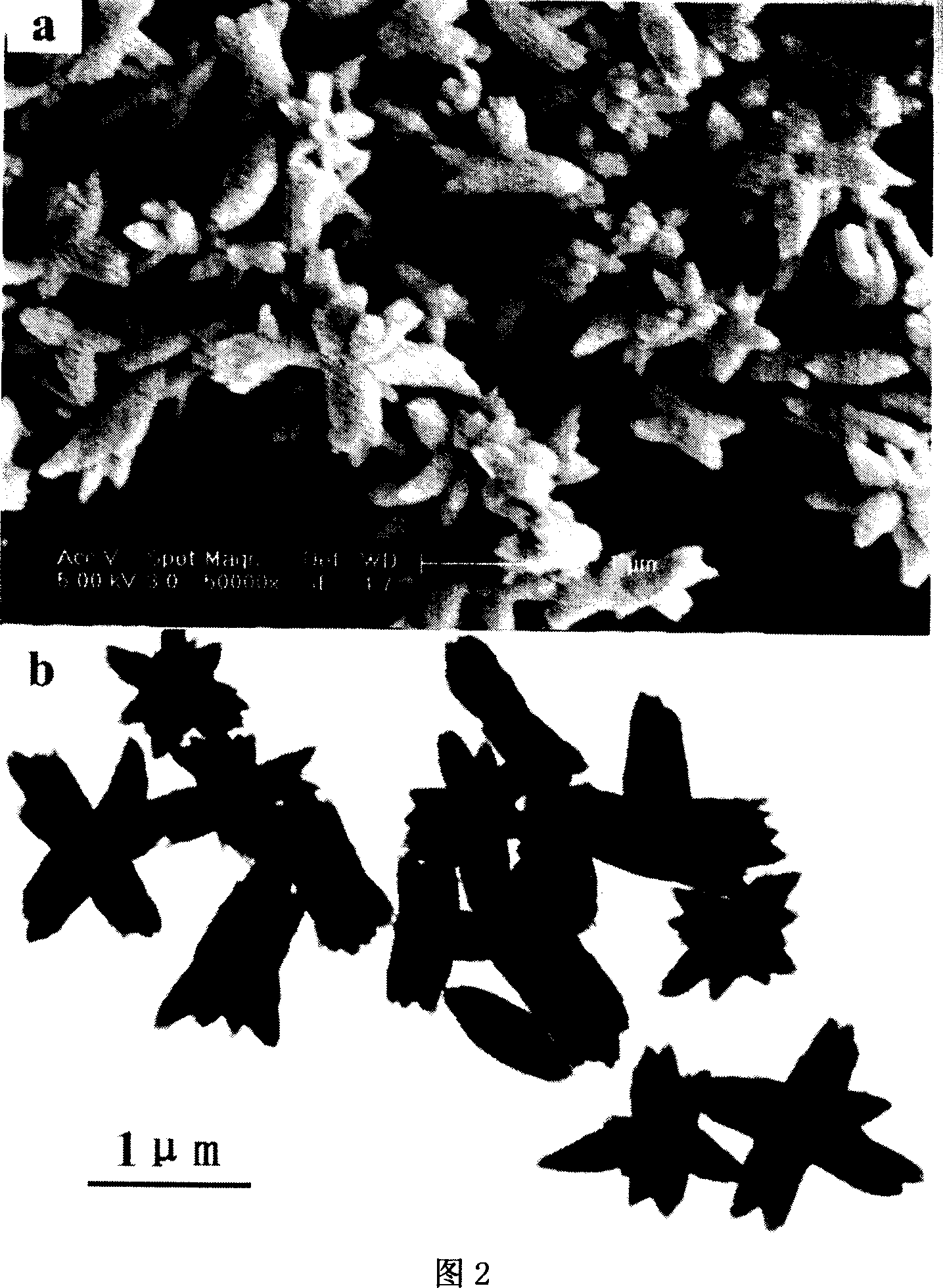

Method for preparing dielectric crystal of calcium tungstate rapidly

InactiveCN1958884AInhibit rapid growthAchieving directed self-assemblyPolycrystalline material growthSingle crystal growth detailsDielectricHigh volume manufacturing

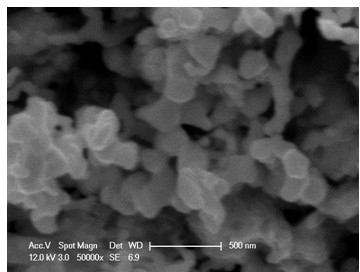

This invention relates to a method for rapidly preparing calcium tungstate mesorystals. The method adopts microemulsions as the media, and can obtain the product with a very short reaction time. The method comprises: adding n-octane, n-butanol and cetyl trimethyl ammonium bromide into the same amount and concentration of calcium salt aqueous solution and sodium tungstate aqueous solution, respectively, to obtain two transparent microemulsions, rapidly mixing the two microemulsions within a certain temperature range, stirring for 10 min, and terminating the reaction to obtain calcium tungstate mesocrystals. The method has such advantages as simple process, low cost and rapid reaction. The size distribution of the obtained calcium tungstate mesocrystals is uniform.

Owner:SHANGHAI JIAO TONG UNIV

Method for synchronously extracting tungsten, aluminum, sodium and iron from tungsten slag and red mud

ActiveCN108384960AAvoid combiningEasy Magnetic SortingMagnetic separationProcess efficiency improvementRed mudAluminium hydroxide

The invention discloses a method for synchronously extracting tungsten, aluminum, sodium and iron from tungsten slag and red mud. The method comprises the steps that the tungsten slag and the red mudare ground, crushed and mixed and then are subjected to reducing roasting to obtain a sintered material; the sintered material is subjected to leaching through an alkaline solution and then subjectedto solid-liquid separation; leached residues are subjected to magnetic separating to obtain iron ore concentrate; the pH of a leaching solution is adjusted so as to deposit aluminum, and then the leaching solution is subjected to solid-liquid separation to obtain a liquid phase I and aluminum hydroxide precipitations; tungsten is deposited from the liquid phase I through calcium salt, and a liquidphase II and calcium tungstate precipitations are obtained through solid-liquid separation; the liquid phase II is subjected to causticizing through slaked lime to obtain a sodium hydroxide solutionand calcium-containing precipitations. The method has the advantages that operation is easy, energy consumption is low, chemical consumption is low, valuable metal elements in the tungsten slag and the red mud can be extracted synchronously, and industrial production is facilitated.

Owner:CENT SOUTH UNIV

Method for preparing nano-tungsten powder from calcium tungstate

The invention provides a method for preparing nano-tungsten powder from calcium tungstate. The method comprises the following steps: allowing the calcium tungstate to be closely contacted with conductive metal to form a cathode for electrolysis, taking a soluble or insoluble material as an anode matched with the cathode, and taking a mixture of CaCl<2> and other alkali metals or alkaline-earth metals as electrolyte; placing the electrolyte in a heatable sealed electrolytic cell for heating to remove moisture in the electrolyte, and then heating to reaction temperature for electrolysis under protection of inert atmosphere; heating the electrolyte after the reaction, soaking the cathode in molten salt under inert atmosphere, and washing so as to remove residual impurities; and taking out the obtained cathode product, soaking the product in deionized water so as to remove the surface residual electrolyte, and finally carrying out vacuum drying to obtain the nano-tungsten powder. By utilizing the method, defects such as poor quality of deposited tungsten powder, slow electrolytic speed at the later stage of the direct solid-state reduction process and the like in the existing molten salt electrolysis technology are overcome.

Owner:WUHAN UNIV

High-temperature nickel-metal hydride battery and manufacturing method thereof

InactiveCN102496745AImprove high temperature performanceReduce usageFinal product manufactureCell component detailsRare-earth elementLithium hydroxide

The invention discloses a high-temperature nickel-metal hydride battery. The high-temperature nickel-metal hydride battery comprises an anode, a cathode, a battery diaphragm and one or more electrolytes. The anode comprises a matrix, an active substance, a conductive agent, cobalt oxide and one or more additives. The one or more additives are selected from sodium tungstate, potassium tungstate and calcium tungstate. The weight of the one or more additives is 0.5 to 5% of the total weight of the anode. The battery diaphragm is a polypropylene diaphragm which is subjected to grafting or fluorination treatment. The one or more electrolytes are selected from sodium hydroxide, lithium hydroxide and potassium hydroxide. The concentration of the one or more electrolytes is in a range of 6.5 to 10mol / L. The high-temperature nickel-metal hydride battery has the advantage that the one or more additives are selected from sodium tungstate, potassium tungstate and calcium tungstate so that nickel-metal hydride battery high-temperature performances are improved effectively; rare-earth element utilization is avoided; and a production cost is greatly reduced. The invention also discloses a manufacturing method of the high-temperature nickel-metal hydride battery. The manufacturing method of the high-temperature nickel-metal hydride battery has simple processes.

Owner:QUANZHOU JINTION ELECTRONICS

Hydrometallurgical method for refining tungsten from tungsten oxide limonite

The invention discloses a hydrometallurgical method for refining tungsten from tungsten oxide limonite and belongs to separation and enrichment technologies for low-grade tungsten. The method comprises the steps: (1) carrying out physical enrichment on the limonite; (2) roasting enriched concentrates; (3) carrying out alkali leaching; (4) neutralizing to deslag; (5) producing calcium tungstate; (6) treating waste liquid. According to the method, the limonite is subjected to physical enrichment, the other ingredients of tailings are almost unchanged except for tungsten oxide, precipitated residue is still a raw material for cement production, tail water is reused unlimitedly, and no chemical adjuvant is required, so that the method is very environmentally friendly and very energy-saving; after slag, obtained after filtering, is cleaned, the slag is also limonite for firing cement, so that no waste solid is produced.

Owner:李海波

Electrochemical machining method, electrochemical machining device, and electrochemical machining solution

ActiveCN105705283APrevent spoilageMachining working mediaMachining working media supply/regenerationElectrolysisSodium tungstate dihydrate

The invention provides an electrochemical machining method, an electrochemical machining device, and an electrochemical machining solution. In order to separate and remove sodium tungstate (Na2WO4) resulting from machining, the present invention provides a method for electrochemically machining a superhard alloy while switching the polarity, the method having a configuration wherein an aqueous common-salt solution (aqueous NaCl solution) or an aqueous sodium nitrate solution (Na(NO3)) is used as an electrochemical machining solution and a calcium salt is added beforehand to the electrochemical machining solution, thereby reacting the sodium tungstate (Na2WO4) resulting from the electrochemical machining with the calcium salt to yield calcium tungstate (CaWO4), and the calcium compound is separated and recovered on the basis of a difference in specific gravity.

Owner:MITSUBISHI ELECTRIC CORP

Preparation method of CaWO4 hollow spheres

InactiveCN102701282ARaw materials are easy to obtainLow reaction temperatureTungsten compoundsActive agentMicrosphere

The invention discloses a method for preparing dispersed CaWO4 micrometer-sized hollow spheres. Sodium tungstate and calcium chloride are mixed, the pH value of the mixed solution is adjusted by hydrochloric acid and sodium hydroxide, the solution is uniformly mixed under the action of magnetic stirring, and then the mixed solution is subjected to hydrothermal reaction in an autoclave with a polytetrafluoroethylene liner, after furnace cooling, the product is washed, filtered and dried, and then calcium tungstate microspheres with the diameter of 3 microns to 5micros can be obtained. With the invention, dispersed calcium tungstate micrometer-sized hollow spheres can be synthetized at one step without adding any surfactant, the synthesis temperature is lower, and the method is simple, and is easy to operate.

Owner:无锡润鹏复合新材料有限公司

Method for deeply purifying ammonium tungstate solution

PendingCN110563041AReduce consumption costReduce manufacturing costTungsten compoundsVulcanizationSlag

The invention discloses a method for deeply purifying ammonium tungstate solution. The method comprises the following steps: adding excessive (NH4)2S into a coarsely treated ammonium tungstate solution under a stirring condition until S2<-> reaches a set concentration, and then carrying out vulcanization reaction at a set temperature, so that molybdenum in the ammonium tungstate solution is converted into thiomolybdate ions (MoS42 <->) to obtain a vulcanized ammonium tungstate solution; adding a calcium agent into the vulcanized ammonium tungstate solution under a stirring condition, and thencarrying out stirring reaction under a set condition, so as to obtain calcium tungstate precipitate and a mother liquor containing ammonia water after the reaction is finished; adding the calcium tungstate precipitate into a hydrochloric acid solution at a set temperature under a stirring condition, carrying out heat preservation and stirring reaction, and filtering after the reaction is finished,so as to obtain refined tungstic acid and an acid decomposition mother liquor; cleaning the refined tungstic acid, putting the cleaned tungstic acid into ammonia water for ammonia dissolution, and filtering to obtain ammonia dissolution slag and an ammonium tungstate deep purification liquid.

Owner:CENT SOUTH UNIV

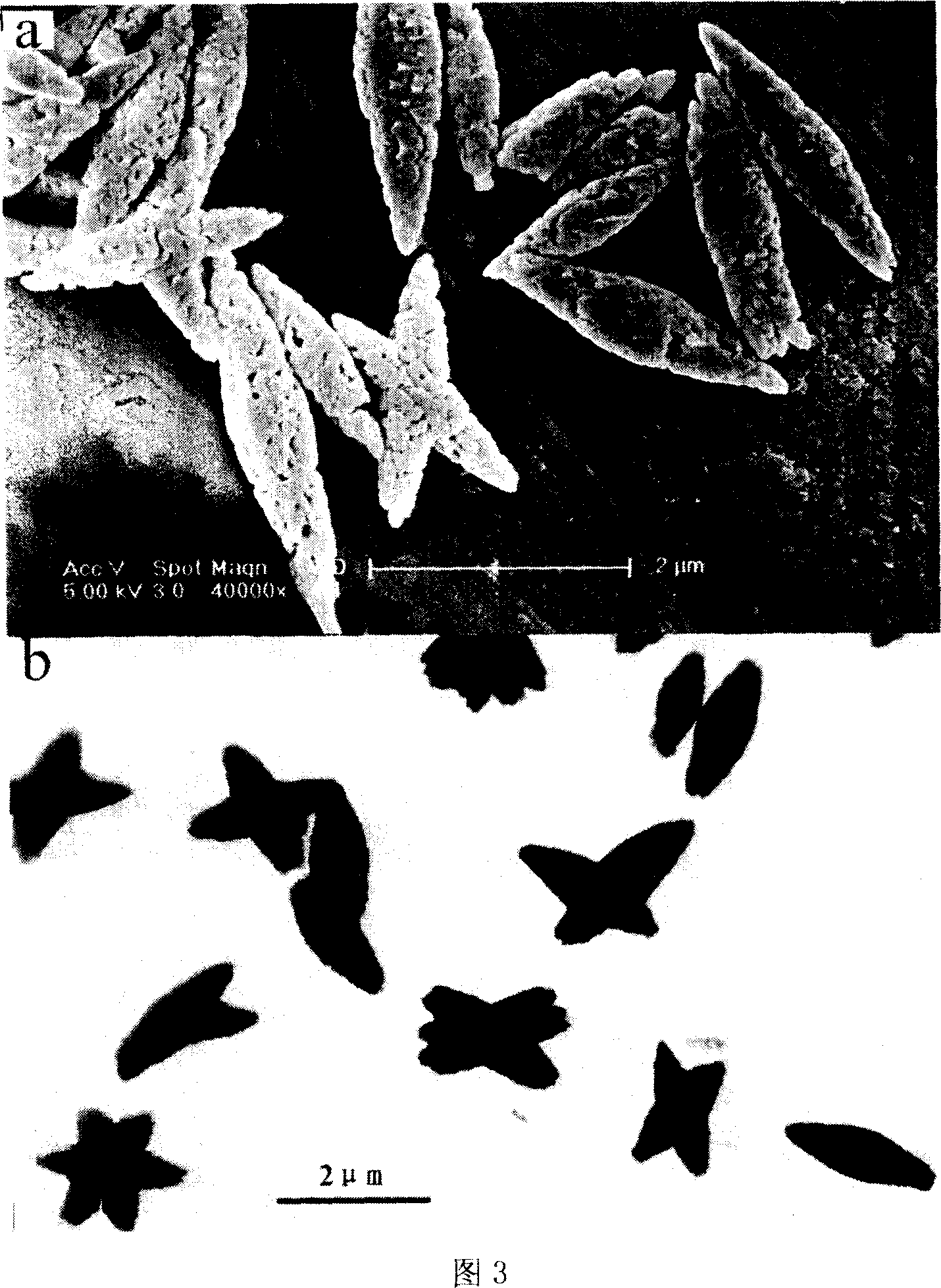

Method for preparing calcium tungstate europium-doped nano material using sodium tungstate

The invention discloses a making method of calcium tungstate with doped europium nanometer material through sodium tungstate in the inorganic chemical technical domain, which is characterized by the following: weighing 25-35ml 0.4-0.5mol / l sodium tungstate solution, 25-35ml 9%-11% ammonium citrate solution and 2. 5-3. 5g hexadecyl trimethyl-ammonium bromide as surface activator to add in the beaker sequently; stirring evenly; blending 25-30ml 0.4-0.5mol / l calcium chloride solution and 5. 5-6. 5ml 0.9-1. 1mol / l europium chloride solution; pouring compound in the separatory funnel; dripping composite solution of calcium chloride and europium chloride into beaker through separatory funnel; stirring through magnetic force; generating white sediment; fetching suspension; placing the suspension in the centrifuger; putting in the toaster to do heat disposal at 100-120 deg. c; placing the solid in the electric furnace to do heat disposal at 550-650 deg. c; grinding solid for 30-40 min to obtain the product.

Owner:UNIV OF SCI & TECH BEIJING

Method of treating scheelite

The present invention relates to a method of treating scheelite. The method comprises the following steps: 1) mixing the scheelite and a sodium carbonate solution, performing a pressure cooking reaction to obtain a crude sodium tungstate solution, performing evaporation concentration until a concentration of tungsten trioxide in the crude sodium tungstate solution is higher than 600 g / L, controlling the temperature at 200-250 DEG C, performing a reaction, and performing filtration to obtain a solid precipitate and solution; and 2) mixing the solid precipitate and hydrogen peroxide for a reaction, and performing filtration to obtain a calcium peroxo-tungstate solution; or, mixing the solid precipitate, hydrogen peroxide and an ammonium salt to obtain an ammonium peroxo-tungstate solution, wherein the ammonium salt is one or more selected from the group consisting of ammonium carbonate, ammonium oxalate, ammonium sulfate and ammonium phosphate. The method provided by the invention greatly reduces consumption of the sodium carbonate, directly converts the calcium tungstate into the calcium peroxo-tungstate by adopting the hydrogen peroxide without using an ion exchange process, and reduces discharge of wastewater.

Owner:CENT SOUTH UNIV

Comprehensive resource utilization method of tungsten-containing crystallization mother liquor and ammonia-containing steam

ActiveCN103253711AThe effect of achieving zero emissionsReduce consumptionAmmonium halidesTungsten compoundsAmmonium paratungstateResource utilization

The invention relates to a comprehensive resource utilization method of tungsten-containing crystallization mother liquor and ammonia-containing steam in a process of preparing products including para-ammonium tungstate and the like by evaporating and crystallizing. After the method is implemented, zero-pollution discharge can be realized. Ammonium tungstate crystallization mother liquor and ammonia-containing steam are generated in a process of preparing a para-ammonium tungstate (APT) product by evaporating and crystallizing an ammonium tungstate solution. The comprehensive resource utilization method comprises the following steps of: adding auxiliary materials to react with tungsten in the crystallization mother liquor, wherein the solid phase after solid-liquid separation is a calcium tungstate product, and the liquid phase is a mixed solution of calcium chloride and ammonia; recycling the calcium chloride product by evaporating and recycling the mixed solution of the calcium chloride and the ammonia, wherein the gas phase is ammonia-containing steam; and enabling the ammonia-containing steam generated by calcium chloride evaporation and ammonia-containing steam generated by evaporating and crystallizing to enter a deamination tower after being mixed for recycling to be ammonia water or for further preparing to be an ammonia product. The comprehensive resource utilization method disclosed by the invention is simple to operate, cheap in materials and capable of realizing zero-pollution discharge in the process, so that the tungsten in the crystallization mother liquor and the ammonia in the steam can be recycled, and are easily industrialized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of rare earth-doped calcium tungstate phosphor

The invention discloses a preparation method of rare earth-doped calcium tungstate phosphor, comprising the steps of: by taking a peeled sponge-shaped cuttlebone as a main raw material, adding a proper amount of calcium tungstate and then adding rare earth nitrate to perform reaction for 24 hours at a temperature of 120-180 DEG C via a hydrothermal method, cooling, drying, and respectively calcining at a temperature of 200-1000 DEG C to obtain the rare earth-doped calcium tungstate phosphor with different luminescence properties. The invention successfully realizes the effective regulation and control to the luminescence color of the calcium tungstate phosphor, obtains the rare earth-doped calcium tungstate phosphor with uniform grain diameter, favorable dispersibility excellent physicochemical property, and wide application prospect in the fields of biomaterial, luminescent paint and fluorescent lamps and the like. The invention has the advantages of simple preparation process, low cost and little equipment investment, and is suitable for mass production.

Owner:NINGBO UNIV

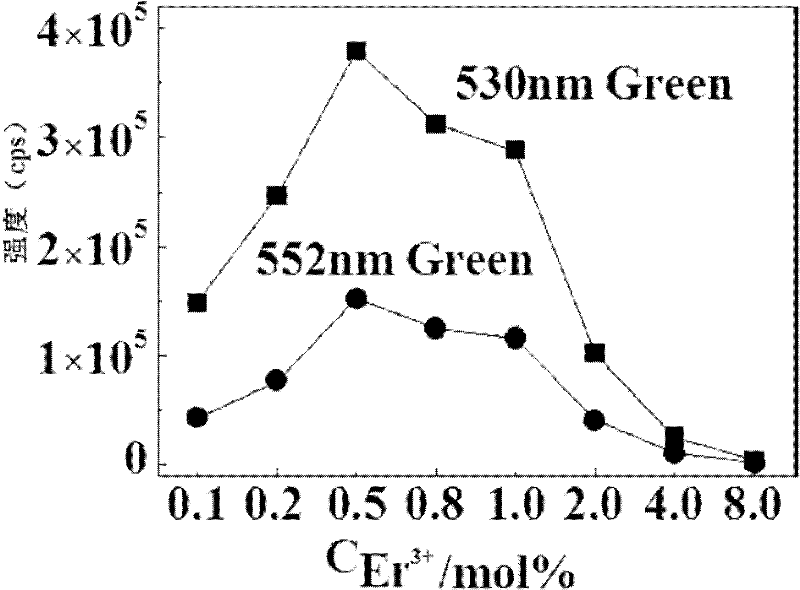

Ytterbium erbium double-doped calcium tungstate polycrystal powder green ray up-conversion material and preparation method thereof

InactiveCN102191049AExcellent up-conversion green emissionLight evenlyLuminescent compositionsRare-earth elementMetallurgy

The invention provides an ytterbium erbium double-doped calcium tungstate polycrystal powder green ray up-conversion material and a preparation method thereof, and relates to an rare-earth element doped calcium tungstate polycrystal powder green ray up-conversion material and a preparation method thereof. By the ytterbium erbium double-doped calcium tungstate polycrystal powder green ray up-conversion material and the preparation method thereof, the problem that emitted light with high singleness is difficult to obtain when the rare-earth elements are doped in a matrix material is solved. The chemical formula of the ytterbium erbium double-doped calcium tungstate polycrystal powder green ray up-conversion material is Ca0.99-xWO4:Yb0.01 / Erx, wherein x is more than or equal to 0.001 and less than or equal to 0.08. The preparation method comprises the following steps of: 1, weighing according to the stoichiometric ratio of the chemical formula; 2, grinding and tabletting; and 3, sintering at a high temperature. The ytterbium erbium double-doped calcium tungstate polycrystal powder green ray up-conversion material can emit bright up-conversion green ray uniformly under the conditions of laser pumping of 980 nm and laser power of 300 mW.

Owner:HARBIN INST OF TECH

Comprehensive utilization method of gypsum containing tungsten and fluorine

InactiveCN102976410AHigh purityHigh recovery rateCalcium/strontium/barium carbonatesAmmonium sulfatesSulfateIon exchange

The invention belongs to the field of chemical industrial waste residue comprehensive utilization and discloses a comprehensive utilization method of gypsum containing tungsten and fluorine. The method comprises the following steps: firstly, levigating residue of gypsum containing tungsten and fluorine, secondly, adding concentrated acid to the levigated residue, stirring, washing, removing impurities and obtaining refined calcium sulfate, thirdly, adopting additive agents and water to pulpify the refined calcium sulfate, fourthly, adding a certain amount of decomposing agents, stirring for a period of time under a heat preservation condition, filtering, washing, and obtaining decomposing liquid of light calcium carbonate products and ammonium sulfate containing tungsten, finally, adopting an ion exchange method and a precipitation method to prepare calcium tungstate products from the decomposing liquid and adopting an evaporation crystallization method to prepare ammonium sulfate products. The comprehensive utilization method of gypsum containing tungsten and fluorine has the advantages that the residue of gypsum containing tungsten and fluorine can be comprehensively processed under a mild condition, calcium, sulfur and tungsten resources of the residue can be respectively and sufficiently utilized, the light calcium carbonate products, the ammonium sulfate products and the calcium tungstate products have high additional value and are produced.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL +1

Method for extracting valuable elements from waste denitration catalysts by virtue of medium-temperature tunnel type solid-state activation

ActiveCN110218859ARealize efficient recovery of leaching rateTo achieve process environmental protectionProcess efficiency improvementLiquid wasteFiltration

The invention discloses a method for extracting valuable elements from waste denitration catalysts by virtue of medium-temperature tunnel type solid-state activation. The method comprises the following steps of carrying out superfine treatment on broken the SCR denitration waste catalysts which are used as raw materials, adding proper alkali salt and an activating agent, mixing, carrying out extrusion forming, feeding the mixture into a tunnel type activation reaction machine to be activated, carrying out water quenching on the activated material, carrying out slurry mixing, pumping slurry toan ultrasonic high-efficiency leaching tank, and leaching ore pulp to obtain leached residues and vanadium-containing and tungsten-containing filtrate through filtration; washing and drying the leaching residues to obtain a titanium dioxide product; adding a double salt into the filtrate to remove impurities of silicon and aluminum, adding a precipitant into liquid with the impurities removed to precipitate vanadium and tungsten, then after conducting washing and filtering on the precipitate and selectively leaching the vanadium out of the precipitate, carrying out liquid-solid separation, andwashing and drying the obtained slag phase to obtain a calcium tungstate product; and adding ammonium hydroxide into the vanadium-containing filtrate to precipitate vanadium, and finally recovering the vanadium element in the form of ammonium metavanadate. According to the method disclosed by the invention, the valuable elements in the waste catalysts are finely separated, the recovery rate is high, the energy consumption is low, and the produced waste liquid is recycled, thus avoiding secondary pollution.

Owner:云南方圆矿产资源再生综合利用研究院有限公司

Ytterbium and thulium double-doped calcium tungstate polycrystalline powder blue upconversion material and preparation method thereof

The invention discloses an ytterbium and thulium double-doped calcium tungstate polycrystalline powder blue upconversion material and a preparation method thereof, and relates to a rare earth element doped calcium tungstate polycrystalline powder blue upconversion material and a preparation method thereof. The problems that the emitted light with high oneness is difficult to obtain because rare earth elements are doped in a matrix material, and the intensity of upconversion blue light generated by doping Tm<3+> is low are solved. A chemical formula of the ytterbium and thulium double-doped calcium tungstate polycrystalline powder blue upconversion material is Ca0.99-xWO4:Ybx / Tm0.01, wherein x is more than or equal to 0.01 and is less than or equal to 0.08. The preparation method comprisesthe following steps of: 1, weighing according to the stoichiometric ratio of the chemical formula; 2, grinding and tabletting; and 3, sintering at high temperature. The ytterbium and thulium double-doped calcium tungstate polycrystalline powder blue upconversion material can emit bright upconversion blue light uniformly under the condition that the laser pumping length is 980nm and the exciting power is 300mW.

Owner:HARBIN INST OF TECH

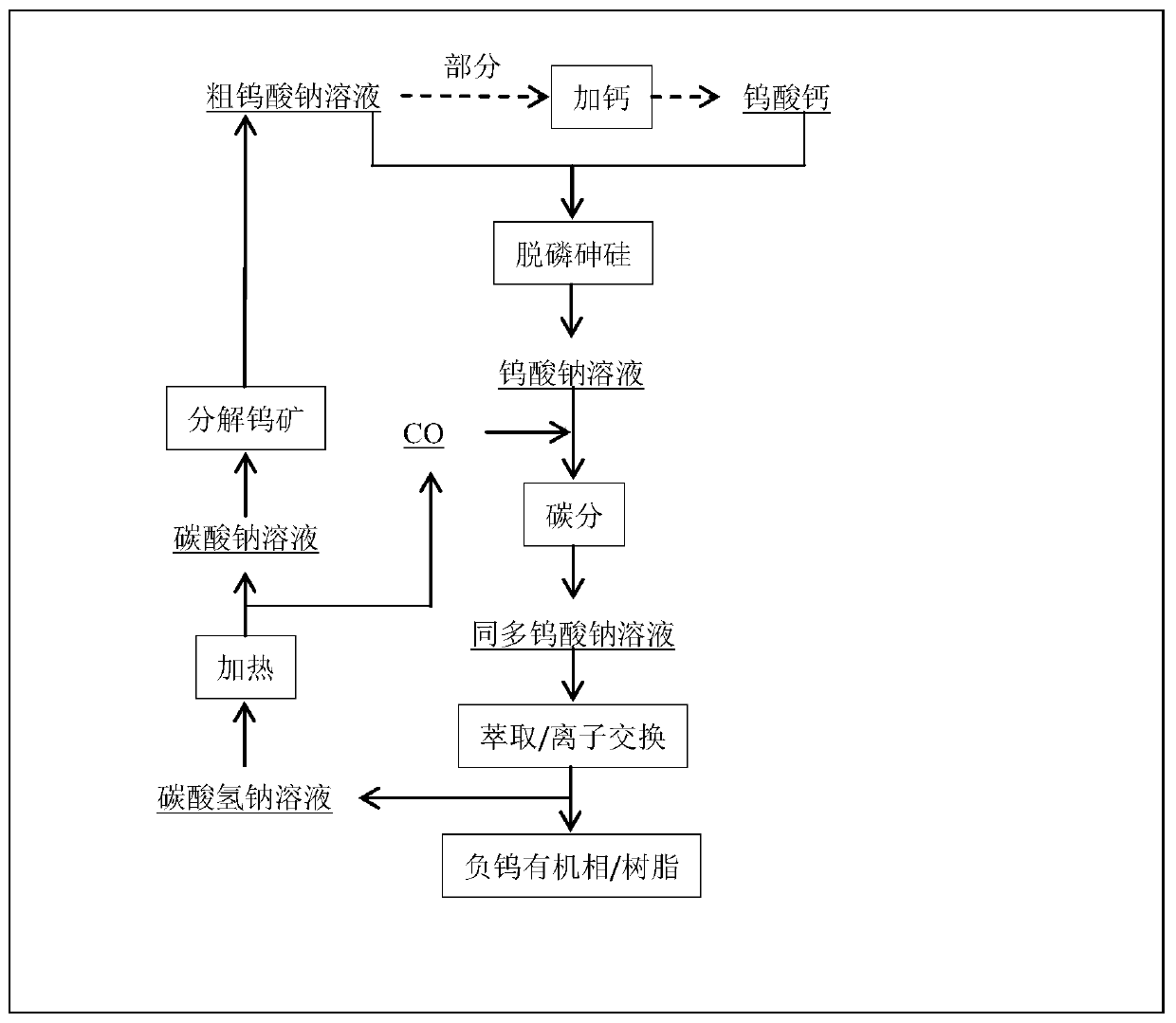

Method for efficiently removing phosphorus, arsenic and silicon impurities, extracting tungsten and recovering alkali from crude sodium tungstate solution

ActiveCN110451567AEfficient removal of impuritiesEnable recyclingCarbon compoundsAlkali metal carbonatesSodium bicarbonateIon-exchange resin

The invention discloses a method for efficiently removing phosphorus, arsenic and silicon impurities, extracting tungsten and recovering alkali from a crude sodium tungstate solution. The method includes the following steps of mixing calcium tungstate with the crude sodium tungstate solution for reaction, conducting filtering to obtain a sodium tungstate solution, introducing carbon dioxide into the sodium tungstate solution until the pH of the solution is 3.0-6.5 to obtain a sodium polytungstate solution, conducting adsorbing through weak-base anion-exchange resin or extracting through a weakly alkaline extractant on tungsten in the sodium polytungstate solution to obtain a raffinate or exchanged liquid as a sodium bicarbonate solution, heating the obtained sodium bicarbonate solution toobtain a sodium carbonate solution and carbon dioxide, returning the sodium carbonate solution for decomposing tungsten ore to prepare the crude sodium tungstate solution and returning carbon dioxidefor decomposing sodium tungstate solution. By means of the method, the phosphorus, arsenic and silicon impurities in the crude sodium tungstate solution can be effectively removed, the tungsten can beeffectively extracted, and the alkali can be effectively recycled.

Owner:CENT SOUTH UNIV

Preparation method of twinborn spheroidal calcium tungstate microcrystallines

InactiveCN103771520ARegular shapeGood dispersionTungsten compoundsPhysical chemistrySodium tungstate dihydrate

The invention provides a preparation method of twinborn spheroidal calcium tungstate microcrystallines, which is characterized in that raw materials comprise 0.05-0.2 mol / L sodium tungstate, 0.05-0.2 mol / L calcium nitrate and 3.8-7.6 g / L beta cyclodextrins. The method disclosed by the invention has the characteristics of environmental protection, energy conservation, high efficiency and rapidness, and the like, and prepared twinborn spheroidal calcium tungstate is regular in appearance, good in dispersibility, high in yield and good in stability, and formed spheres are 4 mu m in size, and uniform in size; and required raw materials are environment-friendly and easily obtained, and the preparation process is simple and easy to implement, therefore, the method is suitable for large-scale industrial production.

Owner:CHONGQING UNIV OF ARTS & SCI

Lubricating oil additive for engineering machinery and preparation method thereof

InactiveCN108485754AImprove physical performanceExcellent wear resistanceAdditivesAntioxidantNanoparticle

The invention discloses a lubricating oil additive for engineering machinery. The lubricating oil additive comprises the following raw materials by weight: 24-30 parts of graphene oxide, 16-20 parts of nanometer copper oxide, 14-18 parts of nanoparticles, 8-12 parts of organic bentonite, 4-10 parts of calcium tungstate, 6-10 parts of a silane coupling agent, 3-7 parts of a heat stabilizer, 2-4 parts of an antioxidant, 1-3 parts of an extreme pressure agent and 1-3 parts of polyethylene glycol. The objective of the invention is to provide the lubricating oil additive for engineering machinery and the preparation method thereof. The lubricating oil additive can reduce friction loss and repair wear loss, and has high use value and good application prospects.

Owner:HEFEI KANGZHIHENG MACHINERY TECH CO LTD

Method for extracting tungsten or molybdenum from tungstate solutions or molybdate solutions

ActiveCN110218868APromote generationImplement extractionProcess efficiency improvementMolybdateTungstate

The invention relates to a method for extracting tungsten or molybdenum from tungstate solutions or molybdate solutions. The method includes the following steps that (1) the tungstate solutions or themolybdate solutions and calcium-containing compounds are mixed for reaction to obtain solid sediments containing calcium tungstate or solid sediments containing calcium molybdate; and (2) the solid sediments containing calcium tungstate or the solid sediments containing calcium molybdate obtained in the first step are mixed with hydrogen peroxide for reaction, filtering is conducted to obtain peroxy calcium tungstate solutions or peroxy calcium molybdate solutions, or the solid sediments containing calcium tungstate or the solid sediments containing calcium molybdate obtained in the first step are mixed with hydrogen peroxide and ammonium salt for reaction, filtering is conducted to obtain peroxy calcium tungstate solutions or peroxy calcium molybdate solutions, and the ammonium salt is one or more of ammonium carbonate, ammonium oxalate, ammonium sulfate and ammonium phosphate. The tungsten or the molybdenum can be efficiently extracted from the tungstate solutions or the molybdate solutions by means of the method.

Owner:CENT SOUTH UNIV

Method for preparing nano-tungsten powder from calcium tungstate

The invention provides a method for preparing nano-tungsten powder from calcium tungstate. The method comprises the following steps: allowing the calcium tungstate to be closely contacted with conductive metal to form a cathode for electrolysis, taking a soluble or insoluble material as an anode matched with the cathode, and taking a mixture of CaCl<2> and other alkali metals or alkaline-earth metals as electrolyte; placing the electrolyte in a heatable sealed electrolytic cell for heating to remove moisture in the electrolyte, and then heating to reaction temperature for electrolysis under protection of inert atmosphere; heating the electrolyte after the reaction, soaking the cathode in molten salt under inert atmosphere, and washing so as to remove residual impurities; and taking out the obtained cathode product, soaking the product in deionized water so as to remove the surface residual electrolyte, and finally carrying out vacuum drying to obtain the nano-tungsten powder. By utilizing the method, defects such as poor quality of deposited tungsten powder, slow electrolytic speed at the later stage of the direct solid-state reduction process and the like in the existing molten salt electrolysis technology are overcome.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com