Comprehensive utilization method of gypsum containing tungsten and fluorine

A technology of fluorogypsum and solid-to-liquid ratio, which is applied in the fields of tungsten products, light calcium carbonate, and ammonium sulfate. It can solve the problems of utilization, resource waste, and low impurity content, and achieve simple operation, high recovery rate, and low equipment requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

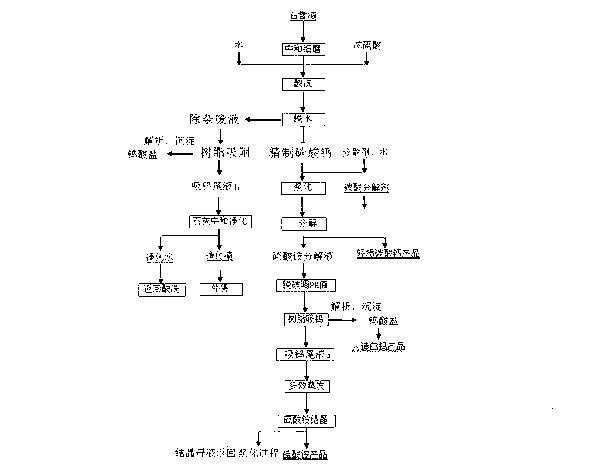

[0030] A comprehensive utilization method of tungsten-containing fluorogypsum, the process flow is as follows figure 1 As shown, the specific steps are:

[0031] (1) Fluorogypsum slag containing tungsten (composition CaSO 4 97.2%, Fe0.23%, Al0.45%, WO 3 0.17%), take 500g, slurry with 1500ml tap water, add 10ml of sulfuric acid with a concentration of 93%, leaching for 3h at 50°C, filter and wash to obtain refined calcium sulfate and impurity removal waste liquid; the iron and aluminum removal rate of the refined calcium sulfate They are: 87.85%, 95.38%, and the tungsten retention rate is 84.66%.

[0032] (2) Add 800ml of water containing 0.1g polyethylene glycol to the refined calcium sulfate to make a slurry, then add 800ml of a solution containing 400g of ammonium carbonate to decompose, after the addition is completed, keep stirring at 40°C for 3 hours, and finally obtain the calcium carbonate product and the solution containing The decomposition liquid of ammonium tungs...

Embodiment 2

[0039] A comprehensive utilization method of tungsten-containing fluorogypsum, the process flow is as follows figure 1 As shown, the specific steps are:

[0040] (1) Fluorogypsum slag containing tungsten (containing CaSO 4 97.2%, Fe0.23%, Al0.45%, WO 3 0.17%), take 500g, slurry with 1200ml tap water, add 15ml of sulfuric acid with a concentration of 93%, leaching at 20°C for 10h, filter and wash to obtain refined calcium sulfate and impurity removal waste liquid; the impurity removal process of the refined calcium sulfate iron, The elution rates of aluminum are 92.85% and 97.38%, respectively, and the retention rate of tungsten is 82.11%.

[0041] (2) Refined calcium sulfate is slurried by adding 500ml of tap water containing 0.1g of sodium dodecylsulfonate, and then adding 600ml of ammonium bicarbonate + ammonia water (containing 325g of ammonium bicarbonate and 360ml of 24% ammonia water) for decomposition , the process was reacted at 35°C for 6h, and the calcium carbonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com