Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "To achieve the purpose of separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

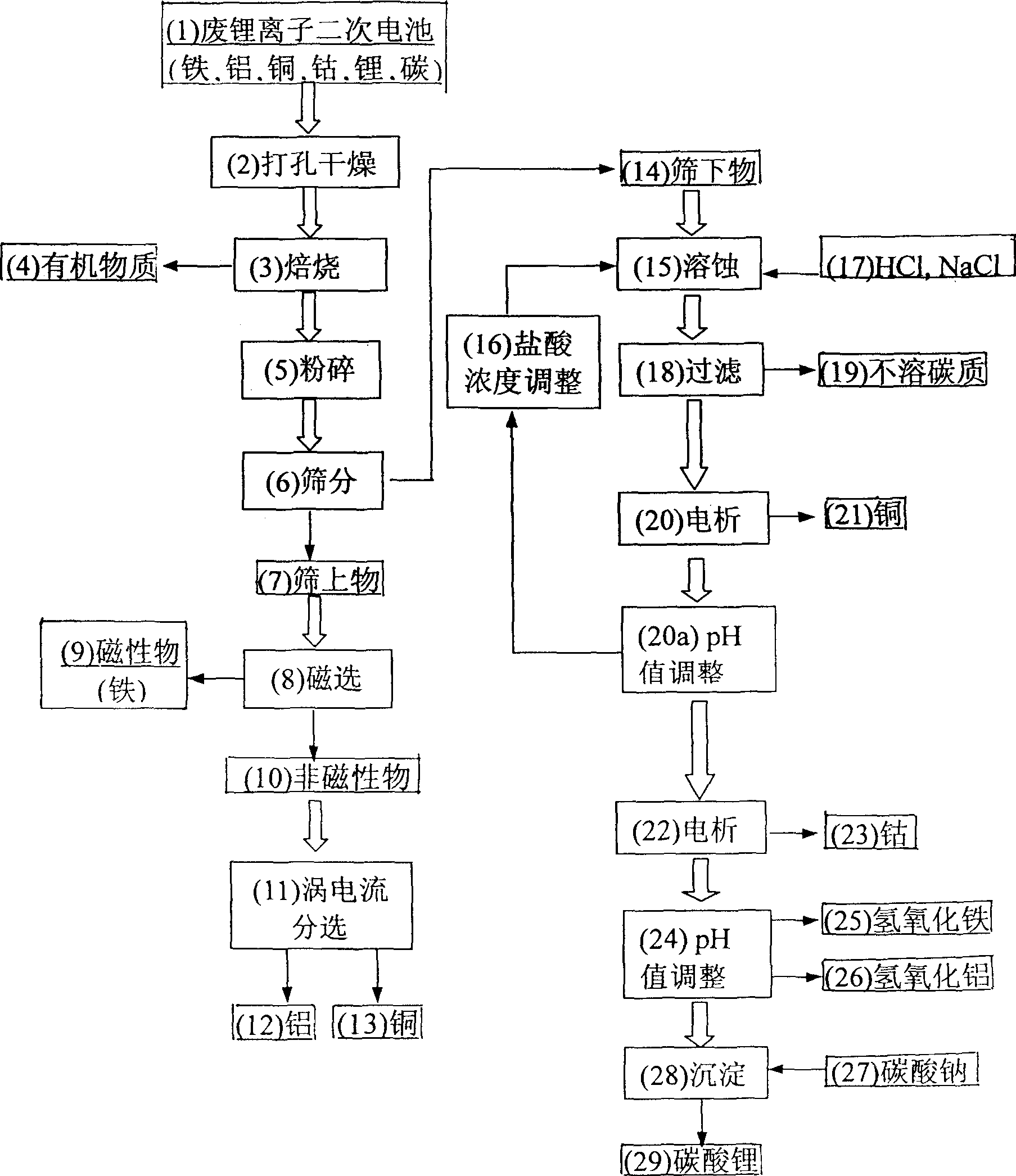

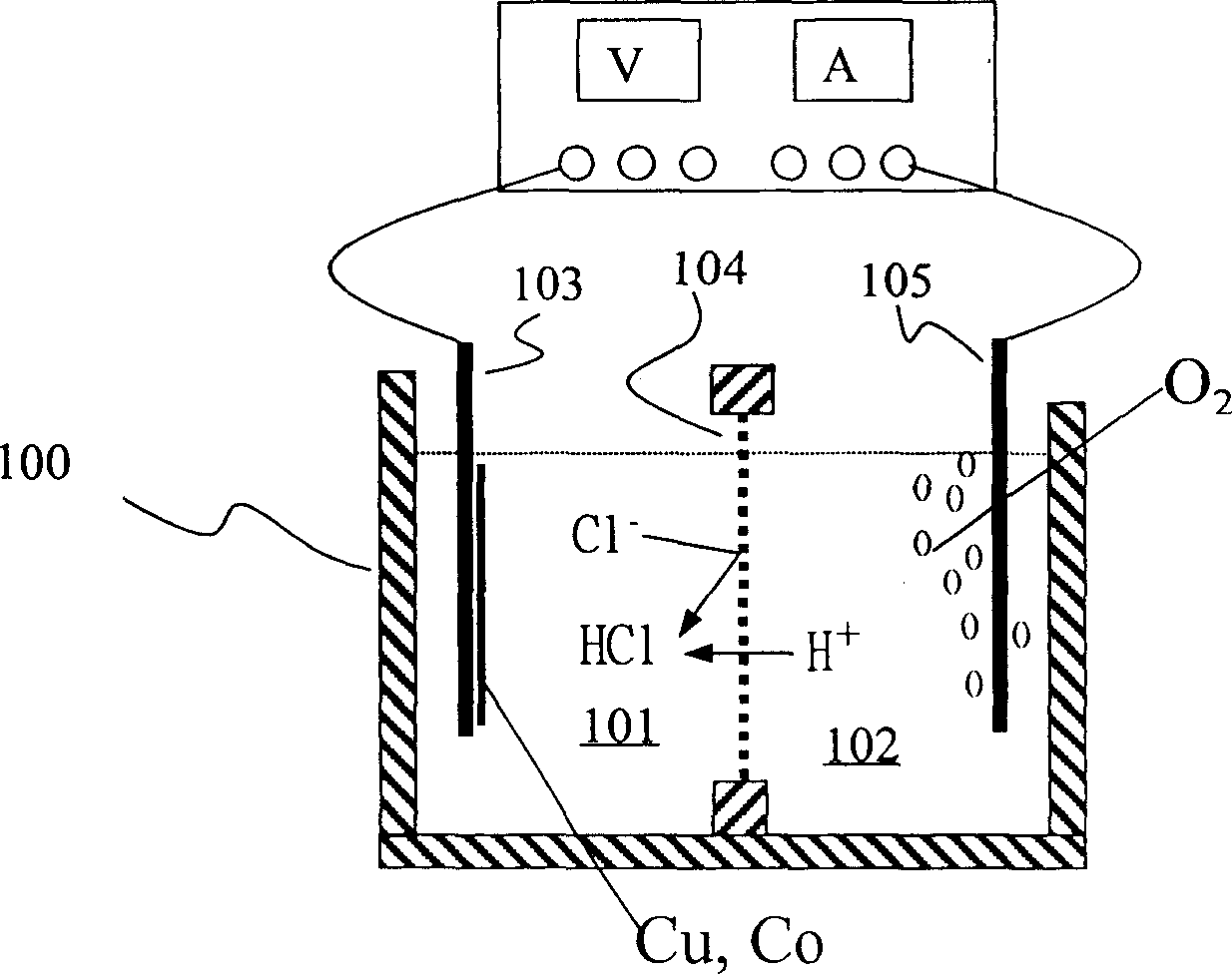

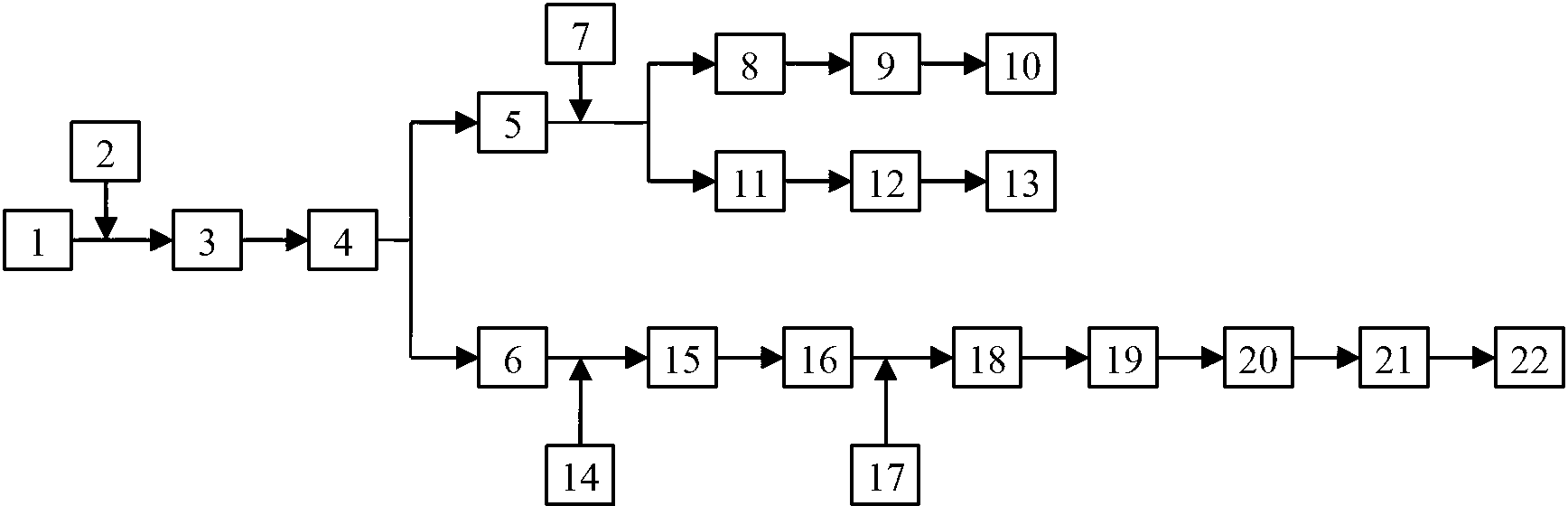

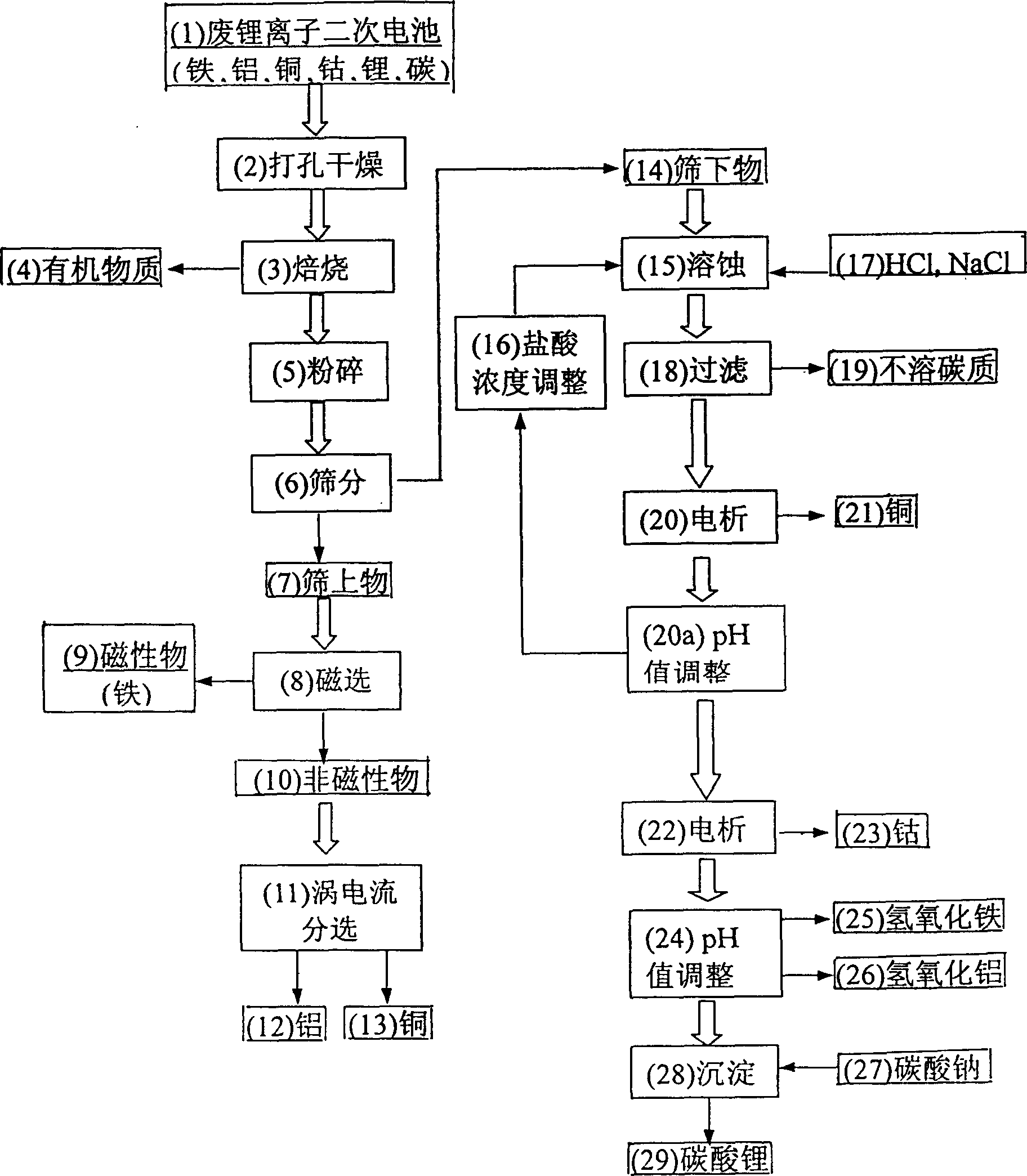

Method for recovering metal from used Li ion cell

InactiveCN1402376ATo achieve the purpose of separationReduce lossWaste accumulators reclaimingBattery recyclingDielectricCopper foil

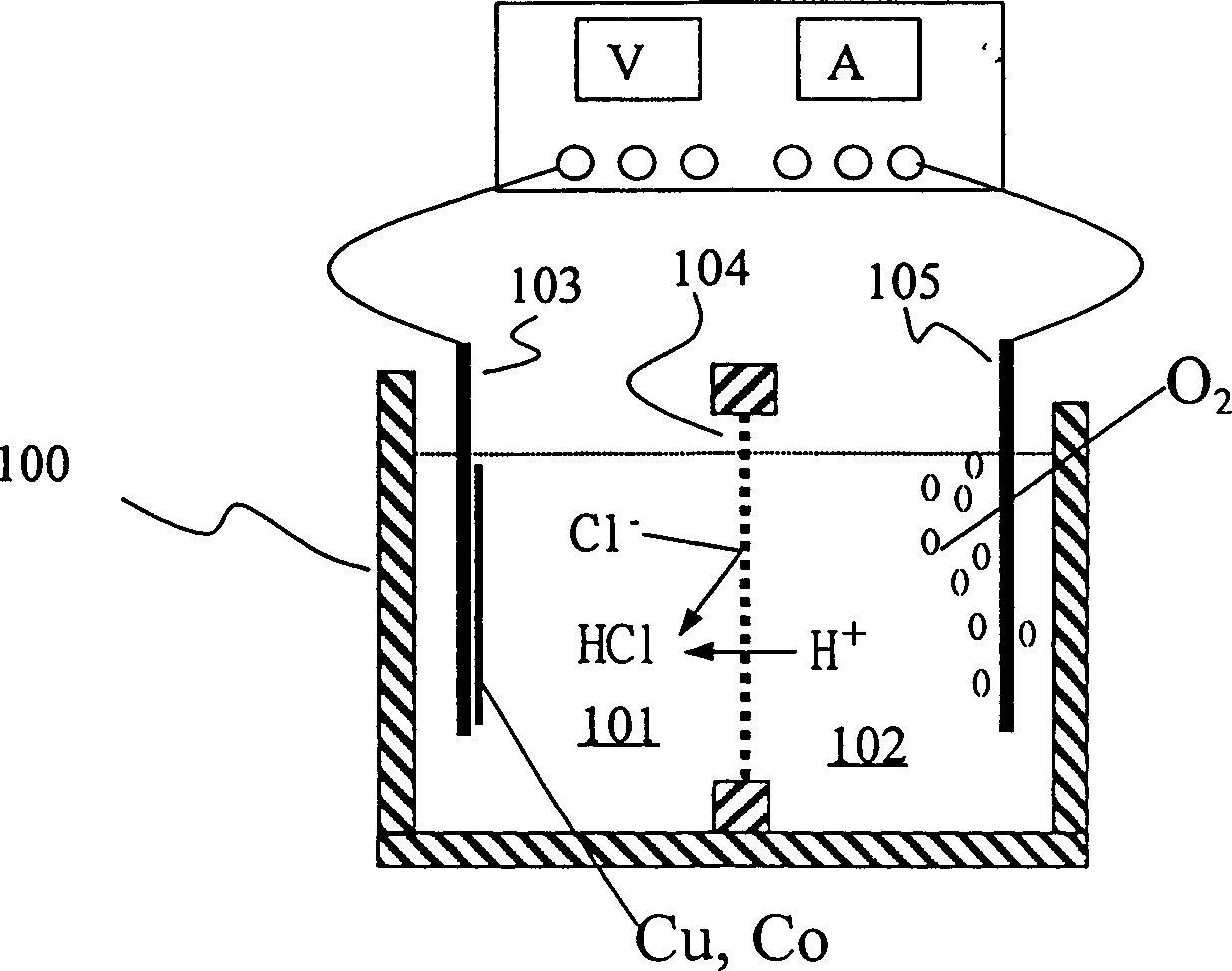

The invented method includes the physical separation method combining with the preparation procedure of the cleaning wet recycle, providing the features of simple and high purity of the recovered metal. The invention includes following steps. With the disused lithium ion cells being burned in the high-temperature furnace, the organic dielectric is removed. After the smashing and sieving treatment, the oversize material is processed through the magnetic separation and the eddy current sorting so as to obtain the iron case, copper foil and aluminium foil etc. The undersize is processed through the steps of corrosion, filtering and electrolysis so as to obtain copper and cobalt. With carbonic acid radical being added to the solution richen in lithium ion, the high purity carbonate of lithiumis formed so as to recovery lithium.

Owner:IND TECH RES INST

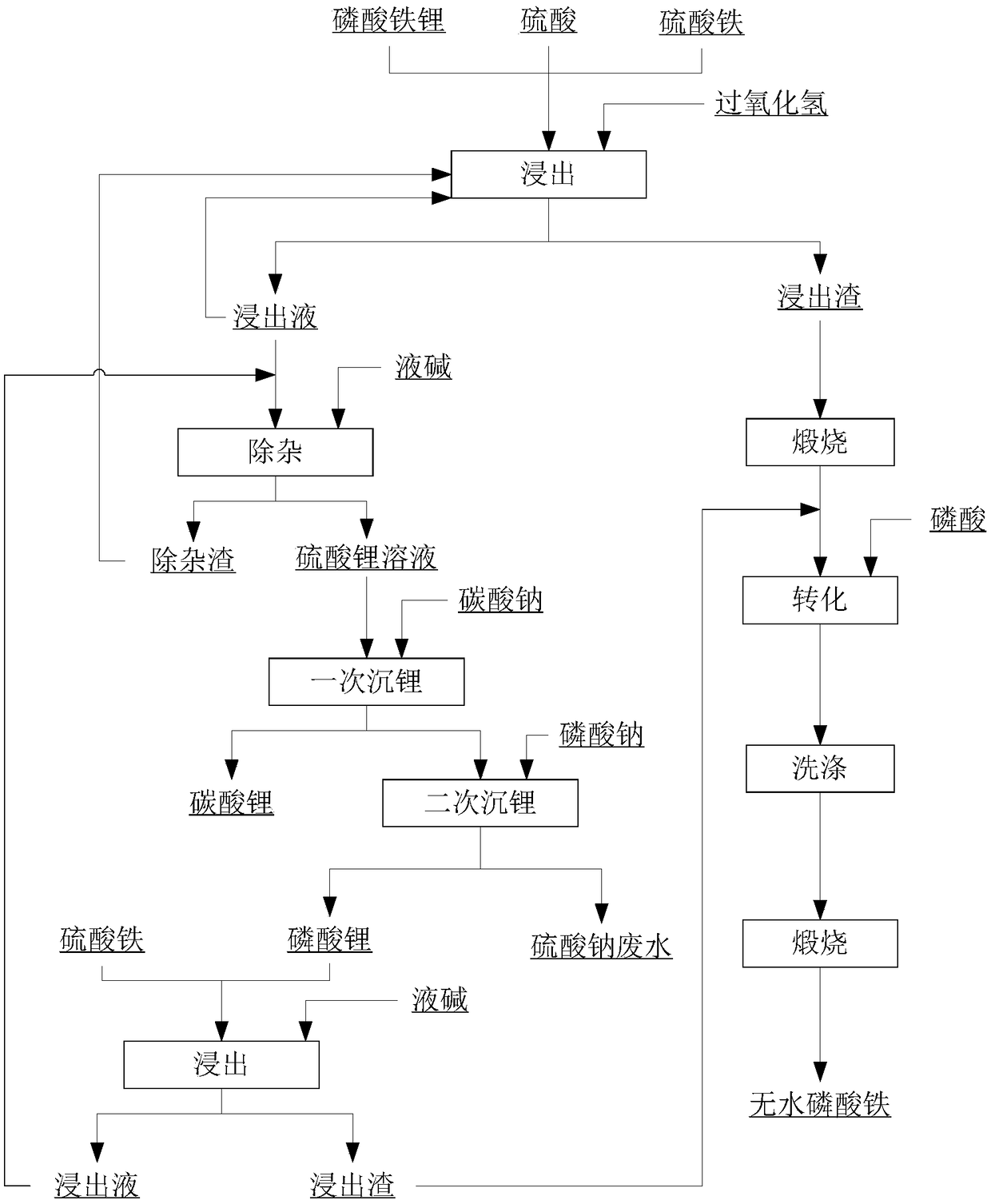

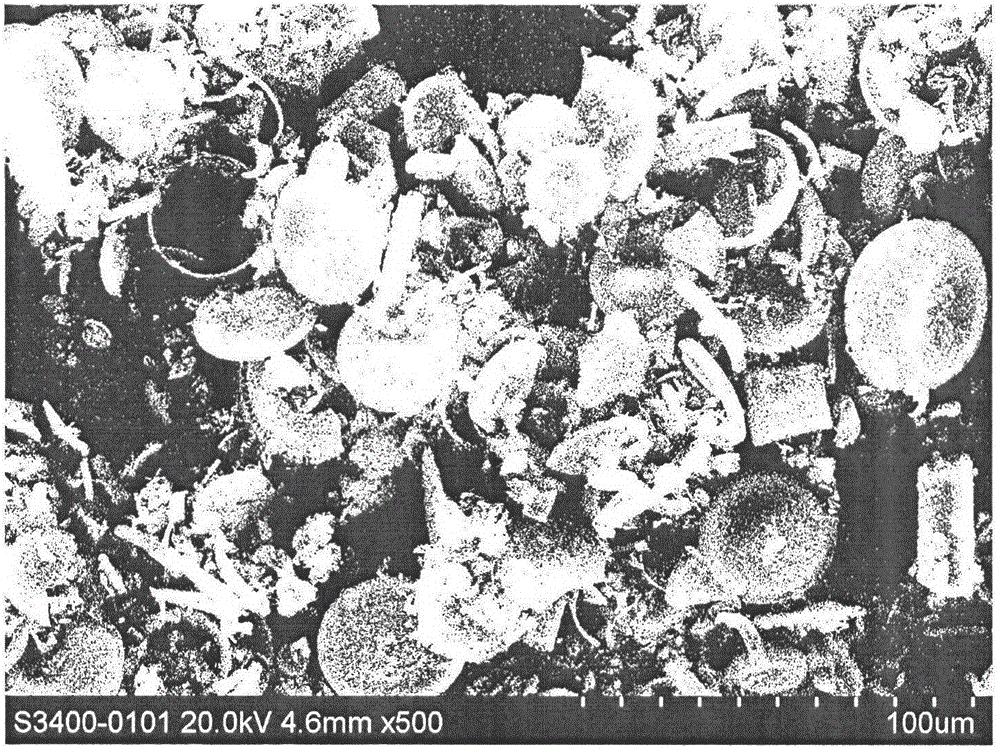

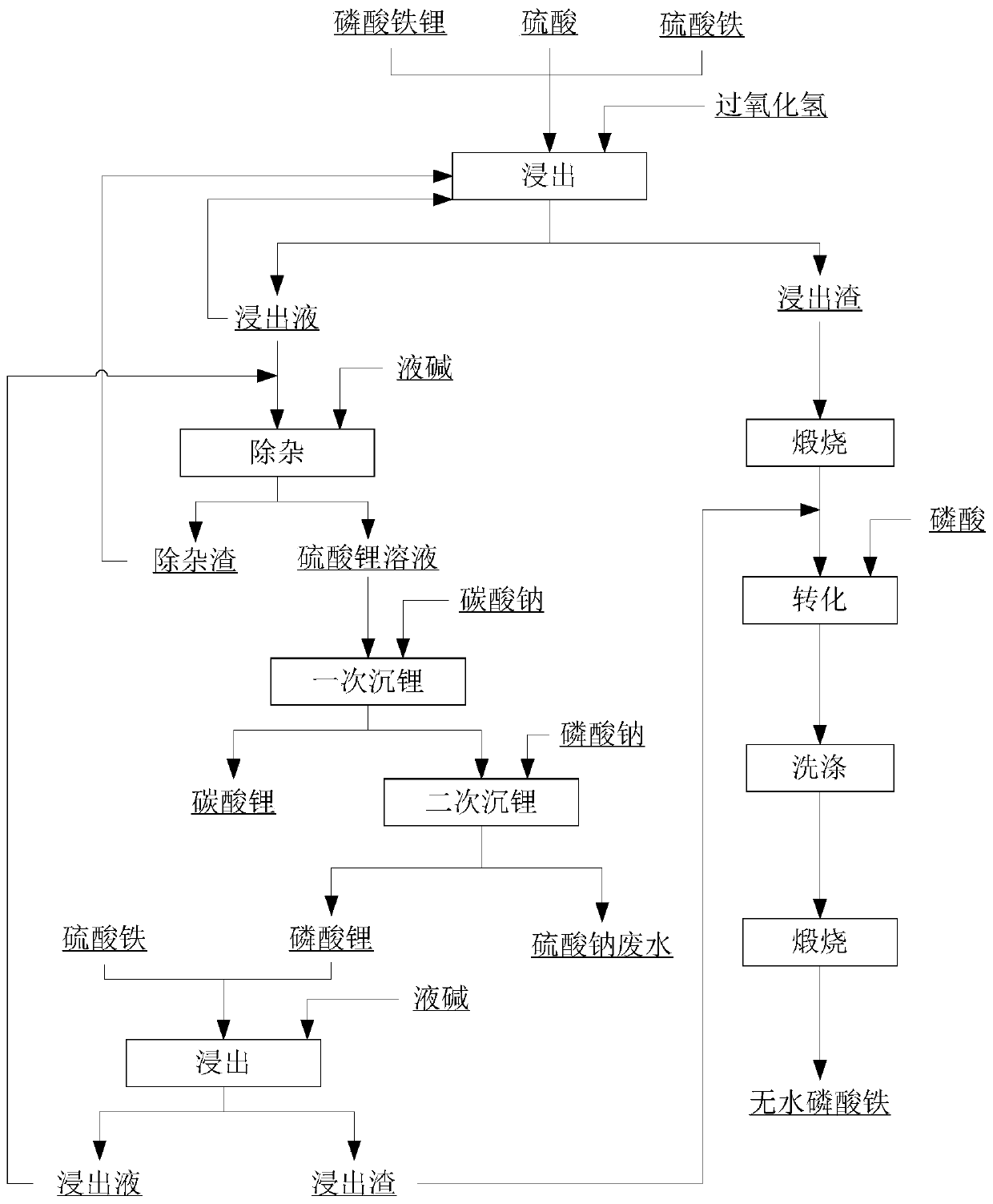

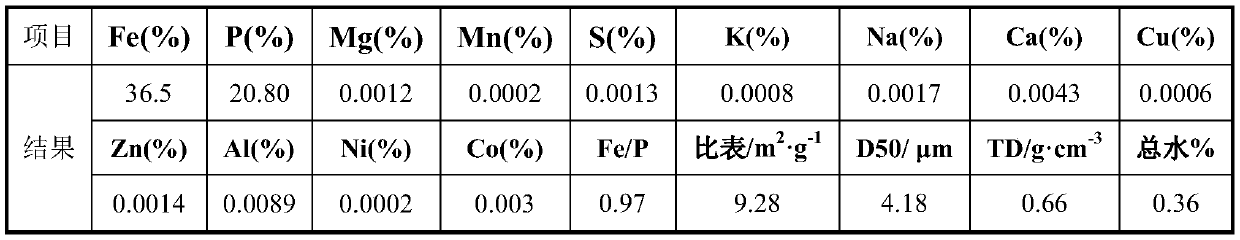

Method for recovering lithium from lithium iron phosphate

ActiveCN108899601ADoes not affect the leaching rateHigh purityWaste accumulators reclaimingProcess efficiency improvementFerric hydroxideIron sulphate

The invention discloses a method for recovering lithium from lithium iron phosphate. The method disclosed by the invention comprises the following steps: dissolving waste lithium iron phosphate slag with sulfuric acid and ferric sulfate, leaching iron, lithium and phosphorus, adding an oxidizing agent, reacting iron and phosphate radicals to produce an iron phosphate precipitate and a small amountof ferric hydroxide, converting lithium into a water-soluble lithium sulfate solution, filtering to obtain the lithium sulfate solution, adding sodium carbonate into the lithium sulfate solution to prepare a lithium carbonate product, and adding sodium phosphate or phosphoric acid to prepare lithium phosphate; dissolving the lithium phosphate with ferric sulfate again to obtain the lithium sulfate solution and a compound taking iron phosphate as a principle component, returning the lithium sulfate solution to the system to prepare lithium carbonate, and calcining the iron phosphate slag to remove organic matters and carbon in the slag; and slurrying to prepare cell grade iron phosphate. According to the method for recovering lithium from lithium iron phosphate disclosed by the invention,the lithium is totally converted into the product lithium carbonate in the method, the process flow is short, the cost is low, the lithium recovery rate is 97%, the metal lithium in the lithium iron phosphate can be effectively recovered, and all the slag is converted into the cell grade iron phosphate.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

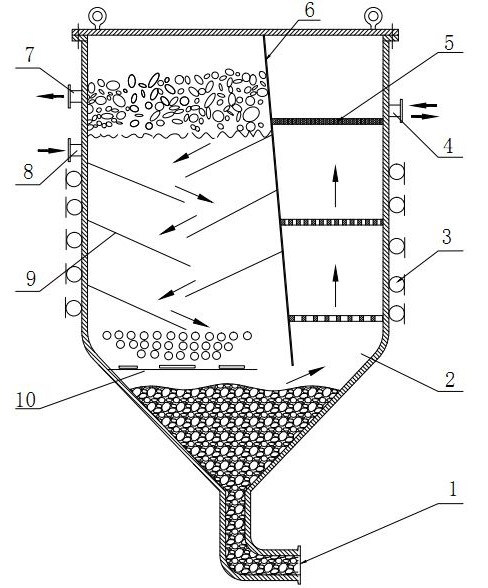

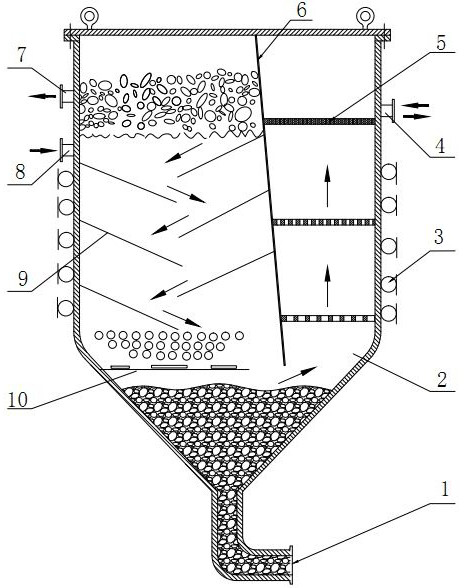

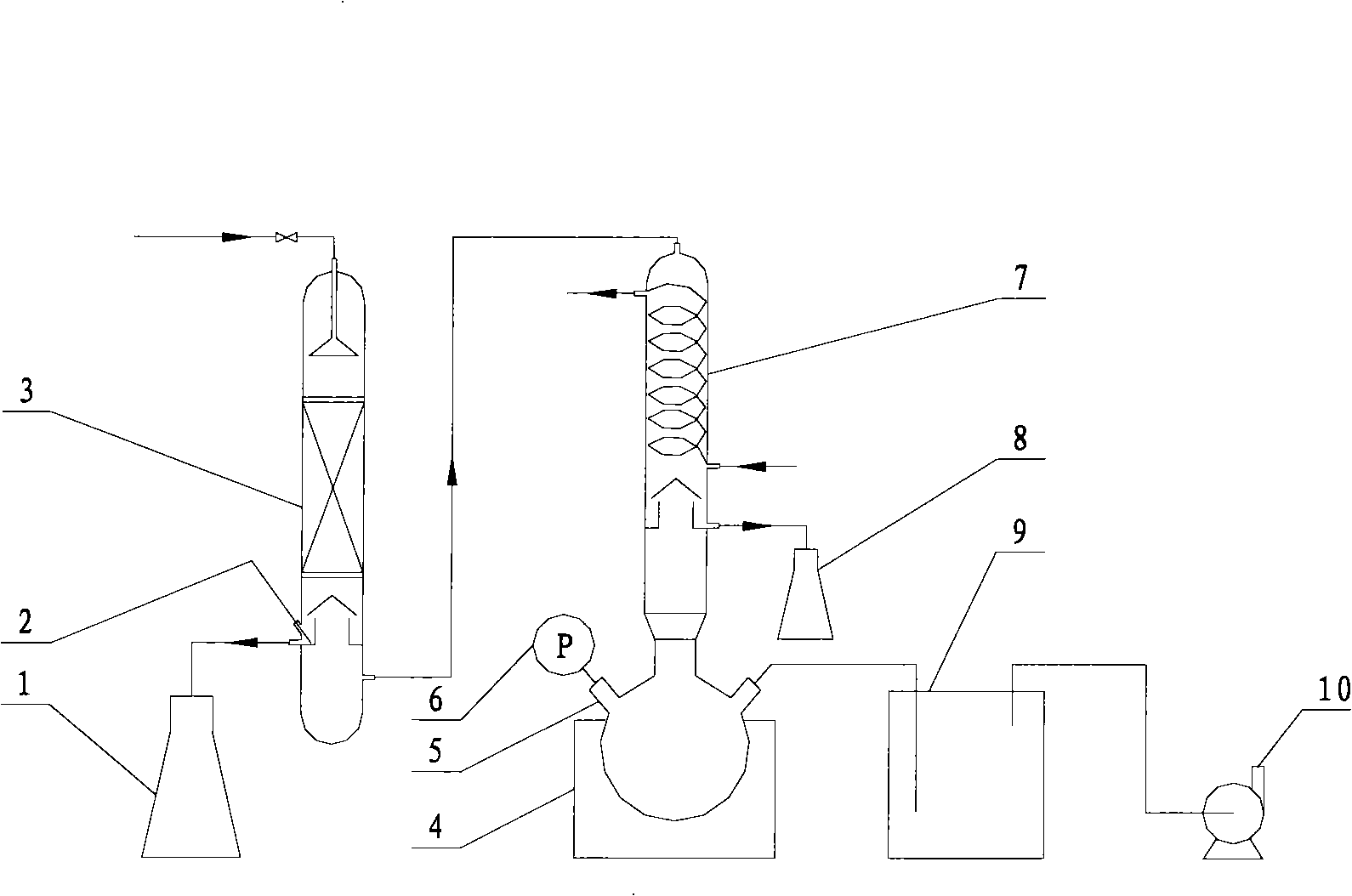

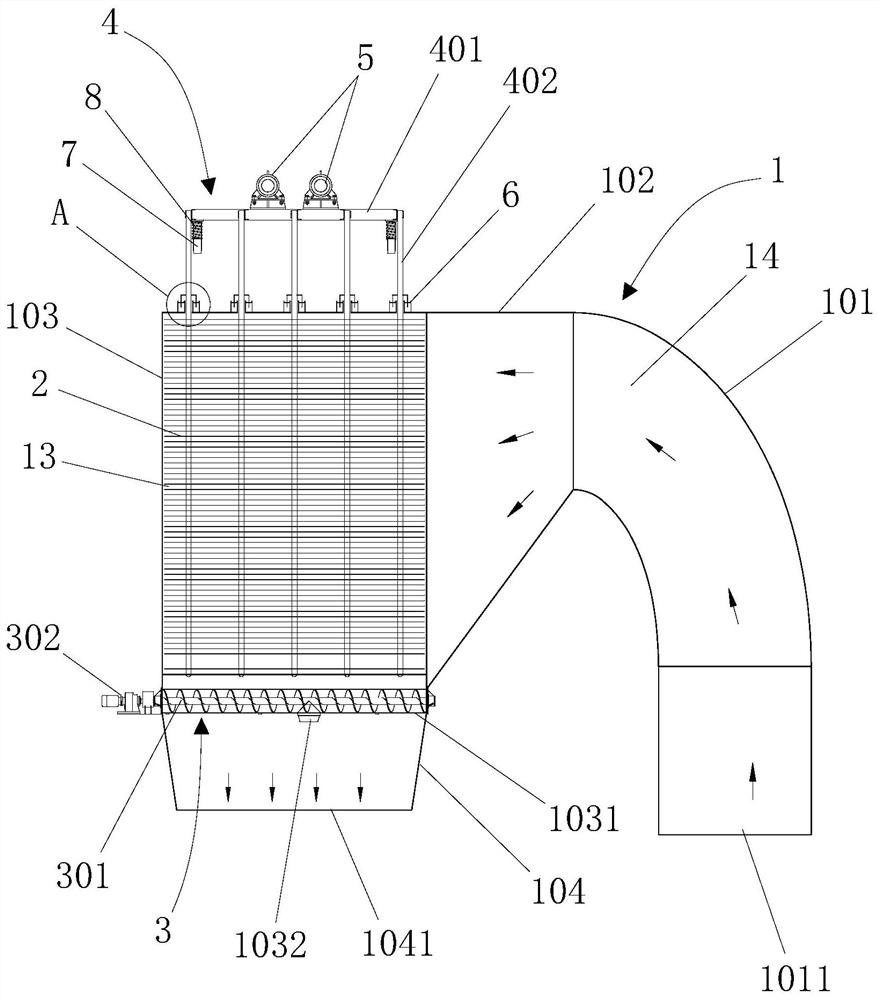

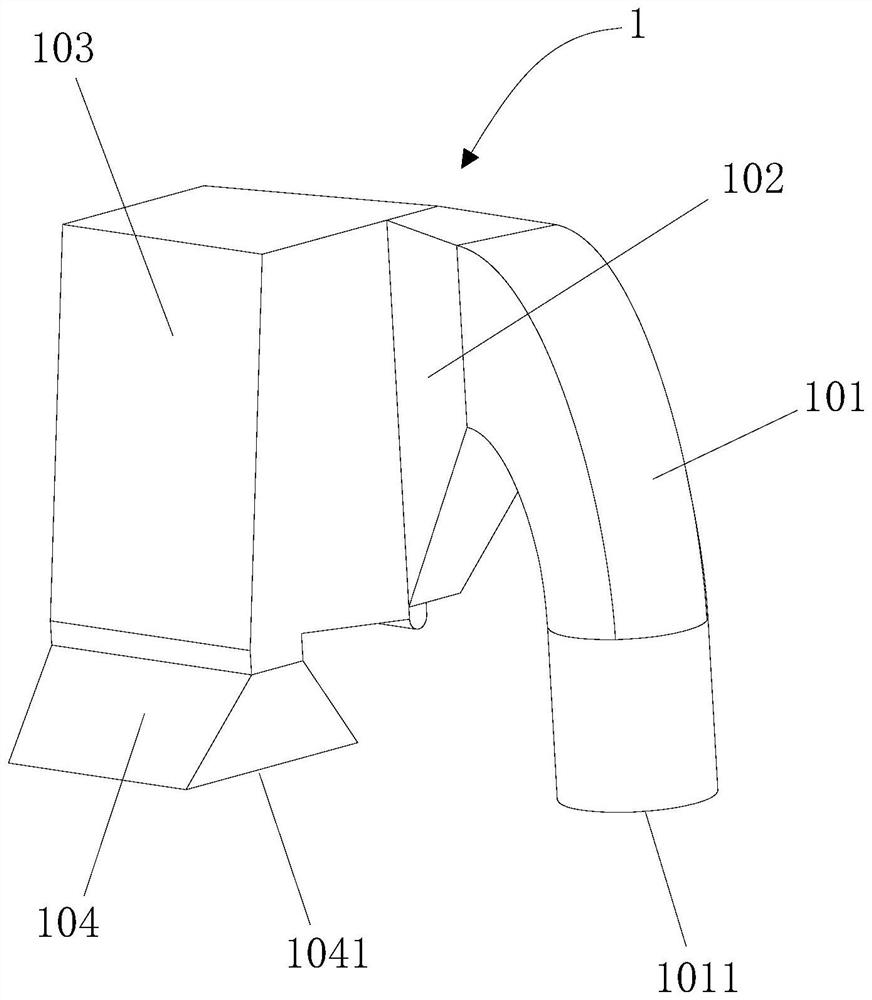

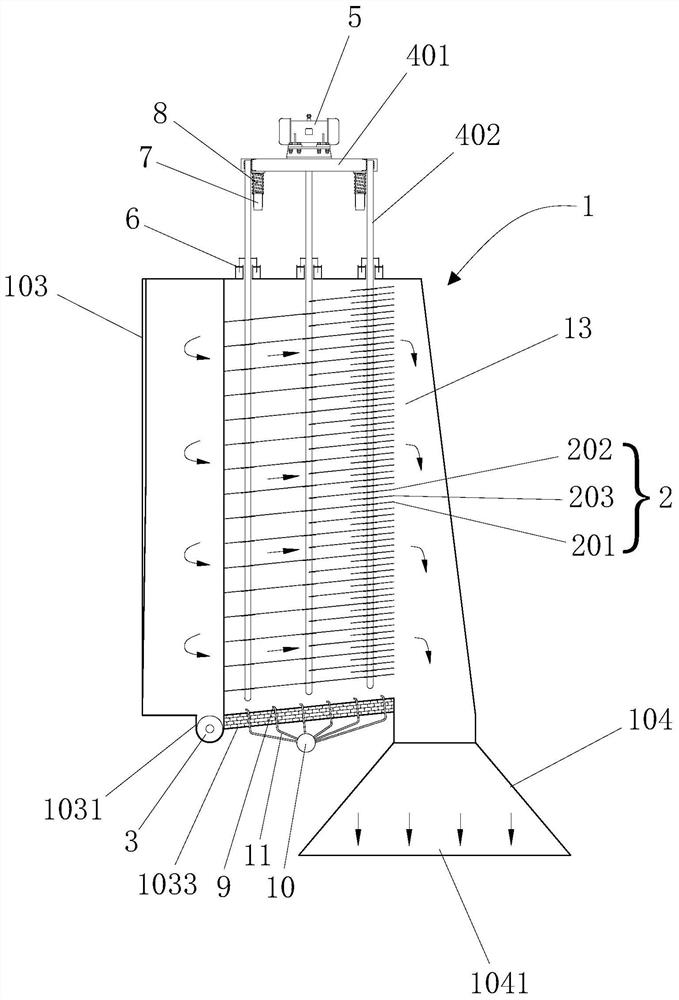

Method and device for continuously separating oil-water slag without dismantling and cleaning

InactiveCN102503008ABeneficial to emergeEasy dischargeWater/sewage treatment with mechanical oscillationsMultistage water/sewage treatmentStopped workSlag

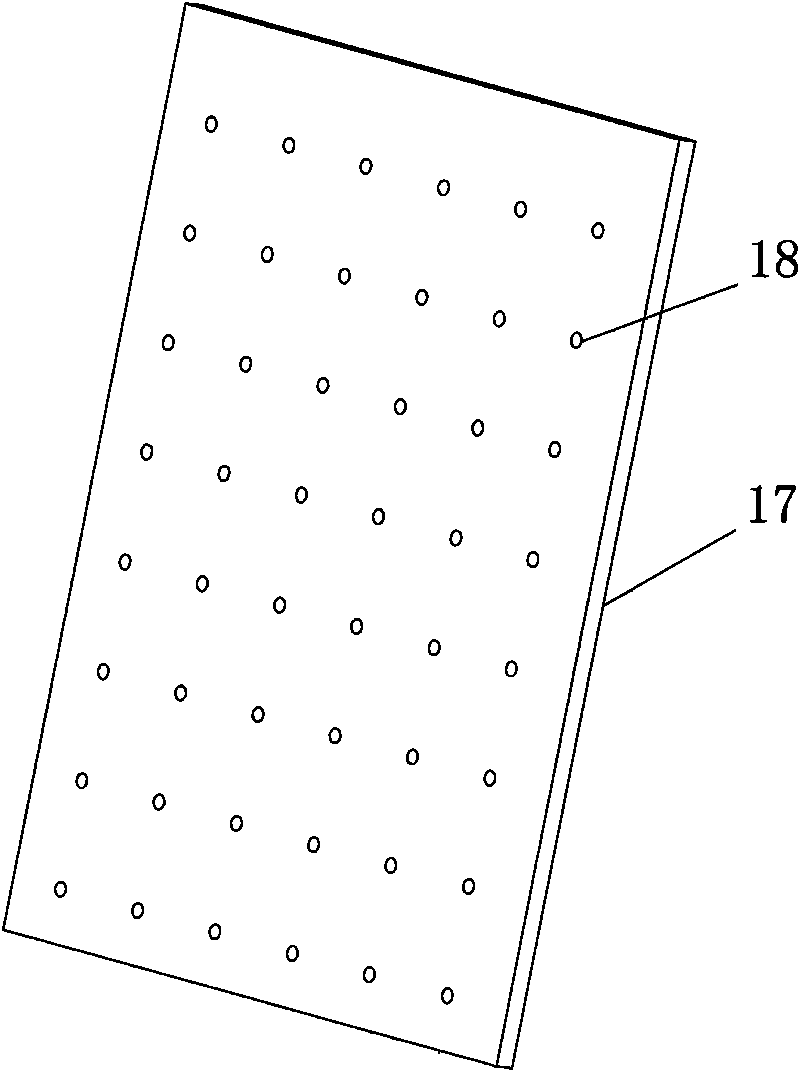

The invention provides a method and a device for continuously separating oil-water slag with dismantling and cleaning. Due to the adoption of a technology of combining gravity separation, air floatation separation, ultrasonic separation and cleaning and the like, wastewater containing oil and slag is separated and treated. The device is a vertical tank type sealing container which is arranged vertically, wherein the upper part of the container is rectangular; the lower part of the container is of an inverted pyramidal shape; a rectangular casing is externally surrounded by an ultrasonic generator and is internally divided into two inner cavities with the different sizes by a partition board; an oil drain port, a wastewater inlet, rectangular inclined plates arranged in a staggered way andan air floatation coiled pipe are arranged in the bigger inner cavity; a clear water outlet, a rectangular dense hole filtering mesh plate, a rectangular mesoporous filtering mesh plate and a rectangular gross porous filtering mesh plate are respectively arranged in the smaller inner cavity; and a slag discharging opening is connected to the lower end of a groove body at the tank bottom of the inverted pyramidal shape. The device is advanced in separation method, simple in structure and high in treatment efficiency; and particularly, in the production, internal cleaning can be carried out without stopping work and dismantling a casing of the device, and thus the continuous high-efficiency operation of the equipment can be ensured.

Owner:HUBEI UNIV +1

Method for combined extraction of variety of functional components of ginger

ActiveCN103012095AStrong acid-base sensitivityTo achieve the purpose of separationHydrolasesCarbonyl compound separation/purificationWater bathsFiltration

The invention relates to a method for combined extraction of a variety of functional components of ginger. The method comprises the following steps of: cutting the ginger into small pieces, adding anhydrous ethanol, pulping, centrifuging, performing rotary evaporation on supernatant fluid after centrifuging in vacuum, treating a rotary evaporation solution in a water bath to volatilize the ethanol, drying the solution to obtain gingerol, and drying a concentrated solution to obtain a powdery curcumin finished product; and re-dissolving sediment after centrifuging in a phosphate buffer solution, filtering, centrifuging the supernatant fluid, slowly adding the ethanol, performing ice bath on the supernatant fluid, standing, performing suction filtration to obtain wet enzyme powder, freezing and drying to obtain dry enzyme powder. By adopting the method, three types of active ingredients including the gingerol, curcumin and ginger protease can be obtained synchronously, so that the production efficiency is improved, the production cost is reduced, the utilization ratio of raw materials is improved, and the method is high in applicability and wide in application range and has a broad industrialization and market prospect.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Method for separating and extracting calcium tungstate and tin slag by utilizing tungsten-containing tin furnace residue or tungsten-tin middlings

InactiveCN101148268ATo achieve the purpose of separationNo pollution in the processCalcium/strontium/barium compoundsTungsten compoundsSlagHigh pressure

The process of separating and extracting calcium tungstate and tin slag from tungsten-containing tin slag or mixed W-Sn middlings includes the steps of grinding tungsten-containing tin slag or mixed W-Sn middlings into powder, adding NaOH and oxidant through high pressure stirring and leaching to obtain Na2WO4 solution with impurity and tin slag, depurating the Na2WO4 solution to obtain purified Na2WO4 solution, adding CaCl2 to react obtaining wet CaWO4 and stoving to obtain calcium tungstate. The process is simple, and has great production capacity, best utilization of non-ferrous metal resource, environment friendship and other advantages.

Owner:黄玄俊

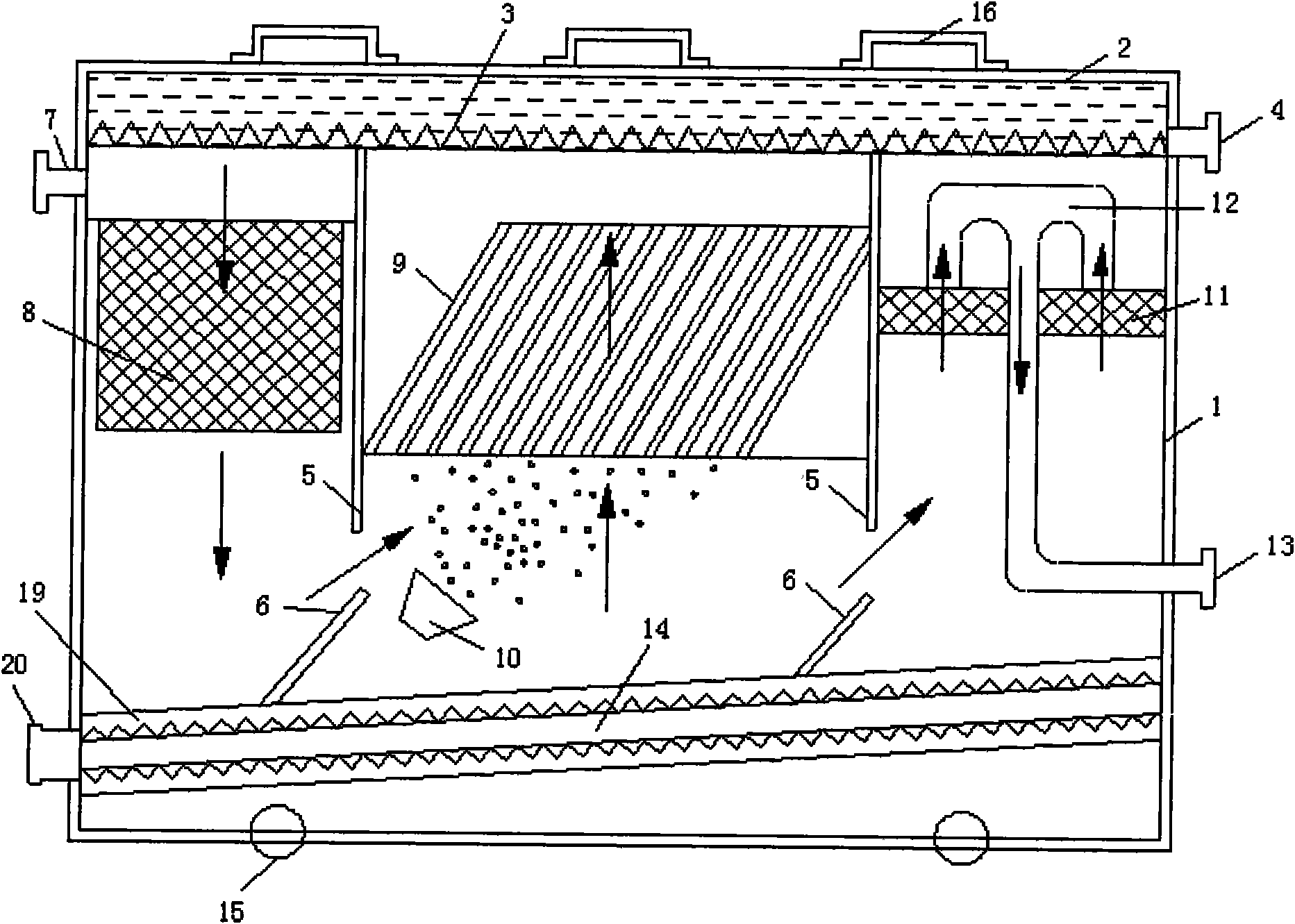

Residue, water and oil separator

InactiveCN101597109AEasy to separateAchieve the purpose of initial precipitationFatty/oily/floating substances removal devicesMultistage water/sewage treatmentFiberMicro bubble

The invention discloses a residue, water and oil separator, comprising a tank body, a cover plate covering the tank body, a saw tooth-shaped overflow weir is arranged at the inner wall of the upper part of the tank body, an oil outlet is arranged at the outer side of the upper part of the tank body, the tank body is divided into three grids by two clap boards, the lower part of the two clap boards is provided with two river-diversion and water-distribution plates; a sewage water inlet is arranged at one side of a first grid, a slag-separating screen cloth basket is arranged on the upper part of the first grid, a shallow bed is arranged on the upper part of the second grid, micro-bubble spray nozzle is arranged at the lower part of the shallow bed and is externally connected with an air pump, a fiber adsorbent bed is arranged on the upper part of the third grid, a water outlet is arranged on the upper part of the fiber adsorbent bed, the water outlet guides to the pure water outlet in the lower part. The residue, water and oil separator of the invention has good separating effect and wide range of application.

Owner:黄巧玲

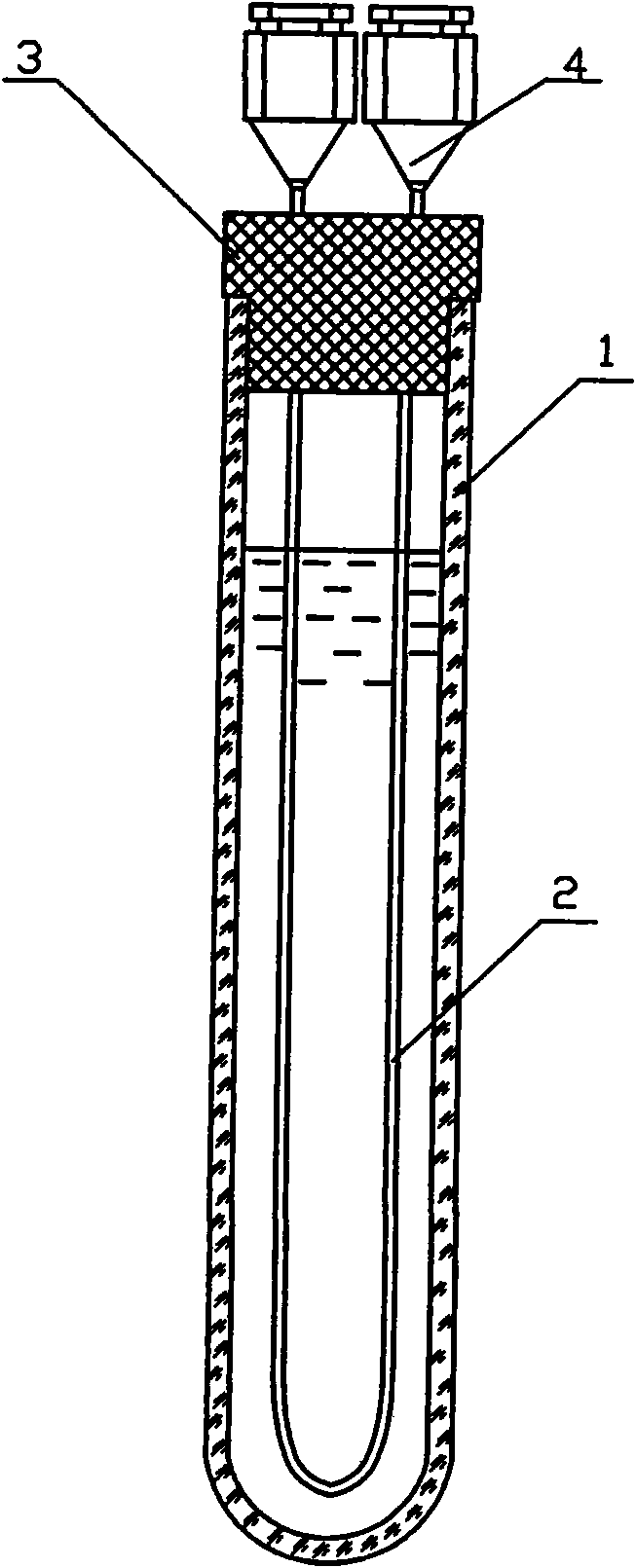

Centrifugal ultrafiltration device suitable to be used in preprocessing of micro sample

InactiveCN101898088AEasy to manufactureTo achieve the purpose of separationSemi-permeable membranesPreparing sample for investigationFiberUltrafiltration

The invention discloses a centrifugal ultrafiltration device suitable to be used in the preprocessing of a micro sample, which comprises a centrifuge tube, and is characterized in that a hollow fiber film which is parallel to the axis of the centrifuge tube and of which the outlet extends out of the centrifuge tube are arranged in the centrifuge tube. The centrifugal ultrafiltration device can bewidely used in the preprocessing of the micro sample as well as the separation, purification and concentration of micro biological samples. The use of the device is simple, quick and convenient; the processed sample suffers little interference and has high sensitivity; and, the service life of a chromatographic column is prolonged effectively.

Owner:HEBEI MEDICAL UNIVERSITY

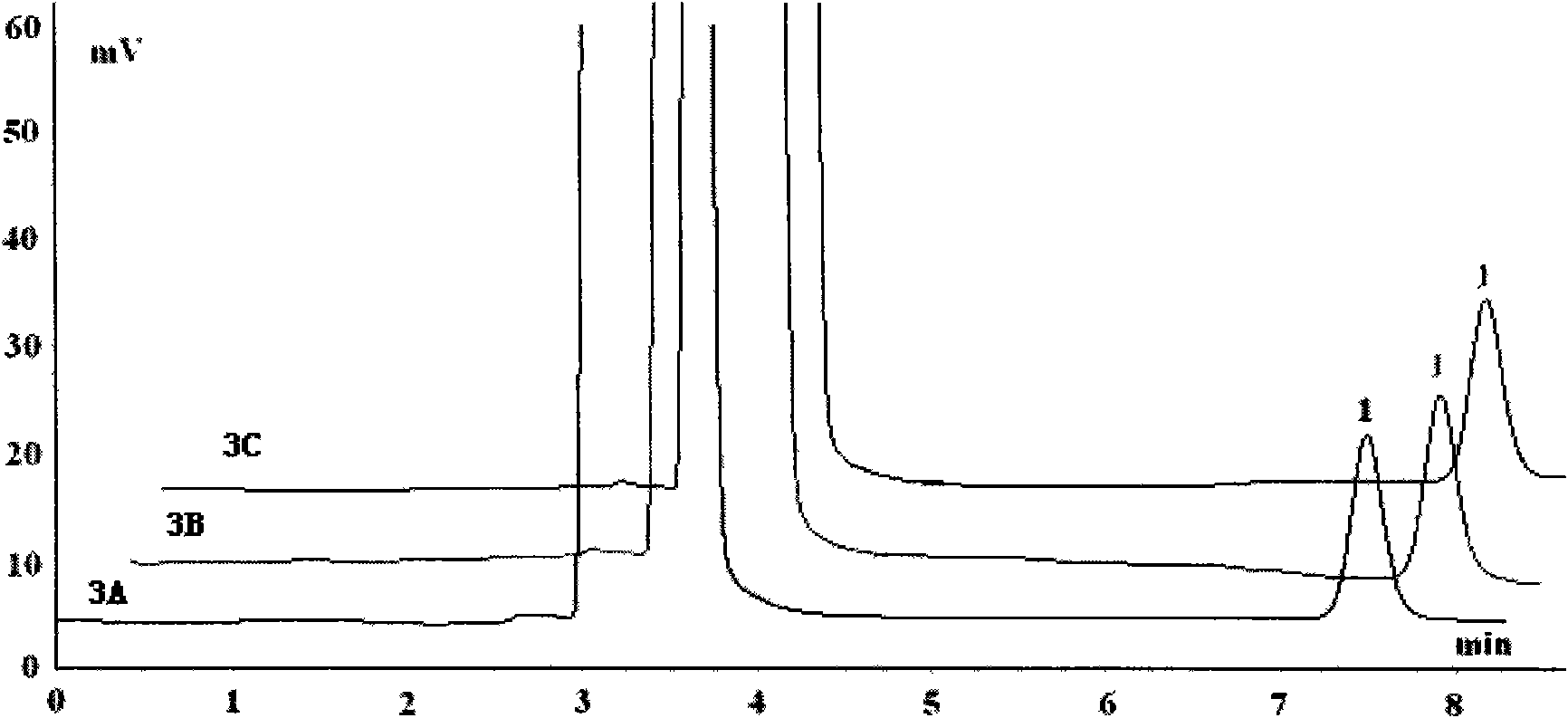

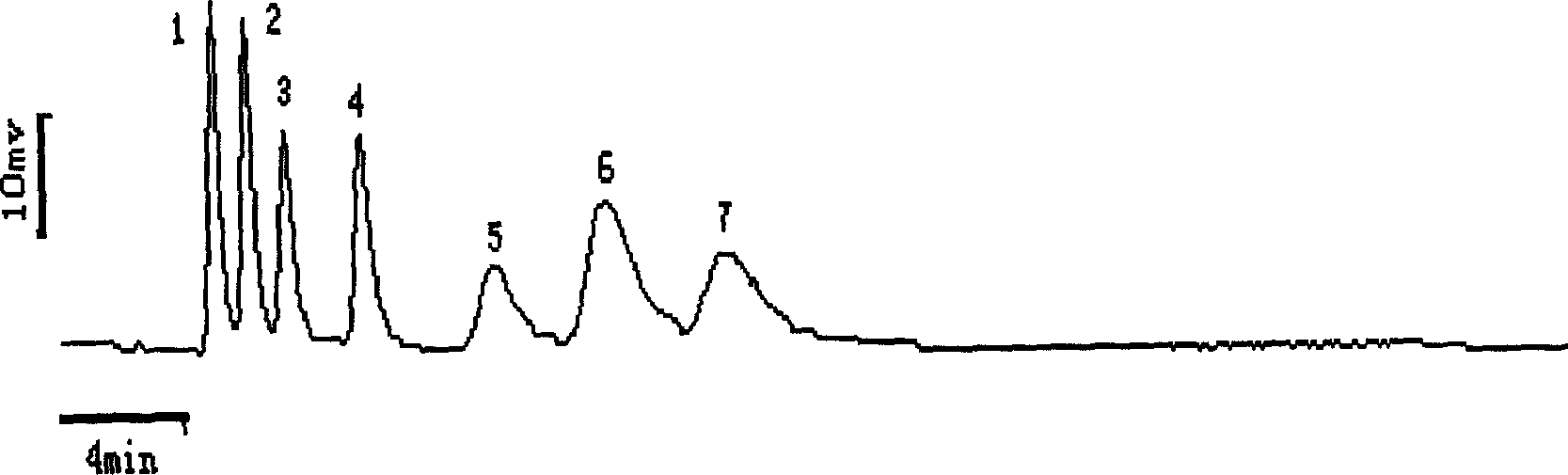

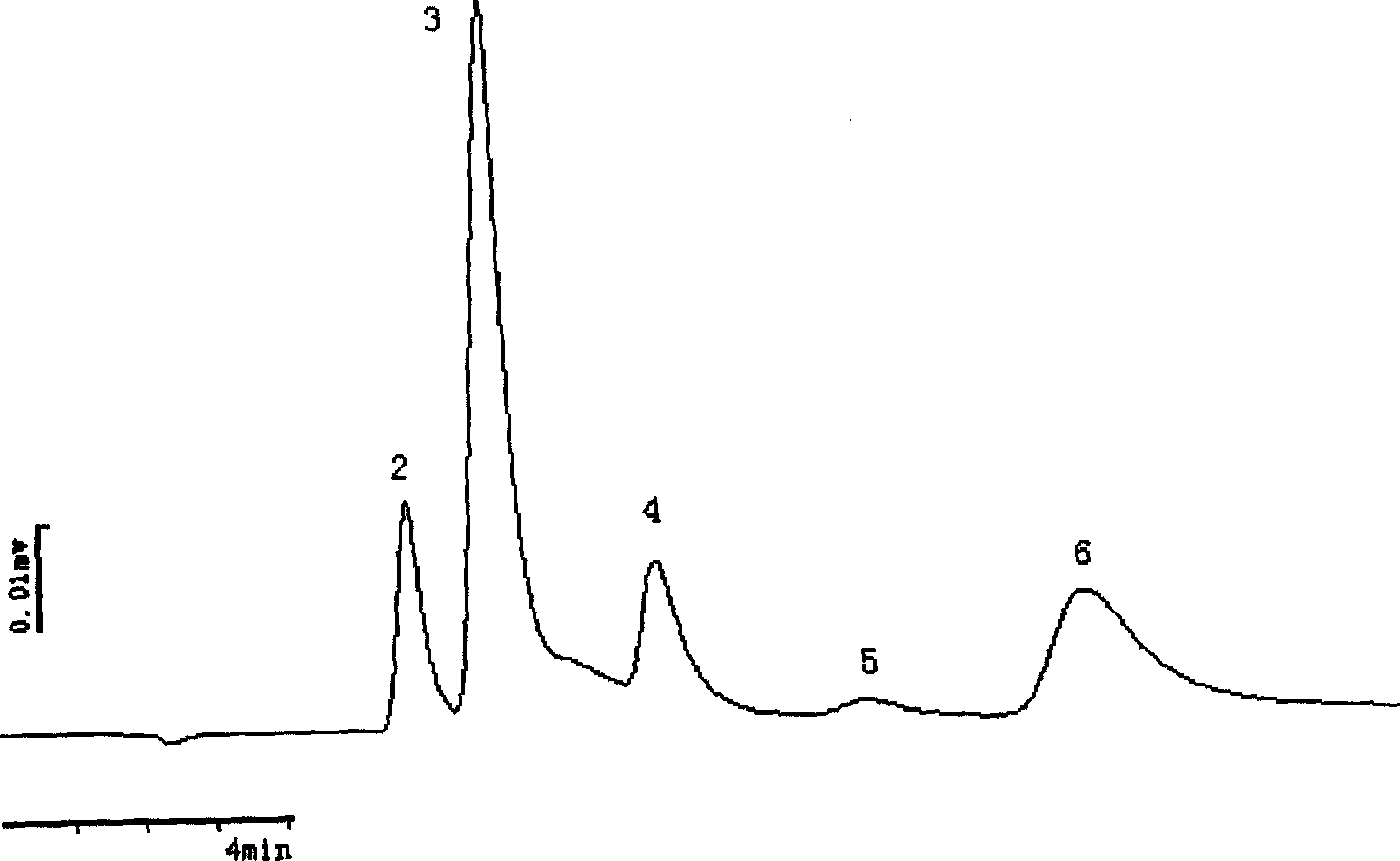

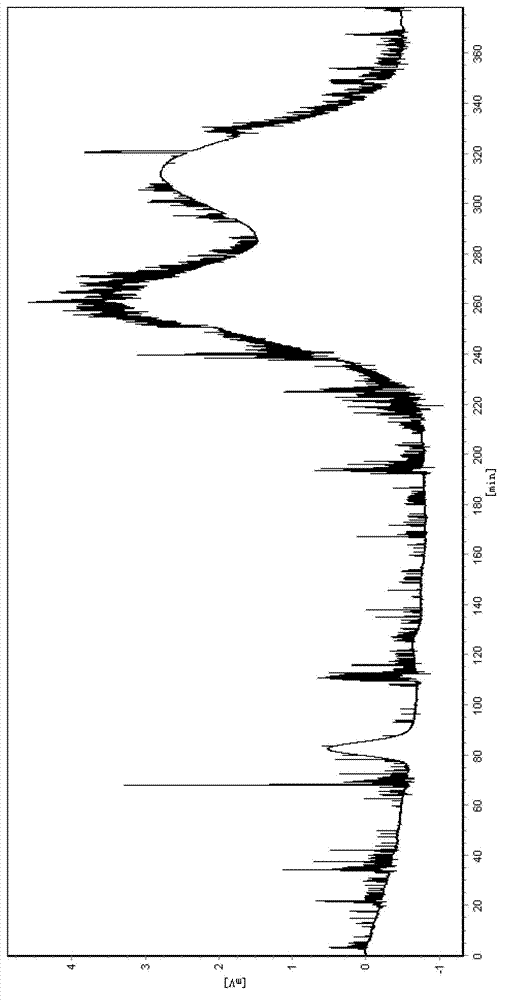

Linkage type cation chromatographic column and its preparation method

InactiveCN1591005AAdjustable exchange capacitySatisfied with the analysis effectComponent separationAlkaline earth metalIon exchange

The present invention provides a preparation method of cationic chromatographic column. It is characterized by that said method uses styrene-divinylbenzene filler as base body, and adopts grafting chemical process to make the weakly cationic ion-exchange function groups of carboxylic group and phosphonic group be bonded no the high-molecular base body so as to obtain the invented high-effective cationic chromatographic column which can be used for separating cations of alkali metal, ammonium and alkali earth metal, etc. by means of one-step process.

Owner:ZHEJIANG UNIV

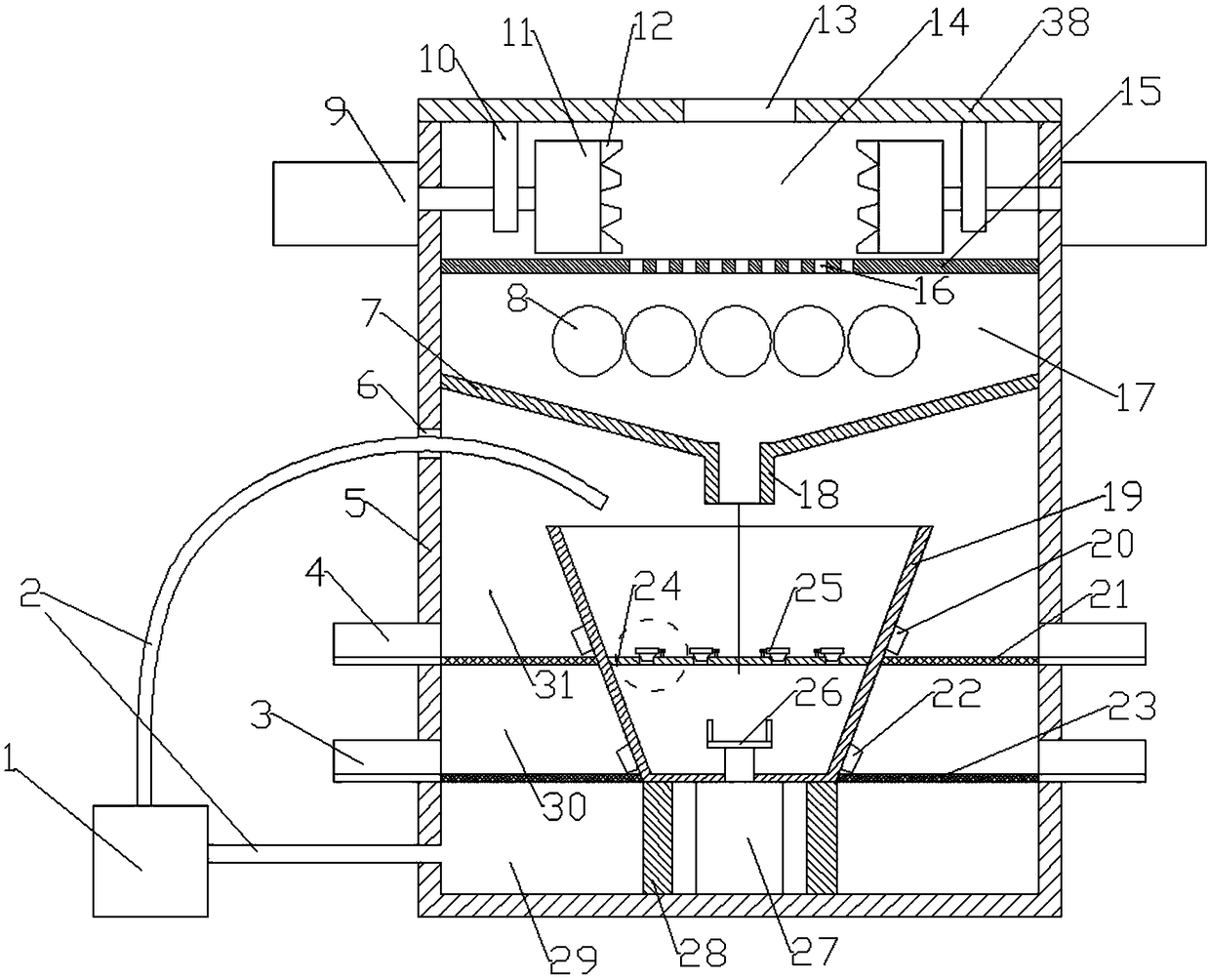

Apparatus used for sorting fine grained metal ore

InactiveCN108816480ACrushed fullyTo achieve the purpose of separationGrain treatmentsWet separationEngineeringFine grain

The invention discloses an apparatus used for sorting fine grained metal ore. The apparatus comprises a cuboid housing and a top cover at top of the housing, a feed inlet is arranged at middle of thetop cover, a material is added in the housing from the feed inlet, a blanking plate, a tunnel plate, a second filter screen and a first filter screen are arranged in the housing from up to down, a crushing chamber is arranged between the top cover and the blanking plate, a grinding chamber is arranged between the blanking plate and the tunnel plate, a second material chamber is arranged between the tunnel plate and the second filter screen, a first material chamber is arranged between the second filter screen and the first filter screen, a water chamber is arranged between the first filter screen and a housing base plate, a separating cylinder is arranged at the middle part of a second material chamber and the first material chamber, a separation plate is arranged at the middle in the separating cylinder, holes are uniformly distributed at the separation plate, a floating plug is arranged in the hole, and a stirring head is arranged at the bottom of the separating cylinder. The motor is used for driving the water in the separating cylinder through a stirring head to form eddy, which achieves a purpose of particle separating, and a method is advanced.

Owner:郑金华

Method for enriching and preparing pure gold from antimony-gold alloy through potential control

ActiveCN107460337AImprove direct yieldTo achieve the purpose of separationProcess efficiency improvementSulfite saltSlurry

Provided is a method for enriching and preparing pure gold from an antimony-gold alloy through potential control. The method for enriching and preparing the pure gold from the antimony-gold alloy through potential control comprises the following steps that after the antimony-gold alloy is crushed and levigated to a required particle size, hydrogen peroxide is added into a pure hydrochloric acid system to conduct potential controlling and oxidizing leaching, slurry after being leached is added into copper powder to conduct potential controlling and displacing, raw gold powder is obtained after displacement residue is soaked and digested in concentrated sulfuric acid, the hydrogen peroxide is added into a hydrochloric acid solution containing the raw gold powder to conduct potential controlling and gold leaching by chlorination, gold leaching liquid is added into sodium hydroxide and sodium sulfite to conduct potential controlling and reduction, and gold powder is obtained, and pure gold powder is obtained after the gold powder is washed. According to the method for enriching and preparing the pure gold from the antimony-gold alloy through potential control, a potential control mode is adopted to achieve the purpose that the processes of oxidation leaching, displacement, gold leaching by chlorination, reduction and the like are adjustable and controllable, and the direct recovery rates of gold and silver reach to over 99.9% and 99.0% correspondingly. The method has the advantages of being good in metal separation effect, stable in technical index, short in technological process and the like.

Owner:CENT SOUTH UNIV

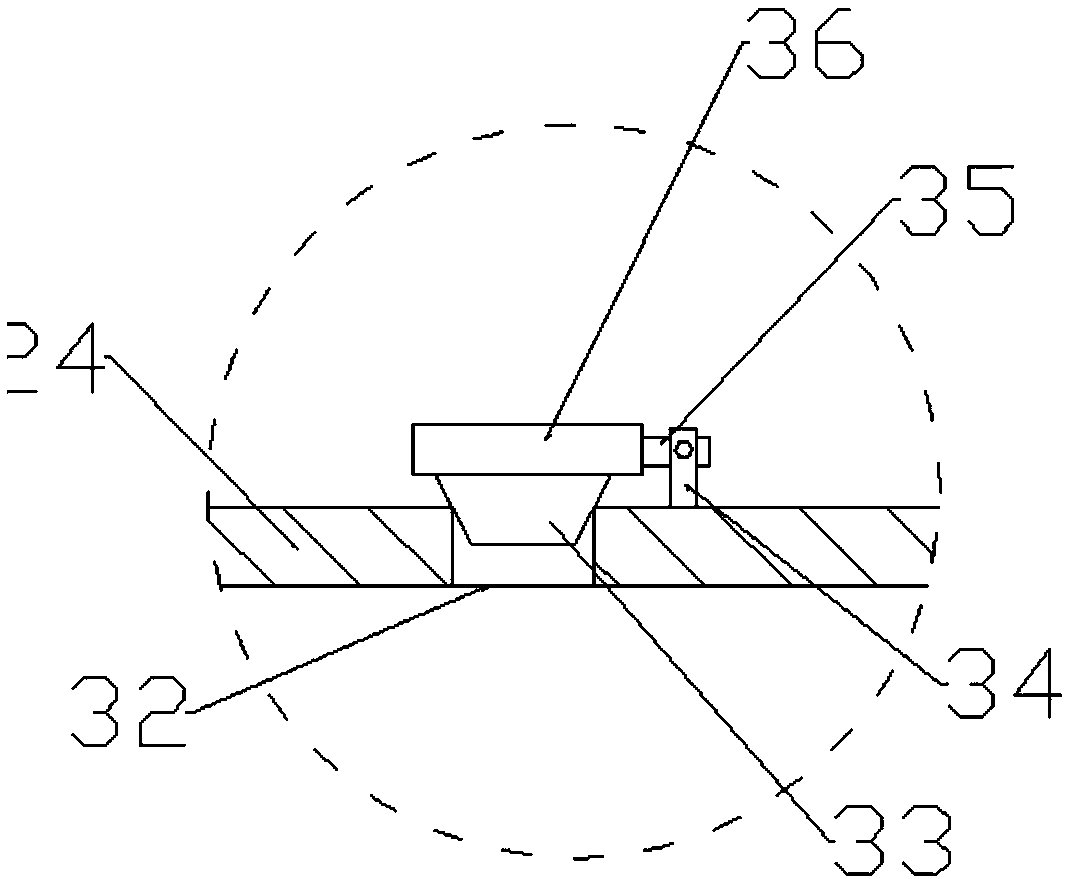

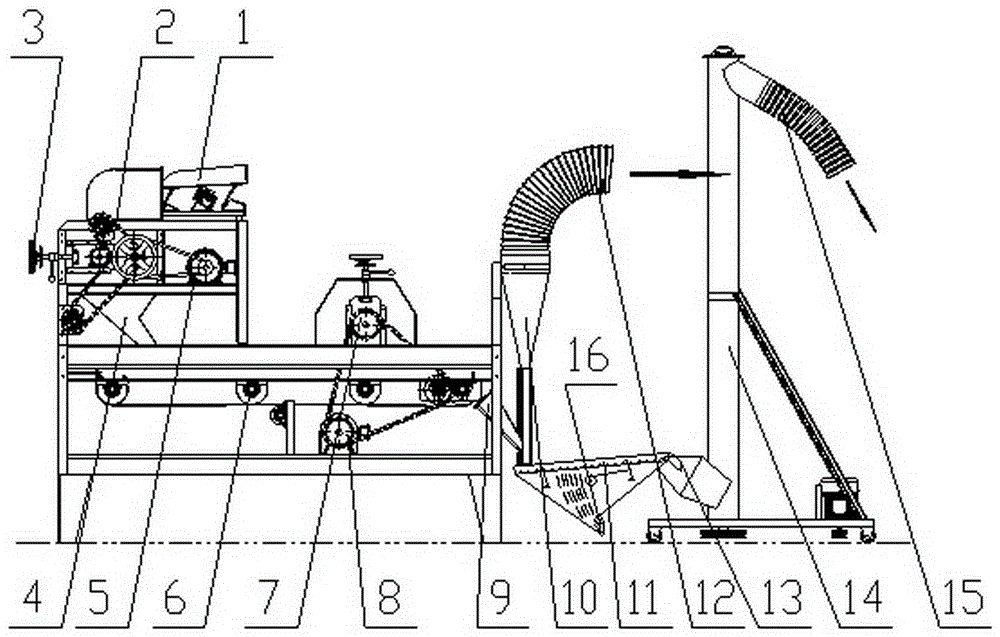

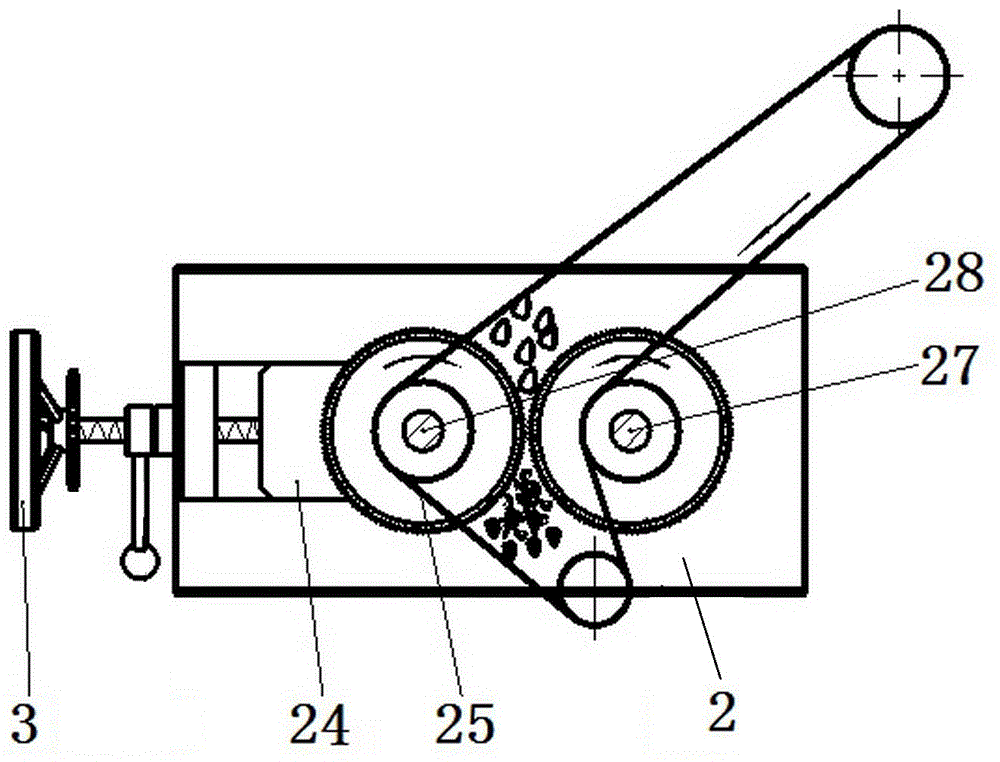

Combined badam shell breaking and shell-kernel separating machine

PendingCN106723119AImprove the efficiency of breaking upTo achieve the purpose of separationGas current separationHuskingDrive motorEngineering

The invention discloses a combined badam shell breaking and shell-kernel separating machine. A primary shell breaker with a vibratory feeder is arranged above the front portion of a rack, a driving shell breaking roller and a driven shell breaking roller are horizontally arranged in the primary shell breaker side by side at intervals, chain wheels are installed at the shaft ends of the driving shell breaking roller and the driven shell breaking roller, the driving shell breaking roller and the driven shell breaking roller are driven to perform opposite rotation by a driving motor through chains, a discharging hopper below the primary shell breaker is located above a conveying belt, the discharging end of the conveying belt is in linkage with a feeding hopper of a secondary shell breaker installed in the middle of the rack, concave pits or convex ribs are evenly distributed on the surfaces of the driving shell breaking roller and the driven shell breaking roller in the secondary shell breaker at intervals, a discharging port of the secondary shell breaker is connected with an air inlet pipe of a negative pressure fan, the lower end of the air inlet pipe of the negative pressure fan is located on a vibratory separation machine, a kernel discharging port is formed in the lower end of the vibratory separation machine, an outer-side-end separation discharging port of the vibratory separation machine is in linkage with a vertical lifter, and a discharging pipe of the vertical lifter is in linkage with the vibratory feeder.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

Extraction and refining method of polygonatum polysaccharide

The invention relates to an extraction and refining method of polygonatum polysaccharide, belonging to the technical field of extraction processes of polygonatum extracts. The method of the inventionsolves the problems of a plurality of impurity types, complex refining process, long technological process and low product rate in conventional polygonatum polysaccharide extraction methods. Accordingto the method, a membrane extraction technology and a complexing extraction technology are combined; organic boric acid is adopted as a complexing agent of polygonatum polysaccharide at an extractionagent side, the organic boric acid and the polysaccharide are subjected to specific complexing, polar polygonatum polysaccharide is changed into a non-polar complex through a complexing reaction, andcomplexing extraction is conducted, so the purpose of separation is achieved; and after the complexing extraction is finished, the complexing action and an organic solvent are removed through back extraction so as to obtain a high-purity polygonatum polysaccharide product. During membrane extraction in the invention, the combined action of membrane extraction and complexing extraction is realized; namely, besides separation through polarity difference in the membrane extraction process, the screening action of a membrane is added.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Preparation method of high-purity indole

The invention relates to a preparation method of high-purity indole and belongs to the technical field of organic synthesis. The preparation method comprises: subjecting indole as a raw material to additive reaction with sodium hydrogen sulfite to obtain 2-sodium sulfonate indoline, solvent washing to remove impurities, and adding alkali for hydrolyzing to obtain the high-purity indole. The preparation method is characterized mainly in that main impurity 3-methylindole contained in indole during a reaction process never reacts with sodium hydrogen sulfite for the purpose of separating indole and 3-methylindole. Both the additive reaction and hydrolytic reaction use as water a reaction medium, a solvent is recyclable, the materials are low in cost, and yield is high.

Owner:NANTONG WANNIANCHANG PHARMA

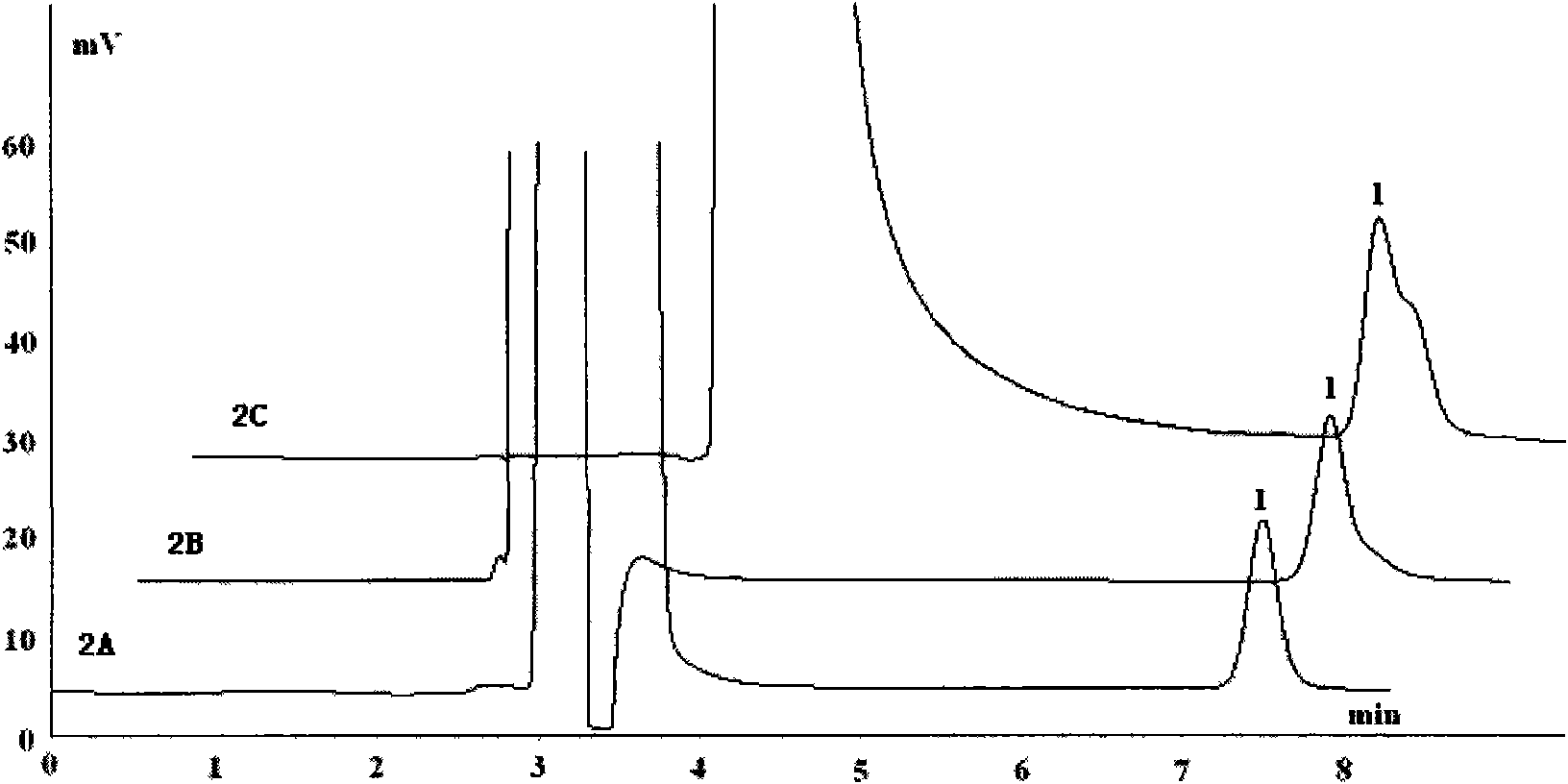

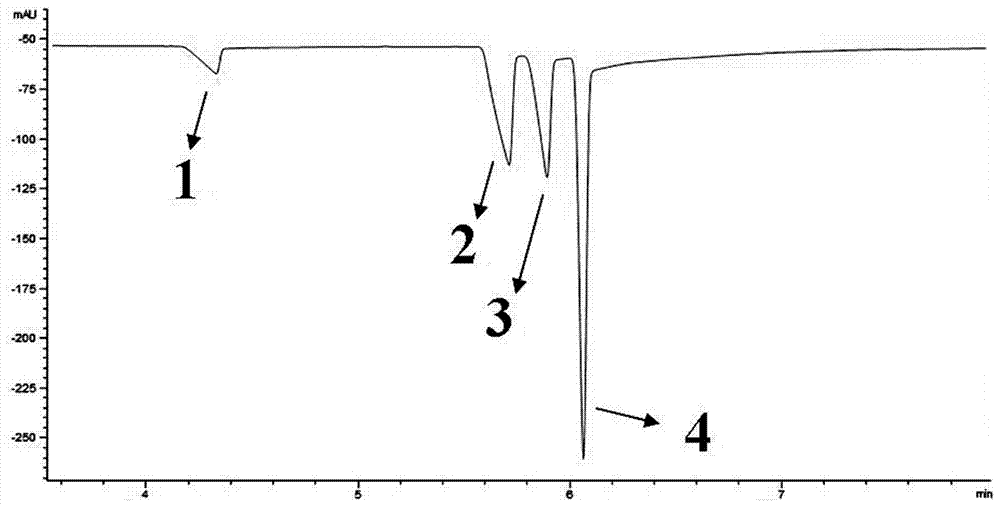

Method for detecting metal cations in liquid by capillary electrophoresis

InactiveCN107389774AReduced UV signalTo achieve the purpose of detectionMaterial analysis by electric/magnetic meansCapillary electrophoresisElectrophoresis

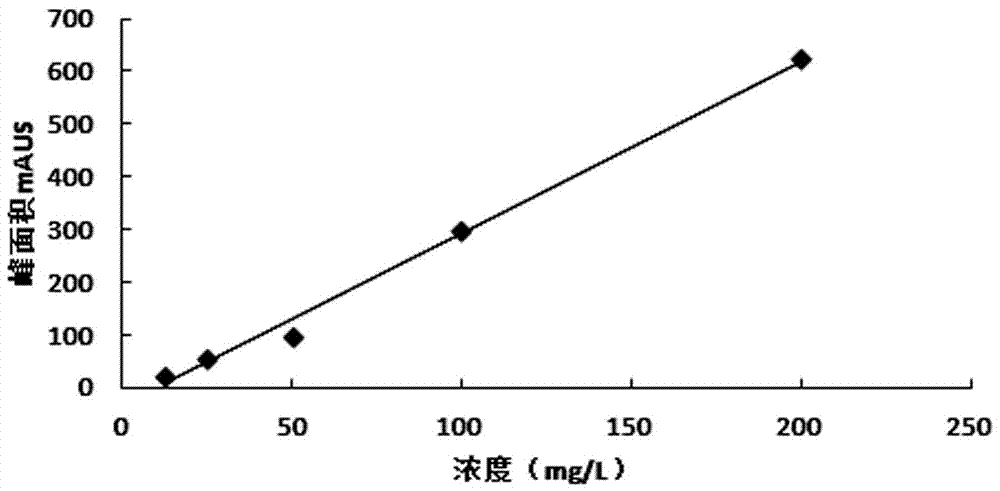

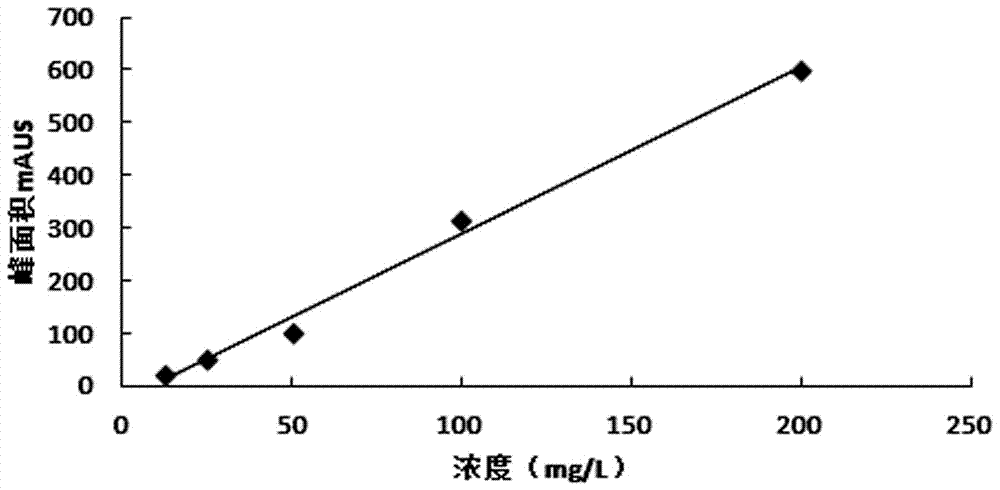

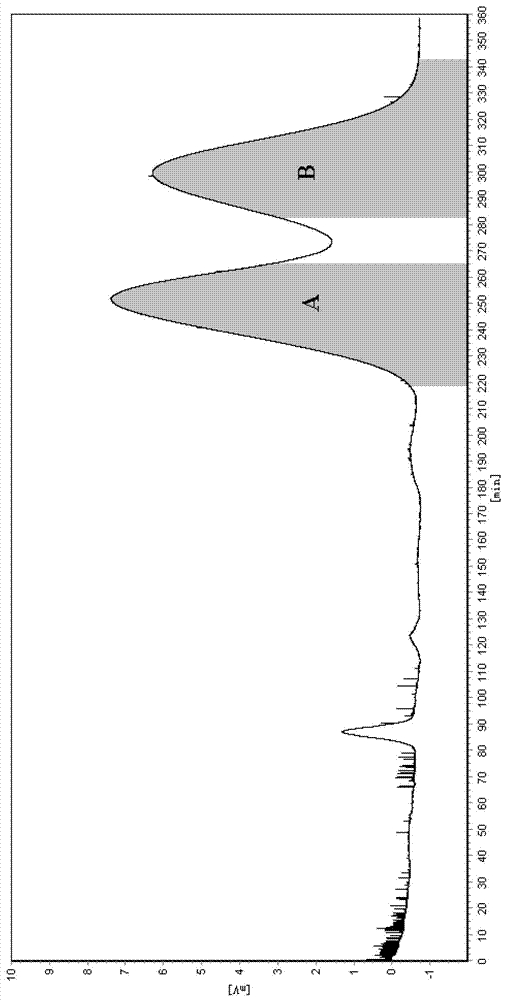

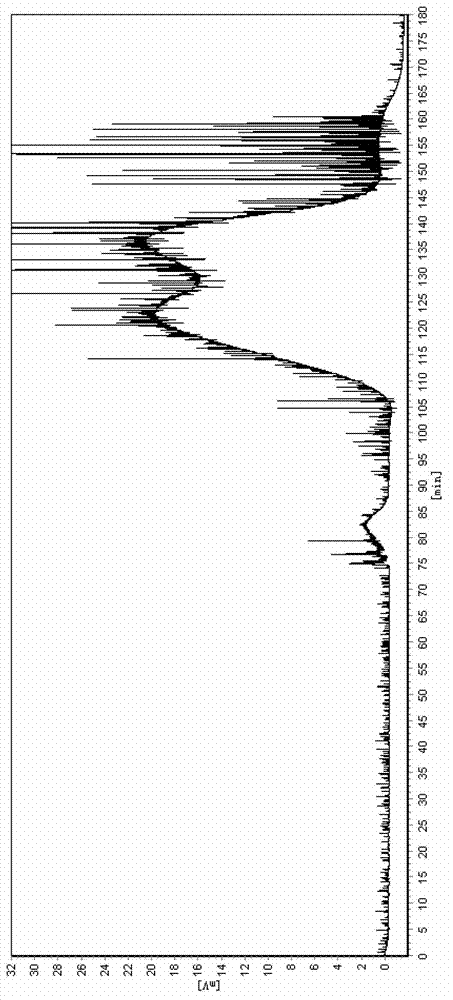

The invention discloses a method for detecting metal cations in a liquid by capillary electrophoresis, belongs to the technical field of chemical detection, and can solve the problem of a narrow linear range of detection techniques in the prior art. The method comprises the following steps: respectively preparing single standard solutions of ions, and using a capillary electrophoresis apparatus to obtain peak appearance time of the ions; preparing mixing standard solutions with different concentrations of the ions, and using the capillary electrophoresis apparatus to obtain the linear characteristic relationship between the concentrations of the ions and peak areas; detecting a sample to be tested to obtain the peak areas, calculating the concentrations of the ions in the sample to be tested. The method has the advantages of large peak interval, wide linear range, high accuracy and high detection speed.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

Splitting method for racemic 2-benzene propanoic acid

InactiveCN103113211ATo achieve the purpose of separationCarboxylic compound separation/purification3-phenylpropanoic acidBenzene

The invention discloses a splitting method for racemic 2-benzene propanoic acid. The splitting method comprises the following steps: using an organic solvent A, an organic solvent B and a phosphate buffer solution containing hydroxypropyl-beta-cyclodextrin to constitute a solvent system according to the volume ratio of 1-8: 2-6: 10, uniformly mixing, and standing for stratification to get an organic phase and a water phase; dissolving racemic 2-benzene propanoic acid with the obtained water phase to prepare a sample; and splitting racemic 2-benzene propanoic acid by adopting high-speed counter-current chromatography, separating a prepeak eluate and a postpeak eluate, and recovering to get levo-2-benzene propanoic acid monomer and dextro-2-benzene propanoic acid monomer. By adopting the method disclosed by the invention to split racemic 2-benzene propanoic acid, the higher separation degree can be achieved; and the method is further suitable for various types of preparation type counter-current chromatographic instruments, and the levo-2-benzene propanoic acid monomer and the dextro-2-benzene propanoic acid monomer can be obtained by separation.

Owner:ZHEJIANG UNIV OF TECH

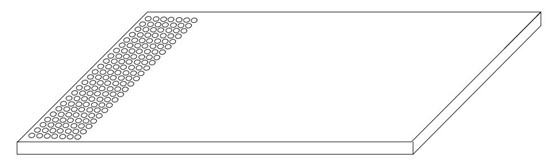

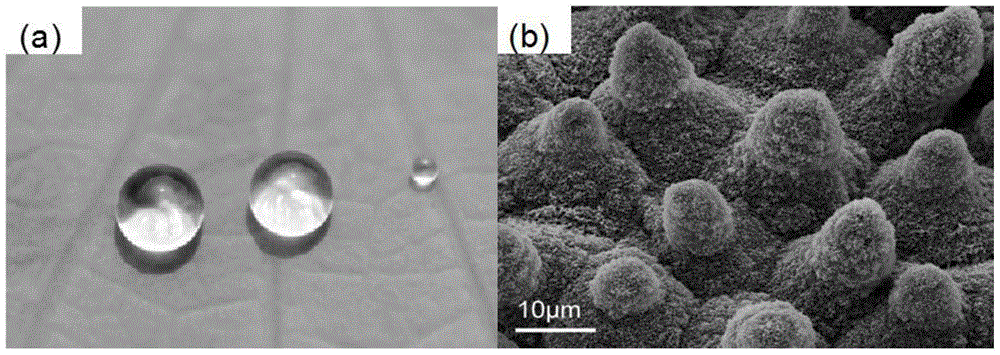

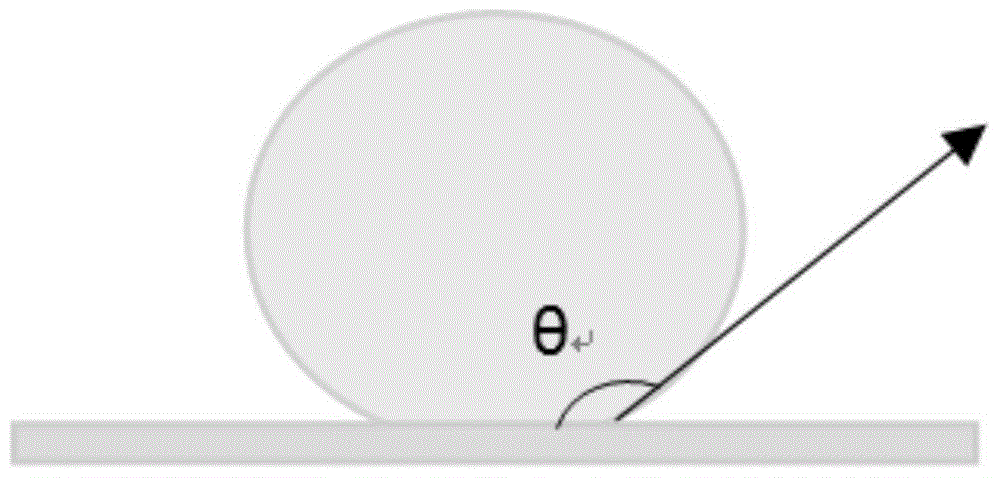

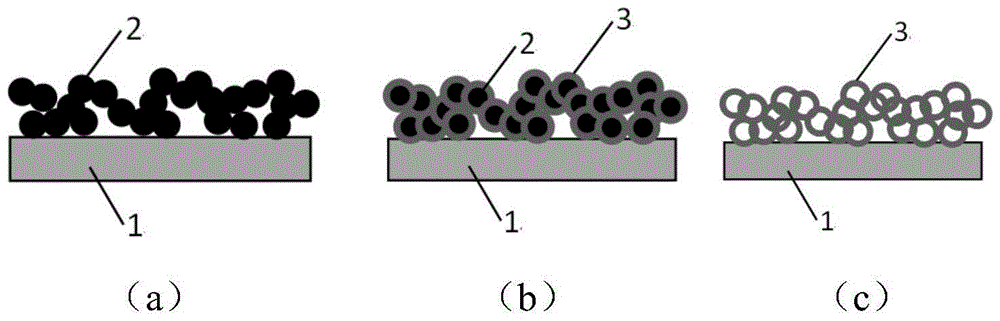

Preparation method of oil-water separation device

ActiveCN105664533AEfficient separationImprove separation efficiencyFatty/oily/floating substances removal devicesChemical vapor deposition coatingChemical reactionPhysical chemistry

The invention relates to a preparation method of an oil-water separation device. A copper mesh is used as a material, and a carbon black film is used as a template. A microscopic surface is constructed on the copper mesh by a chemical reaction, and then hydrophobic treatment is carried out to obtain a special invasive surface for oil-water separation. Before modification, the copper mesh is super-hydrophilic and superoleophobic. After modification, the copper mesh is super-hydrophobic and superoleophilic. Thus, different oil-water separation purposes can be achieved according to different actual situations. By different surface tension properties of water and oil, pollutants in dissolved state and emulsification state can be effectively separated. Thus, separation efficiency is greatly increased. The preparation method is simple to operate and consumes short time.

Owner:彭长四

Method for preparing high-quality diatomite by oscillation-based hydrochloric acid process

InactiveCN104310411AIncreased quality and use of chemical activityDiffusion fastSilicaAfter treatmentIron content

The invention relates to a method for preparing high-quality diatomite by an oscillation-based hydrochloric acid process. According to the method, diatomite concentrate obtained by preliminary purification is taken as a raw material, heating reaction is performed with HCl under oscillation, filtration is performed to filter out sigma x TCln soluble matters, hydrochloric acid and the like, and washing, drying and calcination are performed to remove organic impurities, carbon and water in micropores of diatomite so as to obtain high-purity diatomite. According to the method provided by the invention, perfect biological porous active structure properties of amorphous SiO2 of diatomite are retained, diatomite after treatment has the advantages of high activity, high whiteness and low iron content, the whiteness can achieve 88-96, the content of SiO2 in diatomite is more than 98%, the iron content is lower than 0.4%, the specific surface is more than 20m<2> / g, and the quality and using properties of a product are greatly improved.

Owner:桂林新竹大自然生物材料有限公司 +1

A method for reclaiming lithium and iron from lithium iron phosphate

ActiveCN108899601BDoes not affect the leaching rateHigh purityWaste accumulators reclaimingProcess efficiency improvementFerric hydroxideIron sulfate

The invention discloses a method for recovering lithium from lithium iron phosphate. The method disclosed by the invention comprises the following steps: dissolving waste lithium iron phosphate slag with sulfuric acid and ferric sulfate, leaching iron, lithium and phosphorus, adding an oxidizing agent, reacting iron and phosphate radicals to produce an iron phosphate precipitate and a small amountof ferric hydroxide, converting lithium into a water-soluble lithium sulfate solution, filtering to obtain the lithium sulfate solution, adding sodium carbonate into the lithium sulfate solution to prepare a lithium carbonate product, and adding sodium phosphate or phosphoric acid to prepare lithium phosphate; dissolving the lithium phosphate with ferric sulfate again to obtain the lithium sulfate solution and a compound taking iron phosphate as a principle component, returning the lithium sulfate solution to the system to prepare lithium carbonate, and calcining the iron phosphate slag to remove organic matters and carbon in the slag; and slurrying to prepare cell grade iron phosphate. According to the method for recovering lithium from lithium iron phosphate disclosed by the invention,the lithium is totally converted into the product lithium carbonate in the method, the process flow is short, the cost is low, the lithium recovery rate is 97%, the metal lithium in the lithium iron phosphate can be effectively recovered, and all the slag is converted into the cell grade iron phosphate.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

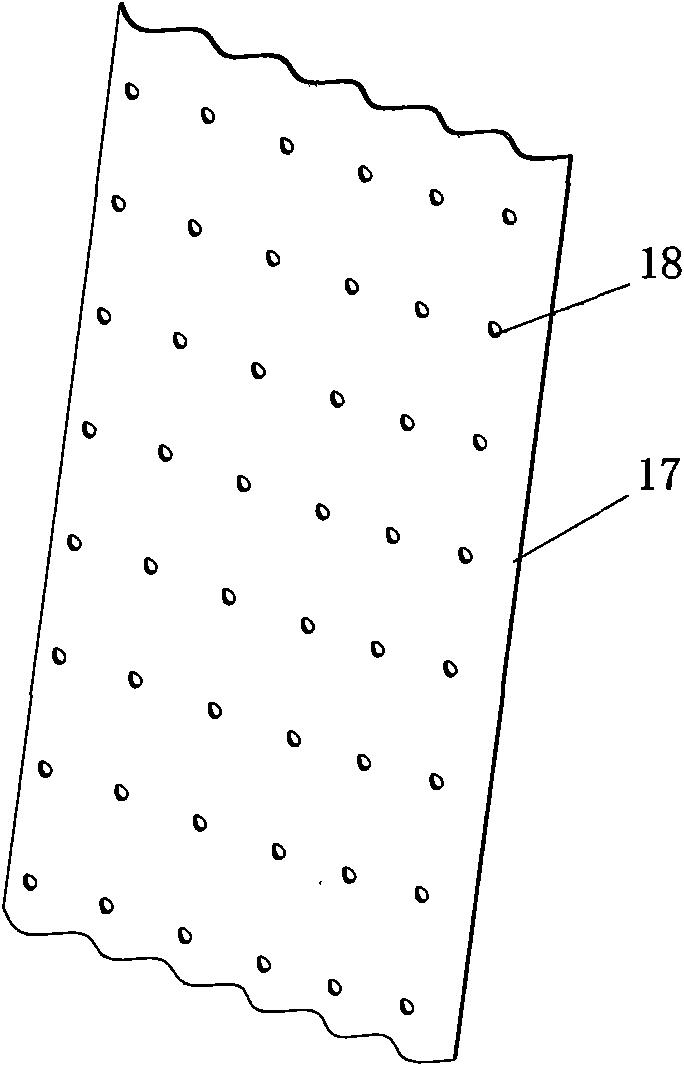

Novel fluid-air exchange filler

InactiveCN104307459AEvenly distributedFull exchangeGas treatmentDispersed particle separationPorosityAir purifiers

The invention relates to novel fluid-air exchange filler. The filler is formed by tightly winding or overlapping strip-shaped silk screens, and has the porosity of 86-95%, the bulk density of 660-760Kg / m<3>, and the specific area of 2000-3600m<2> / m<3>. The filler is dense in texture and uniform in pores, and can enable a fluid to form a uniform film on the surface of the filler to facilitate fluid-air exchange. When the novel fluid-air exchange filler is used in an air purifier, absorption liquid and polluted air are made to exchange sufficiently so as to remove pollutants for achieving the purpose of air purification. The novel fluid-air exchange filler can also be used for tail gas treatment and chemical rectification.

Owner:BEIJING YUZHUFENG TECH

Method for recovering metal from used it ion cell

InactiveCN1172404CTo achieve the purpose of separationReduce lossWaste accumulators reclaimingBattery recyclingDielectricCopper foil

The invented method includes the physical separation method combining with the preparation procedure of the cleaning wet recycle, providing the features of simple and high purity of the recovered metal. The invention includes following steps. With the disused lithium ion cells being burned in the high-temperature furnace, the organic dielectric is removed. After the smashing and sieving treatment, the oversize material is processed through the magnetic separation and the eddy current sorting so as to obtain the iron case, copper foil and aluminium foil etc. The undersize is processed through the steps of corrosion, filtering and electrolysis so as to obtain copper and cobalt. With carbonic acid radical being added to the solution richen in lithium ion, the high purity carbonate of lithiumis formed so as to recovery lithium.

Owner:IND TECH RES INST

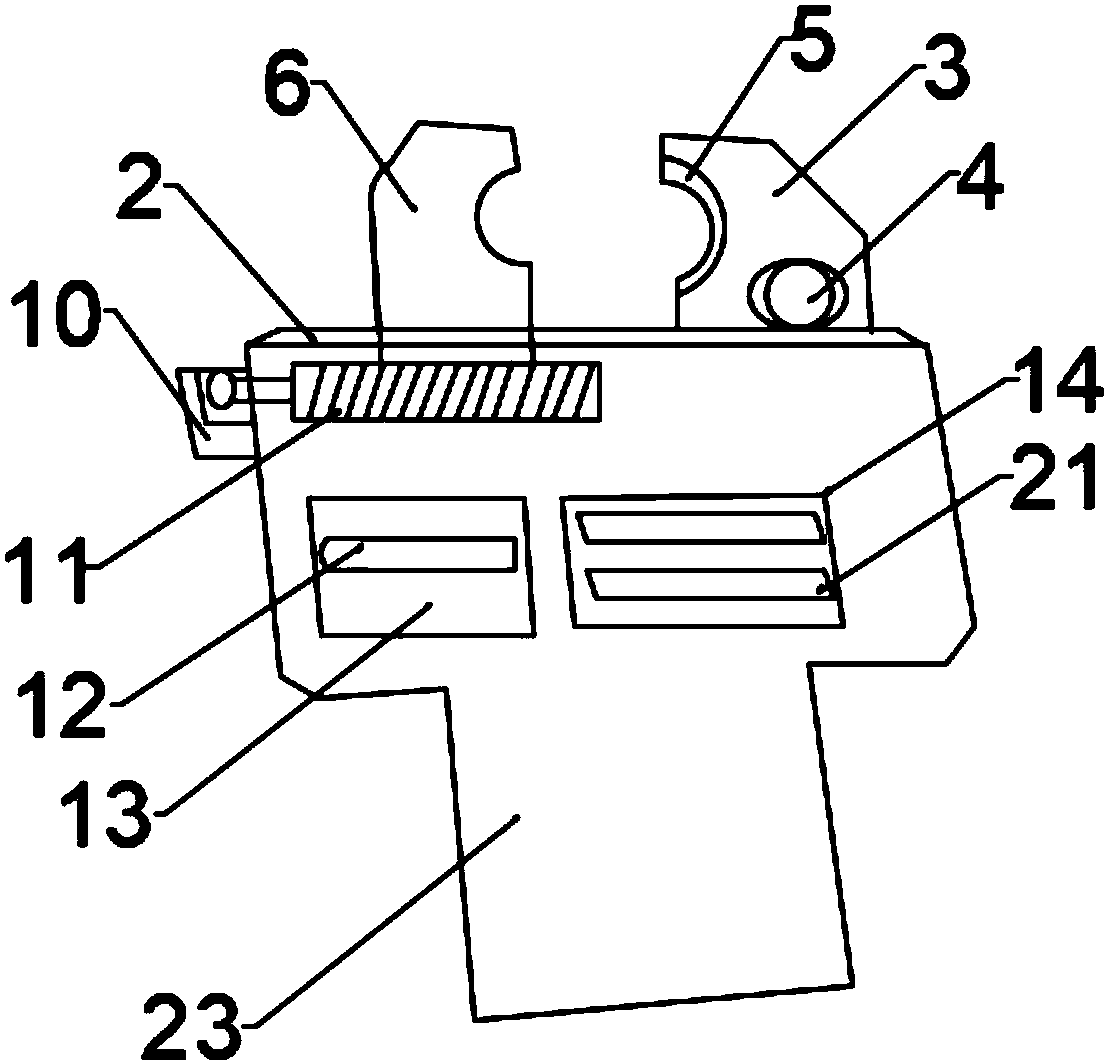

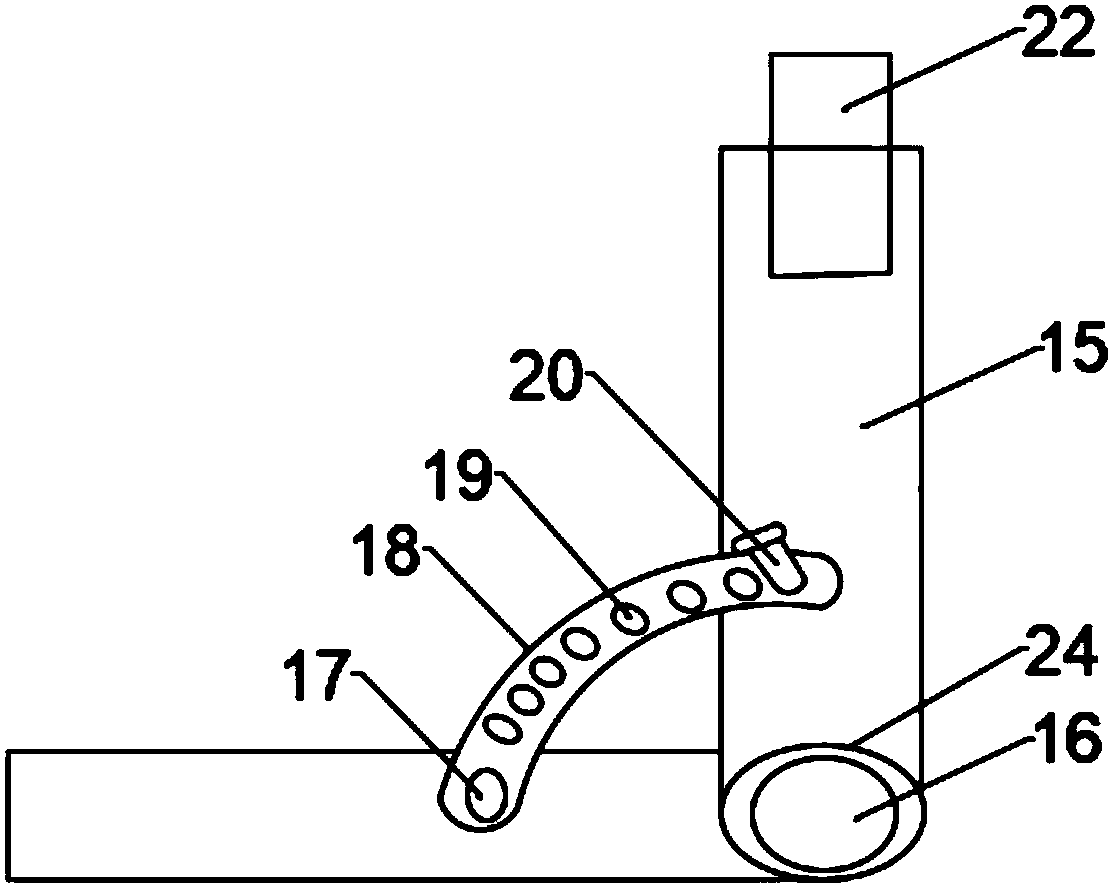

Anti-loose wire-clamping device used for low-voltage electric appliance

InactiveCN107607748ARealize separation and combinationSufficient insulation distanceMeasurement instrument housingClamped/spring connectionsCouplingLow voltage

The invention discloses an anti-loose wire-clamping device used for a low-voltage electric appliance. The anti-loose wire-clamping device comprises a plate type clamp head and an adjustable fixing andconnecting device. The lower end of the plate type clamp head is connected with a shaft coupling through a rotation shaft. The shaft coupling is fixedly arranged on the inner wall of the adjustable fixing and connecting device. The left end of the adjustable fixing and connecting device is in hub connection with a fixing shaft. The plate type clamp head includes a stainless steel body, a moving clamping head and a static clamping head. A slide guide rail is arranged on the upper surface of the stainless steel body, the static clamping head is fixedly arranged on the left end of the slide guide rail, and the upper surface of the slide guide rail is in sliding connection with the moving clamping head. Through adoption of the adjustable fixing and connecting device, the entire anti-loose wire-clamping device can freely rotate 360 degrees, and has turning and fixing functions. Moreover, a control module is arranged inside the plate type clamp head to control joints to move, so the wire clamping control force is increased and over-tight or loosening situations during wire clamping can be overcame effectively.

Owner:WUHU KAIXIN ARRESTER

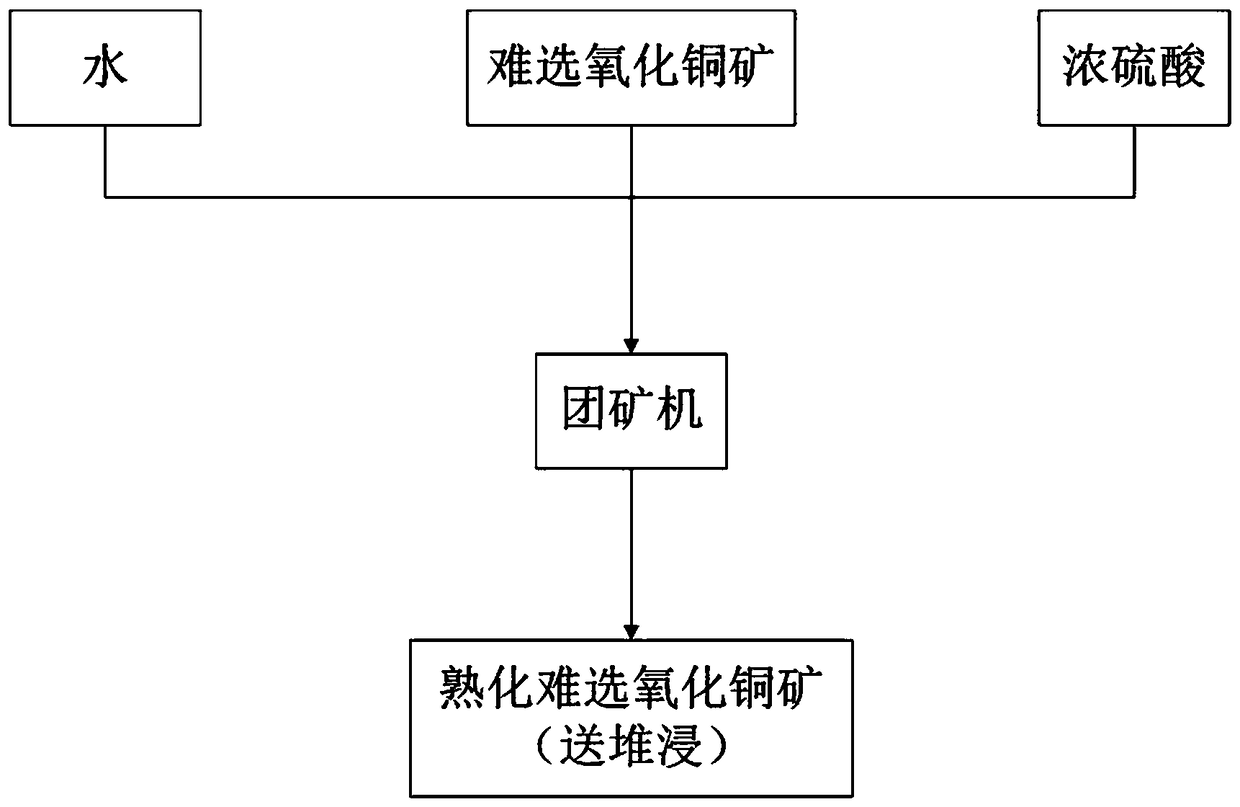

Difficult-to-separate copper oxide ore and sulfuric acid curing pretreatment method

InactiveCN108546820ATo achieve the purpose of separationHigh porosityProcess efficiency improvementPorosityPretreatment method

The invention discloses a difficult-to-separate copper oxide ore and sulfuric acid curing pretreatment method and belongs to the technical field of metallurgy. The difficult-to-separate copper oxide ore and sulfuric acid curing pretreatment method comprises the following steps that difficult-to-separate copper oxide ore, water and sulfuric acid are added into a briquetting machine according to a certain proportion; and the difficult-to-separate copper oxide ore, the water and the sulfuric acid react to allow copper to be dissociated from gangue or other minerals, so that the purposes that thecopper is separated from other valuable metals and gangue minerals, the difficult-to-separate copper oxide ore is loosened, and the porosity factor is increased are achieved. With the adoption of thedifficult-to-separate copper oxide ore and sulfuric acid curing pretreatment method, dump leaching economic and technical indexes are increased substantially, so that the copper leaching rate, the recovery rate and the resource utilization rate are increased substantially, and the production cost is reduced.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Method for continuously vacuum volatilizing and separating azeotrope and device

InactiveCN101274147ALarge specific surface areaIncrease the evaporation areaVacuum distillation separationZeotropic mixtureMass transfer

The invention relates to a method and a device which are used for separating azeotrope by continuous vacuum volatilization. In the method, by the operation in vacuum, the heating temperature of a system is lower than bubble point of an article to be separated so as to avoid the boiling of the article; according to the difference of volatilization speed and diffusion speed between components, azeotropic limit is broken through, thus achieving the separation object. Furthermore, the volatile area is increased by a filing material layer, a mass transfer process is reinforced, and a testing device of continuous vacuum volatilization separation method is established. Compared with existing azeotrope separation method, the method of the invention has the advantages of requiring no third component, friendly environment, simple equipment, convenient operation and low energy consumption. The method of the invention is suitable for the separation of azeotropic mixture.

Owner:TIANJIN UNIV

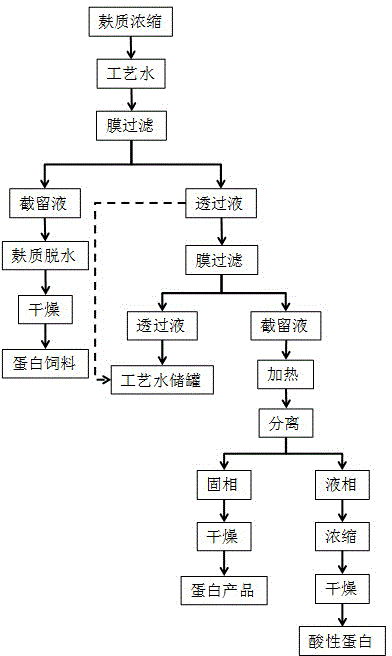

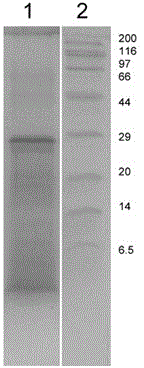

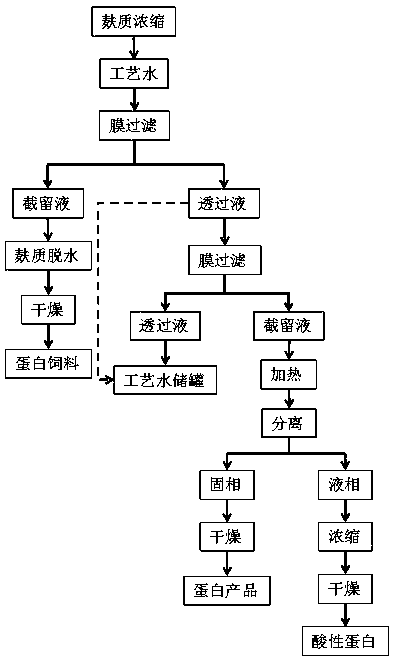

Corn starch process water protein recovery technique

ActiveCN104672299ALittle impact on utilizationGood dispersionPeptide preparation methodsEngineeringCorn starch

The invention provides a corn starch process water protein recovery technique which comprises the following steps: 1) treating process water, which is generated in the gluten concentration step in a wet-grinding technique for producing corn starch, to obtain a first permeation solution and a first trapped fluid containing rich com gluten meal; 2) filtering the first permeation solution through a hyperfiltration membrane with the molecular weight cut-off of 10-200 kDa under the conditions of 3-4 Bar and 35-45 DEG C to obtain a second permeation solution and a second trapped fluid containing rich soluble proteins; and 3) heating the second trapped fluid at 75-150 DEG C for 0.3 second-31 minutes, coagulating to precipitate a first protein product, separating to obtain a first protein product and a separation liquid, and concentrating and drying the separation liquid to obtain a second protein product. The recovery technique overcomes the defect that the traditional technique only treats the insoluble com gluten meal in the process water generated by the gluten concentration step, can obtain the two protein products, and can enhance the yield of the com gluten meal.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Method for raising proportion of capsaicin monomer in capsicum oleoresin

ActiveCN105331291AEasy to separateGood physical and chemical stabilityNatural resin purificationDihydrocapsaicinAlcohol

The invention discloses a method for raising the proportion of capsaicin monomer in capsicum oleoresin. The method comprises the steps of dissolving the capsicum oleoresin obtained through organic solvent extraction and decompressed concentration with an alcoholic solution, injecting the capsicum oleoresin into a chromatographic column filled with macroporous adsorption resin, leaving the capsicum oleoresin standing still for being adsorbed for 2-4 hours, then using an alcoholic solution for elution, conducting decompressed concentration on an elution solution, and obtaining capsicum oleoresin free of peculiar smell, wherein the total capsaicin content is 90-91%, and the proportion of the capsaicin monomers reaches 80-85%; continuing with elution with the alcoholic solution till eluant contains no capsaicin, conducting decompressed concentration on the eluant, and obtaining capsicum oleoresin free of peculiar smell, wherein the total capsaicin content is 93-94%, and the proportion of dihydrocapsaicin monomer reaches 45-50%. The method is obvious in effect, simple in process and easy and convenient to operate for separating capsaicin and dihydrocapsaicin, the solvent and resin can be recycled, no emission of industrial wastewater, waste gases and residues is generated, and the method is suitable for large-scale industrialized production.

Owner:云南宏绿辣素有限公司

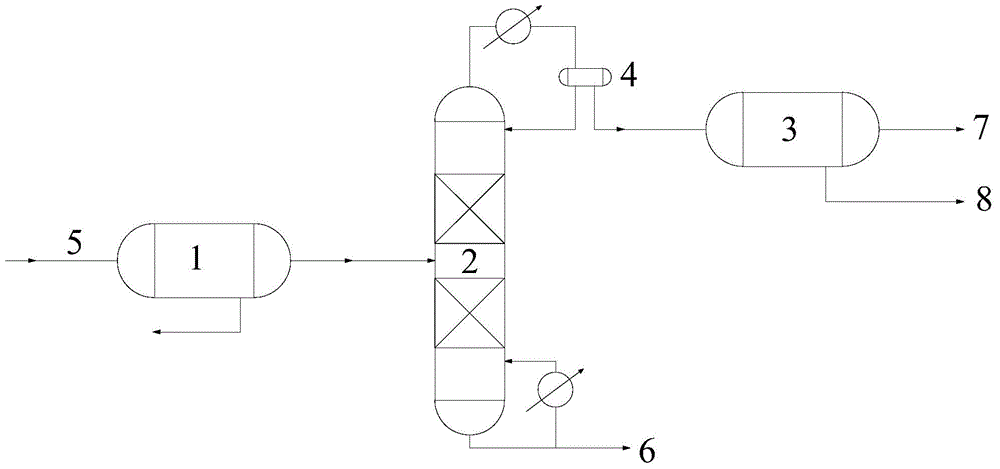

Method for separating dichloromethane, triethylamine and water

ActiveCN104086355AStable separationEfficient separationAmino compound purification/separationHalogenated hydrocarbon separation/purificationPhase splittingTower

The invention relates to a method for separating dichloromethane, triethylamine and water. The method comprises the following steps of firstly feeding feed liquor containing dichloromethane, triethylamine and water into a first phase splitting tank; feeding material flow separated out from upper-layer feed liquor of the first phase splitting tank into a rectifying tower, carrying out normal-pressure rectifying operation, keeping a tower-top temperature at 37-38 DEG C, keeping a tower-kettle temperature at 88-89 DEG C, extracting triehylamine from the tower kettle; feeding tower-top extracting liquor of the rectifying tower into a second phase splitting tank, thereby obtaining dichloromethane from the upper-liquid feed liquor of the second phase splitting tank and obtaining water from the material flow separated out from the lower-layer feed liquor of the second phase splitting tank. The method disclosed by the invention can effectively separate a mixture of dichloromethane, triethylamine and water to obtain 99.6% dichloromethane and 99.9% triethylamine.

Owner:HEBEI UNIV OF TECH

A kind of water protein recovery process of corn starch process

ActiveCN104672299BLittle impact on utilizationGood dispersionPeptide preparation methodsEngineeringCorn starch

The invention provides a corn starch process water protein recovery technique which comprises the following steps: 1) treating process water, which is generated in the gluten concentration step in a wet-grinding technique for producing corn starch, to obtain a first permeation solution and a first trapped fluid containing rich com gluten meal; 2) filtering the first permeation solution through a hyperfiltration membrane with the molecular weight cut-off of 10-200 kDa under the conditions of 3-4 Bar and 35-45 DEG C to obtain a second permeation solution and a second trapped fluid containing rich soluble proteins; and 3) heating the second trapped fluid at 75-150 DEG C for 0.3 second-31 minutes, coagulating to precipitate a first protein product, separating to obtain a first protein product and a separation liquid, and concentrating and drying the separation liquid to obtain a second protein product. The recovery technique overcomes the defect that the traditional technique only treats the insoluble com gluten meal in the process water generated by the gluten concentration step, can obtain the two protein products, and can enhance the yield of the com gluten meal.

Owner:COFCO NUTRITION & HEALTH RES INST +1

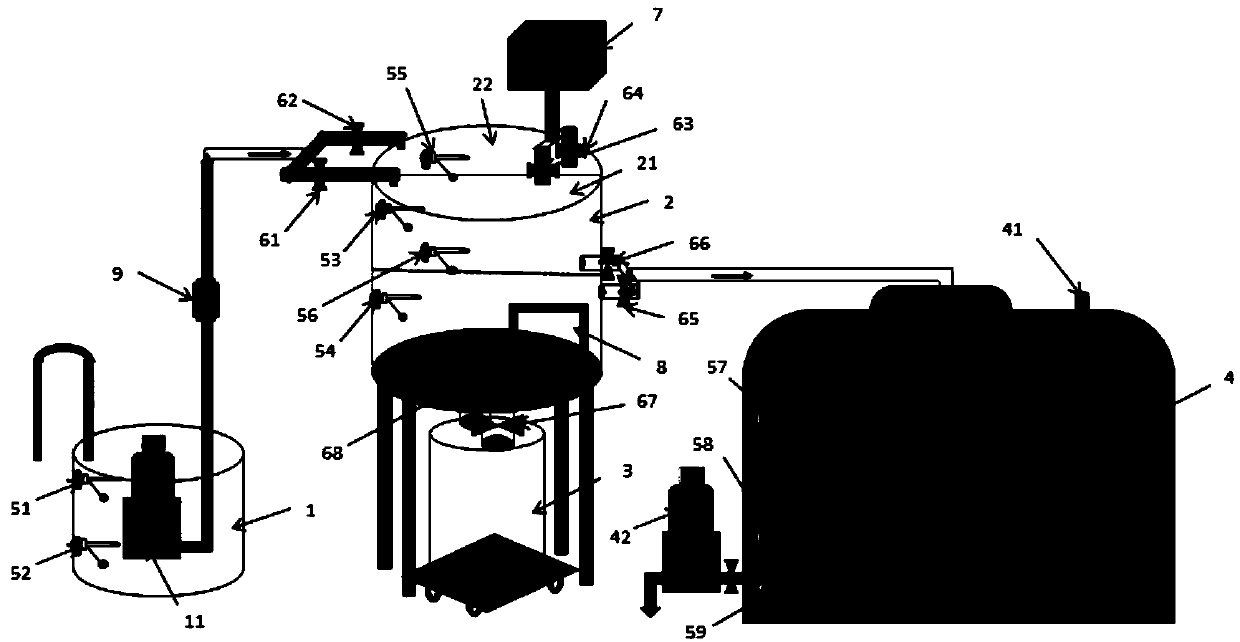

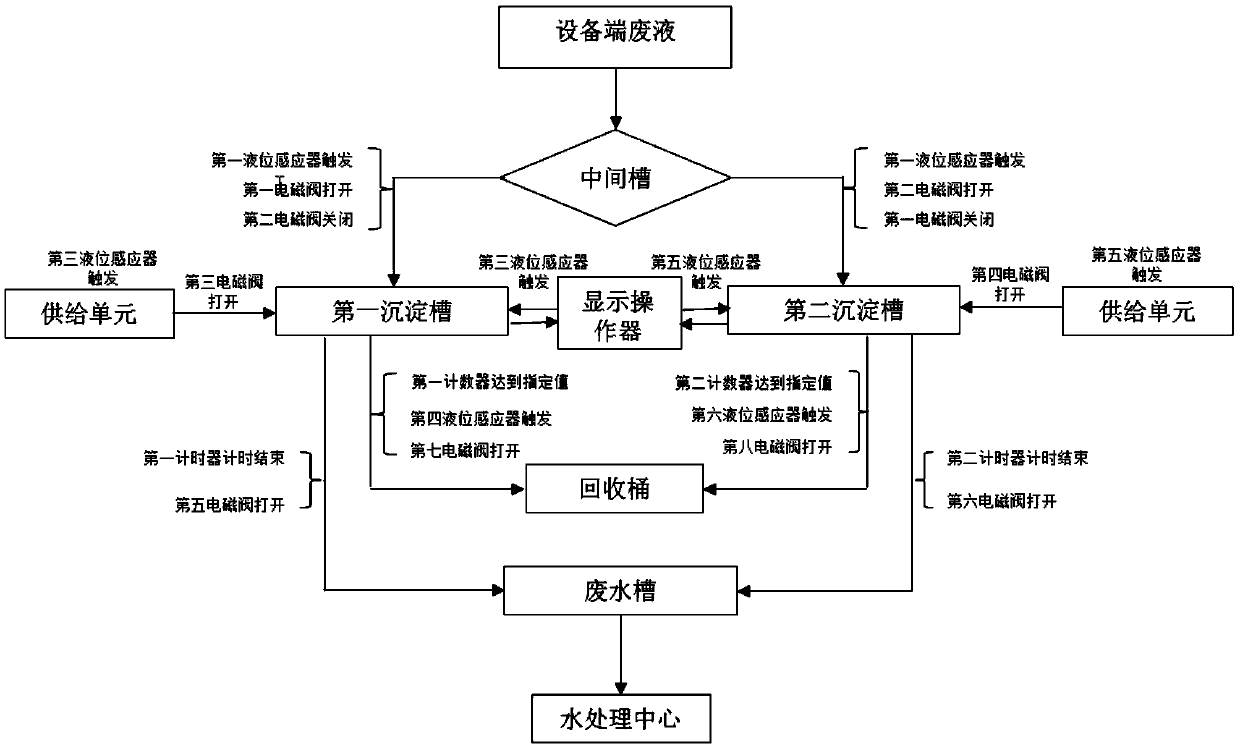

Waste liquid recovery device and waste liquid recovery method thereof

InactiveCN109603217ASolve the blockageTo achieve the purpose of separationSedimentation regulating devicesSedimentation settling tanksRecovery methodSuspended matter

The invention provides a waste liquid recovery device and a waste liquid recovery method thereof. The waste liquid recovery device comprises an intermediate tank for collecting wastewater, a sedimentation tank for precipitating the wastewater, a wastewater tank for collecting clean water and a recovery barrel for collecting waste residues, wherein the sedimentation tank includes a first sedimentation tank body and a second sedimentation tank body which do not communicate with each other, the intermediate tank separately communicates with the first sedimentation tank body and the second sedimentation tank body, and the first sedimentation tank body and the second sedimentation tank body separately communicate with the wastewater tank and the recovery barrel; the wastewater tank does not communicate with the recovery barrel, and automatic switching and operation are performed on the two sedimentation tank bodies. The design of the double sedimentation tank bodies is adopted, switching between the two sedimentation tank bodies can be achieved through an electromagnetic valve and the principle of an interlock circuit, and precipitation of solid suspended matter in the waste liquid is accelerated through addition of a precipitant, so that the purpose of isolation of abrasive powder and water in the waste liquid is achieved; then the clean water is discharged into a general drainagetank, and is discharged into a wastewater treatment center through pressurization; and the waste residues are collected, and the collected waste residues are sent to the wastewater center for treatment, so that blockage of pipelines is avoided.

Owner:NANJING CEC PANDA FPD TECH CO LTD

Method for separating 2,5-dichlorophenol and 2,4-dichlorophenol

InactiveCN105801380AReduce processing costsSimple operation processOrganic chemistryOrganic compound preparationDissolutionDichlorophenol

The invention discloses a method for separating 2,5-dichlorophenol and 2,4-dichlorophenol, belonging to the technical field of fine chemical industry. According to the method, the 2,5-dichlorophenol is separated out by a urea addition process, and then the less 2,5-dichlorophenol is separated from the 2,4-dichlorophenol by steps of ammonia water dissolution, crystallization and the like, so that the 2,5-dichlorophenol is thoroughly separated from the 2,4-dichlorophenol. Compared with the prior art, the method has the advantages of being low in cost, simple in operation technology and less in energy consumption.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

Ash removal device and steelmaking production line

PendingCN112280929ASmall resistanceSmooth circulationDispersed particle separationManufacturing convertersSteelmakingThermodynamics

The invention discloses an ash removal device and a steelmaking production line. The ash removal device comprises a shell and a plurality of ash falling plates for collecting dust in high-temperatureflue gas, wherein the shell is provided with a flue gas input port and a flue gas output port; a containing cavity for containing the ash falling plates and a flue gas conveying channel for conveyingthe high-temperature flue gas are formed in the shell; the two ends of the flue gas conveying channel communicate with the end face of one side of the containing cavity and the flue gas input port correspondingly; the flue gas output port is located below the shell and communicates with the bottom of the containing cavity; the ash falling plates are arranged in the containing cavity in a layered manner from top to bottom, a gap is reserved between every two adjacent ash falling plates, and therefore a flat flue gas runner is formed between every two adjacent ash falling plates; and each ash falling plate is provided with a plurality of ash leaking holes. The ash removal device and the steelmaking production line solve the technical problem that the purification effect of converter flue gasin a high-temperature interval is poor.

Owner:BEIJING JINGCHENGKELIN ENVIRONMENTAL PROTECTION TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com