Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

164 results about "Dump leaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dump leaching is an industrial process to extract precious metals and copper from ores. Dump leaching is similar to heap leaching, however in the case of dump leaching ore is taken directly from the mine and stacked on the leach pad without crushing where, in the case of gold and silver, the dump is irrigated with a dilute cyanide solution that percolates through the ore to dissolve gold and silver. The solution containing gold and silver exits the base of the dump, is collected and precious metals extracted. The resultant barren solution is recharged with additional cyanide and returned to the dump.

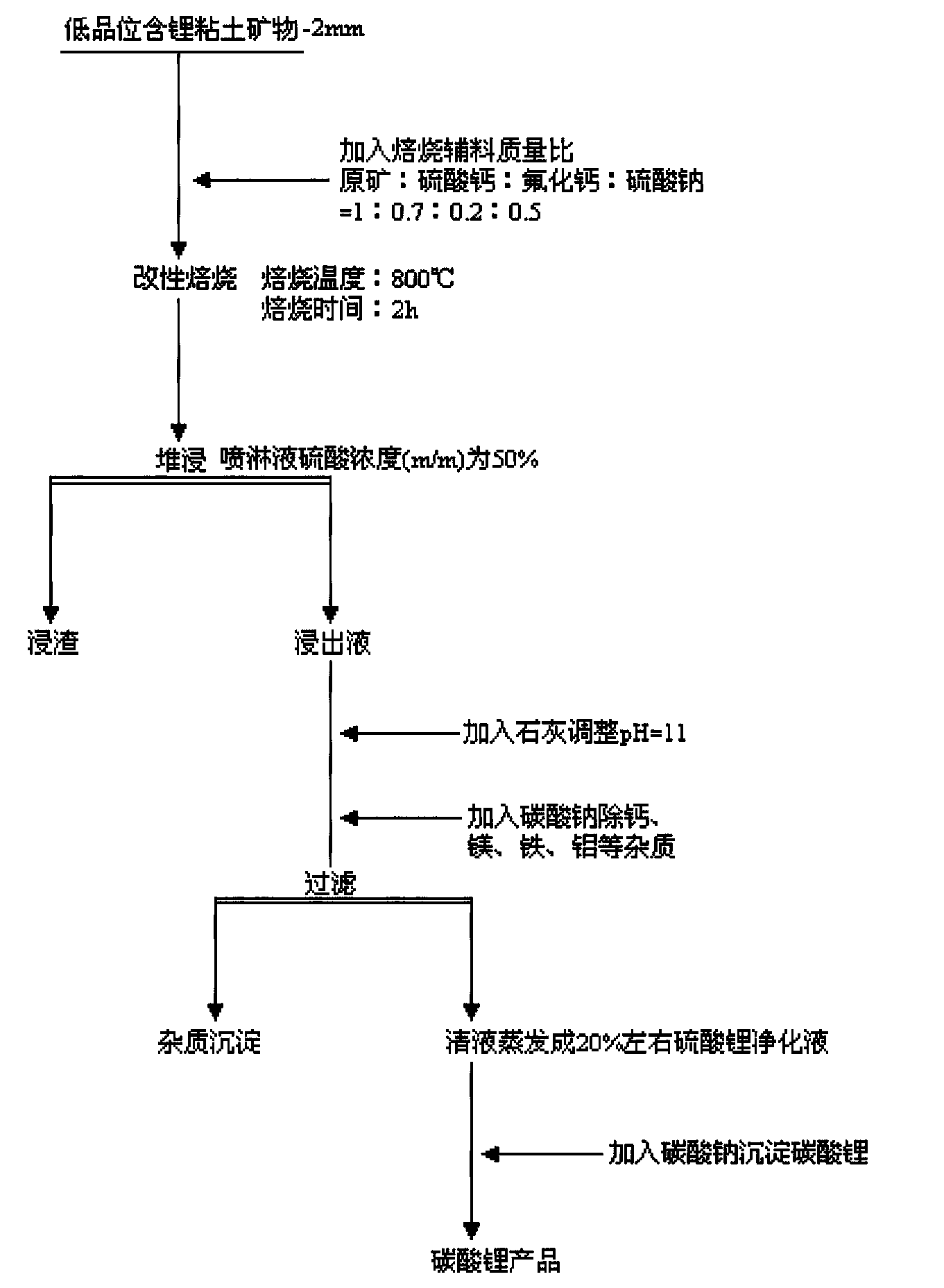

Method for extracting lithium from low grade lithium-containing clay mineral

The invention provides a new technology of 'modifying roasting-dump leaching' for large-scale low grade lithium-containing clay mineral in north of Henan province, solving the problem of utilization of low grade lithium-containing clay in the area. The new technology overcomes the defects of long technological process and high production cost of traditional lithium extraction technology, and the lithium leaching efficiency reaches 91%.

Owner:河南省岩石矿物测试中心

Dump leaching processing method for waste cathode inner lining of aluminum electrolytic bath

InactiveCN107313073ARealize closed-loop resource applicationReduce pressure on environmental protectionEnergy inputCarbon preparation/purificationElectrolysisBrick

Disclosed is a dump leaching processing method for a waste cathode inner lining of an aluminum electrolytic bath. The dump leaching processing method comprises the following steps that insulating bricks, castables, anti-leakage materials and carbon materials in the waste cathode inner lining which is sorted from bath residues generated in overhaul the aluminum electrolytic bath are correspondingly crushed and screened, the crushed waste insulating bricks, castables, anti-leakage materials are mixed and then processed, and the carbon materials are independently processed; the processing method of mixed materials of the waste insulating bricks, the castables and the anti-leakage materials is the same with the processing method of the carbon materials, and the processing method comprises the following steps of pre-leaching, dump leaching and washing which are conducted circularly; pre-leached liquid and dump leached liquid of the mixed materials are subjected to oxidative decyanide treatment and then are filter-pressed; pre-leached liquid and dump leached liquid of the carbon materials are also subjected to oxidative decyanide treatment and then are filter-pressed; and filter-pressed liquid of the mixed materials and filter-pressed liquid of the carbon materials are mixed and subjected to carbon-neutralization treatment, through concentration and crystallization, sodium salt is recovered, and mixture of fluorinated NaHCO3, fluorinated Na2CO3 and NaF is obtained. By means of the dump leaching processing method, innocent treatment and comprehensive using can be conducted on the waste cathode inner lining of the aluminum electrolytic bath.

Owner:YUNNAN RUNXIN ALUMINUM

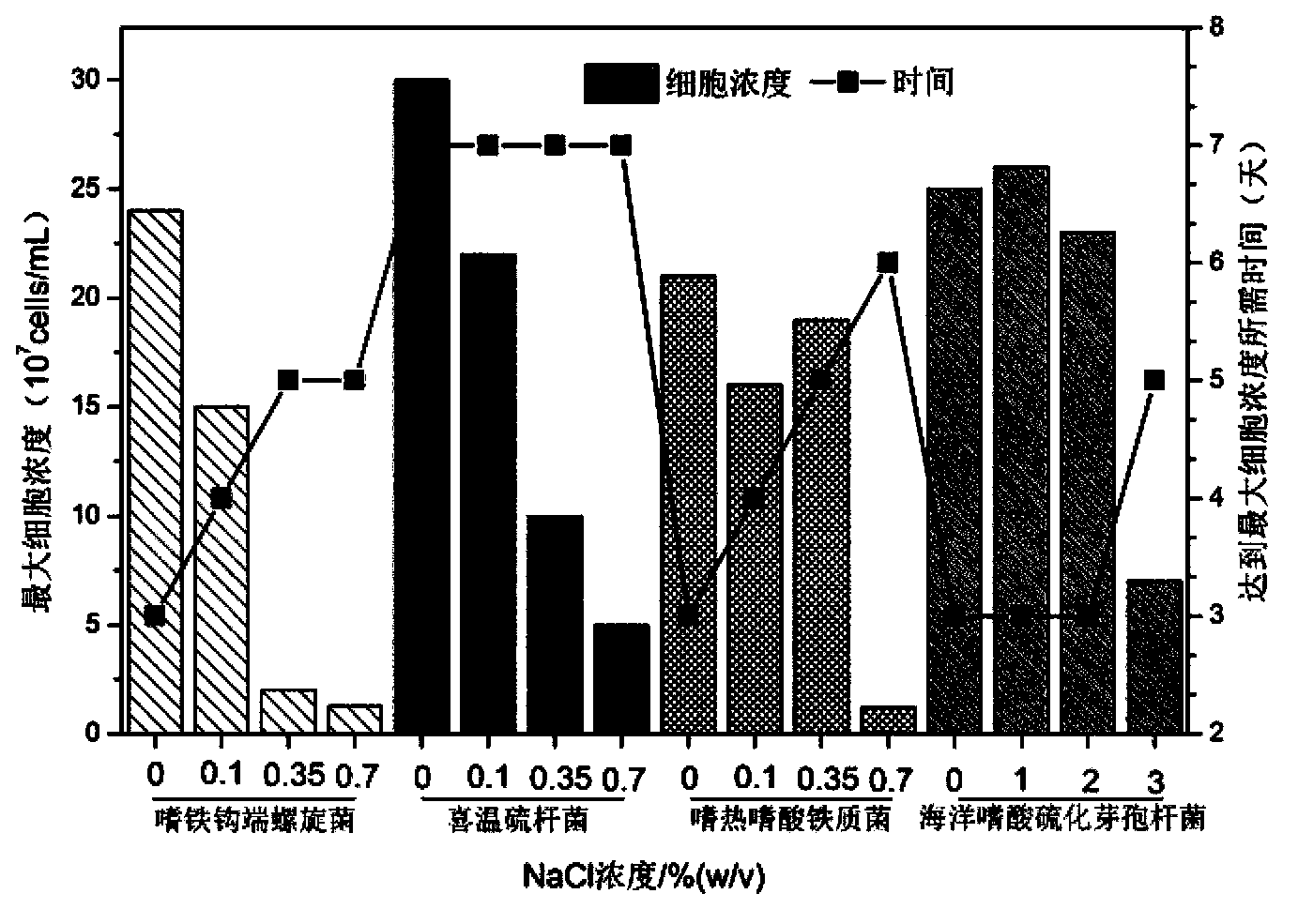

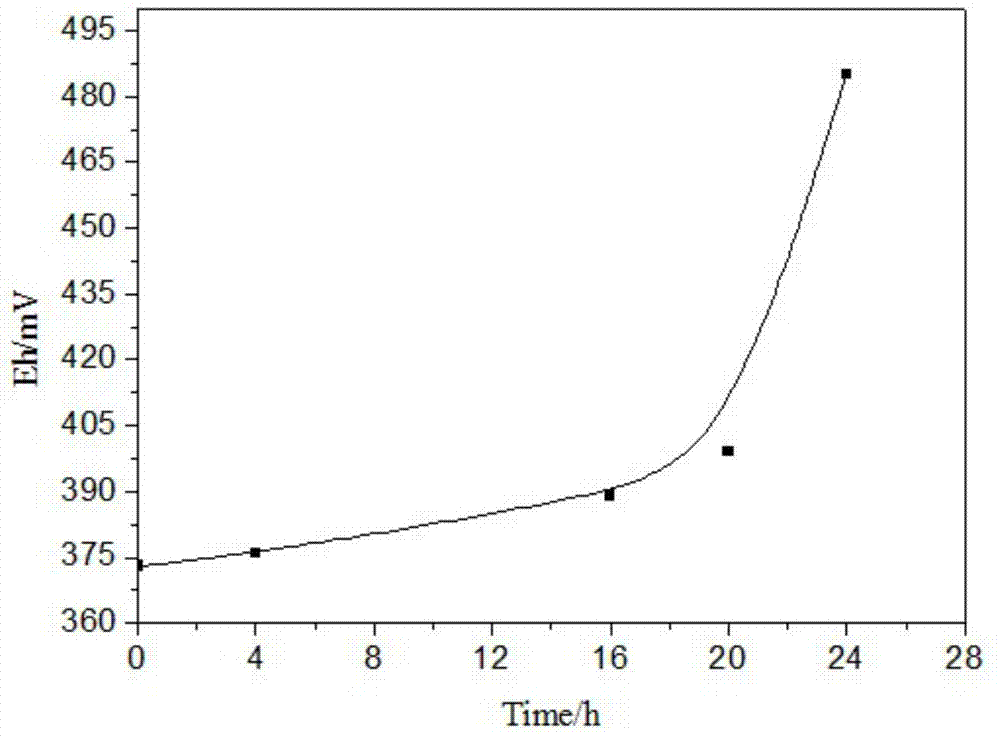

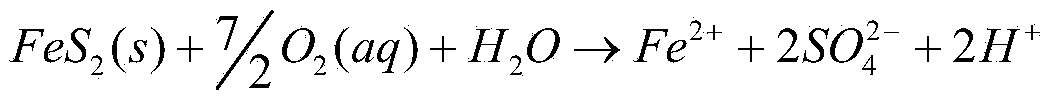

Compound bacterium community capable of efficiently leaching sulphide ore, and compounding method and application method thereof

ActiveCN103396964AIncrease resistanceImprove leaching efficiencyBacteriaMicroorganism based processesChemical reactionEngineering

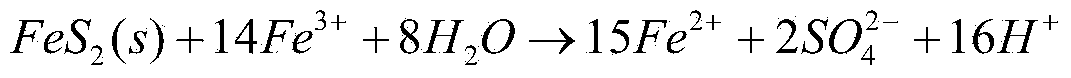

The invention discloses a compound bacterium community capable of efficiently leaching a sulphide ore, and a compounding method and an application method thereof, and belongs to the technical filed of wet-process metallurgy. Aiming at a biological leaching mechanism of the sulphide ore and the physiological-biochemical characteristics of microorganisms, a community capable of efficiently leaching the sulphide ore is compounded by a plurality of mineral leaching microorganisms, wherein the mineral leaching microorganisms comprise marine bacteria which come from deep-sea hydrothermal vents and are capable of enduring high concentration sodium chloride, sulfur-oxidized bacteria, iron-oxidized bacteria and archaea which are from a freshwater environment, autotrophic bacteria and facultative heterotrophic bacteria. Not only can the difficult problem that the mineral leaching microorganisms from the freshwater environment are intolerance of sodium chloride be solved, but also microorganisms required by oxidation and dissolution of the sulphide ore and diversity of chemical reactions are guaranteed. The compound bacterium community can obviously increase leaching efficiency and leaching rate of the sulphide ore such as copper pyrites and can be applied in a leaching process and a dump leaching process of a stirring tank. A certain basis for popularization and application of biological metallurgy of the sulphide ore is provided by the invention.

Owner:CENT SOUTH UNIV +1

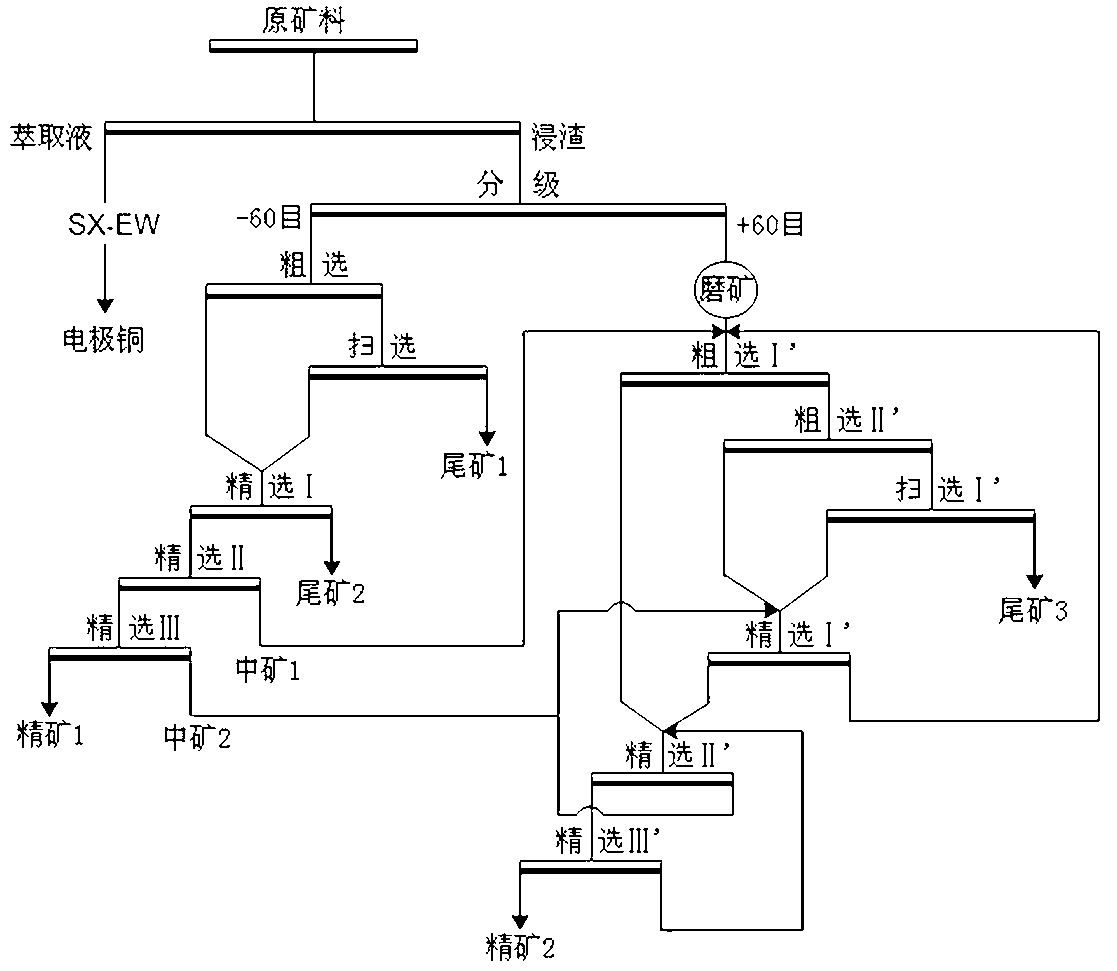

Leaching residue grading and series flotation method for complex copper mine

The invention discloses a leaching residue grading and series flotation method for complex copper mine. The method comprises the working procedures of leaching residue grading, fine flotation and coarse flotation. Particularly, the leaching residue grading comprises the step of dividing leaching residues for hydrometallurgy of copper into fine-grained mine and coarse-grained mine according to a sieve of 60-100 meshes. The fine flotation comprises the step of carrying out series roughing selection, scavenging and fine selection for two to three times on the fine-grained mine to obtain concentrate 1, wherein the fine-grained mine is obtained through grading. The coarse flotation comprises the steps of grinding the coarse-grained mine obtained through grading until the fineness reaches 80% of less than 200 meshes, arranging and connecting the coarse-grained mine in series, carrying out roughing selection for one to two times, scavenging and fine selection for two to three times on mine discharge series to obtain concentrate 2. According to the method, the leaching residues for hydrometallurgy of the low-grade and complex mine with oxygen and sulfur mixed are graded firstly, then the different series flotation and tailing reusing processes are adopted respectively, the mineral recovery rate can be improved to 75-85% of comprehensive recovery from 30-50% of single wet dump leaching, the grade of the leaching residues is reduced to 0.2% or even lower from 0.5% of pre-flotation, the effect of comprehensive recovery is obvious, and meanwhile the pollution to environment by the leaching residues is reduced.

Owner:云南楚雄矿冶有限公司

Method for metal heap and dump leaching coupled with metal solvent extraction

InactiveUS20060088458A1Increase heightImprove recovery rateSolvent extractionSolid sorbent liquid separationLower gradeLow graded

The disclosed invention provides a process for enhanced recovery of one or more metal values from heap and / or dump leaching of ores containing the metal values, the process comprising: (a) providing a high grade leach solution obtained by heap or dump leaching of fresh high grade ore containing a first metal value; (b) subjecting the high grade leach solution to a first solvent extraction of the first metal value and applying the resulting first aqueous raffinate to leach fresh high grade ore; (c) providing a low grade leach solution obtained by heap or dump leaching of partially leached ore or fresh low grade ore of the first metal value; and (d) subjecting the low grade leach solution to a second solvent extraction of the first metal value, separate from the first solvent extraction of the first metal value, and applying the resulting separate, second aqueous to leach partially leached ore or fresh low grade ore, wherein the first and second aqueous raffinates are not intermixed prior to being applied to their respective ores for leaching. Alternatively, the first and second raffinates may be intermixed prior to being applied to their respective ores for leaching, providing that the aqueous raffinate applied to fresh high grade ore comprises at least 60% by volume of the first aqueous raffinate and the aqueous raffinate applied to partially leached ore or fresh low grade ore comprises at least 60% by volume of the second aqueous raffinate.

Owner:COGNIS IP MANAGEMENT GMBH

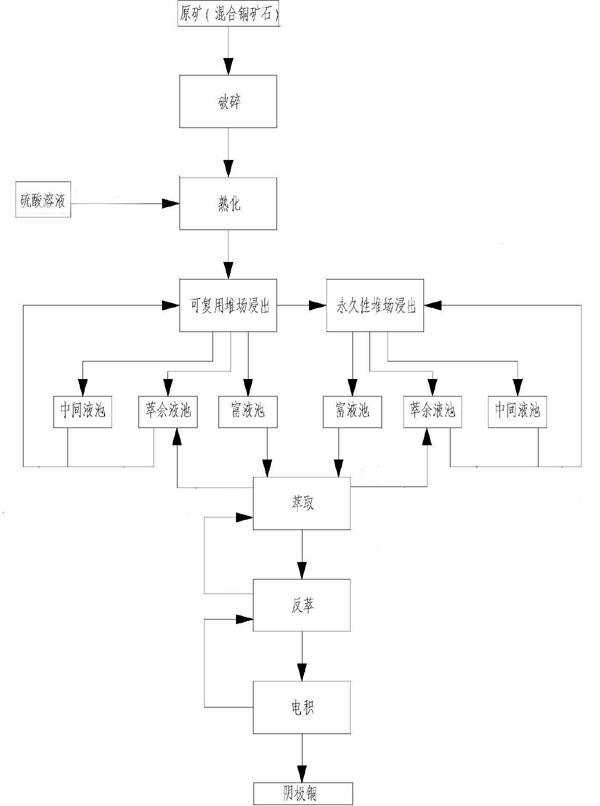

Stage-by-stage dump leaching technology for low-grade mixed copper ore

ActiveCN102643983AImprove leaching rateShort heap leaching cycleProcess efficiency improvementResource utilizationLower grade

The invention discloses a stage-by-stage dump leaching technology for low-grade mixed copper ore, which is used for treating the low-grade mixed copper ore of oxidized ore and sulphide ore. The technology comprises the following steps of: (1) crushing raw ore: carrying out three-section closed-circuit crushing on the raw ore; (2) curing with sulfuric acid; (3) carrying out first-stage dump leaching: carrying out dump leaching by a repeated stock dump; (4) carrying out second-stage dump leaching: carrying out dump leaching by a permanent stock dump; and (5) recovering copper metal: extracting,back extracting and electrically depositing. By using the stage-by-stage dump leaching technology for the low-grade mixed copper ore, the copper metal in the copper oxide mineral can be recovered at a quick leaching speed according to the leaching period difference between the copper oxide ore and the copper sulphide ore and in accordance with the principle 'the earlier the better', and simultaneously the sufficient recovery of the copper metal in the copper sulphide metal can also be considered. According to the stage-by-stage two-step dump leaching, the leaching efficiency of the copper metal in the low-grade mixed copper ore can be improved, the low-grade copper ore can be effectively recovered, and the resource utilization rate can be enlarged.

Owner:CHINA NERIN ENG

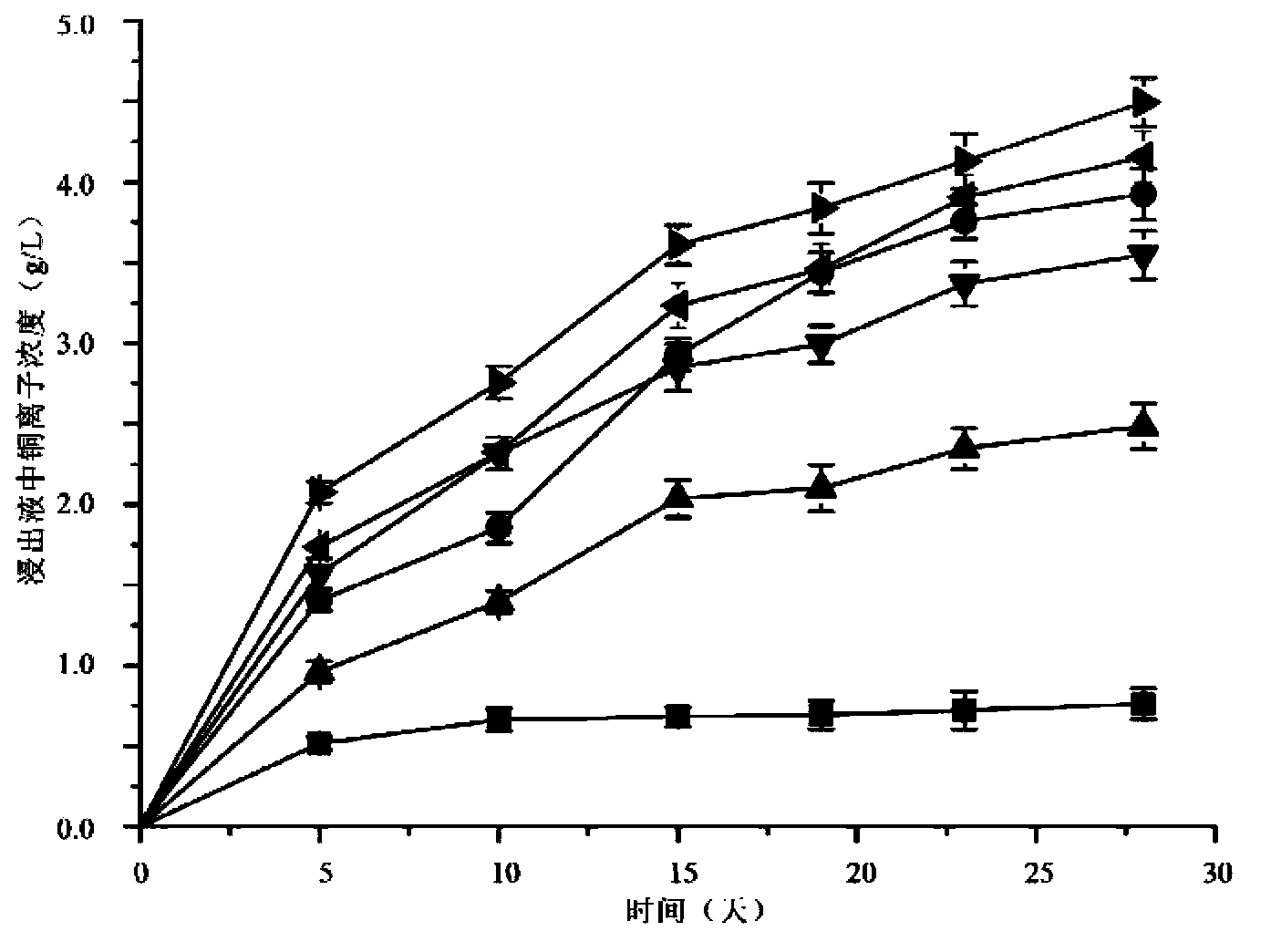

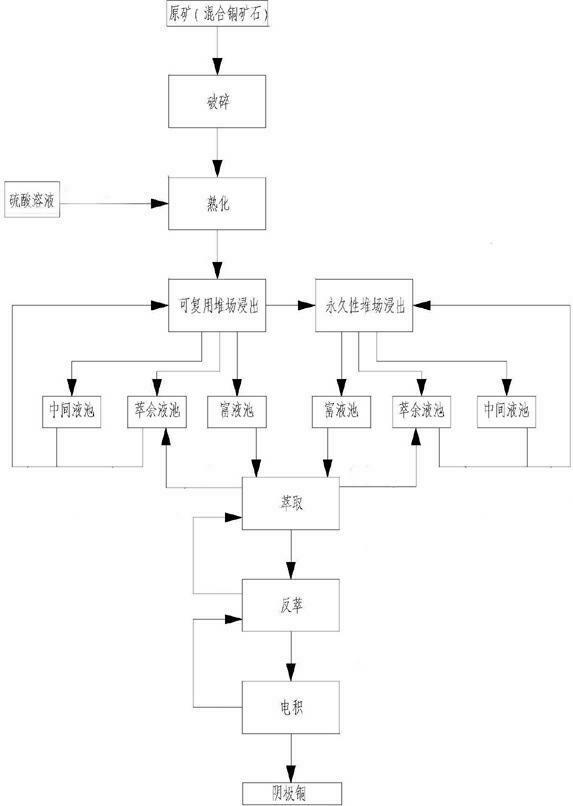

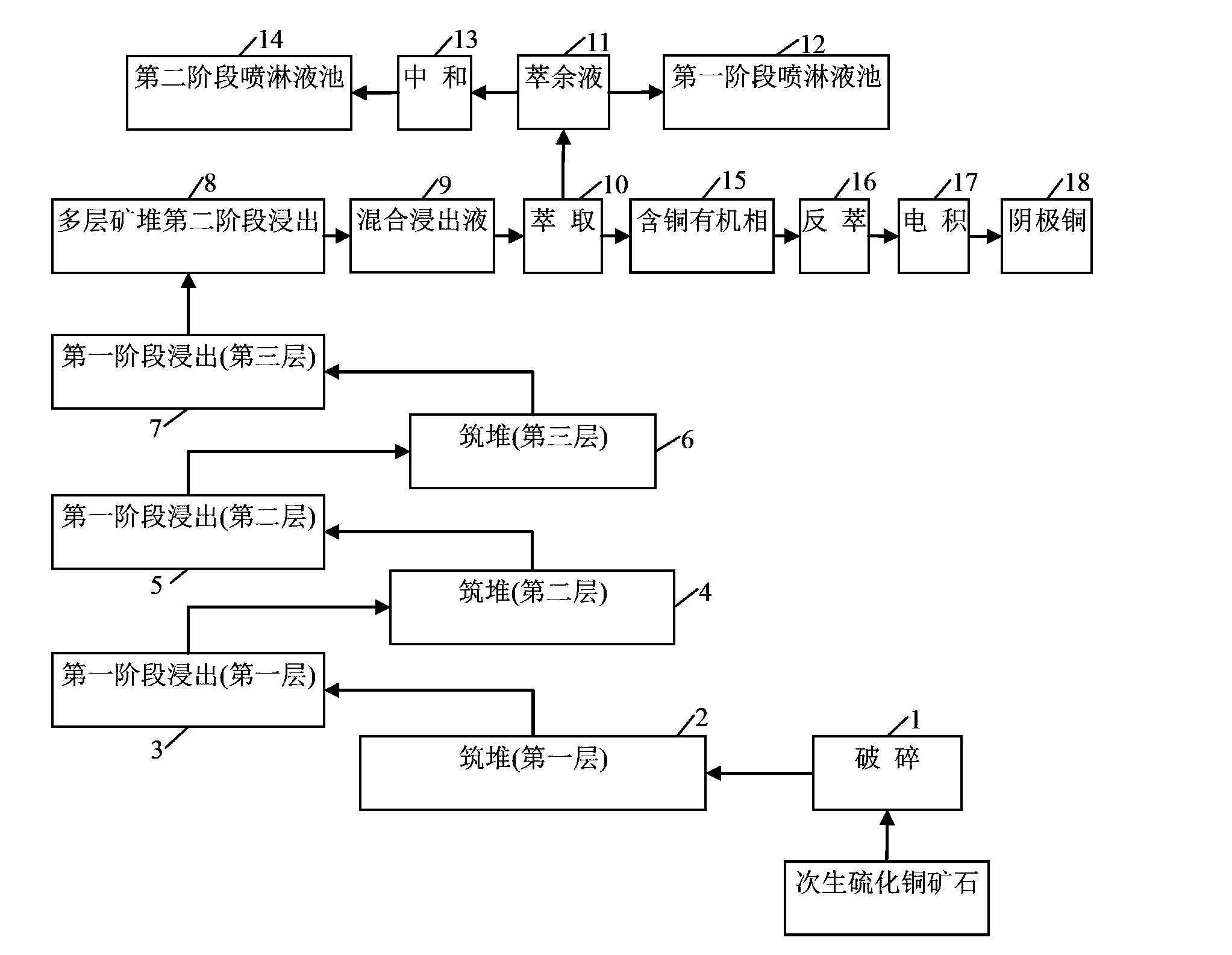

Two-stage biological dump leaching method of secondary copper sulphide ore

ActiveCN104109765APromote leachingDowngradeProcess efficiency improvementPregnant leach solutionResource utilization

Method for two-stage bioleaching of secondary copper sulfide ore, comprising the following steps: 1) feeding secondary copper sulfide ore, after crushing, to a leach pad to build a heap and performing the first stage of leaching, until 40% to 50% copper is leached from the last layer of ore, wherein the concentration of sulfuric acid in a spray solution is greater than or equal to 20 g / L, and the concentration of Fe3+ is greater than or equal to 15 g / L; 2) performing the second stage of leaching on the secondary copper sulfide ore leached from the first stage of leaching in step 1), using a 1.2<pH<1.5 spray solution, and when the temperature of the leached solution is lower than 45°C, reducing spray intensity; 3) a mixed leachate from the first stage of leaching and the second stage of leaching undergoing extraction, stripping, and electrodeposition to obtain cathodic copper. The technique of the method is simple, its process parameters are easy to control, the method effectively facilitates leaching of secondary copper sulfide ore, and significantly lowers the leached copper slag grade, effectively improving overall resource utilization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Fluoride-resistant ore leaching bacterium and application thereof in efficient leaching process of high-fluoride uranium ore

ActiveCN104745498AStrong fluorine resistanceAchieve protectionBacteriaMicroorganism based processesHigh fluorideUranium ore

The invention relates to a fluoride-resistant ore leaching bacterium and application thereof in an efficient leaching process of high-fluoride uranium ore. The fluoride-resistant acidophilus Acidithiobacillus ferrooxidans is collected at China General Microbiological Culture Collection Center (CGMCC for short) on July 1, 2013 and has a collection number of CGMCC NO.7836. The strain can grow in a fluorine-containing solution under an acidic condition, has fluorine resistance of 3.0g / L or above and also has a relatively good capability of oxidizing Fe<2+> into Fe<3+>. When the fluoride-resistant strain (CGMCC NO.7836) is applied to simulated biological dump leaching process of fluorine-containing uranium ore, 55-day uranium leaching rate is improved by 3.70% as compared with that in an acid leaching method; the uranium leaching rate is improved obviously and production cost is reduced; moreover, since adsorption tail liquid during uranium leaching can be recycled, environment pollution can be reduced. Therefore, the strain can be widely applied to biological leaching.

Owner:有研资源环境技术研究院(北京)有限公司

Chemical metallurgy method for extracting beryllium oxide from chrysoberyl

InactiveCN103088206AFully consider the protectionFully consider the comprehensive utilizationProcess efficiency improvementWater vaporDump leaching

The invention discloses a chemical metallurgy method for extracting beryllium oxide from chrysoberyl. The chemical metallurgy method is a comprehensive treatment technology for carrying out chemical metallurgy on refractory chrysoberyl with not more than 0.5% of Be. The chemical metallurgy method is characterized by comprising the following steps of: carrying out structural transformation roasting on the minerals by using ammonium fluosilicate as a structural transforming agent in the presence of activator limestone; cooling the roasted minerals and using water to spray dump leaching beryllium; precipitating beryllium for the ammonium fluoroberyllate solution by using ammonium bicarbonate to obtain basic beryllium carbonate; calcining the basic beryllium carbonate to release carbon dioxide and water vapor to obtain the product beryllium oxide; and concentrating and crystallizing a beryllium-precipitated solution which is the beryllium fluoride solution under reduced pressure, and drying the concentrated and crystallized solution in air flow to obtain the product ammonium fluoride. The chemical metallurgy method disclosed by the invention is simple in process, low in price, free of pollution, high in metal recovery rate, low in production cost and capable of effectively separating and extracting beryllium in the chrysoberyl.

Owner:戴元宁

Microwave processing device for dump leaching uranium ores

The invention discloses a microwave processing device for the dump leaching uranium ores. The device uses microwave to carry out irradiation to dump leaching uranium ores, due to the fact that differences exist among the microwave temperature rising effects of different minerals inside the uranium ore particles, heat stress differences are generated among the different minerals inside the uranium ore particles, the grain boundaries of the different minerals inside uranium ore particles break and the cracks inside the particles extend, therefore the poriness of the uranium ore particles is increased, the permeability of the inner portions of the uranium ore particles is improved, the dissociation degree of the uranium ores is improved, the leaching efficiency of the dump leaching of the uranium ores is improved, and a leaching period is shortened. The whole equipment comprises 16 microwave units, a material conveying system, a support, a temperature detecting and controlling system and a microwave suppressor. When the microwave processing device for the dump leaching uranium ores is used to process the dump leaching uranium ores, the microwave processing device has the advantages of being good in the matching of microwave power and the uranium ores, low in processing energy consumption, large in processing quantity, stable in material conveying, and small in microwave leakage, the poriness of the uranium ores and the dissociation degree of the uranium ores are further improved, the leaching efficiency is further improved, and the leaching period is further shortened and the like. The microwave processing device for the dump leaching uranium ores is also suitable for the processing of dump leaching gold ores, dump leaching copper ores and other dump leaching ores, and has obvious effect in increasing poriness of ore particles, improving the permeability of the inner portion of the ore particles, improving the dissociation degree of useful ores, improving leaching efficiency, and shortening leaching efficiency.

Owner:NANHUA UNIV

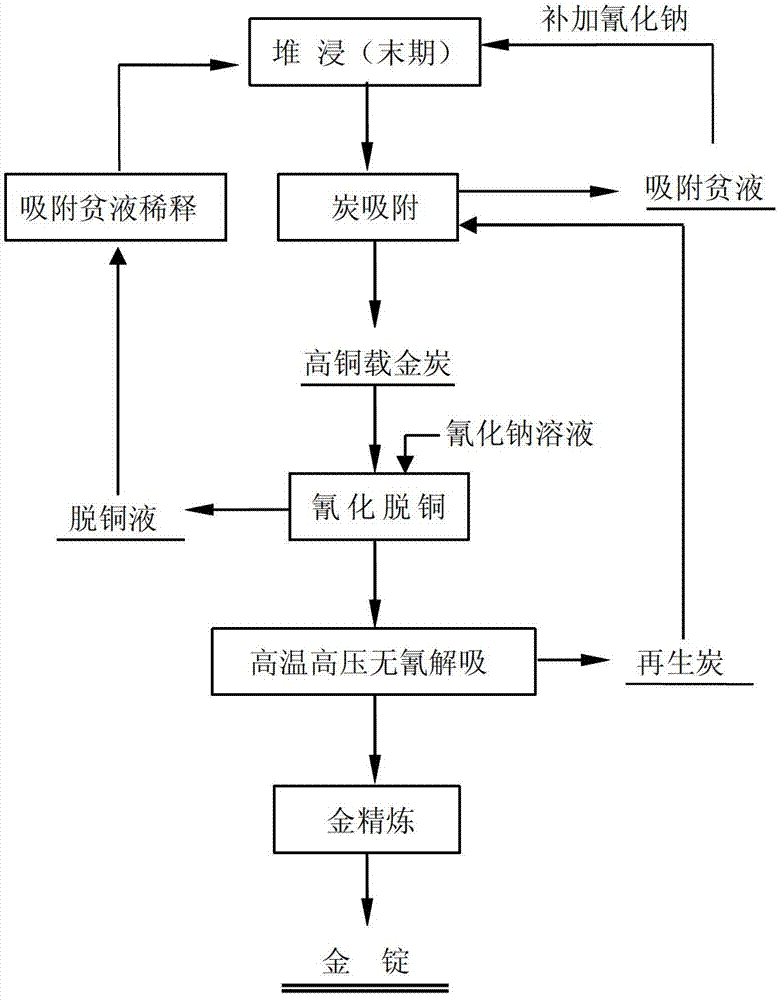

Low-grade copper-bearing gold ore dump leaching-carbon adsorption production method

ActiveCN103194614ASimple processLess investmentPhotography auxillary processesDesorptionDump leaching

The invention relates to a low-grade copper-bearing gold ore dump leaching-carbon adsorption production method. Copper contained in high-copper gold-carried carbon obtained through a low-grade copper-bearing gold ore dump leaching-carbon adsorption procedure is partially removed by adopting a cyaniding decoppering process, a decoppering solution is diluted by utilizing an adsorption barren solution to be used as a spray solution at the late stage of dump leaching, and decoppering carbon is conveyed to a high-temperature high-pressure cyanide-free desorption-electrodeposition system for treatment. The low-grade copper-bearing gold ore dump leaching-carbon adsorption production method disclosed by the invention has the advantages of simple process flow, small investment, no other original paving material addition, low production cost and the like, and is easy to industrially implement; according to the invention, after the high-copper gold-carried carbon is subjected to cyaniding decoppering, the gold desorption rate of the high-copper gold-carried carbon can be enhanced, and the adsorption property of regenerated carbon is enhanced, so that the adsorption rate of gold is enhanced, and the production technology index is optimized; and a part of copper contained in the decoppering solution and the adsorption barren solution can be deposited in a stock dump again by adopting a copper deposition process at the late stage of the dump leaching, the gold can be leached by utilizing sodium cyanide generated through copper deposition reaction, so that the concentration of copper contained in the dump leaching-carbon adsorption system can be effectively controlled, and the production system can be in a good operating environment all the time.

Owner:ZIJIN MINING GROUP

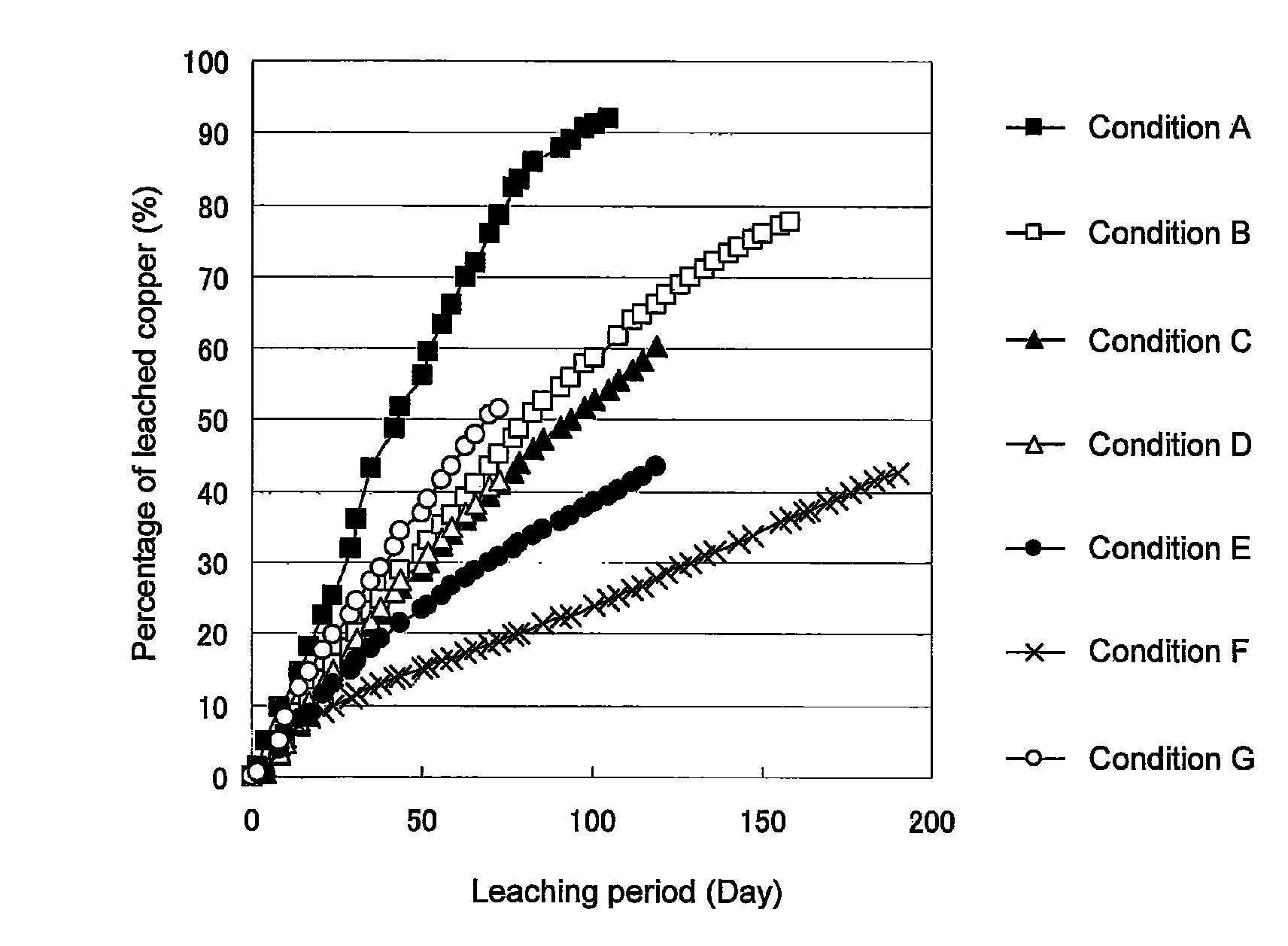

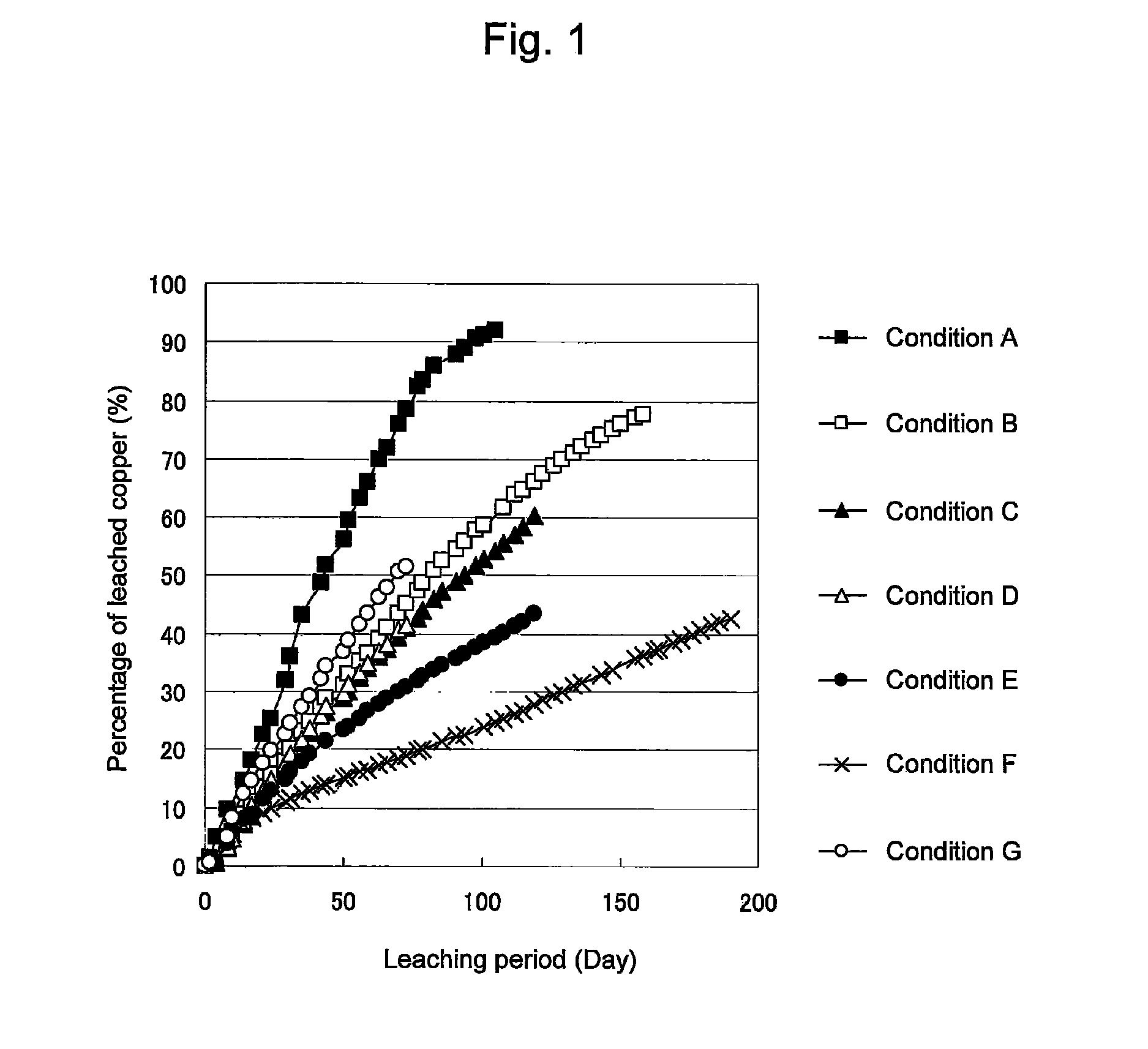

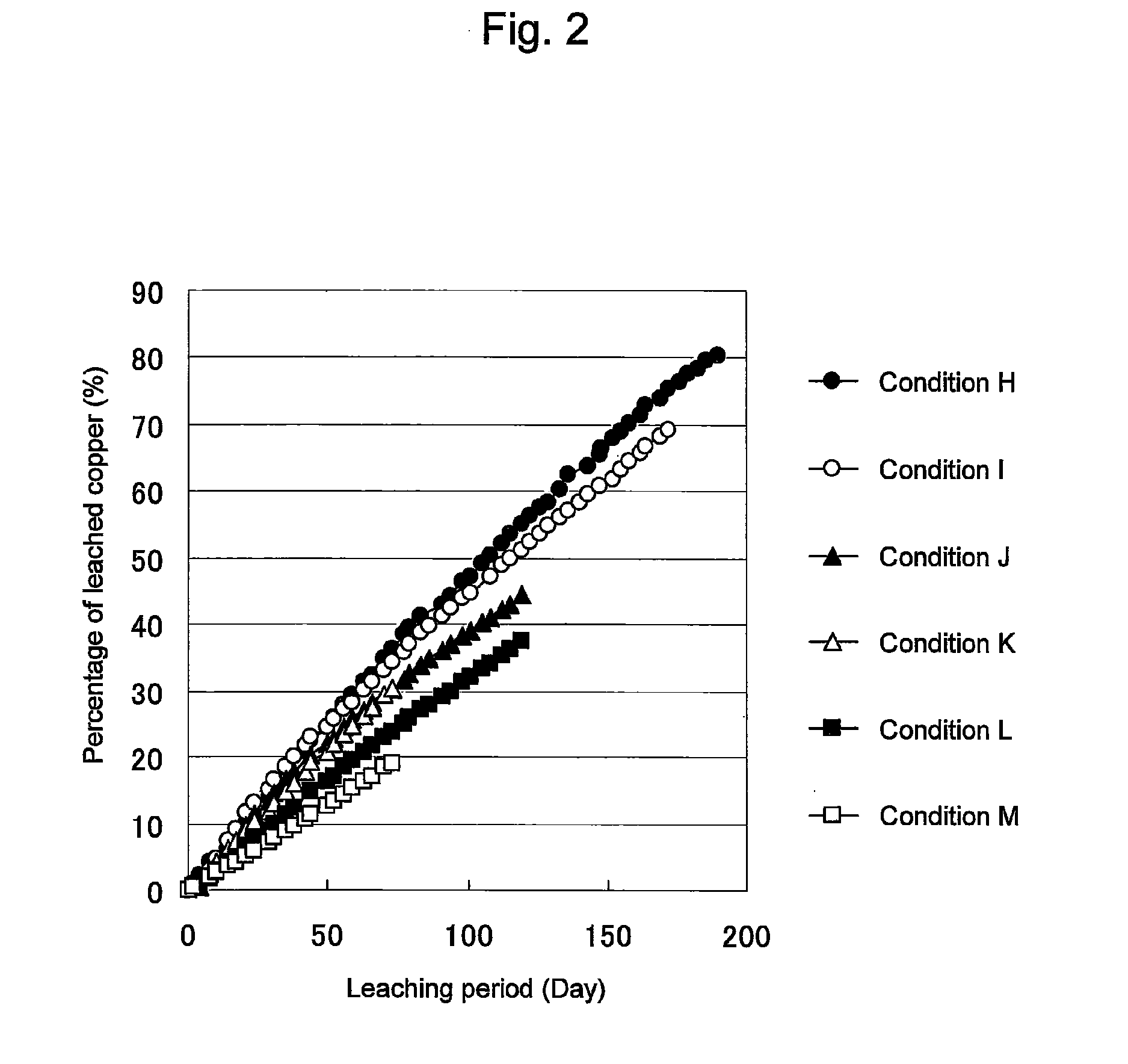

Method of heap or dump leaching of copper from copper sulfide ore

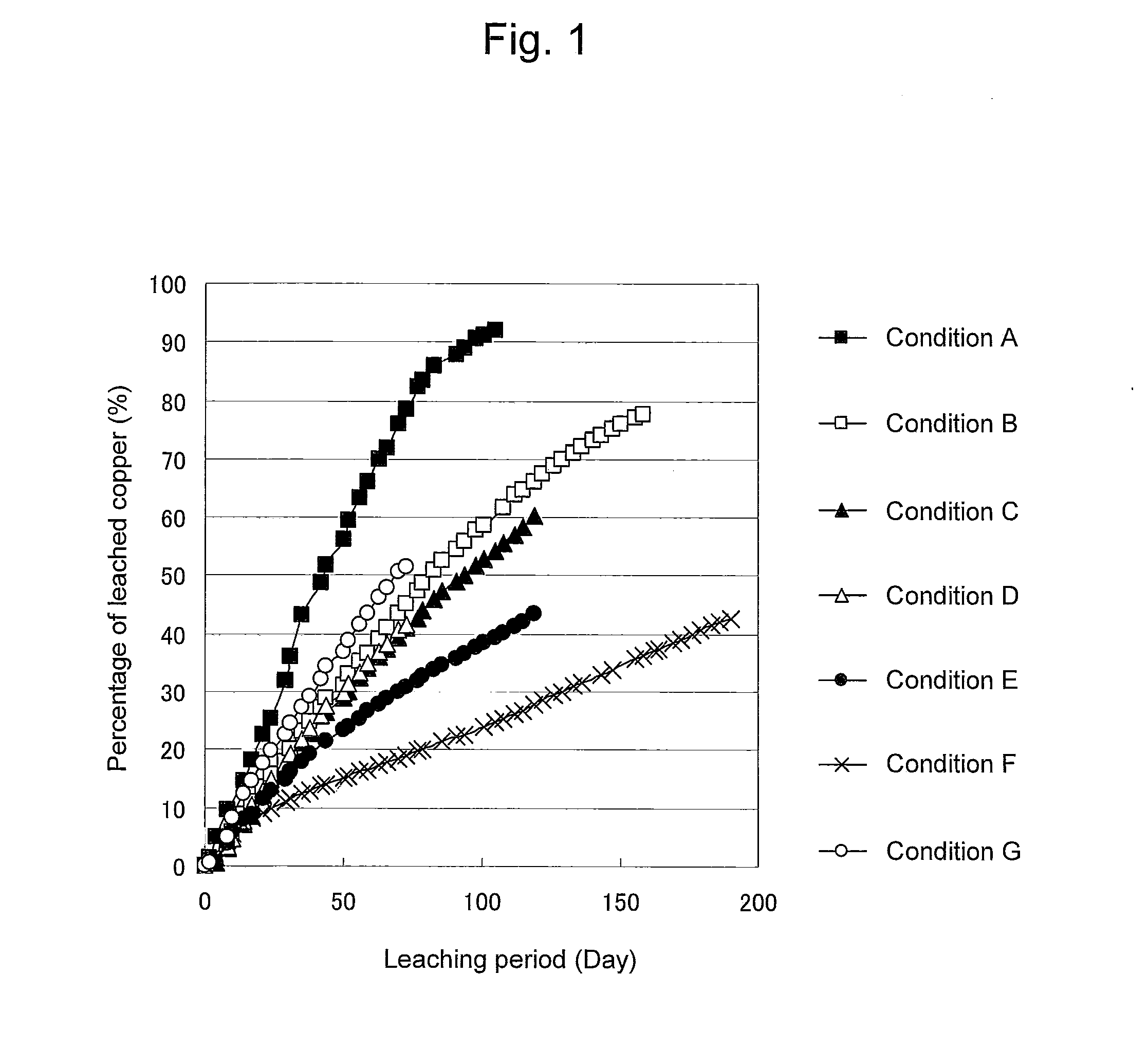

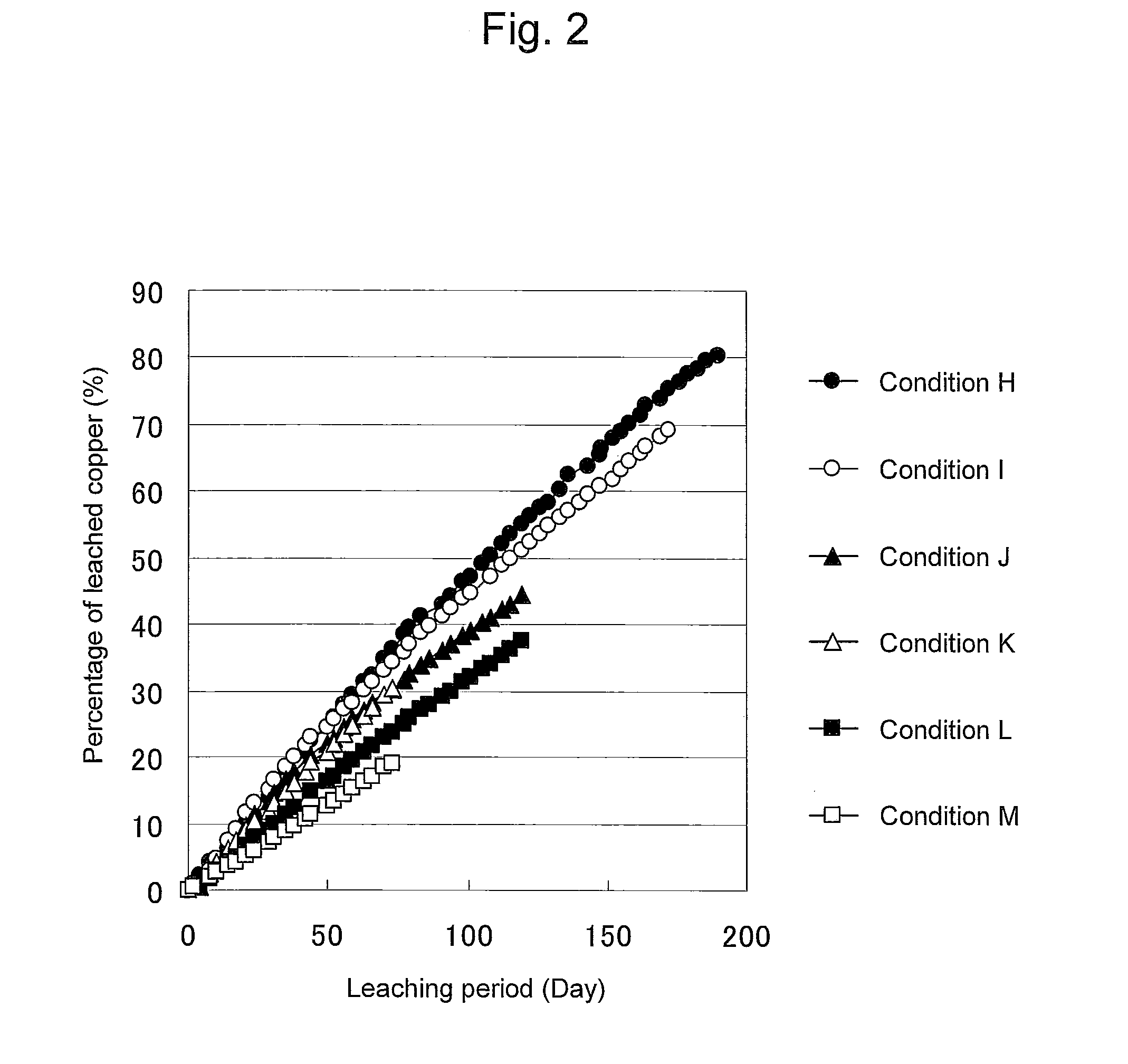

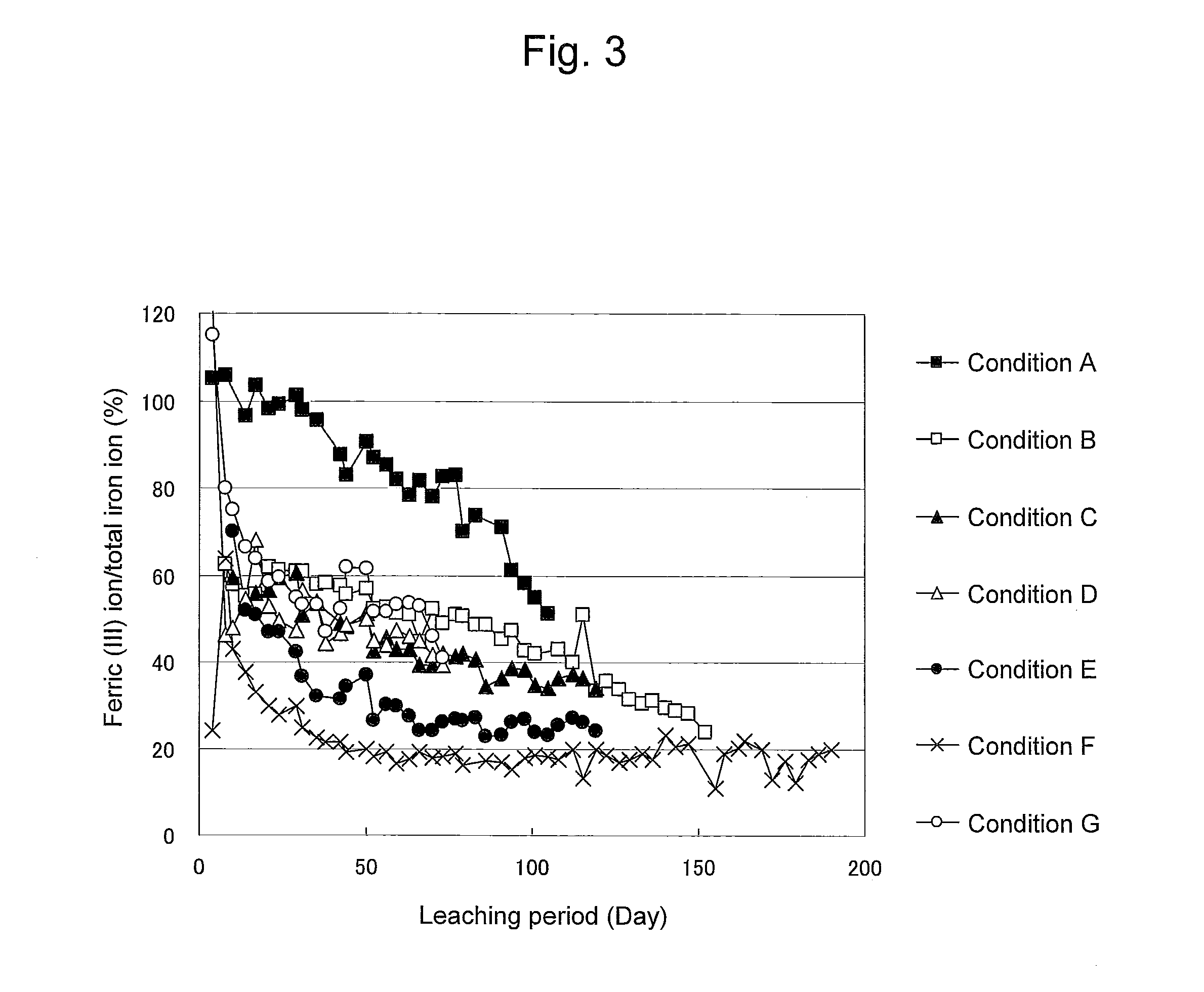

ActiveUS8287623B2Efficient leachingIncrease ratingsSolvent extractionGold compoundsDump leachingHeap leaching

Disclosed is a method of efficiently leaching copper not only from a readily-soluble copper ore but also a poorly-soluble copper sulfide ore partially containing or consisting of chalcopyrite and / or covellite by means of ore heap leaching under versatile conditions for actual operation. Also disclosed is a method of leaching copper from a copper sulfide ore, including leaching copper from an ore including a copper sulfide ore by heap or dump leaching with the use of a sulfuric acid solution containing ferric (III) ions and iodide ions at a total iodine concentration of 8 to 100 mg / L as a leaching solution.

Owner:JX NIPPON MINING & METALS CORP

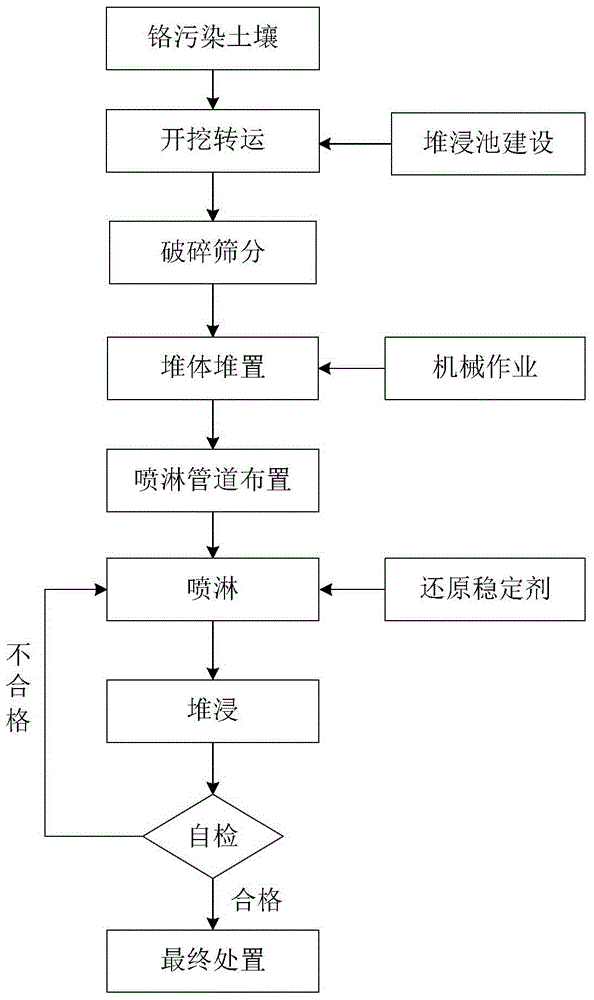

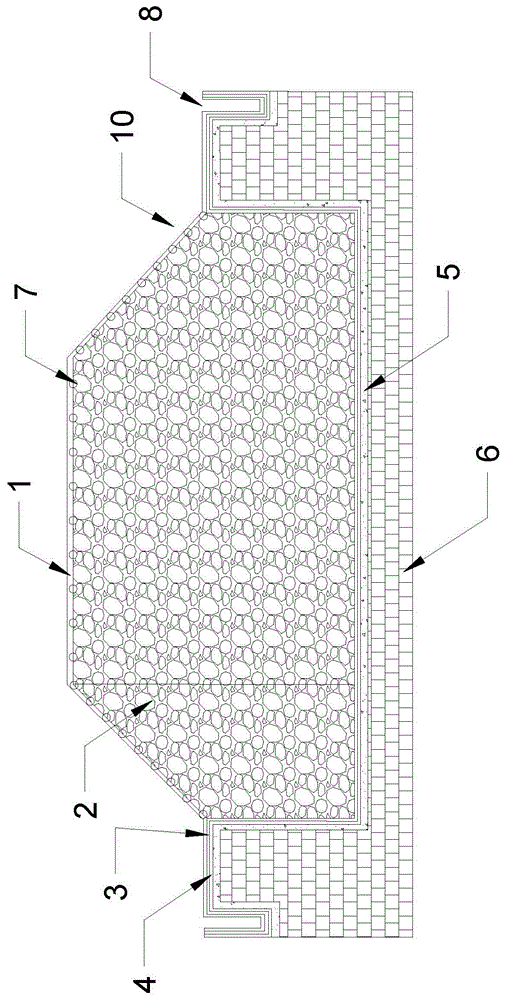

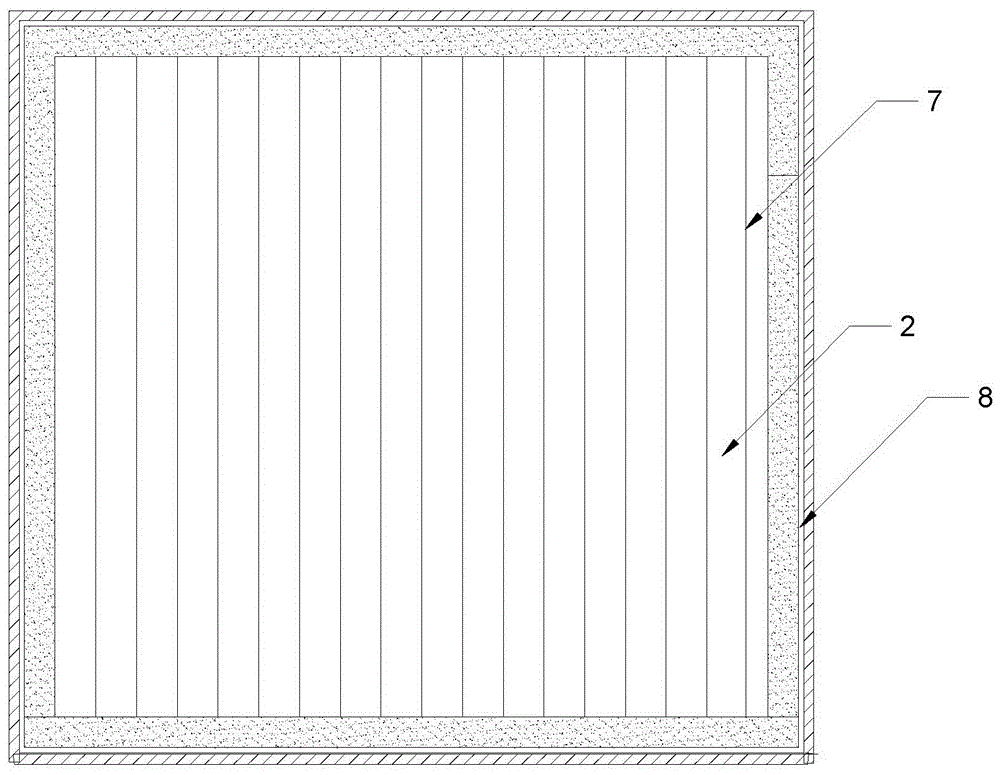

Dump leaching restoration system and restoration process of chromium pollution soil

InactiveCN106345801AAvoid it happening againAvoid secondary pollutionContaminated soil reclamationBrickSurface layer

The invention discloses a dump leaching restoration system of chromium pollution soil. The dump leaching restoration system comprises a dump leaching pool, a chromium pollution soil pile body, a spraying pipeline and a covering layer, wherein the dump leaching pool is formed by building a brick built substrate layer and a cement concrete surface layer covering the brick built substrate layer; the dump leaching pool comprises a dump leaching pool body and an anchoring groove; the anchoring groove is in an annular shape, and surrounds the outer side of the dump leaching pool body; an impermeable membrane and geotechnical cloth are sequentially paved on the cement concrete surface layer of the dump leaching pool body; the edges of the impermeable membrane and the geotechnical cloth extend out of the dump leaching pool body and are fixed in the anchoring groove; the chromium pollution soil pile is piled in the dump leaching pool body; the spraying pipeline is used for supplying restoration medicaments and moisture, and is paved on the upper surface of the chromium pollution soil pile body; the covering layer covers the spraying pipeline; the edges of the covering layer the edges of the covering layer extend out of the dump leaching pool body and are fixed in the anchoring groove.

Owner:BEIJING GEOENVIRON ENG & TECH

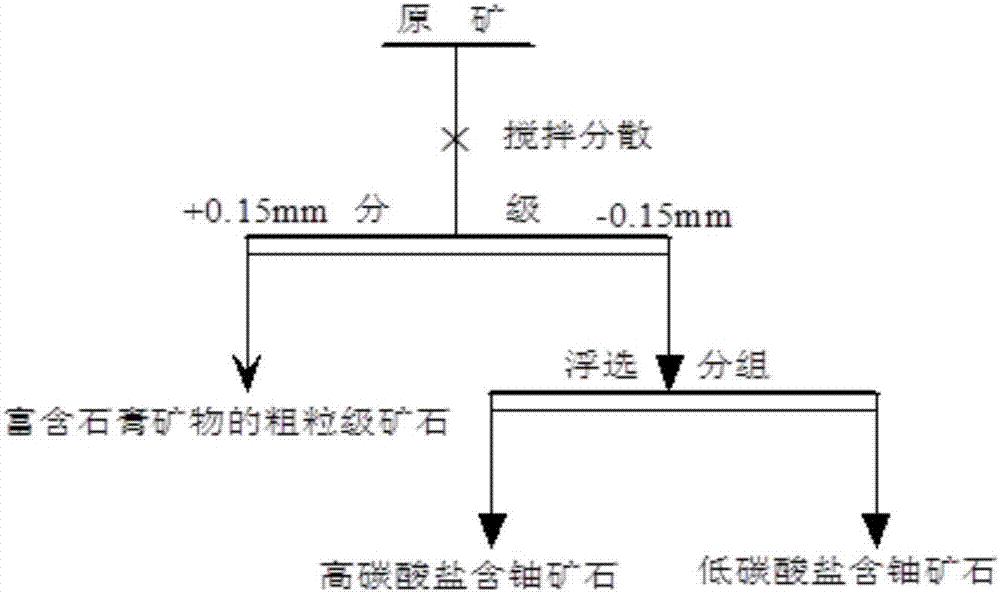

Pretreatment method for mud uranium ores

ActiveCN106944243AHigh recovery rateCost savingFlotationWet separationPretreatment methodUranium ore

The invention belongs to the technical field of uranium mining and metallurgy, and relates to a pretreatment method for mud uranium ores, in particular to a pretreatment method of mud uranium ores rich in gypsum and carbonate minerals. According to the pretreatment method for the mud uranium ores, firstly coarse-grained ores rich in the gypsum are separated, and the coarse-grained ores can recycle uranium through a dump leaching method, the ores grinding cost can be saved and the reagent consumption when fine-grained ores are leached through a alkaline process can be reduced. The fine-grained ores rich in the carbonate minerals are divided into two parts of high-carbonated uranium ores and low-carbonated uranium ores through a flotation method; the uranium can be recycled through subtractive leaching and acid leaching in the follow-up leaching, the reagent consumption can be saved, and the leaching rate is improved.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

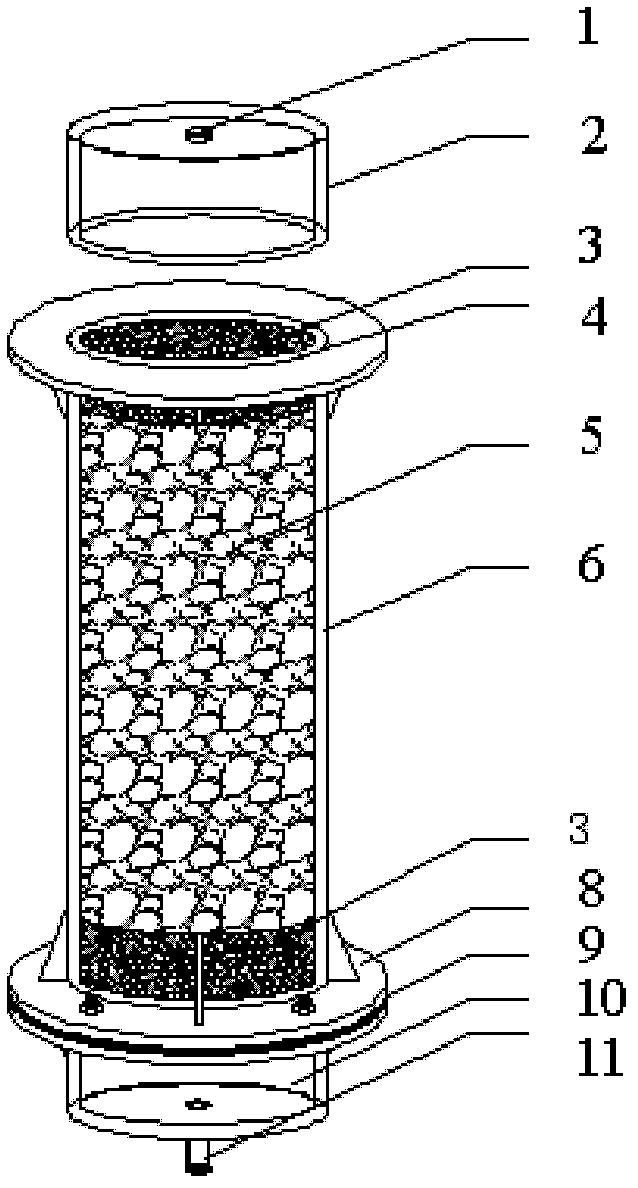

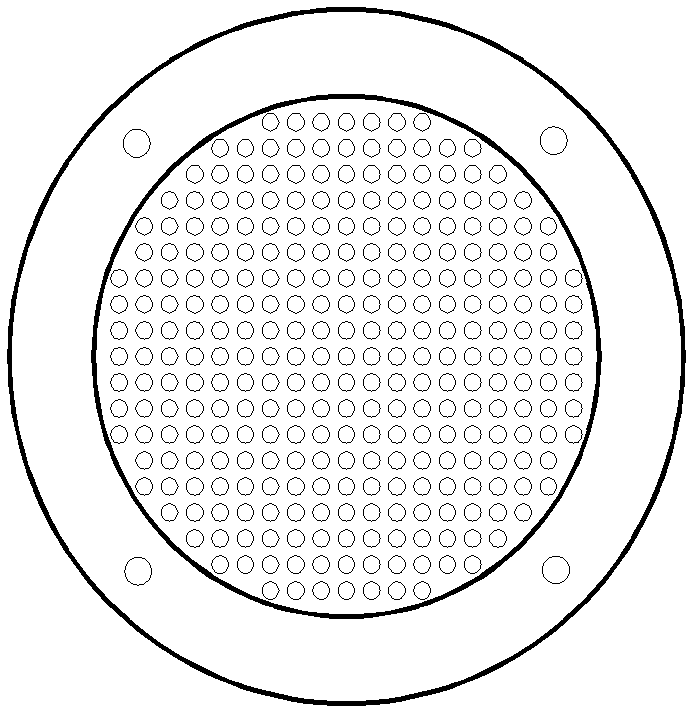

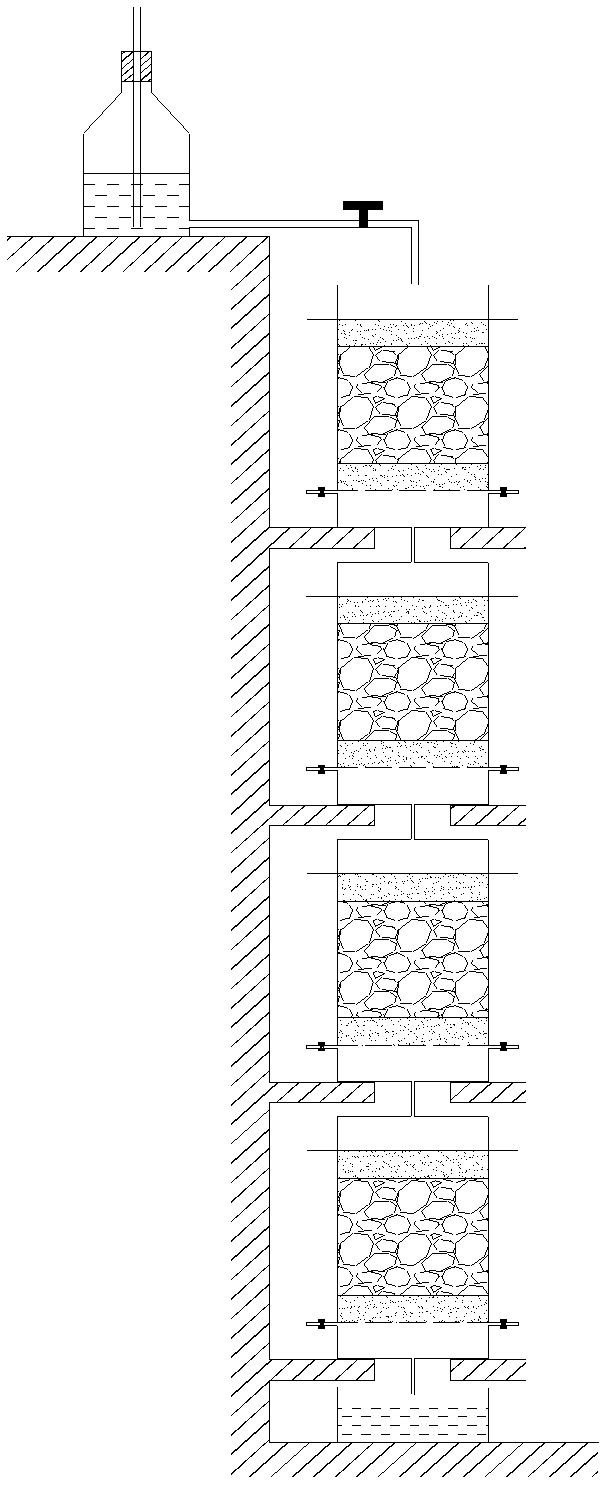

Tandem column soak test device

ActiveCN102560099AFlexible combinationSolve the problem of difficult liquid samplingProcess efficiency improvementDump leachingEngineering

The invention provides a tandem column soak test device. The tandem column soak test device is formed by connecting n unit columns in series, wherein a unit column comprises a communicating hole (1), a sealing cover (2), quartz sand (3), a sealing groove (4), a test ore (5), an organic glass column pipe (6), a flange (8), a perforated plate (9), a buffer space (10) and a communicating pipe (11); the sealing cover (2) is connected to the upper part of the organic glass column pipe (6) by the sealing groove (4) and can be opened; the buffer space (10) is connected to the lower part of the organic glass column pipe (6) by the flange (8), and the middle part of the buffer space is spaced by using the perforated plate (9); small round holes are arranged on the perforated plate (9), and the aperture of each of the small round holes is determined according to the particle size of the test ore; and the unit columns are connected in series by inserting the communicating pipe (11) of the previous unit column into the communicating hole (1) of the next unit column. According to the tandem column soak test device provided by the invention, the change of parameters such as the leaching rates of useful metals at different depths of an ore pile in a field dump leaching process, the consumption amounts of a leaching agent and an oxidant, the pH, the Eh and the like can be simulated, and reasonable process parameters in the field dump leaching process are determined. The tandem column soak test device is simple in structure, low in manufacturing and maintenance cost, convenient to take samples and easy to operate.

Owner:NANHUA UNIV

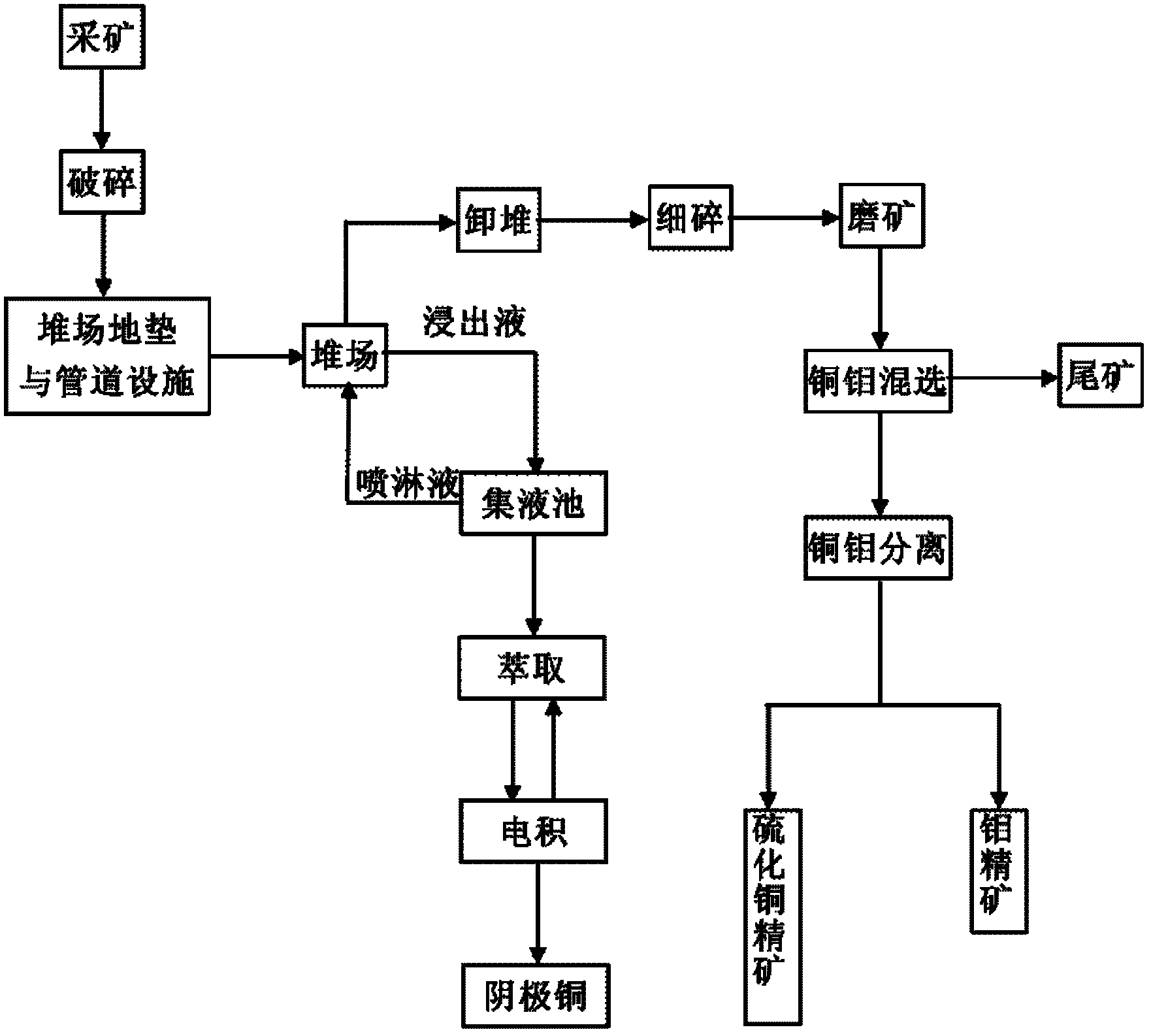

Selection-smelting combined technology for treating mixed ore containing molybdenum, oxygen, sulfur and copper

InactiveCN103184334AReduce manufacturing costImprove resource utilizationFlotationProcess efficiency improvementResource utilizationSulfur

The invention relates to a selection-smelting combined technology for treating mixed ore containing molybdenum, oxygen, sulfur and copper, wherein the copper ore in the mixed ore containing molybdenum, oxygen, sulfur and copper is copper oxide ore and copper sulphide ore, molybdenum ore is molybdenite; the selection-smelting combined technology is characterized in that the copper oxide ore in raw ores can be leached through a dump leaching process, processes of unstacking and crushing can be carried out after the dump leaching process is finished, and then the copper sulphide ore and molybdenum ore can be recovered through a select flotation process. The selection-smelting combined technology is capable of reducing the production cost, increasing the resource utilization rate and bringing good economic benefit for enterprises.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Method for producing aluminum-Me intermediate alloy by one-step electrolysis method

InactiveCN101298684AReduce manufacturing costPurification Heap Leach Discharge ReductionElectrolysisResource utilization

The invention discloses a method for producing an Al-Me master alloy through one-step electrolysis, which comprises following steps: by utilizing the conditions of existing aluminum electrolysis techniques, a cheap metallic oxide A that can be reduced by aluminum is taken as a raw material, and according to the ingredients of an aluminum master alloy to be prepared, a metallic oxide B that contains the corresponding ingredients is added into an existing aluminum electrolysis slot so as to produce the Al-Me master alloy. The method for producing the Al-Me master alloy through one-step electrolysis can remarkably lower the production cost of the Al-Me master alloy; and as the raw material with lower decontamination standard is used, the method can obtain greatly raised utilization rate of resources, reduce the dump leaching and discharging for raw material decontamination, and reduce the energy consumption of secondary remelting.

Owner:熊超

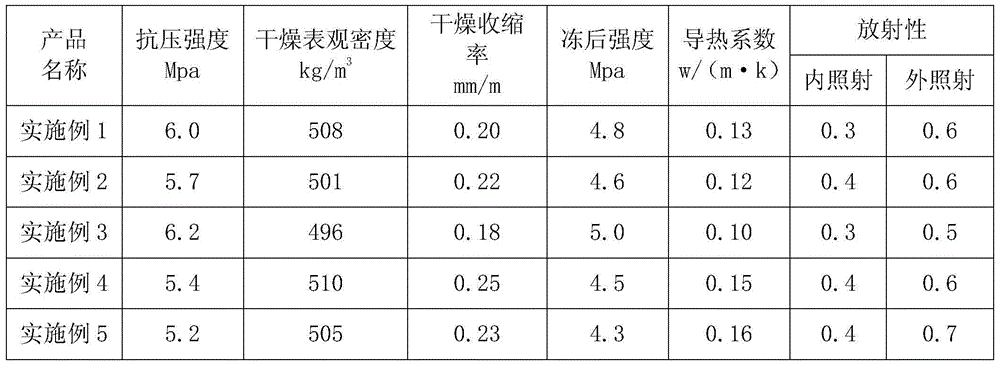

Aerated concrete block produced by dump-leached slags

ActiveCN103819217AGood weather resistanceHigh strengthSolid waste managementCeramicwareSlagSuperplasticizer

The invention relates to an aerated concrete block produced by dump-leached slags. The block comprises the following raw materials in parts by weight: 200 to 500 parts of dump-leached slags, 80 to 150 parts of quick lime, 50 to 200 parts of cement, 3 to 10 parts of gypsum, 0.4 to 1.2 parts of aluminium powder and 8 to 15 parts of superplasticizer, wherein the dump-leached slags are waste residues formed after silicate minerals are processed by acid. The aerated concrete block has the advantages of light weight, high strength, heat preservation, heat insulation and the like, utilizes wastes, is environmental-friendly, saves resources and is a green building material with excellent performance.

Owner:广西建筑材料科学研究设计院有限公司 +1

Wet method lixiviating method for copper-contained tailings

ActiveCN101812587AAlleviate shortagesSimple processPhotography auxillary processesProcess efficiency improvementGranularityEconomic benefits

The invention discloses a wet method lixiviating method for copper-contained tailings, belonging to a tailing comprehensive utilization technical method. The method comprises the following steps of: firstly carrying out soda treatment on the copper-contained tailings, then adding ammonium salt with a certain concentration, respectively carrying out dump leaching and agitation leaching according to the thickness of the granularity of the copper-contained tailings to obtain lixivium having higher copper concentration, finally recovering metal copper with conventional extraction, electrowinning process or direct electrowinning, and returning an ammonium salt contained solution for lixiviating. The method has the advantages of simple process, short process, low energy consumption, no additional equipment, easy implementation, comprehensive recovery of copper resource, less investment and low production cost, and is a copper recovering method which is easy to realize industrial production and has good economic benefits.

Owner:ZIJIN MINING GROUP

Copper extraction and iron removal method of copper ore acid leaching liquid

ActiveCN104232924AImprove the effect of iron removalSimple stepsRotary drum furnacesCrucible furnacesSlagIon exchange

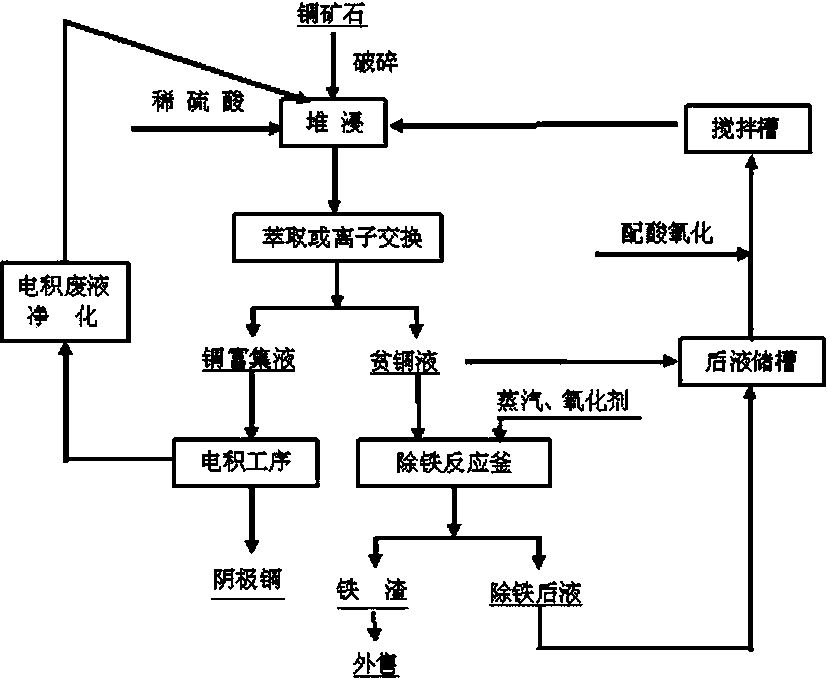

The invention discloses a copper extraction and iron removal method of copper ore acid leaching liquid. The method comprises the following steps: breaking secondary copper oxide ore and secondary copper sulfate ore, mixing and performing wet-process dump leaching; using dilute sulphuric acid as a leaching agent for conducting spraying and leaching to obtain faintly acid leaching liquid; extracting copper from the leaching liquid through extraction or ion exchange to obtain copper-rich liquid and copper-deficient liquid; electrodepositing the copper-rich liquid to obtain cathode copper; performing high-temperature high-pressure continuous iron removal on the copper-deficient liquid in an oxidizing atmosphere to obtain ore pulp, filtering to obtain hematite slag, acidifying and oxidizing part of the copper-deficient liquid, and feeding to a stock dump for cyclic leaching. According to the method, iron ions and the copper sulfate ore are subjected to oxidative reduction in the dump leaching process; iron ions in the dump leaching liquid mainly exist in the form of divalent iron ions, so that the step of reducing divalent iron ions is removed for subsequent copper extraction; iron is removed by a high-temperature high-pressure process, so that the slag yield is low, the environmental protection pressure is small, and the iron slag can be reutilized; sulfuric acid generated in the iron removal process does not need to be neutralized and directly returns to the stock dump for cyclic leaching, so that the comprehensive utilization effect is good.

Owner:HENAN GONGXIN ENVIRONMENTAL PROTECTION & TECH CO LTD

Dressing technology for recycling ultra-low-level gold ore

ActiveCN104307626AGuaranteed leaching rateImprove leaching rateProcess efficiency improvementWet separationMining engineeringGold content

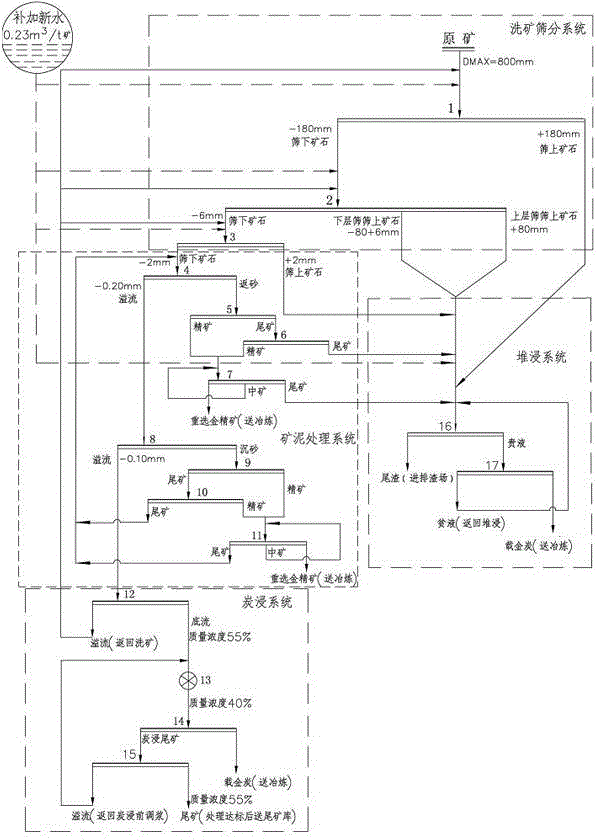

The invention provides a dressing technology for recycling ultra-low-level gold ore. The dressing technology for recycling the ultra-low-level gold ore is composed of an ore washing and screening system, a slime processing system, a carbon leaching system and a dump leaching system, wherein the technological raw ore is directly screened and washed, the ore sand is subjected to dump leaching, the slime is subjected to the stage classification, stage reelecting recycling particle minding and the carbon leaching, gold concentrate, dump leaching gold loaded carbon and carbon leaching gold loaded carbon of a first segment reelecting returning path and a second segment reelecting returning path are obtained, and the reelecting gold concentrate and the gold loaded carbon are sent to a gold melting plant for treatment to obtain gold ingot. According to the dressing technology, the oxidized gold ore with the gold content of the raw ore being under 0.4g / t and the mud content being above 25% is adopted, the gold dressing recycling rate reaches above 75%, the ultra-low-level gold ore resource is fully used, the gold ore resource is enlarged, the water returning use is strengthened in all steps, the corresponding work is returned according to the water returning quality, water is saved, and the ore per unit consumes under 0.23m3 / t of water.

Owner:CHINA NERIN ENG

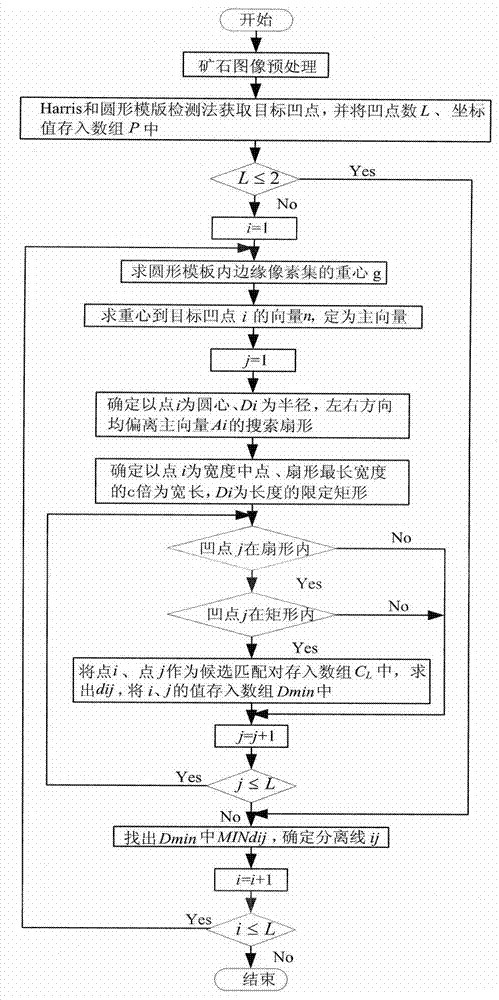

Image analysis-based dump leaching uranium ore particle size parameter identification method

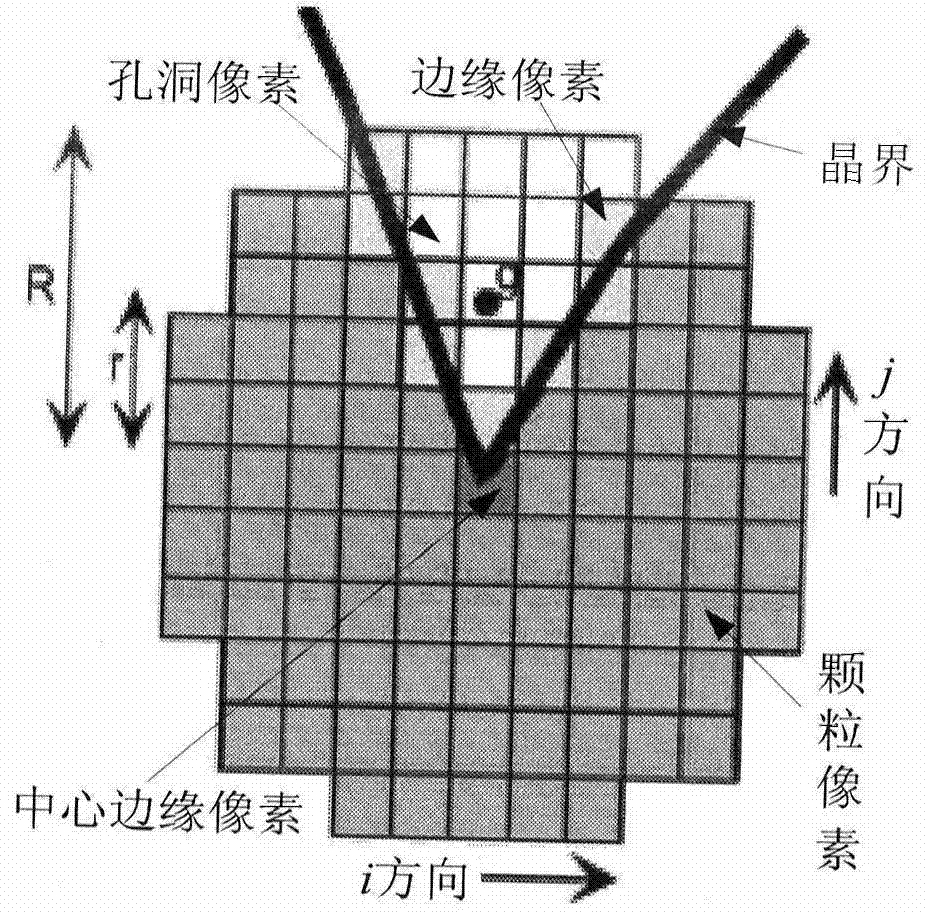

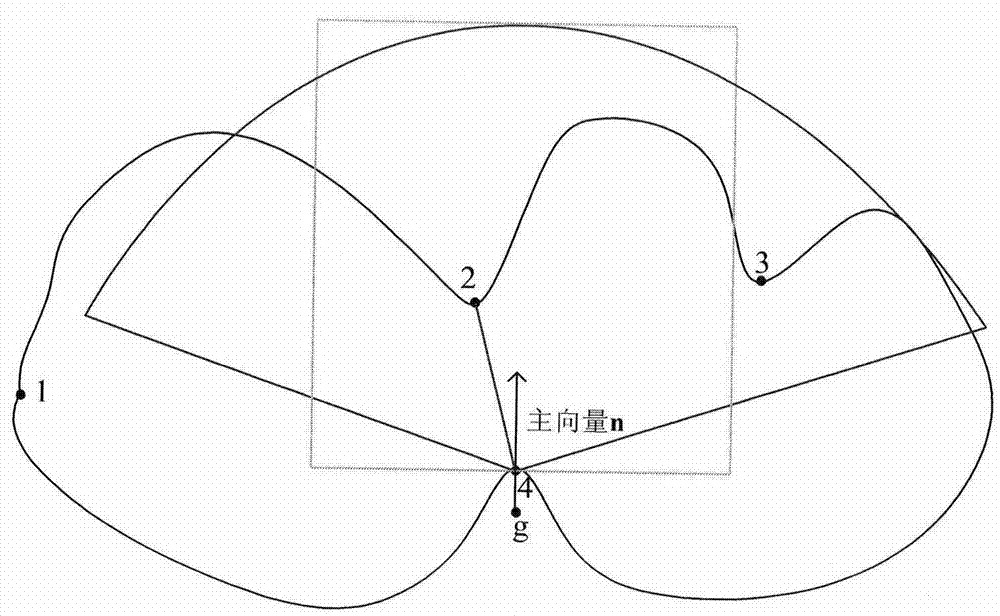

InactiveCN104851092AAccurately screen size distribution dataImage analysisImaging analysisMathematical model

The invention provides an image analysis-based dump leaching uranium ore particle size parameter identification method. The image analysis-based heap leaching uranium ore particle size parameter identification method includes the following steps that: three dimensional feature information of a typical uranium ore is extracted, the minimum projection area of the uranium ore is calculated, and the screening size of the uranium ore is determined according to the minimum projection area; a single-layer broken uranium ore image adhesion phenomenon is processed, and single-layer broken uranium ore three-dimensional feature information is extracted, and the screening size and block distribution of a broken uranium ore are calculated; calculation errors are analyzed, the uranium ore block distribution which is obtained through calculation is corrected; and an optimum block distribution prediction mathematic model can be obtained through derivation according to the uranium ore lock distribution situation. According to the image analysis-based dump leaching uranium ore particle size parameter identification method of the invention, an ore screening size manual detection method is simulated, and therefore, defects of existing 2D or 3D image analysis methods can be eliminated, and more accurate uranium ore screening size distribution data can be obtained.

Owner:宁志刚

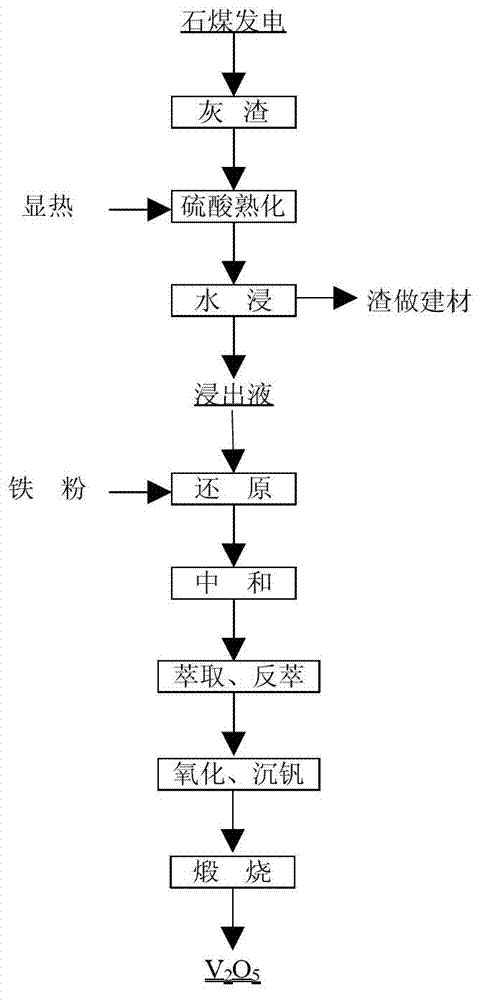

Method for extracting vanadium by using vanadium-containing stone coal power generation ash with sensible heat and low energy consumption

InactiveCN103290240ASimple processReduce energy consumptionProcess efficiency improvementCombustionGranularity

The invention discloses a method for extracting vanadium by using vanadium-containing stone coal power generation ash with sensible heat and low energy consumption. Through controlling the granularity of vanadium-containing stone coal to be below 8mm in advance, vanadium is directly leached from stone coal ash after being used for combustion power generation by adopting a method of similar dump leaching of concentrated sulfuric acid without being cooled, crushed and ground. According to the method, the sensible heat of the vanadium-containing stone coal power generation ash is fully utilized, the process is simplified, the energy consumption is reduced, and carbon and vanadium resources of the stone coal are comprehensively utilized.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

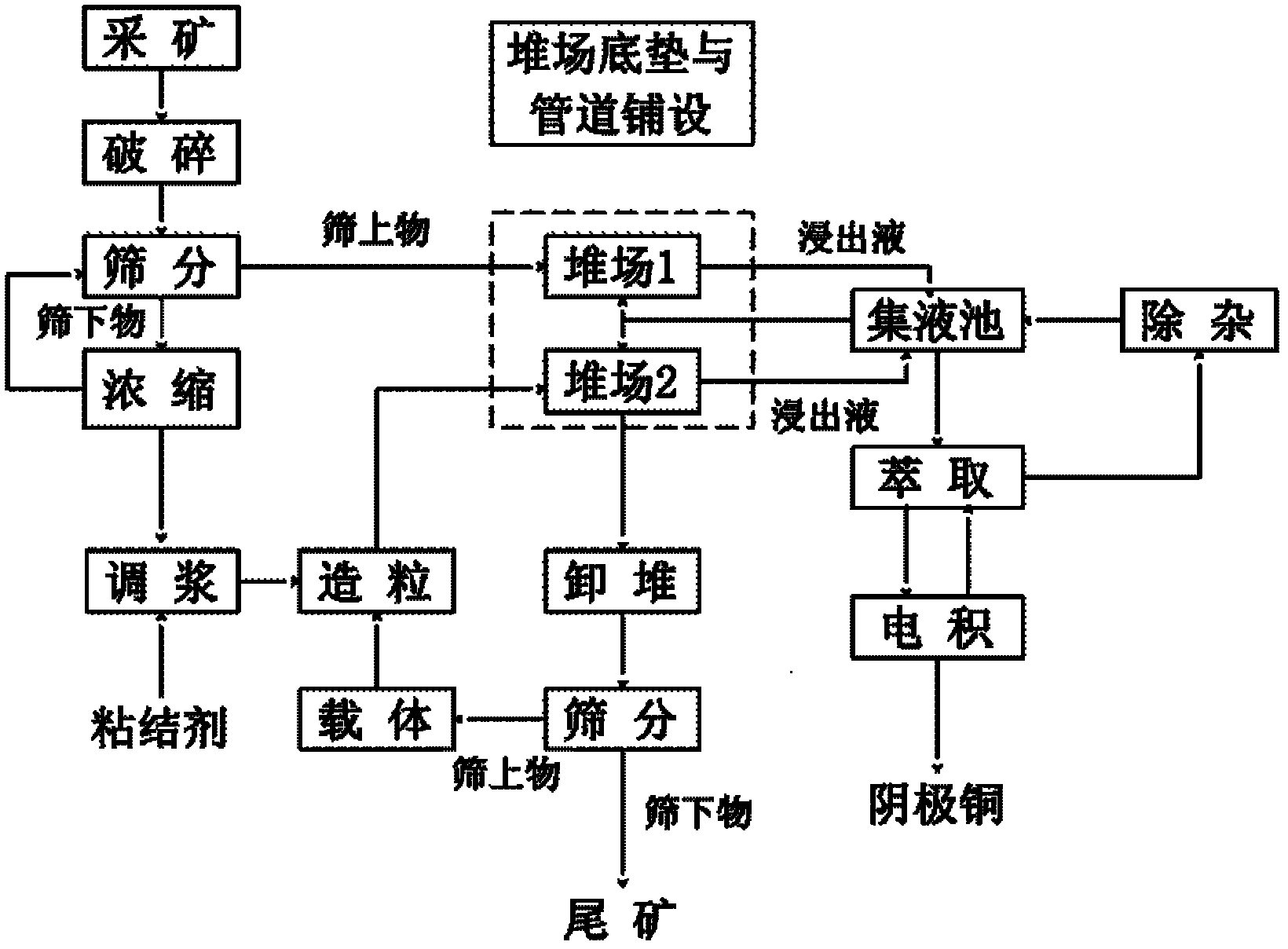

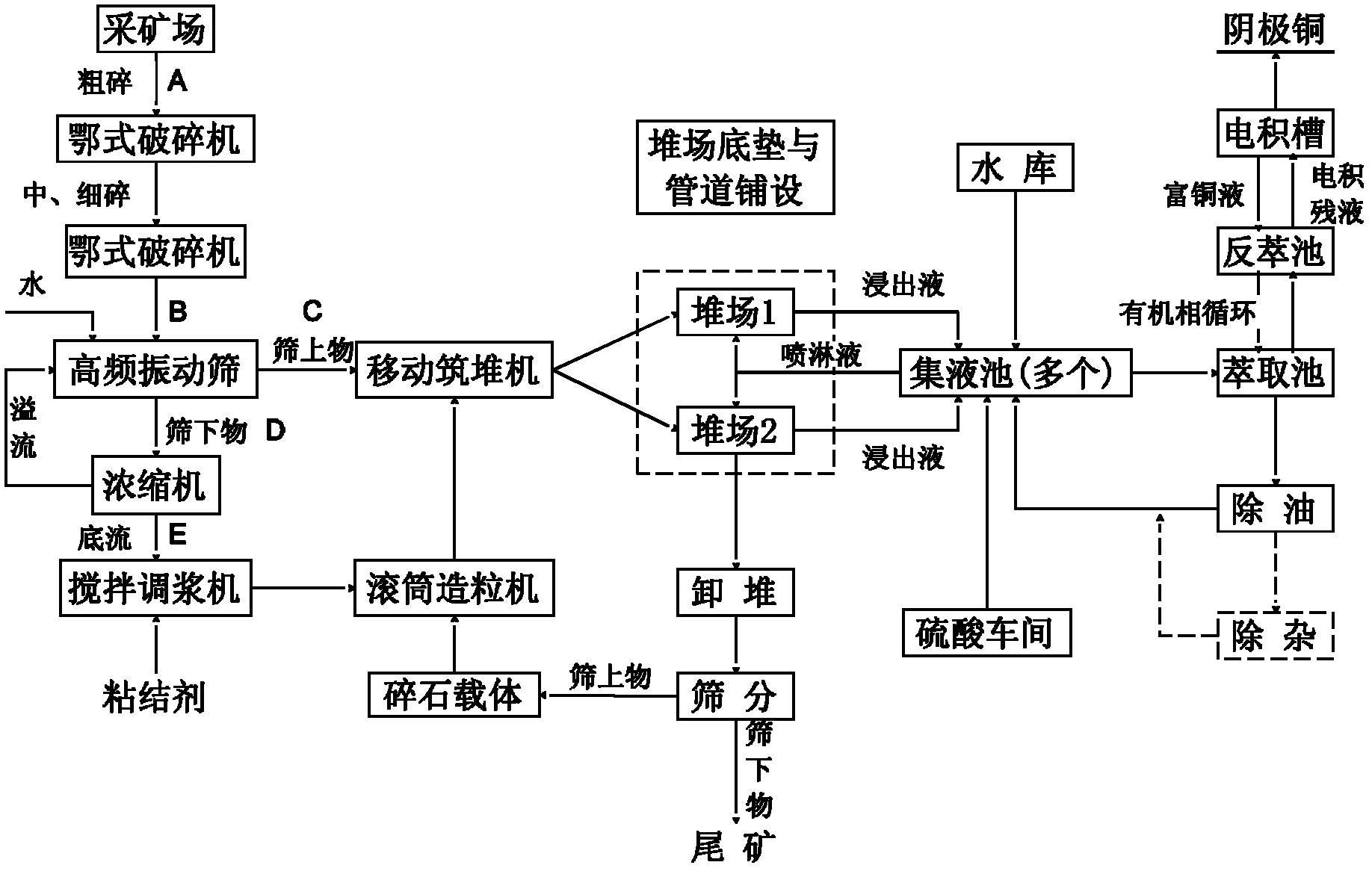

Acid dump leaching technology of atacamite

InactiveCN103173612AHigh recovery rateEfficient recyclingPhotography auxillary processesProcess efficiency improvementPregnant leach solutionClay minerals

The invention provides an acid dump leaching technology of atacamite. The acid dump leaching technology comprises the following steps of: crushing atacamite ores in two sections; screening; directly conveying oversize products to a stock dump to carry out the acid dump leaching; conveying a screen underflow into a thickener; adding an adhesion agent to the underflow in the thickener to mix the size; transferring the underflow into a granulator to mix with an acid-proof gravel carrier to granulate, so as to obtain mineral particles with a layer of atacamites covered on the surface; conveying the obtained mineral particles to the stock dump to carry out the acid dump leaching, wherein the concentration variation condition of the acid and copper in leaching liquor is monitored on real time during leaching, and the acidity as well as the spray intensity of the spray liquid are adjusted based on the monitoring data; treating copper-rich leaching liquor which is circularly sprayed at a plurality of times in the stock dump by the processes of extracting, reverse extracting and electrodeposition, so as to obtain a cathode copper product; treating extraction raffinate by degreasing or purifying process; and then returning to the dump leaching process. The acid dump leaching technology of the atacamite, provided by the invention, is a technology for treating clay-containing minerals and easily-slimed atacamite ores in the Gobi Desert Region; and atacamite resources which are difficulty utilized in the past can be fully utilized by the acid dump leaching technology.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Method of heap or dump leaching of copper from copper sulfide ore

ActiveUS20110041654A1Efficient leachingIncrease ratingsSolvent extractionGold compoundsIodideDump leaching

The object of the present invention is to provide a method of efficiently leaching copper not only from a readily-soluble copper ore but also a poorly-soluble copper sulfide ore partially containing or consisting of chalcopyrite and / or covellite by means of ore heap leaching under versatile conditions for actual operation.This invention relates to a method of leaching copper from a copper sulfide ore, comprising leaching copper from an ore comprising a copper sulfide ore by heap or dump leaching with the use of a sulfuric acid solution containing ferric (III) ions and iodide ions at a total iodine concentration of 8 to 100 mg / L as a leaching solution.

Owner:JX NIPPON MINING & METALS CO LTD

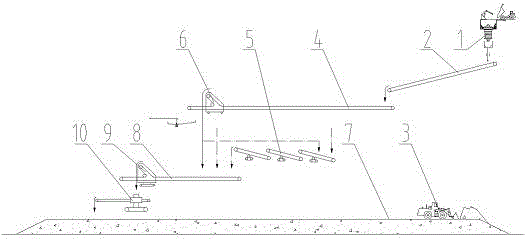

System and method for stacking or dumping waste ore through large self-moving bridge type distributing machine

ActiveCN105858253ASmall compactionSmall permeability impactConveyorsLoading/unloadingTransportation capacityBridge type

The invention discloses a system and method for stacking or dumping waste ore through a large self-moving bridge type distributing machine. The system comprises main devices, including a breaking device, a fixed type rubber belt conveyor, a fixed type rubber belt conveyor provided with a dumper, a lightweight rubber belt conveyor belt, a travelling type rubber belt conveyor and a self-moving bridge type distributor which are sequentially arranged. The method is characterized in that the waste ore is broken and then sequentially conveyed through the rubber belt conveyors and the dumper; the self-moving bridge type distributor is arranged at the tail end of the system and can freely move in a dump leaching site or a waste ore site to arrange the waste ore; after the one layer is arranged, the self-moving bridge type distributor can independently build to raise to an upper channel so as to automatically finish layer rising. The system for stacking or dumping the waste ore in the dump leaching site has the advantages that the permeability of the ore on the top part of a dump leaching ore stack is influenced a little while stacking or dumping the waste ore; the system reliability is high; the area used is small; the energy can be saved, and the environment can be protected; the transportation capacity is high, and the operation cost is low.

Owner:CHINA NERIN ENG

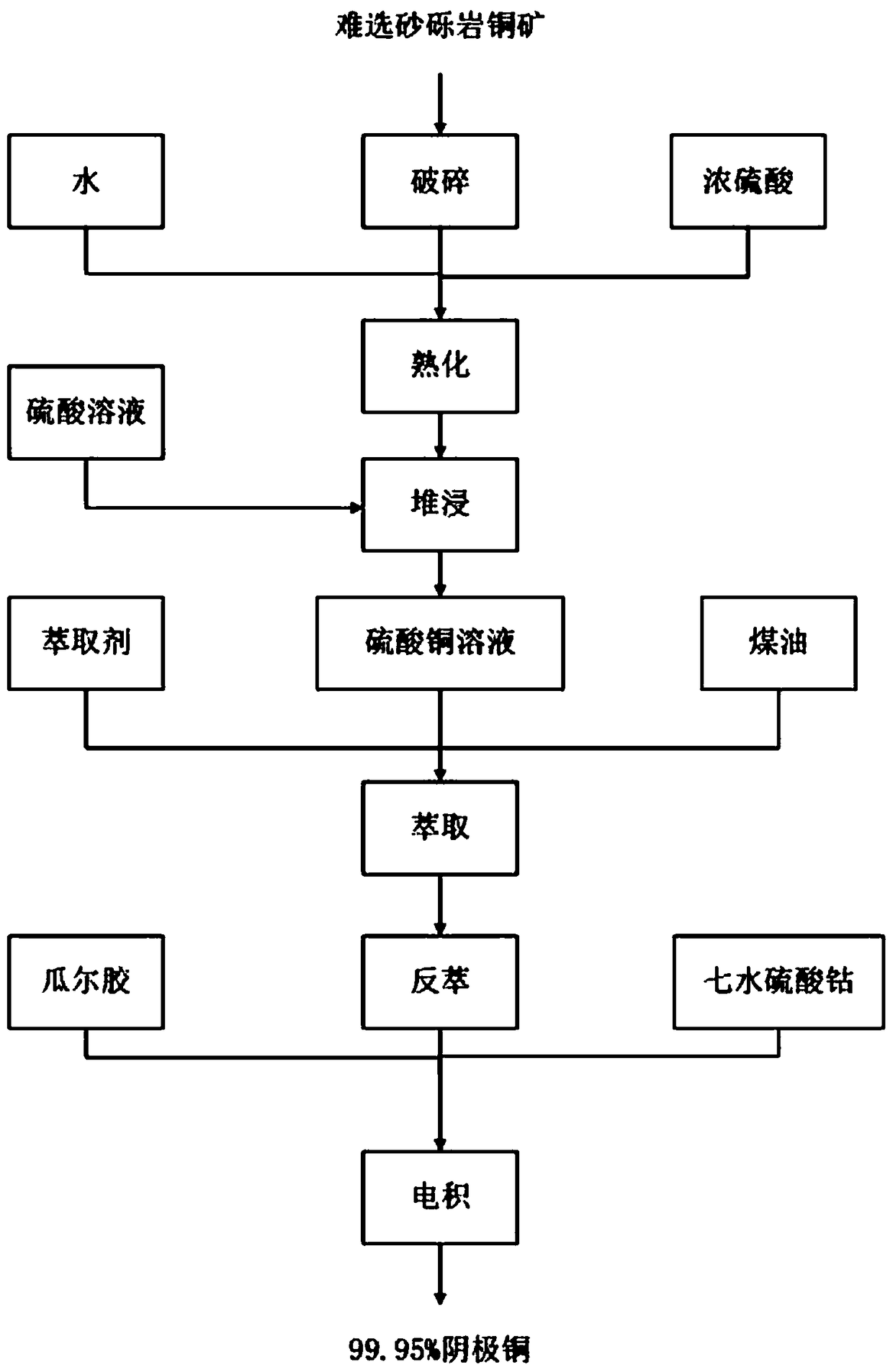

Method for producing cathode copper through refractory glutenite copper ore

InactiveCN108505065AImprove copper leaching rateHigh recovery ratePhotography auxillary processesProcess efficiency improvementMineral SourcesEconomic benefits

The invention discloses a method for producing cathode copper through refractory glutenite copper ore, and belongs to the technical field of metallurgy. According to the method, the refractory glutenite copper ore is crushed, granulated and subjected to curing treatment, dump leaching, extraction and electrodeposition treatment, and the cathode copper is prepared. Before dump leaching treatment, raw ore particles are subjected to sulfating curing pretreatment, copper is separated from gangue or other minerals, meanwhile, the refractory glutenite copper ore is loosened, the purpose of porosityincreasing is achieved, dump leaching is facilitated, the leaching rate is improved by 10%-20%, and a good condition is provided for later cathode copper production. The produced cathode copper purityis high, the yield is large, the copper leaching rate and the recycling rate of the refractory glutenite copper ore are effectively improved, the mineral resource is more efficiently utilized, and economic benefits are improved.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

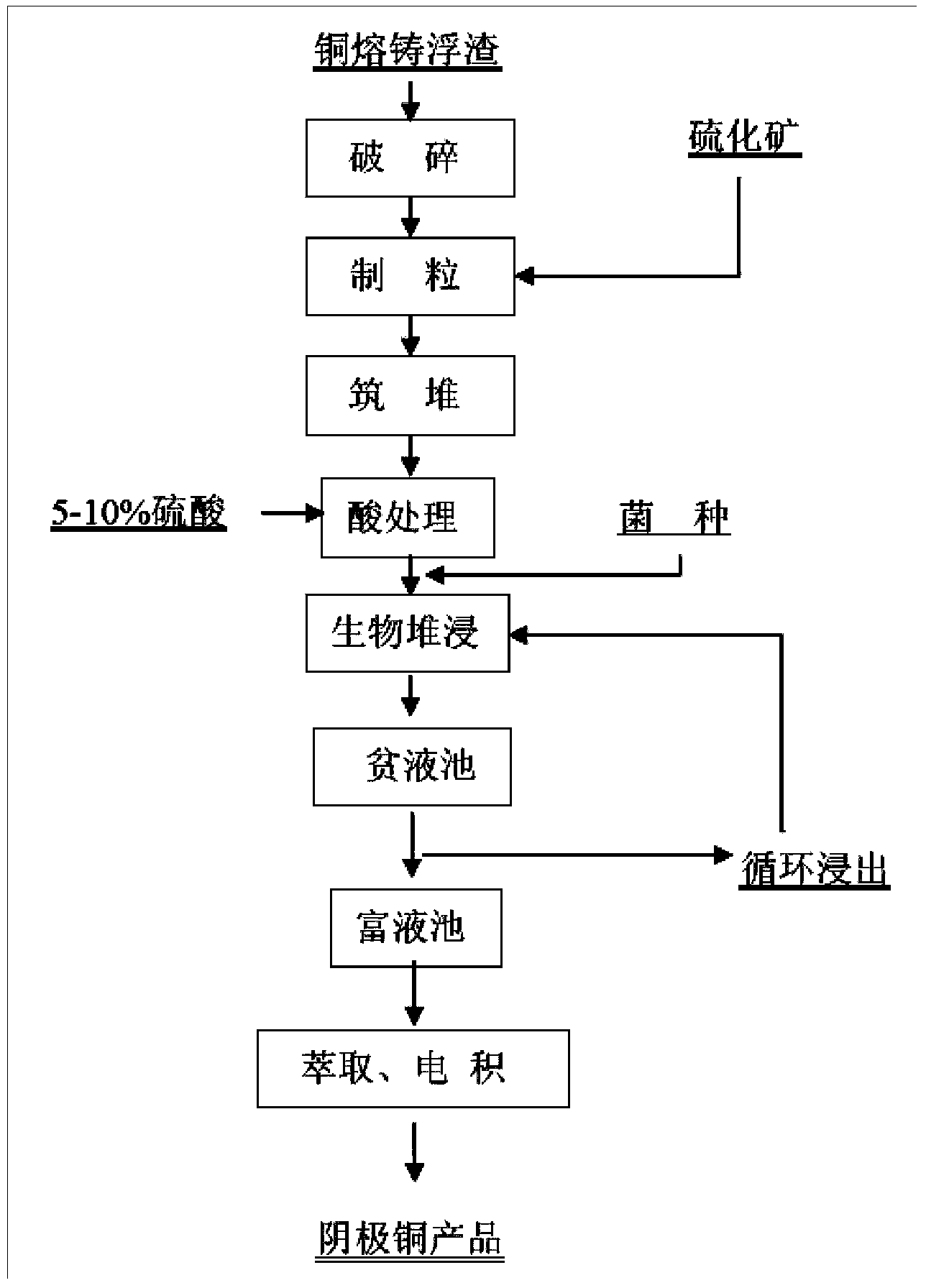

Copper recycling process of copper casting scum by utilizing biological dump leaching

The invention provides a copper recycling process of copper casting scum by utilizing biological dump leaching. The process comprises the steps of: crushing copper casting scrum to be below 20mm by virtue of a crushing system; adding pyrite with the granularity of below 10mm or mixed ore of the pyrite and copper sulphide ore after the crushing to ensure that the weight ratio of sulphide ore to the copper casting scum is 1: 1 to 5:1; pelleting by virtue of a drum polletizing machine; delivering to a stock dump by virtue of a self-discharging automobile or a belt for dumping; eluting the stock heap by utilizing sulfuric acid with the concentration of 5-10 percent and thus regulating a pH value of the stock heap is 1.5-2.5; inoculating microorganisms into the stock heap for oxidizing iron into ferric iron by utilizing the function of the microorganisms; producing acid by utilizing a ferric iron and organism leaching process for oxidizing and leaching copper, wherein the height in the dump leaching process is 1-6m, the dump leaching period is 1-6 months, and the spraying intensity is 5-30 L / (h.m<2>). The copper resource comprehensive recycling process is simple, low in investment and cost, simple in equipment and easy to carry out, so that the copper recycling process of copper casting scum by utilizing biological dump leaching takes the obvious advantage.

Owner:JIANGXI UNIV OF SCI & TECH

Novel environmentally-friendly precious metal mineral separation agent

ActiveCN104250693AReduce distractionsHigh recovery rateProcess efficiency improvementSolubilityLead nitrate

The invention discloses a novel environmentally-friendly precious metal mineral separation agent. The novel environmentally-friendly precious metal mineral separation agent comprises, by mass, 2.5% of sodium carbonate, 2.5% of sodium chloride, 2.5% of calcium chloride, 2.5% of lead nitrate, 10% of bismuth nitrate, 10% of ammonium nitrate, 10% of potassium permanganate, 20% of sodium hypochlorite, 20% of potassium iodide and 20% of lime sulphur. The lead nitrate is used as a stabilizing agent. A preparation method of the novel environmentally-friendly precious metal mineral separation agent comprises simple processes of weighing the raw materials according to the above ratio and mixing the raw materials to obtain a uniform mixture, wherein the mixture is powder, has good solubility and can be completely dissolved in 10min by an appropriate amount of water. The method can realize effective leaching of gold ions, improves a recovery rate and is suitable for large-scale production. The method utilizes lead nitrate as an effective stabilizing agent thereby reducing interference produced by harmful substances such as sulfur and antimony. Compared with the conventional carbonitriding dump leaching, the method shortens a production period by 20%.

Owner:大冶市金欣环保科技有限公司

Uranium ore dump leaching-agitation leaching combined hydrometallurgical method

The invention belongs to the technical field of a uranium ore leaching process in uranium hydrometallurgy and particularly relates to a uranium ore dump leaching-agitation leaching combined hydrometallurgical method. The uranium ore dump leaching-agitation leaching combined hydrometallurgical method comprises the following steps that (1) uranium ore dump leaching dumped ores are broken through theprocess of three stages with a single closed circuit; (2) through wet-type screening and grading, fine silt with the size fraction being smaller than 0.15 mm in screen underflow of the broken uraniumore dump leaching dumped ores in the step (1) is separated; (3) thin ore pulp in the step (2) enters a thickener to be concentrated; (4) the thickener underflow ore pulp in the step (3) enters an agitation leaching system to be leached, and the leached ore pulp is obtained; and (5) the leached ore pulp which is obtained in the step (4) is filtered and washed. According to the technical scheme, the grade of separated muddy ore uranium is higher than the average grade of the ores, the higher leaching rate can be obtained through agitation leaching, thus the leaching concept of 'low-dump and high-smelting' is achieved, and the ore treating technology tends to be more reasonable accordingly.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com