Dump leaching restoration system and restoration process of chromium pollution soil

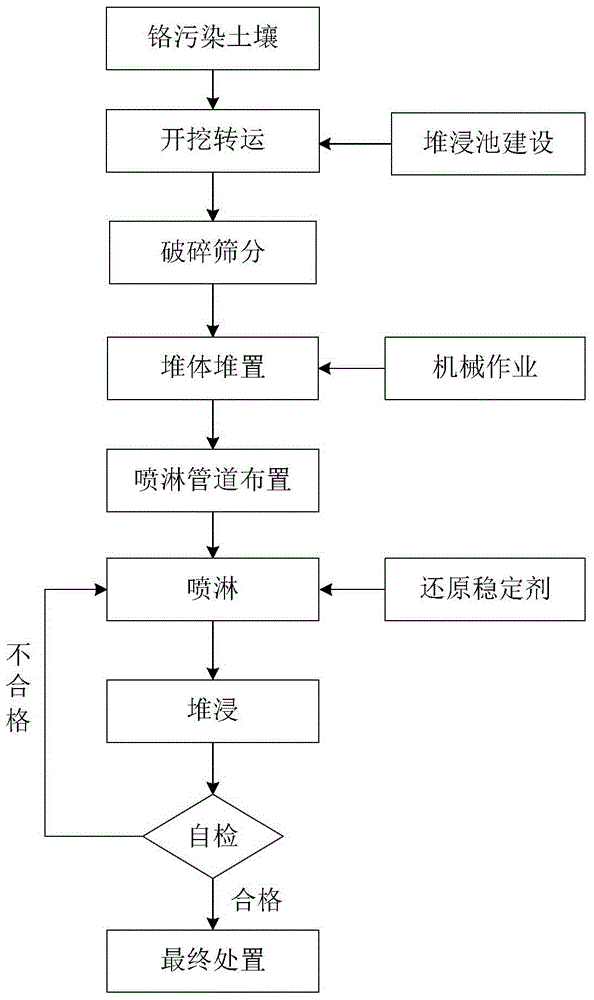

A chromium-contaminated soil and repair system technology, applied in the restoration of contaminated soil, etc., can solve the problems of long infrastructure construction period, unfavorable use of small and medium-sized projects, time-consuming and labor-intensive demolition of structures, etc., to achieve strong engineering applicability and construction The effect of fast speed and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The content of the present invention will be further explained and illustrated below in conjunction with the accompanying drawings.

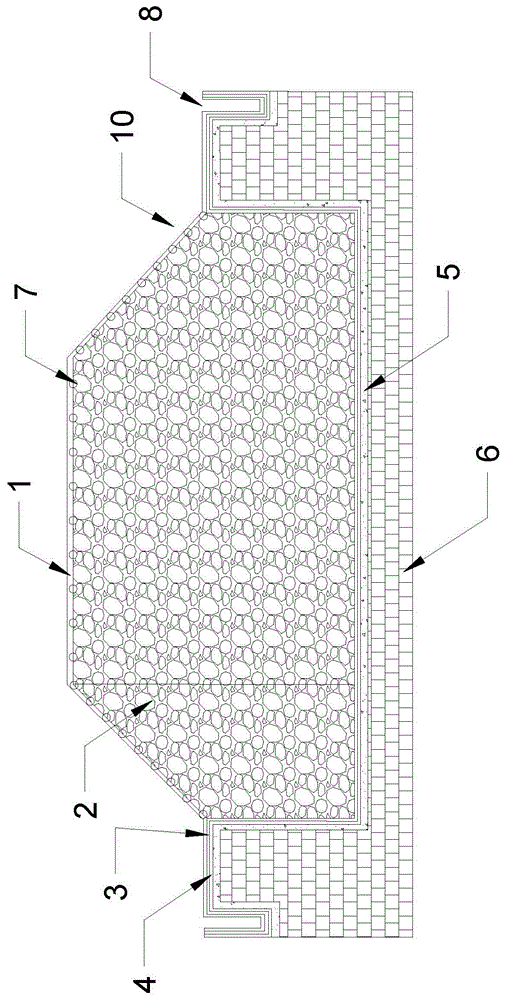

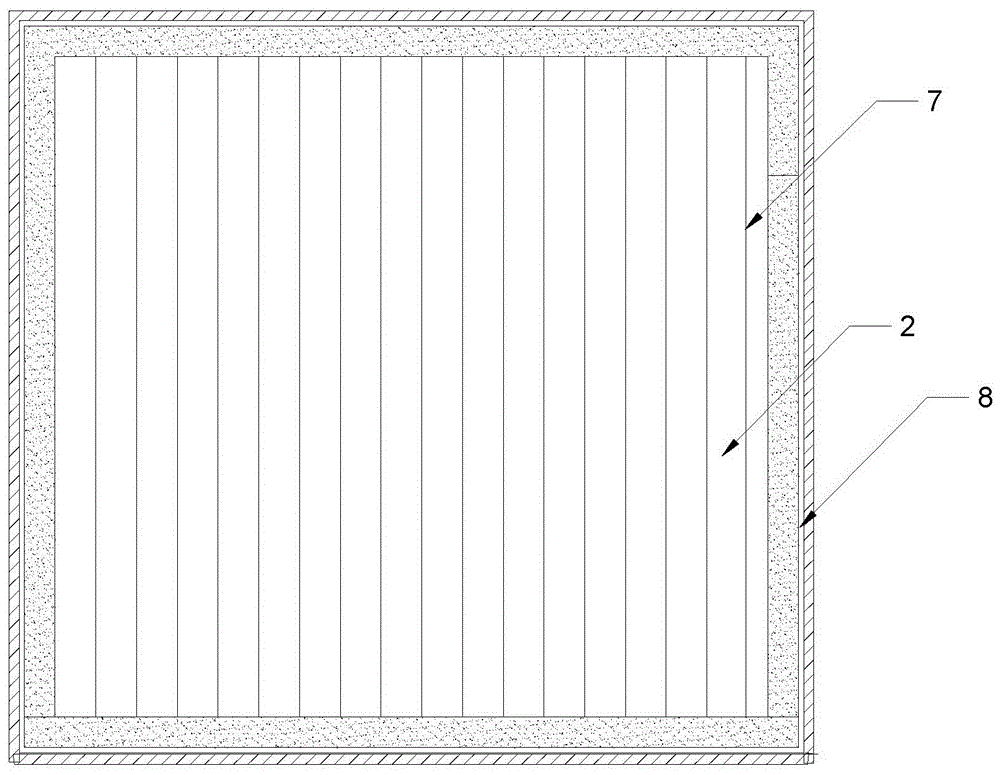

[0035] combine figure 2 and image 3 , the heap leaching restoration system of chromium-contaminated soil of the present invention, comprising:

[0036] A heap leach tank, which is constructed from a brick base layer 6 and a concrete surface layer 5 (thickness 5-15cm) covering the brick base layer 6; the heap leach tank includes: a heap leach tank body 10 and an anchor Ditch 8; the anchoring ditch 8 is annular and surrounds the outside of the heap leach tank body 10; wherein, the concrete surface layer 5 of the heap leach tank body 10 is successively laid with an anti-seepage membrane 4 and a geotextile 3, and the anti-seepage membrane 4 (high-density polyethylene film with a thickness of 15cm, bentonite waterproof blanket or composite geomembrane) and geotextile 3 (600g / m 2 The edge of the nonwoven geotextile) protrudes out of the he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com