Tandem column soak test device

A test device and column leaching technology, applied in the field of serial column leaching test devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

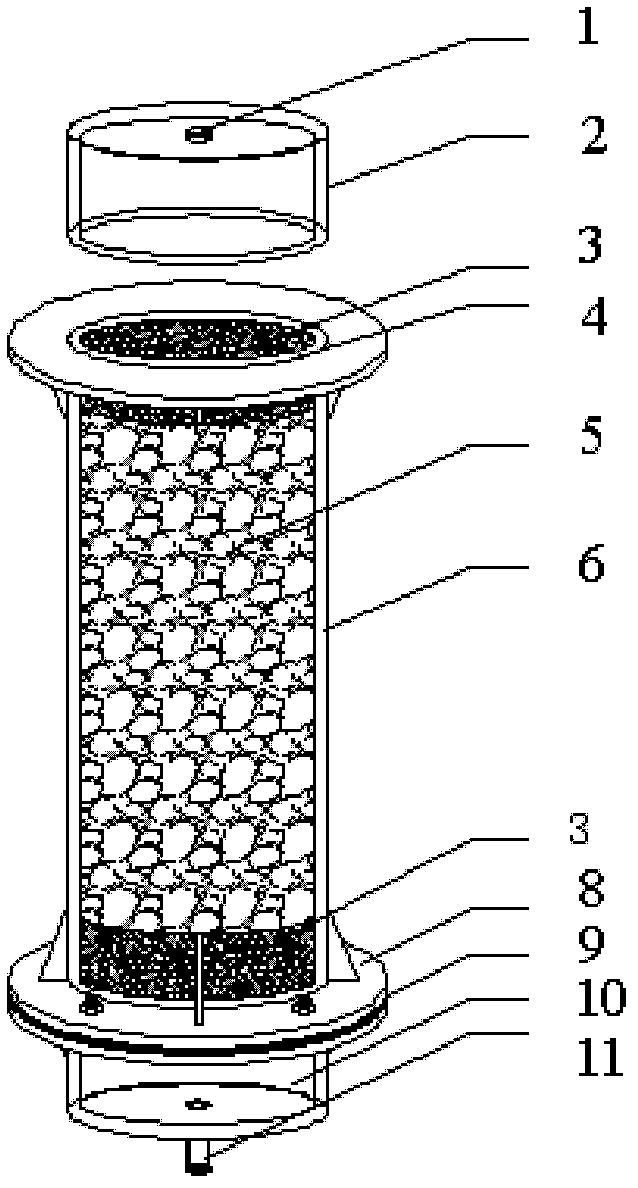

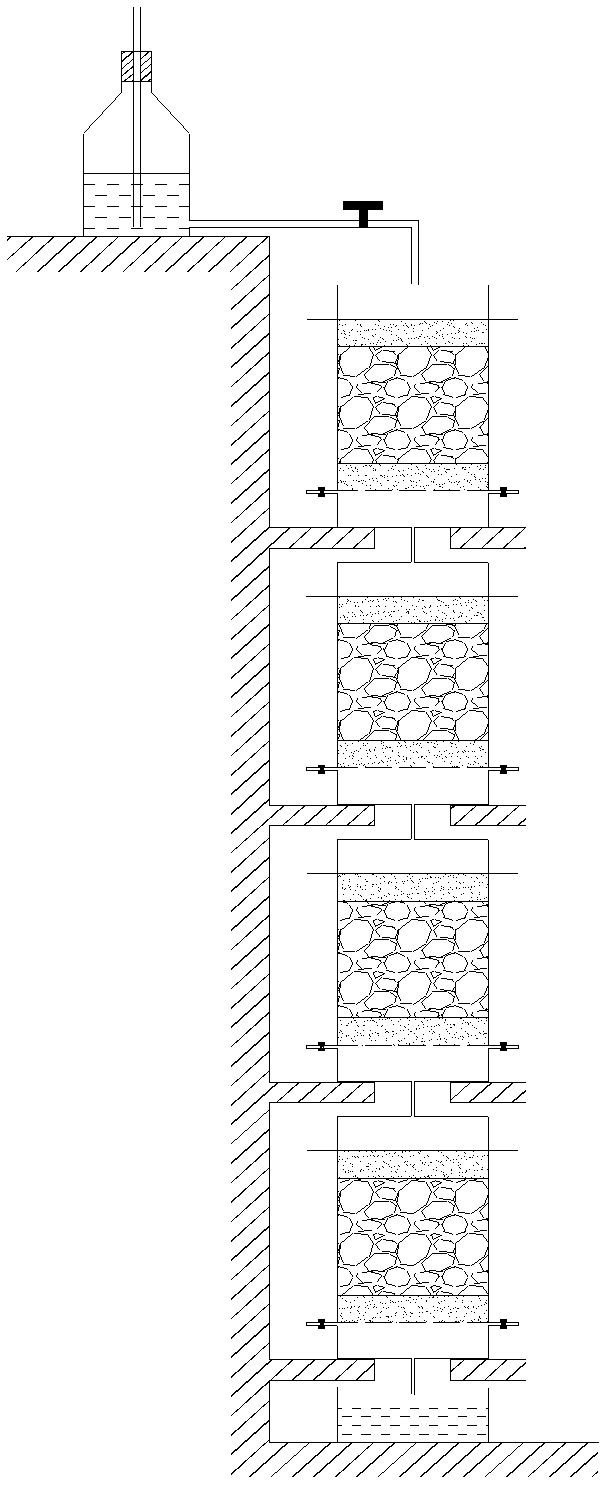

[0035] The patent of the present invention provides a series column leaching test device for simulating on-site ore heap leaching. image 3 After the installation of the device is completed, liquid distribution is carried out every day according to the parameters of the concentration of the immersion solution, oxidant concentration, liquid distribution strength, liquid-solid ratio, and liquid distribution time set by the test. At the same time, the leaching rate of useful metals, The consumption of leaching agent and oxidant, as well as parameters such as pH and Eh can be detected to determine the time-varying law of parameters such as useful metal ion concentration, pH, Eh, residual acidity, and oxidant concentration at different depths during the on-site ore heap leaching process.

[0036] If you need to understand the leaching rate of useful metals at various depths of the ore heap, the consumption of leaching agents and oxidants, and the changes in parameters such as pH and...

Embodiment 1

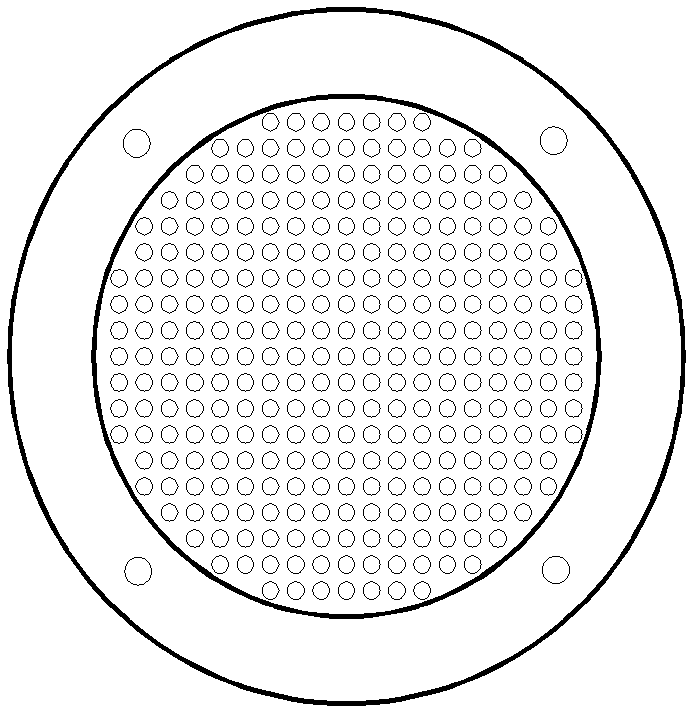

[0042] The prepared uranium ore samples with a particle size of 1-2mm and a uranium grade of 0.177% were evenly packed into four unit columns with an inner diameter of 88mm. The height of the uranium ore columns was 250mm, and a layer of granular Quartz sand with a diameter of 1-2mm and a thickness of 30mm. Then place four unit columns on a layered bench to form a serial column immersion test device. The liquid-solid ratio of 0.1L / kg is used for distributing liquid every day. The concentration of sulfuric acid in the immersion liquid is 5-20g / L, and the initial sulfuric acid concentration is 20g / L. Then adjust the concentration of sulfuric acid according to the change of pH value to make the later pH Keep it between 1-2. The liquid distribution time is 8 hours per day, and the liquid distribution strength is 20.55L / h m 2 , The leaching time is 35d. The sampling time of each unit column is 4-4.5 hours after the liquid spraying every day. The total leachate was sampled befor...

Embodiment 2

[0044] The prepared uranium ore sample with a particle size of 3-4mm and a uranium grade of 0.177% is evenly loaded into four unit columns with an inner diameter of 88mm. The height of the uranium ore column is 250mm, and a layer of granular Quartz sand with a diameter of 3-4mm and a thickness of 30mm. Then place four unit columns on a layered bench to form a serial column immersion test device. Use a liquid-solid ratio of 0.1L / kg to distribute the liquid every day. The concentration of sulfuric acid in the immersion solution is 5-20g / L, and the initial sulfuric acid concentration is 20g / L. Then adjust the concentration of sulfuric acid according to the change of pH value to keep the pH in the later stage. Between 1-2. The liquid distribution time is 8 hours per day, and the liquid distribution strength is 20.55L / h m 2 , The leaching time is 35d. The sampling time of each unit column is 4-4.5 hours after the liquid spraying every day. The total leachate was sampled before ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com